3.1. Analysis of Glass Envelope

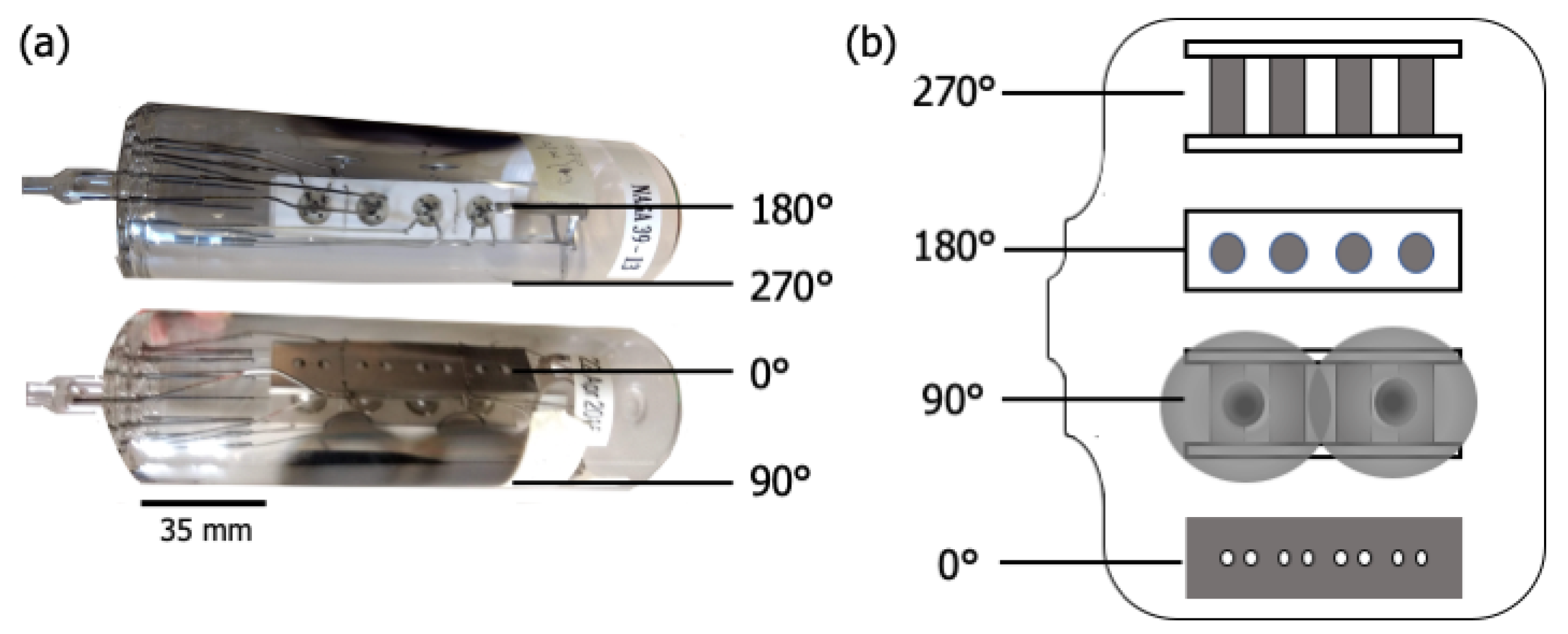

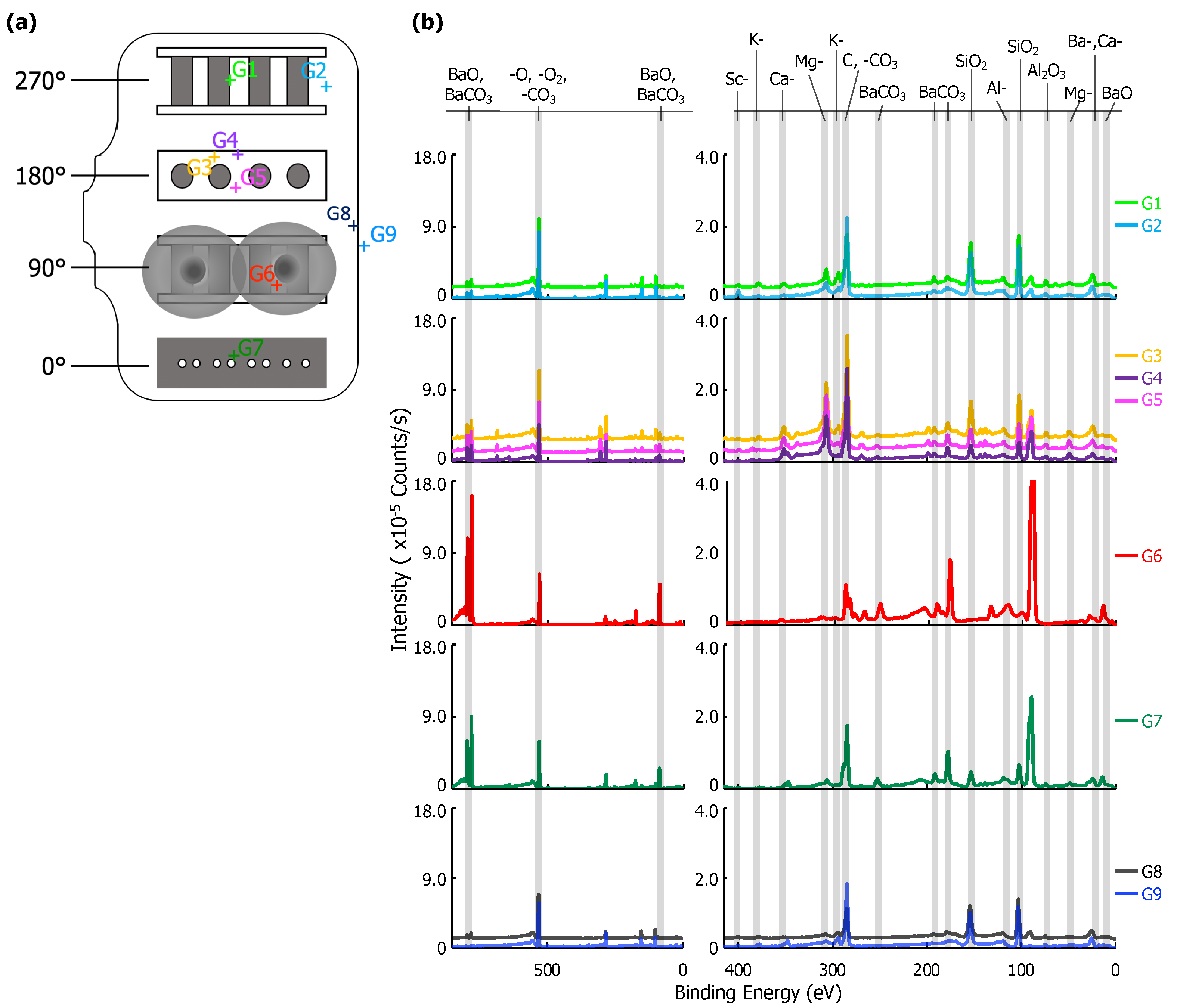

XPS point scans from eight positions on the interior and one position on the exterior of the glass envelope are shown in

Figure 3. Arbitrary vertical shifts were applied to facilitate plotting multiple spectra. Full scans (850–0 eV) are generally dominated by the Ba-, O-, and C- peaks above 400 eV. Peaks below 400 eV are highlighted in a separate spectra; both are included in

Figure 3b.

The location of each point scan is indicated in

Figure 3a. G7 is above the cathodes opposite the anode plate, which has pinholes with ~0.5 mm diameters directly in line with the cathodes (see

Figure 1 and

Figure 2). G1 and G2 are adjacent to the cathode assembly, and G6 is within the Ba-Al flash region. G3, G4, and G5 are behind the cathodes (see

Figure 1). G8 is a reference interior point opposite the sealed opening, and G9 is a similarly located exterior reference. Peak binding energies, background-deducted counts, S/N ratios, spectral lines, and species identification for each position can be found in tables located in the

Appendix A.

