Study of Natural and Artificial Aging on AlSi9Cu3 Alloy at Different Ratios of Returnable Material in the Batch

Abstract

1. Introduction

2. Materials and Methods

2.1. Experimental Material

2.2. Experimental Methods

3. Results

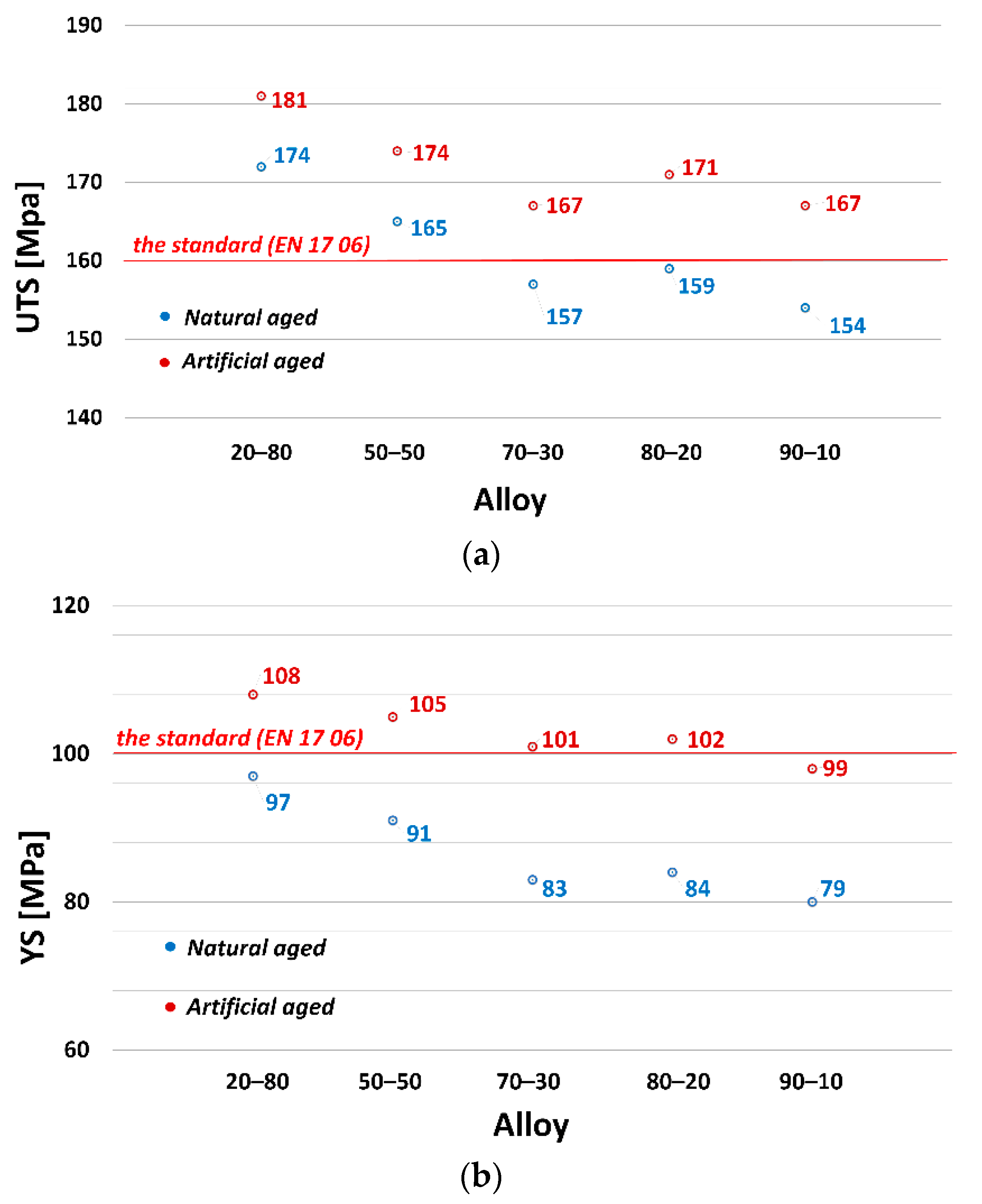

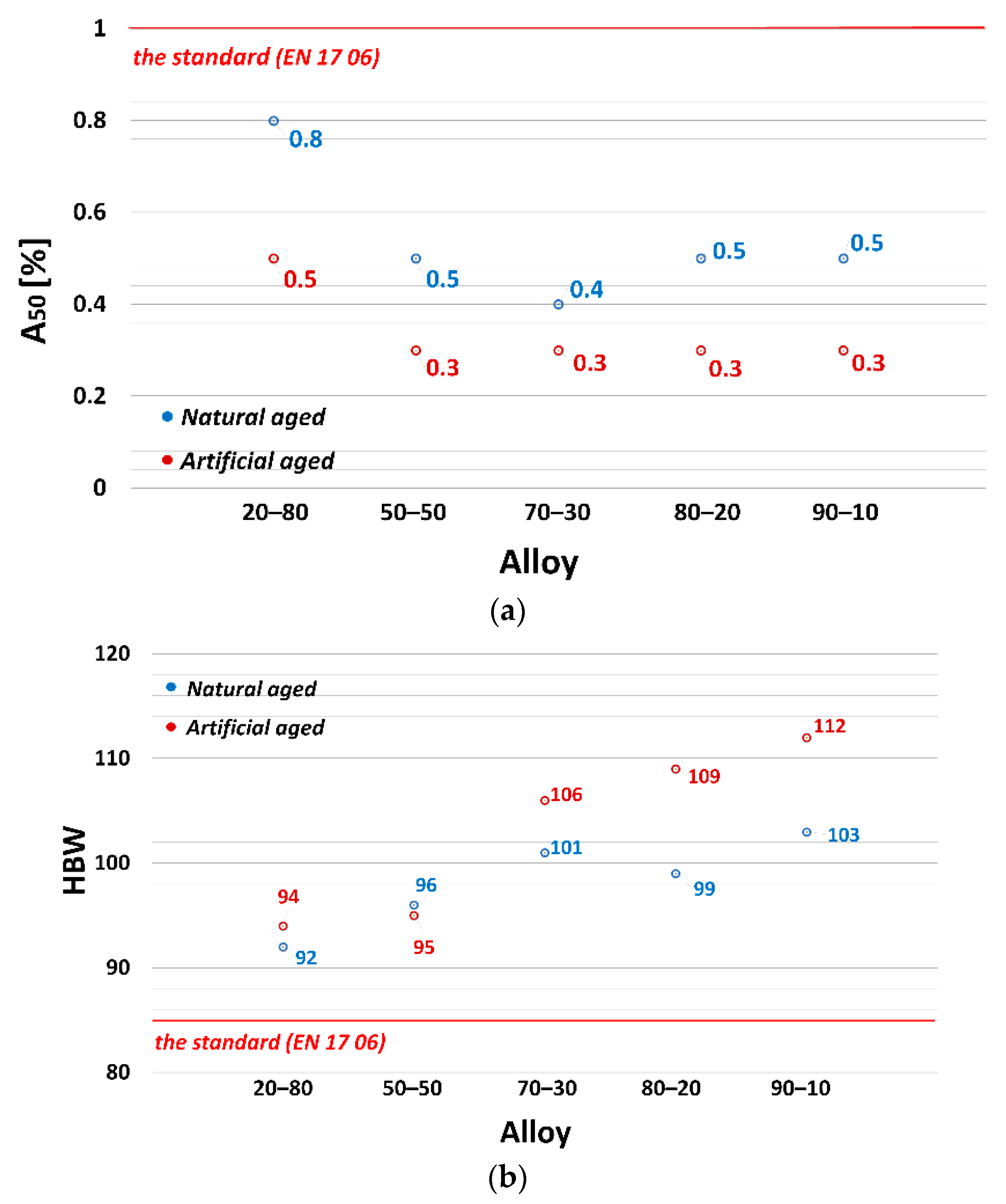

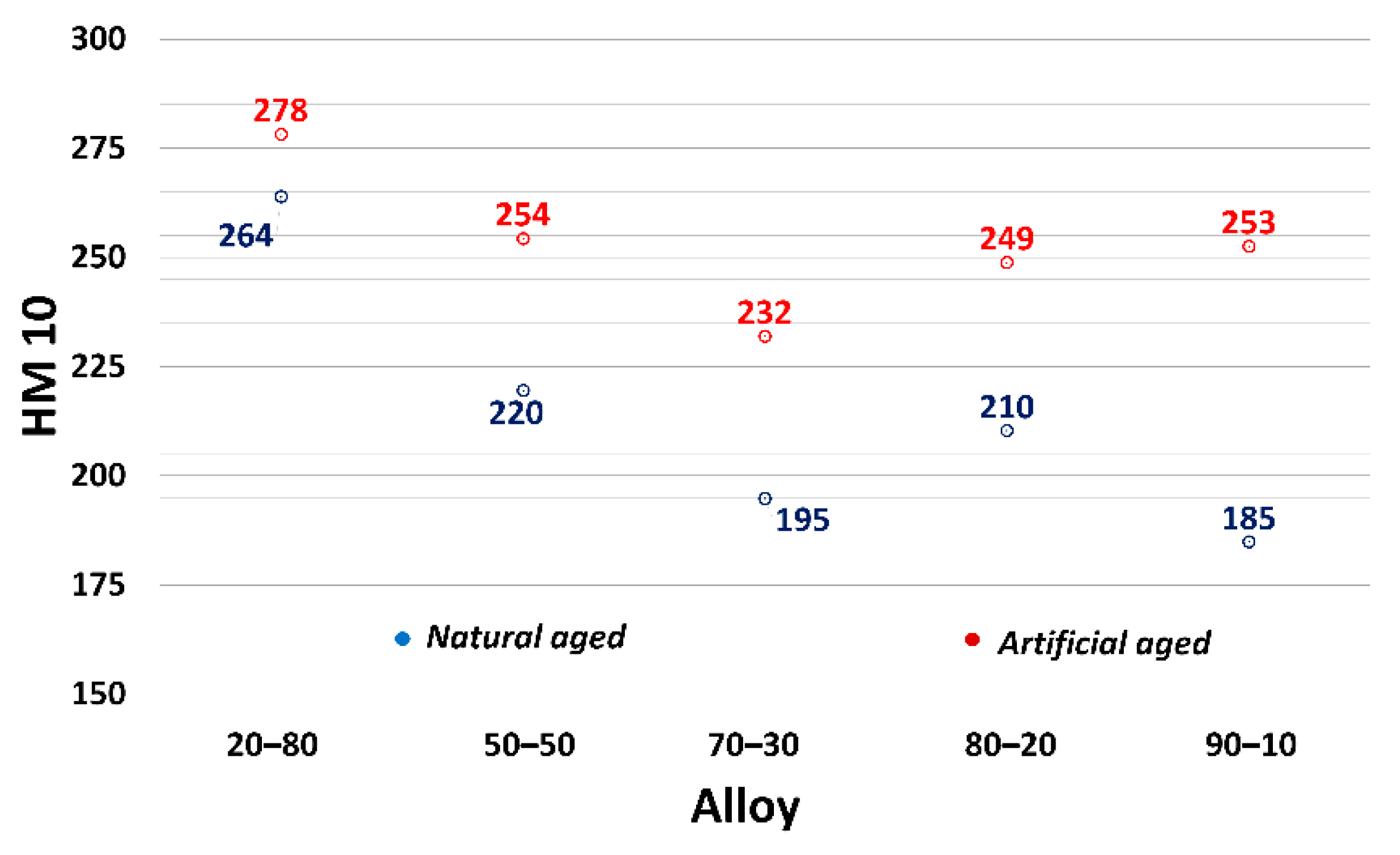

3.1. Mechanical Properties

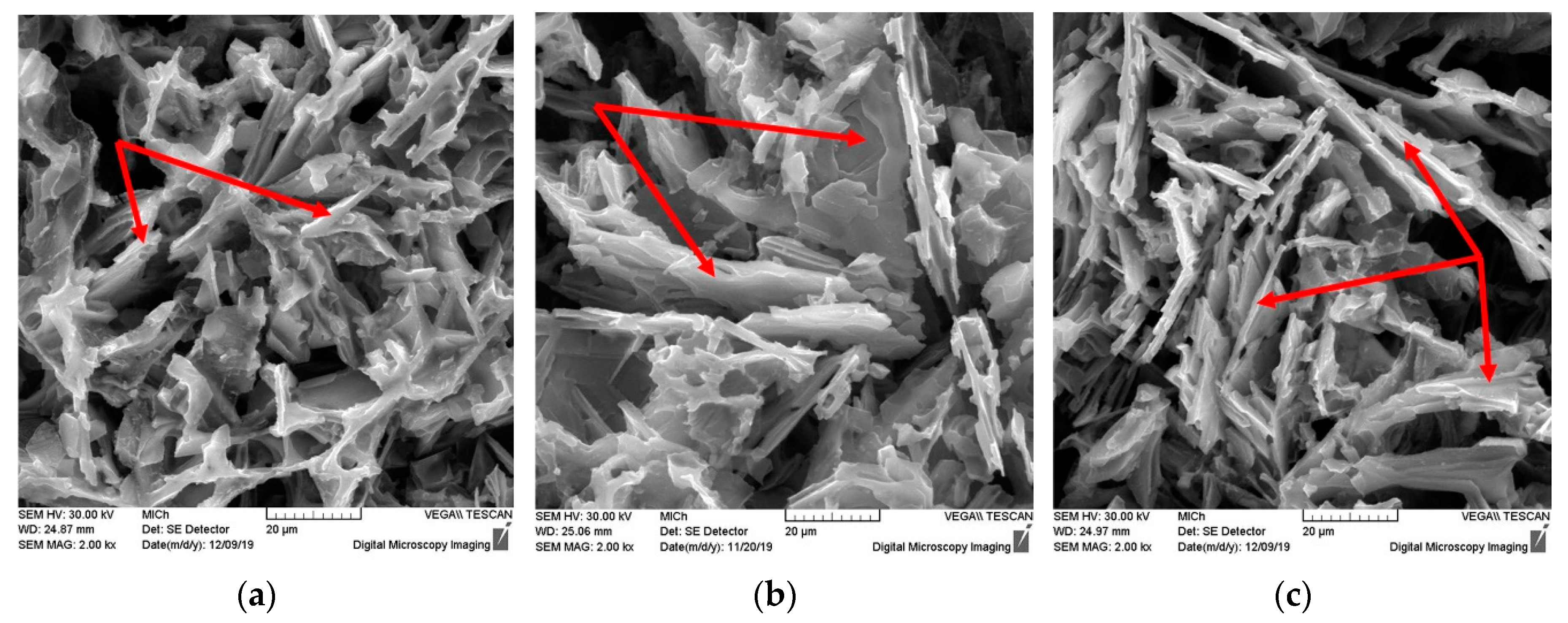

