Influence of Cemented Carbide Composition on Cutting Temperatures and Corresponding Hot Hardnesses

Abstract

1. Introduction

2. Materials and Methods

2.1. Fabrication and Characterization of Cemented Carbides

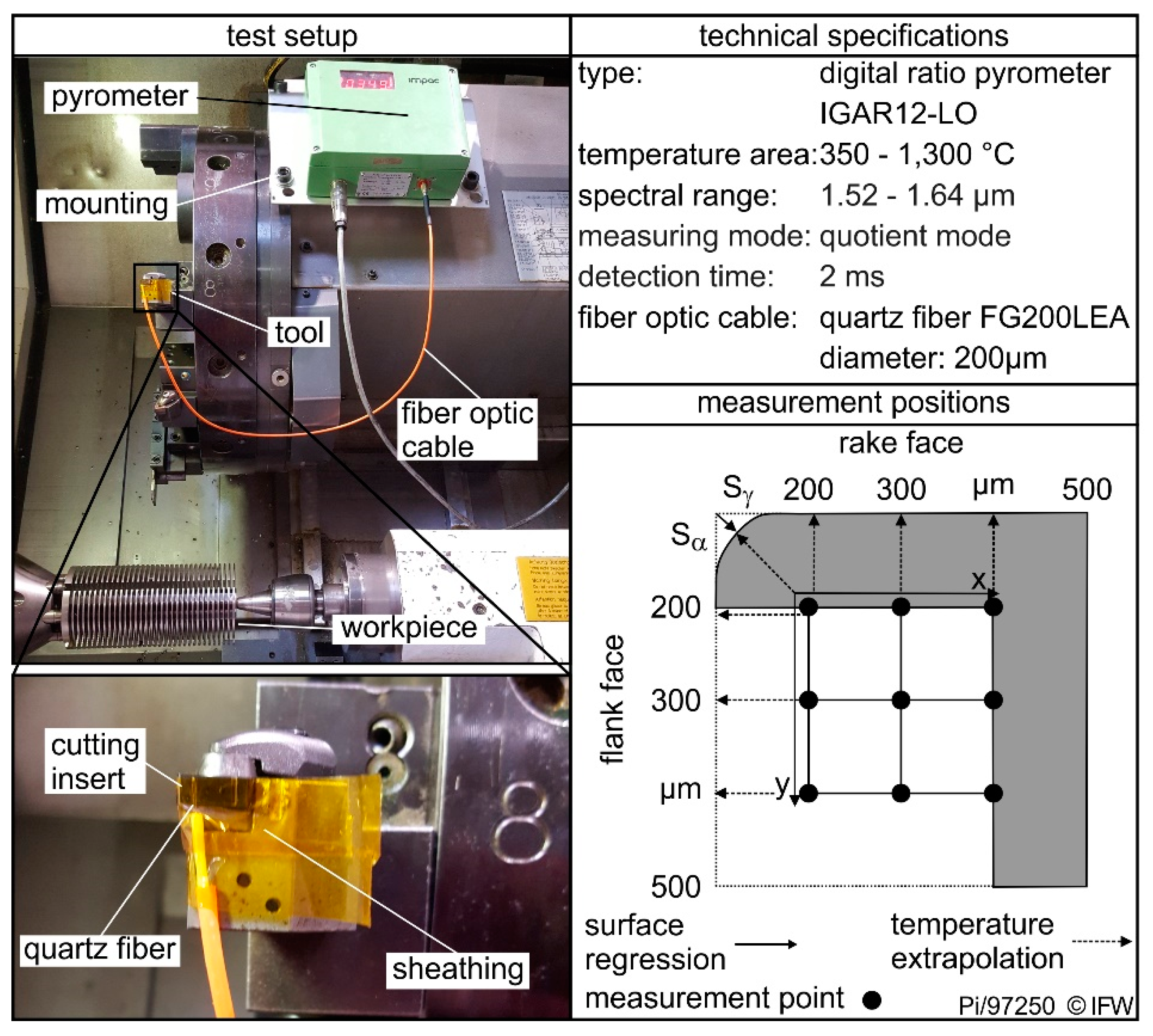

2.2. Measurement of Cutting Process Temperatures

3. Results

