High-Accuracy 3D Optical Profilometry for Analysis of Surface Condition of Modern Circulated Coins

Abstract

1. Introduction

| Application | Method | References |

|---|---|---|

| Analysis of chemical composition and microstructure | EDS (EDX) | [5] 1, [6] 2 |

| EDXRF | [7] 4, [8,9,10,11] | |

| GRT | [12] | |

| LAMQS | [8] | |

| LIBS | [13,14] | |

| ND | [15,16] | |

| PIXE | [6] 2, [17] 3, [18], [6] 2, [19], [20] 3, [21,22,23,24,25,26] | |

| RBS | [25] | |

| XPS | [27] 4, [28] | |

| XRD | [5] 1, [7] 4, [16,28] | |

| XRF | [12,13,29,30], [31] 3 | |

| SRXRF | [6] 2, [19] 4 | |

| SEM | [32] 3, [33,34] | |

| TEM | [33,35] | |

| Analysis of the corrosion products | EDS (EDX) | [36] 1,5 |

| PIXE | [37,38] 3 | |

| XPS | [36] 1,5 | |

| XRD | [36] 1,5, [38] 3, [39] 4 | |

| XRF | [38] 3 | |

| Reconstruction | CT | [40,41,42] |

- Phase I: Slight wear (the coin entering the circulation begins to show signs of manipulation, abrasion, or slight wear, which can be stated after a visual analysis of changes in fragments of the surface texture and differences in the sharpness of fine elements (mint mark, motto, etc.), as well as slight differences in their color).

- Phase II: Average wear (the coin in circulation, after a period of time, begins to show signs of medium wear. It can be stated after a visual analysis of the design’s highest points, which begin to lose their sharpness and slightly round or flatten, while fine elements close together begin to connect).

- Phase III: Extensive wear (the coin in circulation, after a long time, begins to show signs of extensive wear. It can be stated after a visual analysis of the design sharpness. High points begin to connect with the next lower elements of the design. After flattening the protective rim, the entire surface begins to flatten—most of the details connect with itself or partially with the surface).

- Phase IV: Critical wear (the coin in circulation, after a long time, begins to show signs of critical wear. This phase causes the completely flattening of the protective rim, design, and all other elements of the coin. Both the obverse and reverse are difficult to identify. The coin cannot fulfill the tender function and must be withdrawn from circulation).

