Effect of Electrolyzed Alkaline-Reduced Water on the Early Strength Development of Cement Mortar Using Blast Furnace Slag

Abstract

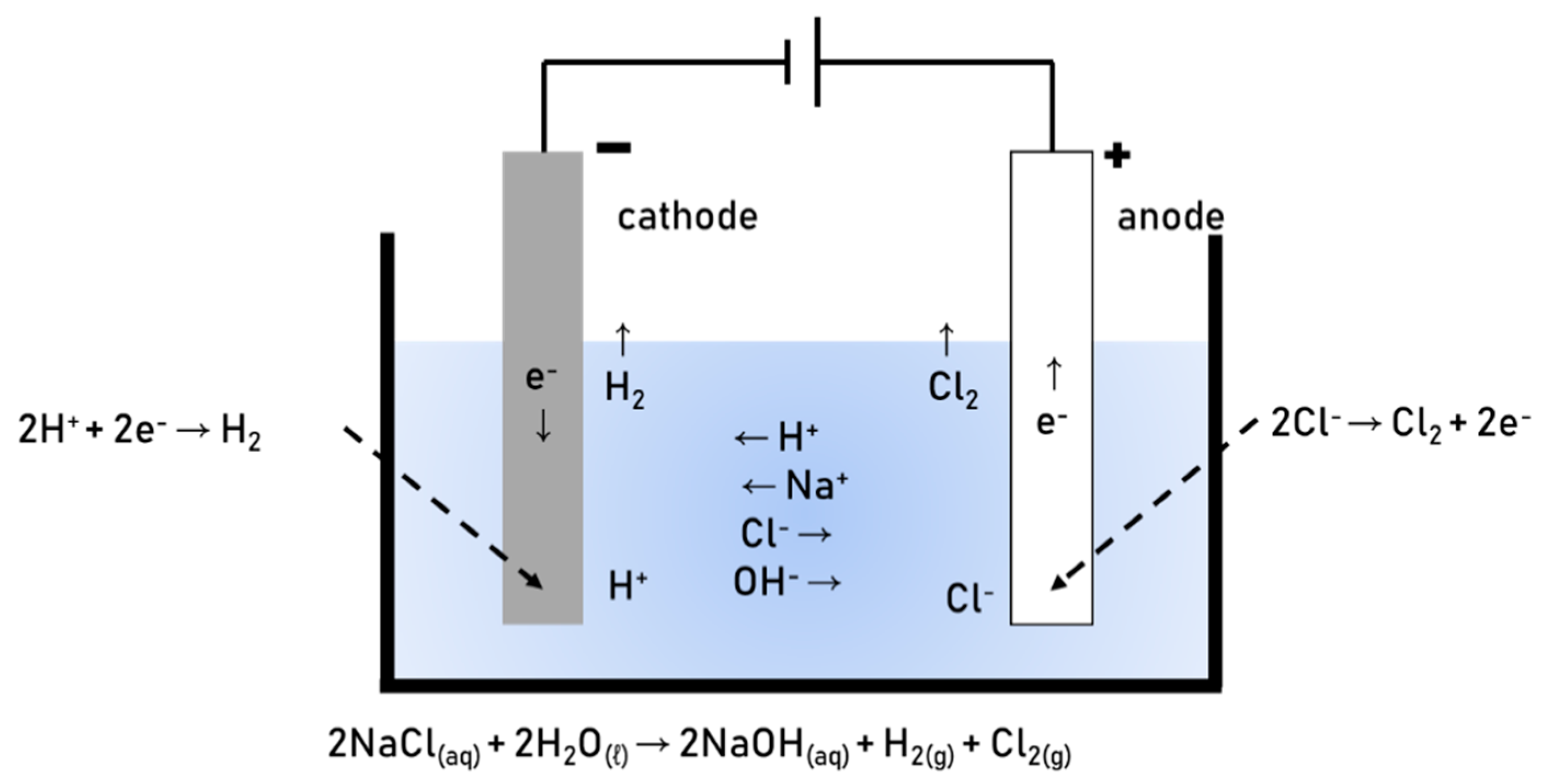

