Morphological Evolutions of Ni-Rich Phases in Al-Si Piston Alloys during 250–400 °C Thermal Exposure Processes

Abstract

1. Introduction

2. Experimental Procedures

2.1. Materials Preparation

2.2. Microstructure Characterization

2.3. Mechanical Properties

3. Results

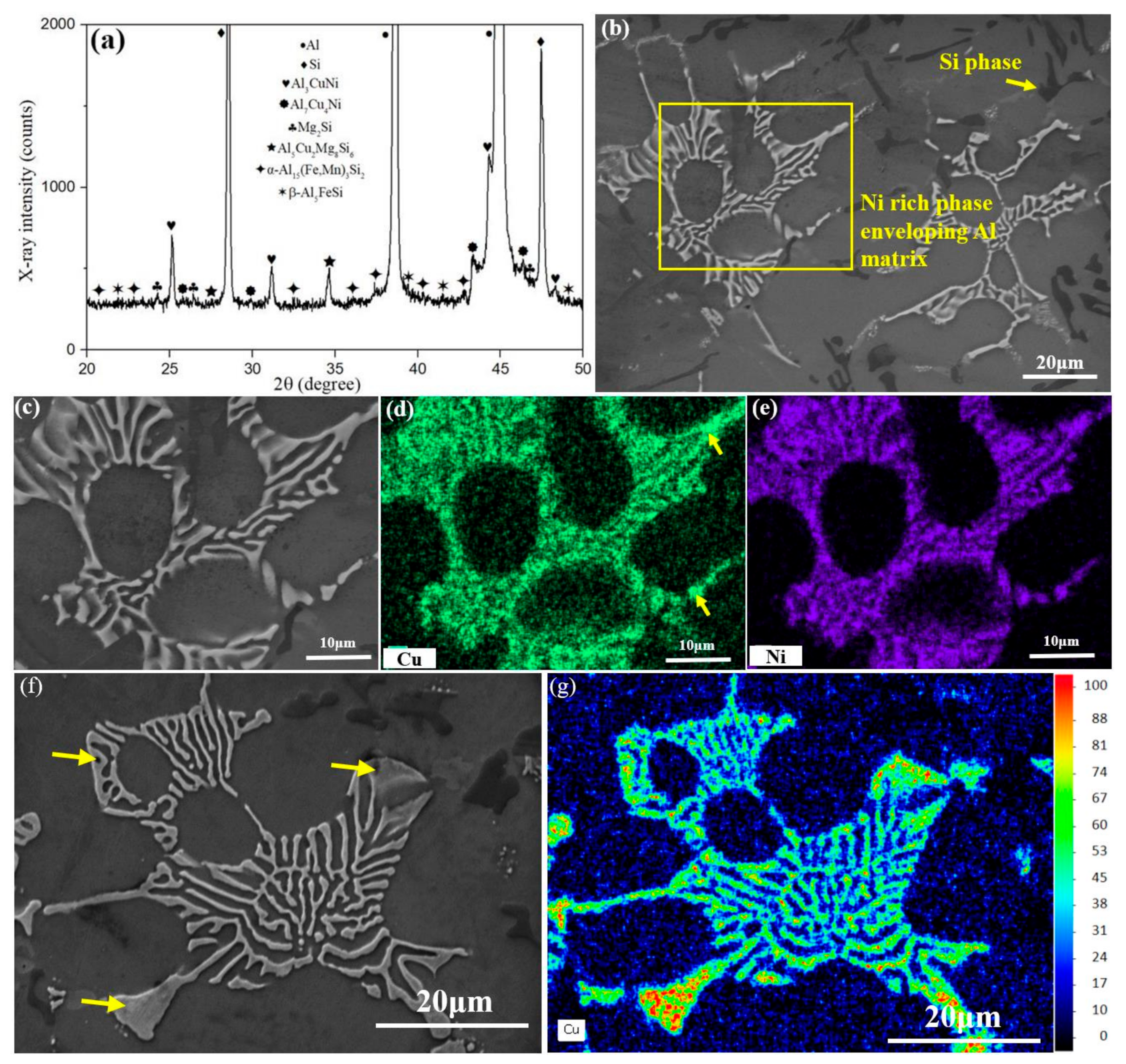

3.1. Microstructures of As-Cast of Al-Si Piston Alloy

3.2. Heat Treated Al-Si Alloys with Relative Thermal Stabilities

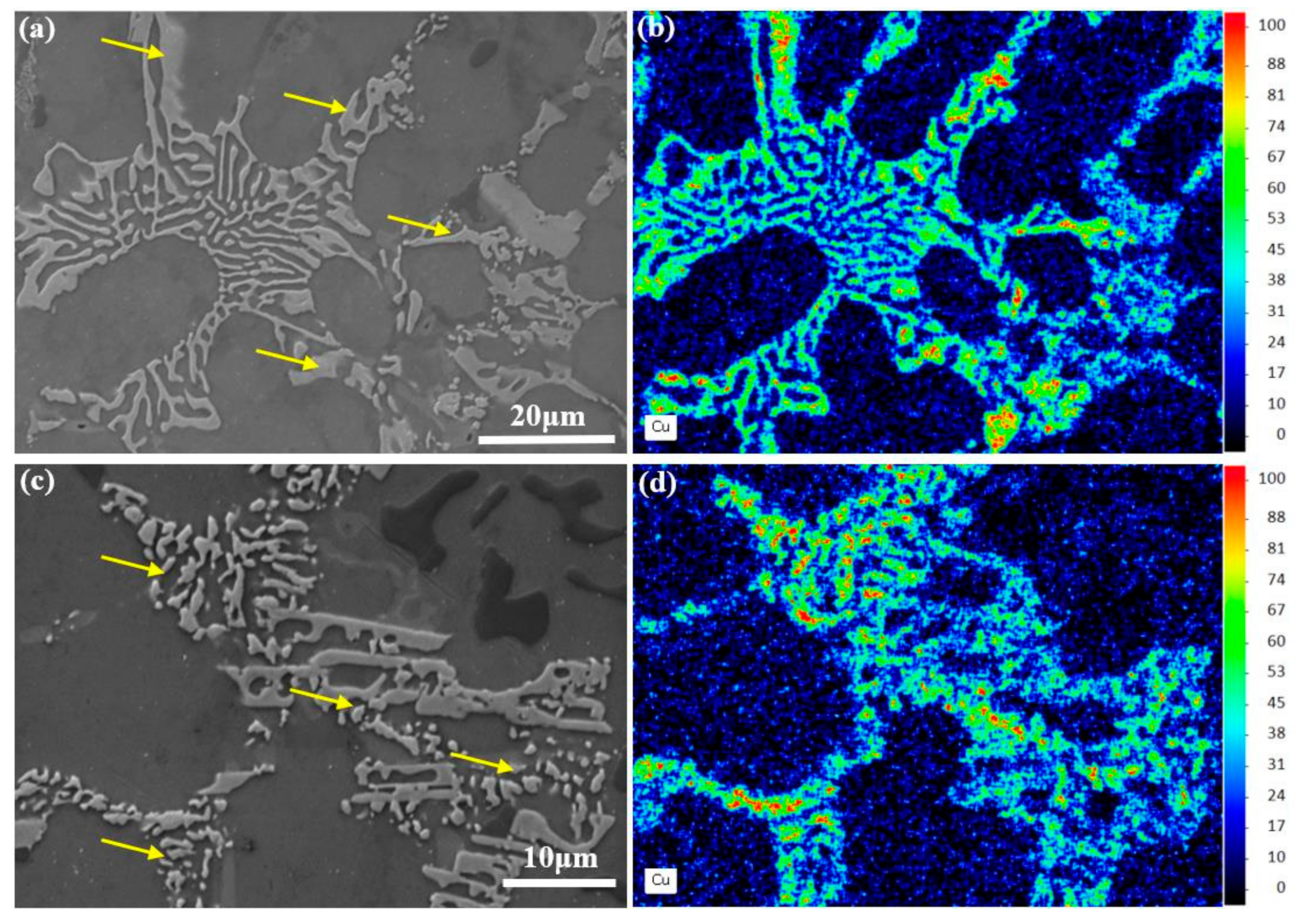