Six elements were observed in XPS scans at various points on the glass envelope: Al, Ba, Ca, K, Mg, and Si. Ba signal, likely originating from BaO and BaCO, was observed on all interior surfaces, but were absent from the exterior reference point (G9). The strongest Ba signal was observed at G6, which is directly opposite the Ba-Al flash pans, while trace Ba signal was observed at G8, an interior point far from the flash pans and the cathodes. Moderate SiO signal was observed everywhere except at point G6 (Ba-Al flash region), and its strength decreased noticeably at G7 (interior point in front of cathodes). Trace K, Mg, and Ca signal appeared everywhere SiO is present; however, K is absent at G7 and Mg signal is significantly enhanced at G1-G5. Al signal was observed at all points. Signal plausibly originating from Sc was only observed at G2, where its S/N ratio = 4. However, it is important to note that the Mo 3p3/2 peak overlaps that of Sc 2p3/2. As Mo is the primary component of the anode, it cannot be asserted with absolute certainty that it is absent on the glass.

Results from G9 give a baseline for the glass envelope itself: Al, Ca, K, Mg, and Si are all present. These results indicate a standard aluminosilicate glass with K, Ca, and Mg dopants [

17]. Ca and Al are also both present in the impregnate (known from processing history), but K, Mg, and Si are unique to the glass. Therefore, the absence of K, Mg, and Si at G6 shows that the layer deposited by the Ba-Al flash in this region is thicker than 10 nm, the sampling depth for XPS.

