Tribological Properties of Chromium Nitride on the Cylinder Liner under the Influence of High Temperature

Abstract

1. Introduction

2. Methods and Experiments

2.1. Materials for Experiment

2.2. Coating Deposition

2.3. Characterization and Analysis Instruments

3. Result and Discussion

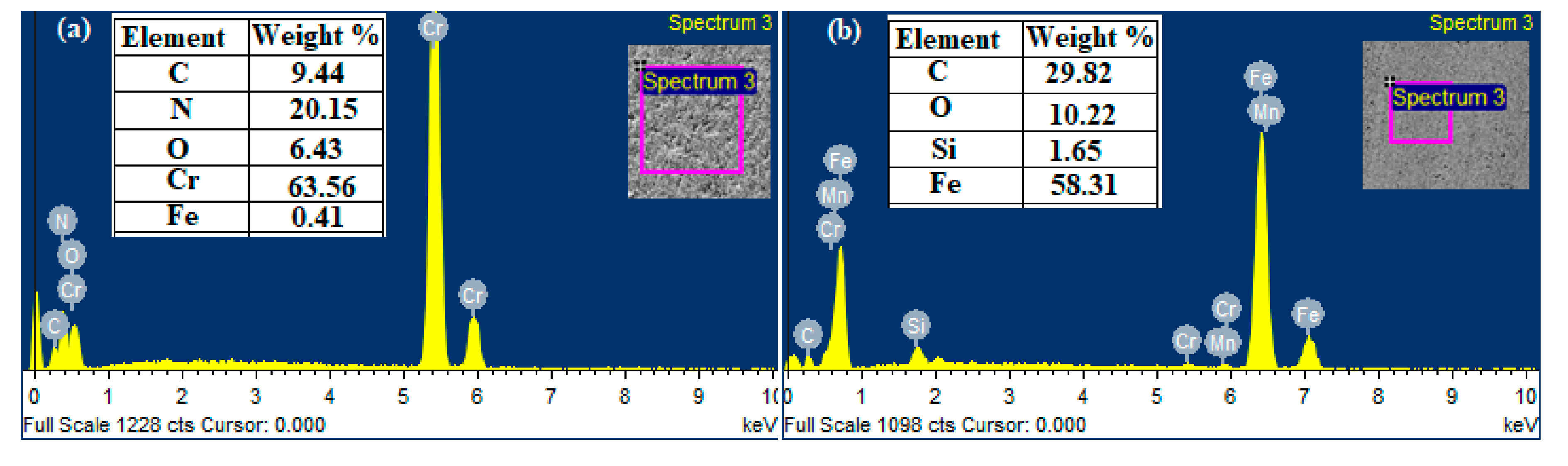

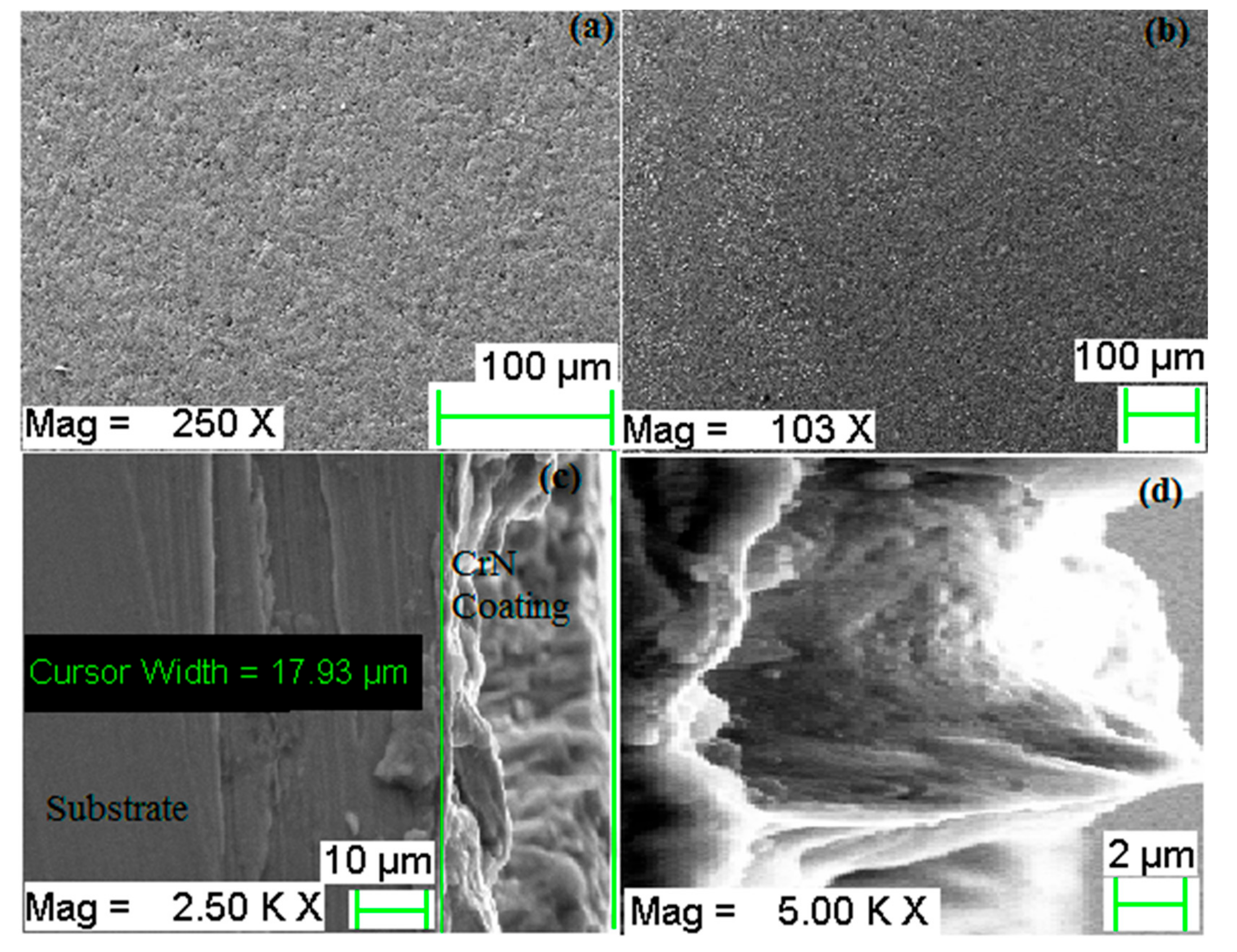

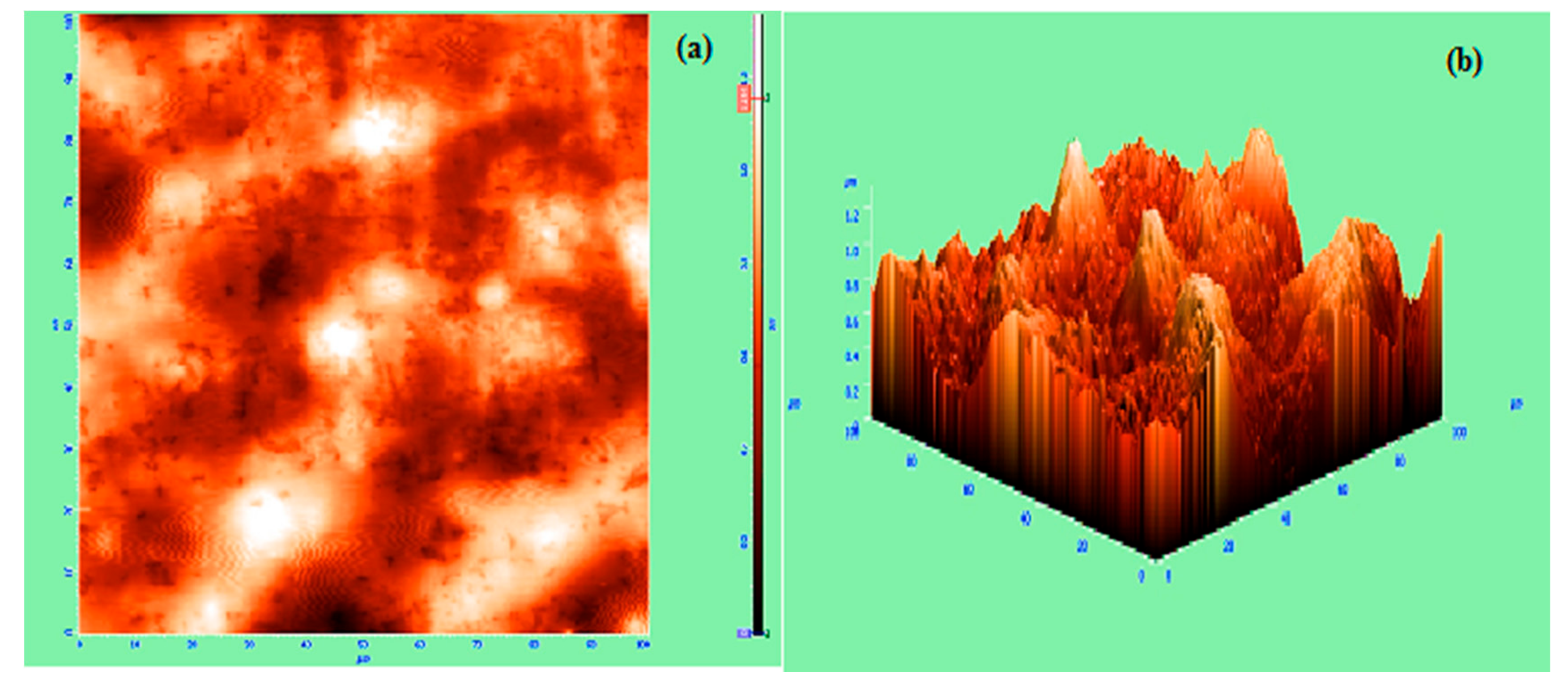

3.1. Coating Characterization

