Effects of Groove and Steel Fiber on Shear Properties of Concrete with Recycled Coarse Aggregate

Abstract

1. Introduction

2. Experimental Program

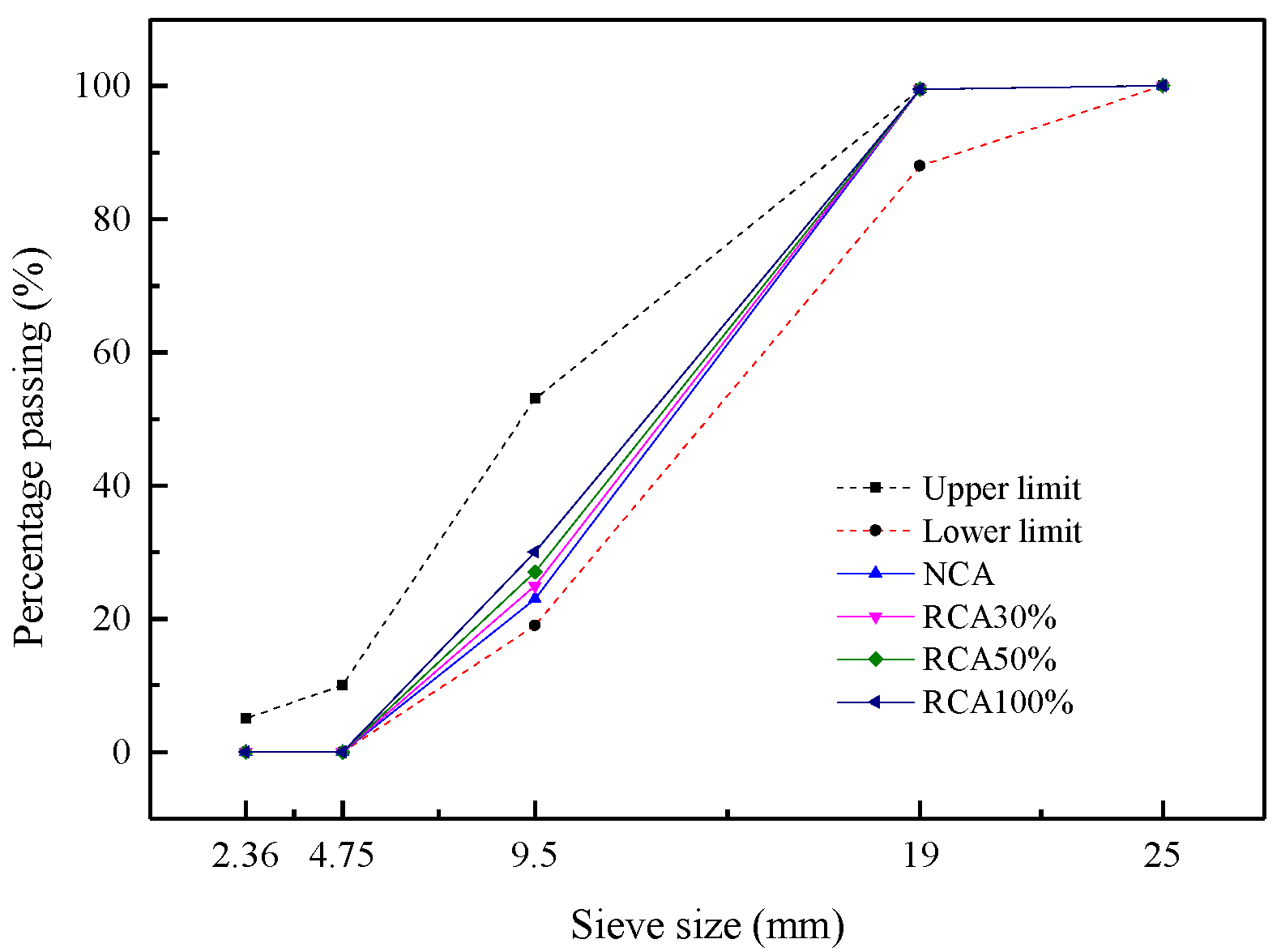

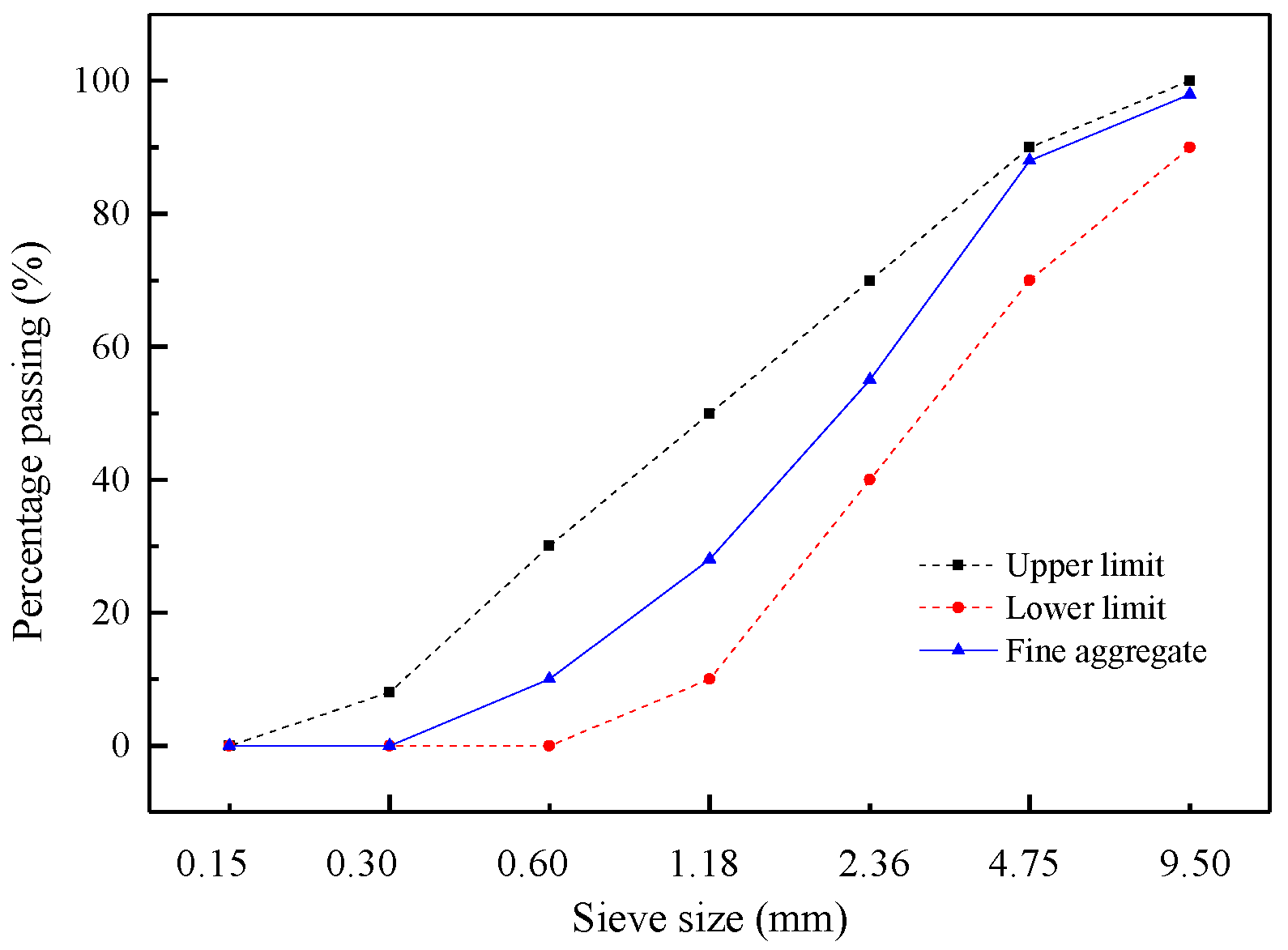

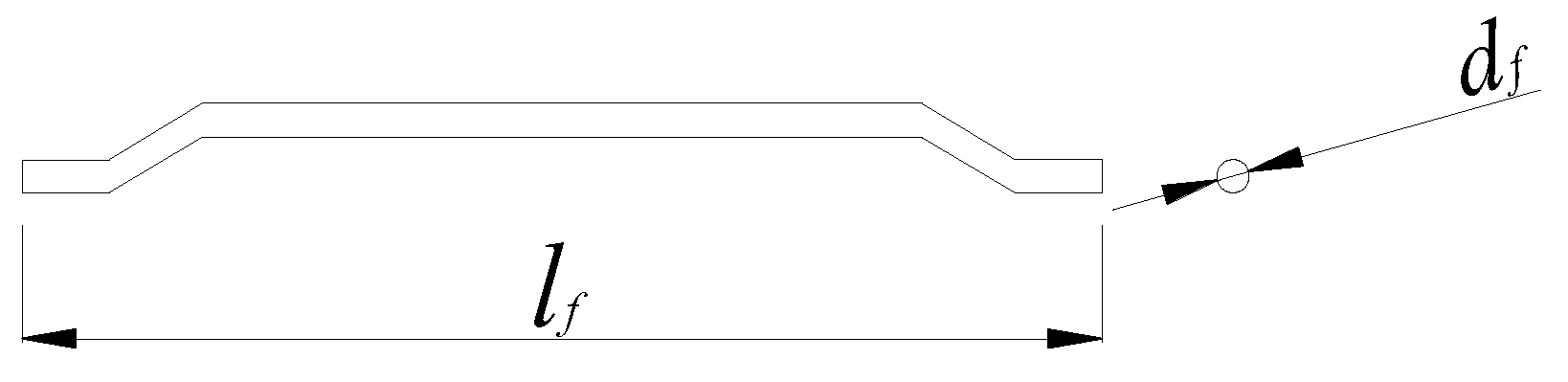

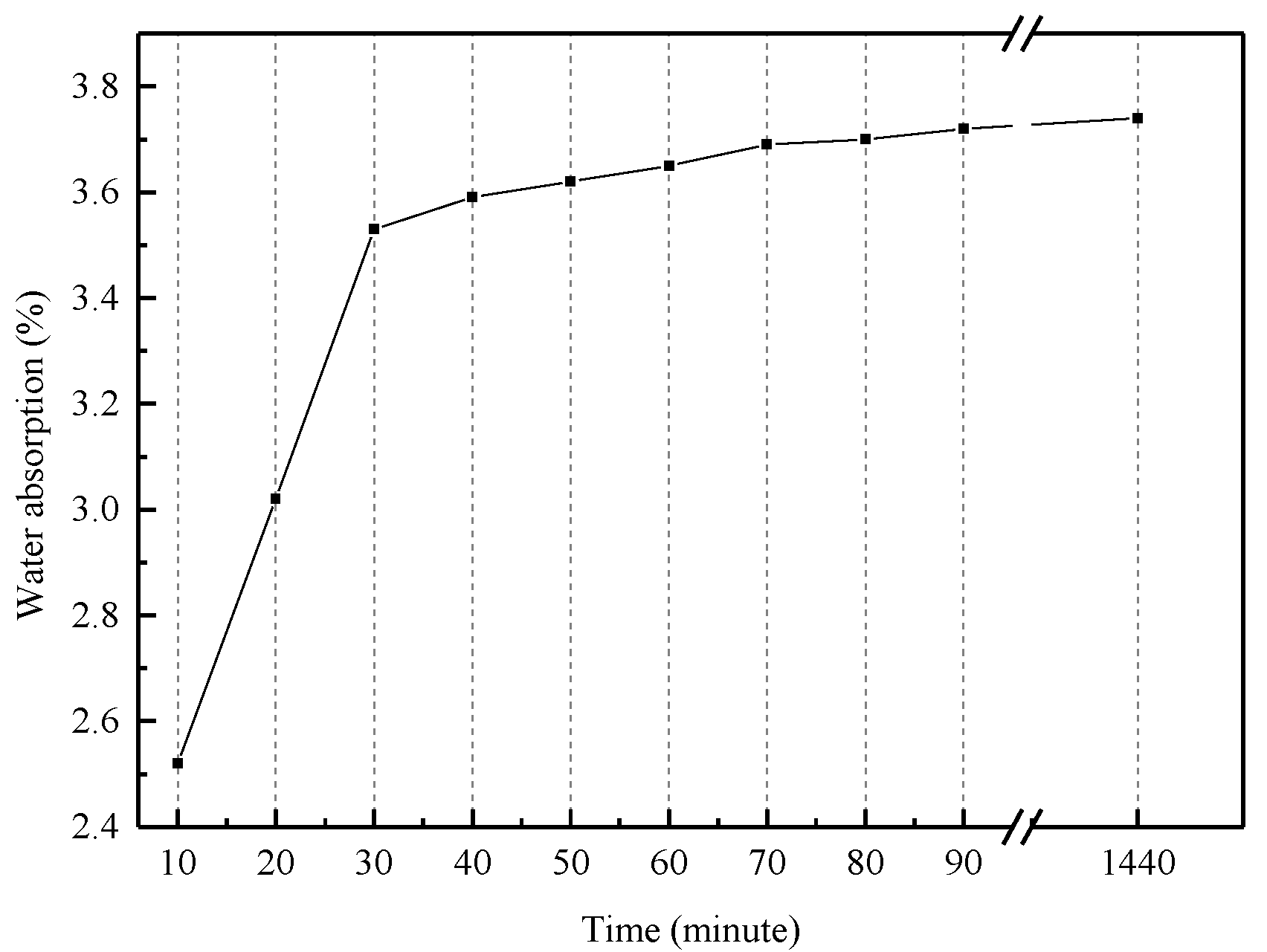

2.1. Materials

2.2. Test Parameters and Mixture Proportions

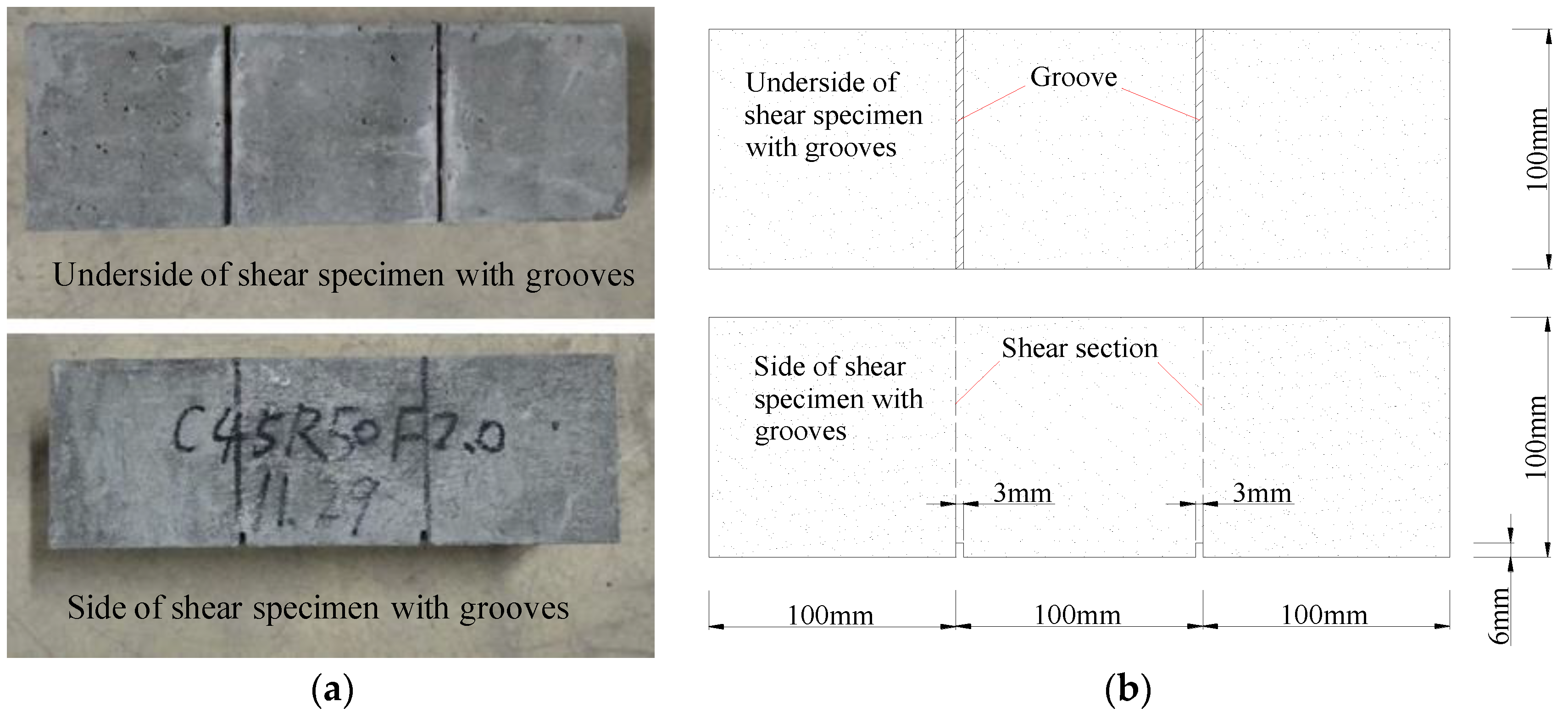