3.3. Basic Morphological Features T6 (235 °C) Al-Si Alloys

4. Discussion

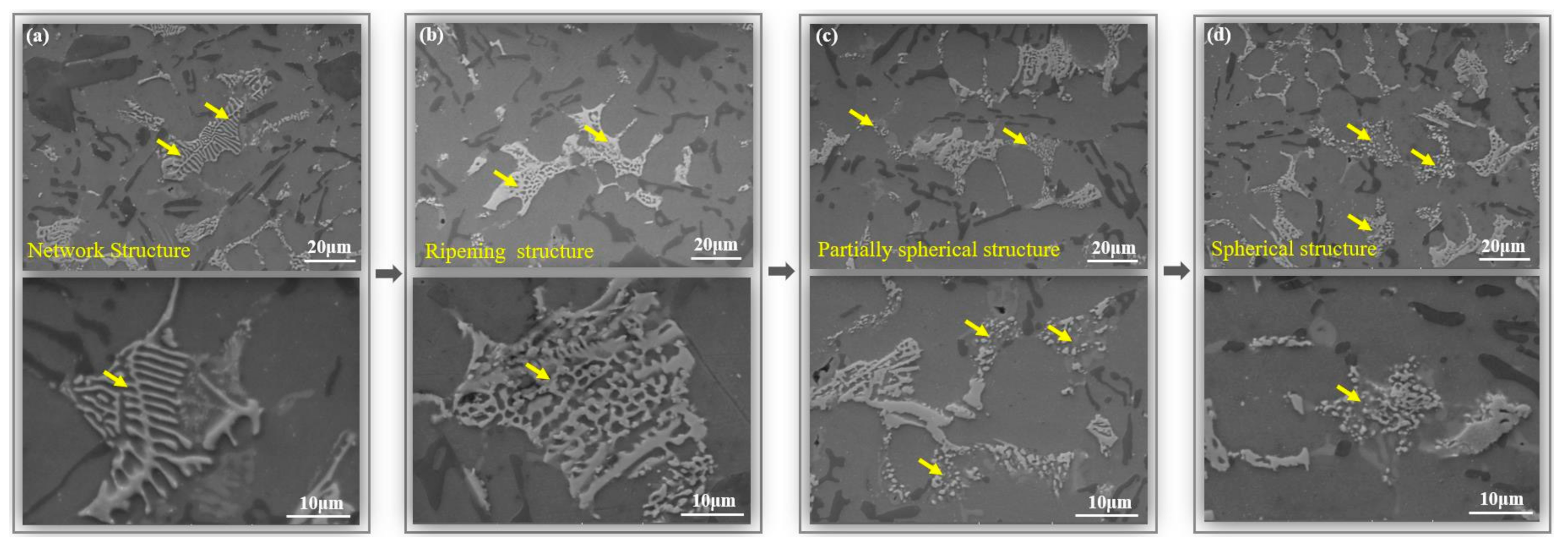

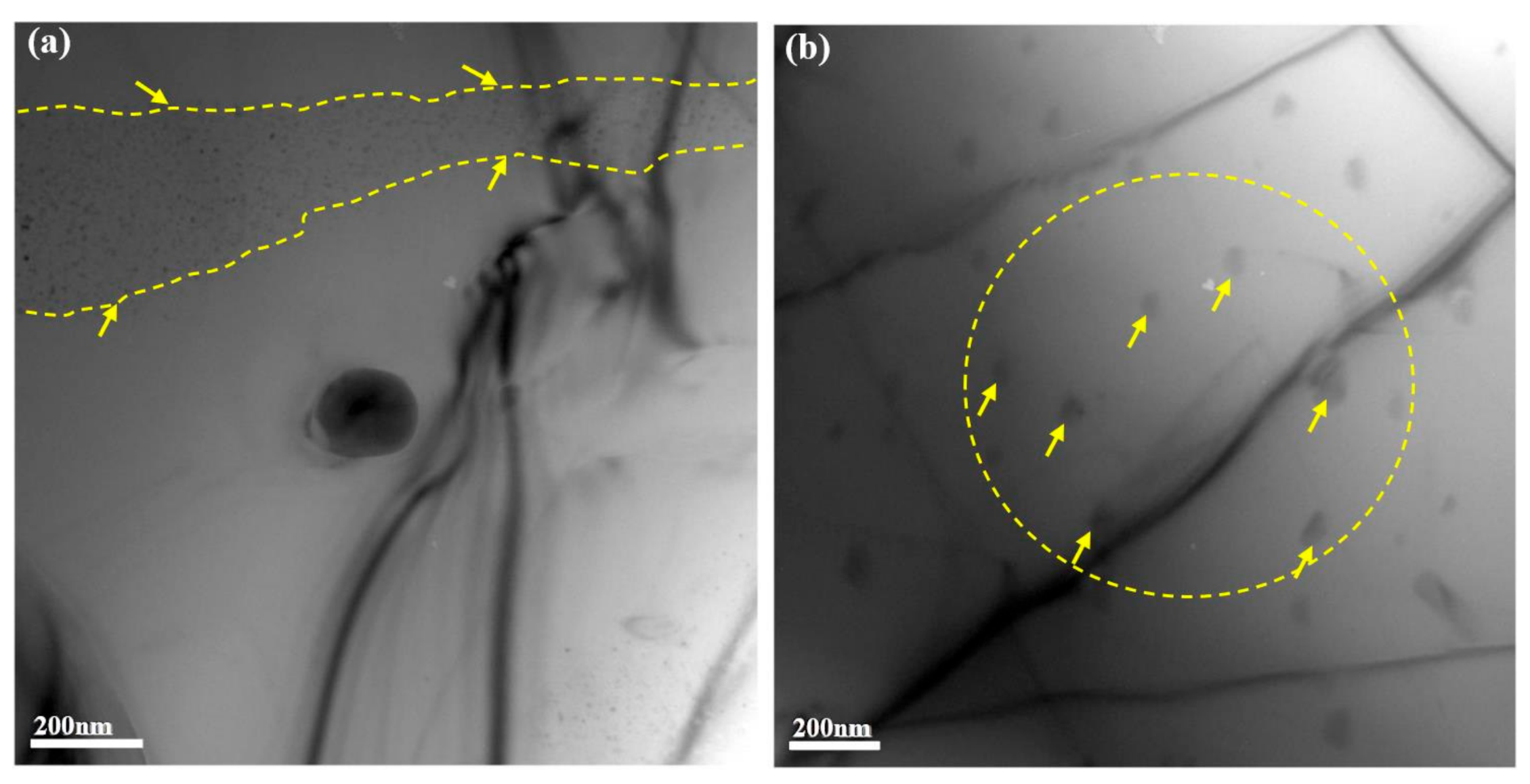

4.1. Morphological Evolution of Ni-Rich Phases during 300 °C Thermal Exposure Process