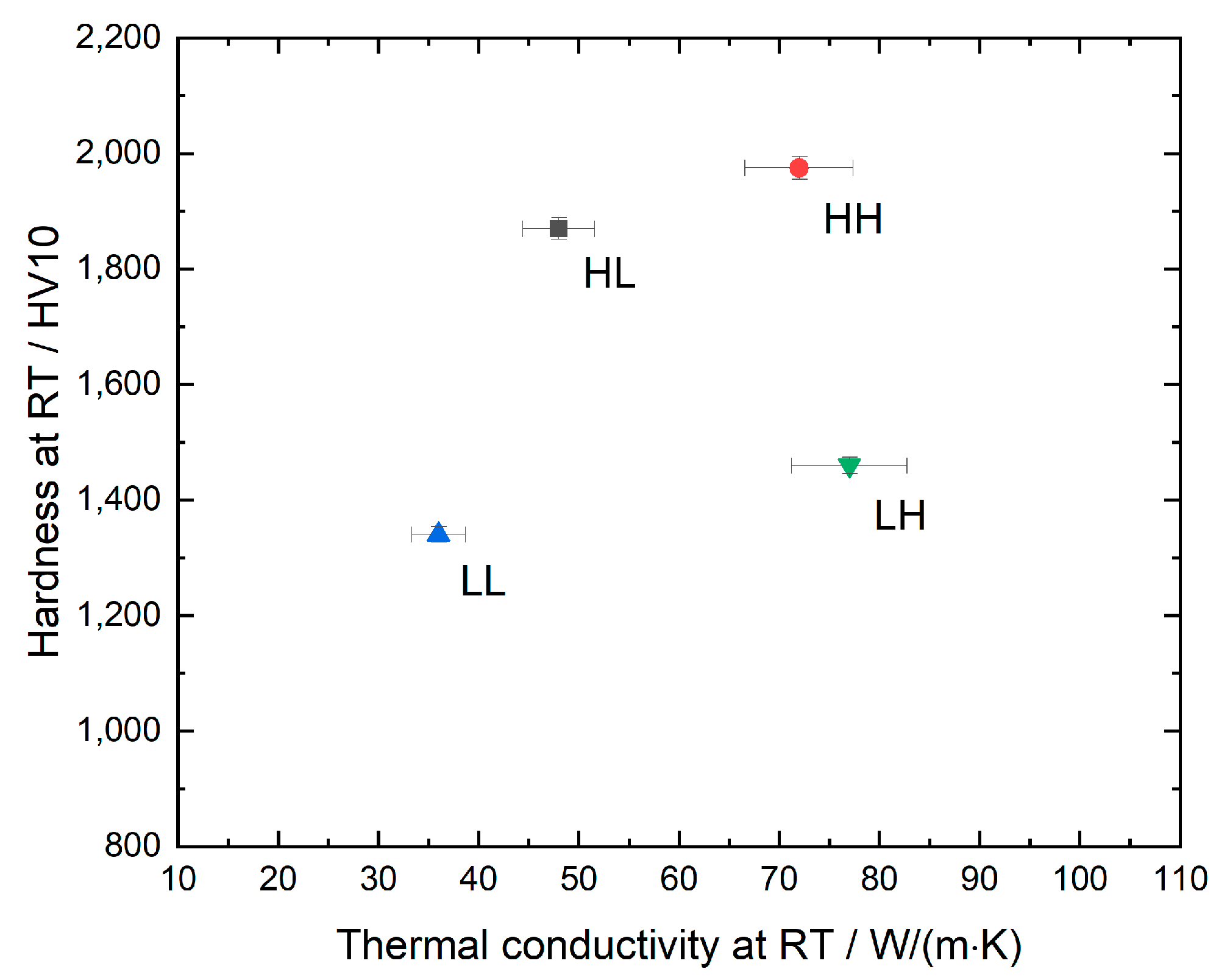

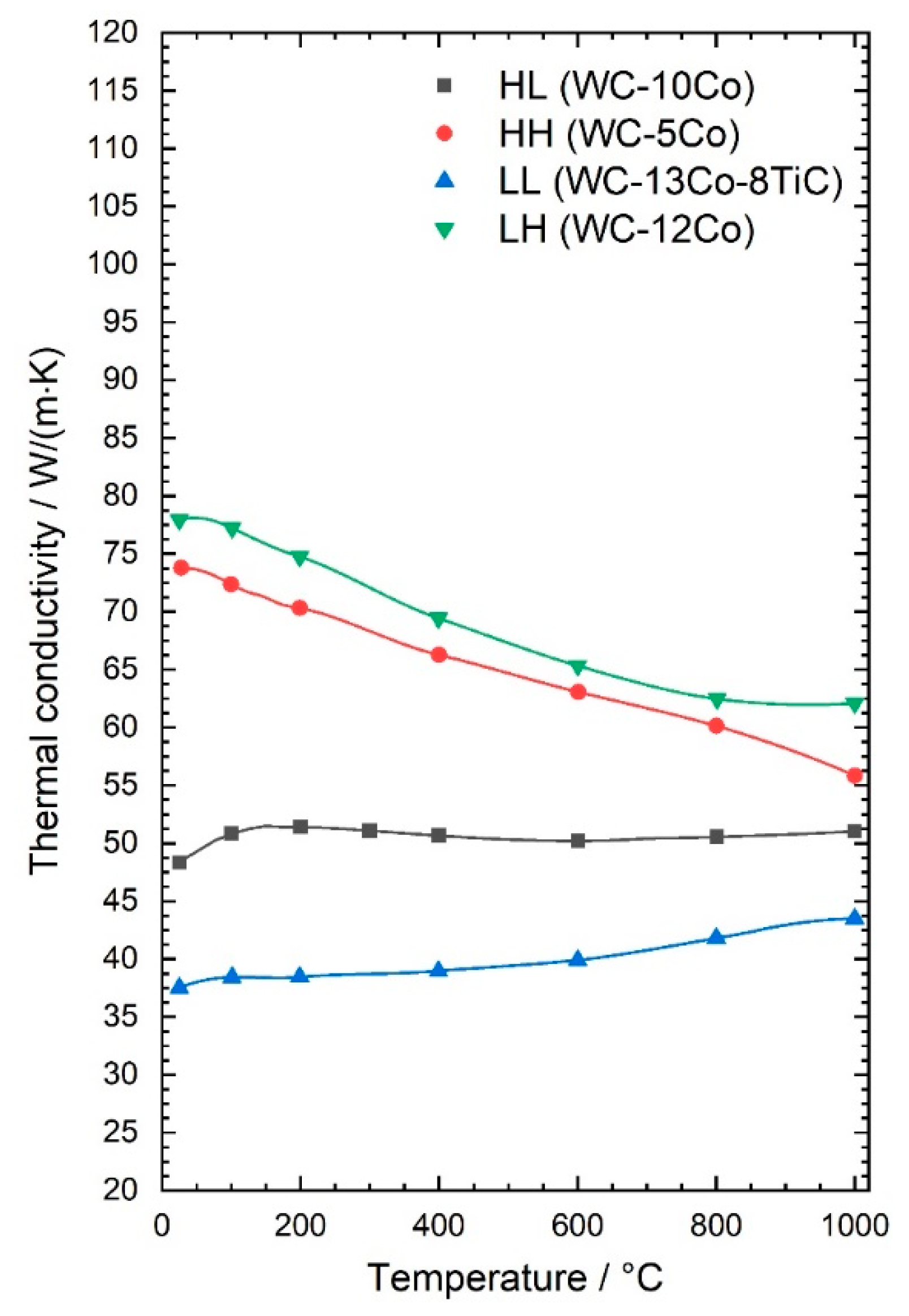

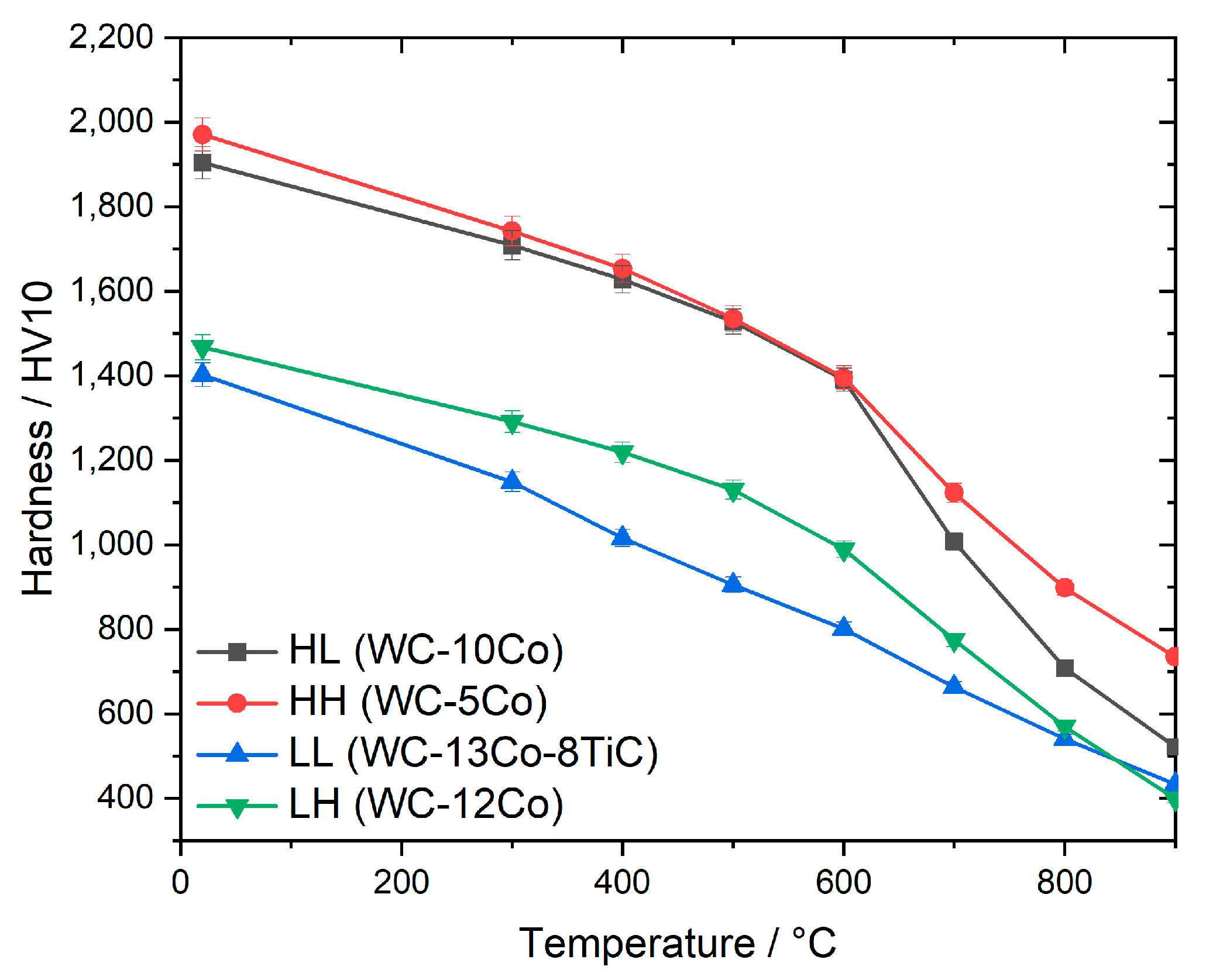

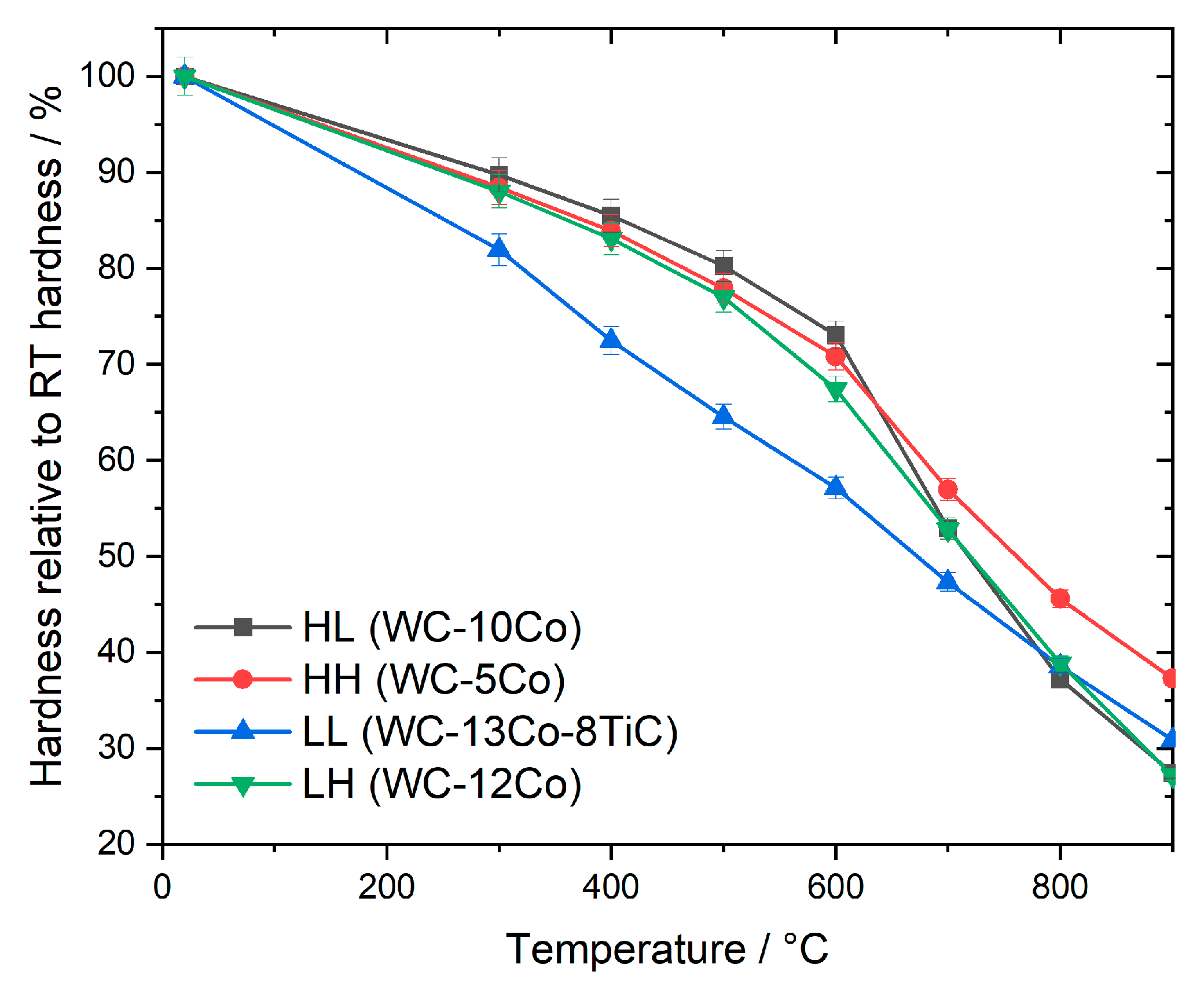

3.1. Cemented Carbide Properties at Elevated Temperatures

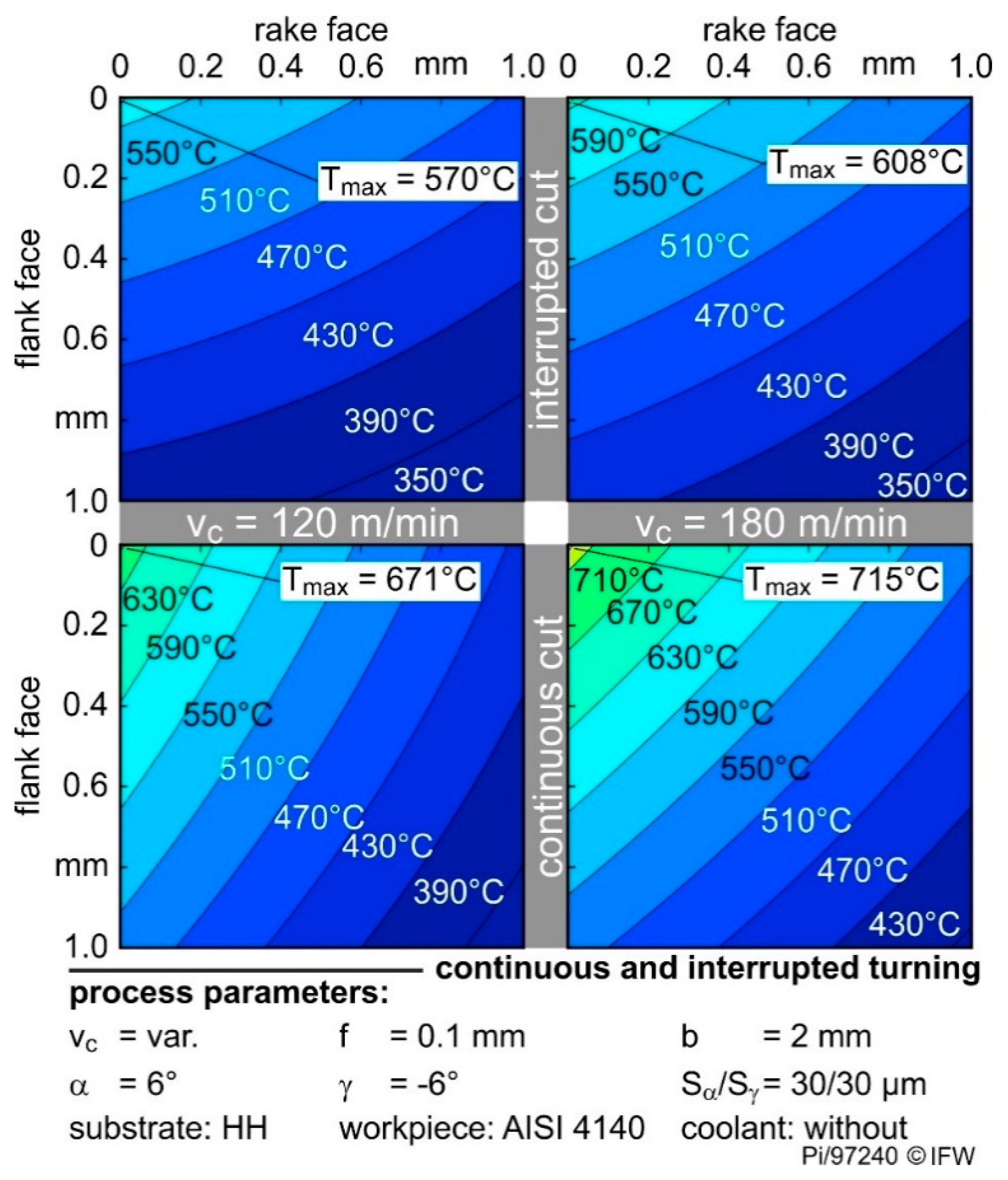

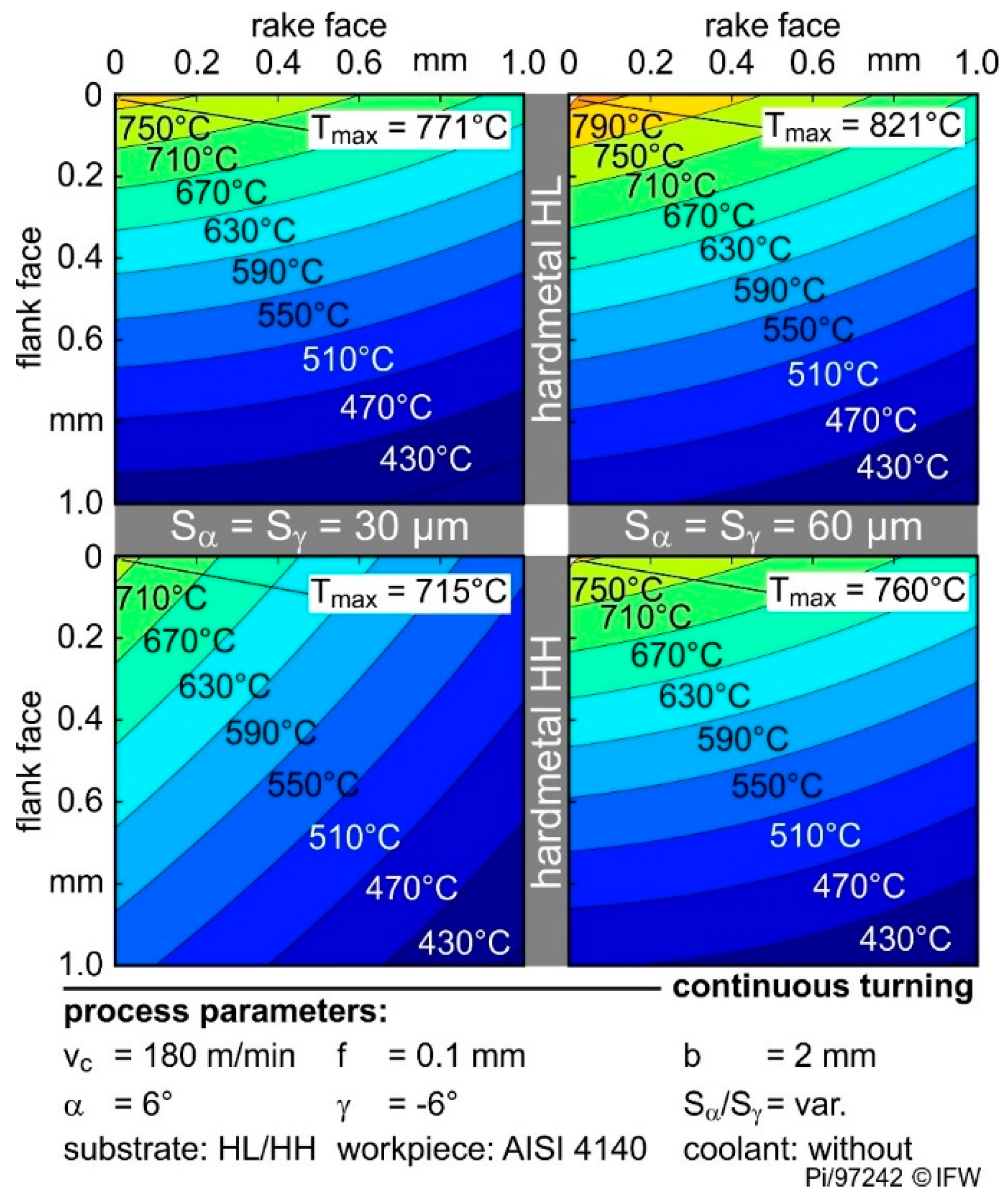

