Cathodoluminescence Spectroscopic Stress Analysis for Silicon Oxide Film and Its Damage Evaluation

Abstract

1. Introduction

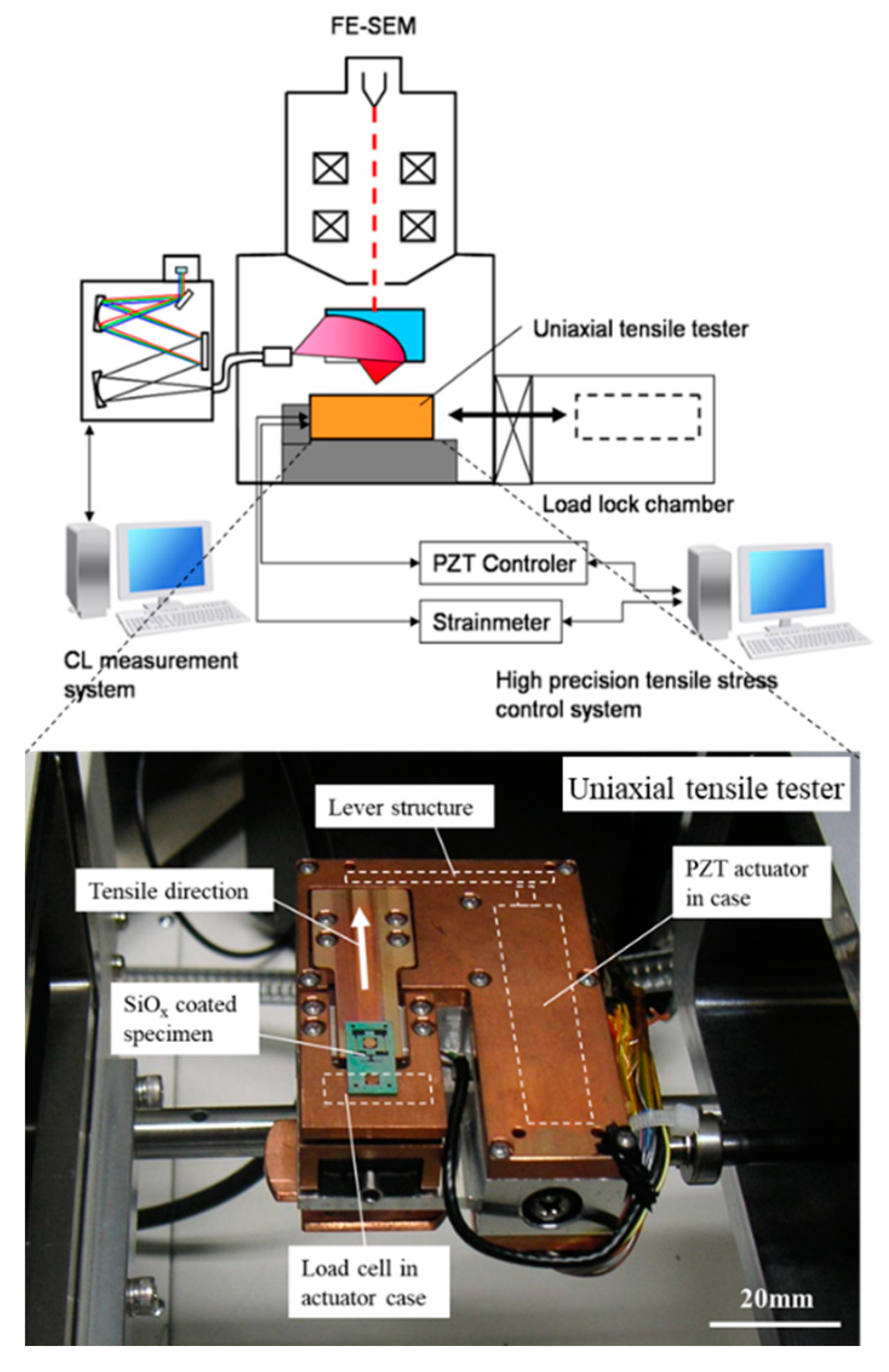

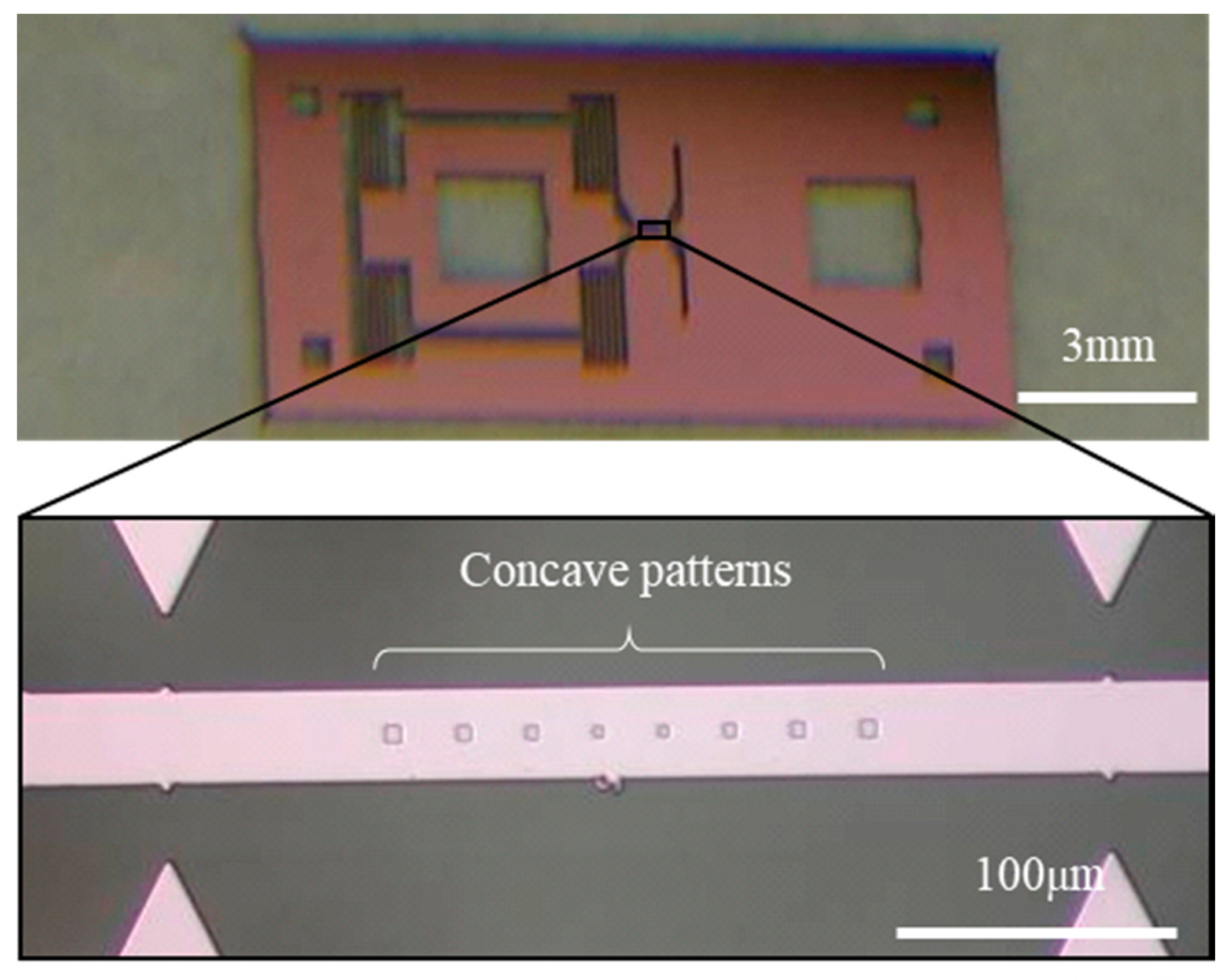

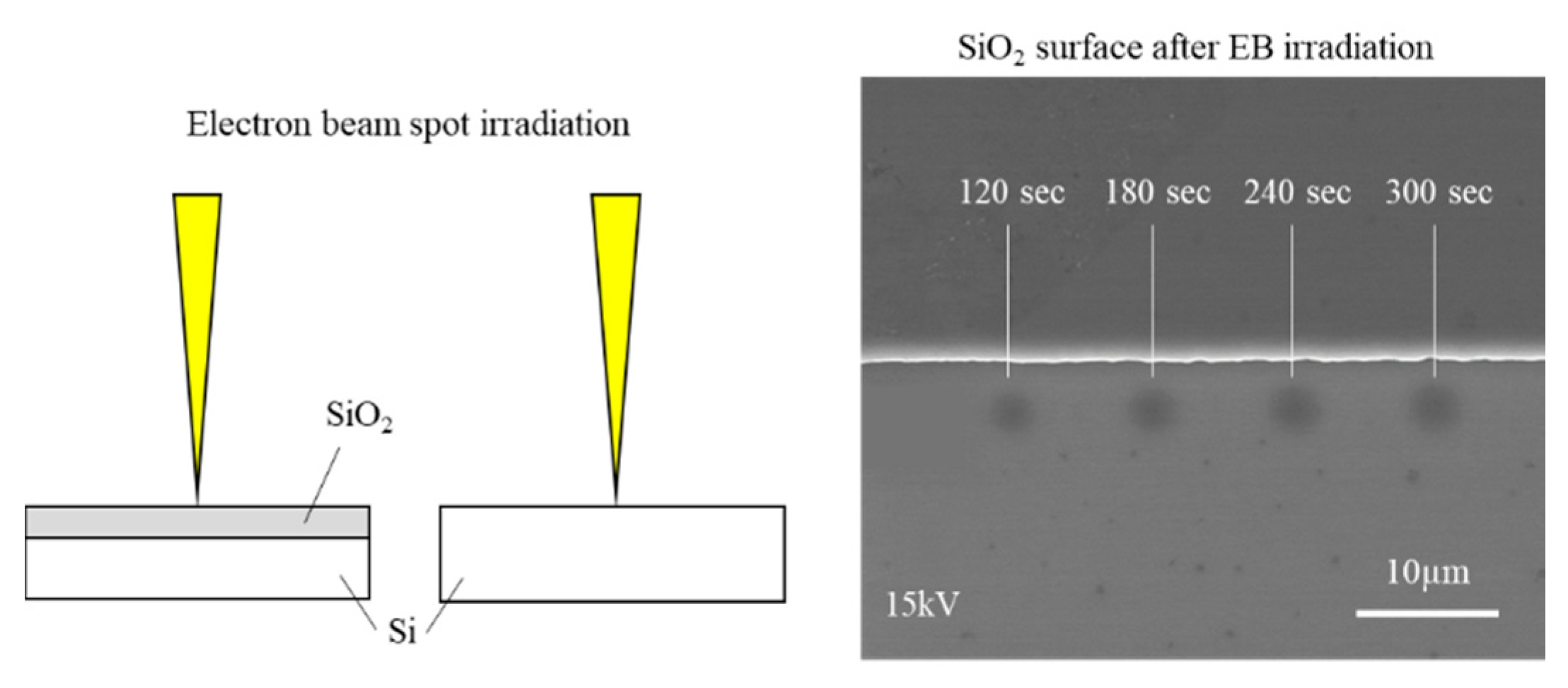

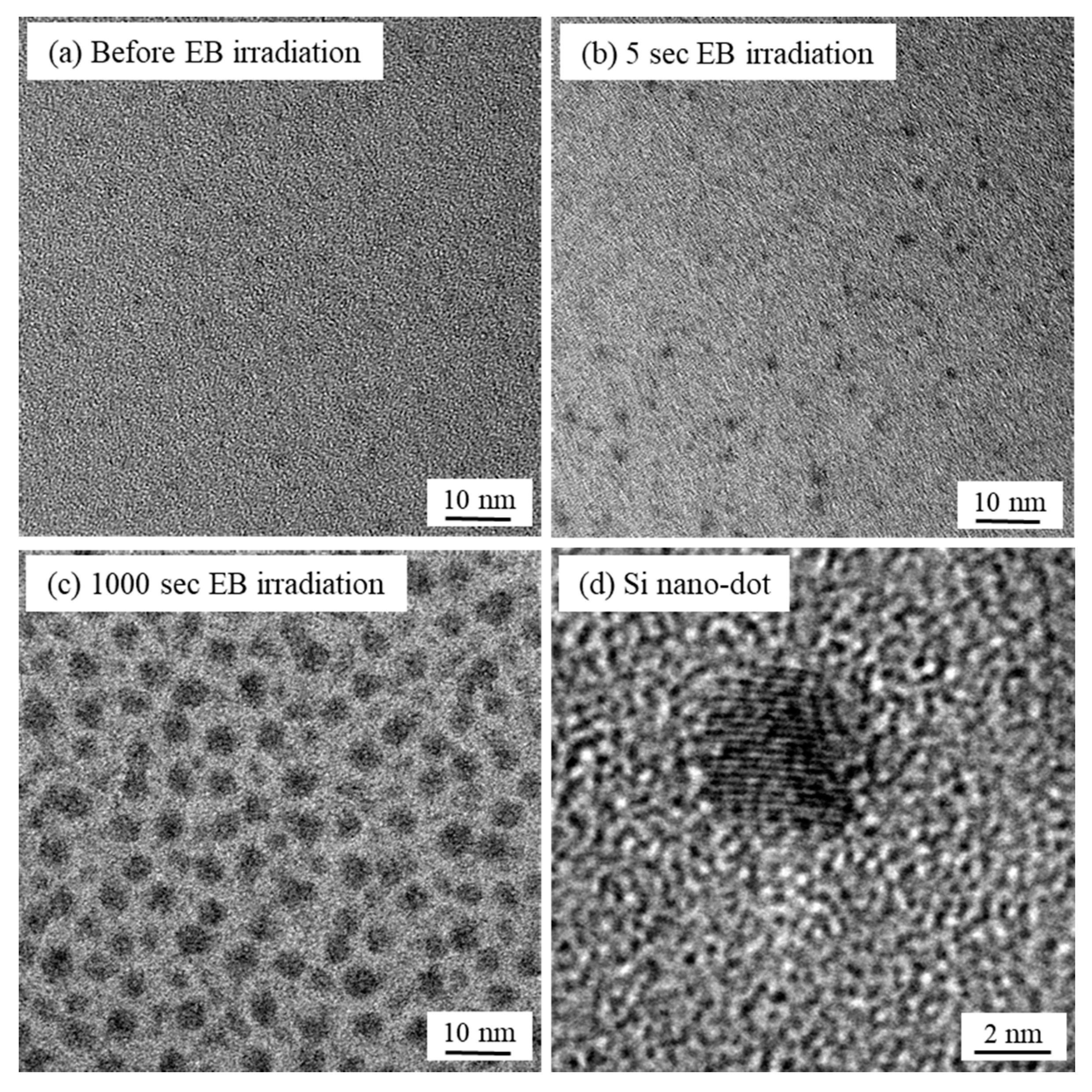

2. Experimental Procedure

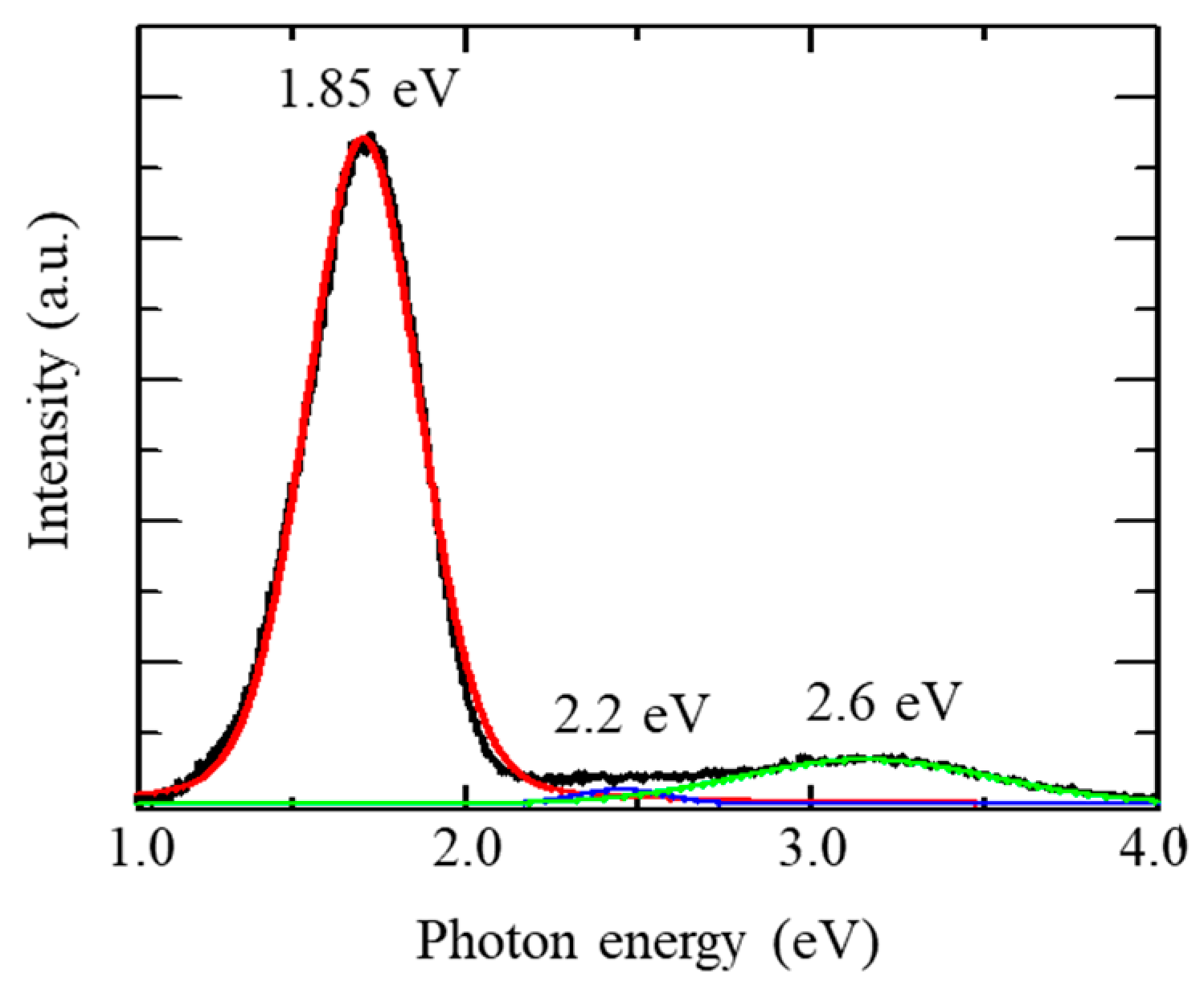

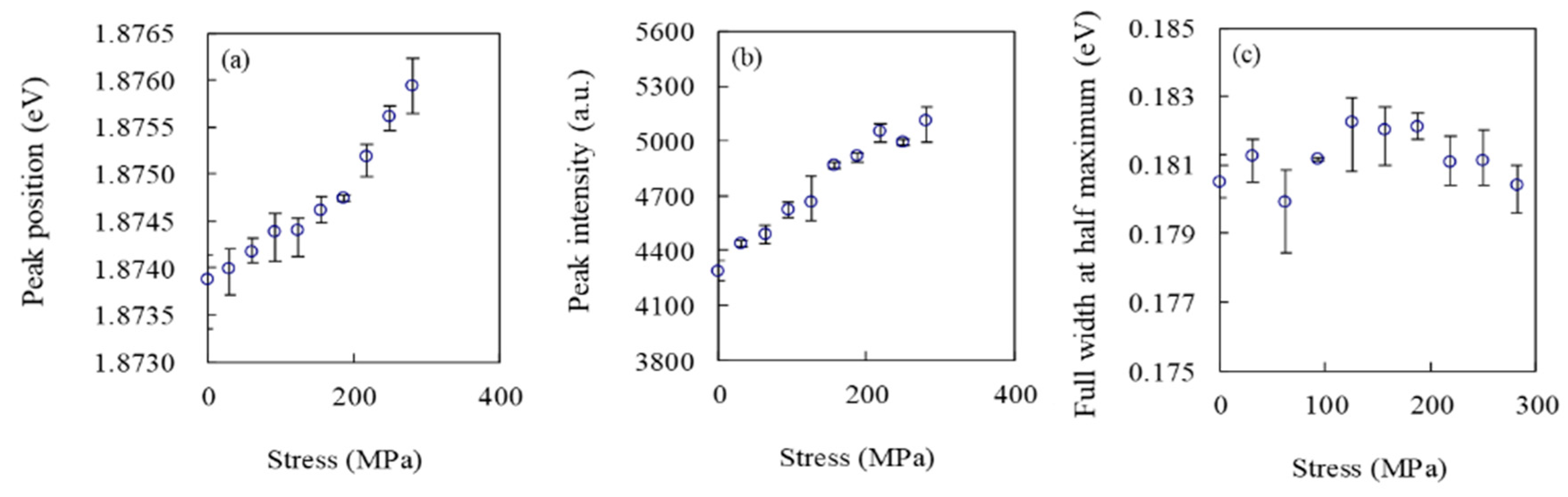

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Naka, N.; Kashiwagi, S.; Nagai, Y.; Namazu, T.; Inoue, S.; Ohtsuki, K. Raman Spectroscopic Study for Determining Stress Component in Single