Valorization of Fine Recycled Aggregates Contaminated with Gypsum Residues: Characterization and Evaluation of the Risk for Secondary Ettringite Formation

Abstract

1. Introduction

2. Materials and Methods

2.1. Characterization

2.2. Swelling Tests

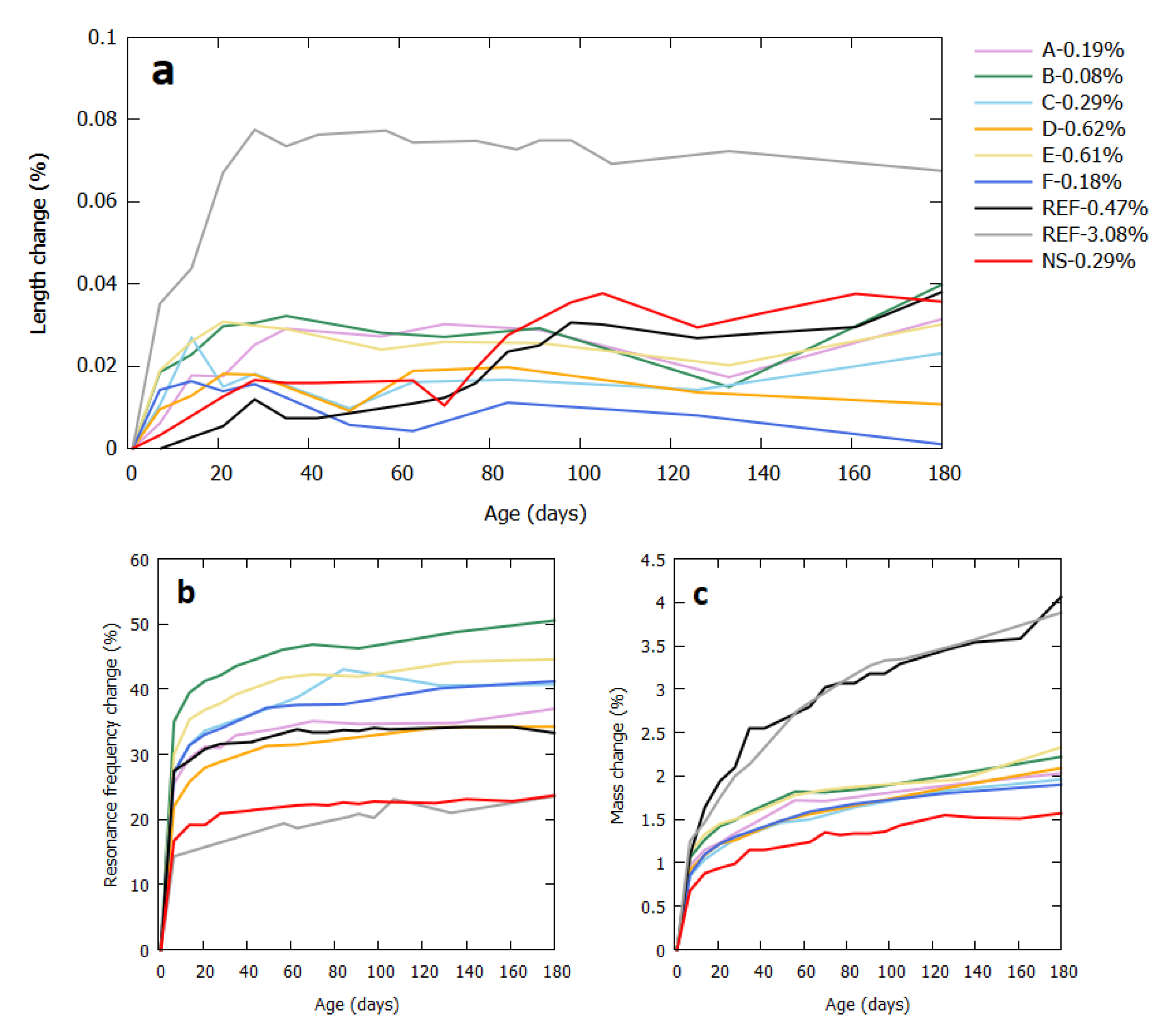

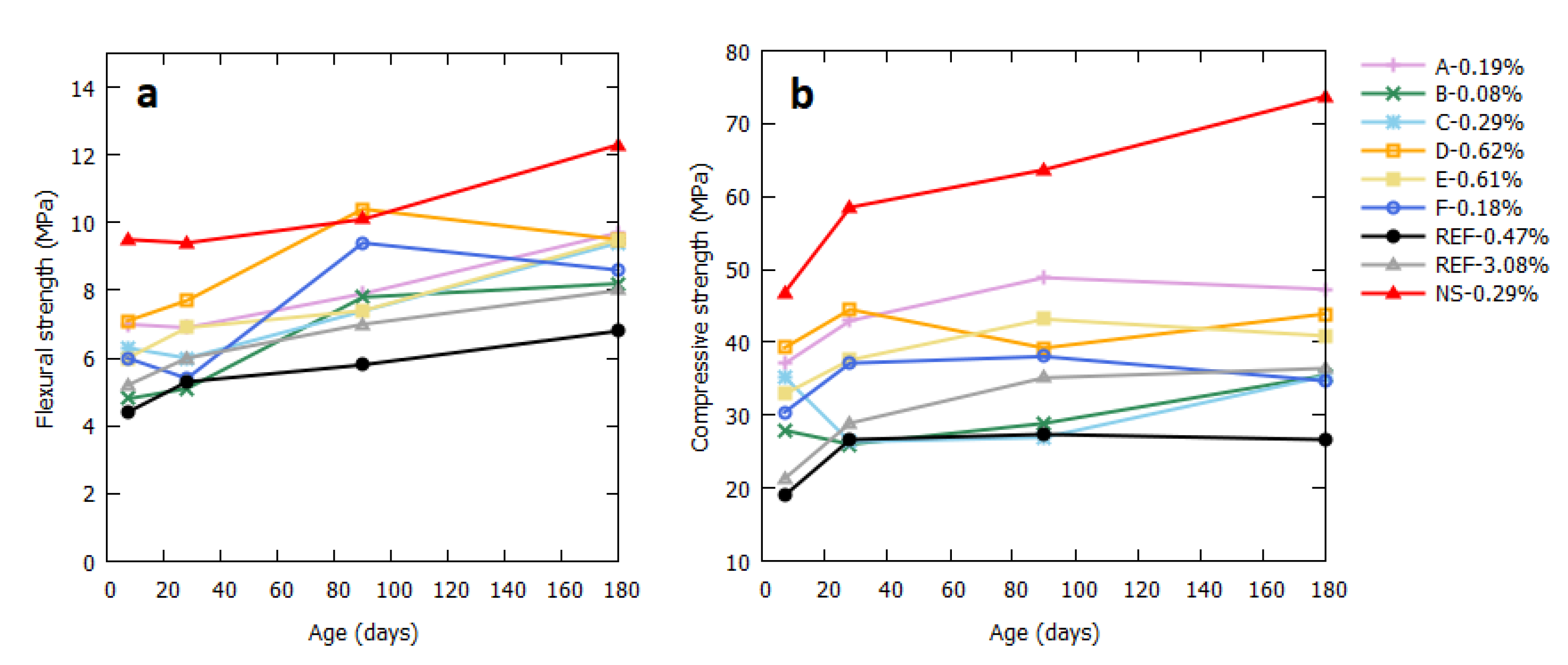

- Two mixes that will compare the industrial FRA with either a natural aggregate (named “NS”) and a pure crushed concrete (the reference FRA named “REF”). Both the natural and the recycled aggregate are manually contaminated with 0.5 mass% of gypsum. This 0.5% of gypsum corresponds to to 0.29% of sulfates, which reflects the sulfate contents found in industrial FRA. In the case of FRA, this manual contamination is in addition to the water soluble sulfates already found during the characterization, bringing its total sulfate content to 0.47%.

- One mix made with the reference FRA and a very high gypsum content of 5 mass%— corresponding to 2.9% of sulfates—to exaggerate the consequences of sulfate attack. Again, this manual contamination is in addition to the sulfates already present in this FRA, bringing the total sulfate content to 3.08%.