1. Introduction

2. Experimental Work

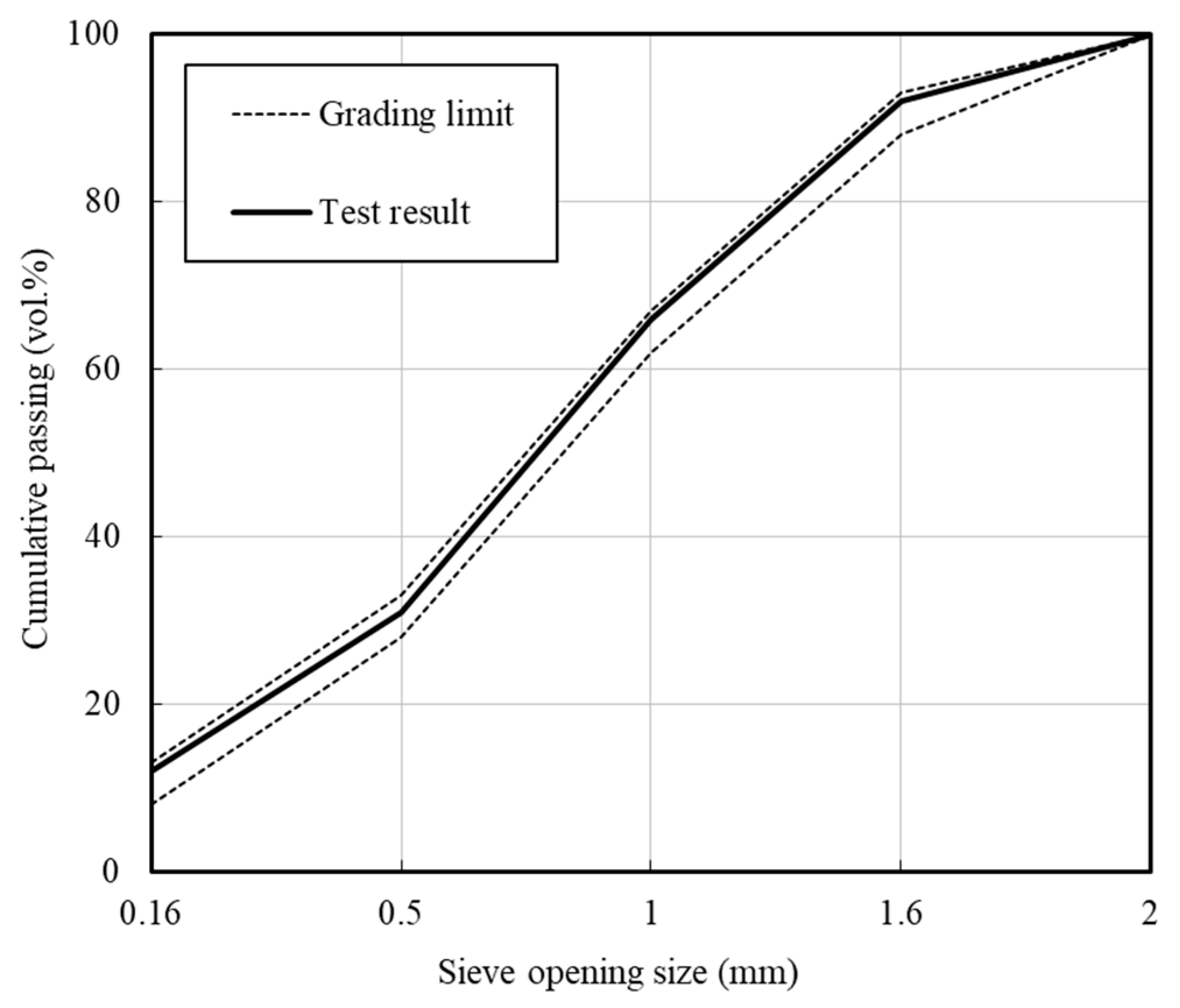

2.1. Materials

2.2. Experimental Design and Mix Proportions

2.3. Test Methods

3. Experimental Results and Discussions

