Influence of Annealing on the Damping Behavior of Ni-Cu-Mn-Ga Ferromagnetic Shape Memory Alloys

Abstract

1. Introduction

2. Materials and Methods

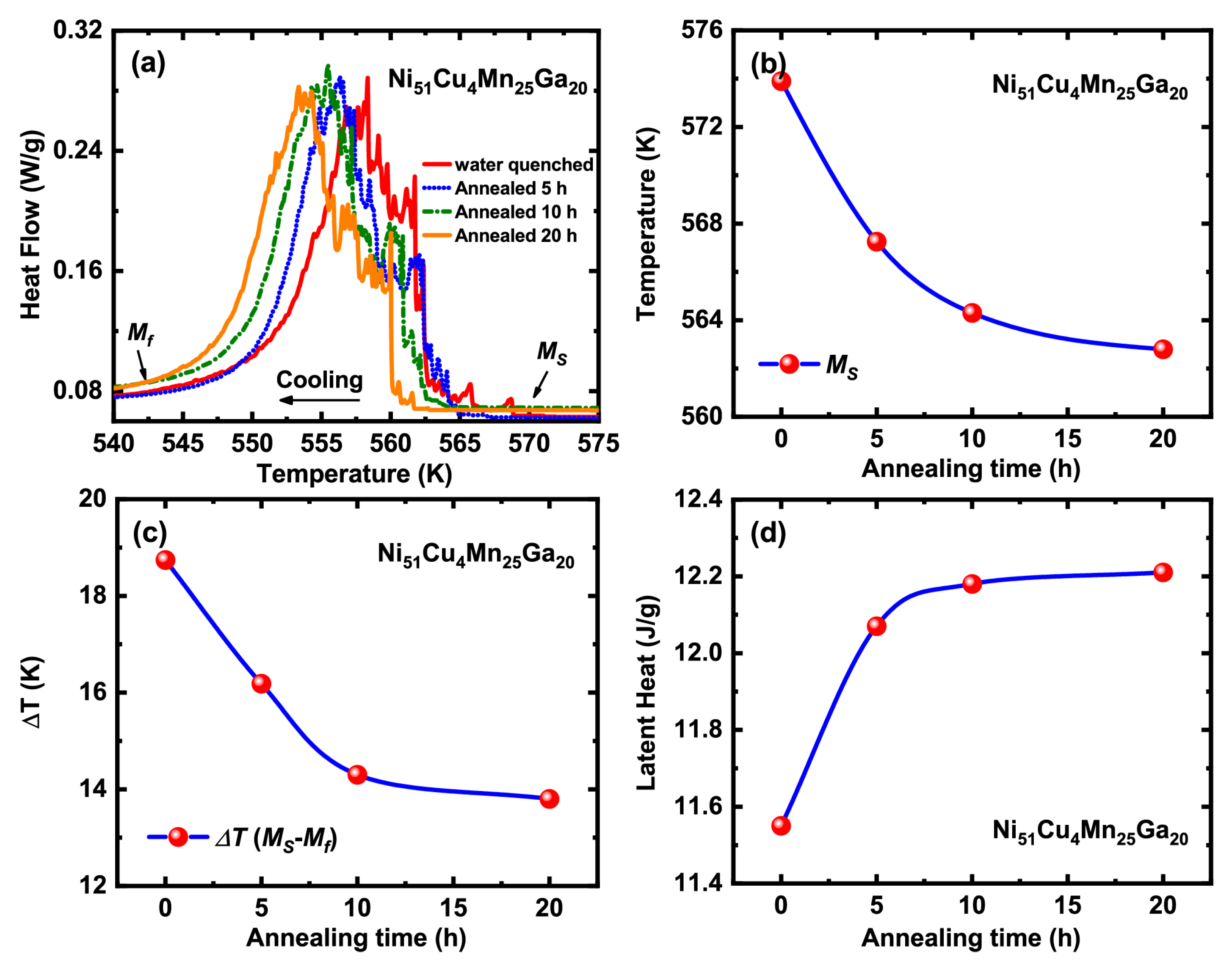

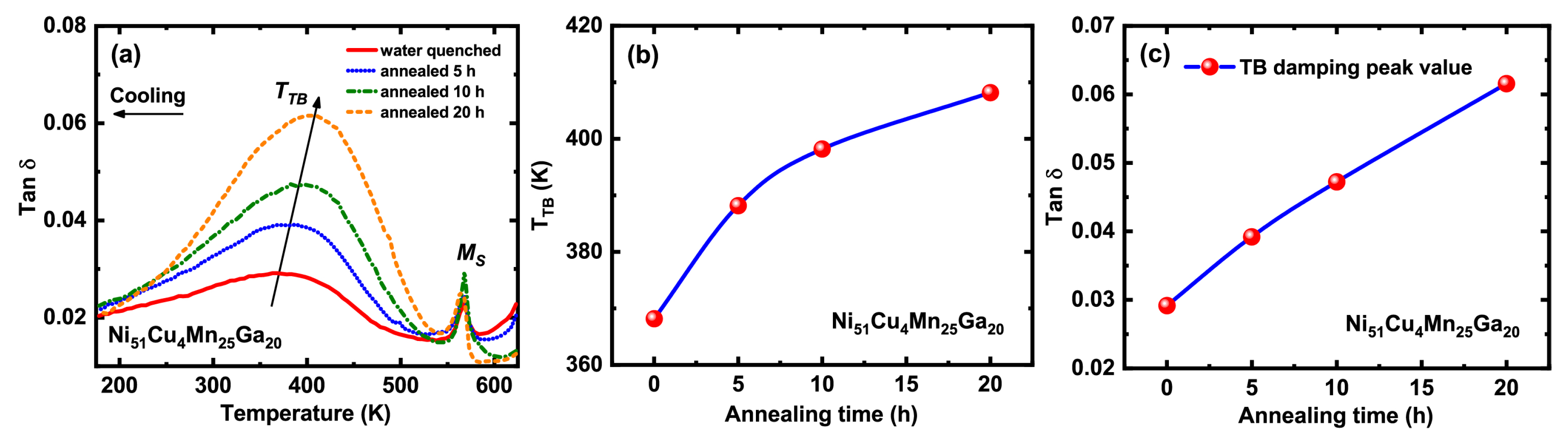

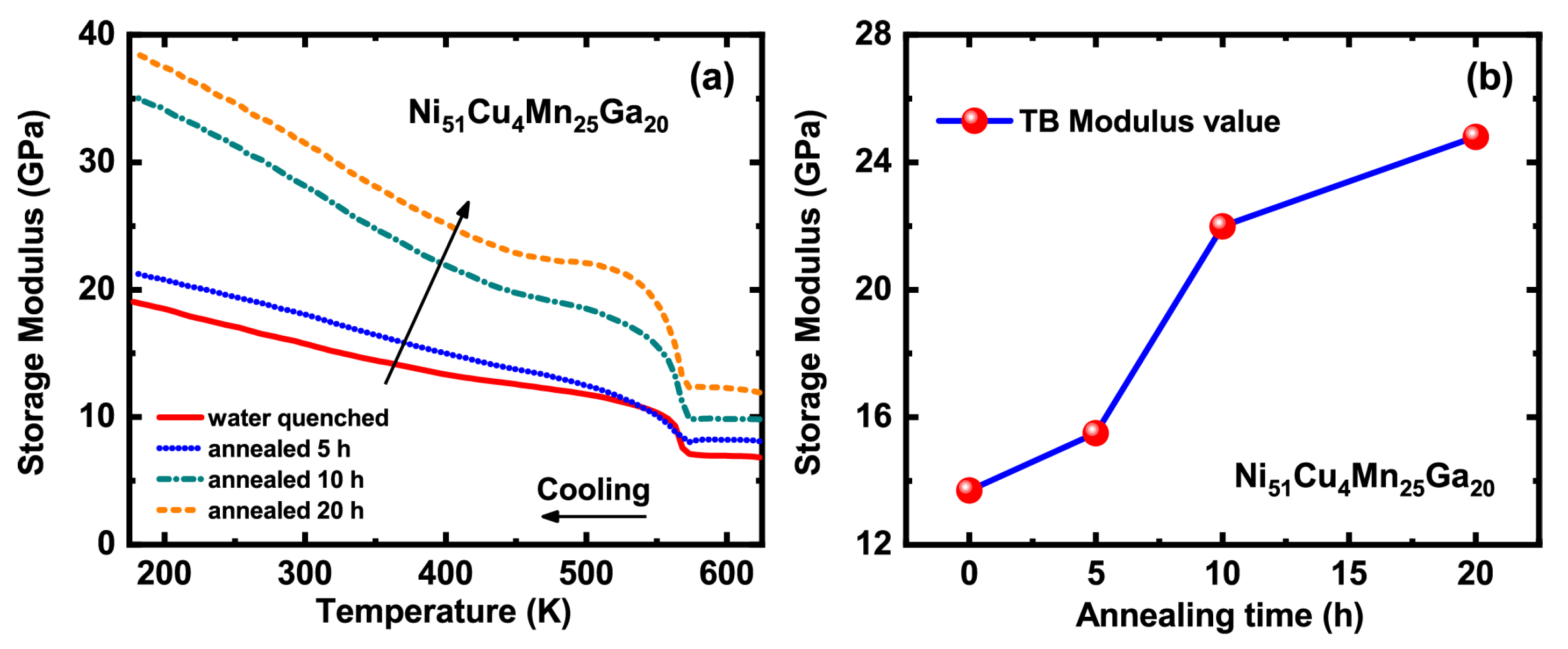

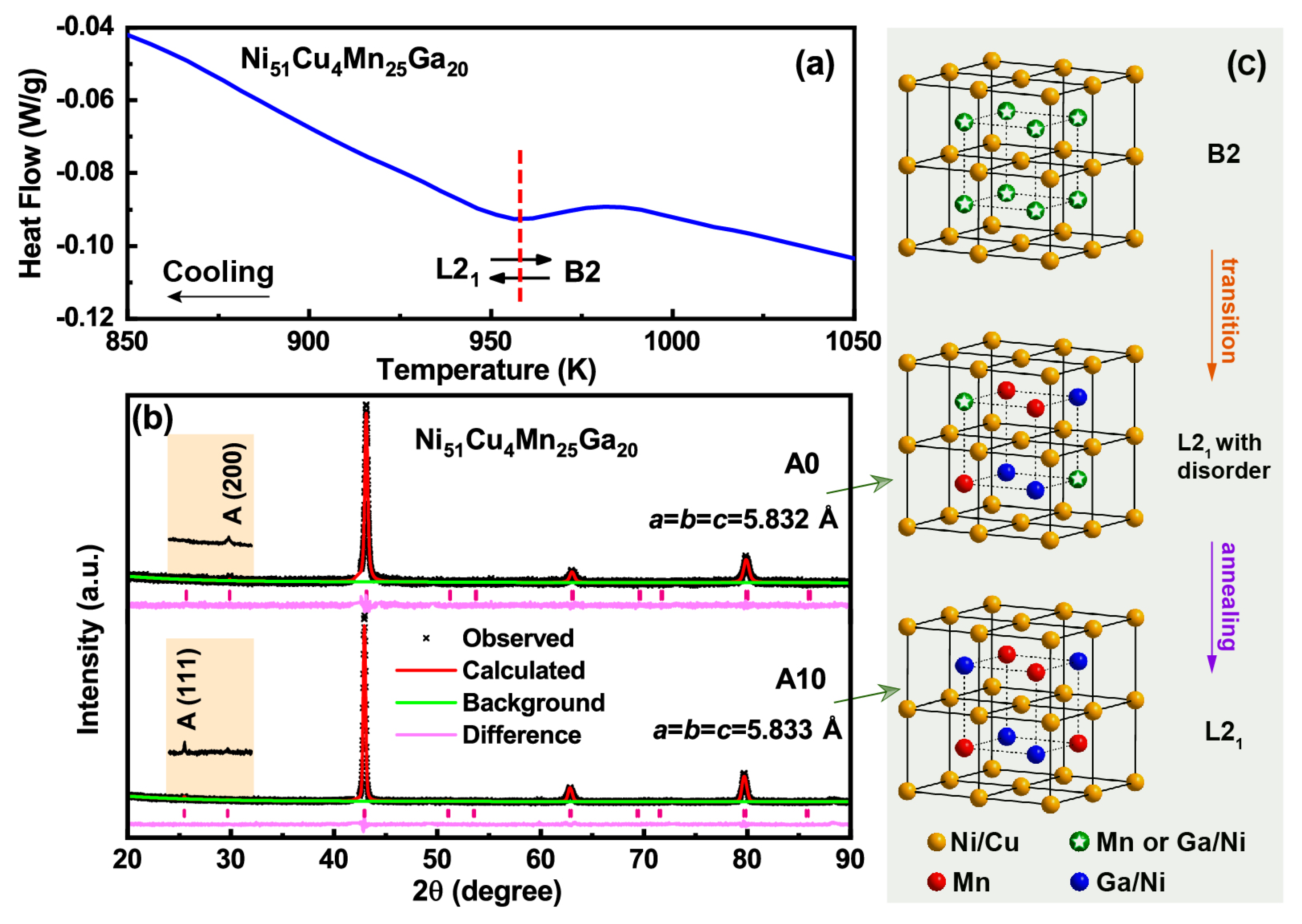

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Chung, D.D.L. Materials for vibration damping. J. Mater. Sci. 2001, 36, 5733–5737. [Google Scholar] [CrossRef]