The spectrum at G8 differs from that of G9 only by the presence of moderate Ba signal, showing that Ba from the Ba-Al flash and/or impregnate desorption condenses onto all interior glass surfaces. The remaining points show BaO/BaCO peaks increasing in strength from G1/G2 to G3–G5, and reaching a maximum signal (excepting point G6) at G7, a point on the glass envelope in front of the cathodes. The implication is that the thickness of deposited Ba-containing layers in these regions is no more than 10 nm, as signal from elements present only in the glass substrate is observed. While points G3-G5 and G7 are all 90 away from the flash pans, point G7, in front of the cathodes, is associated with greater Ba signal than points G3-G5, which are located behind the cathodes.

The MgO signal is dramatically enhanced at points G3–G5 and somewhat enhanced at G1–G2. This is likely due to Auger enhancement of the Mg signal due to fluorescence from C-containing layers atop the MgO-containing glass [

18]. C-containing layers less than a monolayer thick would yield minimal Auger enhancement of MgO emission (due to reduced intensity of C fluorescence) from the glass, while thicker overlayers (e.g., multiple monolayers) of C-containing material would absorb MgO Auger emissions, also reducing observed signal enhancement. Given that the amount of MgO is likely consistent throughout the glass, variations in MgO peak intensity likely arise from variations in the thickness of C-containing overlayers. While adventitious C is certainly present everywhere, it is likely distributed uniformly on the envelope interior, implying that it is the amount of deposited BaCO

that varies from region to region. Peak intensity data in

Figure 3 for BaO/BaCO

and (Auger enhanced) MgO indicates that the Ba-containing layer is (i) thin, potentially less than 1 monolayer, at G1 and G2 (limiting Auger enhancement of the MgO signal); (ii) on the order of a monolayer (maximizing enhancement of MgO signal) at G3-G5; and (iii) thicker than a single monolayer—though less than 10 nm thick—at G7 (reducing, but not obstructing, Auger enhancement).

