Fracture Toughness, Breakthrough Morphology, Microstructural Analysis of the T2 Copper-45 Steel Welded Joints

Abstract

1. Introduction

2. Materials and Methods

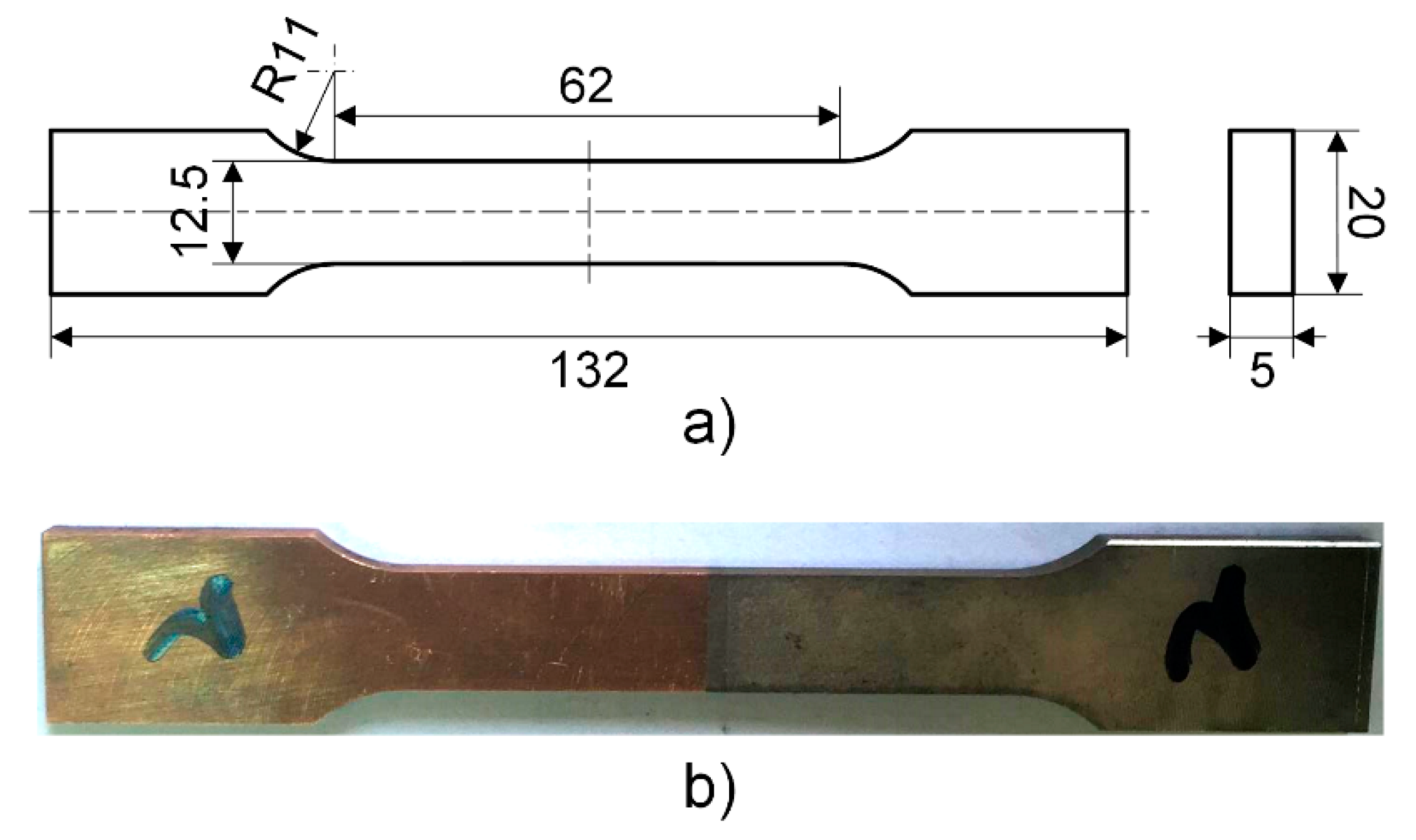

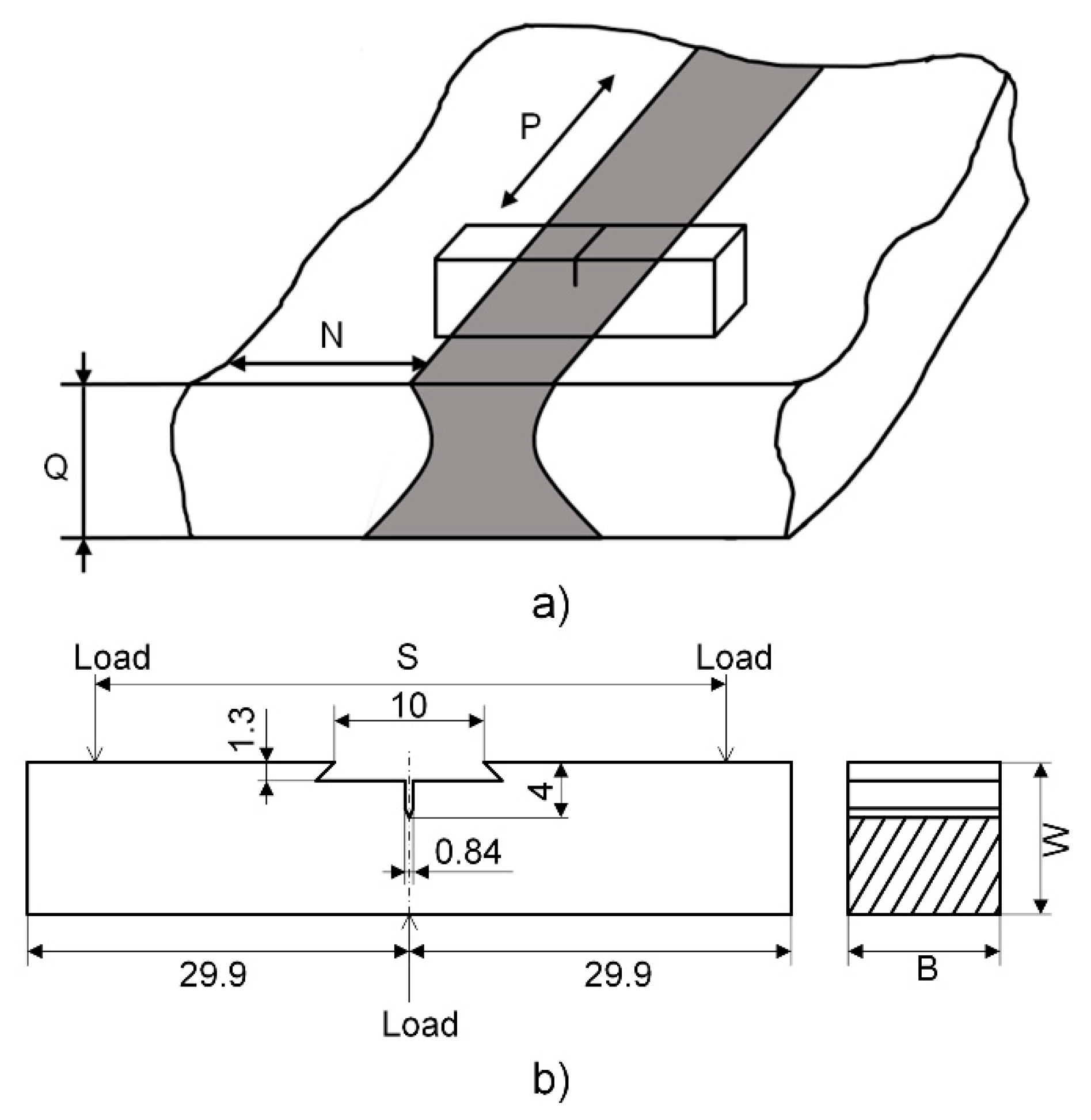

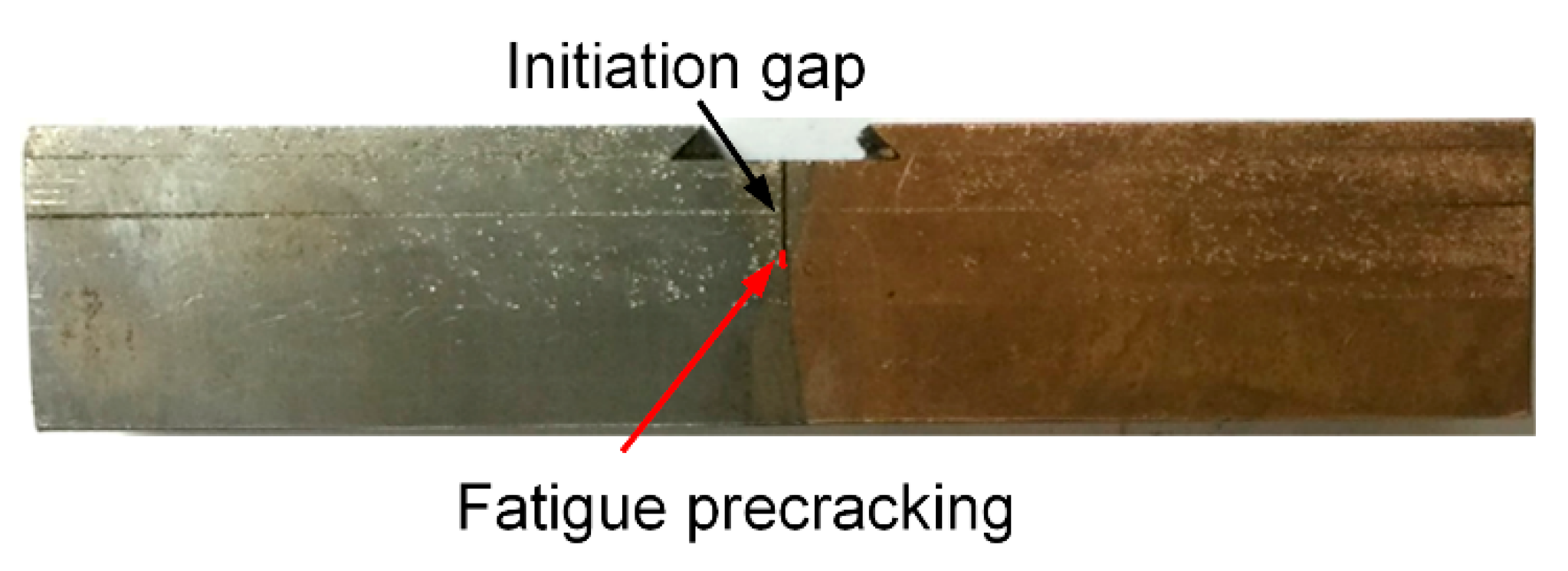

2.1. Parameter Test Method for Joint Property

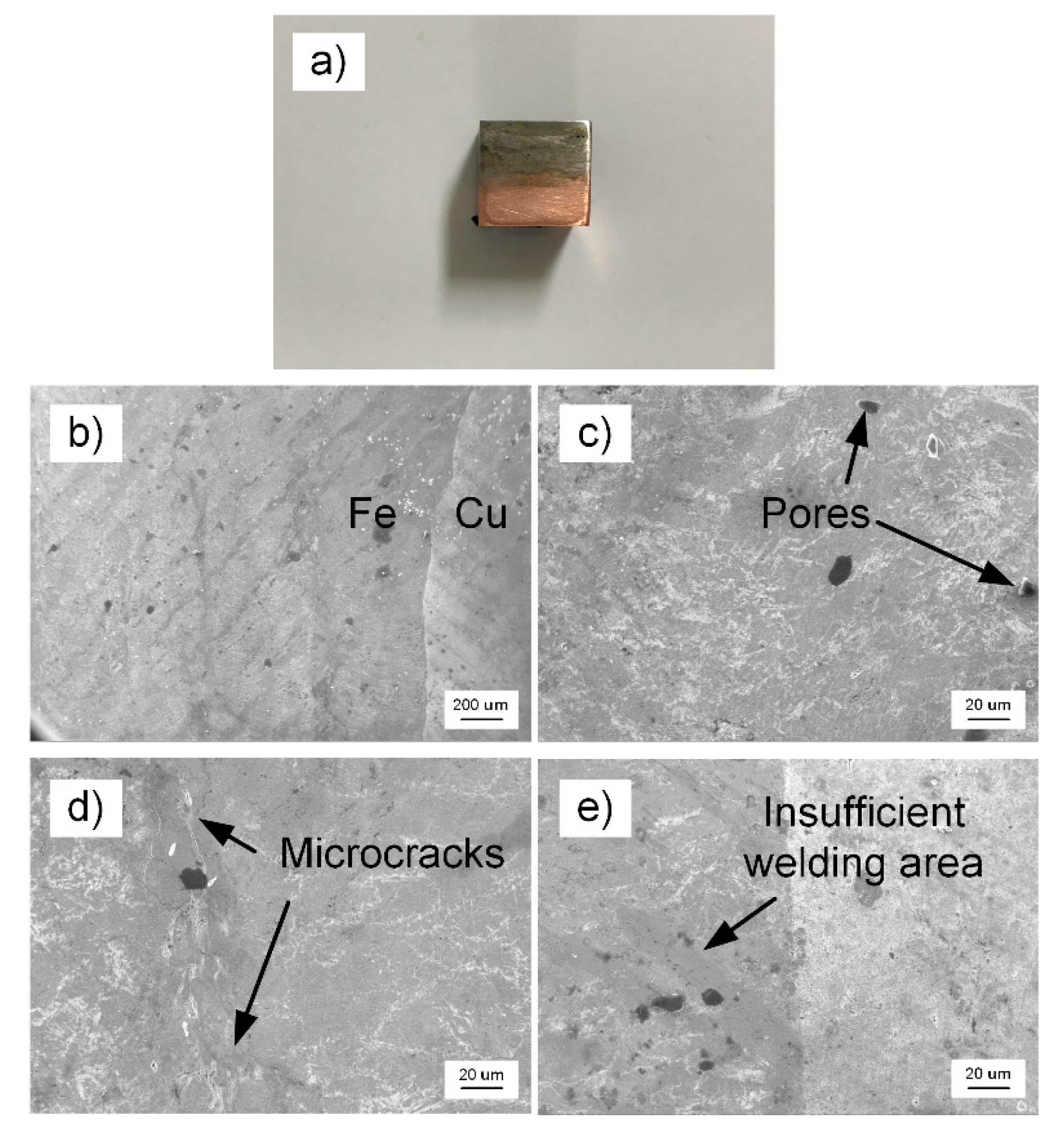

2.2. Characterization Results of Joint Property Parameters

3. Results and Discussion

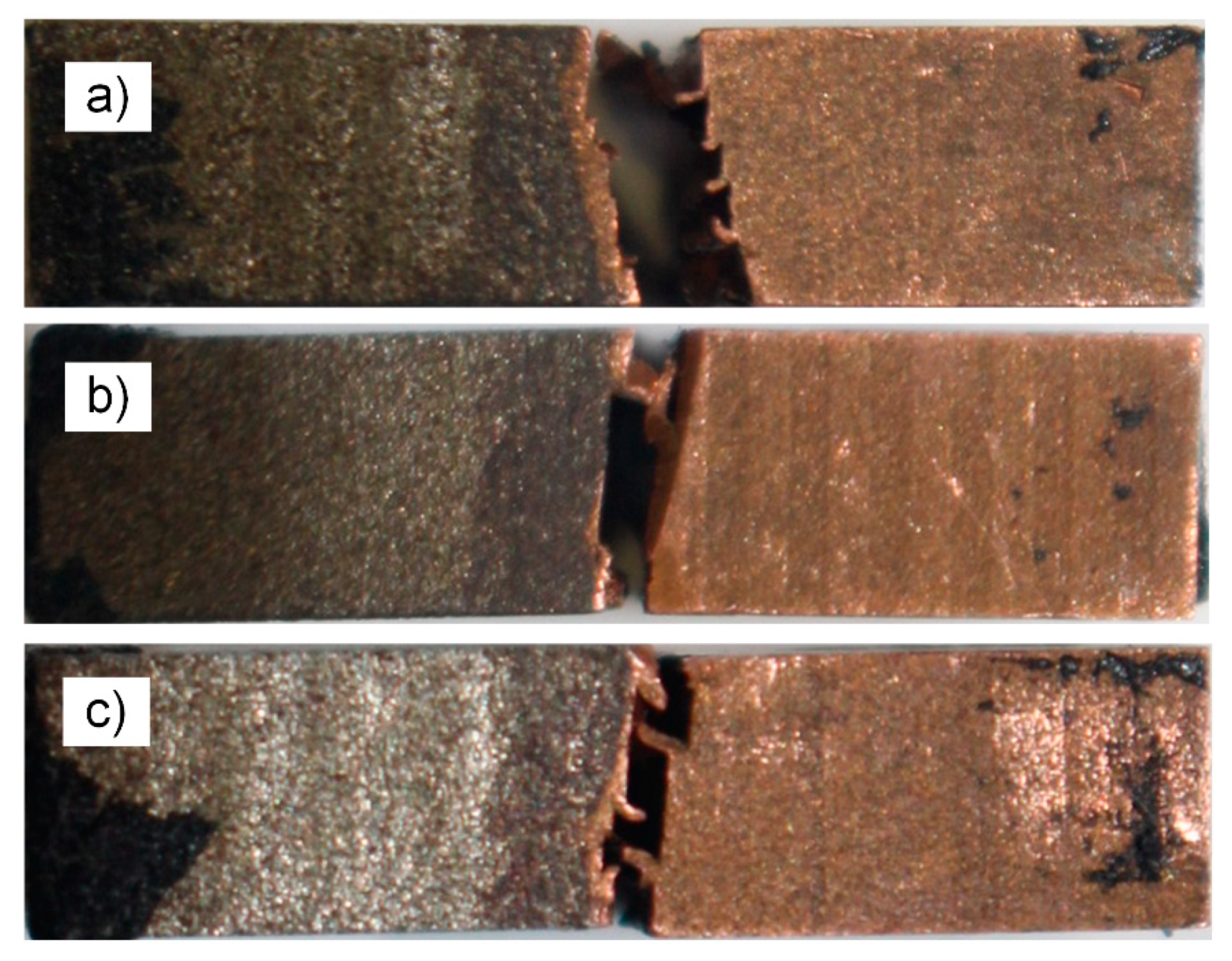

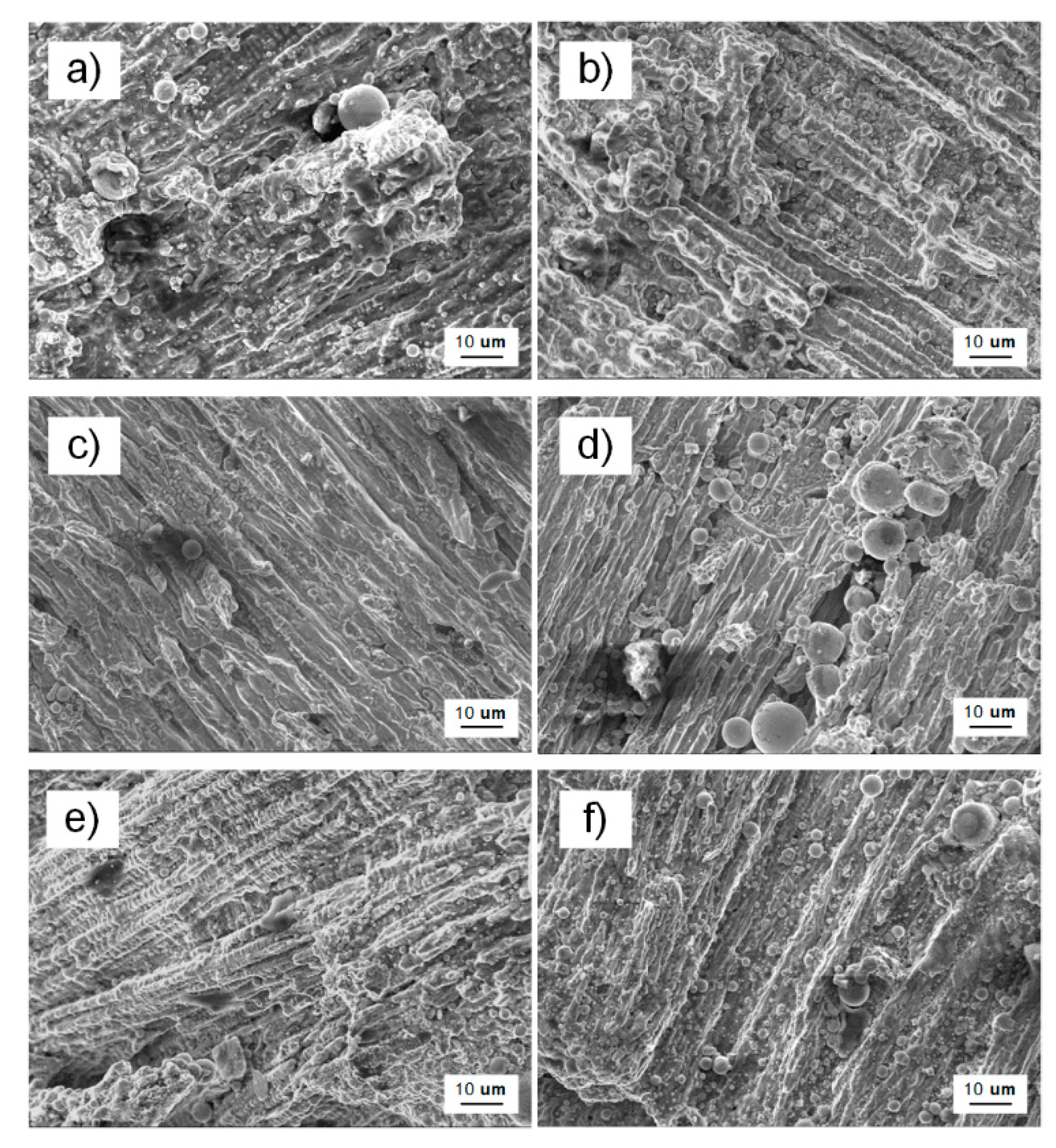

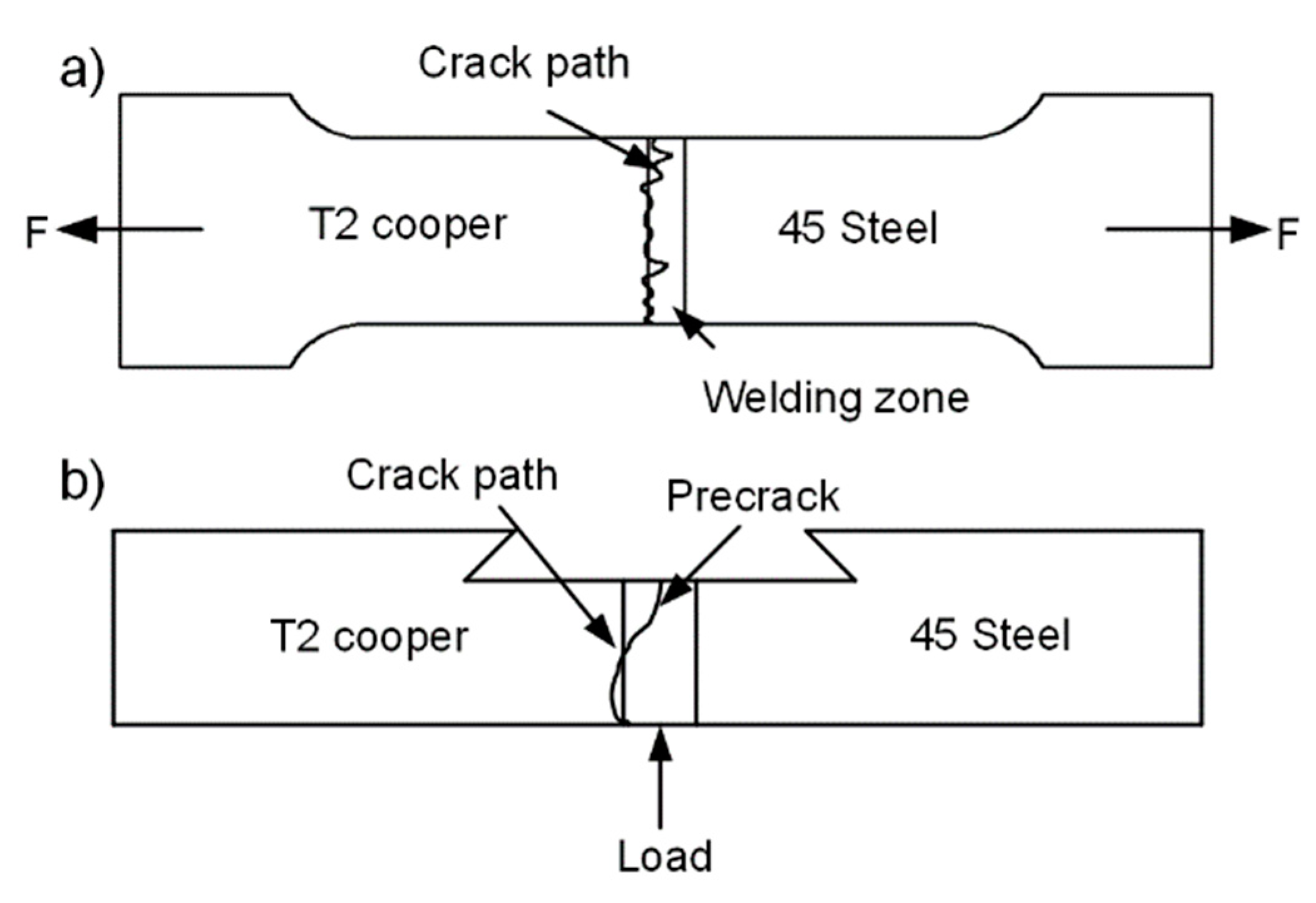

3.1. Fracture Analysis of Tensile Test

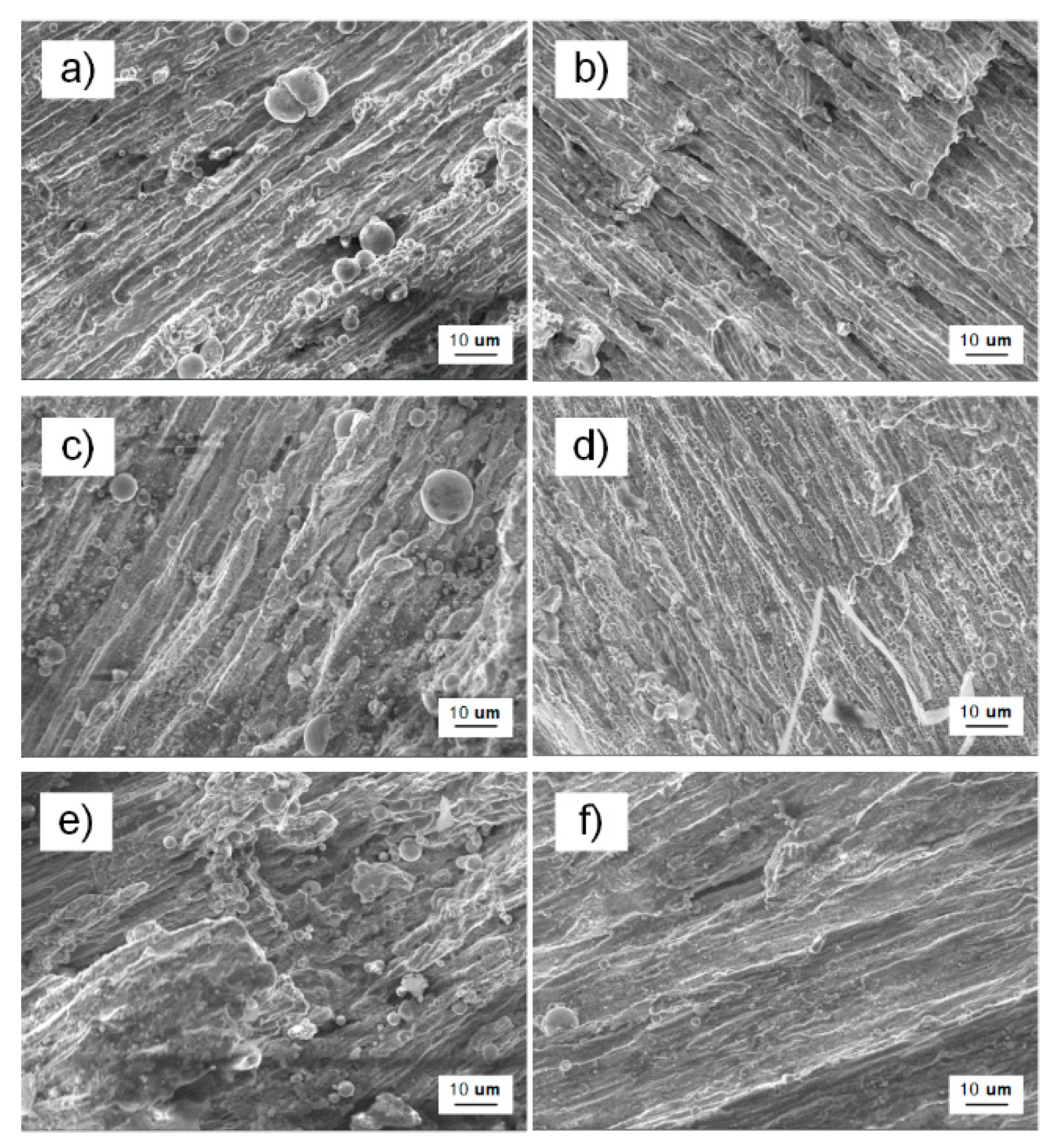