| Application | Method | References |

|---|---|---|

| Measurements of shape and surface profile (2D) | FP | [49] |

| FP + SP | [50] | |

| FP + PS | [51] | |

| FP + PS + TPU + DIA | [52] | |

| MI | [53] | |

| Measurements of shape (3D) | SL | [54] |

| Measurements of surface profile and topography (3D) | FP | [54,55,56,57] |

| FVM | [58] | |

| CLSM | [59] | |

| CS | [60,61] | |

| SL | [62] |

2. Experimental Studies

2.1. Selection and Characteristics of the Coins

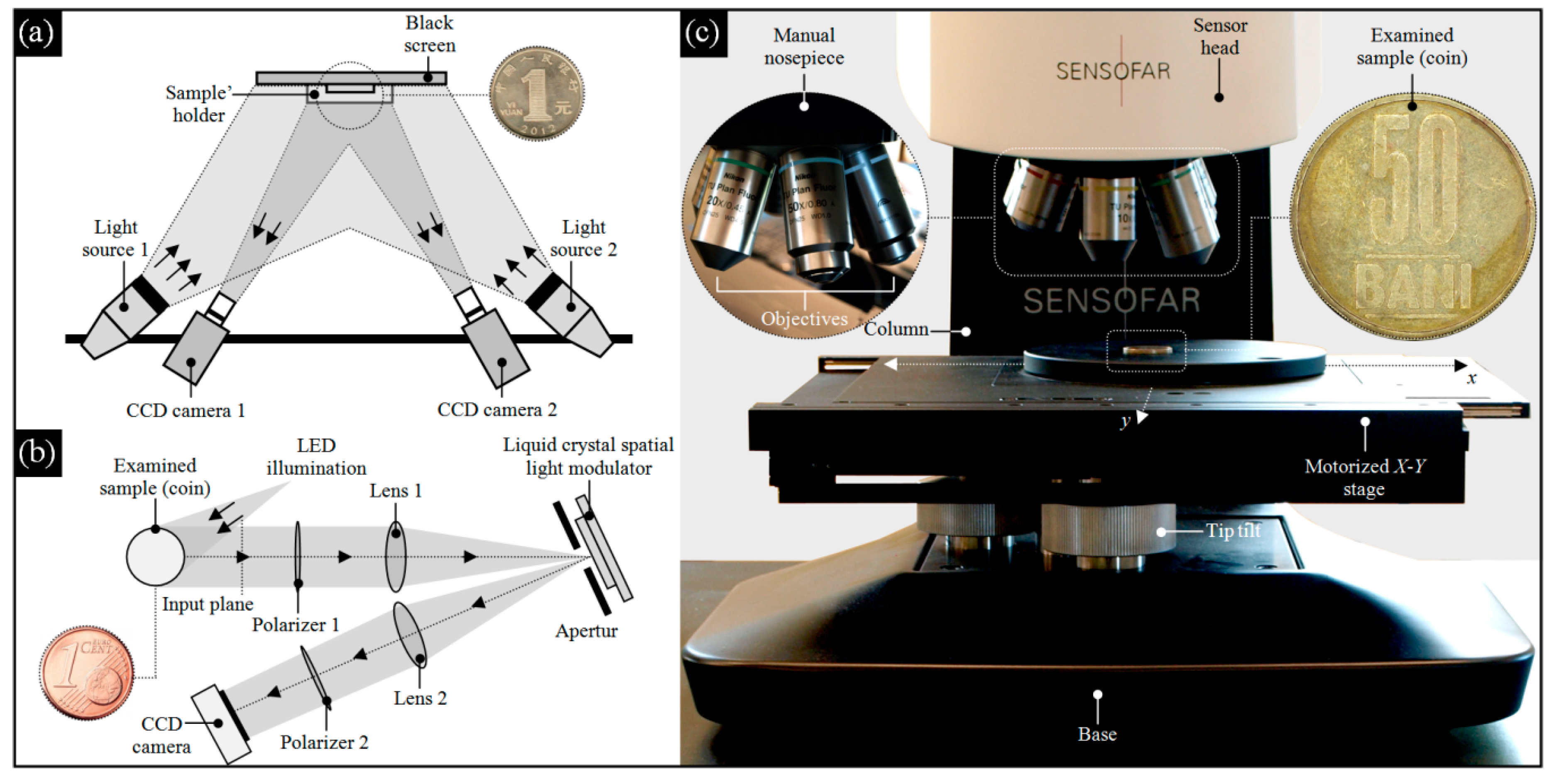

2.2. Characteristics of Observation Measurement Systems

3. Results and Discussion

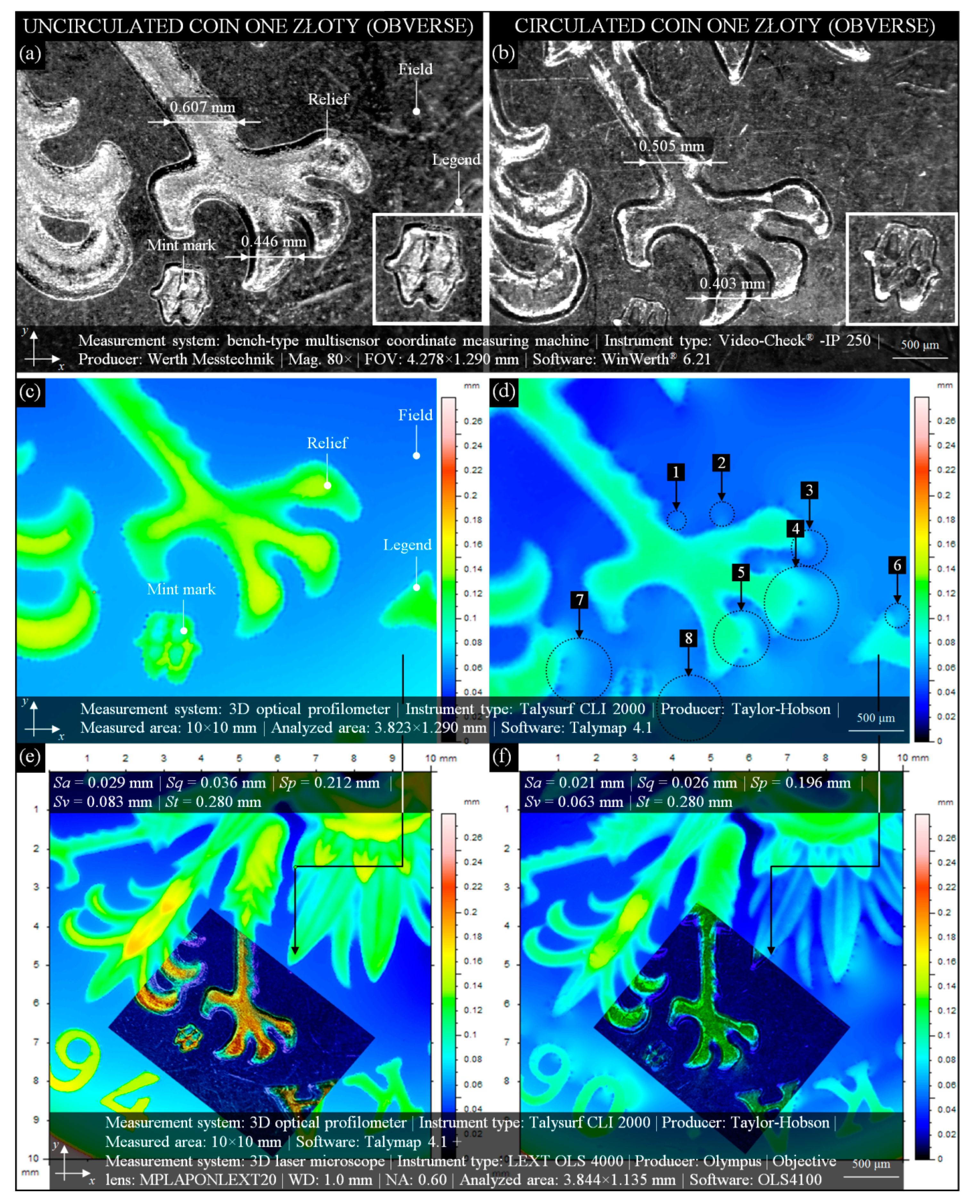

3.1. Comparative Analysis of Uncirculated/Circulated 1 Złoty (Obverse) Coin’s Surface Condition

3.2. Analysis of the Circulated 1 Franc and 50 Bani Coins’ Edge Surface Condition

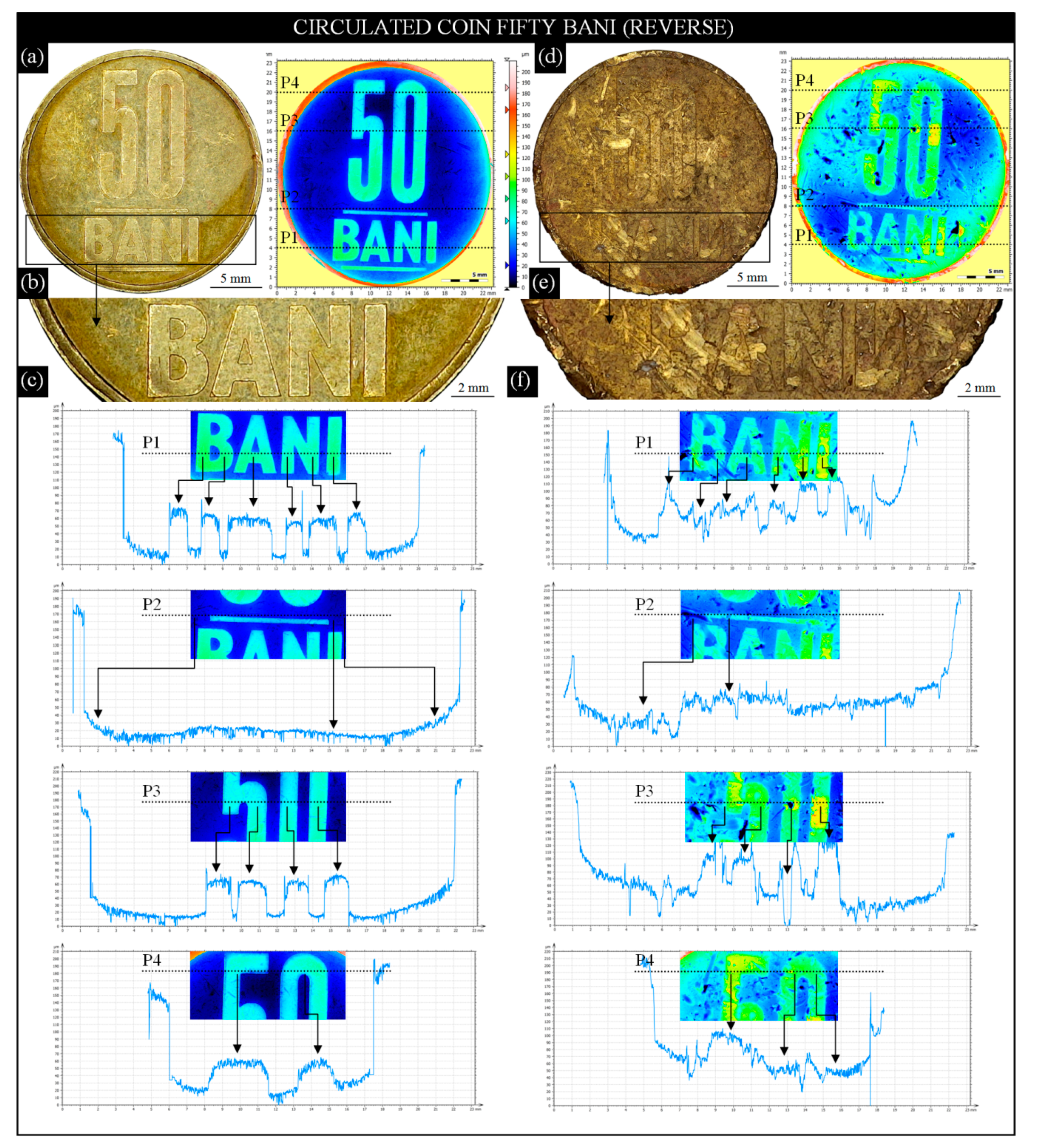

3.3. Comparative Analysis of the Circulated 50 Bani (Reverse) Coin’s Surface Condition

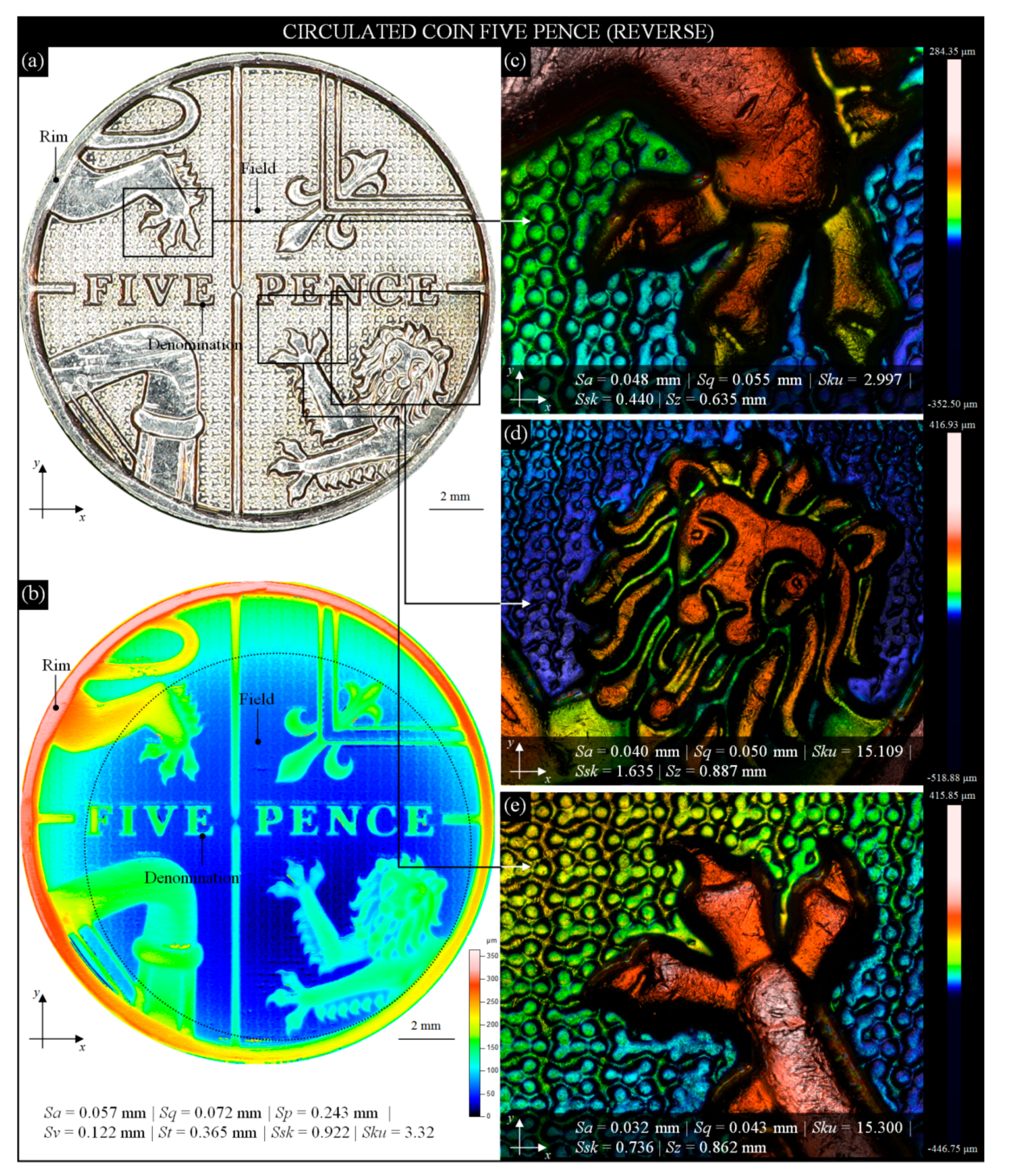

3.4. Analysis of the Circulated 5 Pence (Reverse) Coin’s Surface Condition

4. Conclusions

- Most of the analyses of modern circulation coins focus on the precise determination of their chemical composition. In this case, modern varieties of X-ray-based observation measurement methods, such as EDS (EDX), EDXRF, LAMQS, and, PIXE, were used (Section 1). To extend the results of the spectroscopic examinations, 2D/3D dimensional-shape measurements (macroscale) and surface texture measurements (micro scale) were carried out. Additionally, the authors located and recognized the surface defects. Modern measurement methods, such as CLSM, FVM, and advanced variants of interferometry, using optical profilometry, prove to be helpful in these activities.

- The authors of the article showed that optical profilometry could be successfully used in the analysis of the surface condition of modern circulation coins representing Phases I–IV of surface wear. The measurement capabilities of the systems used (Section 2.1) turned out to be sufficient for the needs of the carried-out experimental tests. The undoubted advantages of the 3D optical profilometers used were relatively quick measurement time, noncontact method of assessment, high resolution and measurement range, integration of (optical) measurement methods in one instrument, and advanced processing and visualization of measurement data. In more complex cases, this type of tests may be carried out with the use of additional measuring instruments or more specialized computer software—it depends on the application.