2.3. Specimen Preparation

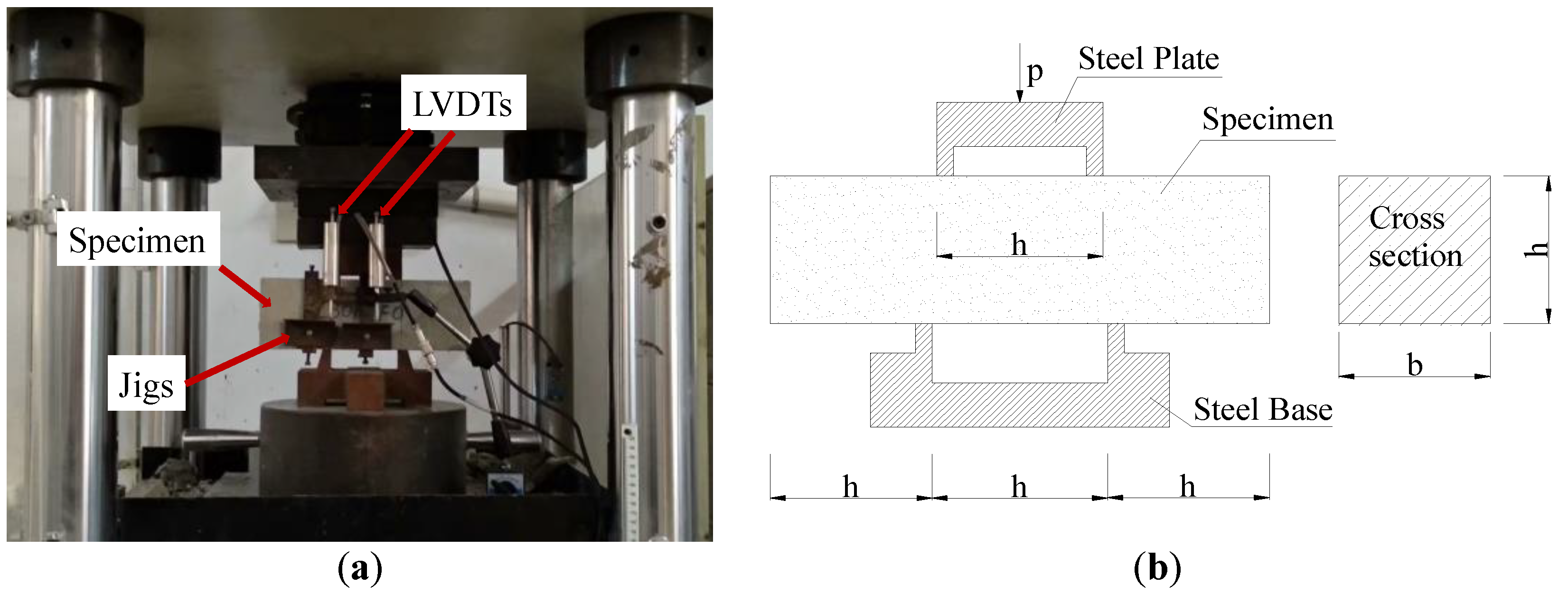

2.4. Test Procedures

3. Test Results and Analysis

3.1. Shear Failure Mode

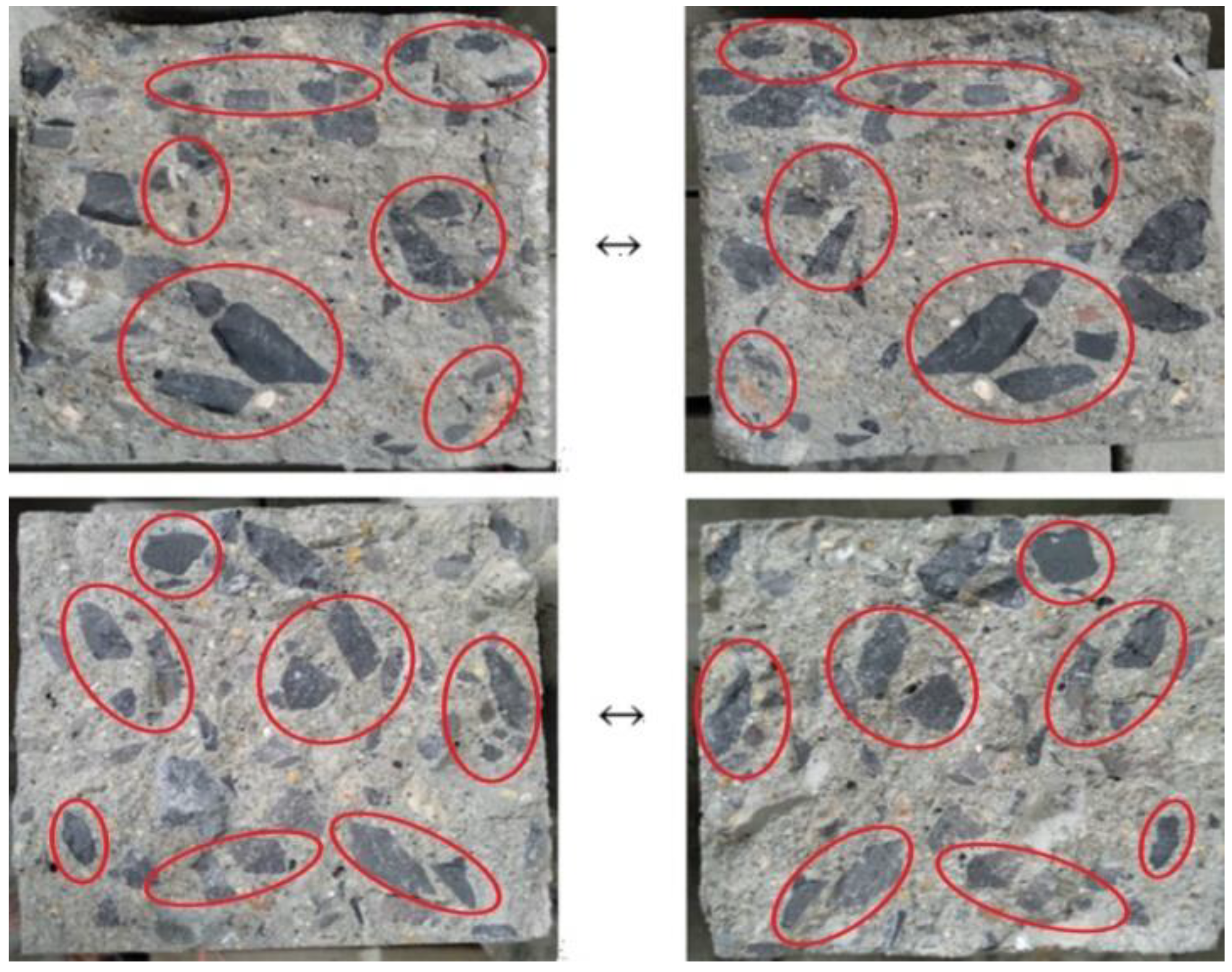

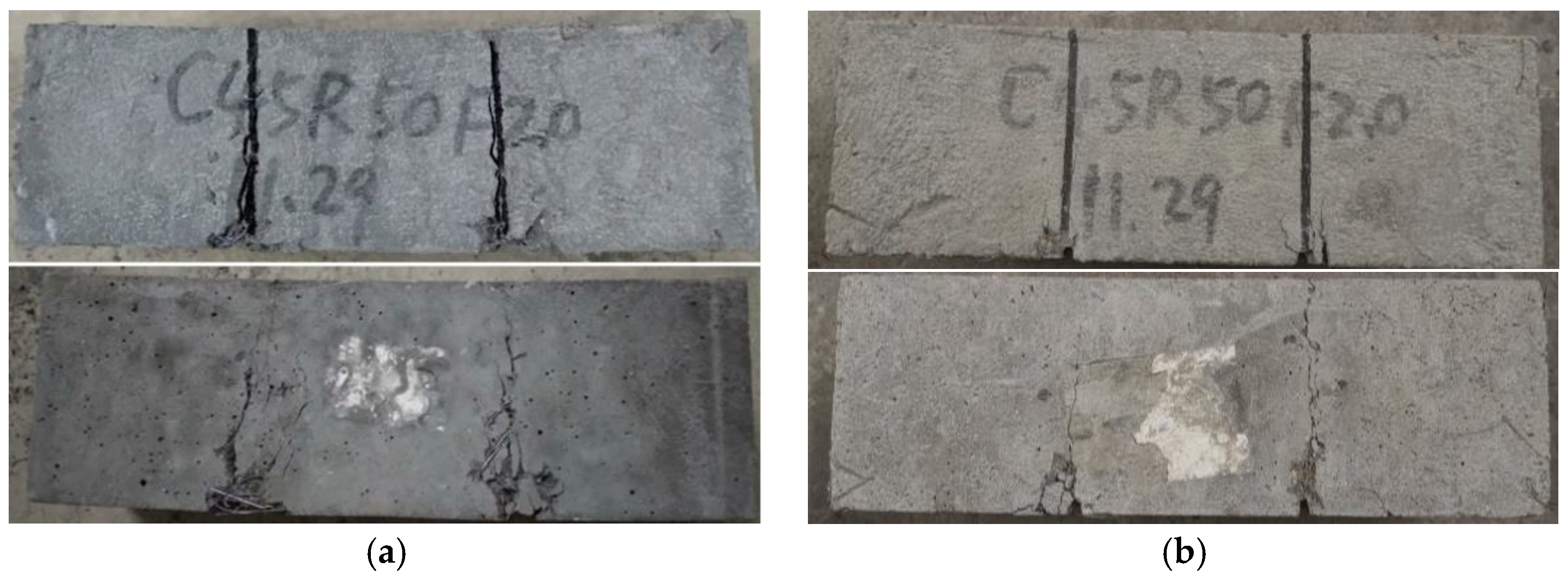

3.1.1. Shear Failure Mode of the Specimens without Steel Fibers

3.1.2. Shear Failure Mode of the Specimens with Steel Fibers

3.2. Shear Load-Deformation Curves

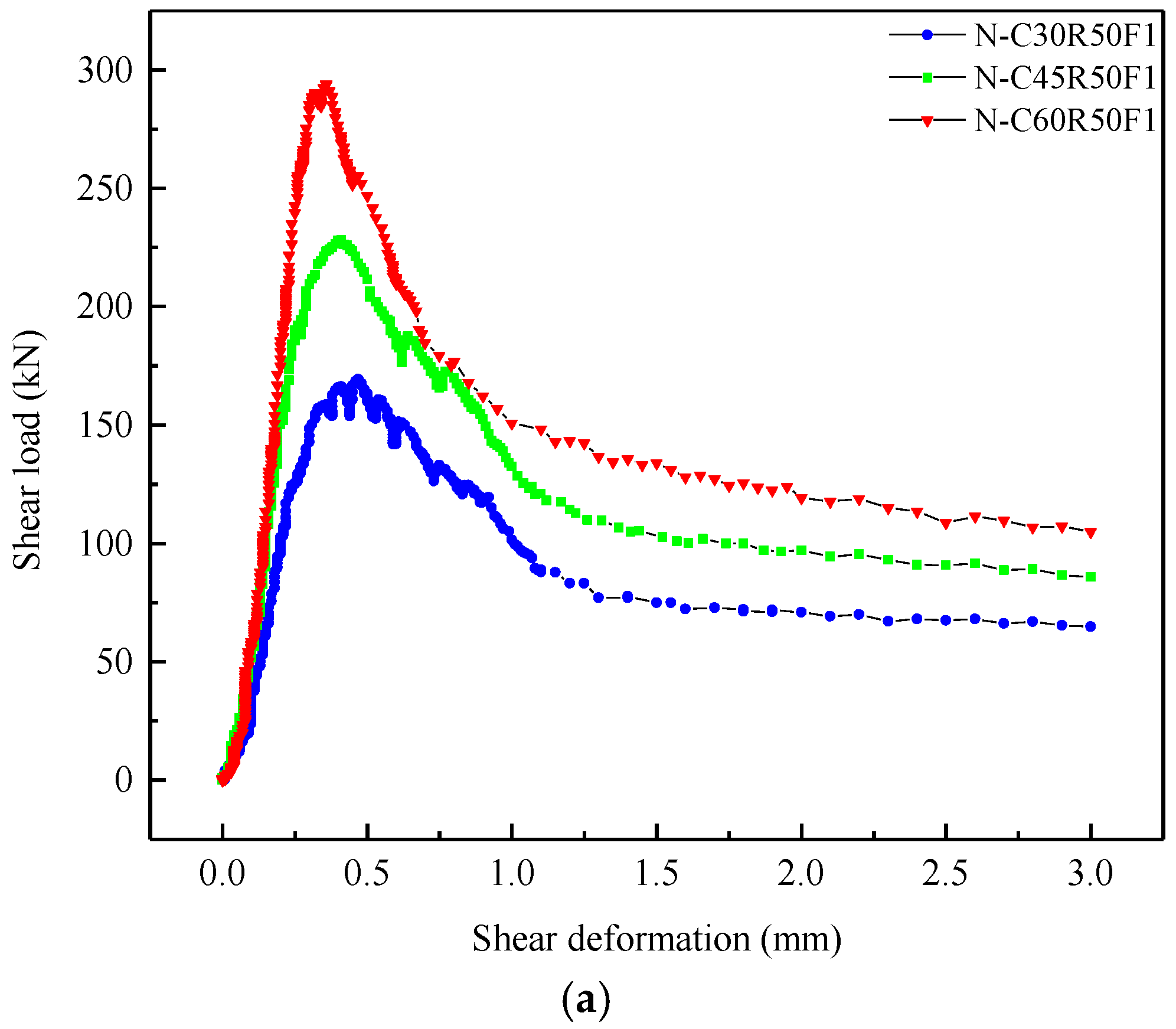