3.2. Fracture Analysis of Three-Point Bending Test

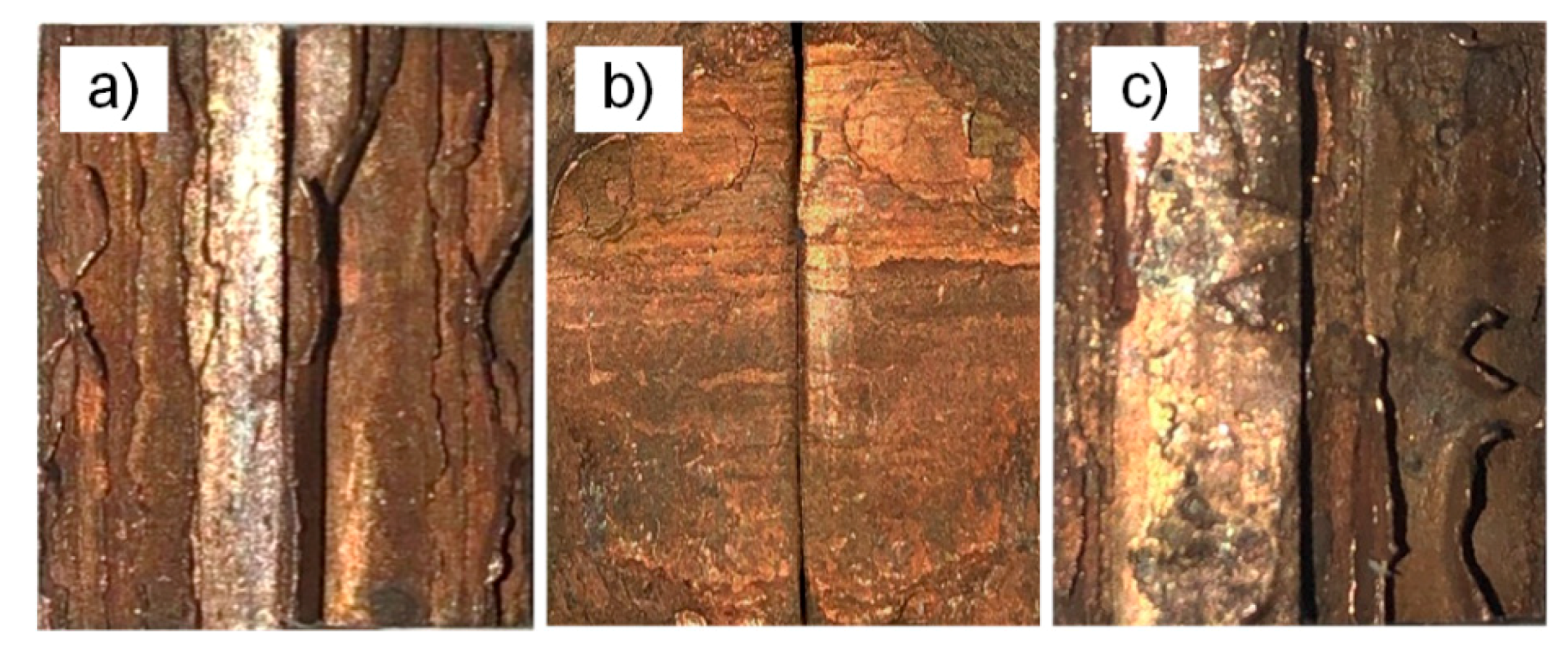

3.3. Analysis of Crack Propagation Direction

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Verma, J.; Taiwade, R.V. Effect of welding processes and conditions on the microstructure, mechanical properties and corrosion resistance of duplex stainless steel weldments—A review. J. Manuf. Process. 2017, 25, 134–152. [Google Scholar] [CrossRef]

- Magnabosco, I.; Ferro, P.; Bonollo, F.; Arnberg, L. An investigation of fusion zone microstructures in electron beam welding of copper–stainless steel. Mater. Sci. Eng. A 2006, 424, 163–173. [Google Scholar] [CrossRef]