- Snoek, J.L. Effect of small quantities of carbon and nitrogen on the elastic and plastic properties of iron. Physica 1941, 8, 711–733. [Google Scholar] [CrossRef]

- Zener, C. Stress induced preferential orientation of pairs of solute atoms in metallic solid solution. Phys. Rev. 1947, 71, 34–38. [Google Scholar] [CrossRef]

- Batist, D. Internal Friction of Structural Defects in Crystalline Solids; North-Holland Pub. Co.: Amsterdam, The Netherlands, 1972. [Google Scholar]

- Schaller, R.; Fantozzi, G.; Gremaud, G. Mechanical Spectroscopy Q−1 2001; Trans Tech Publications Ltd.: Bäch, Switzerland, 2001. [Google Scholar]

- Yin, F.X.; Sakaguchi, T.; Tian, Q.C.; Sakurai, A.; Nagai, K. The twinning microstructure and damping behavior in Mn-30Cu (at %) alloy. Mater. Trans. 2005, 46, 2164–2168. [Google Scholar] [CrossRef]

- Fan, G.; Zhou, Y.; Otsuka, K.; Ren, X.; Suzuki, T.; Yin, F. On the internal friction due to the twin boundary-H interaction in martensite. In Proceedings of the International Conference on Martensitic Transformations (ICOMAT-08), Santa Fe, NM, USA, 29 June–5 July 2009; pp. 435–444. [Google Scholar]

- Yoshida, I.; Ono, T.; Asai, M. Internal friction of Ti-Ni alloys. J. Alloys Compd. 2000, 310, 339–343. [Google Scholar] [CrossRef]

- Yoshida, I.; Monma, D.; Iino, K.; Ono, T.; Otsuka, K.; Asai, M. Internal friction of Ti-Ni-Cu ternary shape memory alloys. Mater. Sci. Eng. A 2004, 370, 444–448. [Google Scholar] [CrossRef]

- Fan, G.L.; Zhou, Y.M.; Otsuka, K.; Ren, X. Ultrahigh damping in R-phase state of Ti-Ni-Fe alloy. Appl. Phys. Lett. 2006, 89, 161902. [Google Scholar] [CrossRef]

- Xue, D.Z.; Zhou, Y.M.; Ding, X.D.; Otsuka, K.; Lookman, T.; Sun, J.; Ren, X.B. Ambient-temperature high damping capacity in TiPd-based martensitic alloys. Mater. Sci. Eng. A 2015, 632, 110–119. [Google Scholar] [CrossRef]

- Wang, W.H.; Ren, X.; Wu, G.H. Martensitic microstructure and its damping behavior in Ni52Mn16Fe8Ga24 single crystals. Phys. Rev. B 2006, 73, 092101. [Google Scholar] [CrossRef]

- Seguí, C.; Cesari, E.; Pons, J.; Chernenko, V. Internal friction behaviour of Ni-Mn-Ga. Mater. Sci. Eng. A 2004, 370, 481–484. [Google Scholar] [CrossRef]

- Chang, S.H.; Wu, S.K. Low-frequency damping properties of near-stoichiometric Ni2MnGa shape memory alloys under isothermal conditions. Scr. Mater. 2008, 59, 1039–1042. [Google Scholar] [CrossRef]

- Liu, J.Y.; Wang, J.M.; Jiang, C.B.; Xu, H.B. Internal friction associated with the premartensitic transformation and twin boundary motion of Ni50+xMn25−xGa25 (x= 0 − 2) alloys. J. Appl. Phys. 2013, 113, 103502. [Google Scholar] [CrossRef]

- Aaltio, I.; Lahelin, M.; Söderberg, O.; Heczko, O.; Löfgren, B.; Ge, Y.; Seppälä, J.; Hannula, S.P. Temperature dependence of the damping properties of Ni-Mn-Ga alloys. Mater. Sci. Eng. A 2008, 481, 314–317. [Google Scholar] [CrossRef]

- Aaltio, I.; Mohanchandra, K.P.; Heczko, O.; Lahelin, M.; Ge, Y.; Carman, G.P.; Söderberg, O.; Löfgren, B.; Seppälä, J.; Hannula, S.P. Temperature dependence of mechanical damping in Ni-Mn-Ga austenite and non-modulated martensite. Scr. Mater. 2008, 59, 550–553. [Google Scholar] [CrossRef]