4.2. Thermal Stability of T6(235 °C) Al-Si Alloy under 250–400 °C Thermal Exposures

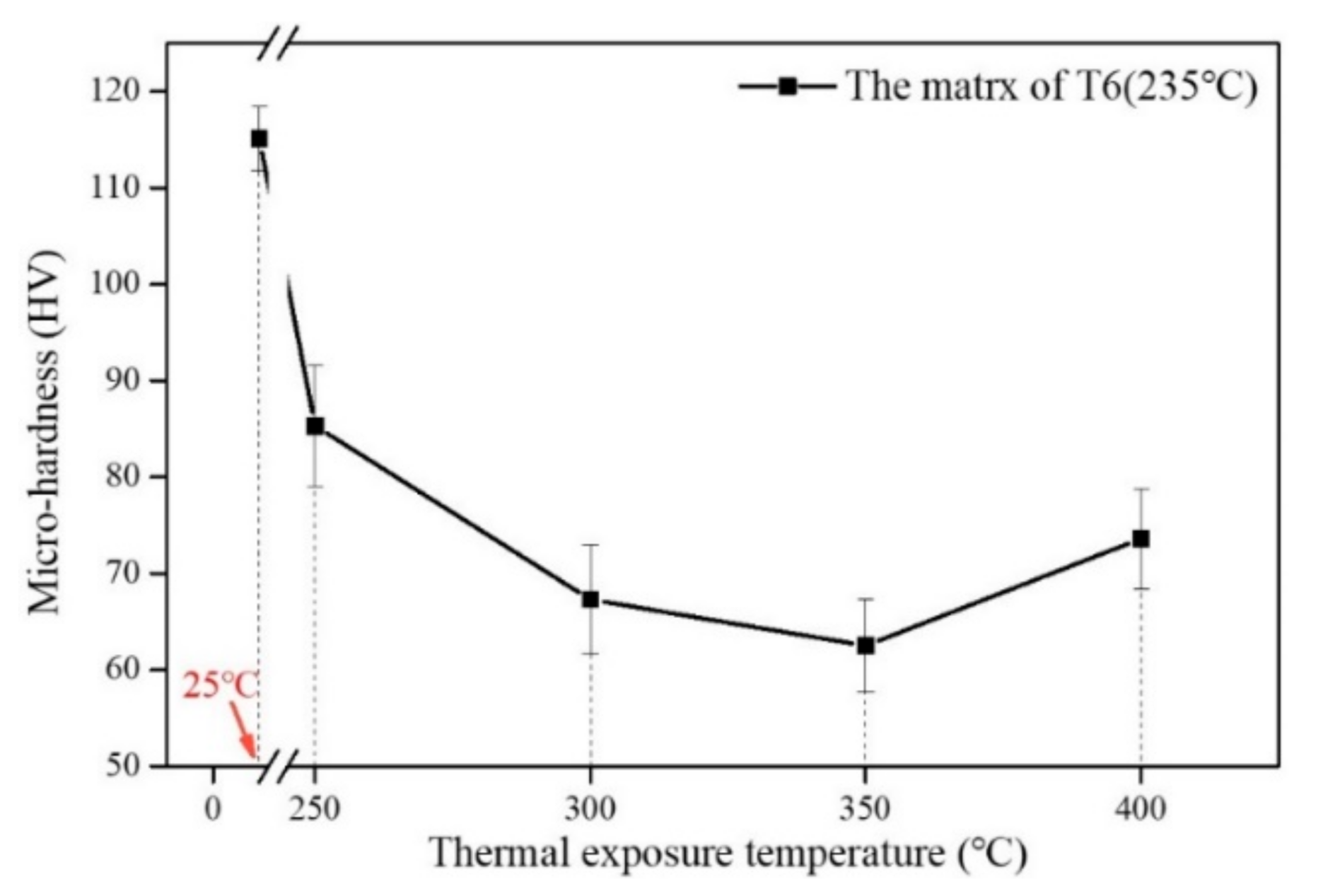

4.3. The Effect of Thermal Exposure on the Micro-Hardness of Al Matrix

5. Conclusions

- (1)