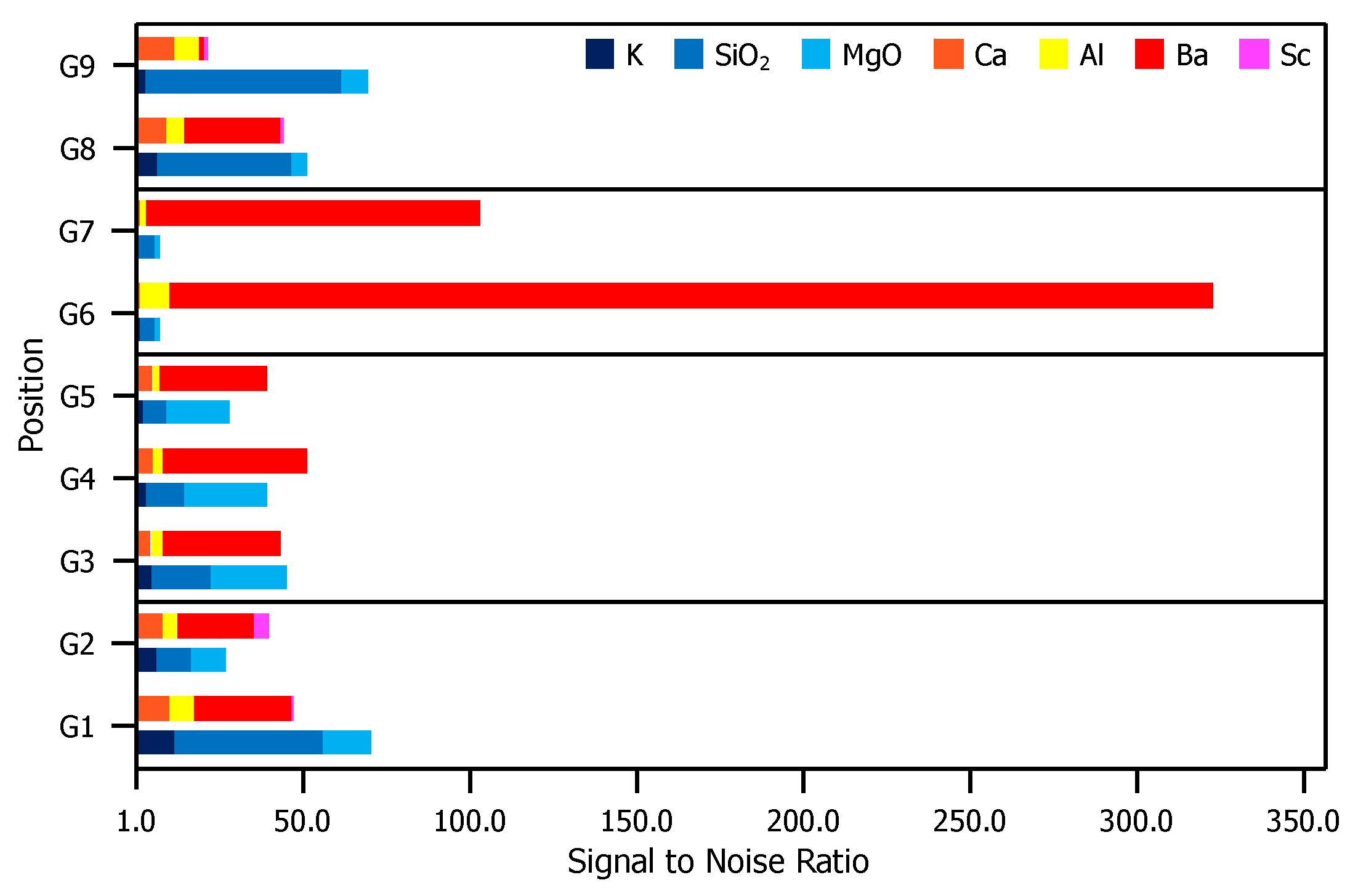

Figure 4 is a comparison of XPS results for the glass envelope. For each peak labeled in

Figure 3, the S/N ratio (included in the

Appendix A), is plotted for each evaluated position. Contrasts in the S/N ratio observed from position-to-position indicate significantly dissimilar compositions.