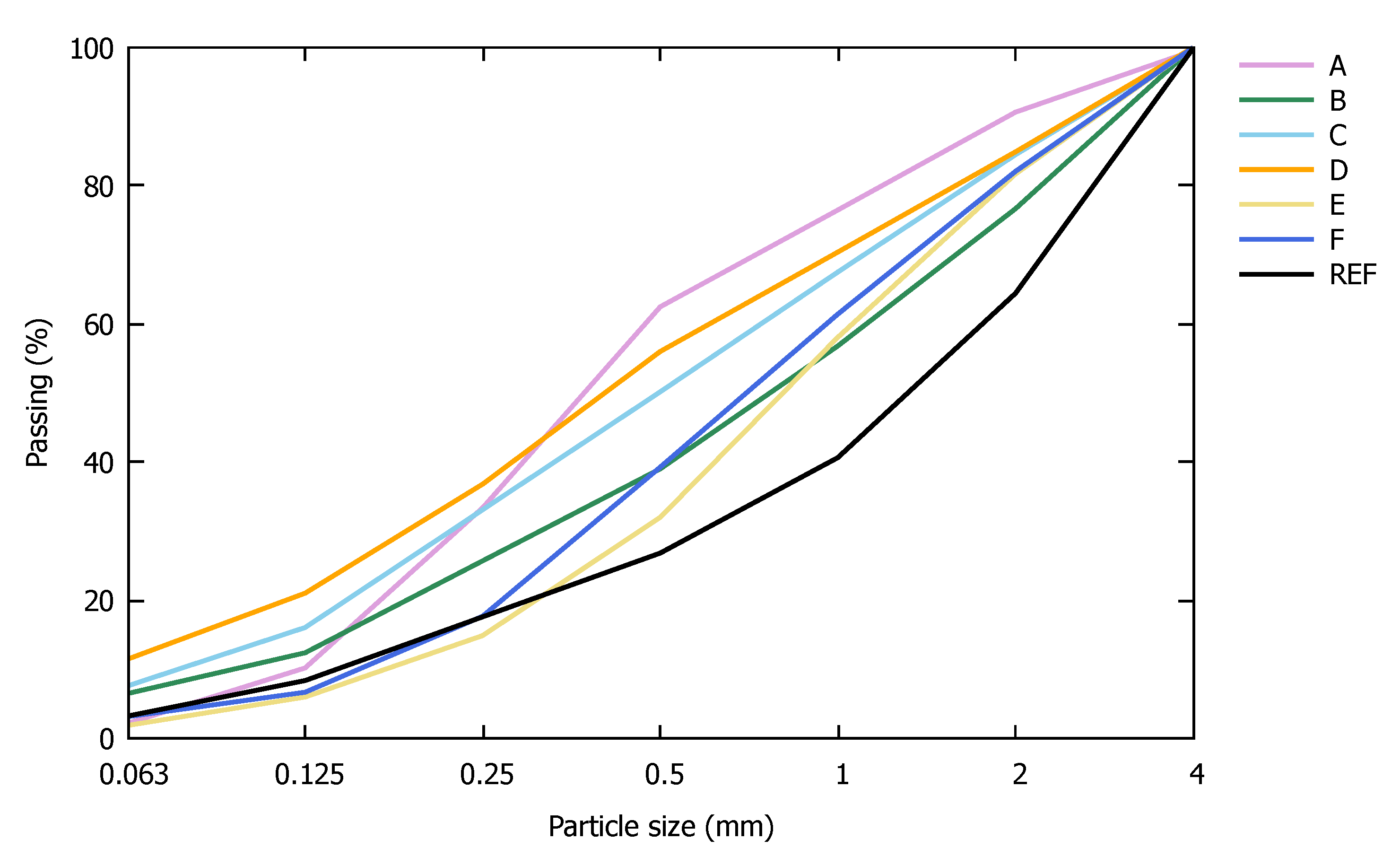

- To account for their difference in size distribution, all aggregates were recomposed to match the size distribution of the reference FRA. This adaptation caused a slight change in the total sulfate content, water absorption, and density. These new values were recalculated.

- To account for their difference in density, a volumetric equivalent of every aggregate was added to the mortars instead of a mass equivalent, to keep the aggregate envelope volume constant.

- To account for their difference in water absorption, all aggregates were pre-saturated one week before mixing, with their absorbed water and 10% of the mixing water. This assures the same amount of effective water in all mixes, proven to be an important factor in the swelling process [39].