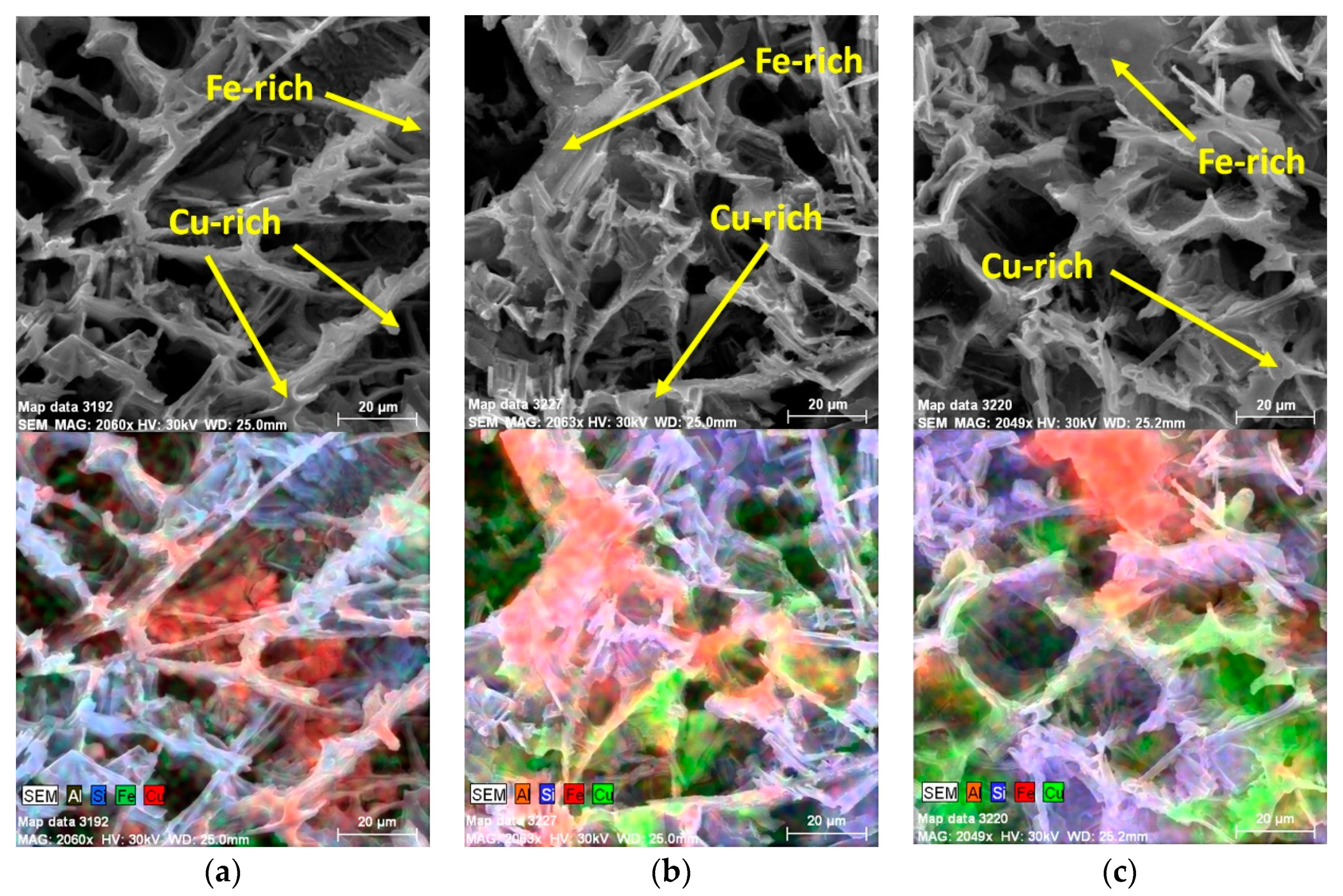

3.2. Microstructure

3.2.1. Natural Aging

3.2.2. Artificial Aging

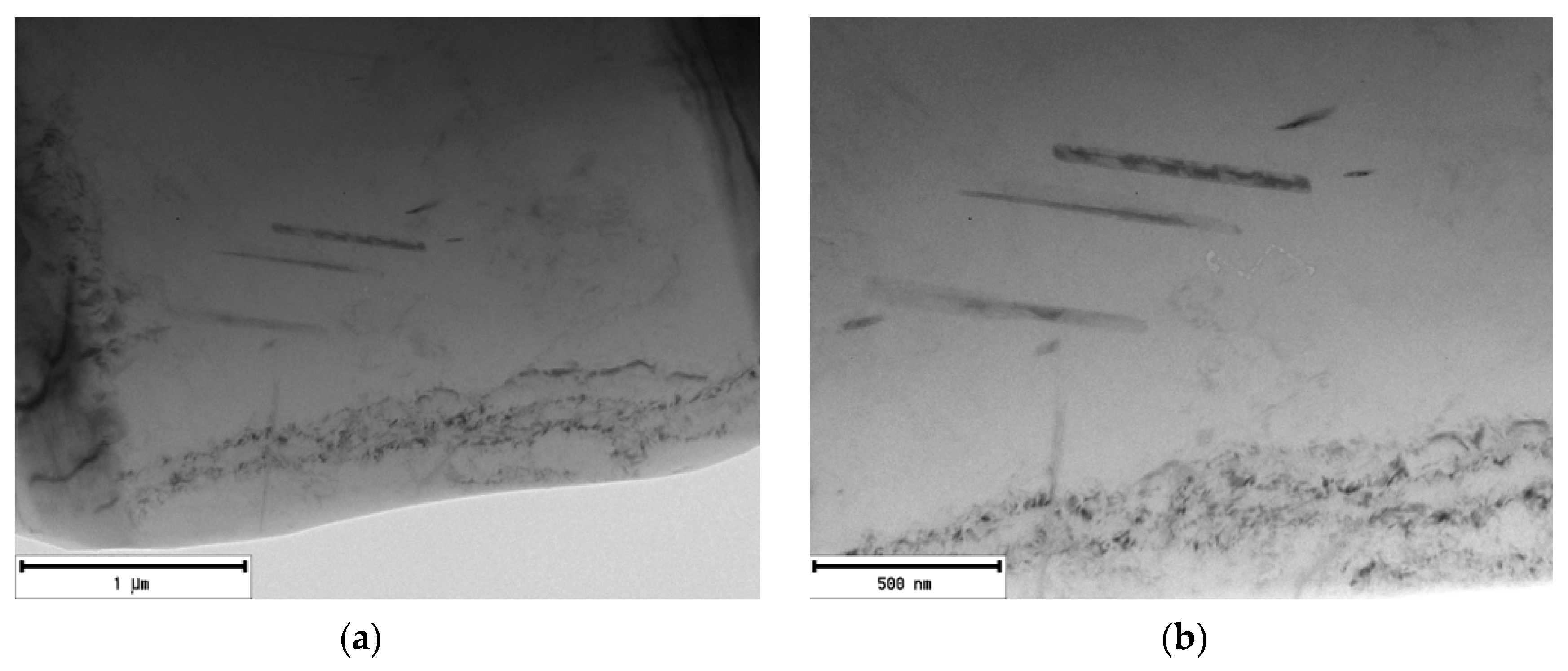

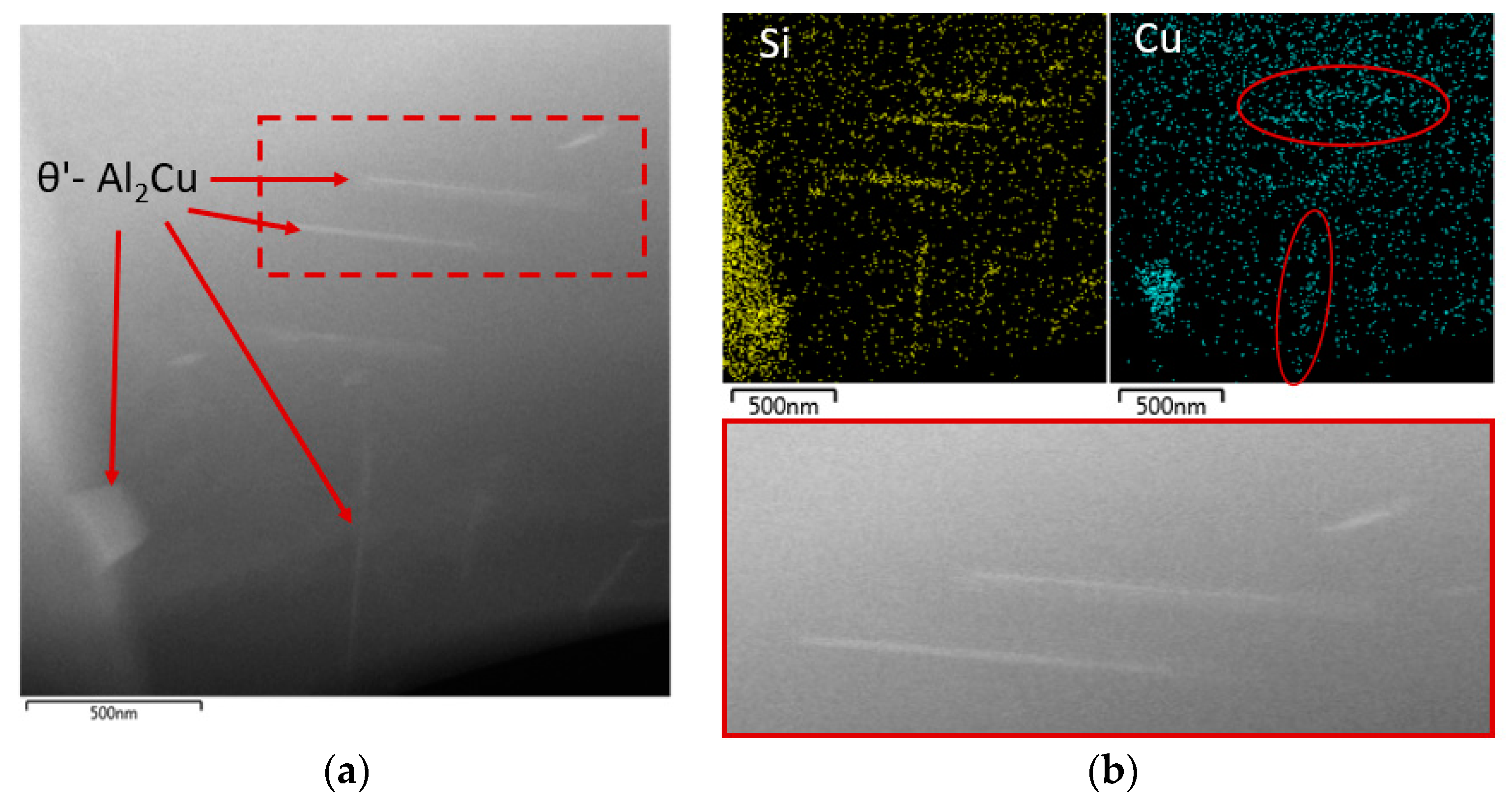

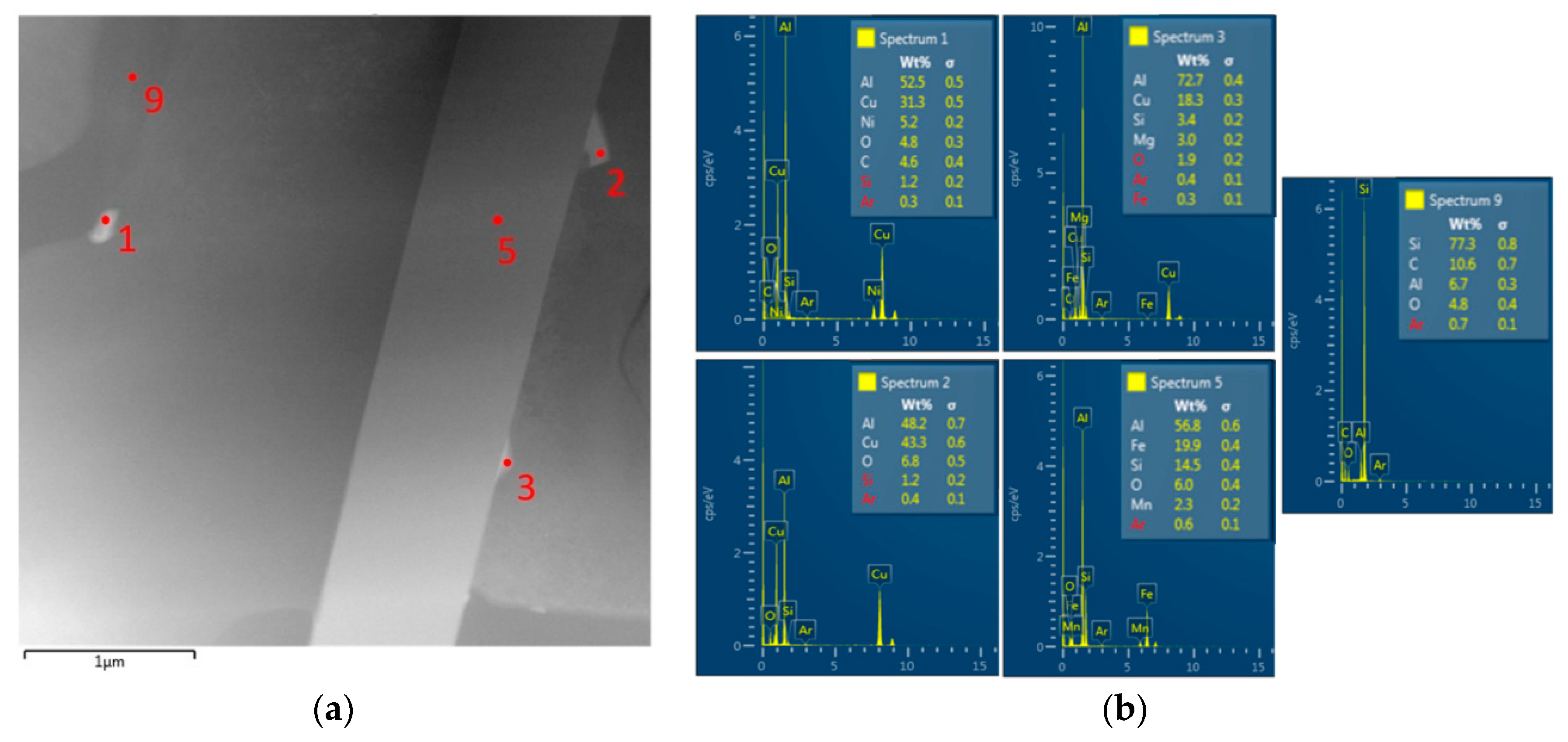

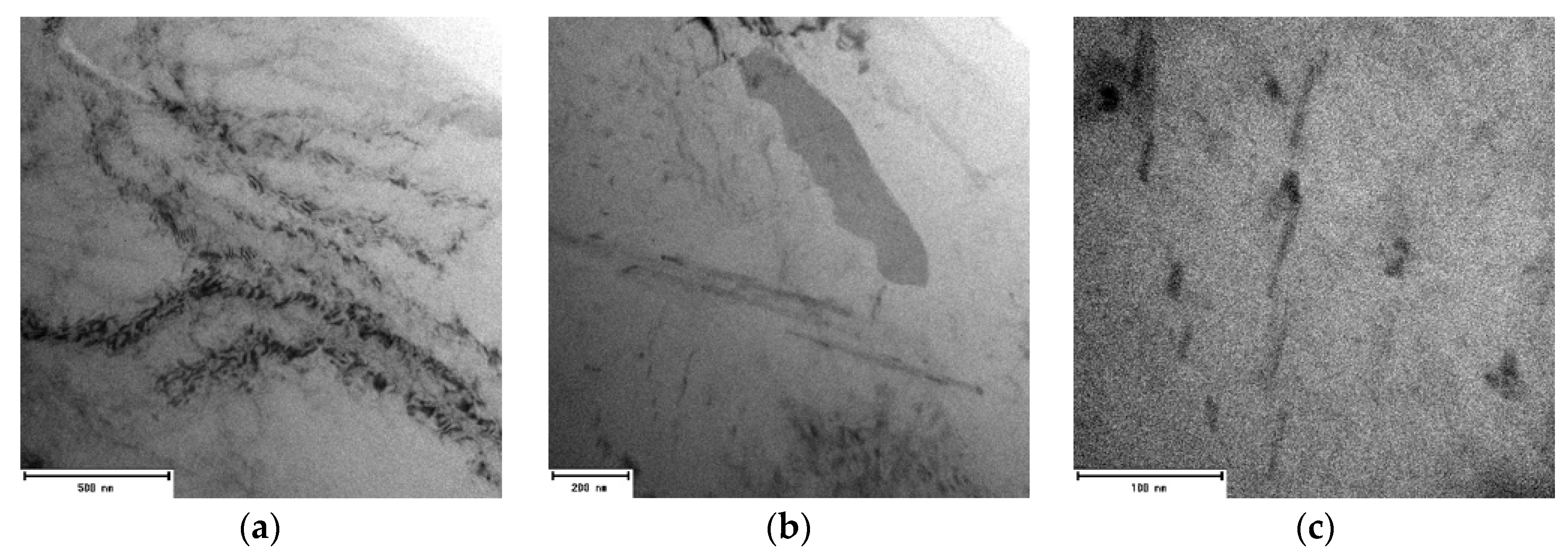

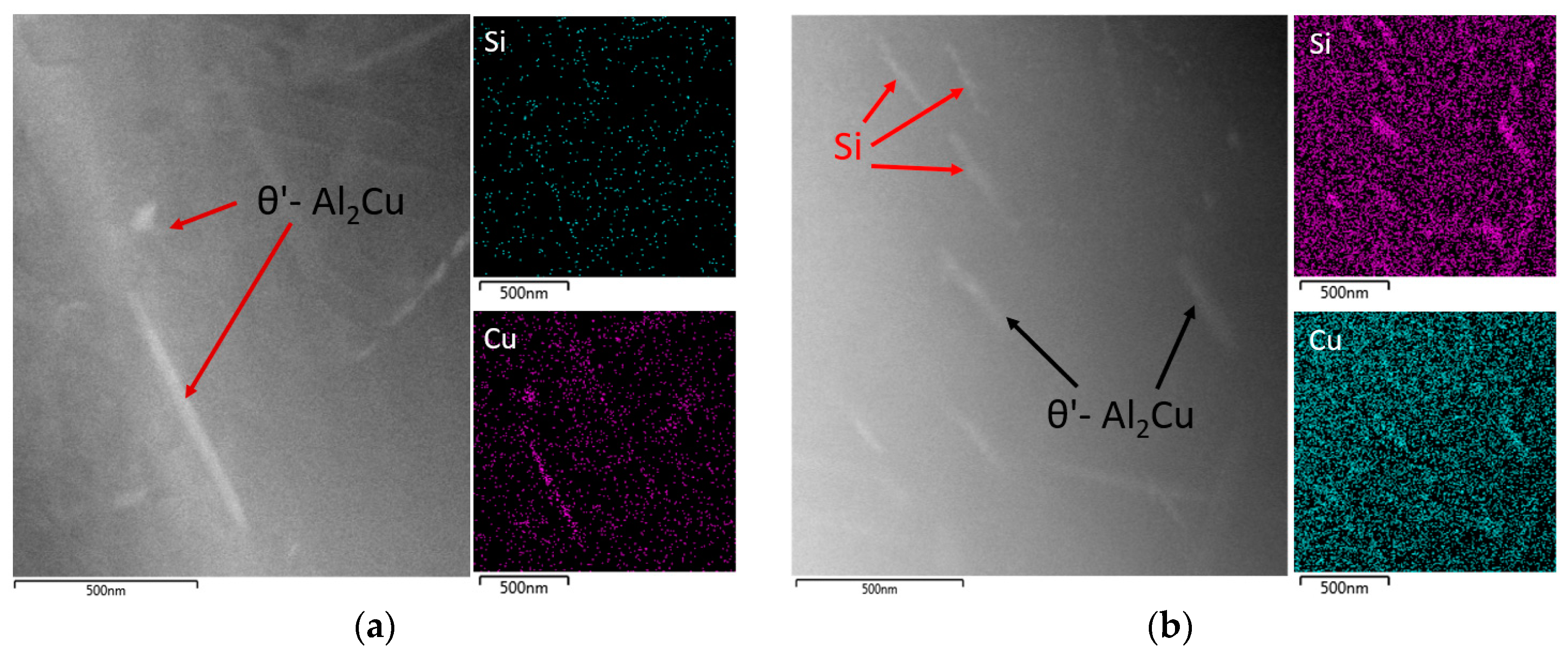

3.3. Substructure

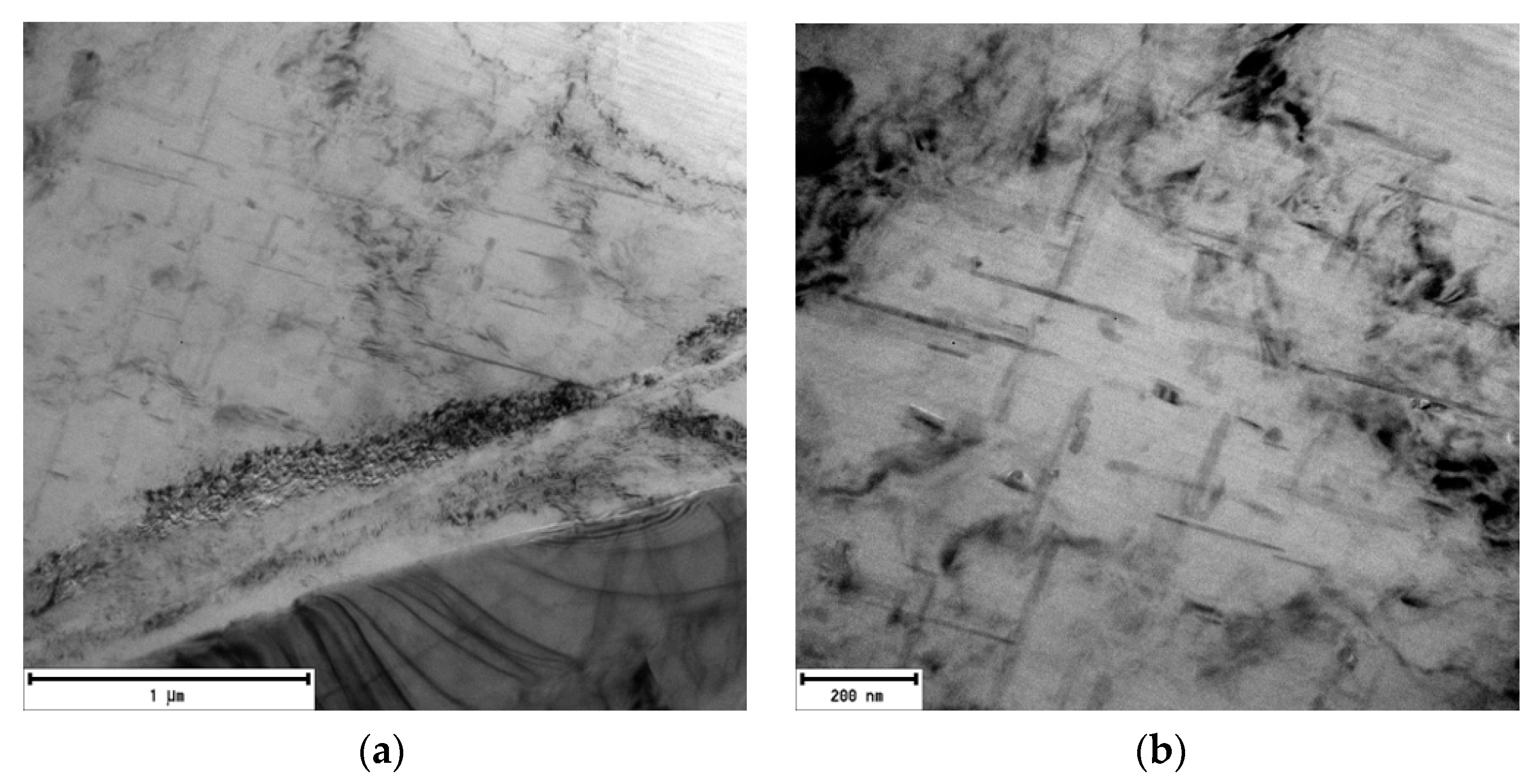