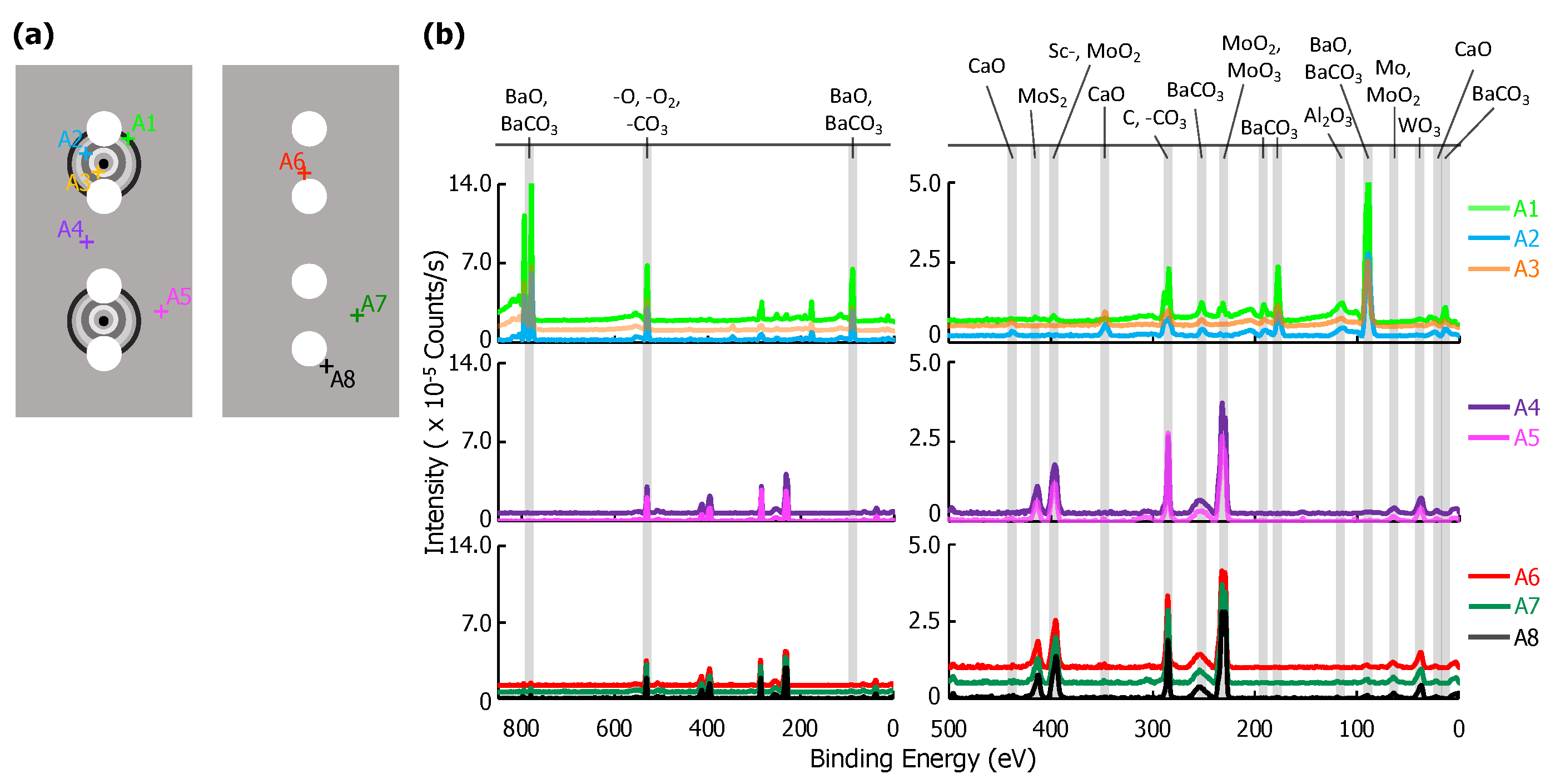

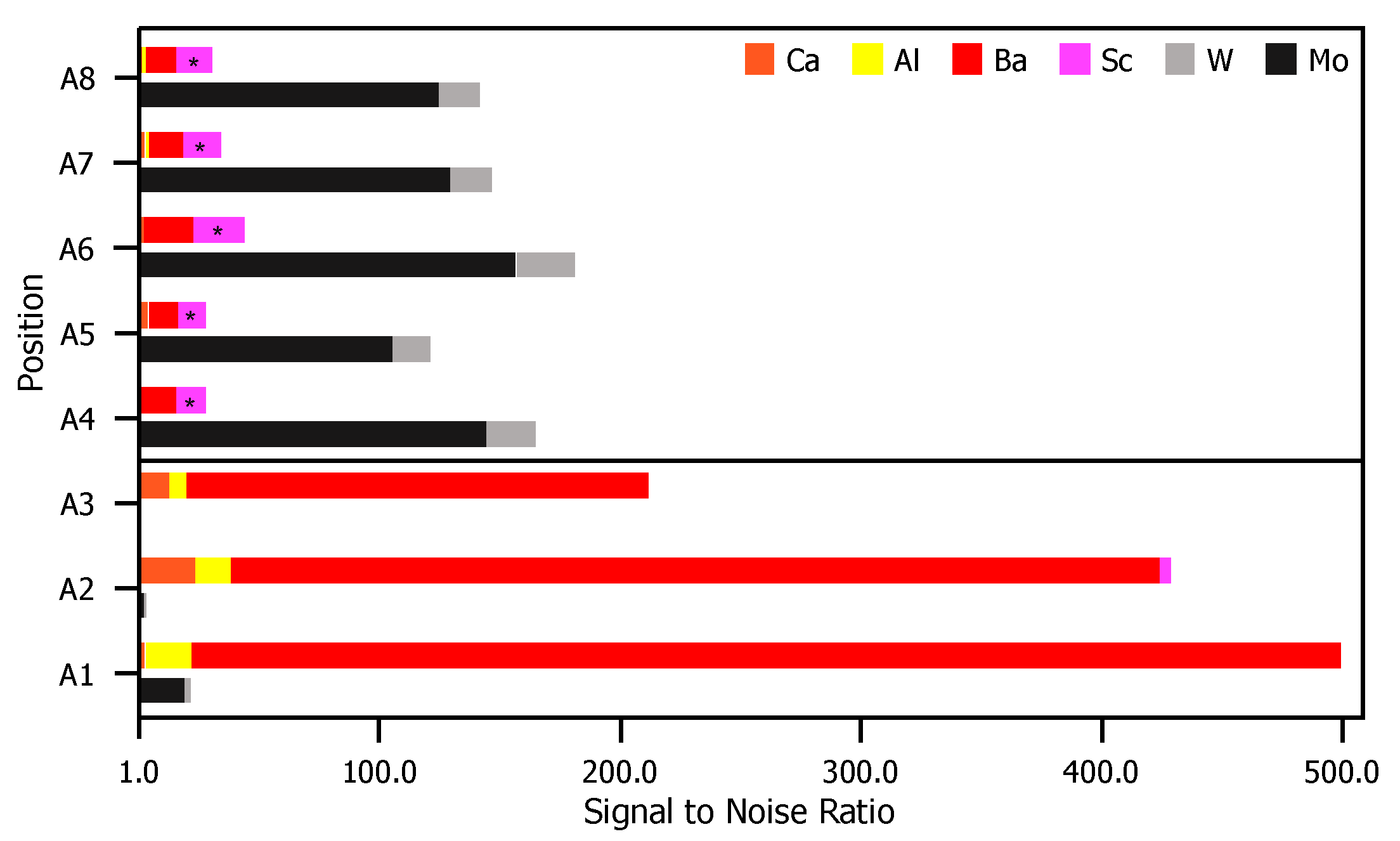

3.2. Analysis of Anode

XPS results for eight point scans on the anode—five on the cathode-facing side, A1–A5, and three on the opposite side, A6–A8—are shown in

Figure 5. The location of each point scan is indicated in the diagram included as

Figure 5a, and the two columns of spectra in

Figure 5b are as described above for the glass envelope. Arbitrary vertical shifts were applied to improve readability. The eight point scans can be separated into three groups: A1, A2, and A3 are all located on discolored rings discernible on the cathode-facing anode surface (

Figure 2). A4 and A5 are also on the cathode-facing side of the anode, but away from discolored rings. A6, A7, and A8 are distributed across the back of the anode, which directly face the glass envelope. Peak binding energies, background-deducted counts, S/N ratios, spectral lines, and species identification for each position can be found in tables located in the

Appendix A.