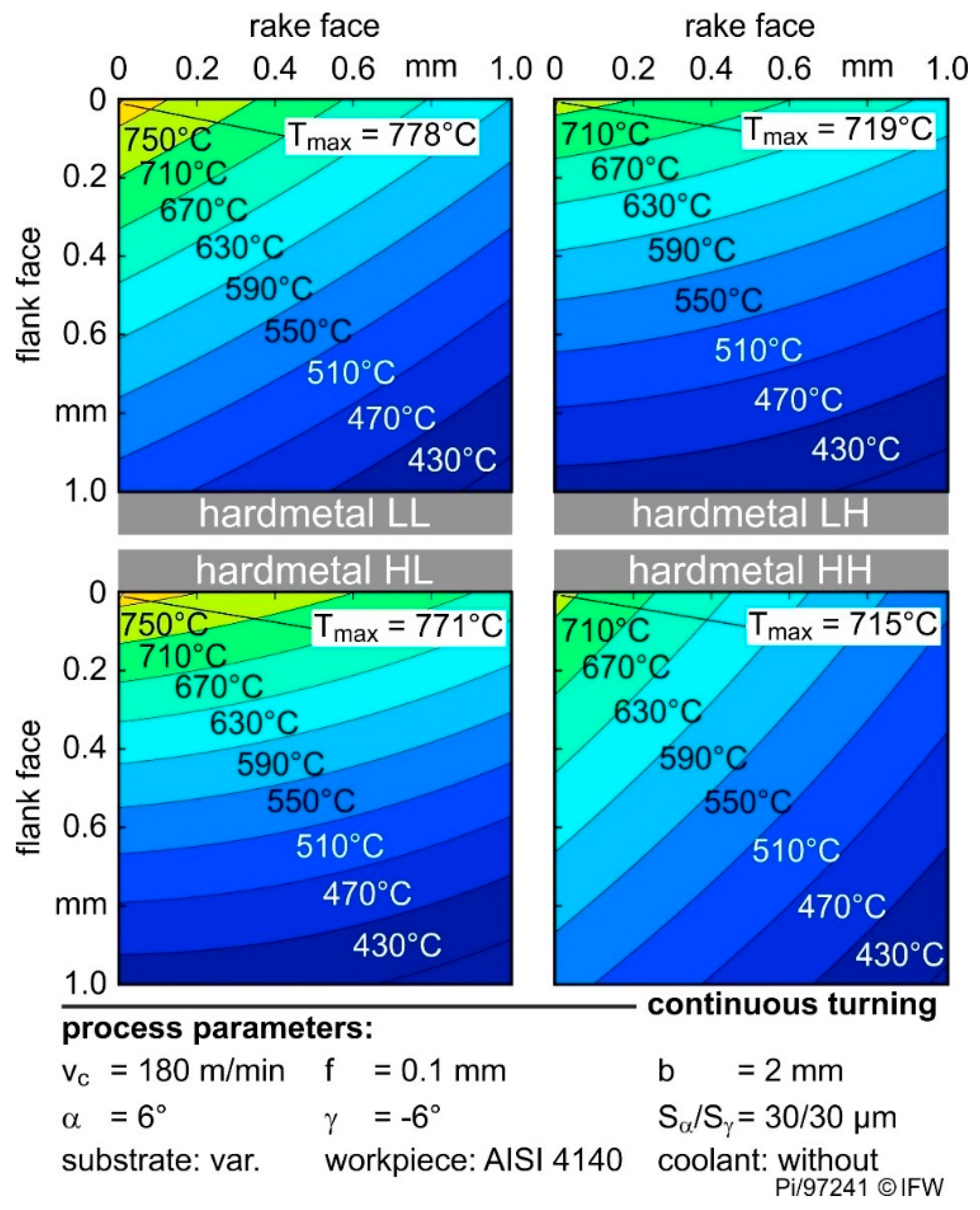

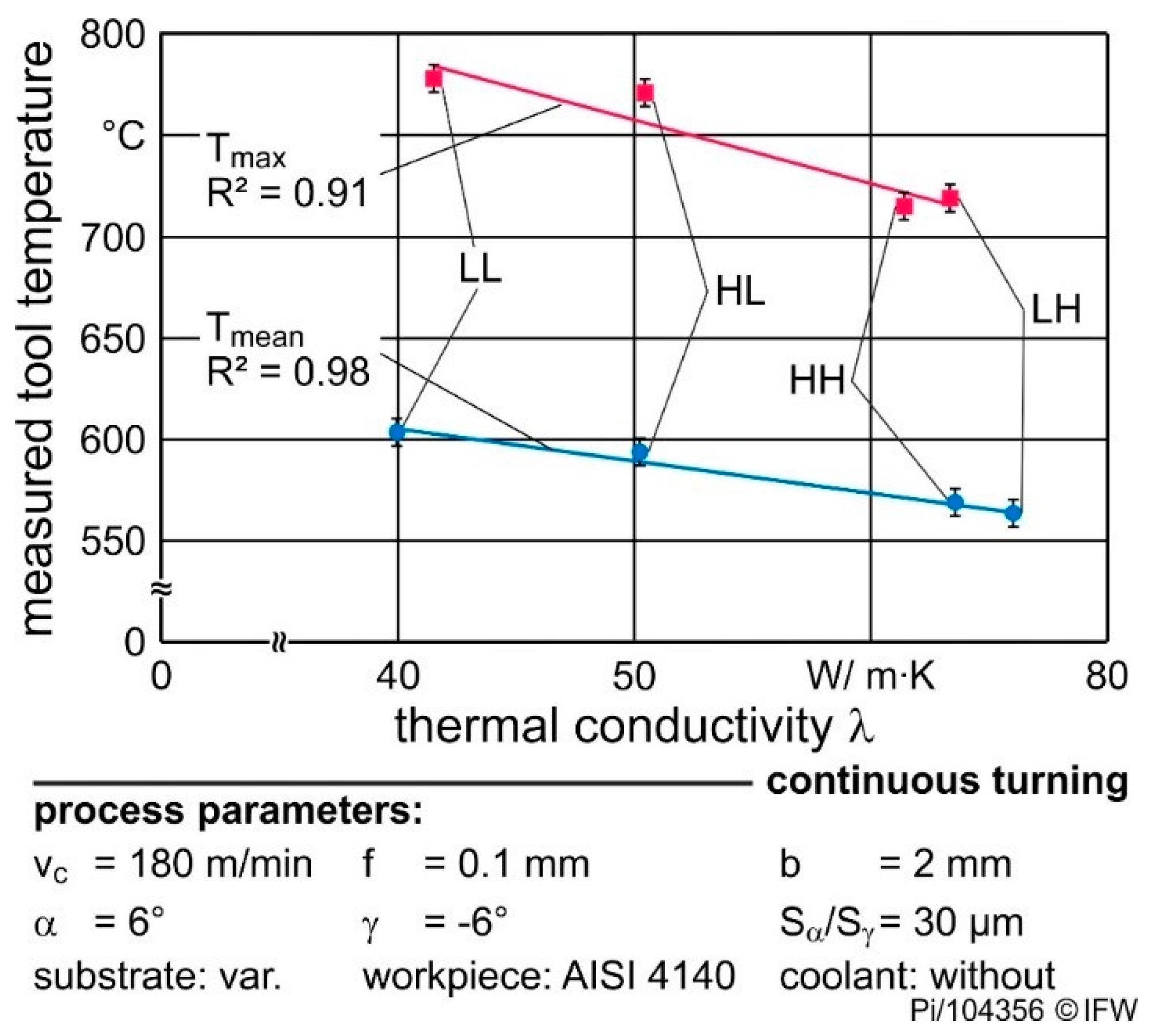

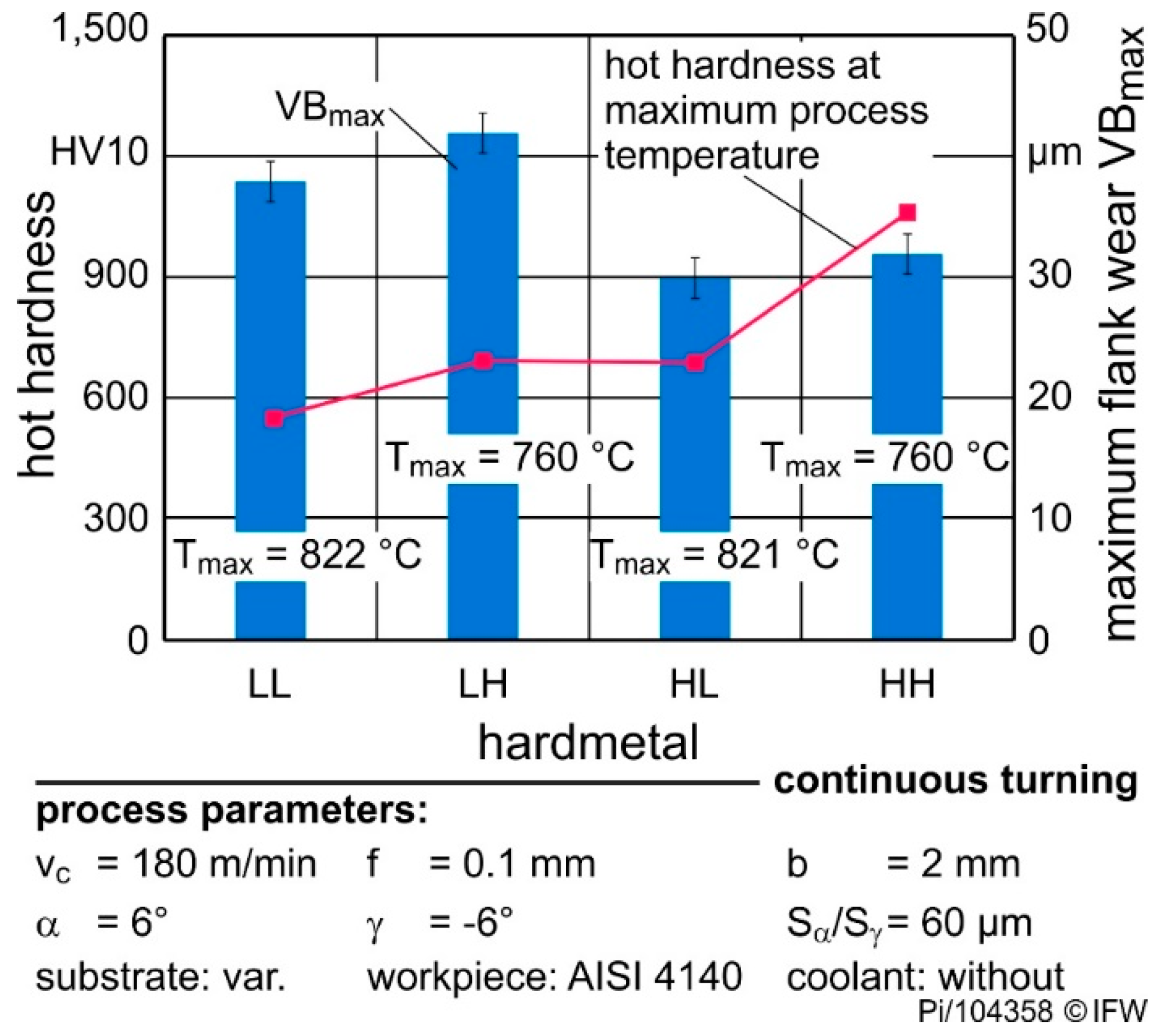

3.2. Cutting Process Temperature during Continous and Interrupted Cutting

4. Discussion

4.1. Influence of Tool Material Properties on Cutting Process Temperature

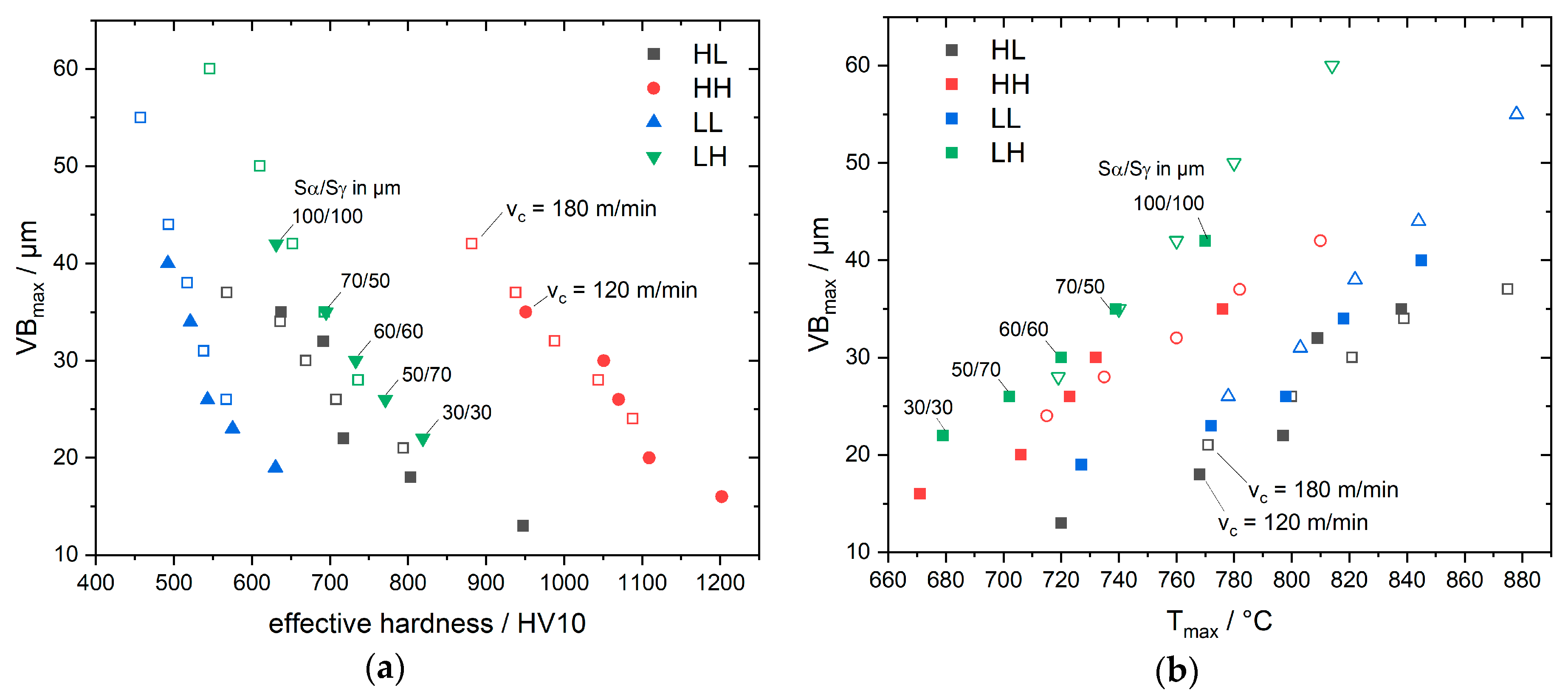