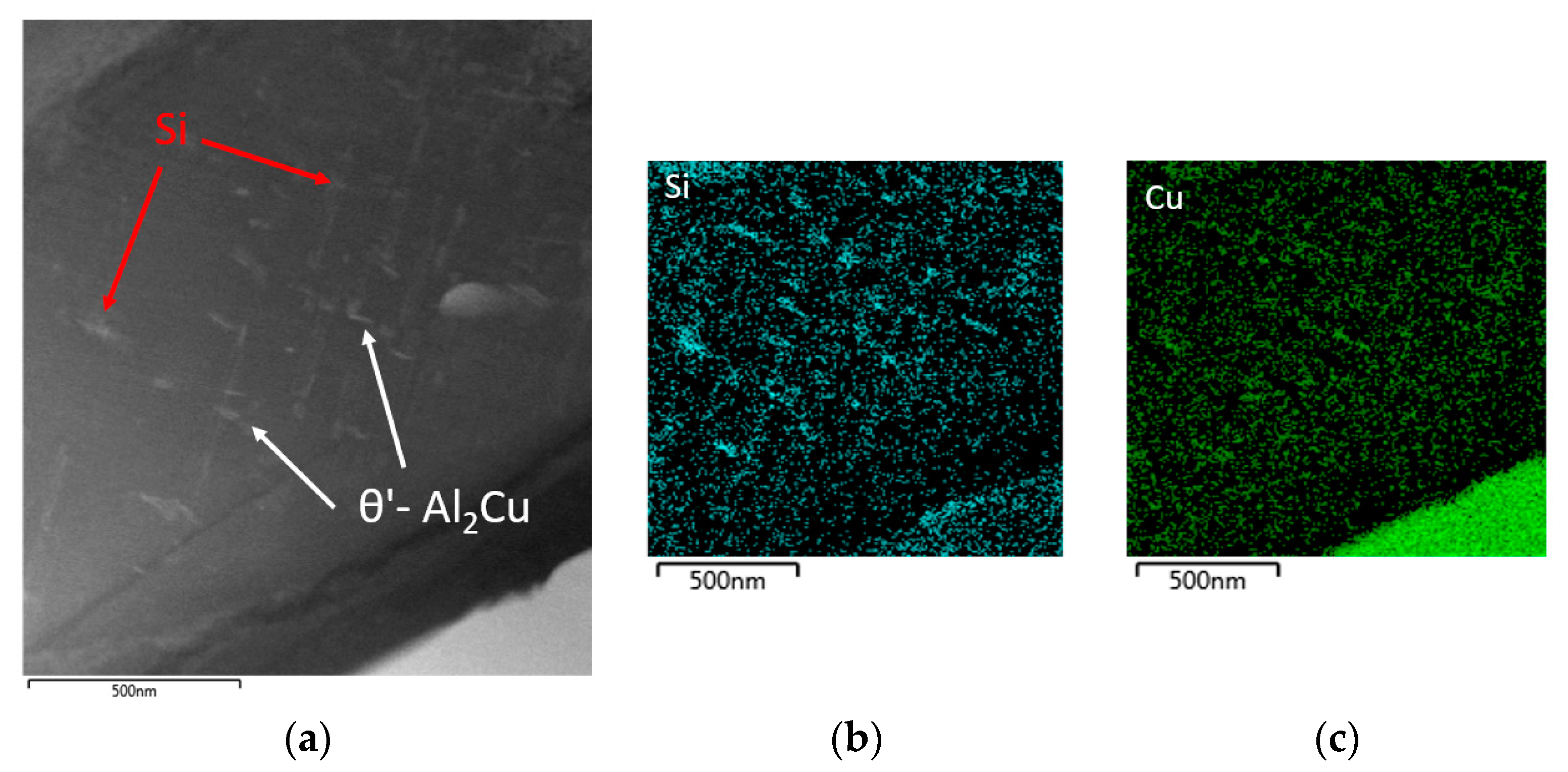

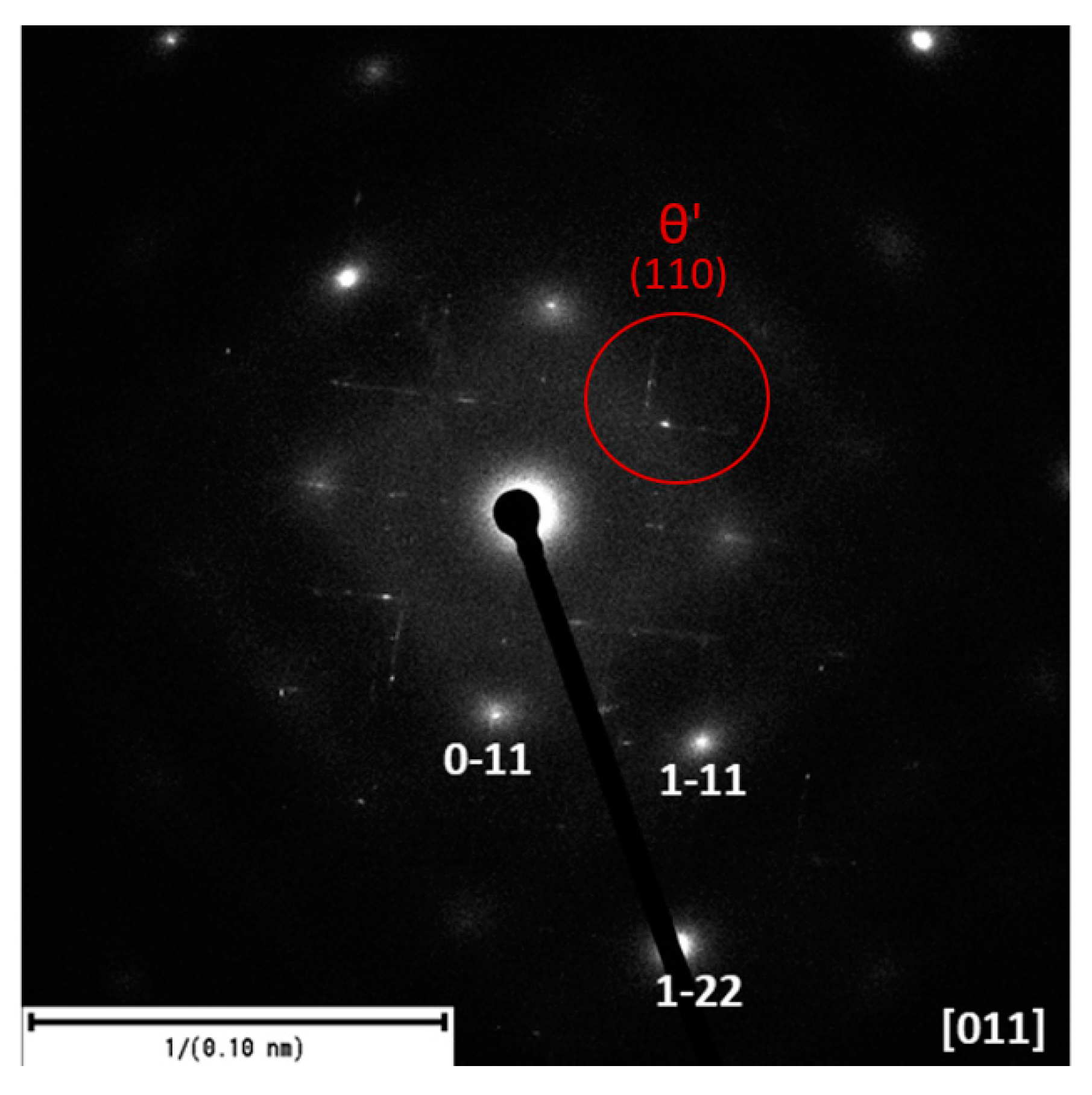

3.3.1. 20–80 Alloy

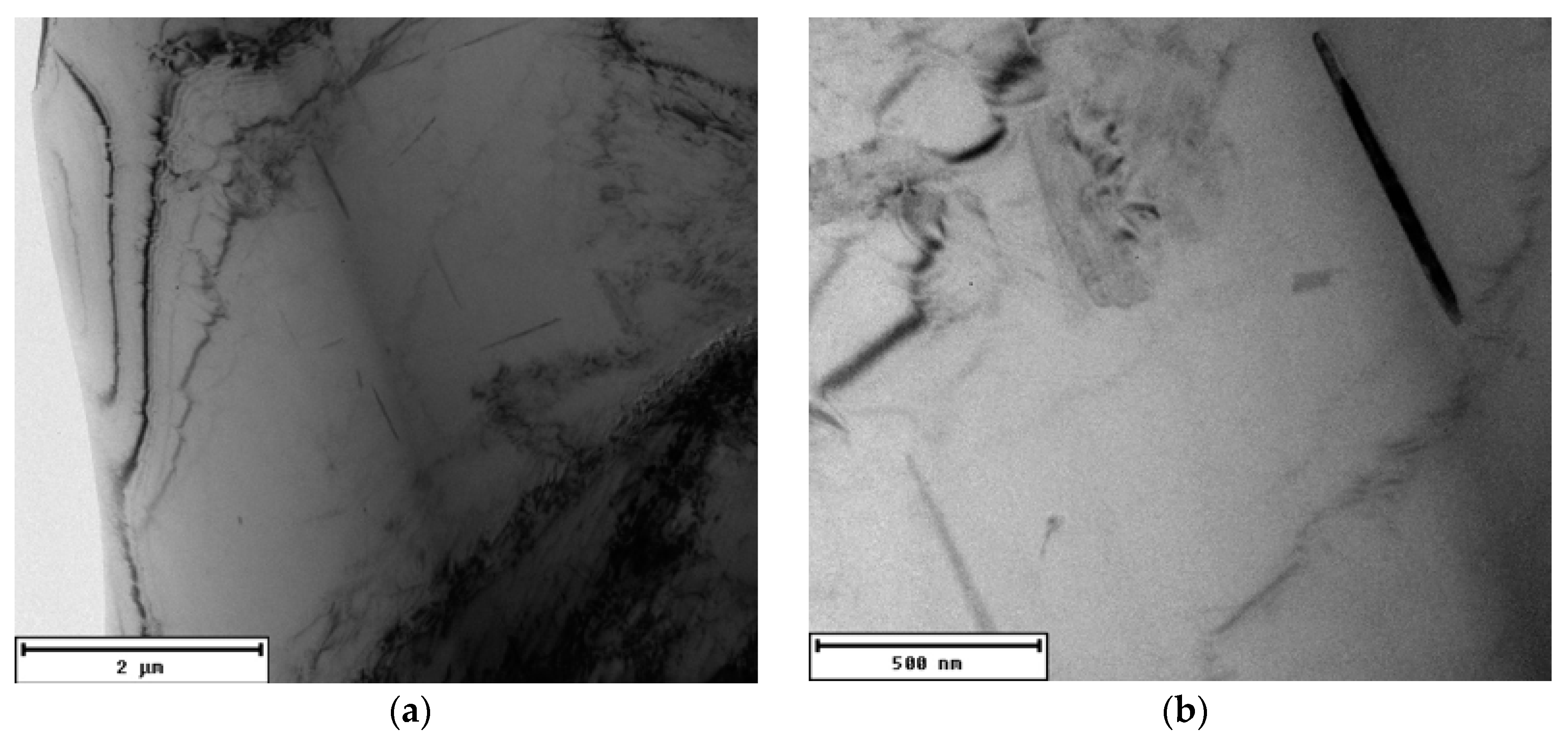

3.3.2. 90–10 Alloy

4. Discussion

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Das, K.S.; Green, J.A.S. Aluminum Industry and Climate Change-Assessment and Responses. JOM 2010, 62, 27–31. [Google Scholar] [CrossRef]