Crystal Silicon Microstructure using Multivariate Analysis. In Proceedings of the 2007 International Conference on Solid State Devices and Materials, Tsukuba, Tokyo, 18–21 September 2007; pp. 392–393. [Google Scholar] [CrossRef]

- Walraven, J.A. Future challenges for mems failure analysis. In Proceedings of the International Test Conference, Charlotte, NC, USA, 30 September–2 October 2003; Volume 1, pp. 850–855. [Google Scholar]

- Komatsubara, M.; Namazu, T.; Naka, N.; Kashiwagi, S.; Ohtsuki, K.; Inoue, S. Non-Destructive Quantitative Measurement Method for Normal and Shear Stresses on Single-Crystalline Silicon Structures for Reliability of Silicon-MEMS. In Proceedings of the 2009 IEEE 22nd International Conference on Micro Electro Mechanical Systems, Sorrento, Italy, 25–29 January 2009; pp. 659–662. [Google Scholar]

- De Wolf, I. Stress measurements in Si microelectronics devices using Raman spectroscopy. J. Raman Spectrosc. 1999, 30, 877–883. [Google Scholar] [CrossRef]

- Xu, Z.; He, Z.; Song, Y.; Fu, X.; Rommel, M.; Luo, X.; Hartmaier, A.; Zhang, J.; Fang, F. Application of Raman Spectroscopy Characterization in Micro/Nano-Machining. Micromachines 2018, 9, 361. [Google Scholar] [CrossRef] [PubMed]