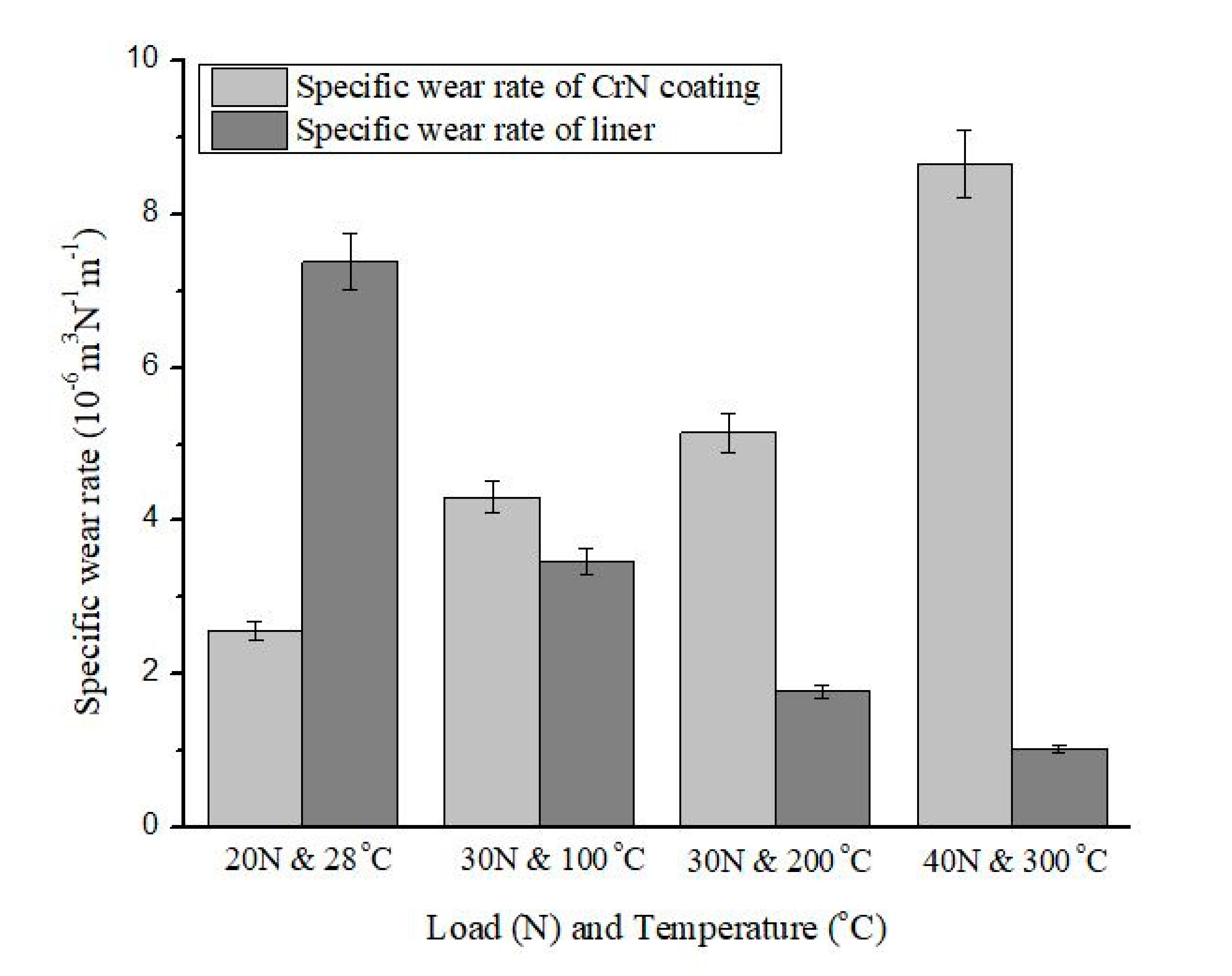

3.2. Specific Wear Rate

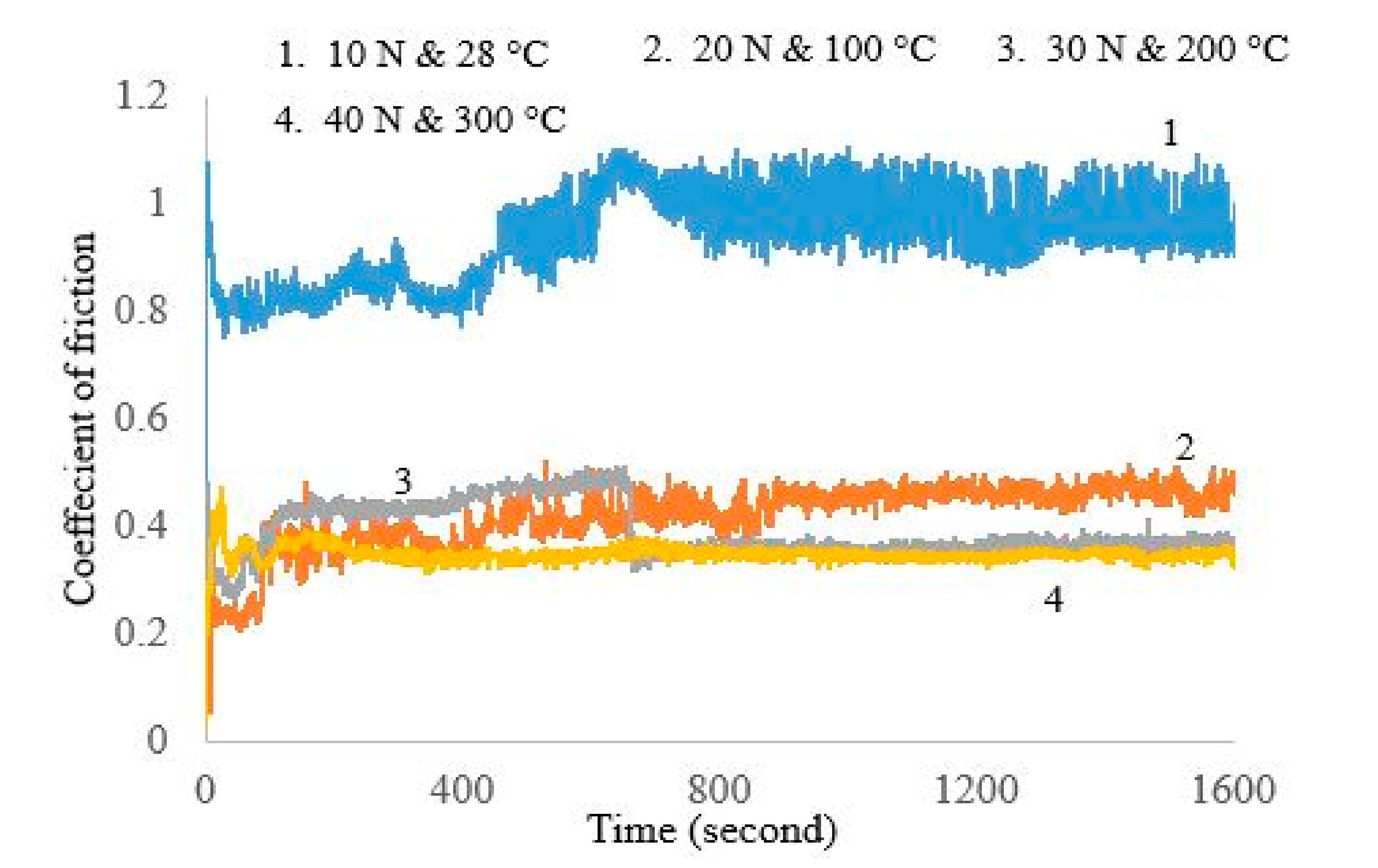

3.3. Evolution of Coefficient of Friction at Interface

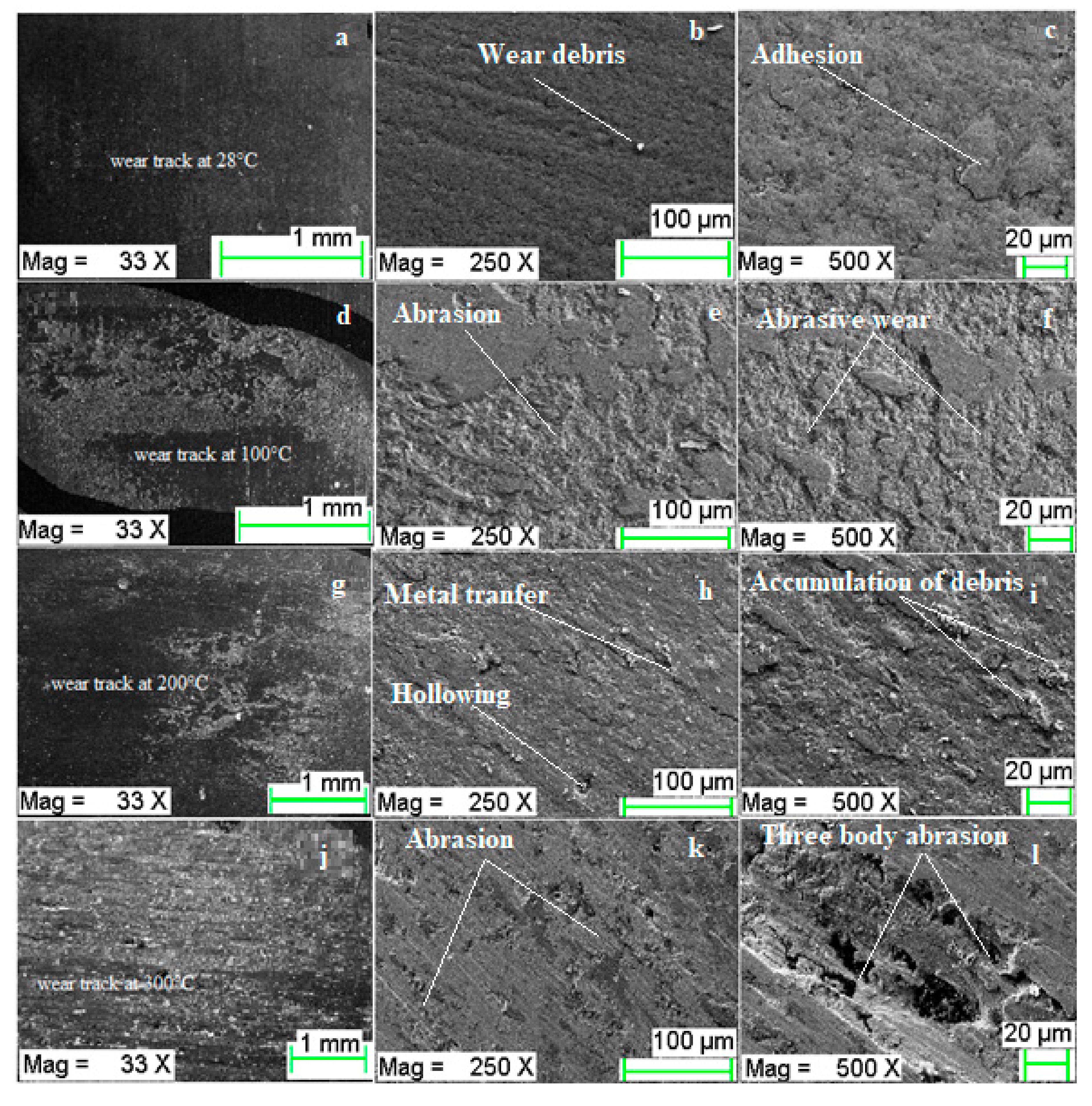

3.4. Wear Mechanism of Coating

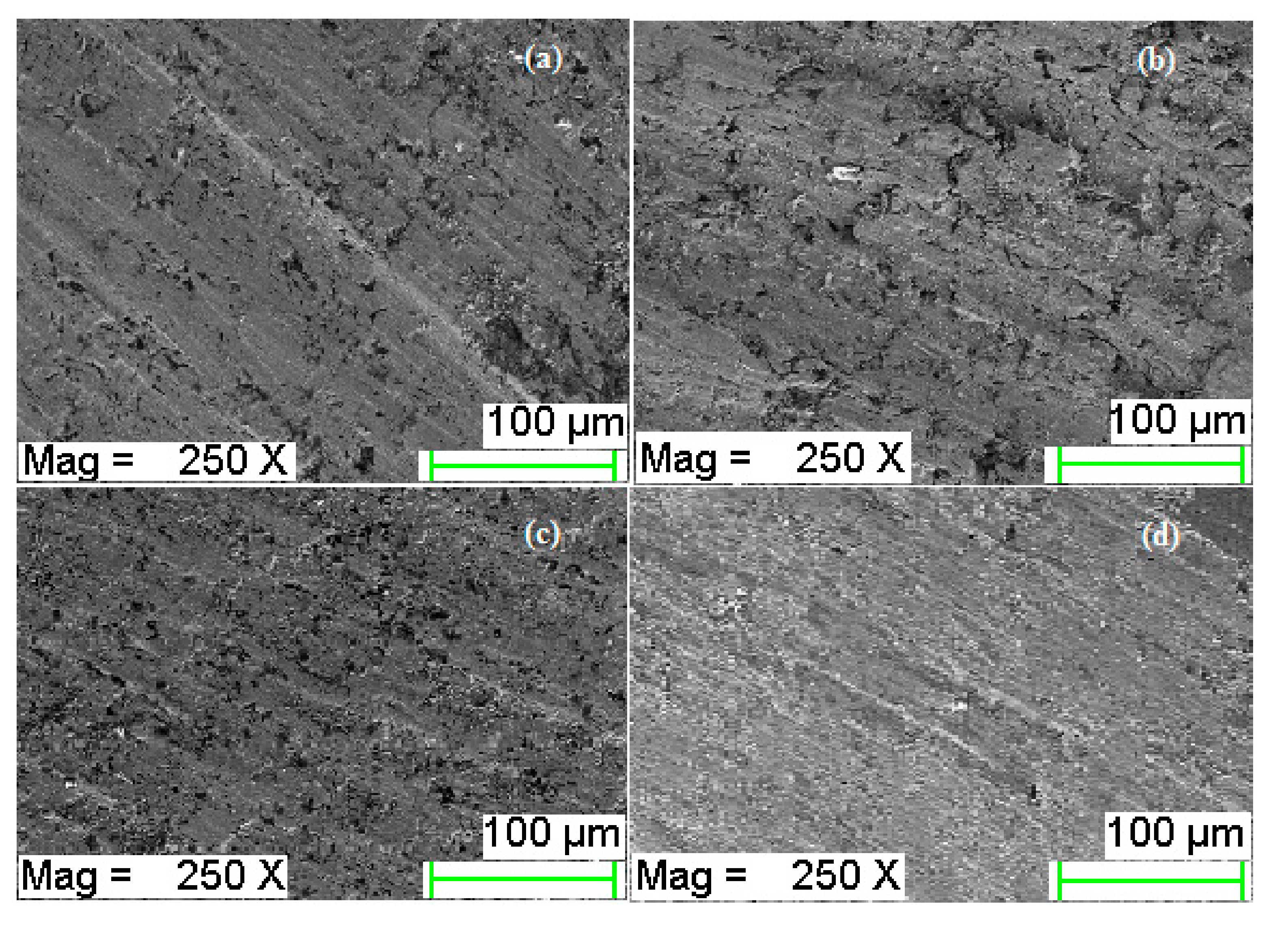

3.5. Wear Mechanism of Counter-Body

4. Conclusions

- (1)

- The chromium nitride coating primarily composed of a small grain and hard phase of CrN, the thickness of 17.93 µm