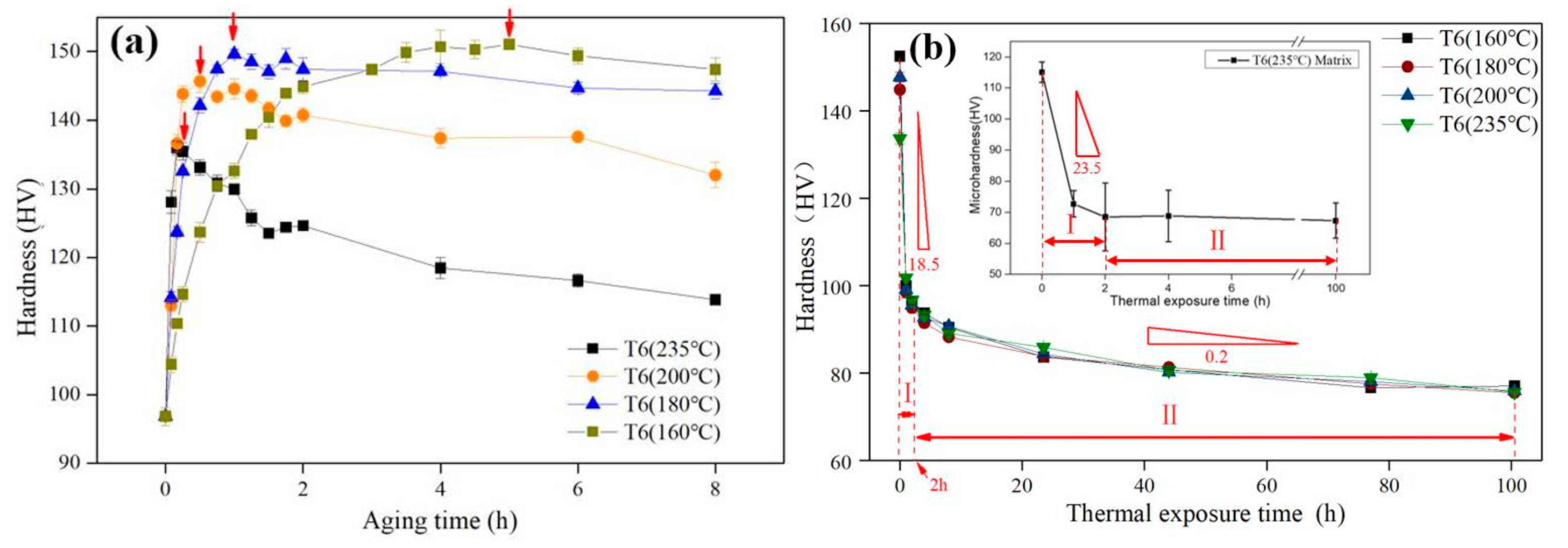

- Through the T6 treatment, the lower aging temperature can induce the higher hardness among four PA states (160 °C, 180 °C, 200 °C and 235 °C). However, the final hardness values are similar in these states by the thermal exposure. Normally, based on the hardness evolution of the alloys and micro-hardness fluctuation of matrix, the thermal exposure process can be divided into two stages using T6 (235 °C) as an example. The first stage is associated with coarsening of the precipitates, and the second stage is correlated with the evolution of the Ni-rich phases.

- (2)

- The morphological evolution of the Ni-rich phases during the thermal exposure has followed the sequence: network structure → ripening structure → spherical cluster structure. The Cu content sequence is: network structure < ripening structure < spherical cluster structure. The micro-hardness sequence is: spherical cluster structure < network structure < ripening structure. The Ni-rich phases with ripening structure has played an important role in improving the thermal stability of the alloy. The simultaneous decrease of the network structure and the increase of the spherical cluster structure should cause the hardness reduction of the alloy.

- (3)

- Statistical results of the Ni-rich phases show that the area fractions of three morphologies have varied with the exposure temperature. The network phase and spherical cluster phase change linearly with the increasing exposure temperature, and the former is inversely proportional while the latter is in direct proportion. However, the area fraction of the Ni-rich phases with ripening structure changes with exposure temperature in a U-shaped curve.

- (4)

- The hardness of the Al-Si alloy, the micro-hardness of the matrix and the weighted hardness of the Ni-rich phases have obeyed the similar trend with exposure temperature. Their values decrease in the temperature range of 250 °C to 350 °C, and then increase when the temperature climates to 400 °C.

- (5)

- The hardness improvement at 400 °C can be attributed to both the increase of the area fraction of Ni-rich phases with ripening structure and the precipitation of new dispersoids Al2(Cu, Fe).

Author Contributions

Funding

Conflicts of Interest

References

- Yang, Y.; Zhong, S.-Y.; Chen, Z.; Wang, M.; Ma, N.; Wang, H. Effect of Cr content and heat-treatment on the high temperature strength of eutectic Al–Si alloys. J. Alloys Compd. 2015, 647, 63–69. [Google Scholar] [CrossRef]

- Asghar, Z.; Requena, G.; Degischer, H.; Cloetens, P. Three-dimensional study of Ni aluminides in an AlSi12 alloy by means of light optical and synchrotron microtomography. Acta Mater. 2009, 57, 4125–4132. [Google Scholar] [CrossRef]

- Lima, J.; Barbosa, C.R.; Magno, I.; Nascimento, J.; Barros, A.; Oliveira, M.; Souza, F.; Rocha, O.L. Microstructural evolution during unsteady-state horizontal solidification of Al-Si-Mg (356) alloy. Trans. Nonferrous Met. Soc. China 2018, 28, 1073–1083. [Google Scholar] [CrossRef]

- Asghar, Z.; Requena, G.; Zahid, G.; Din, R.U. Effect of thermally stable Cu- and Mg-rich aluminides on the high temperature strength of an AlSi12CuMgNi alloy. Mater. Charact. 2014, 88, 80–85. [Google Scholar] [CrossRef]

- Lasagni, F.; Marks, E.; Holzapfel, C.; Mücklich, F.; Degischer, H. Three-dimensional characterization of ‘as-cast’ and solution-treated AlSi12(Sr) alloys by high-resolution FIB tomography. Acta Mater. 2007, 55, 3875–3882. [Google Scholar] [CrossRef]

- Abdelaziz, M.H.; Doty, H.; Valtierra, S.; Samuel, F.H. Static versus dynamic thermal exposure of transition elements-containing Al-Si-Cu-Mg cast alloy. Mater. Sci. Eng. A 2019, 739, 499–512. [Google Scholar] [CrossRef]

- Bugelnig, K.; Sket, F.; Germann, H.; Steffens, T.; Koos, R.; Wilde, F.; Boller, E.; Requena, G. Influence of 3D connectivity of rigid phases on damage evolution during tensile deformation of an AlSi12Cu4Ni2 piston alloy. Mater. Sci. Eng. A 2018, 709, 193–202. [Google Scholar] [CrossRef]