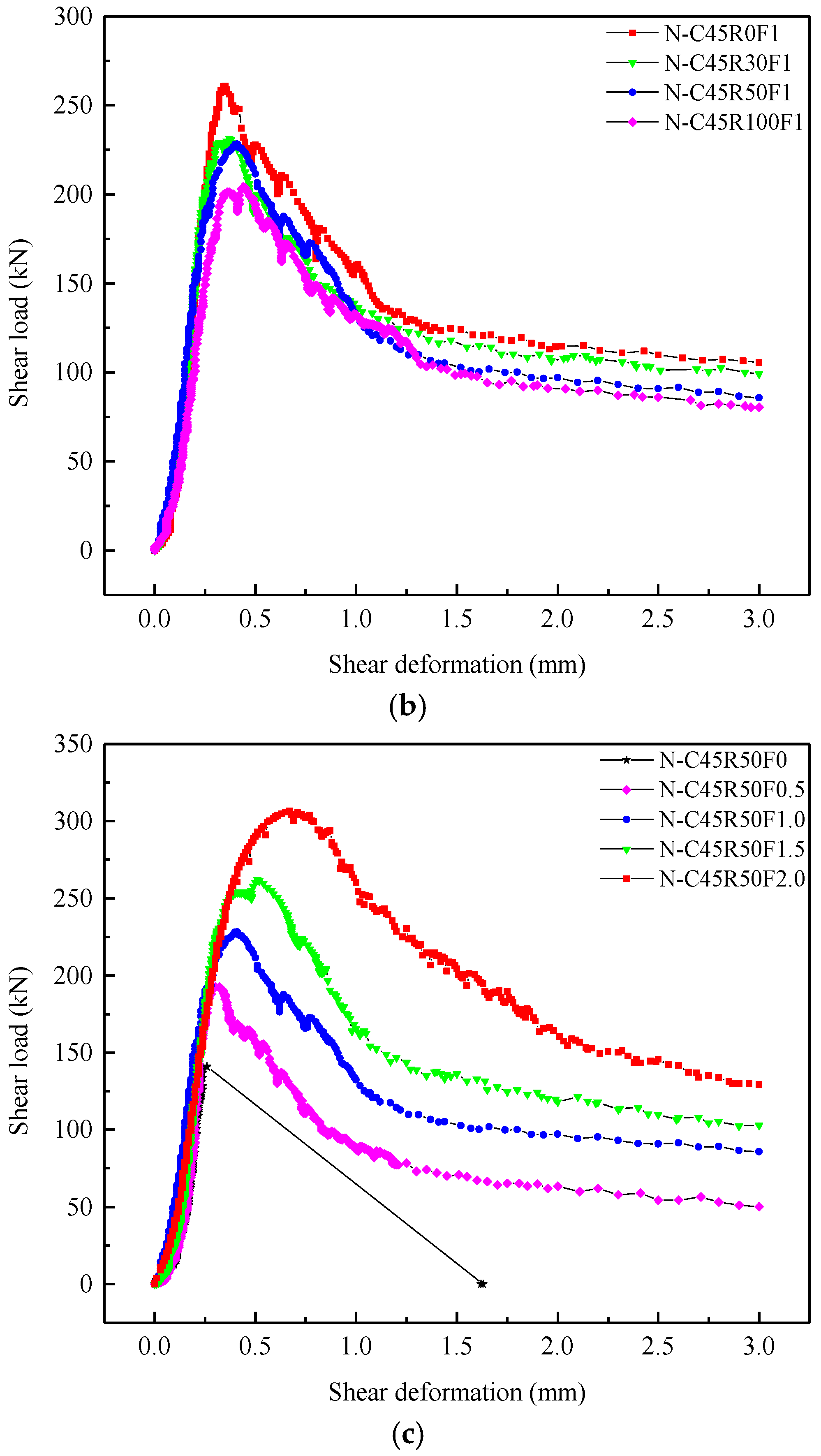

3.2.1. Shear Load-Deformation Curves of Specimens without Grooves

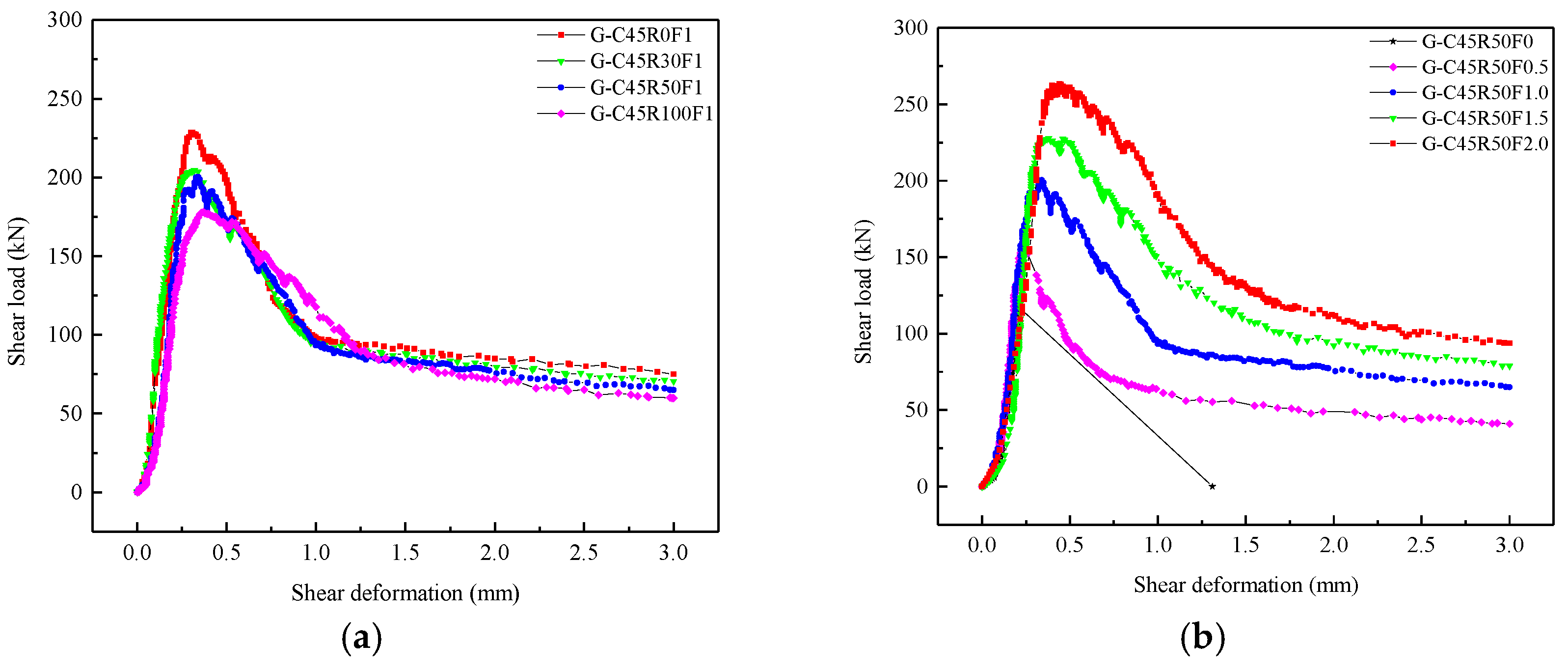

3.2.2. Shear Load-Deformation Curves of Specimens with Grooves

3.3. Shear Strength

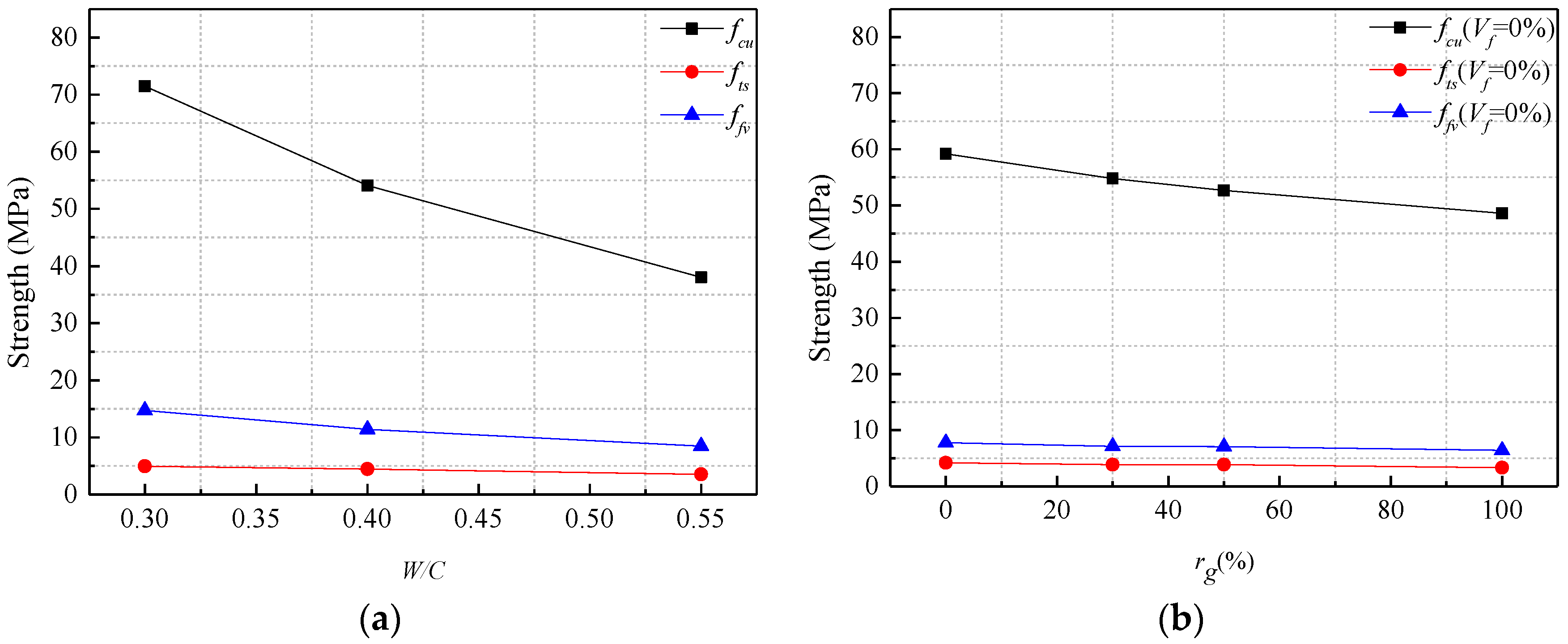

3.3.1. Influence of W/C, rg and Vf on the Shear Specimens without Grooves

3.3.2. Influence of rg and Vf on Shear Strength of Specimens with Grooves

3.3.3. Calculation Method of Shear Strength of SFRCAC

4. Conclusions

- The shear strength and shear deformation of specimens with grooves were lower than those of specimens without grooves under the same mixture of SFRCAC. Among them, the height of the shear section decreased by 6%, and the shear strength decreased by more than 6%. For the shear specimens with grooves, the influence of the replacement ratio of RCA and volume content of steel fibers on shear strength and shear deformation had the same trend as that of shear specimens without grooves. According to the above research results, it could be concluded that the effect of groove on the shear strength of SFRCAC was obvious. It was necessary to consider the influence of this change factor on the shear strength of SFRCAC in the future research steps.