- International Aluminum Institute. Global Aluminum Recycling: A Cornerstone of Sustainable Development; International Aluminum Institute: London, UK, 2009. [Google Scholar]

- Ciu, J.; Roven, H.J. Recycling of automotive aluminum. Trans. Nonferrous Met. Soc. China 2010, 20, 2057–2063. [Google Scholar] [CrossRef]

- Gaustad, G.; Olivetti, E.A.; Kirchain, R. Improving aluminum recycling: A survey of sorting and impurity removal technologies. Resour. Conserv. Recycl. 2012, 58, 79–87. [Google Scholar] [CrossRef]

- Green, J.A.S. Aluminum Recycling and Processing for Energy Conservation and Sustainability; ASM International: Russell Township, OH, USA, 2007. [Google Scholar]

- Kasińska, J.; Bolibruchová, D.; Matejka, M. The influence of remelting on the properties of AlSi9Cu3 alloy with higher iron content. Materials 2020, 13, 575. [Google Scholar] [CrossRef]

- ASM International. Metals Handbook Metallography and Microstructures; ASM International: Russell Township, OH, USA, 2004; Volume 9. [Google Scholar]

- Bolibruchová, D.; Pastirčák, R. Foundry Metallurgy of Non-Ferrous Metals; University of Žilina: Žilina, Slovakia, 2018. (In Slovak) [Google Scholar]

- Medlen, D.; Bolibruchová, D. The influence of remelting on the properties of AlSi6Cu4 alloy modified by antimony. Foundry Eng. 2012, 12. [Google Scholar] [CrossRef]

- Taylor, J.A. Iron-containing intermetallic phase in Al-Si based casting alloys. Procedia Mater. Sci. 2012, 1, 19–33. [Google Scholar] [CrossRef]

- Kuchariková, L.; Tillová, E.; Matvija, M.; Belan, J.; Chalupová, M. Study of the precipitation hardening process in recycled Al-Si-Cu cast alloys. Met. Mater. 2017, 62. [Google Scholar] [CrossRef]