4.2. Relationship between Cutting Temperature, Cemented Carbide Properties and Tool Wear

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- García, J.; Collado Ciprés, V.; Blomqvist, A.; Kaplan, B. Cemented carbide microstructures: A review. Int. J. Refract. Met. Hard Mater. 2019, 80, 40–68. [Google Scholar] [CrossRef]

- Oduola, O.; Awopetu, O.; Ikutegbe, C.; Akinluwade, K.; Adetunji, A. An Outlook on Tool Wear Mechanisms of Selected Cutting Tool Materials. BJAST 2016, 14, 1–9. [Google Scholar] [CrossRef]

- Usui, E.; Shirakashi, T.; Kitagawa, T. Analytical prediction of cutting tool wear. Wear 1984, 100, 129–151. [Google Scholar] [CrossRef]

- Li, B. A review of tool wear estimation using theoretical analysis and numerical simulation technologies. Hardmetals Raw Mater. Technol. Appl. 2012, 35, 143–151. [Google Scholar] [CrossRef]

- Hosseinkhani, K.; Ng, E.-G. A Unique Methodology for Tool Life Prediction in Machining. JMMP 2020, 4, 16. [Google Scholar] [CrossRef]

- Tiffe, M.; Aßmuth, R.; Saelzer, J.; Biermann, D. Investigation on cutting edge preparation and FEM assisted optimization of the cutting edge micro shape for machining of nickel-base alloy. Prod. Eng. Res. Devel. 2019, 13, 459–467. [Google Scholar] [CrossRef]