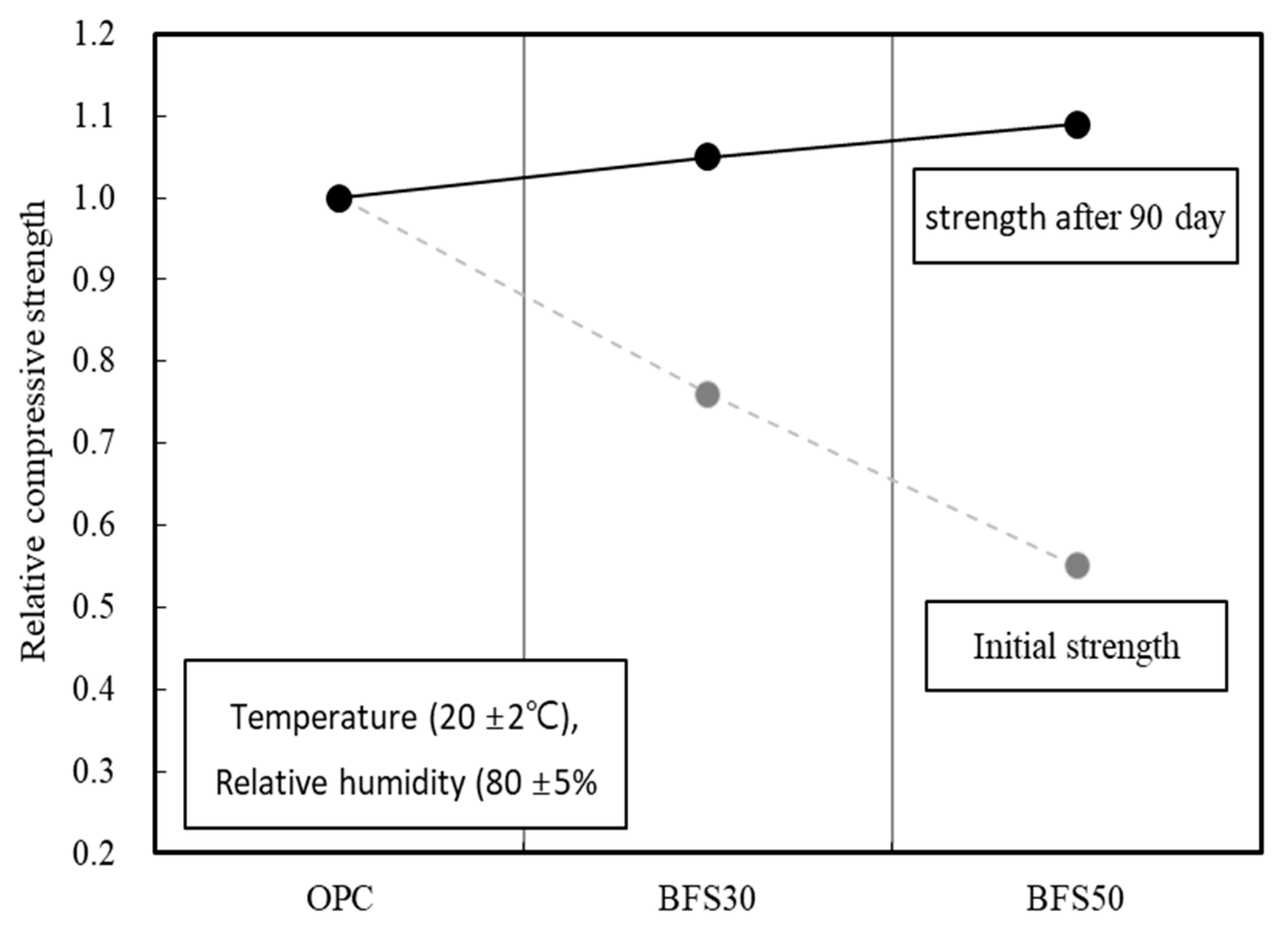

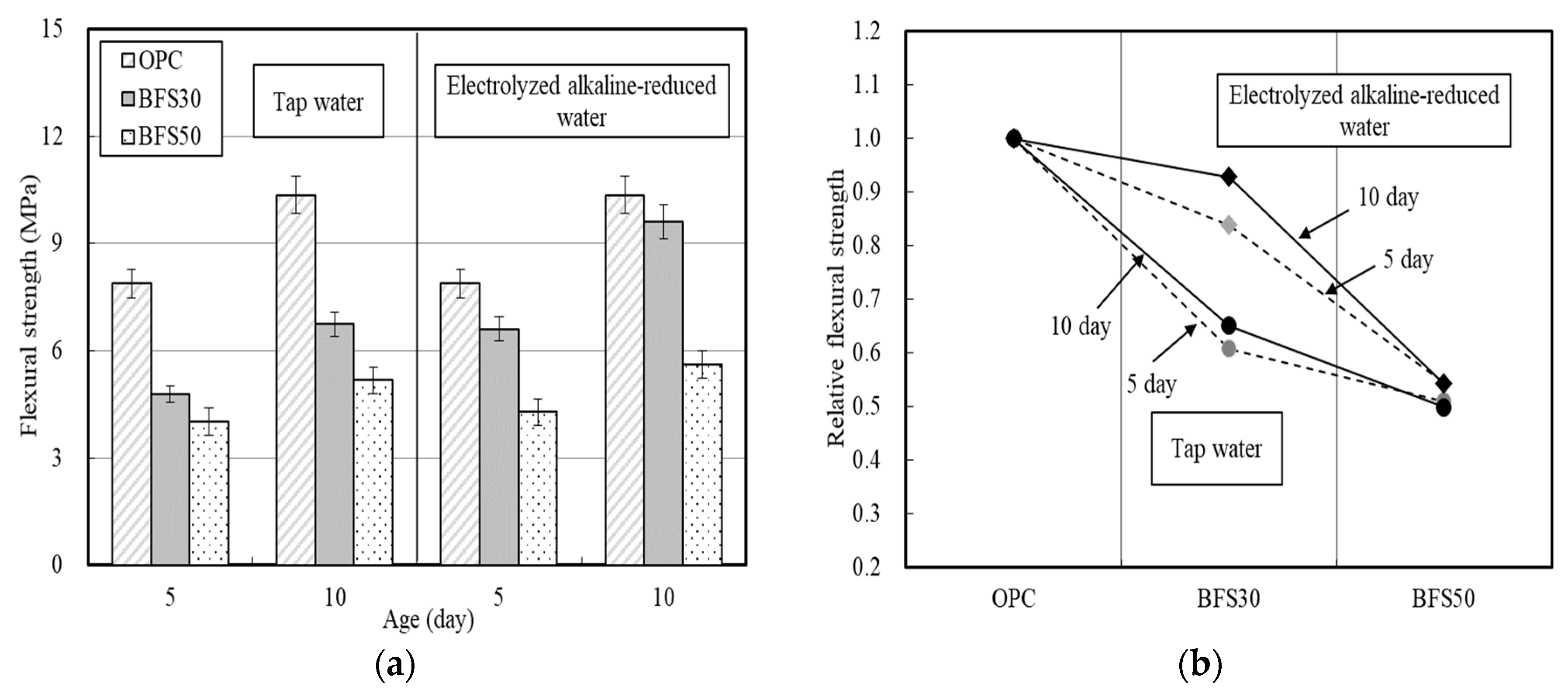

3.1. Strength Properties

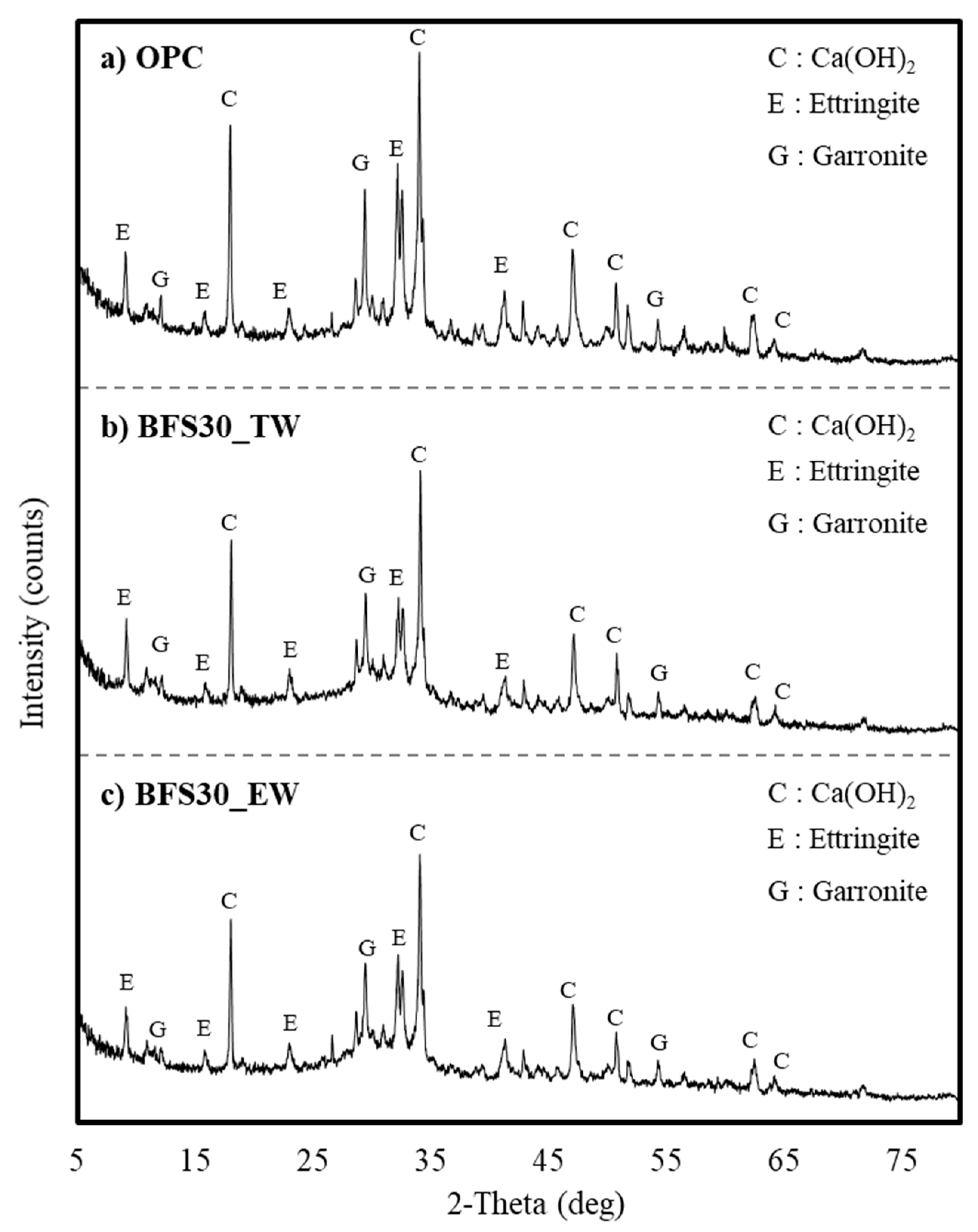