- Jung, J.-G.; Lee, S.-H.; Lee, J.-M.; Cho, Y.-H.; Kim, S.-H.; Yoon, W.-H. Improved mechanical properties of near-eutectic Al-Si piston alloy through ultrasonic melt treatment. Mater. Sci. Eng. A 2016, 669, 187–195. [Google Scholar] [CrossRef]

- Liao, H.; Li, G.; Liu, Q. Ni–Rich Phases in Al–12%Si–4%Cu–1.2%Mn–x%Ni Heat–Resistant Alloys and Effect of Ni–Alloying on Tensile Mechanical Properties. J. Mater. Eng. Perform. 2019, 28, 5398–5408. [Google Scholar] [CrossRef]

- Yang, Y.; Yu, K.; Li, Y.; Zhao, D.; Liu, X. Evolution of nickel-rich phases in Al–Si–Cu–Ni–Mg piston alloys with different Cu additions. Mater. Des. 2012, 33, 220–225. [Google Scholar] [CrossRef]

- Qian, Z.; Liu, X.; Zhao, D.; Zhang, G. Effects of trace Mn addition on the elevated temperature tensile strength and microstructure of a low-iron Al–Si piston alloy. Mater. Lett. 2008, 62, 2146–2149. [Google Scholar] [CrossRef]

- Zuo, L.; Ye, B.; Feng, J.; Zhang, H.; Kong, X.; Jiang, H. Effect of ε-Al3Ni phase on mechanical properties of Al–Si–Cu–Mg–Ni alloys at elevated temperature. Mater. Sci. Eng. A 2020, 772, 138794. [Google Scholar] [CrossRef]

- Li, Y.; Yang, Y.; Wu, Y.; Wang, L.; Liu, X. Quantitative comparison of three Ni-containing phases to the elevated-temperature properties of Al–Si piston alloys. Mater. Sci. Eng. A 2010, 527, 7132–7137. [Google Scholar] [CrossRef]

- Zuo, L.; Ye, B.; Feng, J.; Xu, X.; Kong, X.; Jiang, H. Effect of δ-Al3CuNi phase and thermal exposure on microstructure and mechanical properties of Al-Si-Cu-Ni alloys. J. Alloys Compd. 2019, 791, 1015–1024. [Google Scholar] [CrossRef]

- Kang, H.G.; Kida, M.; Miyahara, H.; Ogi, K. Age hardening behaviour of alumina continuous fibre reinforced Al–Si–Cu and Al–Si–Cu–Mg alloys. Int. J. Cast Met. Res. 2016, 15, 1–7. [Google Scholar] [CrossRef]

- Tian, L.; Guo, Y.; Li, J.; Wang, J.; Duan, H.; Xia, F.; Liang, M. Elevated re-aging of a piston aluminium alloy and effect on the microstructure and mechanical properties. Mater. Sci. Eng. A 2018, 738, 375–379. [Google Scholar] [CrossRef]

- Sjölander, E.; Seifeddine, S. The heat treatment of Al–Si–Cu–Mg casting alloys. J. Mater. Process. Technol. 2010, 210, 1249–1259. [Google Scholar] [CrossRef]

- Akopyan, T.K.; Belov, N.A.; Letyagin, N.V. Effect of Trace Addition of Sn on the Precipitation Hardening in Al-Si-Cu Eutectic Alloy. JOM 2019, 71, 1768–1775. [Google Scholar] [CrossRef]

- Colombo, M.; Gariboldi, E.; Morri, A. Er addition to Al-Si-Mg-based casting alloy: Effects on microstructure, room and high temperature mechanical properties. J. Alloys Compd. 2017, 708, 1234–1244. [Google Scholar] [CrossRef]

- Gholizadeh, R.; Shabestari, S.G. Investigation of the Effects of Ni, Fe, and Mn on the Formation of Complex Intermetallic Compounds in Al-Si-Cu-Mg-Ni Alloys. Met. Mater. Trans. A 2011, 42, 3447–3458. [Google Scholar] [CrossRef]

- Liu, Y.; Bian, Z.; Chen, Z.; Wang, M.; Chen, D.; Wang, H. Effect of Mn on the elevated temperature mechanical properties of Al-La alloys. Mater. Charact. 2019, 155, 109821. [Google Scholar] [CrossRef]

- Becker, H.; Thum, A.; Distl, B.; Kriegel, M.J.; Leineweber, A. Effect of Melt Conditioning on Removal of Fe from Second Al–Si Alloys Containing Mg, Mn, and Cr. Metall. Mater. Trans. A 2018, 49, 6375–6389. [Google Scholar] [CrossRef]

- Wang, E.; Hui, X.; Chen, G. Eutectic Al–Si–Cu–Fe–Mn alloys with enhanced mechanical properties at room and elevated temperature. Mater. Des. 2011, 32, 4333–4340. [Google Scholar] [CrossRef]

- Jin, L.; Liu, K.; Chen, X.-G. Evolution of dispersoids and their effects on elevated-temperature strength and creep resistance in Al-Si-Cu 319 cast alloys with Mn and Mo additions. Mater. Sci. Eng. A 2020, 770, 138554. [Google Scholar] [CrossRef]

- Costa, T.A.; Dias, M.; Gomes, L.G.; Rocha, O.L.; Garcia, A. Effect of solution time in T6 heat treatment on microstructure and hardness of a directionally solidified Al–Si–Cu alloy. J. Alloys Compd. 2016, 683, 485–494. [Google Scholar] [CrossRef]