3. Results and Discussion

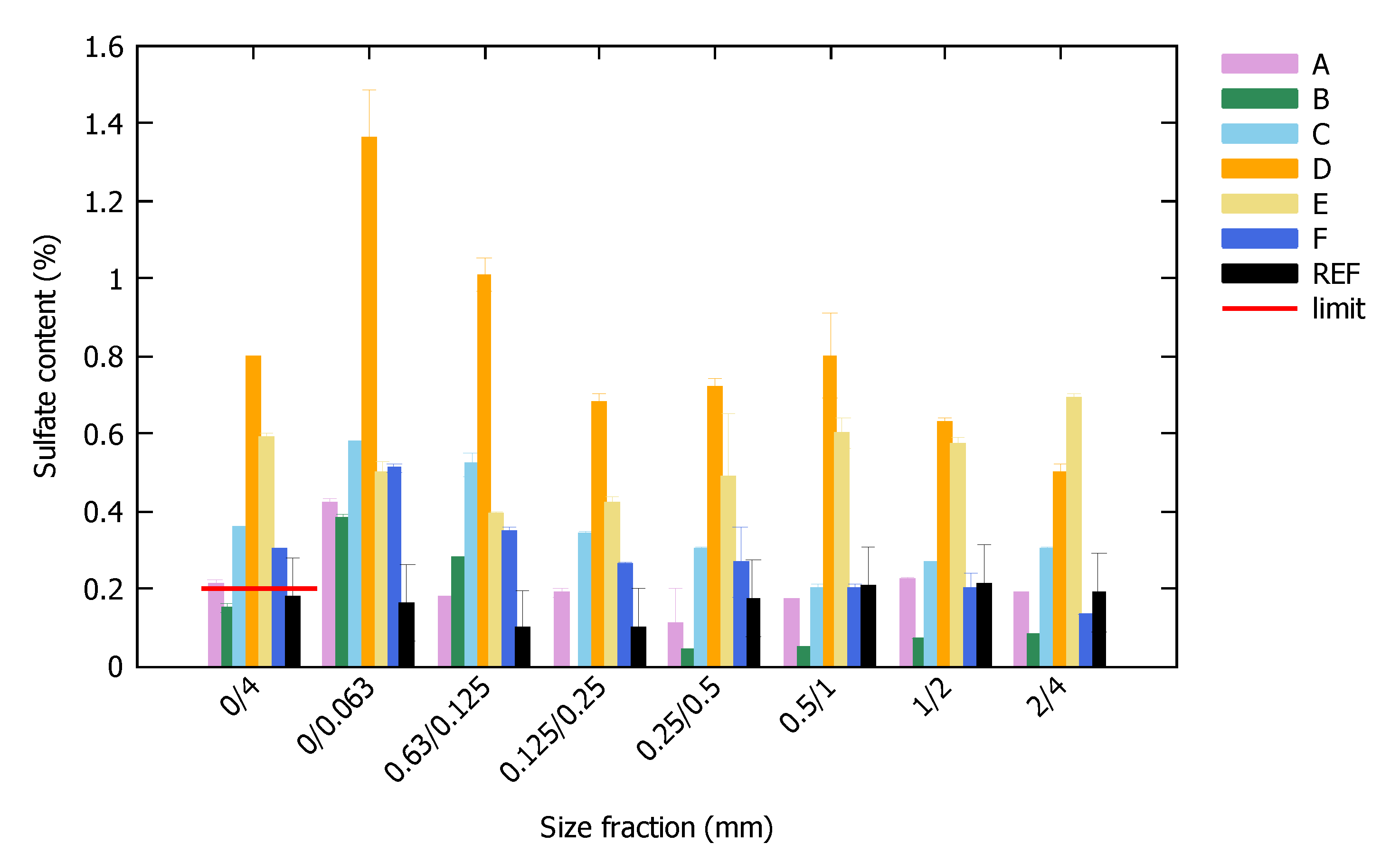

3.1. Characterization

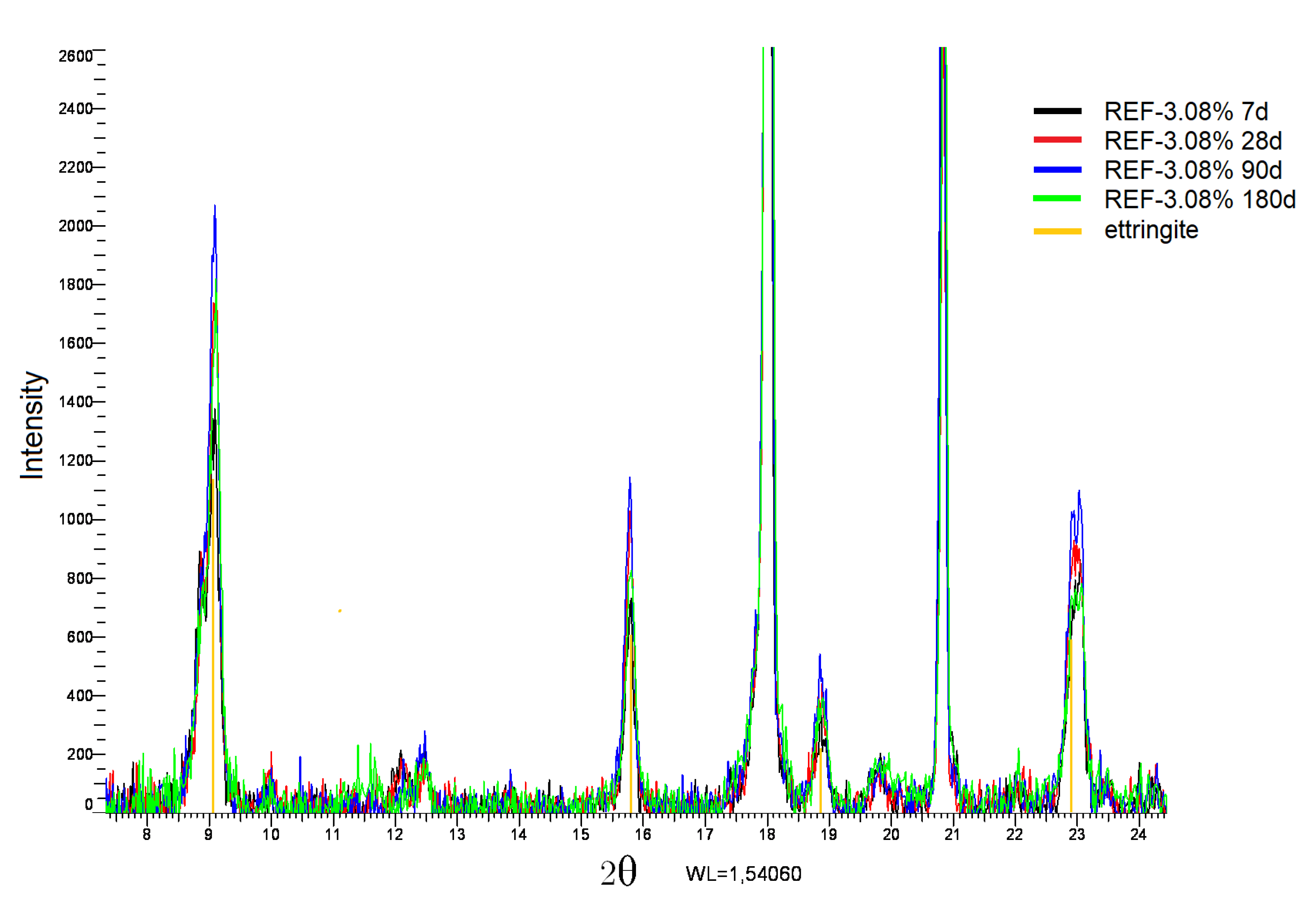

3.2. Swelling Tests

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

References

- United Nations Environment Programme. Sustainable Buildings and Climate Initiative; United Nations Environment Programme: Nairobi, Kenya, 2016. [Google Scholar]

- Coelho, A.; De Brito, J. Influence of construction and demolition waste management on the environmental impact of buildings. Waste Manag. 2012, 32, 532–541. [Google Scholar] [CrossRef] [PubMed]

- European Commission. On Resource Efficiency Opportunities in the Building Sector. COM/2014/0445fina. 2014. Available online: https://ec.europa.eu/environment/eussd/pdf/SustainableBuildingsCommunication.pdf (accessed on 6 August 2020).

- Behera, M.; Bhattacharyya, S.; Minocha, A.; Deoliya, R.; Maiti, S. Recycled aggregate from C&D waste and its use in concrete: A breakthrough towards sustainability in construction sector: A review. Constr. Build. Mater. 2014, 68, 501–516. [Google Scholar] [CrossRef]

- Deloitte. Study on Resource Efficient Use of Mixed Wastes, Improving Management of Construction and Demolition Waste: Final Report; Prepared for the European Commission; Deloitte: London, UK, 2017. [Google Scholar]

- Council Directive 2008/98/EC of the European Parliament. On Waste and Repealing Certain Directives. Official Journal of the European Union L312. 2008. Available online: http://data.europa.eu/eli/dir/2008/98/2018-07-05 (accessed on 6 September 2020).

- European Aggregates Association. Annual Review. 2017. Available online: https://uepg.eu/mediatheque/media/AR_2017-2018.pdf (accessed on 6 September 2020).

- Thormark, C. Conservation of energy and natural resources by recycling building waste. Resour. Conserv. Recycl. 2001, 33, 113–130. [Google Scholar] [CrossRef]

- Wilburn, D.; Goonan, T. Aggregates from Natural and Recycled Sources: Economic Assessments for Construction Applications, a Materials Flow Analysis; Technical Report; U.S. Department of the Interior: Washington, DC, USA, 1998.