with a contribution of 63.56% chromium and 20.18% nitrogen by weight. Coating shows very good bonding with the substrate, associated with diffusion bonding.

- (2)

- The average value of the friction coefficient of CrN coating against the cylinder liner at 28 °C, 100 °C, 200 °C, and 300 °C is 0.93, 0.41, 0.39, and 0.34, respectively. The average friction coefficient of the tested CrN coating decreased mainly because the smooth hard layer gradually formed on the worn surface of the coating.

- (3)

- The specific wear rate of the coating was 3.15 × 10−6 gm/N·m, 2.67 × 10−6 gm/N·m, 1.69 × 10−6 gm/N·m, and 0.612 × 10−6 gm/N·m at 28 °C, 100 °C, 200 °C, and 300 °C, respectively. The formation of chromium-oxide film and re-deposition of hard wear debris plays an important role in the reduction in the wear rate and friction coefficient.

- (4)

- The wear mechanism of CrN coating is mild and at 28 °C and 10 N load, the wear mechanism was mainly adhesive wear, accompanied with three-body abrasion. From 28 °C to 100 °C, the wear mechanism included abrasive wear and oxidation wear. From 200 °C to 300 °C, the wear mechanism of CrN was mainly oxidation wear and abrasive wear.

Author Contributions

Funding

Conflicts of Interest

References

- Cassar, G.; Wilson, J.A.; Banfield, S.; Housden, J.; Matthews, A.; Leyland, A. A study of the reciprocating-sliding wear performance of plasma surface treated titanium alloy. Wear 2010, 269, 60–70. [Google Scholar] [CrossRef]

- Bhushan, B. Modern Tribology Handbook, Two Volume Set; CRC Press: Boca Raton, FL, USA, 2000. [Google Scholar]

- Qiu, Y.; Zhang, S.; Li, B.; Wang, Y.; Lee, J.W.; Li, F.; Zhao, D. Improvement of tribological performance of CrN coating via multilayering with VN. Surf. Coat. Technol. 2013, 231, 357–363. [Google Scholar] [CrossRef]