3.2. X-ray Diffaction Analysis

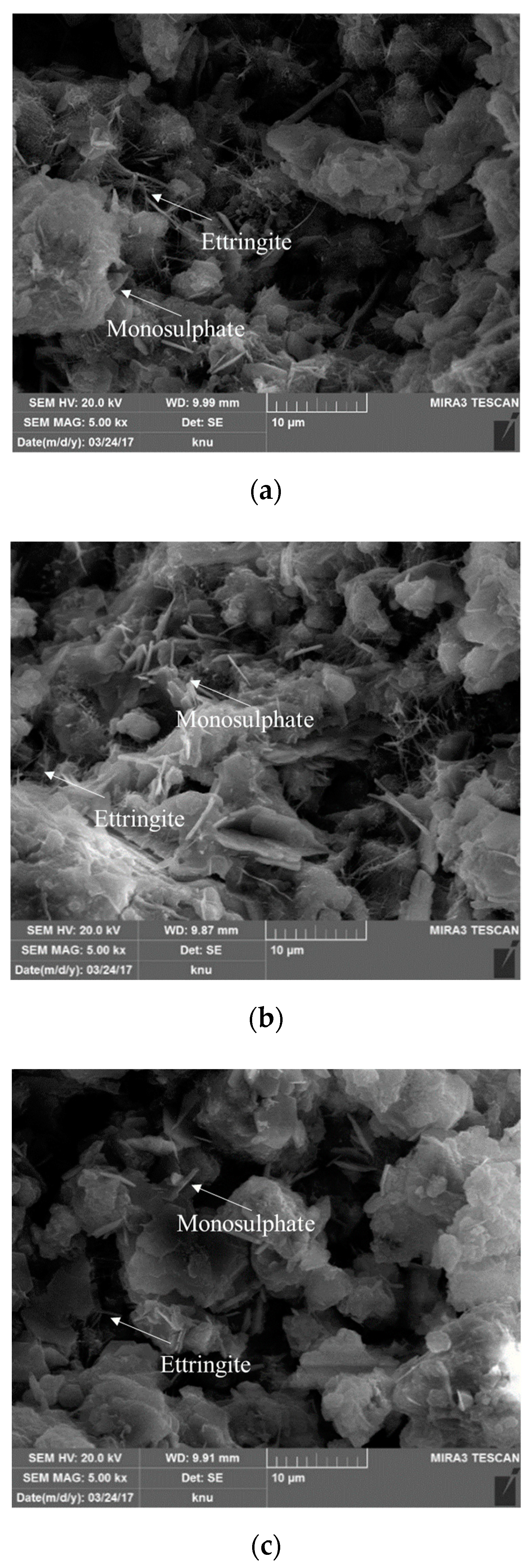

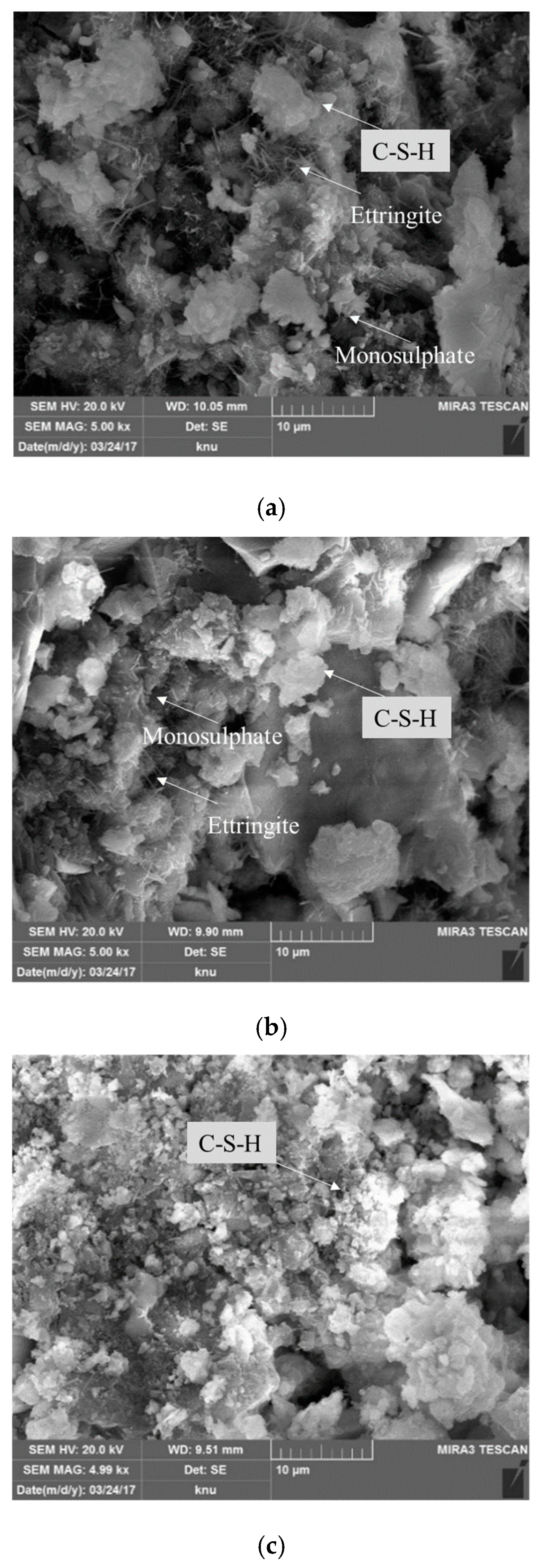

3.3. Scanning Electron Microscopy

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Kim, S.E. Greenhouse gas regulation and response efforts and future direction of cement industry. J. Korea Cem. Assoc. 2008, 179, 18–24. [Google Scholar] [CrossRef]