- Chen, X.; Ma, X.; Xi, H.; Zhao, G.; Wang, Y.; Xu, X. Effects of heat treatment on the microstructure and mechanical properties of extruded 2196 Al-Cu-Li alloy. Mater. Des. 2020, 192, 108746. [Google Scholar] [CrossRef]

- Ceschini, L.; Morri, A.; Balducci, E.; Cavina, N.; Rojo, N.; Calogero, L.; Poggio, L. Experimental observations of engine piston damage induced by knocking combustion. Mater. Des. 2017, 114, 312–325. [Google Scholar] [CrossRef]

- Knipling, K.E.; Seidman, D.N.; Dunand, D.C. Ambient– and high–temperature mechanical properties of isochronally aged Al–0.06Sc, Al–0.06Zr and Al–0.06Sc–0.06Zr (at.%) alloys. Acta Mater. 2011, 59, 943–954. [Google Scholar] [CrossRef]

- Yang, Y.; Li, Y.; Wu, W.; Zhao, D.; Liu, X. Effect of existing form of alloying elements on the microhardness of Al–Si–Cu–Ni–Mg piston alloy. Mater. Sci. Eng. A 2011, 528, 5723–5728. [Google Scholar] [CrossRef]

- Jang, J.-I.; Lance, M.; Wen, S.; Tsui, T.Y.; Pharr, G. Indentation-induced phase transformations in silicon: Influences of load, rate and indenter angle on the transformation behavior. Acta Mater. 2005, 53, 1759–1770. [Google Scholar] [CrossRef]

- De Luca, A.; Seidman, D.N.; Dunand, D.C. Effects of Mo and Mn microadditions on strengthening and over-aging resistance of nanoprecipitation-strengthened Al-Zr-Sc-Er-Si alloys. Acta Mater. 2019, 165, 1–14. [Google Scholar] [CrossRef]

- Beroual, S.; Boumerzoug, Z.; Paillard, P.; Borjon-Piron, Y. Effects of heat treatment and addition of small amounts of Cu and Mg on the microstructure and mechanical properties of Al-Si-Cu and Al-Si-Mg cast alloys. J. Alloys Compd. 2019, 784, 1026–1035. [Google Scholar] [CrossRef]

- Asghar, Z.; Requena, G.; Boller, E. Three–dimensional rigid multiphase networks providing high–temperature strength to cast AlSi10Cu5Ni1–2 piston alloys. Acta Mater. 2011, 59, 6420–6432. [Google Scholar] [CrossRef] [PubMed]

- Jeon, J.; Shin, J.; Bae, D. Si phase modification on the elevated temperature mechanical properties of Al-Si hypereutectic alloys. Mater. Sci. Eng. A 2019, 748, 367–370. [Google Scholar] [CrossRef]

- Li, Y.; Yang, Y.; Wu, Y.; Wei, Z.; Liu, X. Supportive strengthening role of Cr-rich phase on Al–Si multicomponent piston alloy at elevated temperature. Mater. Sci. Eng. A 2011, 528, 4427–4430. [Google Scholar] [CrossRef]

- Wang, T.; Cao, F.; Zhou, P.; Kang, H.; Chen, Z.; Fu, Y.; Xiao, T.; Huang, W.; Yuan, Q. Study on diffusion behavior and microstructural evolution of Al/Cu bimetal interface by synchrotron X-ray radiography. J. Alloys Compd. 2014, 616, 550–555. [Google Scholar] [CrossRef]

- Eivani, A.R.; Taheri, A.K. Modeling age hardening kinetics of an Al–Mg–Si–Cu aluminum alloy. J. Mater. Process. Technol. 2008, 205, 388–393. [Google Scholar] [CrossRef]

- Bourgeois, L.; Dwyer, C.; Weyland, M.; Nie, J.-F.; Muddle, B.C. Structure and energetics of the coherent interface between the θ′ precipitate phase and aluminium in Al–Cu. Acta Mater. 2011, 59, 7043–7050. [Google Scholar] [CrossRef]

- Jin, S.; Ngai, T.; Zhang, G.; Zhai, T.; Jia, S.; Li, L. Precipitation strengthening mechanisms during natural ageing and subsequent artificial aging in an Al-Mg-Si-Cu alloy. Mater. Sci. Eng. A 2018, 724, 53–59. [Google Scholar] [CrossRef]

- Belkharchouche, A.; Boudiaf, A.; Belouchrani, M.E.A. A comparison between 2017A and 4047A aluminum alloys microstructure changes under thermal fatigue loading. Mater. Sci. Eng. A 2017, 689, 96–102. [Google Scholar] [CrossRef]

- Gaber, A.; Gaffar, M.; Mostafa, M.; Zeid, E.F.A. Precipitation kinetics of Al–1.12 Mg2Si–0.35 Si and Al–1.07 Mg2Si–0.33 Cu alloys. J. Alloys Compd. 2007, 429, 167–175. [Google Scholar] [CrossRef]

- Song, L.; Liu, H.; Nie, S.; Yu, B.; Wang, S.; Zheng, L.; Li, R. Microstructure and fracture behavior of Al-Si-Mg alloy prepared with recycled alloy. Mater. Werkst. 2019, 50, 462–470. [Google Scholar] [CrossRef]