- Lorenzo-Martin, C.; Ajayi, O.; Erdemir, A.; Fenske, G.R.; Wei, R. Effect of microstructure and thickness on the friction and wear behavior of CrN coatings. Wear 2013, 302, 963–971. [Google Scholar] [CrossRef]

- Chen, Y.; Nie, X. Study on fatigue and wear behaviors of a TiN coating using an inclined impact-sliding test. Surf. Coat. Technol. 2011, 206, 1977–1982. [Google Scholar] [CrossRef]

- Tribology of Diamond-Like Carbon Films: Fundamentals and Applications; Donnet, C., Erdemir, A., Eds.; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2007. [Google Scholar]

- Petrogalli, C.; Montesano, L.; Gelfi, M.; La Vecchia, G.M.; Solazzi, L. Tribological and corrosion behavior of CrN coatings: Roles of substrate and deposition defects. Surf. Coat. Technol. 2014, 258, 878–885. [Google Scholar] [CrossRef]

- Ortmann, S.; Savan, A.; Gerbig, Y.; Haefke, H. In-process structuring of CrN coatings, and its influence on friction in dry and lubricated sliding. Wear 2003, 254, 1099–1105. [Google Scholar] [CrossRef]

- Dejun, K.; Haoyuan, G. Microstructures and high-temperature wear performances of cathodic arc ion plating on YT14 cutting tool. Int. J. Adv. Manuf. Technol. 2016, 85, 2597–2605. [Google Scholar] [CrossRef]

- Truhan, J.J.; Qu, J.; Blau, P.J. The effect of lubricating oil condition on the friction and wear of piston ring and cylinder liner materials in a reciprocating bench test. Wear 2005, 259, 1048–1055. [Google Scholar] [CrossRef]

- Singh, S.K.; Chattopadhyaya, S.; Pramanik, A.; Kumar, S. Wear behavior of chromium nitride coating in dry condition at lower sliding velocity and load. Int. J. Adv. Manuf. Technol. 2018, 96, 1665–1675. [Google Scholar] [CrossRef]

- Tribology of Natural Fiber Polymer Composites; Fahim, M., Chand, N., Eds.; Elsevier: Amsterdam, The Netherlands, 2008. [Google Scholar]

- Liu, J.; Liao, R.; Xie, G.; Xiang, J.; Luo, J.; Liao, B.; Liu, Q. Tribological properties of CrN coating deposited on 20CrMo against tin bronze. Sci. China Technol. Sci. 2018, 61, 1713–1722. [Google Scholar] [CrossRef]

- Warcholinski, B.; Gilewicz, A.; Myslinski, P. Tribological properties of TiAlCrN thin films. Rev. Adv. Mater. Sci. 2009, 22, 81–88. [Google Scholar]

- Polcar, T.; Parreira, N.M.; Novák, R. Friction and wear behaviour of CrN coating at temperatures up to 500 °C. Surf. Coat. Technol. 2007, 201, 5228–5235. [Google Scholar] [CrossRef]

- Zhang, C.; Gu, L.; Tang, G.; Mao, Y. Wear transition of CrN coated M50 steel under high temperature and heavy load. Coatings 2017, 7, 202. [Google Scholar] [CrossRef]

- Pramanik, A. Effects of reinforcement on wear resistance of aluminum matrix composites. Trans. Nonferrous Met. Soc. China 2016, 26, 348–358. [Google Scholar] [CrossRef]

- Hakami, F.; Pramanik, A.; Islam, N.; Basak, A.; Ridgway, N. Study of effective parameters on wear behavior of rubbers based on statistical methods. Polym. Adv. Technol. 2019, 30, 1415–1426. [Google Scholar] [CrossRef]

- Bandeira, A.L.; Trentin, R.; Aguzzoli, C.; da Costa, M.M.; Michels, A.F.; Baumvol, I.J.; Farias, M.C.; Figueroa, C.A. Sliding wear and friction behavior of CrN-coating in ethanol and oil–ethanol mixture. Wear 2013, 301, 786–794. [Google Scholar] [CrossRef]

- Nohava, J.; Dessarzin, P.; Karvankova, P.; Morstein, M. Characterization of tribological behavior and wear mechanisms of novel oxynitride PVD coatings designed for applications at high temperatures. Tribol. Int. 2015, 81, 231–239. [Google Scholar] [CrossRef]

- Bolelli, G.; Cannillo, V.; Lusvarghi, L.; Manfredini, T. Wear behaviour of thermally sprayed ceramic oxide coatings. Wear 2006, 261, 1298–1315. [Google Scholar] [CrossRef]