- The analyses presented in the article (Section 3) are general and illustrative—they are shown against the background of hardware and software capabilities. Analyses of the surface condition of coins can be much more advanced (comprehensive) or strictly focused on a specific feature of the assessed surface. For example, it can relate with mint-made errors (errors from a three fundamental groups, including blank planchet, fundamental die-setting, and broadstrike) generated during the coin manufacturing process. Such errors occurring during the minting practice must be located and adequately analyzed. Another interesting area is concerning the analyses carried out to establish the authenticity of a given coin or group of coins. Such activities usually refer to the antique coin(s), but in justified cases, they may also refer to coins illegally released into circulation.

- Special computer software (especially based on Mountains Technology®) provided significant support in the carried-out analyses. Its universal character and the number of implemented functions it performed were useful in characterizing coin surfaces. In case of a need to generate the output large area topography, the image stitching procedure was conducive.

- In the authors’ opinion, the subject discussed in this article is extremely interesting and has a chance to be further developed. There is a plan to carry out a more detailed study (e.g., analysis of surface wear in the context of changes of coin relief height). Such changes are extremely important because critical wear makes it impossible to use a given coin as a legal tender and, as a result, causes its withdrawal from circulation. The authors also plan to carry out a wider research program using advanced X-ray-based observation measurement methods supported by noncontact techniques (optical profilometry), where issues regarding the influence of elemental composition on the wear process will be considered.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Nomenclature

| 3D-DIC | Three-dimensional digital image correlation (3D-DIC) |

| AOI | Area of interest |

| CH | Conoscopic holography |

| CS | Confocal sensor |

| CSI | Computational shear interferometry |

| CLA | Chromatic light aberration phenomenon |

| CLSM | Confocal laser scanning microscopy |

| CMM | Coordinate measuring machine |