- Delvoie, S.; Zhao, Z.; Michel, F.; Courard, L. Market analysis of recycled sands and aggregates in NorthWest Europe: Drivers and barriers. In Proceedings of the IOP Conference series: Earth and Environmental Science, Brussels, Belgium, 5–7 February 2019; pp. 1–8. [Google Scholar] [CrossRef]

- Oikonomou, N. Recycled concrete aggregates. Cem. Concr. Compos. 2005, 27, 315–318. [Google Scholar] [CrossRef]

- Bravo, M.; De Brito, J.; Pontes, J.; Evangelista, L. Mechanical performance of concrete made with aggregates from construction and demolition waste recycling plants. J. Clean. Prod. 2015, 99, 59–74. [Google Scholar] [CrossRef]

- Gutierrez, P.; Sanchez de Juan, M. Utilization of Recycled Concrete Aggregate for Structural Concrete; Service Life Design for Infrastructures: Delft, The Netherlands, 2018. [Google Scholar]

- Rao, A.; Jha, K.; Misra, S. Use of aggregates from recycled construction and demolition waste in concrete. Resour. Conserv. Recycl. 2007, 50, 71–81. [Google Scholar] [CrossRef]

- Zhao, Z.; Courard, L.; Groslambert, S.; Jehin, T.; Léonard, A.; Xiao, J. Use of recycled concrete aggregates from precast block for the production of new building blocks: An industrial scale study. Resour. Conserv. Recycl. 2020, 157, 104786. [Google Scholar] [CrossRef]

- Evangelista, L.; De Brito, J. Concrete with fine recycled aggregates: A review. Eur. J. Environ. Civ. Eng. 2014, 18, 129–172. [Google Scholar] [CrossRef]

- Khatib, J. Properties of concrete incorporating fine recycled aggregate. Cem. Concr. Res. 2005, 35, 763–769. [Google Scholar] [CrossRef]

- Zhao, Z.; Rémond, S.; Damidot, D.; Xu, W. Influence of hardened cement paste content on the water absorption of fine recycled concrete aggregates. J. Sustain. Cem. Based Mater. 2013, 2, 186–203. [Google Scholar] [CrossRef]

- Tam, V.; Tam, C.; Le, K. Removal of cement mortar remains from recycled aggregate using pre-soaking approaches. Resour. Conserv. Recycl. 2007, 50, 82–101. [Google Scholar] [CrossRef]

- Bravo, M.; de Brito, J.; Pontes, J.; Evangelista, L. Durability performance of concrete with recycled aggregates from construction and demolition waste plants. Constr. Build. Mater. 2015, 77, 357–369. [Google Scholar] [CrossRef]

- Braymand, S.; Roux, S.; Deodonne, K.; Mihalcea, C.; Feugeas, F.; Fond, C. Les Granulats RecycléS de BéTons: Un MatéRiau à Fort Potentiel de Valorisation Dans Les BéTons; Matériaux: Montpellier, France, 2014. [Google Scholar]

- Collepardi, M. A state of the art review on delayed ettringite attack on concrete. Cem. Concr. Compos. 2003, 25, 401–407. [Google Scholar] [CrossRef]

- Asakura, H.; Watanabe, Y.; Ono, Y.; Yamada, M.; Inoue, Y.; Alfaro, A.M. Characteristics of fine processed construction and demolition waste in Japan and method to obtain fines having low gypsum component and wood contents. Waste Manag. Res. 2010, 28, 634–646. [Google Scholar] [CrossRef] [PubMed]

- Ambrós, W.; Sampaio, C.; Cazacliu, B.; Miltzarek, G.; Miranda, L.R. Separation in air jigs of mixed construction and demolition waste. In Advances in Recycling and Management of Construction and Demolition Waste; Delft University of Technology: Delft, The Netherlands, 2017; pp. 25–28. [Google Scholar]

- Agrela, F.; de Juan, M.S.; Ayuso, J.; Geraldes, V.; Jiménez, J. Limiting properties in the characterisation of mixed recycled aggregates for use in the manufacture of concrete. Constr. Build. Mater. 2011, 25, 3950–3955. [Google Scholar] [CrossRef]

- Diamond, S. Delayed Ettringite Formation: Processes and Problems. Cem. Concr. Compos. 1996, 18, 205–215. [Google Scholar] [CrossRef]

- Breysse, D. Deterioration processes in reinforced concrete: An overview. In Non-Destructive Evaluation of Reinforced Concrete Structures: Deterioration Processes and Standard Test Methods; Maierhofer, C., Reinhardt, H., Dobmann, G., Eds.; Woodhead Publishing: Sawston, UK, 2010. [Google Scholar]

- Taylor, H.; Famy, C.; Scrivener, K. Delayed ettringite formation. Cem. Concr. Res. 2001, 31, 683–693. [Google Scholar] [CrossRef]