- Yuliang, Z.; Weiwen, Z.; Chao, Y.; Datong, Z.; Zhi, W. Effect of Si on Fe-rich intermetallic formation and mechanical properties of heat-treated Al–Cu–Mn–Fe alloys. J. Mater. Res. 2018, 33, 898–911. [Google Scholar] [CrossRef]

- Capuzzi, S.; Timelli, G.; Fabrizi, A.; Bonollo, F. Influence of Ageing Heat Treatment on Microstructure and Mechanical Properties of a Secondary Rheocast AlSi9Cu3(Fe) Alloy. Mater. Sci. Forum 2015, 828–829, 212–218. [Google Scholar] [CrossRef]

- Labisz, K.; Mariusz, K.; Dobrzanski, L.A. Phases morphology and distribution of the Al-Si-Cu alloy. J. Achiev. Mater. Manuf. Eng. 2009, 37, 309–316. [Google Scholar]

- Vicen, M.; Fabian, P.; Tillová, E. Self-Hardening AlZn10Si8Mg Aluminium Alloy as an Alternative Replacement for AlSi7Mg0.3 Aluminium Alloy. Arch. Foundry Eng. 2017, 17. [Google Scholar] [CrossRef]

- Andersen, S.J.; Marioara, C.D.; Friis, J.; Wenner, S.; Holmestad, R. Precipitates in aluminium alloys. Adv. Phys. X 2018, 3, 790–813. [Google Scholar] [CrossRef]

- Zhang, X.; Hashimoto, T.; Lindsay, J.; Zhou, X. Investigation of the De-alloying Behaviour of θ-phase (Al2Cu) in AA2024-T351 Aluminium Alloy. Corros. Sci. 2016, 108, 85–93. [Google Scholar] [CrossRef]

- He, H.; Yi, Y.; Huang, S.; Zhang, Y. Effects of deformation temperature on second-phase particles and mechanical properties of 2219 Al-Cu alloy. Mater. Sci. Eng. A 2017, 712. [Google Scholar] [CrossRef]

- Bachagha, T.; Daly, R.; Escoda, R.; Suñol, J.J.; Khitouni, M. Amorphization of Al50(Fe2B)30Nb20 Mixture by Mechanical Alloying. Metall. Mater. Trans. A 2013, 44. [Google Scholar] [CrossRef]

- Belov, N.A.; Aksenov, A.A.; Eskin, D.G. Multicomponent Phase Diagrams-Applications for Commercial Aluminum Alloys; Elsevier: Oxford, UK, 2005. [Google Scholar]

- Belov, N.A.; Aksenov, A.A.; Eskin, D.G. Iron in Aluminum Alloys: Impurity and Alloying Element; CRC Press: London, UK, 2002. [Google Scholar]

- Campbell, J. Complete Casting Handbook: Metal Casting Processes, Metallurgy, Techniques and Design; Butterworth-Heinemann: Oxford, UK, 2011. [Google Scholar]

- Makhlouf, M.B.; Bachagha, T.; Suñol, J.J.; Dammak, M.; Khitouni, M. Synthesis and Characterization of Nanocrystalline Al-20 at. % Cu Powders Produced by Mechanical Alloying. Metals 2016, 6, 145. [Google Scholar] [CrossRef]

- Fatmi, M.; Ghebouli, B.; Ghebouli, M.A.; Chihi, T.; Ouakdi, E.; Heiba, Z.A. Tudy of Precipitation Kinetics in Al-3.7 wt% Cu Alloy during Non-Isothermal and Isothermal Ageing. Chin. J. Phys. 2013, 51. [Google Scholar] [CrossRef]

- Ast, J.; Ghidelli, M.; Durst, K.; Göken, M.; Sebastiani, M.; Korsunsky, A.M. A review of experimental approaches to fracture toughness evaluation at the micro-scale. Mater. Des. 2019, 173. [Google Scholar] [CrossRef]

- Ghidelli, M.; Sebastiani, M.; Collet, C.; Guillemet, R. Determination of the elastic moduli and residual stresses of freestanding Au-TiW bilayer thin films by nanoindentation. Mater. Des. 2016, 106, 436–445. [Google Scholar] [CrossRef]

- Zhang, L.; Gao, J.; Damoah, L.; Robertson, D.G. Removal of iron from aluminum: A review. Miner. Process. Extr. Metall. Rev. 2012, 33. [Google Scholar] [CrossRef]

- Podprocka, R.; Bolibruchova, D. Iron Intermetallic Phases in the Alloy Based on Al-Si-Mg by Applying Manganese. Arch. Foundry Eng. 2017, 17, 217–221. [Google Scholar] [CrossRef]

- Freitas, B.; Otani, L.B.; Kiminami, C.S.; Botta, W.J.; Bolfarini, C. Effect of iron on the microstructure and mechanical properties of the spray-formed and rotary-swaged 319 aluminum alloy. Int. J. Adv. Manuf. Technol. 2019, 102. [Google Scholar] [CrossRef]

| Elements | Si | Fe | Cu | Mn | Mg | Ni | Zn | Ti | Cr |

|---|---|---|---|---|---|---|---|---|---|

| Primary AlSi9Cu3 (EN 1706) | 8.0–11.0 | 0.6–1.1 | 2.0–4.0 | 0.55 | 0.15–0.55 | 0.55 | 1.20 | 0.20 | 0.15 |

| Commercial purity AlSi9Cu3 | 9.563 | 1.081 | 2.206 | 0.184 | 0.426 | 0.092 | 1.160 | 0.038 | 0.027 |

| Returnable AlSi9Cu3 | 9. 294 | 1.674 | 2.074 | 0.184 | 0.348 | 0.129 | 1.016 | 0.034 | 0.113 |

| Elements | Si | Fe | Cu | Mn | Mg | Ni | Zn | Ti | Cr |

|---|---|---|---|---|---|---|---|---|---|

| 20–80 | 9.507 | 1.294 | 2.197 | 0.231 | 0.391 | 0.122 | 1.044 | 0.035 | 0.049 |

| 50–50 | 9.418 | 1.419 | 2.173 | 0.223 | 0.361 | 0.134 | 1.041 | 0.033 | 0.072 |

| 70–30 | 9.245 | 1.569 | 2.02 | 0.209 | 0.344 | 0.108 | 0.961 | 0.031 | 0.112 |

| 80–20 | 9.415 | 1.617 | 2.08 | 0.206 | 0.358 | 0.156 | 1.07 | 0.032 | 0.101 |

| 90–10 | 9.291 | 1.643 | 2.143 | 0.199 | 0.357 | 0.127 | 1.046 | 0.032 | 0.106 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bolibruchová, D.; Matejka, M.; Michalcová, A.; Kasińska, J. Study of Natural and Artificial Aging on AlSi9Cu3 Alloy at Different Ratios of Returnable Material in the Batch. Materials 2020, 13, 4538. https://doi.org/10.3390/ma13204538

Bolibruchová D, Matejka M, Michalcová A, Kasińska J. Study of Natural and Artificial Aging on AlSi9Cu3 Alloy at Different Ratios of Returnable Material in the Batch. Materials. 2020; 13(20):4538. https://doi.org/10.3390/ma13204538

Chicago/Turabian StyleBolibruchová, Dana, Marek Matejka, Alena Michalcová, and Justyna Kasińska. 2020. "Study of Natural and Artificial Aging on AlSi9Cu3 Alloy at Different Ratios of Returnable Material in the Batch" Materials 13, no. 20: 4538. https://doi.org/10.3390/ma13204538

APA StyleBolibruchová, D., Matejka, M., Michalcová, A., & Kasińska, J. (2020). Study of Natural and Artificial Aging on AlSi9Cu3 Alloy at Different Ratios of Returnable Material in the Batch. Materials, 13(20), 4538. https://doi.org/10.3390/ma13204538