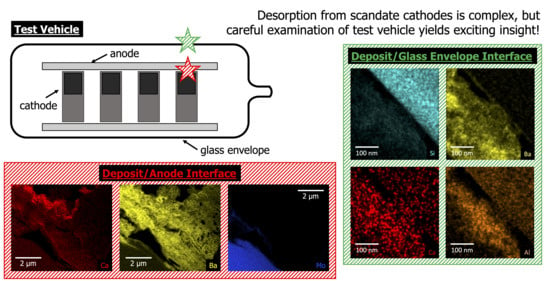

Species related to five elements were observed on the anode: Al, Ba, Ca, Mo, and W. Mo, the primary component of the anode, was observed at all points except A2 and A3. This indicates that deposits in these regions are >10 nm thick and correspond to the discolored rings. Ca signal was observed for points A2 and A3, but were extremely weak or absent at all other points. Al is present only as AlO, and only at A1–A3 (in the discolored rings). As Ca is not present at A1, the presence of Al could suggest that the Al and Ca do not originate from the same sources, or that the materials were deposited at different times. Ba-containing compounds (BaO or BaCO) are detected everywhere, but are particularly strong at points A1–A3. W was also detected, but only at points A4–A8 that are either on the back of the anode, or well away from the deposition rings facing the cathodes.

Sc and ScO binding energies are similar to those of Mo (within 2 eV of each other at ~400 eV). Signal corresponding to energies of ~400 eV only appear far away from the cathode (A4–A5), or on the back of the anode (A6–A8). At these locations signals from other impregnate elements are absent or trace. In contrast, at locations where other impregnate elements yield strong signals, the signal at ~400 eV is absent. As Sc desorbed from the cathode would be expected to be present on the side of anode facing the cathode and strongest near the cathode or where other impregnate materials is found, we conclude that observed signals ~400 eV arise from Mo.

Figure 6 is a comparison of XPS results for the anode. For each peak labeled in

Figure 5, the S/N ratio (included in the

Appendix A) is plotted for each evaluated position. Similar to the case for the envelope, there are again contrasts in the observed signal position-to-position. Positions near the pinhole directly opposite the cathodes (A1–A3) shown signal from elements originating in the impregnate, while signal in the other positions (A4–A8) are correlated to elements that are primary components of the substrate.