- Weng, K.W.; Lin, T.N.; Wang, D.Y. Tribological property enhancement of CrN films by metal vapor vacuum arc implantation of vanadium and carbon ions. Thin Solid Film. 2008, 516, 1012–1019. [Google Scholar] [CrossRef]

- Bhushan, B.; Jahsman, W.E. Propagation of weak waves in elastic-plastic and elastic-viscoplastic solids with interfaces. Int. J. Solids Struct. 1978, 14, 39–51. [Google Scholar] [CrossRef]

- Kumar, D.; Murtaza, Q.; Singh, R.C. Sliding wear behavior of aluminum alloy coating prepared by two-wire electric arc spray process. Int. J. Adv. Manuf. Technol. 2016, 85, 237–252. [Google Scholar] [CrossRef]

- Najafi, H.; Karimi, A.; Dessarzin, P.; Morstein, M. Correlation between anionic substitution and structural properties in AlCr (OxN1−x) coatings deposited by lateral rotating cathode arc PVD. Thin Solid Film. 2011, 520, 1597–1602. [Google Scholar] [CrossRef]

- Wagner, J.; Hochauer, D.; Mitterer, C.; Penoy, M.; Michotte, C.; Wallgram, W.; Kathrein, M. The influence of boron content on the tribological performance of Ti–N–B coatings prepared by thermal CVD. Surf. Coat. Technol. 2006, 201, 4247–4252. [Google Scholar] [CrossRef]

- Shouyu, Z.; Dejun, K. Microstructures and Friction–Wear Behaviors of Cathodic Arc Ion Plated Chromium Nitride Coatings at High Temperatures. J. Tribol. 2018, 140. [Google Scholar] [CrossRef]

- Pei, Y.; Xia, D.; Wang, S.; Cong, L.; Wang, X.; Wang, D. Effects of Temperature on the Tribological Properties of NM600 under Sliding Wear. Materials 2019, 12, 4009. [Google Scholar] [CrossRef]

- Singh, S.K.; Chattopadhyaya, S.; Pramanik, A.; Kumar, S.; Basak, A.K. Effect of lubrication on the wear behaviour of CrN coating deposited by PVD process. Int. J. Surf. Sci. Eng. 2019, 13, 60–78. [Google Scholar] [CrossRef]

- Singh, S.K.; Chattopadhyaya, S.; Pramanik, A.; Kumar, S.; Basak, A.K. Wear of chromium nitride coating under high loads and speeds. Int. J. Surf. Sci. Eng. 2019, 13, 263–282. [Google Scholar] [CrossRef]

| Serial No. | Load (N) | Temperature (°C) | Frequency (Hz) | Stroke Length (mm) | Speed (m/s) | Sliding Distance (m) |

|---|---|---|---|---|---|---|

| Test-1 | 10 | 28°C | 30 | 5 | 0.3 | 500 |

| Test-2 | 20 | 100°C | 30 | 5 | 0.3 | 500 |

| Test-3 | 30 | 200°C | 30 | 5 | 0.3 | 500 |

| Test-4 | 40 | 300°C | 30 | 5 | 0.3 | 500 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Singh, S.K.; Chattopadhyaya, S.; Pramanik, A.; Kumar, S.; Basak, A.K.; Pandey, S.M.; Murtaza, Q.; Legutko, S.; Litak, G. Tribological Properties of Chromium Nitride on the Cylinder Liner under the Influence of High Temperature. Materials 2020, 13, 4497. https://doi.org/10.3390/ma13204497

Singh SK, Chattopadhyaya S, Pramanik A, Kumar S, Basak AK, Pandey SM, Murtaza Q, Legutko S, Litak G. Tribological Properties of Chromium Nitride on the Cylinder Liner under the Influence of High Temperature. Materials. 2020; 13(20):4497. https://doi.org/10.3390/ma13204497

Chicago/Turabian StyleSingh, Shailesh Kumar, Somnath Chattopadhyaya, Alokesh Pramanik, Sanjeev Kumar, Animesh K. Basak, Shailesh M. Pandey, Qasim Murtaza, Stanislaw Legutko, and Grzegorz Litak. 2020. "Tribological Properties of Chromium Nitride on the Cylinder Liner under the Influence of High Temperature" Materials 13, no. 20: 4497. https://doi.org/10.3390/ma13204497

APA StyleSingh, S. K., Chattopadhyaya, S., Pramanik, A., Kumar, S., Basak, A. K., Pandey, S. M., Murtaza, Q., Legutko, S., & Litak, G. (2020). Tribological Properties of Chromium Nitride on the Cylinder Liner under the Influence of High Temperature. Materials, 13(20), 4497. https://doi.org/10.3390/ma13204497