- Olovsjö, S.; Nyborg, L. Influence of microstructure on wear behaviour of uncoated WC tools in turning of Alloy 718 and Waspaloy. Wear 2012, 282–283, 12–21. [Google Scholar] [CrossRef]

- Hoier, P.; Malakizadi, A.; Klement, U.; Krajnik, P. Characterization of abrasion- and dissolution-induced tool wear in machining. Wear 2019, 426–427, 1548–1562. [Google Scholar] [CrossRef]

- Saketi, S.; Bexell, U.; Östby, J.; Olsson, M. On the diffusion wear of cemented carbides in the turning of AISI 316L stainless steel. Wear 2019, 430–431, 202–213. [Google Scholar] [CrossRef]

- Denkena, B.; Lucas, A.; Bassett, E. Effects of the cutting edge microgeometry on tool wear and its thermo-mechanical load. CIRP Ann. 2011, 60, 73–76. [Google Scholar] [CrossRef]

- Wyen, C.-F. Rounded Cutting Edges and Their Influence in Machining Titanium. Ph.D. Thesis, ETH Zurich, Zurich, Switzerland, 2011. [Google Scholar]

- Klocke, F.; König, W. Fertigungsverfahren 1. Drehen, Fräsen, Bohren; Springer: Berlin, Germany, 2007; ISBN 3540234586. [Google Scholar]

- Denkena, B.; Biermann, D. Cutting edge geometries. CIRP Ann. 2014, 63, 631–653. [Google Scholar] [CrossRef]

- Denkena, B.; Michaelis, A.; Herrmann, M.; Pötschke, J.; Krödel, A.; Vornberger, A.; Picker, T. Influence of tool material properties on the wear behavior of cemented carbide tools with rounded cutting edges. Wear 2020, 456–457, 203395. [Google Scholar] [CrossRef]

- DIN EN ISO 3738. Hardmetals–Vickers Hardness Test; DIN, Deutsches Institut für Normung e.V: Berlin, Germany, 1991. [Google Scholar]

- DIN EN 821-2. Advanced Technical Ceramics-Monolithic Ceramics, Thermo-Physical Properties-Part 2: Determination of Thermal Diffusity by the Laser Flash (or Heat Pulse) Method; DIN, Deutsches Institut für Normung e.V: Berlin, Germany, 1997. [Google Scholar]

- DIN EN ISO 3369. Impermeable Sintered Metal Materials and Hardmetals-Determination of Density; DIN, Deutsches Institut für Normung e.V: Berlin, Germany, 2010. [Google Scholar]

- Bergmann, B. Grundlagen zur Auslegung von Schneidkantenverrundungen. Ph.D. Thesis, Leibniz Universität Hannover, Hannover, Germany, 2017. [Google Scholar]

- Bassett, E. Belastungsspezifische Auslegung und Herstellung von Schneidkanten für Drehwerkzeuge. Ph.D. Thesis, Leibniz Universität Hannover, Hannover, Germany, 2013. [Google Scholar]

- Smith, D.S.; Puech, F.; Nait-Ali, B.; Alzina, A.; Honda, S. Grain boundary thermal resistance and finite grain size effects for heat conduction through porous polycrystalline alumina. Int. J. Heat Mass Transf. 2018, 121, 1273–1280. [Google Scholar] [CrossRef]

- Vornberger, A.; Pötschke, J.; Gestrich, T.; Herrmann, M.; Michaelis, A. Influence of microstructure on hardness and thermal conductivity of hardmetals. J. Refract. Met. Hard Mater. 2020, 88, 1–8. [Google Scholar] [CrossRef]

- Brnic, J.; Turkalj, G.; Canadija, M.; Lanc, D.; Brcic, M. Study of the Effects of High Temperatures on the Engineering Properties of Steel 42CrMo4. High Temp. Mater. Process. 2015, 34. [Google Scholar] [CrossRef]

| Designation | WC Powder | WC/wt% | TiC/wt% | Co/wt% | Cr3C2/wt% | VC/wt% | Milling Time/h |

|---|---|---|---|---|---|---|---|

| HL | WC DN4.0 | Bal. | - | 10 | 0.70 | 0.40 | 24 |

| HH | WC DS50 | Bal. | - | 5 | 0.35 | - | 12 |

| LL | WC DS250 | Bal. | 8 | 13 | - | - | 12 |

| LH | WC DS80 | Bal. | - | 12 | 0.42 | - | 12 |

| Designation | Sintered WC Grain Size/µm | Hardness at RT/HV10 | Thermal Conductivity at RT/W/(m·K) |

|---|---|---|---|

| HL | 0.1 ± 0.01 | 1870 ± 20 | 48 ± 4 |

| HH | 0.3 ± 0.01 | 1975 ± 20 | 72 ± 5 |

| LL | 0.8 ± 0.02 | 1310 ± 15 | 36 ± 3 |

| LH | 0.4 ± 0.01 | 1460 ± 15 | 77 ± 6 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Vornberger, A.; Picker, T.; Pötschke, J.; Herrmann, M.; Denkena, B.; Krödel, A.; Michaelis, A. Influence of Cemented Carbide Composition on Cutting Temperatures and Corresponding Hot Hardnesses. Materials 2020, 13, 4571. https://doi.org/10.3390/ma13204571

Vornberger A, Picker T, Pötschke J, Herrmann M, Denkena B, Krödel A, Michaelis A. Influence of Cemented Carbide Composition on Cutting Temperatures and Corresponding Hot Hardnesses. Materials. 2020; 13(20):4571. https://doi.org/10.3390/ma13204571

Chicago/Turabian StyleVornberger, Anne, Tobias Picker, Johannes Pötschke, Mathias Herrmann, Berend Denkena, Alexander Krödel, and Alexander Michaelis. 2020. "Influence of Cemented Carbide Composition on Cutting Temperatures and Corresponding Hot Hardnesses" Materials 13, no. 20: 4571. https://doi.org/10.3390/ma13204571

APA StyleVornberger, A., Picker, T., Pötschke, J., Herrmann, M., Denkena, B., Krödel, A., & Michaelis, A. (2020). Influence of Cemented Carbide Composition on Cutting Temperatures and Corresponding Hot Hardnesses. Materials, 13(20), 4571. https://doi.org/10.3390/ma13204571