- Chung, F.K.; Wei, P.S. Mass, Momentum, and Energy Transport in a Molten Pool When Welding Dissimilar Metals. J. Heat Transf. 1999, 121, 451–461. [Google Scholar] [CrossRef]

- Sun, Z.; Karppi, R. The application of electron beam welding for the joining of dissimilar metals: An overview. J. Mater. Process. Technol. 1996, 59, 257–267. [Google Scholar] [CrossRef]

- Zumelzu, E.; Cabezas, C. Study on welding such dissimilar materials as AISI 304 stainless steel and DHP copper in a sea-water environment. Influence of weld metals on corrosion. J. Mater. Process. Technol. 1996, 57, 249–252. [Google Scholar] [CrossRef]

- Mai, T.A.; Spowage, A.C. Characterisation of dissimilar joints in laser welding of steel-kovar, copper-steel and copper-aluminium. Mater. Sci. Eng. A 2004, 374, 224–233. [Google Scholar] [CrossRef]

- Srinivasan, P.B.; Muthupandi, V.; Dietzel, W.; Sivan, V. An assessment of impact strength and corrosion behaviour of shielded metal arc welded dissimilar weldments between UNS 31803 and IS 2062 steels. Mater. Des. 2006, 27, 182–191. [Google Scholar] [CrossRef]

- Wei, P.S.; Kuo, Y.K.; Ku, J.S. Fusion Zone Shapes in Electron-Beam Welding Dissimilar Metals. J. Heat Transf. 2000, 122, 626–631. [Google Scholar] [CrossRef]