| CT | X-ray computed tomography |

| DIA | Digital image acquisition |

| EDS | Energy-dispersive X-ray spectrometry |

| EDXRF | Energy-dispersive X-ray fluorescence spectrometry |

| EMA | Electron microprobe analysis |

| FP | Fringe projection |

| FVM | Focus variation microscopy |

| GRT | Gamma-ray transmission |

| LAMQS | Laser ablation coupled to mass quadrupole spectrometry |

| LIBS | Laser-induced breakdown spectroscopy |

| MI | Moiré interferometry |

| ND | Neutron diffraction |

| OM | Optical microscopy |

| PIXE | Particle (proton)-induced X-ray emission |

| PS | Phase stepping |

| RBS | Rutherford backscattering spectrometry |

| XPS | X-ray photoelectron spectroscopy |

| XRD | X-ray diffraction |

| SEM | Scanning electron microscopy |

| SL | Structured light |

| SP | Speckle projection |

| SRXRF | Synchrotron radiation X-ray fluorescence spectrometry |

| TEM | Transmission electron microscopy |

| TPU | Temporal phase unwrapping |

| WD | Working distance, mm |

| Sa | Arithmetic mean deviation of the surface, µm |

| Sku | Kurtosis of the height distribution, - |

| Sp | Maximum height of summits, µm |

| Sq | Root-mean-square deviation of the surface, µm |

| Ssk | Skewness of the height distribution, - |

| St | Total height of the surface, µm |

| Sv | Maximum depth of valleys, µm |

Glossary

- Circulated—a term used to refer to a coin characterized by various conditions of surface wear (from slight wear to critical wear).

- Circulation—a term used to refer to a coin that is currently or was in the past in circulation as a means of payment (money).

- Denomination—a value assigned by a government to a given coin.

- Design—motif, pattern, or emblem used in the coin.

- Edge—the third side of a coin, containing reeds, lettering, or other ornaments. The edge can also be plain.

- Field—a flat (or slightly curved) area of a coin with no emblem or inscription.

- Motto—word, sentence, or phrase inscribed on a coin to express a guiding national principle.

- Obverse—front or head side of the coin.

- Relief—any element of a coin’s design that is raised above the field. The opposite of relief is incuse.

- Reverse—back or tail side of the coin.

- Rim—raised portion of the design along the edge that protects the coin from wear.

- Uncirculated—theoretically, a coin that has never circulated and thus retains all of its original mint conditions (a coin without wear with excellent surface condition).