- Toda, H.; Nishimura, T.; Uesugi, K.; Suzuki, Y.; Kobayashi, M. Influence of high-temperature solution treatments on mechanical properties of an Al–Si–Cu aluminum alloy. Acta Mater. 2010, 58, 2014–2025. [Google Scholar] [CrossRef]

- Santos-Güemes, R.; Bellón, B.; Esteban-Manzanares, G.; Segurado, J.; Capolungo, L.; Llorca, J. Multiscale modelling of precipitation hardening in Al–Cu alloys: Dislocation dynamics simulations and experimental validation. Acta Mater. 2020, 188, 475–485. [Google Scholar] [CrossRef]

- Sui, Y.; Han, L.; Wang, Q.-D. Effects of Thermal Exposure on the Microstructure and Mechanical Properties of Al-Si-Cu-Ni-Mg-Gd Alloy. J. Mater. Eng. Perform. 2019, 28, 908–915. [Google Scholar] [CrossRef]

- Liu, G.; Blake, P.; Ji, S. Effect of Zr on the high cycle fatigue and mechanical properties of Al–Si–Cu–Mg alloys at elevated temperatures. J. Alloys Compd. 2019, 809, 151795. [Google Scholar] [CrossRef]

- Liu, H.; Pang, J.C.; Wang, M.; Li, S.; Zhang, Z. The effect of thermal exposure on the microstructure and mechanical properties of multiphase AlSi12Cu4MgNi2 alloy. Mater. Charact. 2020, 159, 110032. [Google Scholar] [CrossRef]

- Dong, L.; Chu, S.; Hu, B.; Zeng, X.; Chen, B. Atomic-scale investigation into precipitated phase thickening in Al-Si-Mg-Cu alloy. J. Alloys Compd. 2018, 766, 973–978. [Google Scholar] [CrossRef]

- Sui, Y.; Ji, D.; Han, L.; Wang, Q. Characterization of the Aging Precipitates of Al–12Si–4Cu–2Ni– 0.8Mg–0.2Gd Piston Alloy. JOM 2018, 71, 366–372. [Google Scholar] [CrossRef]

| Element | Si | Cu | Ni | Mg | Mn | Fe | Al |

| Nominal Composition | 12.00 | 4.00 | 2.00 | 1.00 | 0.10 | 0.10 | Bal |

| ICP Value | 12.12 | 4.00 | 1.86 | 0.94 | 0.10 | 0.10 | Bal |

| Peak Aged Hardness (HV) | Final Hardness (HV) | ΔHV (HV) | Hardness Retention Ratio | |

|---|---|---|---|---|

| T6 (160 °C) | 151.1 ± 0.3 | 77.1 ± 0.5 | −75.4 | 50.6% |

| T6 (180 °C) | 149.7 ± 1.5 | 75.5 ± 0.7 | −69.3 | 52.1% |

| T6 (200 °C) | 145.7 ± 1.6 | 75.9 ± 0.7 | −71.8 | 51.4% |

| T6 (235 °C) | 136.0 ± 1.0 | 75.7 ± 0.4 | −58.0 | 56.6% |

| f1 (%) | f2 (%) | f3 (%) | HVN (HV) | |

|---|---|---|---|---|

| 250 °C | 38.3 | 51.5 | 10.1 | 181.0 |

| 300 °C | 28.4 | 47.4 | 24.1 | 172.1 |

| 350 °C | 8.3 | 51.3 | 40.4 | 164.3 |

| 400 °C | 1.5 | 56.6 | 41.8 | 166.1 |

| Atomic Percentage (%) | ||

|---|---|---|

| (a) | (b) | |

| Al | 69.7 | 67.8 |

| Cu | 15.6 | 16.3 |

| Fe | 14.7 | 15.9 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

An, H.; Geng, J.; Bian, Z.; Liu, G.; Wang, M.; Chen, D.; Wang, H. Morphological Evolutions of Ni-Rich Phases in Al-Si Piston Alloys during 250–400 °C Thermal Exposure Processes. Materials 2020, 13, 5212. https://doi.org/10.3390/ma13225212

An H, Geng J, Bian Z, Liu G, Wang M, Chen D, Wang H. Morphological Evolutions of Ni-Rich Phases in Al-Si Piston Alloys during 250–400 °C Thermal Exposure Processes. Materials. 2020; 13(22):5212. https://doi.org/10.3390/ma13225212

Chicago/Turabian StyleAn, Haowei, Jiwei Geng, Zeyu Bian, Gen Liu, Mingliang Wang, Dong Chen, and Haowei Wang. 2020. "Morphological Evolutions of Ni-Rich Phases in Al-Si Piston Alloys during 250–400 °C Thermal Exposure Processes" Materials 13, no. 22: 5212. https://doi.org/10.3390/ma13225212

APA StyleAn, H., Geng, J., Bian, Z., Liu, G., Wang, M., Chen, D., & Wang, H. (2020). Morphological Evolutions of Ni-Rich Phases in Al-Si Piston Alloys during 250–400 °C Thermal Exposure Processes. Materials, 13(22), 5212. https://doi.org/10.3390/ma13225212