- Tosto, S.; Nenci, F.; Jiandong, H. Microstructure of copper-AISI type 304L electron beam welded alloy. Mater. Sci. Technol. 2003, 19, 519–522. [Google Scholar] [CrossRef]

- Weigl, M.; Schmidt, M. Modulated laser spot welding of dissimilar copper-aluminium connections. In Proceedings of the 6th International Conference on Multi-Material Micro Manufacture, Forschungszentrum Karlsruhe, Germany, 23–25 September 2009. [Google Scholar]

- Velu, M.; Bhat, S. Metallurgical and mechanical examinations of steel-copper joints arc welded using bronze and nickel-base superalloy filler materials. Mater. Des. 2013, 47, 793–809. [Google Scholar] [CrossRef]

- Wu, M.F.; Si, N.C.; Chen, J. Contact reactive brazing of Al alloy/Cu/stainless steel joints and dissolution behaviors of interlayer. Trans. Nonferrous Met. Soc. China 2011, 21, 1035–1039. [Google Scholar] [CrossRef]

- Yaghi, A.H.; Hyde, T.H.; Becker, A.A.; Sun, W. Finite element simulation of residual stresses induced by the dissimilar welding of a P92 steel pipe with weld metal IN625. Int. J. Press. Vessel. Pip. 2013, 111, 173–186. [Google Scholar] [CrossRef]

- Yao, C.W.; Xu, B.S.; Zhang, X.C.; Huang, J.; Fu, J.; Wu, Y.X. Interface microstructure and mechanical properties of laser welding copper-steel dissimilar joint. Opt. Lasers Eng. 2009, 47, 807–814. [Google Scholar] [CrossRef]