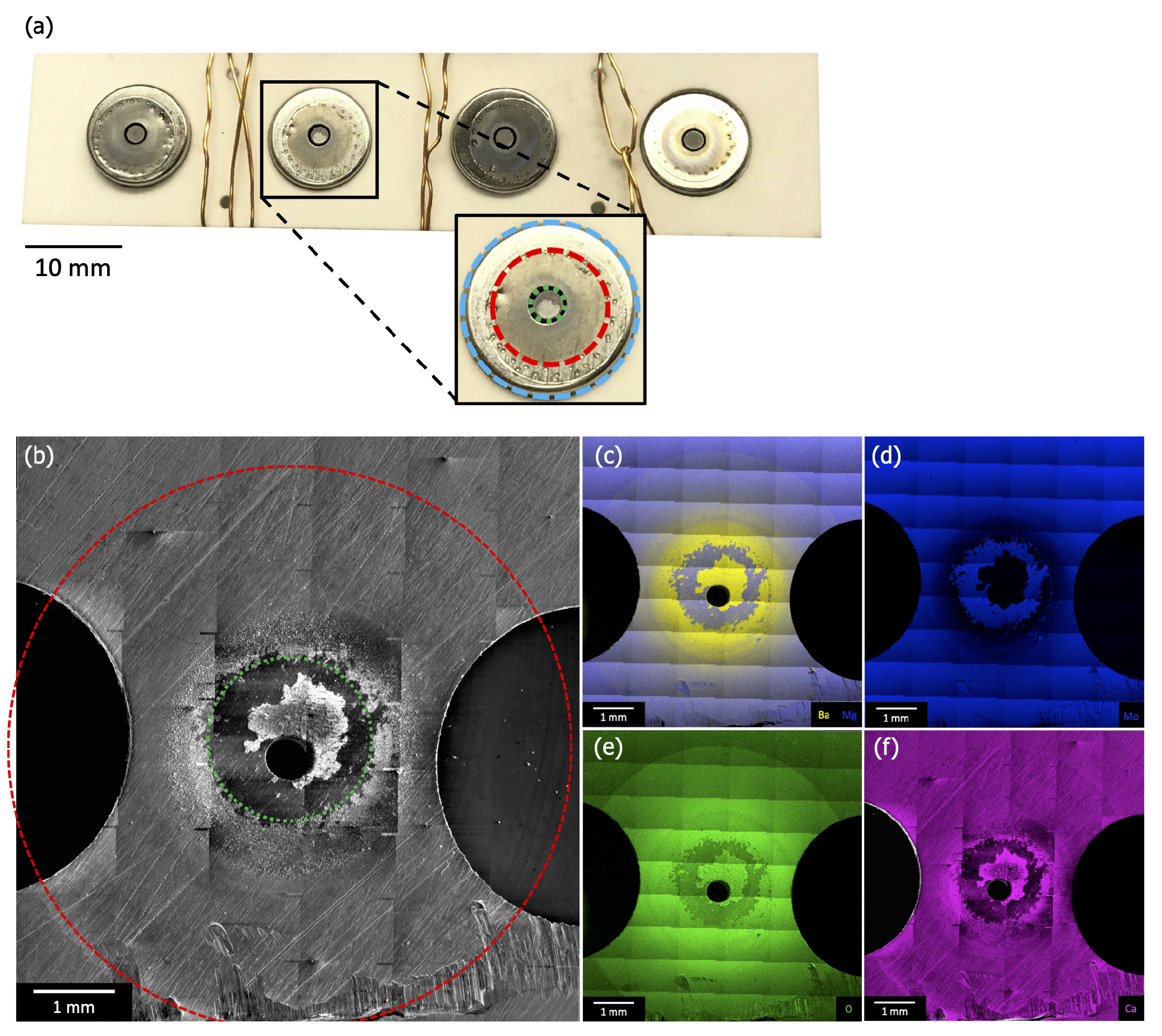

Figure 7a is a photograph of the cathode assembly before removal of the cathodes but after removal of the anode plate. The cathode housings (blue ring in “zoom in” image) are visible through holes in the (off-white) ceramic spacer, and the cathodes themselves are visible through holes in this housing (green ring in “zoom-in”, ~2 mm in diameter). The copper wiring is

not a part of the original cathode assembly, and was added to secure the remaining components after disassembly.

Figure 7b–f shows plan-view SEM and EDS results from one of the ring regions of the anode directly opposite the cathodes’ emitting surface (

Figure 2). Each image is comprised of multiple scans combined to produce a single large area image, allowing for examination of the entire deposition region (red ring in

Figure 7b, ~6 mm in diameter).

SEM and EDS reveal a radial pattern of deposited material consistent with an emission source located under an anode pinhole (diameter ~0.5 mm), and therefore being consistent with the position of the cathode. EDS shows that the deposited material contains Ba, O, and Ca. Large area scans indicate that, beyond the primary deposition area centered on the pinhole (green ring in panel

Figure 7b), the deposited layer is thinner than the 1–2 micron sampling depth for EDS. Little or no deposition is observed beyond ~3 mm from the pinhole. This outer deposition region is consistent with features of the cathode housing, as highlighted by equivalent red ring in

Figure 7a,b.

The thickness of deposited material increases closer to the primary deposition area (green ring), eventually becoming thick enough to obstruct Mo signal. This area corresponds directly to the size, shape, and position of the cathode itself, as highlighted by equivalent ~2 mm diameter green ring in

Figure 7a,b. Portions of the primary deposition area are bare of deposit, as highlighted in

Figure 7b–f. Ba, Ca, and Mo scans show that the Mo substrate is exposed in this area, consistent with close examination of SEM images, which show surface scratches on the Mo anode disappearing under the deposited layer, then reappearing. This is hypothesized to be evidence that deposited material flaked off the anode, either during disassembly of the test vehicle or, possibly, during activation or operation.