- European Committee for Standardization. EN 206 ‘Concrete: Specification, Performance, Production and Conformity: Annex E.3 on Recycled Aggregates’; European Committee for Standardization: Brussels, Belgium, 2014. [Google Scholar]

- Yammine, A.; Nordine, L.; Choinska, M.; Bignonnet, F.; Mechling, J. DEF damage in heat cured mortars made of recycled concrete sand aggregate. Constr. Build. Mater. 2020, 252. [Google Scholar] [CrossRef]

- Rougeau, P.; Schmitt, L.; Nai-Nhu, J.; Djerbi, A.; Saillio, M.; Ghorbel, E.; Mechling, J.M.; Lecomte, A.; Trauchessec, R.; Bulteel, D.; et al. Durability-related properties. In Concrete Recycling : Research and Practice; De Larrard, F., Colina, H., Eds.; CRC Press: Boca Raton, FL, USA, 2019. [Google Scholar]

- European Committee for Standardization. EN 933 ’Tests for Geometrical Properties of Aggregates. Part 1: Determination of Particle Size Distribution’; European Committee for Standardization: Brussels, Belgium, 2012. [Google Scholar]

- European Committee for Standardization. EN 1744-1 ‘Tests for Chemical Properties of Aggregates. Part 1: Chemical Analysis’; European Committee for Standardization: Brussels, Belgium, 2014. [Google Scholar]

- Bock, E. On the solubility of anhydrous calcium sulphate and of gypsum in concentrated solutions of sodium chloride at 25 ∘C, 30 ∘C, 40 ∘C and 50 ∘C. Can. J. Chem. 1961, 39, 1746–1751. [Google Scholar] [CrossRef]

- Colman, C.; Zhao, Z.; Michel, F.; Rémond, S.; Bulteel, D.; Courard, L. Gypsum Residues in Recycled Materials: Characterization of Fine Recycled Aggregates; Service Life Design for Infrastructures: Delft, The Netherlands, 2018. [Google Scholar]

- European Committee for Standardization. EN 1097-6 ‘Tests for Mechanical and Physical Properties of Aggregates. Part 6: Determination of Particle Density and Water Absorption’; European Committee for Standardization: Brussels, Belgium, 2001. [Google Scholar]

- IFSTTAR. Test Method No. 78:2011. Tests on Aggregates for Concrete: Measurement of Total Water Absorption by a Crushed Sand; IFSTTAR: Paris, France, 2011.

- Le, T.; Remond, S.; Le Saout, G.; Garcia-Diaz, E. Fresh behavior of mortar based on recycled sand: Influence of moisture condition. Constr. Build. Mater. 2016, 106, 35–42. [Google Scholar] [CrossRef]

- Delobel, F.; Bulteel, D.; Mechling, J.; Lecomte, A.; Cyr, M.; Rémond, S. Application of ASR tests to recycled concrete aggregates: Influence of water absorption. Constr. Build. Mater. 2016, 124, 714–721. [Google Scholar] [CrossRef]

- European Committee for Standardization. EN 196-1 ’Methods of Testing Cement. Part 1: Determination of Strength’; European Committee for Standardization: Brussels, Belgium, 2014. [Google Scholar]

- Colman, C.; Zhao, Z.; Michel, F.; Rémond, S.; Bulteel, D.; Courard, L. Internal Sulfate Attack Caused by Gypsum Contamination of Recycled Aggregates: Development of a Swelling Test Protocol; Journées Scientifiques RF2B: Anglet, France, 2018. [Google Scholar]

- Hansen, T.; Narud, H. Strength of recycled concrete made from crushed concrete coarse aggregate. Concr. Int. 1983, 5, 79–83. [Google Scholar]

- Nassar, R.; Soroushian, P. Strength and durability of recycled aggregate concrete containing milled glass as partial replacement for cement. Constr. Build. Mater. 2012, 29, 368–377. [Google Scholar] [CrossRef]

- Poon, C.; Shui, Z.; Lam, L. Effect of microstructure of ITZ on compressive strength of concrete prepared with recycled aggregates. Constr. Build. Mater. 2004, 18, 461–468. [Google Scholar] [CrossRef]

- Pavoine, A.; Brunetaud, X.; Divet, L. The impact of cement parameters on Delayed Ettringite Formation. Cem. Concr. Compos. 2012, 34, 521–528. [Google Scholar] [CrossRef]

- Aubert, J.; Escadeillas, G.; Leklou, N. Expansion of five-year-old mortars attributable to DEF. Constr. Build. Mater. 2009, 23, 3583–3585. [Google Scholar] [CrossRef][Green Version]