References

- Du Toit, M.; van der Lingen, E.; Glaner, L.; Süss, R. The development of a novel gold alloy with 995 fineness and increased hardness. Gold Bull. 2002, 35, 46–52. [Google Scholar] [CrossRef]

- Mendoza-López, M.L.; Pérez-Bueno, J.J.; Rodríguez-García, M.E. Characterizations of silver alloys used in modern Mexican coins. Mater. Charact. 2009, 60, 1041–1048. [Google Scholar] [CrossRef]

- Dow, J.A. Ancient Coins through the Bible; Tate Publishing & Enterprises: Mustang, OK, USA, 2011. [Google Scholar]

- Metcalf, W.E. (Ed.) The Oxford Handbook of Greek and Roman Coinage; Oxford University Press: Oxford, UK, 2012. [Google Scholar]

- He, L.; Liang, J.; Zhao, X.; Jiang, B. Corrosion behavior and morphological features of archeological bronze coins from ancient China. Microchem. J. 2012, 99, 203–212. [Google Scholar] [CrossRef]

- Rodrigues, M.; Schreiner, M.; Melcher, M.; Guerra, M.; Salomon, J.; Radtke, M.; Alram, M.; Schindel, N. Characterization of the silver coins of the Hoard of Beçin by X-ray based methods. Nucl. Instrum. Methods Phys. Res. B 2011, 269, 3041–3045. [Google Scholar] [CrossRef]

- Mousser, H.; Amri, R.; Madani, A.; Darchen, A.; Mousser, A. Microchemical surface analysis of two Numidian coins. Appl. Surf. Sci. 2011, 257, 5961–5965. [Google Scholar] [CrossRef]

- Torrisi, L.; Italiano, A.; Torrisi, A. Ancient bronze coins from Mediterranean basin: LAMQS potentiality for lead isotopes comparative analysis with former mineral. Appl. Surf. Sci. 2016, 387, 529–538. [Google Scholar] [CrossRef]

- Pitarch, A.; Queralt, I. Energy dispersive X-ray fluorescence analysis of ancient coins: The case of Greek silver drachmae from the Emporion site in Spain. Nucl. Instrum. Methods Phys. Res. B 2010, 268, 1682–1685. [Google Scholar] [CrossRef]

- Pitarch, A.; Queralt, I.; Alvarez-Perez, A. Analysis of Catalonian silver coins from the Spanish war of independence period (1808–1814) by energy dispersive X-ray fluorescence. Nucl. Instrum. Methods Phys. Res. B 2011, 269, 308–312. [Google Scholar] [CrossRef]

- Gore, D.B.; Davis, G. Suitability of transportable EDXRF for the on-site assessment of ancient silver coins and other silver artifacts. Appl. Spectrosc. 2016, 70, 840–851. [Google Scholar] [CrossRef]

- Ager, F.J.; Gómez-Tubío, B.; Paúl, A.; Gómez-Morón, A.; Scrivano, S.; Ortega-Feliu, I.; Respaldiza, M.A. Combining XRF and GRT for the analysis of ancient silver coins. Microchem. J. 2016, 126, 149–154. [Google Scholar] [CrossRef]

- Pardini, L.; El Hassan, A.; Ferretti, M.; Foresta, A.; Legnaioli, S.; Lorenzetti, G.; Nebbia, E.; Catalli, F.; Harith, M.A.; Diaz Pace, D.; et al. X-ray fluorescence and laser-induced breakdown spectroscopy analysis of Roman silver denarii. Spectrochim. Acta B 2012, 74, 156–161. [Google Scholar] [CrossRef]

- Awasthi, S.; Kumar, R.; Rai, G.K.; Rai, A.K. Study of archaeological coins of different dynasties using LIBS coupled with multivariate analysis. Opt. Laser. Eng. 2016, 79, 29–38. [Google Scholar] [CrossRef]

- Corsi, J.; Grazzi, F.; Lo Giudice, A.; Re, A.; Scherillo, A.; Angelici, D.; Allegretti, S.; Barello, F. Compositional and microstructural characterization of Celtic silver coins from northern Italy using neutron diffraction analysis. Microchem. J. 2016, 126, 501–508. [Google Scholar] [CrossRef]

- Griesser, M.; Kockelmann, W.; Hradil, K.; Traum, R. New insights into the manufacturing technique and corrosion of high leaded antique bronze coins. Microchem. J. 2016, 126, 181–193. [Google Scholar] [CrossRef]

- Flament, C.; Marchetti, P. Analysis of ancient silver coins. Nucl. Instrum. Methods Phys. Res. B 2004, 226, 179–184. [Google Scholar] [CrossRef]

- Hajivaliei, M.; Mohammadifar, Y.; Ghiyasi, K.; Jaleh, B.; Lamehi-Rachti, M.; Oliaiy, P. Application of PIXE to study ancient Iranian silver coins. Nucl. Instrum. Methods Phys. Res. B 2008, 266, 1578–1582. [Google Scholar] [CrossRef]

- Hajivaliei, M.; Nadooshan, F.K. Compositional study of Parthian silver coins using PIXE technique. Nucl. Instrum. Methods Phys. Res. B 2012, 289, 56–58. [Google Scholar] [CrossRef]

- Šmit, Ž.; Šemrov, A. Analysis of Greek small coinage from the classic period. Nucl. Instrum. Methods Phys. Res. B 2018, 417, 100–104. [Google Scholar] [CrossRef]

- Tripathy, B.B.; Rautray, T.R.; Rautray, A.C.; Vijayan, V. Elemental analysis of silver coins by PIXE technique. Appl. Radiat. Isot. 2010, 68, 454–458. [Google Scholar] [CrossRef]

- Rautray, T.R.; Nayak, S.S.; Tripathy, B.B.; Das, S.; Das, M.R.; Das, S.R.; Chattopadhyay, P.K. Analysis of ancient Indian silver punch-marked coins by external PIXE. Appl. Radiat. Isot. 2011, 69, 1385–1389. [Google Scholar] [CrossRef]

- Abdelouahed, H.B.; Gharbi, F.; Roumié, M.; Baccouche, S.; Romdhane, K.B.; Nsouli, B.; Trabelsi, A. PIXE analysis of medieval silver coins. Mater. Charact. 2010, 61, 59–64. [Google Scholar] [CrossRef]