- Zhang, B.G.; Zhao, J.; Li, X.P.; Chen, G.Q. Effects of filler wire on residual stress in electron beam welded QCr0.8 copper alloy to 304 stainless steel joints. Appl. Therm. Eng. 2015, 80, 261–268. [Google Scholar] [CrossRef]

- Liu, S.; Liu, F.; Xu, C.; Zhang, H. Experimental investigation on arc characteristic and droplet transfer in CO2 laser–metal arc gas (MAG) hybrid welding. Int. J. Heat Mass Transf. 2013, 62, 604–611. [Google Scholar] [CrossRef]

- Liu, F.; Zhang, Z.; Liu, L. Microstructure evolution of Al/Mg butt joints welded by gas tungsten arc with Zn filler metal. Mater. Character. 2012, 69, 84–89. [Google Scholar] [CrossRef]

- Dong, H.; Hu, W.; Duan, Y.; Wang, X.; Dong, C. Dissimilar metal joining of aluminum alloy to galvanized steel with Al–Si, Al–Cu, Al–Si–Cu and Zn–Al filler wires. J. Mater. Process. Technol. 2012, 212, 458–464. [Google Scholar] [CrossRef]

- Chen, S.H.; Li, L.Q.; Chen, Y.B.; Liu, D.J. Si diffusion behavior during laser welding-brazing of Al alloy and Ti alloy with Al-12Si filler wire. Trans. Nonferrous Met. Soc. China 2010, 20, 64–70. [Google Scholar] [CrossRef]

- Li, H.M.; Sun, D.Q.; Cai, X.L.; Dong, P.; Wang, W.Q. Laser welding of TiNi shape memory alloy and stainless steel using Ni interlayer. Mater. Des. 2012, 39, 285–293. [Google Scholar] [CrossRef]

- Miles, M.; Kohkonen, K.; Weickum, B.; Feng, Z. Friction Bit Joining of Dissimilar Material Combinations of High Strength Steel DP 980 and Al Alloy AA 5754. SAE Tech. Pap. 2009. [Google Scholar] [CrossRef]

- Curtis, T.; Widener, C.; West, M.; Jasthi, B.; Hovanski, Y.; Carlson, B.; Szymanski, R.; Bane, W. Friction Stir Scribe Welding of Dissimilar Aluminum to Steel Lap Joints. In Friction Stir Welding and Processing VIII; Mishra, R.S., Mahoney, M.W., Sato, Y., Hovanski, Y., Eds.; Springer: Cham, Switzerland, 2015. [Google Scholar]

- Semak, V.; Matsunawa, A. The role of recoil pressure in energy balance during laser materials processing. J. Phys. D Appl. Phys. 1999, 30, 2541. [Google Scholar] [CrossRef]

- IMAM. How Do SLM Process Defects Impact Ti64 Mechanical Properties? Available online: http://www.insidemetaladditivemanufacturing.com/blog/how-doslm-process-defects-impact-ti64-mechanical-properties (accessed on 1 May 2019).

- Kar, J.; Roy, S.K.; Roy, G.G. Effect of beam oscillation on electron beam welding of copper with AISI-304 stainless steel. J. Mater. Process. Technol. 2016, 233, 174–185. [Google Scholar] [CrossRef]

- Wei, P.S.; Chung, F.K. Unsteady Marangoni Flow in a Molten Pool When Welding Dissimilar Metals. Metall. Mater. Trans. B 2000, 1, 1387–1403. [Google Scholar] [CrossRef]

- Blouin, A.; Chapuliot, S.; Marie, S.; Niclaeys, C.; Bergheau, J.M. Brittle fracture analysis of Dissimilar Metal Welds. Eng. Fract. Mech. 2014, 131, 58–73. [Google Scholar] [CrossRef]

- Gilles, P.; Brosse, A.; Pignol, M. Simulation of Ductile Tearing in a Dissimilar Material Weld up to Pipe Wall Break-Through. In Proceedings of the Asme Pressure Vessels & Piping Division/k-pvp Conference, New York, NY, USA, 18–22 July 2010. [Google Scholar]

- Samal, M.K.; Seidenfuss, M.; Roos, E.; Balani, K. Investigation of failure behavior of ferritic–austenitic type of dissimilar steel welded joints. Eng. Fail. Anal. 2011, 18, 999–1008. [Google Scholar] [CrossRef]

- GB/T 21143-2014 Metallic Materials-Unified Method of Test for Determination of Quasistatic Fracture Toughness; Standards Press of China: Beijing, China, 2014.

- Faidy, C. Structural Integrity of Bi-Metallic Welds in Piping Fracture Testing and Analysis. In Proceedings of the Asme Pressure Vessels & Piping Conference, New York, NY, USA, 18–22 July 2010. [Google Scholar]

- Ashari, S.E.; Mohammadi, S. Delamination analysis of composites by new orthotropic bimaterial extended finite element method. Int. J. Numer. Methods Eng. 2011, 86, 1507–1543. [Google Scholar] [CrossRef]

- Belytschko, T.Y.; Black, T. Elastic Crack Growth in Finite Elements with Minimal Remeshing. Int. J. Numer. Methods Eng. 2015, 45, 601–620. [Google Scholar] [CrossRef]

- Nicak, T.; Schendzielorz, H.; Keim, E.; Meier, G. STYLE: Study on Transferability of Fracture Material Properties from Small Scale Specimens to a Real Component. In Proceedings of the Asme Pressure Vessels & Piping Conference, New York, NY, USA, 18–22 July 2010. [Google Scholar]

- Motamedi, D.; Mohammadi, S. Dynamic crack propagation analysis of orthotropic media by the extended finite element method. Int. J. Fract. 2009, 161, 21–39. [Google Scholar] [CrossRef]

- Zhang, Z.; Ma, W.L.; Wu, H.L.; Wu, H.P.; Jiang, S.F.; Chai, G.Z. A rigid thick Miura-Ori structure driven by bistable carbon fibre-reinforced polymer cylindrical shell. Compos. Sci. Technol. 2018, 167, 411–420. [Google Scholar] [CrossRef]