- Kroehong, W.; Sinsiri, T.; Jaturapitakkul, C.; Chindaprasirt, P. Effect of palm oil fuel ash fineness on the microstructure of blended cement paste. Constr. Build. Mater. 2011, 25, 4095–4104. [Google Scholar] [CrossRef]

- Choi, D.A. Fundamental Study on the Response of the Concrete Industry to Climate Change; KCI 502; Eco-Friendly Concrete Committee of the Korea Concrete Institute: Seoul, Korea, 2009. [Google Scholar]

- Yi, Y.; Lu, K.; Liu, S.; Al-Tabbaa, A. Property changes of reactive magnesia–stabilized soil subjected to forced carbonation. Can. Geotech. J. 2016, 53, 314–325. [Google Scholar] [CrossRef]

- Rosković, R.; Bjegović, D. Role of mineral additions in reducing CO2 emission. Cem. Concr. Res. 2005, 35, 974–978. [Google Scholar] [CrossRef]

- Pacheco-Torgal, F.; Castro-Gomes, J.; Jalali, S. Alkali-activated binders: A review: Part 1. Historical background, terminology, reaction mechanisms and hydration products. Constr. Build. Mater. 2008, 22, 1305–1314. [Google Scholar] [CrossRef]

- Lee, J.; Lee, T. Influences of Chemical Composition and Fineness on the Development of Concrete Strength by Curing Conditions. Materials 2019, 12, 4061. [Google Scholar] [CrossRef]

- Parron-Rubio, M.E.; García, F.P.; González-Herrera, A.; Oliveira, M.J.; Rubio-Cintas, M.D. Slag Substitution as a Cementing Material in Concrete: Mechanical, Physical and Environmental Properties. Materials 2019, 12, 2845. [Google Scholar] [CrossRef] [PubMed]

- Amato, I. Concrete solutions: Cement manufacturing is a major source of greenhouse gases. But cutting emissions means mastering one of the most complex materials known. Nature 2013, 494, 300–302. [Google Scholar] [CrossRef]

- Jacobsen, J.; Rodrigues, M.S.; Telling, M.T.F.; Beraldo, A.L.; Dos Santos, S.F.; Aldridge, L.P.; Bordallo, H. Nano-scale hydrogen-bond network improves the durability of greener cements. Sci. Rep. 2013, 3, 2667. [Google Scholar] [CrossRef]

- Yi, Y.; Gu, L.; Liu, S.; Jin, F. Magnesia reactivity on activating efficacy for ground granulated blast furnace slag for soft clay stabilisation. Appl. Clay Sci. 2016, 126, 57–62. [Google Scholar] [CrossRef]

- Mohan, A.; Mini, K. Strength and durability studies of SCC incorporating silica fume and ultra fine GGBS. Constr. Build. Mater. 2018, 171, 919–928. [Google Scholar] [CrossRef]

- Lee, J.; Kim, G.; Kim, Y.; Mun, K.; Nam, J. Engineering Properties and Optimal Conditions of Cementless Grouting Materials. Materials 2019, 12, 3059. [Google Scholar] [CrossRef] [PubMed]

- Kavitha, S.; Kala, T.F. Evaluation of Strength Behavior of Self-Compacting Concrete using Alccofine and GGBS as Partial Replacement of Cement. Indian J. Sci. Technol. 2016, 9, 1–5. [Google Scholar] [CrossRef]

- Pal, S.C.; Mukherjee, A.; Pathak, S.R. Effect of curing conditions on the mortars with and without GGBFS. Cem. Concr. Res. 2003, 33, 1481–1486. [Google Scholar] [CrossRef]

- Jin, F.; Gu, K.; Al-Tabbaa, A. Strength and hydration properties of reactive MgO-activated ground granulated blastfurnace slag paste. Cem. Concr. Compos. 2015, 57, 8–16. [Google Scholar] [CrossRef]

- Peng, H.; Yin, J.; Song, W. Mechanical and Hydraulic Behaviors of Eco-Friendly Pervious Concrete Incorporating Fly Ash and Blast Furnace Slag. Appl. Sci. 2018, 8, 859. [Google Scholar] [CrossRef]