- Beck, L.; Bosonnet, S.; Réveillon, S.; Eliot, D.; Pilon, F. Silver surface enrichment of silver–copper alloys: A limitation for the analysis of ancient silver coins by surface techniques. Nucl. Instrum. Methods Phys. Res. B 2004, 226, 153–162. [Google Scholar] [CrossRef]

- Beck, L.; Alloin, E.; Berthier, C.; Réveillon, S.; Costa, V. Silver surface enrichment controlled by simultaneous RBS for reliable PIXE analysis of ancient coins. Nucl. Instrum. Methods Phys. Res. B 2008, 266, 2320–2324. [Google Scholar] [CrossRef]

- Denker, A.; Opitz-Coutureau, J.; Griesser, M.; Denk, R.; Winter, H. Non-destructive analysis of coins using high-energy PIXE. Nucl. Instrum. Methods Phys. Res. B 2004, 226, 163–171. [Google Scholar] [CrossRef]

- Ingo, G.M.; Riccucci, C.; Faraldi, F.; Pascucci, M.; Messina, E.; Fierro, G.; Di Carlo, G. Roman sophisticated surface modification methods to manufacture silver counterfeited coins. Appl. Surf. Sci. 2017, 421, 109–119. [Google Scholar] [CrossRef]

- Caridi, F.; Torrisi, L.; Cutroneo, M.; Barreca, F.; Gentile, C.; Serafino, T.; Castrizio, D. XPS and XRF depth patina profiles of ancient silver coins. Appl. Surf. Sci. 2013, 272, 82–87. [Google Scholar] [CrossRef]

- Gorghinian, A.; Esposito, A.; Ferretti, M.; Catalli, F. XRF analysis of Roman Imperial coins. Nucl. Instrum. Methods Phys. Res. B 2013, 309, 268–271. [Google Scholar] [CrossRef]

- Del Hoyo-Meléndez, J.M.; Świt, P.; Matosz, M.; Woźniak, M.; Klisińska-Kopacz, A.; Bratasz, Ł. Micro-XRF analysis of silver coins from medieval Poland. Nucl. Instrum. Methods Phys. Res. B 2015, 349, 6–16. [Google Scholar] [CrossRef]

- Hložek, M.; Trojek, T. Silver and tin plating as medieval techniques of producing counterfeit coins and their identification by means of micro-XRF. Radiat. Phys. Chem. 2017, 137, 234–237. [Google Scholar] [CrossRef]

- Marjo, C.E.; Davis, G.; Gong, B.; Gore, D.B. Spatial variability of elements in ancient Greek (ca. 600–250 BC) silver coins using scanning electron microscopy with energy dispersive spectrometry (SEM-EDS) and time of flight-secondary ion mass spectrometry (ToF-SIMS). Powder Diffr. 2017, 32, 95–100. [Google Scholar] [CrossRef]

- Vasiliev, A.L.; Kovalchuk, M.V.; Yatsishina, E.B. Electron microscopy methods in studies of cultural heritage sites. Crystallogr. Rep. 2016, 61, 873–885. [Google Scholar] [CrossRef]

- Khramchenkova, R.; Safina, I.; Drobyshev, S.; Batasheva, S.; Nuzhdin, E.; Fakhrullin, R. Advanced microscopy techniques for nanoscale diagnostic of cultural heritage: Scanning electron microscopy for investigation of medieval coins and frescos from the Republic of Tatarstan. In Nanotechnologies and Nanomaterials for Diagnostic, Conservation and Restoration of Cultural Heritage; Lazzara, G., Fakhrullin, R., Eds.; Elsevier: Amsterdam, The Netherlands, 2019; pp. 1–23. [Google Scholar]

- Pistofidis, N.; Vourlias, G.; Pavlidou, E.; Dilo, T.; Civici, N.; Stamati, F.; Gjongecaj, S.; Prifti, I.; Bilam, O.; Stergioudis, G.; et al. Microscopical examination of ancient silver coins. AIP Conf. Proc. 2004, 899, 798. [Google Scholar]

- Liang, C.; Yang, C.; Huang, N. Investigating the tarnish and corrosion mechanisms of Chinese gold coins. Surf. Interface Anal. 2011, 43, 763–769. [Google Scholar] [CrossRef]

- Cruz, J.; Corregidor, V.; Alves, L.C. Simultaneous use and self-consistent analyses of μ-PIXE and μ-EBS for the characterization of corrosion layers grown on ancient coins. Nucl. Instrum. Methods Phys. Res. B 2017, 406, 324–328. [Google Scholar] [CrossRef]

- Fierascu, R.C.; Fierascu, I.; Ortan, A.; Constantin, F.; Mirea, D.A.; Tatescu, M. Complex archaeometallurgical investigation of silver coins from the XVIth-XVIIIth century. Nucl. Instrum. Methods Phys. Res. B 2017, 401, 318–324. [Google Scholar] [CrossRef]

- Abdel-Kareem, O.; Al-Zahrani, A.; Arbach, M. Authentication and conservation of corroded archaeological Qatabanian and Himyarite silver coins. J. Archaeol. Sci. Rep. 2016, 9, 565–576. [Google Scholar] [CrossRef]

- Miles, J.; Mavrogordato, M.; Sinclair, I.; Hinton, D.; Boardman, R.; Earl, G. The use of computed tomography for the study of archaeological coins. J. Archaeol. Sci. Rep. 2016, 6, 35–41. [Google Scholar] [CrossRef]

- Bozzini, B.; Gianoncelli, A.; Mele, C.; Siciliano, A.; Mancini, L. Electrochemical reconstruction of a heavily corroded Tarentum hemiobolus silver coin: A study based on microfocus X-ray computed microtomography. J. Archaeol. Sci. 2014, 52, 24–30. [Google Scholar] [CrossRef]

- Van Loon, L.L.; Nelson, A.J.; Kagan, U.W.; Barron, K.; Banerjee, N.R. Bubbles in the bullion: Micro-CT imaging of the internal structure of ancient coins. Microsc. Microanal. 2019, 25, 420–421. [Google Scholar] [CrossRef]

- Spagnolo, G.S.; Majo, R.; Carli, M.; Ambrosini, D.; Paoletti, D. Virtual gallery of ancient coins through conoscopic holography. Proc. SPIE 2003, 5146, 202–209. [Google Scholar]