- Batic, O.; Milanesi, C.; Maiza, P.; Marfil, S. Secondary ettringite formation in concrete subjected to different curing conditions. Cem. Concr. Res. 2000, 30, 1407–1412. [Google Scholar] [CrossRef]

- Mehdipour, I.; Khayat, K. Understanding the role of particle packing characteristics in rheophysical properties of cementitious suspensions: A literature review. Constr. Build. Mater. 2018, 161, 340–353. [Google Scholar] [CrossRef]

- Colman, C.; Bulteel, D.; Thiery, V.; Rémond, S.; Michel, F.; Courard, L. Internal sulfate attack in mortars containing contaminated fine recycled concrete aggregates. Constr. Build. Mater. Unpublished.

- Matias, D.; De Brito, J.; Rosa, A.; Pedro, D. Mechanical properties of concrete produced with recycled coarse aggregates: Influence of the use of superplasticizers. Constr. Build. Mater. 2013, 44, 101–109. [Google Scholar] [CrossRef]

| A | B | C | D |

|---|---|---|---|

| 0/4 | 0/10 | 0/32 | 0/20 |

|  |  |  |

| E | F | FRA | NS |

| 0/90 | 0/10 | ||

|  |  |  |

| Water Absorption | SSD Particle Density | SO42 Content | ||||

|---|---|---|---|---|---|---|

| (%) | (g/cm3) | (%) | ||||

| Source | Original | Recomposed | Original | Recomposed | Original | Recomposed |

| A | 6.1 | 7.1 | 2.14 | 2.15 | 0.21 | 0.19 |

| B | 8.9 | 9.7 | 2.10 | 2.00 | 0.15 | 0.08 |

| C | 11.5 | 10.6 | 1.99 | 1.97 | 0.36 | 0.29 |

| D | 10.6 | 8.8 | 2.00 | 1.92 | 0.80 | 0.62 |

| E | 14.6 | 12.6 | 1.97 | 1.92 | 0.59 | 0.61 |

| F | 13.0 | 11.8 | 1.96 | 1.85 | 0.30 | 0.18 |

| REF | 9.8 | 1.95 | 0.18 | |||

| Name | Cement | Water | Aggregate | Extra Gypsum | |

|---|---|---|---|---|---|

| Effective | Absorbed | (0/4 mm) | |||

| A-0.19% | 1350 | 675 | 79.15 | 1116.3 | 0 |

| B-0.08% | 1350 | 675 | 100.32 | 1038.5 | 0 |

| C-0.29% | 1350 | 675 | 108.22 | 1022.9 | 0 |

| D-0.62% | 1350 | 675 | 87.33 | 996.9 | 0 |

| E-0.61% | 1350 | 675 | 125.71 | 996.9 | 0 |

| F-0.18% | 1350 | 675 | 113.16 | 960.6 | 0 |

| REF-0.47% | 1350 | 675 | 98.52 | 1007.4 | 5.1 |

| REF-3.08% | 1350 | 675 | 94.07 | 961.9 | 50.6 |

| NS-0.29% | 1350 | 675 | 0 | 1343.2 | 6.8 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Colman, C.; Bulteel, D.; Rémond, S.; Zhao, Z.; Courard, L. Valorization of Fine Recycled Aggregates Contaminated with Gypsum Residues: Characterization and Evaluation of the Risk for Secondary Ettringite Formation. Materials 2020, 13, 4866. https://doi.org/10.3390/ma13214866

Colman C, Bulteel D, Rémond S, Zhao Z, Courard L. Valorization of Fine Recycled Aggregates Contaminated with Gypsum Residues: Characterization and Evaluation of the Risk for Secondary Ettringite Formation. Materials. 2020; 13(21):4866. https://doi.org/10.3390/ma13214866

Chicago/Turabian StyleColman, Charlotte, David Bulteel, Sébastien Rémond, Zengfeng Zhao, and Luc Courard. 2020. "Valorization of Fine Recycled Aggregates Contaminated with Gypsum Residues: Characterization and Evaluation of the Risk for Secondary Ettringite Formation" Materials 13, no. 21: 4866. https://doi.org/10.3390/ma13214866

APA StyleColman, C., Bulteel, D., Rémond, S., Zhao, Z., & Courard, L. (2020). Valorization of Fine Recycled Aggregates Contaminated with Gypsum Residues: Characterization and Evaluation of the Risk for Secondary Ettringite Formation. Materials, 13(21), 4866. https://doi.org/10.3390/ma13214866