- Zhang, Z.; Li, Y.; Wu, H.L.; Chen, D.D.; Yang, J.; Wu, H.P.; Jiang, S.F.; Chai, G.Z. Viscoelastic bistable behaviour of antisymmetric laminated composite shells with time-temperature dependent properties. Thin-Walled Struct. 2018, 122, 403–415. [Google Scholar] [CrossRef]

- Rivalin, F.; Besson, J.; Pineau, A.; Fant, M.D. Ductile tearing of pipeline-steel wide plates: II. Modeling of in-plane crack propagation. Eng. Fract. Mech. 2001, 68, 347–364. [Google Scholar] [CrossRef]

- Kar, J.; Dinda, S.K.; Roy, G.G.; Roy, S.K.; Srirangam, P. X-ray tomography study on porosity in electron beam welded dissimilar copper–304SS joints. Vacuum 2018, 149, 200–206. [Google Scholar] [CrossRef]

- Guo, S.; Zhou, Q.; Kong, J.; Peng, Y.; Xiang, Y.; Luo, T.; Wang, K.; Zhu, J. Effect of beam offset on the characteristics of copper/304stainless steel electron beam welding. Vacuum 2016, 128, 205–212. [Google Scholar] [CrossRef]

- Zhang, B.G.; Zhao, J.; Xiao-Peng, L.I.; Feng, J.C. Electron beam welding of 304 stainless steel to QCr0.8 copper alloy with copper filler wire. Trans. Nonferrous Met. Soc. China 2014, 24, 4059–4066. [Google Scholar] [CrossRef]

- Chen, G.; Shu, X.; Liu, J.; Zhang, B.; Feng, J. Crystallographic texture and mechanical properties by electron beam freeform fabrication of copper/steel gradient composite materials. Vacuum 2020, 171, 109009. [Google Scholar] [CrossRef]

- Tomashchuk, I.; Sallamand, P.; Jouvard, J.M.; Grevey, D. The simulation of morphology of dissimilar copper–steel electron beam welds using level set method. Comput. Mater. Sci. 2010, 48, 827–836. [Google Scholar] [CrossRef]

- GB/T 5231-2012 Designation and Chemical Composition of Wrought Copper and Copper Alloys; Standards Press of China: Beijing, China, 2012.

- GB/T 699-2015 Quality Carbon Structure Steels; Standards Press of China: Beijing, China, 2015.

- GB/T 228.1-2010 Metallic Materials-Tensile Testing-Part 1: Method of Test at Room Temperature; Standards Press of China: Beijing, China, 2010.

- GB/T 28896-2012 Metallic Materials-Method of Test for the Determination of Quasistatic Fracture Toughness of Welds; Standards Press of China: Beijing, China, 2012.

- Turichin, G.A.; Klimova, O.G.; Babkin, K.D.; Pevzner, Y.B. Effect of Thermal and Diffusion Processes on Formation of the Structure of Weld Metal in Laser Welding of Dissimilar Materials. Met. Sci. Heat Treat. 2014, 55, 569–574. [Google Scholar] [CrossRef]

- Qin, E.W.; Lu, L.; Tao, N.R.; Tan, J.; Lu, K. Enhanced fracture toughness and strength in bulk nanocrystalline Cu with nanoscale twin bundles. Acta Mater. 2009, 57, 6215–6225. [Google Scholar] [CrossRef]

| Case | Thickness /mm | Acceleration Voltage/kV | Electron Beam/mA | Welding Speed/mm·min−1 |

|---|---|---|---|---|

| Kar, J. [25,39] | 3 | 60 | 65, 73, 80 | 1000 |

| Guo, S. [40] | 5 | 60 | 43–70 | 600 |

| Zhang, B.G. [15,41] | 2.7 | 60 | 25, 30, 35 | 100, 200, 300 |

| Chen, G. [42] | 5 | 60 | 15 | 400 |

| Tomashchuk, I. [43] | 2 | 20–40 | 20–40 | 200–900 |

| Sample | Cu + Ag (Minimum Value) | Bi | Sb | As | Fe | Pb | S | |

| T2 copper | 99.90 | 0.001 | 0.002 | 0.002 | 0.005 | 0.005 | 0.005 | |

| Sample | C | Si | Mn | P | S | Cr | Ni | Cu |

| 45 steel | 0.42–0.50 | 0.17–0.37 | 0.50–0.80 | 0.035 | 0.035 | 0.25 | 0.30 | 0.25 |

| No. | Ultimate Strength | Yield Strength | Elastic Modulus |

|---|---|---|---|

| σb/MPa | σs/MPa | E/GPa | |

| 1 | 102.45 | 81.02 | 88.37 |

| 2 | 84.67 | 78.64 | 110.53 |

| 3 | 94.06 | 66.45 | 127.68 |

| Average value | 93.73 | 75.37 | 108.86 |

| No. | KQ/MPa·m1/2 | a0/mm | B/mm | (W − a0)/mm | Kf/MPa·m1/2 |

|---|---|---|---|---|---|

| 1 | 5.827 | 10.17 | 12.35 | 0.33 | 31.426 |

| 2 | 6.072 | 10.21 | 12.47 | 0.35 | 33.325 |

| 3 | 6.181 | 11.08 | 12.61 | 0.36 | 35.217 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ding, H.; Huang, Q.; Liu, P.; Bao, Y.; Chai, G. Fracture Toughness, Breakthrough Morphology, Microstructural Analysis of the T2 Copper-45 Steel Welded Joints. Materials 2020, 13, 488. https://doi.org/10.3390/ma13020488

Ding H, Huang Q, Liu P, Bao Y, Chai G. Fracture Toughness, Breakthrough Morphology, Microstructural Analysis of the T2 Copper-45 Steel Welded Joints. Materials. 2020; 13(2):488. https://doi.org/10.3390/ma13020488

Chicago/Turabian StyleDing, Hao, Qi Huang, Peng Liu, Yumei Bao, and Guozhong Chai. 2020. "Fracture Toughness, Breakthrough Morphology, Microstructural Analysis of the T2 Copper-45 Steel Welded Joints" Materials 13, no. 2: 488. https://doi.org/10.3390/ma13020488

APA StyleDing, H., Huang, Q., Liu, P., Bao, Y., & Chai, G. (2020). Fracture Toughness, Breakthrough Morphology, Microstructural Analysis of the T2 Copper-45 Steel Welded Joints. Materials, 13(2), 488. https://doi.org/10.3390/ma13020488