- Roumie, M.; Nsouli, B.; Chalhoub, G.; Hamdan, M. Quality control of coins mint using PIXE and RBS analysis. Nucl. Instrum. Methods Phys. Res. B 2010, 268, 1916–1919. [Google Scholar] [CrossRef]

- Papp, Z.; Kovacs, I. Surface analysis of a modern silver coin: SEM/EDS measurements. Rev. Roum. Chim. 2013, 58, 65–67. [Google Scholar]

- Corregidor, V.; Alves, L.C.; Cruz, J. Analysis of surface stains on modern gold coins. Nucl. Instrum. Methods Phys. Res B 2013, 306, 232–235. [Google Scholar] [CrossRef]

- Kapłonek, W.; Nadolny, K.; Ungureanu, M.; Pimenov, D.Y.; Zieliński, B. SEM-based observations and analysis of the green silicon carbide grinding wheel active surfaces after the graphite and silicone impregnation process. Int. J. Surf. Sci. Eng. 2019, 13, 181–200. [Google Scholar] [CrossRef]

- Bustillo, A.; Pimenov, D.Y.; Matuszewski, M.; Mikolajczyk, T. Using artificial intelligence models for the prediction of surface wear based on surface isotropy levels. Robot. Comput. Integr. Manuf. 2018, 53, 215–217. [Google Scholar] [CrossRef]

- Peng, J.; Wang, M.; Deng, D.; Liu, X.; Yin, Y.; Peng, X. Distortion correction for microscopic fringe projection system with Scheimpflug telecentric lens. Appl. Opt. 2015, 54, 10055–10062. [Google Scholar] [CrossRef]

- Liu, C.; Chen, L.; He, X.; Thang, V.D.; Kofidis, T. Coaxial projection profilometry based on speckle and fringe projection. Opt. Commun. 2015, 341, 228–236. [Google Scholar] [CrossRef]

- Quan, C.; He, X.Y.; Wang, C.F.; Tay, C.J.; Shang, H.M. Shape measurement of small objects using LCD fringe projection with phase shifting. Opt. Commun. 2001, 189, 21–29. [Google Scholar] [CrossRef]

- Spagnolo, G.S.; Cozzella, L.; Leccese, F. Projected fringes profilometry for cultural heritage studies. In Proceedings of the 2019 IMEKO TC-4 International Conference on Metrology for Archaeology and Cultural Heritage, Florence, Italy, 4–6 December 2019; pp. 435–438. [Google Scholar]

- Steckenrider, J.J.; Steckenrider, J.S. High-resolution moiré interferometry for quantitative low-cost, real-time surface profilometry. Appl. Opt. 2015, 54, 8298–8305. [Google Scholar] [CrossRef]

- Liu, S.; Feng, W.; Zhang, Q.; Liu, Y. Three-dimensional shape measurement of small object based on tri-frequency heterodyne method. Proc. SPIE 2015, 9623, 96231C-1–96231C-5. [Google Scholar]

- Quan, C.; He, X.; Tay, C.J.; Shang, H.M. 3D surface profile measurement using LCD fringe projection. Proc. SPIE 2001, 4317, 511–516. [Google Scholar]

- Quan, C.; Tay, C.J.; Kang, X.; He, X.Y.; Shang, H.M. Shape measurement by use of liquid-crystal display fringe projection with two-step phase shifting. Appl. Opt. 2003, 42, 2329–2335. [Google Scholar] [CrossRef] [PubMed]

- Chen, J.; Guo, T.; Wang, L.; Wu, Z.; Fu, X.; Hu, X. Microscopic fringe projection system and measuring method. Proc. SPIE 2013, 8759, 87594U. [Google Scholar]

- Deininger, L.; Francese, S.; Clench, M.R.; Langenburg, G.; Sears, V.; Sammon, C. Investigation of infinite focus microscopy for the determination of the association of blood with fingermarks. Sci. Justice 2018, 58, 397–404. [Google Scholar] [CrossRef] [PubMed]

- Fabich, M. Advancing confocal laser scanning microscopy: The advantage of optical metrology. Opt. Photonik 2009, 4, 40–43. [Google Scholar] [CrossRef]

- Kapłonek, W.; Sutowska, M.; Ungureanu, M.; Çetinkaya, K. Optical profilometer with confocal chromatic sensor for high-accuracy 3D measurements of the uncirculated and circulated coins. J. Mech. Energy Eng. 2018, 2, 181–192. [Google Scholar] [CrossRef]

- Song, Z.; Chung, R.; Zhang, X.T. An accurate and robust strip-edge-based structured light means for shiny surface micromeasurement in 3-D. IEEE Trans. Ind. Electron. 2013, 60, 1023–1032. [Google Scholar] [CrossRef]

- Carcagni, P.; Daffara, C.; Fontana, R.; Gambino, M.C.; Mastroianni, M.; Mazzotta, C.; Pampaloni, E.; Pezzati, L. Optical micro-profilometry for archaeology. Proc. SPIE 2005, 5857, 58570F. [Google Scholar]

- Yan, T.; Su, Y.; Zhang, Q. Precise 3D shape measurement of three-dimensional digital image correlation for complex surfaces. Sci. China Technol. Sci. 2018, 61, 68–73. [Google Scholar] [CrossRef]

- Falldorf, C.; Agour, M.; Bergmann, R.B. Digital holography and quantitative phase contrast imaging using computational shear interferometry. Opt. Eng. 2015, 54, 024110. [Google Scholar] [CrossRef]

- Fan, W.C.; Cao, P.; Long, L. Degradation of joint surface morphology, shear behavior and closure characteristics during cyclic loading. J. Cent. South Univ. 2018, 25, 653–661. [Google Scholar] [CrossRef]

- Saremi-Yarahmadi, S.; Binner, J.; Vaidhyanathan, B. Erosion and mechanical properties of hydrothermally-resistant nanostructured zirconia components. Ceram. Int. 2018, 44, 10539–10544. [Google Scholar] [CrossRef]