- For specimens with the fixed water cement ratio and replacement ratio of RCA, with the increase of the volume content of steel fibers, the shear strength, shear deformation corresponding to peak load and shear toughness of SFRCAC increased gradually. The shear strength of SFRCAC increased by 117.30% as the volume content of steel fibers increased from 0% to 2.0%.

- With the increase of water cement ratio, the shear strength of SFRCAC decreased, while the shear deformation corresponding to peak load and shear toughness increased gradually. The shear strength of SFRCAC decreased by 42.38% as the water cement ratio increased from 0.3 to 0.55.

- For specimens with the fixed water cement ratio and volume content of steel fibers, with the increase of the replacement ratio of RCA, the shear strength of SFRCAC decreased, while the shear deformation corresponding to peak load and shear toughness increased gradually. The shear strength of SFRCAC decreased by 21.70% as the replacement ratio of RCA increased from 0% to 100%.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Llatas, C. A model for quantifying construction waste in projects according to the European waste list. Waste Manag. 2011, 31, 1261–1276. [Google Scholar] [CrossRef]

- Yuan, H. A model for evaluating the social performance of construction waste management. Waste Manag. 2012, 32, 1218–1228. [Google Scholar] [CrossRef] [PubMed]

- Baldwin, A.; Poon, C.-S.; Shen, L.-Y.; Austin, S.; Wong, I. Designing out waste in high-rise residential buildings: Analysis of precasting methods and traditional construction. Renew. Energy 2009, 34, 2067–2073. [Google Scholar] [CrossRef]

- Behera, M.; Bhattacharyya, S.; Minocha, A.; Deoliya, R.; Maiti, S. Recycled aggregate from C&D waste & its use in concrete—A breakthrough towards sustainability in construction sector: A review. Constr. Build. Mater. 2014, 68, 501–516. [Google Scholar] [CrossRef]

- Senaratne, S.; Gerace, D.; Mirza, O.; Tam, V.W.; Kang, W.-H. The costs and benefits of combining recycled aggregate with steel fibres as a sustainable, structural material. J. Clean. Prod. 2016, 112, 2318–2327. [Google Scholar] [CrossRef]

- Maier, P.L.; Durham, S.A. Beneficial use of recycled materials in concrete mixtures. Constr. Build. Mater. 2012, 29, 428–437. [Google Scholar] [CrossRef]

- Casuccio, M.; Torrijos, M.; Giaccio, G.; Zerbino, R. Failure mechanism of recycled aggregate concrete. Constr. Build. Mater. 2008, 22, 1500–1506. [Google Scholar] [CrossRef]

- Zaetang, Y.; Sata, V.; Wongsa, A.; Chindaprasirt, P. Properties of pervious concrete containing recycled concrete block aggregate and recycled concrete aggregate. Constr. Build. Mater. 2016, 111, 15–21. [Google Scholar] [CrossRef]

- Martínez-Lage, I.; Martínez-Abella, F.; Vázquez-Herrero, C.; Pérez-Ordóñez, J.L. Properties of plain concrete made with mixed recycled coarse aggregate. Constr. Build. Mater. 2012, 37, 171–176. [Google Scholar] [CrossRef]

- Xu, G.; Shen, W.; Zhang, B.; Li, Y.; Ji, X.; Ye, Y. Properties of recycled aggregate concrete prepared with scattering-filling coarse aggregate process. Cem. Concr. Compos. 2018, 93, 19–29. [Google Scholar] [CrossRef]

- Xiao, J.; Li, L.; Tam, V.W.; Li, H. The state of the art regarding the long-term properties of recycled aggregate concrete. Struct. Concr. 2014, 15, 3–12. [Google Scholar] [CrossRef]

- Sobhan, K.; Gonzalez, L.; Reddy, D.V. Durability of a pavement foundation made from recycled aggregate concrete subjected to cyclic wet–dry exposure and fatigue loading. Mater. Struct. 2015, 49, 2271–2284. [Google Scholar] [CrossRef]

- Marinković, S.; Radonjanin, V.; Malešev, M.; Ignjatović, I. Comparative environmental assessment of natural and recycled aggregate concrete. Waste Manag. 2010, 30, 2255–2264. [Google Scholar] [CrossRef]

- Thomas, J.; Ramaswamy, A. Mechanical Properties of Steel Fiber-Reinforced Concrete. J. Mater. Civ. Eng. 2007, 19, 385–392. [Google Scholar] [CrossRef]

- Guo, Y.H.; Xiao, Y.; Yue, L.I. Capacity Analysis of Combination Action of Pressure and Bend on Steel Fiber Reinforced Concrete. J. Mater. Sci. Eng. 2008, 26, 636–641. [Google Scholar]

- Frazão, C.; Camões, A.; Barros, J.A.O.; Gonçalves, D. Durability of steel fiber reinforced self-compacting concrete. Constr. Build. Mater. 2015, 80, 155–166. [Google Scholar] [CrossRef]

- Li, J.J.; Wan, C.J.; Niu, J.G.; Wu, L.F.; Wu, Y.C. Investigation on flexural toughness evaluation method of steel fiber reinforced lightweight aggregate concrete. Constr. Build. Mater. 2017, 131, 449–458. [Google Scholar] [CrossRef]

- Kodur, V.K.R.; Lie, T.T. Fire Resistance of Circular Steel Columns Filled with Fiber-Reinforced Concrete. J. Struct. Eng. 1996, 122, 776–782. [Google Scholar] [CrossRef]

- Fike, R.; Kodur, V. Enhancing the fire resistance of composite floor assemblies through the use of steel fiber reinforced concrete. Eng. Struct. 2011, 33, 2870–2878. [Google Scholar] [CrossRef]

- Banerji, S.; Kodur, V.; Solhmirzaei, R. Experimental behavior of ultra high performance fiber reinforced concrete beams under fire conditions. Eng. Struct. 2020, 208, 110316. [Google Scholar] [CrossRef]

- Carneiro, J.A.; Lima, P.R.L.; Leite, M.B.; Filho, R.D.T. Compressive stress–strain behavior of steel fiber reinforced-recycled aggregate concrete. Cem. Concr. Compos. 2014, 46, 65–72. [Google Scholar] [CrossRef]

- Ramesh, R.B.; Mirza, O.; Kang, W.-H. Mechanical properties of steel fiber reinforced recycled aggregate concrete. Struct. Concr. 2018, 20, 745–755. [Google Scholar] [CrossRef]

- Gao, D.; Zhang, L. Flexural performance and evaluation method of steel fiber reinforced recycled coarse aggregate concrete. Constr. Build. Mater. 2018, 159, 126–136. [Google Scholar] [CrossRef]

- Gao, D.; Zhang, L.; Zhao, J.; You, P. Durability of steel fibre-reinforced recycled coarse aggregate concrete. Constr. Build. Mater. 2020, 232, 117119. [Google Scholar] [CrossRef]

- Gao, D.; Zhang, L.; Nokken, M.; Zhao, J. Mixture Proportion Design Method of Steel Fiber Reinforced Recycled Coarse Aggregate Concrete. Materials 2019, 12, 375. [Google Scholar] [CrossRef] [PubMed]

- Gao, D.; Lv, M.; Yang, L.; Tang, J.; Chen, G.; Meng, Y. Experimental Study of Utilizing Recycled Fine Aggregate for the Preparation of High Ductility Cementitious Composites. Materials 2020, 13, 679. [Google Scholar] [CrossRef]