- Glunz, S.W.; Feldmann, F. SiO2 Surface passivation layers—A key technology for silicon solar cells. Solar Energy Mater. Solar Cells 2018, 158, 260–269. [Google Scholar] [CrossRef]

- Paskov, P.; Schifano, R.; Monemar, B.; Paskova, T.; Figge, S.; Hommel, D. Emission properties of a-plane GaN grown by metal-organic chemical-vapor deposition. J. Appl. Phys. 2005, 98, 93519. [Google Scholar] [CrossRef]

- Imura, M.; Honshio, A.; Miyake, Y.; Nakano, K.; Tsuchiya, N.; Tsuda, M.; Okadome, Y.; Balakrishnan, K.; Iwaya, M.; Kamiyama, S.; et al. Microstructure of Nitrides Grown on Inclined c-Plane Aapphire and SiC Substrate. Phys. Rev. B 2006, 491, 376–377. [Google Scholar]

- Namazu, T.; Yamashita, N.; Kakinuma, S.; Nishikata, K.; Naka, N.; Matsumoto, K.; Inoue, S. In-situ cathodoluminescence spectroscopy of silicon oxide thin film under uniaxial tensile loading. J. Nanosci. Nanotechnol. 2011, 11, 2861–2866. [Google Scholar] [CrossRef] [PubMed]

- Leto, A.; Porporati, A.A.; Zhu, W.; Green, M.; Pezzotti, G. High-resolution stress assessments of interconnect/dielectric electronic patterns using optically active point defects of silica glass as a stress sensor. J. Appl. Phys. 2007, 101, 93514. [Google Scholar] [CrossRef]

- Kodera, M.; Iguchi, T.; Tsuchiya, N.; Tamura, M.; Kakinuma, S.; Naka, N.; Kashiwagi, S. Nano-Scale Stress Field Evaluation with Shallow Trench Isolation Structure Assessed by Cathodoluminescence, Raman Spectroscopy, and Finite Element Method Analyses. Ext. Abst. SSDM 2007, 934–935. [Google Scholar] [CrossRef]

- Namazu, T.; Nagai, Y.; Naka, N.; Araki, N.; Inoue, S. Design and Development of a Biaxial Tensile Test Device for a Thin Film Specimen. J. Eng. Mater. Technol. 2011, 134, 011009. [Google Scholar] [CrossRef]