- Beamud, E.M.; Núñez, P.J.; García-Plaza, E.; Amaro, F.R. Characterization of surface texture in electropolishing processes using 3D surface topography parameters. Procedia Manuf. 2019, 41, 114–120. [Google Scholar] [CrossRef]

- Genna, S.; Giannini, O.; Guarino, S.; Ponticelli, G.S.; Tagliaferri, F. Laser texturing of AISI 304 stainless steel: Experimental analysis and genetic algorithm optimisation to control the surface wettability. Int. J. Adv. Manuf. Technol. 2020, 110, 3005–3022. [Google Scholar] [CrossRef]

- Artigas, R.; Pinto, A.; Laguarta, F. Three-dimensional micromeasurements on smooth and rough surfaces with a new confocal optical profiler. Proc. SPIE 1999, 3824, 93–104. [Google Scholar]

- Ding, W.; Dai, C.; Yu, T.; Xu, J.; Fu, Y. Grinding performance of textured monolayer CBN wheels: Undeformed chip thickness nonuniformity modeling and ground surface topography prediction. Int. J. Mach. Tools Manuf. 2017, 122, 66–80. [Google Scholar] [CrossRef]

- Leksycki, K.; Królczyk, J.B. Comparative assessment of the surface topography for different optical profilometry techniques after dry turning of Ti6Al4V titanium alloy. Measurement 2020, 169, 108378. [Google Scholar] [CrossRef]

- Leksycki, K.; Feldshtein, E.; Królczyk, G.M.; Legutko, S. On the chip shaping and surface topography when finish cutting 17-4 PH precipitation-hardening stainless steel under near-dry cutting conditions. Materials 2020, 13, 2188. [Google Scholar] [CrossRef]

- Tato, W.; Blunt, L.; Llavori, I.; Aginagalde, A.; Townsend, A.; Zabala, A. Surface integrity of additive manufacturing parts: A comparison between optical topography measuring techniques. Procedia CIRP 2020, 87, 403–408. [Google Scholar] [CrossRef]

- International Organization for Standardization. Geometrical Product Specification (GPS)—Surface Texture: Areal—Part. 2: Terms, Definitions and Surface Texture Parameters; Technical Report No. 25178-2:2012; International Organization for Standardization: Geneva, Switzerland, 2012. [Google Scholar]

- Stout, K.J.; Liam, B.; Dong, W.; Mainsah, E.; Luo, N.; Mathia, T.; Sullivan, P.; Zahouani, H. The Development of Methods for the Characterization of Roughness in Three Dimensions; Technical Report, No. EUR 15178 EN; BCR: Brussels, Belgium, 1993. [Google Scholar]

- Artigas, R.; Matilla, A.; Mariné, J.; Pérez, J.; Cadevall, C. Three-dimensional measurements with a novel technique combination of confocal and focus variation with a simultaneous scan. Proc. SPIE 2016, 9890, 98900B. [Google Scholar]

- Bermudez, C.; Matilla, A.; Aguerri, A. Confocal fusion: Towards the universal optical 3D metrology technology. In Proceedings of the 12th LAMDAMAP, Renishaw Innovation Center, Wotton-Under Edge, UK, 15–16 March 2017. [Google Scholar]

- Flys, O.; Berglund, J.; Rosen, B.G. Using confocal fusion for measurement of metal AM surface texture. Surf. Topogr. 2020, 8, 024003. [Google Scholar] [CrossRef]

- Hatami, S.; Ma, T.; Vuoristo, T.; Bertilsson, J.; Lyckfeldt, O. Fatigue strength of 316 L stainless steel manufactured by selective laser melting. J. Mater. Eng. Perform. 2020, 29, 3183–3194. [Google Scholar] [CrossRef]

- Maruda, R.W.; Krolczyk, G.M.; Wojciechowski, S.; Powalka, B.; Klos, S.; Szczotkarz, N.; Matuszak, M.; Khanna, N. Evaluation of turning with different cooling-lubricating techniques in terms of surface integrity and tribologic properties. Tribol. Int. 2020, 148, 106334. [Google Scholar] [CrossRef]

| Coin Value | Country | Type | Years | Composition (Alloy) | Diameter (mm) | Thickness (mm) | Weight (g) |

|---|---|---|---|---|---|---|---|

| 1 złoty | Poland | Standard circulation coin | 1990–2016 | Cu75Ni25 | 23.00 | 1.70 | 5.00 |

| 1 franc | France | 1959–2001 | Ni | 24.00 | 1.79 | 6.00 | |

| 50 bani | Romania | 2005–2017 | Cu80Zn15Ni5 | 23.75 | 1.90 | 6.10 | |

| 5 pence | Great Britain | 2011–2015 | Ni-plated steel | 18.00 | 1.89 | 3.25 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kapłonek, W.; Mikolajczyk, T.; Pimenov, D.Y.; Gupta, M.K.; Mia, M.; Sharma, S.; Patra, K.; Sutowska, M. High-Accuracy 3D Optical Profilometry for Analysis of Surface Condition of Modern Circulated Coins. Materials 2020, 13, 5371. https://doi.org/10.3390/ma13235371

Kapłonek W, Mikolajczyk T, Pimenov DY, Gupta MK, Mia M, Sharma S, Patra K, Sutowska M. High-Accuracy 3D Optical Profilometry for Analysis of Surface Condition of Modern Circulated Coins. Materials. 2020; 13(23):5371. https://doi.org/10.3390/ma13235371

Chicago/Turabian StyleKapłonek, Wojciech, Tadeusz Mikolajczyk, Danil Yurievich Pimenov, Munish Kumar Gupta, Mozammel Mia, Shubham Sharma, Karali Patra, and Marzena Sutowska. 2020. "High-Accuracy 3D Optical Profilometry for Analysis of Surface Condition of Modern Circulated Coins" Materials 13, no. 23: 5371. https://doi.org/10.3390/ma13235371

APA StyleKapłonek, W., Mikolajczyk, T., Pimenov, D. Y., Gupta, M. K., Mia, M., Sharma, S., Patra, K., & Sutowska, M. (2020). High-Accuracy 3D Optical Profilometry for Analysis of Surface Condition of Modern Circulated Coins. Materials, 13(23), 5371. https://doi.org/10.3390/ma13235371