- Dubey, S.; Singh, A.; Kushwah, S.S. Utilization of iron and steel slag in building construction. In Proceedings of the International Conference on Sustainable Materials and Structures for Civil Infrastructures (Smsci2019), Madhya Pradesh, India, 14–15 March 2019; AIP Publishing: Melville, NY, USA, 2019; Volume 2158, p. 020032, ISBN 978-0-7354-1903-2. [Google Scholar]

- Mehta, P.; Monteiro, P. Concrete: Microstructure, Properties, and Materials, 3rd ed.; McGraw-Hill: New York, NY, USA, 2006. [Google Scholar]

- Lohtia, R.; Joshi, R.; Ramachandran, V. Concrete Admixtures Handbook—Properties, Science and Technology, 2nd ed.; Noyes Publications: New Jersey, NJ, USA, 1995. [Google Scholar]

- Ganesh, P.; Murthy, A.R. Tensile behaviour and durability aspects of sustainable ultra-high performance concrete incorporated with GGBS as cementitious material. Constr. Build. Mater. 2019, 197, 667–680. [Google Scholar] [CrossRef]

- Suda, V.R.; Rao, P.S. Experimental Investigation on Optimum Usage of Micro Silica and GGBS for the Strength Characteristics of Concrete; Elsevier BV: Amsterdam, The Netherlands, 2020; Volume 27, pp. 805–811. [Google Scholar]

- Huang, C.-H.; Wu, C.-H.; Lin, S.-K.; Yen, T. Effect of Slag Particle Size on Fracture Toughness of Concrete. Appl. Sci. 2019, 9, 805. [Google Scholar] [CrossRef]

- Cheng, A.; Huang, R.; Wu, J.-K.; Chen, C.-H. Influence of GGBS on durability and corrosion behavior of reinforced concrete. Mater. Chem. Phys. 2005, 93, 404–411. [Google Scholar] [CrossRef]

- Evert, K.-J.; Ballard, E.B.; Elsworth, D.J.; Oquiñena, I.; Schmerber, J.-M.; Stipe, R.E. Encyclopedic Dictionary of Landscape and Urban Planning, 1st ed.; Springer: Berlin, Germany, 2010. [Google Scholar] [CrossRef]

- Architectural Institute of Korea. Korea Architectural Standard Specification Reinforced Concrete Work, KASS 5; Architectural Institute of Korea: Seoul, Korea, 2009. [Google Scholar]

- Architectural Institute of Japan. Japanese Architectural Standard Specification Reinforced Concrete Work JASS 5; Architectural Institute of Japan: Tokyo, Japan, 2009. [Google Scholar]

- Hwang, C.-L.; Chiang, C.-H.; Huynh, T.-P.; Vo, D.-H.; Jhang, B.-J.; Ngo, S.-H. Properties of alkali-activated controlled low-strength material produced with waste water treatment sludge, fly ash, and slag. Constr. Build. Mater. 2017, 135, 459–471. [Google Scholar] [CrossRef]

- Bernal, S.A.; Provis, J.L.; Rose, V.; De Gutierrez, R.M. Evolution of binder structure in sodium silicate-activated slag-metakaolin blends. Cem. Concr. Compos. 2011, 33, 46–54. [Google Scholar] [CrossRef]

- Özbay, E.; Erdemir, M.; Durmuş, H.I. Utilization and efficiency of ground granulated blast furnace slag on concrete properties—A review. Constr. Build. Mater. 2016, 105, 423–434. [Google Scholar] [CrossRef]

- Chakraborty, S.; Jo, B.-W.; Sikandar, M.A. Hydration Mechanism of the Hydrogen-Rich Water Based Cement Paste. J. Phys. Chem. C 2016, 120, 8198–8209. [Google Scholar] [CrossRef]

- Jo, B.W.; Sikandar, M.A.; Chakraborty, S.; Baloch, Z. Investigation of corrosion assessment of hydrogen-rich water-based cement mortars. J. Ceram. Process. Res. 2017, 18, 305–312. [Google Scholar]

- Chikh, N.; Cheikh-Zouaoui, M.; Aggoun, S.; Duval, R. Effects of calcium nitrate and triisopropanolamine on the setting and strength evolution of Portland cement pastes. Mater. Struct. 2007, 41, 31–36. [Google Scholar] [CrossRef]

- Aggoun, S.; Cheikh-Zouaoui, M.; Chikh, N.; Duval, R. Effect of some admixtures on the setting time and strength evolution of cement pastes at early ages. Constr. Build. Mater. 2008, 22, 106–110. [Google Scholar] [CrossRef]

- American Society of Testing and Materials. ASTM C778, Standard Specification for Standard Sand; ASTM: West Conshohocken, PA, USA, 2017; pp. 1–3. [Google Scholar]

- American Society of Testing and Materials. ASTM C348-20. Standard Test Method for Flexural Strength of Hydraulic-Cement Mortars; ASTM: West Conshohocken, PA, USA, 2019; pp. 1–16. [Google Scholar]