- Wang, W.-L.; Kou, S.-C.; Xing, F. Deformation properties and direct shear of medium strength concrete prepared with 100% recycled coarse aggregates. Constr. Build. Mater. 2013, 48, 187–193. [Google Scholar] [CrossRef]

- Bui, N.K.; Satomi, T.; Takahashi, H. Hiroshi Takahashi Recycling woven plastic sack waste and PET bottle waste as fiber in recycled aggregate concrete: An experimental study. Waste Manag. 2018, 78, 79–93. [Google Scholar] [CrossRef]

- Japanese Society of Civil Engineering Standard. JSCE-SF-6. Method of Test for Shear Strength of Steel Fiber Reinforcement Concrete. In Concrete Library International; Japan Society of Civil Engineers: Tokyo, Japan, 1990. [Google Scholar]

- Gao, D.; Zhang, L.; Nokken, M. Mechanical behavior of recycled coarse aggregate concrete reinforced with steel fibers under direct shear. Cem. Concr. Compos. 2017, 79, 1–8. [Google Scholar] [CrossRef]

- CS (Chinese Standard) CECS. 13. Test Methods for Fiber Reinforced Concrete; China Engineering Construction Standardization Society: Beijing, China, 2009. (In Chinese) [Google Scholar]

- Nogueira, C.L. Anti-plane shear strength of plain concrete. Mater. Today Commun. 2020, 24, 101051. [Google Scholar] [CrossRef]

- Kazemi, S.; Lubell, A.S. Influence of Specimen Size and Fiber Content on Mechanical Properties of Ultra-High-Performance Fiber-Reinforced Concrete. ACI Mater. J. 2012, 109, 675–684. [Google Scholar]

- CS (Chinese Standard) GB/T 25177-2010. Recycled Coarse Aggregate for Concrete; General Administration of Quality Supervision, Inspection and Quarantine of the People’s Republic of China: Beijing, China, 2011. (In Chinese)

- CS (Chinese Standard) GB/T 50080-2016. Standard Test Methods for Performance of Ordinary Concrete Mixtures; Ministry of Housing and Urban-Rural Development People’s Republic China: Beijing, China, 2016. (In Chinese)

- Wang, H.; Wang, L. Experimental study on static and dynamic mechanical properties of steel fiber reinforced lightweight aggregate concrete. Constr. Build. Mater. 2013, 38, 1146–1151. [Google Scholar] [CrossRef]

- Timoshenko, S.P.; Goodier, J.N. Theory of Elasticity; McGraw-Hill: New York, NY, USA, 1951. [Google Scholar]

- Zhao, M.; Zhao, M.; Chen, M.; Li, J.; Law, D.W. An experimental study on strength and toughness of steel fiber reinforced expanded-shale lightweight concrete. Constr. Build. Mater. 2018, 183, 493–501. [Google Scholar] [CrossRef]

- Han, J.; Zhao, M.; Chen, J.; Lan, X. Effects of steel fiber length and coarse aggregate maximum size on mechanical properties of steel fiber reinforced concrete. Constr. Build. Mater. 2019, 209, 577–591. [Google Scholar] [CrossRef]

- Shi, X.; Park, P.; Rew, Y.; Huang, K.; Sim, C. Constitutive behaviors of steel fiber reinforced concrete under uniaxial compression and tension. Constr. Build. Mater. 2020, 233, 117316. [Google Scholar] [CrossRef]

- Boulekbache, B.; Hamrat, M.; Chemrouk, M.; Amziane, S. Influence of yield stress and compressive strength on direct shear behaviour of steel fibre-reinforced concrete. Constr. Build. Mater. 2012, 27, 6–14. [Google Scholar] [CrossRef]

- Rao, G.A.; Rao, A.S. Toughness indices of steel fiber reinforced concrete under mode II loading. Mater. Struct. 2009, 42, 1173–1184. [Google Scholar] [CrossRef]

- Banthia, N.; Majdzadeh, F.; Wu, J.; Bindiganavile, V. Fiber synergy in Hybrid Fiber Reinforced Concrete (HyFRC) in flexure and direct shear. Cem. Concr. Compos. 2014, 48, 91–97. [Google Scholar] [CrossRef]

- Yang, M.; Huang, C.; Liu, Y. Experimental research on shear behavior of high-strength SFRC. J. Dalian Univ. Technol. 2005, 45, 67–71. (In Chinese) [Google Scholar]

- Gao, D.; Zhu, H.; Tang, J. Shear strength of steel fiber reinforced high-strength concrete. J. Chin. Ceram. Soc. 2004, 32, 656–660. (In Chinese) [Google Scholar]

- Rahal, K. Mechanical properties of concrete with recycled coarse aggregate. Build. Environ. 2007, 42, 407–415. [Google Scholar] [CrossRef]

- Waseem, S.A.; Singh, B. Shear transfer strength of normal and high-strength recycled aggregate concrete—An experimental investigation. Constr. Build. Mater. 2016, 125, 29–40. [Google Scholar]

| Aggregate Type | Apparent Density (kg/m3) | Loose Bulk Density (kg/m3) | Water Absorption (%) | Crush Index (%) | Porosity (%) |

|---|---|---|---|---|---|

| NCA | 2805 | 1552 | 1.35 | 8.9 | 42.3 |

| RCA | 2650 | 1375 | 4.49 | 14.5 | 49.2 |

| df (mm) | lf (mm) | lf/df | Tensile Strength (MPa) |

|---|---|---|---|

| 0.55 | 35 | 63.64 | 1345 |

| Group | W/C | rg | Vf |

|---|---|---|---|

| N-C30R50F1 | 0.55 | 50% | 1.0% |

| N-C45R50F1 | 0.4 | 50% | 1.0% |

| N-C60R50F1 | 0.3 | 50% | 1.0% |

| N-C45R0F0 | 0.4 | 0% | 0% |

| N-C45R30F0 | 0.4 | 30% | 0% |

| N-C45R50F0 | 0.4 | 50% | 0% |

| N-C45R100F0 | 0.4 | 100% | 0% |

| N-C45R0F1 | 0.4 | 0% | 1.0% |

| N-C45R30F1 | 0.4 | 30% | 1.0% |

| N-C45R50F1 | 0.4 | 50% | 1.0% |

| N-C45R100F1 | 0.4 | 100% | 1.0% |

| N-C45R50F0 | 0.4 | 50% | 0% |

| N-C45R50F0.5 | 0.4 | 50% | 0.5% |

| N-C45R50F1 | 0.4 | 50% | 1.0% |

| N-C45R50F1.5 | 0.4 | 50% | 1.5% |

| N-C45R50F2.0 | 0.4 | 50% | 2.0% |

| G-C45R0F1 | 0.4 | 0% | 1.0% |

| G-C45R30F1 | 0.4 | 30% | 1.0% |

| G-C45R50F1 | 0.4 | 50% | 1.0% |

| G-C45R100F1 | 0.4 | 100% | 1.0% |

| G-C45R50F0 | 0.4 | 50% | 0% |

| G-C45R50F0.5 | 0.4 | 50% | 0.5% |

| G-C45R50F1 | 0.4 | 50% | 1.0% |

| G-C45R50F1.5 | 0.4 | 50% | 1.5% |

| G-C45R50F2.0 | 0.4 | 50% | 2.0% |

| Group | W/C | Water (kg/m3) | Cement (kg/m3) | NCA (kg/m3) | RCA (kg/m3) | Fine Aggregate (kg/m3) | Steel Fiber (kg/m3) | Water Reducer (kg/m3) | Additional Water (kg/m3) |