- Fujii, M.; Namazu, T.; Fujii, H.; Masunishi, K.; Tomizawa, Y.; Inoue, S. Quasi-Static and Dynamic Mechanical Properties of Al-Si-Cu Structural Films in Uniaxial Tension. J. Vac. Sci. Technol. B 2012, 30, 031804. [Google Scholar] [CrossRef]

- Namazu, T.; Fujii, M.; Fujii, H.; Masunishi, K.; Tomizawa, Y.; Inoue, S. Thermal Annealing Effect on Elastic-Plastic Behavior of Al-Si-Cu Structural Films under Uniaxial and Biaxial Tension. J. Microelectromech. Syst. 2013, 22, 1414. [Google Scholar] [CrossRef]

- Namazu, T.; Kuwahara, K.; Fujii, M.; Kanetsuki, S.; Miyake, S.; Inoue, S. Mechanical reliability of reactively-formed NiAl alloys as a structural material. Sens. Mater. 2016, 28, 141. [Google Scholar]

- Brantley, W.A. Calculated elastic constants for stress problems associated with semiconductor devices. J. Appl. Phys. 1973, 44, 534. [Google Scholar] [CrossRef]

- Skuja, L. Optically active oxygen-deficiency-related centers in amorphous silicon dioxide. J. Non-Crystalline Solids 1998, 239, 16–48. [Google Scholar] [CrossRef]

- Katoda, T.; Nakamura, T. Characterization of Semiconductors by Laser-Raman Spectroscopy. Jpn. Soc. Appl. Phys. 1981, 50, 69–76. [Google Scholar]

- Nakayama, K.; Fujii, K. Absolute determination of lattice spacing and the Avogadro constant. Jpn. Soc. Appl. Phys. 1993, 62, 245–252. [Google Scholar]

- Chen, G.S.; Boothroyd, C.B.; Humphreys, C.J. Electron-beam-induced damage in amorphous SiO2 and the direct fabrication of silicon nanostructures. Philos. Mag. A 1998, 78, 491–506. [Google Scholar] [CrossRef]

- Yu, K.; Xu, T.; Wu, X.; Wang, W.; Zhang, H.; Zhang, Q.; Tang, L.; Sun, L. In Situ Observation of Crystalline Silicon Growth from SiO2 at Atomic Scale. Research 2019. [Google Scholar] [CrossRef]

- Dey, P.P.; Khare, A. Fabrication of photoluminescent nc-Si:SiO2 thin films prepared by PLD. Phys. Chem. Chem. Phys. 2017, 19, 21436–21445. [Google Scholar] [CrossRef]

- Nikitin, T.; Khriachtchev, L. Optical and Structural Properties of Si Nanocrystals in SiO2 Films. Nanomaterials 2015, 5, 614–655. [Google Scholar] [CrossRef]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kammachi, S.; Goshima, Y.; Goami, N.; Yamashita, N.; Kakinuma, S.; Nishikata, K.; Naka, N.; Inoue, S.; Namazu, T. Cathodoluminescence Spectroscopic Stress Analysis for Silicon Oxide Film and Its Damage Evaluation. Materials 2020, 13, 4490. https://doi.org/10.3390/ma13204490

Kammachi S, Goshima Y, Goami N, Yamashita N, Kakinuma S, Nishikata K, Naka N, Inoue S, Namazu T. Cathodoluminescence Spectroscopic Stress Analysis for Silicon Oxide Film and Its Damage Evaluation. Materials. 2020; 13(20):4490. https://doi.org/10.3390/ma13204490

Chicago/Turabian StyleKammachi, Shingo, Yoshiharu Goshima, Nobutaka Goami, Naoaki Yamashita, Shigeru Kakinuma, Kentaro Nishikata, Nobuyuki Naka, Shozo Inoue, and Takahiro Namazu. 2020. "Cathodoluminescence Spectroscopic Stress Analysis for Silicon Oxide Film and Its Damage Evaluation" Materials 13, no. 20: 4490. https://doi.org/10.3390/ma13204490

APA StyleKammachi, S., Goshima, Y., Goami, N., Yamashita, N., Kakinuma, S., Nishikata, K., Naka, N., Inoue, S., & Namazu, T. (2020). Cathodoluminescence Spectroscopic Stress Analysis for Silicon Oxide Film and Its Damage Evaluation. Materials, 13(20), 4490. https://doi.org/10.3390/ma13204490