- American Society of Testing and Materials. ASTM C109/C109M REV A, Standard Test Method for Compressive Strength of Hydraulic Cement Mortars; ASTM: West Conshohocken, PA, USA, 2017; pp. 1–10. [Google Scholar]

- American Society of Testing and Materials. ASTM C1723-16. Standard Guide for Examination of Hardened Concrete Using Scanning Electron Microscopy; ASTM: West Conshohocken, PA, USA, 2010; pp. 1–9. [Google Scholar]

- American Society of Testing and Materials. ASTM C1365. Standard Test Method for Determination of the Proportion of Phases in Portland Cement and Portland-Cement Clinker Using X-ray Powder Diffraction Analysis; ASTM: West Conshohocken, PA, USA, 2018; pp. 1–11. [Google Scholar]

- Gebregziabiher, B.S.; Thomas, R.J.; Peethamparan, S. Very early-age reaction kinetics and microstructural development in alkali-activated slag. Cem. Concr. Compos. 2015, 55, 91–102. [Google Scholar] [CrossRef]

- Ding, T.; Ge, Z.; Shi, J.; Xu, Y.-T.; Jones, C.L.; Liu, D.-H. Impact of slightly acidic electrolyzed water (SAEW) and ultrasound on microbial loads and quality of fresh fruits. LWT 2015, 60, 1195–1199. [Google Scholar] [CrossRef]

- Song, Z.-J.; Jiang, L.-H. Review of researches on influence of solution composition on chloride diffusivity coefficient in concrete. Adv. Sci. Technol. Water Res. 2011, 31, 82–87. [Google Scholar]

| Materials | Chemical Composition (%) | L.O.I. 1) | |||||||

|---|---|---|---|---|---|---|---|---|---|

| CaO | SiO2 | Al2O3 | Fe2O3 | MgO | SO3 | K2O | Others | ||

| OPC 2) | 60.3 | 19.8 | 4.9 | 3.3 | 3.8 | 2.9 | 1.1 | 0.9 | 3.0 |

| BFS 3) | 42.5 | 34.2 | 14.5 | 0.6 | 5.3 | 2.0 | 0.0 | 1.0 | 2.1 |

| Material. | Properties |

|---|---|

| OPC | Type I Ordinary Portland Cement Density: 3150 kg/m3, Fineness: 330 m2/kg |

| BFS | Blast Furnace Slag Density: 2250 kg/m3, Fineness: 360 m2/kg |

| Fine Aggregate: | ISO Standard Sand, Particle Size: below 2 mm Fineness Modulus: 2.99, Density: 2620 kg/m3 |

| Experimental Factors | Experimental Levels |

|---|---|

| Type of Binding Material | Ordinary Portland Cement, Blast Furnace Slag |

| Substitution Ratio of BFS (Binder × wt%) | 30 and 50 |

| Type of Binding Water | Tap Water and Electrolyzed Alkaline-Reduced Water |

| W/B | 0.50 |

| Curing Conditions | Temperature: 20 ± 2 °C Relative Humidity: 80 ± 5% |

| Test Items | Flexural Strength (MPa), Compressive Strength (MPa) SEM, XRD |

| Sample | W/B | B:S 1) | Binder (g) | Water (g) | ||

|---|---|---|---|---|---|---|

| Cement | BFS | TW 2) | EW 3) | |||

| OPC | 0.50 | 1:3 | 450 | 225 | ||

| BFS30_TW 2) | 0.50 | 1:3 | 315 | 135 | 225 | |

| BFS30_EW 3) | 0.50 | 1:3 | 315 | 135 | 225 | |

| BFS50_TW | 0.50 | 1:3 | 225 | 225 | 225 | |

| BFS50_EW | 0.50 | 1:3 | 225 | 225 | 225 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lee, T.; Kim, S.; Park, S.-G. Effect of Electrolyzed Alkaline-Reduced Water on the Early Strength Development of Cement Mortar Using Blast Furnace Slag. Materials 2020, 13, 4620. https://doi.org/10.3390/ma13204620

Lee T, Kim S, Park S-G. Effect of Electrolyzed Alkaline-Reduced Water on the Early Strength Development of Cement Mortar Using Blast Furnace Slag. Materials. 2020; 13(20):4620. https://doi.org/10.3390/ma13204620

Chicago/Turabian StyleLee, Taegyu, Suna Kim, and Sun-Gyu Park. 2020. "Effect of Electrolyzed Alkaline-Reduced Water on the Early Strength Development of Cement Mortar Using Blast Furnace Slag" Materials 13, no. 20: 4620. https://doi.org/10.3390/ma13204620

APA StyleLee, T., Kim, S., & Park, S.-G. (2020). Effect of Electrolyzed Alkaline-Reduced Water on the Early Strength Development of Cement Mortar Using Blast Furnace Slag. Materials, 13(20), 4620. https://doi.org/10.3390/ma13204620