|---|---|---|---|---|---|---|---|---|---|

| N-C30R50F1 | 0.55 | 166 | 302 | 540 | 540 | 884 | 78 | 3.02 | 19.06 |

| N-C45R50F1 | 0.40 | 166 | 415 | 512 | 512 | 839 | 78 | 4.15 | 18.08 |

| N-C60R50F1 | 0.30 | 166 | 553 | 479 | 479 | 783 | 78 | 5.53 | 16.89 |

| N-C45R0F0 | 0.40 | 166 | 415 | 1024 | 0 | 839 | 0 | 4.15 | 0 |

| N-C45R30F0 | 0.40 | 166 | 415 | 717 | 307 | 839 | 0 | 4.15 | 10.85 |

| N-C45R100F0 | 0.40 | 166 | 415 | 0 | 1024 | 839 | 0 | 4.15 | 36.16 |

| N-C45R0F1 | 0.40 | 166 | 415 | 1024 | 0 | 839 | 78 | 4.15 | 0 |

| N-C45R30F1 | 0.40 | 166 | 415 | 717 | 307 | 839 | 78 | 4.15 | 10.85 |

| N-C45R100F1 | 0.40 | 166 | 415 | 0 | 1024 | 839 | 78 | 4.15 | 36.16 |

| N-C45R50F0 | 0.40 | 166 | 415 | 512 | 512 | 839 | 0 | 4.15 | 18.08 |

| N-C45R50F0.5 | 0.40 | 166 | 415 | 512 | 512 | 839 | 39 | 4.15 | 18.08 |

| N-C45R50F1.5 | 0.40 | 166 | 415 | 512 | 512 | 839 | 117 | 4.15 | 18.08 |

| N-C45R50F2.0 | 0.40 | 166 | 415 | 512 | 512 | 839 | 156 | 4.15 | 18.08 |

| G-C45R0F1 | 0.40 | 166 | 415 | 1024 | 0 | 839 | 78 | 4.15 | 0 |

| G-C45R30F1 | 0.40 | 166 | 415 | 717 | 307 | 839 | 78 | 4.15 | 10.85 |

| G-C45R50F1 | 0.40 | 166 | 415 | 512 | 512 | 839 | 78 | 4.15 | 18.08 |

| G-C45R100F1 | 0.40 | 166 | 415 | 0 | 1024 | 839 | 78 | 4.15 | 36.16 |

| G-C45R50F0 | 0.40 | 166 | 415 | 512 | 512 | 839 | 0 | 4.15 | 18.08 |

| G-C45R50F0.5 | 0.40 | 166 | 415 | 512 | 512 | 839 | 39 | 4.15 | 18.08 |

| G-C45R50F1.5 | 0.40 | 166 | 415 | 512 | 512 | 839 | 117 | 4.15 | 18.08 |

| G-C45R50F2.0 | 0.40 | 166 | 415 | 512 | 512 | 839 | 156 | 4.15 | 18.08 |

| Specimen No. | fcu (MPa) | fts (MPa) | Peak Load (kN) | Peak Deformation (mm) | ffv (MPa) | SD | ffv/fcu | ffv/fts |

|---|---|---|---|---|---|---|---|---|

| N-C30R50F1 | 38.0 | 3.53 | 169.32 | 0.47 | 8.47 | 0.43 | 0.223 | 2.399 |

| N-C45R50F1 | 54.1 | 4.47 | 228.22 | 0.41 | 11.41 | 0.48 | 0.211 | 2.553 |

| N-C60R50F1 | 71.5 | 4.94 | 293.98 | 0.36 | 14.70 | 0.68 | 0.206 | 2.976 |

| N-C45R0F0 | 59.2 | 4.20 | 155.31 | 0.24 | 7.77 | 0.41 | 0.131 | 1.850 |

| N-C45R30F0 | 54.8 | 3.87 | 142.66 | 0.25 | 7.13 | 0.38 | 0.130 | 1.842 |

| N-C45R100F0 | 48.6 | 3.32 | 137.81 | 0.28 | 6.39 | 0.29 | 0.131 | 1.925 |

| N-C45R0F1 | 61.5 | 4.59 | 260.73 | 0.35 | 13.04 | 0.56 | 0.212 | 2.841 |

| N-C45R30F1 | 56.0 | 4.53 | 231.57 | 0.37 | 11.58 | 0.57 | 0.207 | 2.556 |

| N-C45R100F1 | 48.1 | 4.12 | 204.29 | 0.44 | 10.21 | 0.44 | 0.212 | 2.478 |

| N-C45R50F0 | 52.7 | 3.85 | 140.93 | 0.26 | 7.05 | 0.37 | 0.134 | 1.831 |

| N-C45R50F0.5 | 53.9 | 4.24 | 192.52 | 0.32 | 9.63 | 0.52 | 0.179 | 2.271 |

| N-C45R50F1.5 | 54.6 | 4.53 | 262.12 | 0.51 | 13.11 | 0.66 | 0.240 | 2.894 |

| N-C45R50F2.0 | 55.1 | 4.63 | 306.44 | 0.67 | 15.32 | 0.75 | 0.278 | 3.309 |

| G-C45R0F1 | 61.5 | 4.59 | 228.52 | 0.30 | 12.16 | 0.53 | 0.198 | 2.649 |

| G-C45R30F1 | 56.0 | 4.53 | 204.54 | 0.32 | 10.88 | 0.47 | 0.194 | 2.402 |

| G-C45R50F1 | 54.1 | 4.47 | 200.37 | 0.34 | 10.66 | 0.41 | 0.197 | 2.385 |

| G-C45R100F1 | 48.1 | 4.12 | 177.98 | 0.37 | 9.47 | 0.37 | 0.197 | 2.299 |

| G-C45R50F0 | 52.7 | 3.85 | 119.11 | 0.2 | 6.34 | 0.33 | 0.120 | 1.647 |

| G-C45R50F0.5 | 53.9 | 4.24 | 155.12 | 0.25 | 8.25 | 0.41 | 0.153 | 1.946 |

| G-C45R50F1.5 | 54.6 | 4.53 | 227.86 | 0.38 | 12.12 | 0.52 | 0.222 | 2.675 |

| G-C45R50F2.0 | 55.1 | 4.63 | 263.25 | 0.44 | 14.00 | 0.56 | 0.254 | 3.024 |

| Group | fcu (MPa) | λf | ffv (MPa) | ffv1 (MPa) | ffv/ffv1 |

|---|---|---|---|---|---|

| N-C30R50F1 | 38.0 | 0.636 | 8.47 | 9.30 | 1.10 |

| N-C45R50F1 | 54.1 | 0.636 | 11.41 | 11.30 | 0.99 |

| N-C60R50F1 | 71.5 | 0.636 | 14.70 | 13.17 | 0.90 |

| N-C45R0F1 | 61.5 | 0.636 | 13.04 | 12.12 | 0.93 |

| N-C45R30F1 | 56.0 | 0.636 | 11.58 | 11.51 | 0.99 |

| N-C45R100F1 | 48.1 | 0.636 | 10.21 | 10.59 | 1.04 |

| N-C45R50F0 | 52.7 | 0 | 7.05 | 7.08 | 1.00 |

| N-C45R50F0.5 | 53.9 | 0.318 | 9.63 | 9.22 | 0.96 |

| N-C45R50F1.5 | 54.6 | 0.954 | 13.11 | 13.42 | 1.02 |

| N-C45R50F2.0 | 55.1 | 1.272 | 15.32 | 15.56 | 1.02 |

| N-C45R0F0 | 59.2 | 0 | 7.77 | 7.55 | 0.97 |

| N-C45R30F0 | 54.8 | 0 | 7.13 | 7.23 | 1.01 |

| N-C45R100F0 | 48.6 | 0 | 6.39 | 6.77 | 1.06 |

| Average value | 0.999 | ||||

| Coefficient of variation | 5.09% | ||||

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gao, D.; Yan, Y.; Pang, Y.; Tang, J.; Yang, L.; Gu, Z. Effects of Groove and Steel Fiber on Shear Properties of Concrete with Recycled Coarse Aggregate. Materials 2020, 13, 4537. https://doi.org/10.3390/ma13204537

Gao D, Yan Y, Pang Y, Tang J, Yang L, Gu Z. Effects of Groove and Steel Fiber on Shear Properties of Concrete with Recycled Coarse Aggregate. Materials. 2020; 13(20):4537. https://doi.org/10.3390/ma13204537

Chicago/Turabian StyleGao, Danying, Yongming Yan, Yuyang Pang, Jiyu Tang, Lin Yang, and Zhiqiang Gu. 2020. "Effects of Groove and Steel Fiber on Shear Properties of Concrete with Recycled Coarse Aggregate" Materials 13, no. 20: 4537. https://doi.org/10.3390/ma13204537

APA StyleGao, D., Yan, Y., Pang, Y., Tang, J., Yang, L., & Gu, Z. (2020). Effects of Groove and Steel Fiber on Shear Properties of Concrete with Recycled Coarse Aggregate. Materials, 13(20), 4537. https://doi.org/10.3390/ma13204537