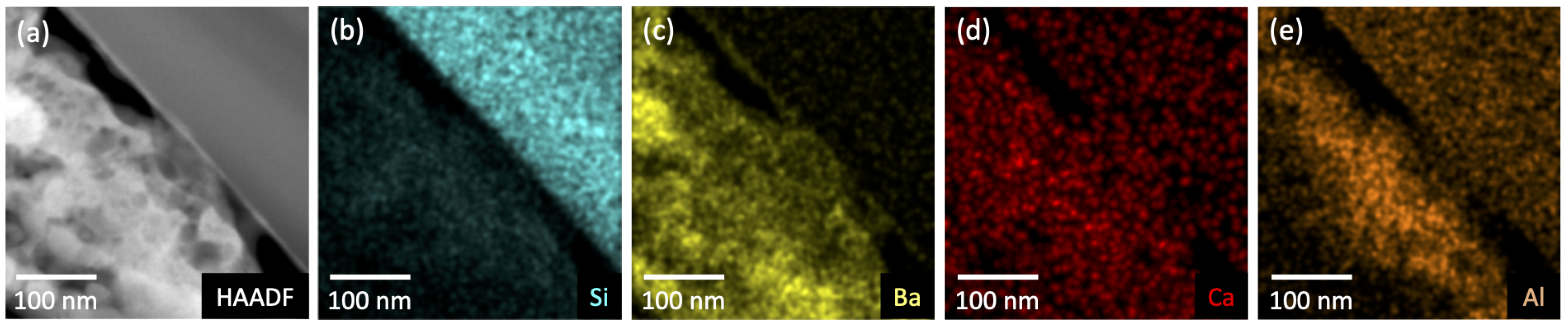

3.5. Ca and Sc Desorption

The XPS signal associated with Ca was observed from almost every region of the glass envelope, although the signal was generally moderate. Ca was also observed in the exterior reference (G9). This implies that in these regions (everywhere except G6) Ca is either present in the top 10 nm of deposited material or that the deposited layer is less than 10 nm thick. The absence of peaks associated with Ca at G6, the Ba-Al flash region, is notable, especially given that elemental mapping of the cross section show that Ca is plausibly present in at least the first few hundred nanometers of the deposit on the glass substrate at G6 (

Figure 8). Scanning electron imaging of the entire FIB lift-out showed the deposit layer to be 2.5–3

m thick. The fact that Ca is not detected in the top 10 nm of material deposited at G6 (based on XPS, see

Figure 3), but

is detected in the first few hundred nanometers of deposit, may suggest that Ca-containing deposits were formed prior to the Ba-Al flash—that is, before both activation and operation, possibly during pre-activation. These initial Ca-containing deposits would have then been covered by the Ba-Al flash residue.

Ca signal is observed at A2 and A3, which are in or near the primary deposition region (the green ring in

Figure 7b). Elemental mapping of an anode lift-out sample originating from A3 shows evidence that Ca deposition did not occur uniformly, seemingly exhibiting layers of Ca-rich deposits (

Figure 9). Assuming that the impregnate desorbs relatively uniformly during operation, these striations in deposition composition suggest the possibility that Ca desorption is nonuniform in time. As cathode environmental conditions are uniform during operation this may, in turn, again suggest that Ca is primarily desorbed during pre-activation and activation.

The detection of Sc given the XPS and EDS results is plausible, but highly ambiguous. G2 is the only point on either the glass or the anode to exhibit an isolated peak around 400 eV—the binding energy associated with Sc 2p3/2. On the anode, Sc signal is observed at this energy; however, it is only present at A4–A8, which are away from the cathodes or on the opposite side of the anode. It is more likely that this signal originates from Mo, which is the primary component of the anode. If Sc was desorbing from the cathode, it would be observed in A1–A3. As it is not, the immediate implication is that, unlike Ba, Ca, and Al, either Sc/Sc

O

desorbs so slowly that even after pre-activation, activation, and ~26,000 h of operation Sc is not detectable, or that Sc does not desorb from the cathode. A dissensus remains in the literature as to the behavior of Sc during operation: some report the presence of Sc at the surface of high-performing scandate cathodes after operation [

20], while others hypothesize that Sc readily desorbs based on studies of model Ba-Sc-O on W surfaces [

21].

3.6. Implications of Anode Deposits

Given the spatial distribution of Ba-containing material deposited on the anode, a crude estimate of the mass deposited on the anode can be made. Approximating the deposited volume as a uniform, 100% dense, 5

m thick layer of pure BaO (the densest species potentially present,

= 5.72 g/cm

) within the primary deposition region (2 mm diameter) yields an estimate of ~0.05 mg of deposited mass. This is likely an overestimate of the amount of deposited material as it ignores porosity in the deposited layer, assumes the deposited material is the most dense of likely species, and neglects potential thinning of the deposited layer towards the edges of primary deposition region. This estimate also assumes that the bare ring evident in

Figure 7 was coated, and the deposited material in this region flaked off during post-operation handling. In addition, it should also be noted that it is not clear

when, during cathode activation and/or operation, deposits on the anode were formed. Despite these limitations, the present calculation is at least a reasonable order-of-magnitude estimate of the mass deposited on the anode. For comparison, similarly manufactured scandate cathodes contain a total of ~4 mg of impregnate prior to activation, as determined by the manufacturer. This suggests that on the order of 1 wt.% of the impregnate is desorbed and deposited on the anode over operating times on the order of 10,000 h.

In addition, EDS analysis strongly indicates that the deposited material primarily consists of Ba/Al/Ca oxide. The presence of an oxide deposit on the anode directly across from the cathode could have significant implications for the apparent emission performance of the cathode. Specifically, a non-conducting, potentially time-dependent coating on the anode will modify details of the applied electric field used to collect emitted current. As noted above, the time and compositional evolution of deposited layers on the anode could not be directly assessed in the present study, but may warrant further examination.