- Gavriljuk, V.G.; Söderberg, O.; Bliznuk, V.V.; Glavatska, N.I.; Lindroos, V.K. Martensitic transformations and mobility of twin boundaries in Ni2MnGa alloys studied by using internal friction. Scr. Mater. 2003, 49, 803–809. [Google Scholar] [CrossRef]

- Wang, W.H.; Liu, G.D.; Wu, G.H. Magnetically controlled high damping in ferromagnetic Ni52Mn24Ga24 single crystal. Appl. Phys. Lett. 2006, 89, 101911. [Google Scholar] [CrossRef]

- Chernenko, V.A.; Pons, J.; Seguí, C.; Cesari, E. Premartensitic phenomena and other phase transformations in Ni-Mn-Ga alloys studied by dynamical mechanical analysis and electron diffraction. Acta Mater. 2002, 50, 53–60. [Google Scholar] [CrossRef]

- Stuhr, U.; Vorderwisch, P.; Kokorin, V.V.; Lindgård, P.A. Premartensitic phenomena in the ferro- and paramagnetic phases of Ni2MnGa. Phys. Rev. B 1997, 56, 14360. [Google Scholar] [CrossRef]

- Otsuka, K.; Wayman, C.M. Shape Memory Materials; Cambridge University Press: Cambridge, UK, 1999. [Google Scholar]

- Salje, E.K.H.; Zhang, H.; Idrissi, H.; Schryvers, D.; Carpenter, M.A.; Moya, X.; Planes, A. Mechanical resonance of the austenite/martensite interface and the pinning of the martensitic microstructures by dislocations in Cu74.08Al23.13Be2.79. Phys. Rev. B 2009, 80, 134114. [Google Scholar] [CrossRef]

- Ahadi, A.; Sun, Q.P. Stress hysteresis and temperature dependence of phase transition stress in nanostructured NiTi-Effects of grain size. Appl. Phys. Lett. 2013, 103, 021902. [Google Scholar] [CrossRef]

- Šittner, P.; Novák, V. Anisotropy of martensitic transformations in modeling of shape memory alloy polycrystals. Int. J. Plast. 2000, 16, 1243–1268. [Google Scholar] [CrossRef]

- Cesari, E.; Seguí, C.; Pons, J.; Perelló, F. Internal friction and Young modulus behaviour of hot-rolled Cu-Al-Ni-Ti shape memory alloys. J. Phys. 1996, 6, 413–416. [Google Scholar] [CrossRef]

- Fan, G.L.; Otsuka, K.; Ren, X.B.; Yin, F.X. Twofold role of dislocations in the relaxation behavior of Ti-Ni martensite. Acta Mater. 2008, 56, 632–641. [Google Scholar] [CrossRef]

- Fan, G.; Zhou, Y.; Otsuka, K.; Ren, X.; Nakamura, K.; Ohba, T.; Suzuki, T.; Yoshida, I.; Yin, F. Effects of frequency, composition, hydrogen and twin boundary density on the internal friction of Ti50Ni50−xCux shape memory alloys. Acta Mater. 2006, 54, 5221–5229. [Google Scholar] [CrossRef]

- Liao, X.Q.; Wang, Y.; Fan, G.L.; Liu, E.K.; Shang, J.R.; Yang, S.; Luo, H.Z.; Song, X.P.; Ren, X.B.; Otsuka, K. High damping capacity of a Ni-Cu-Mn-Ga alloy in wide ambient-temperature range. J. Alloys Compd. 2017, 695, 2400–2405. [Google Scholar] [CrossRef]

- Sánchez-Alarcos, V.; Recarte, V.; Pérez-Landazábal, J.I.; Cuello, G.J. Correlation between atomic order and the characteristics of the structural and magnetic transformations in Ni-Mn-Ga shape memory alloys. Acta Mater. 2007, 55, 3883–3889. [Google Scholar] [CrossRef]

- Recarte, V.; Pérez-Landazabal, J.I.; Sánchez-Alarcos, V.; Rodríguez-Velamazán, J.A. Dependence of the martensitic transformation and magnetic transition on the atomic order in Ni-Mn-In metamagnetic shape memory alloys. Acta Mater. 2012, 60, 1937–1945. [Google Scholar] [CrossRef]

- Ghosh, A.; Mandal, K. Effect of structural disorder on the magnetocaloric properties of Ni-Mn-Sn alloy. Appl. Phys. Lett. 2014, 104, 031905. [Google Scholar] [CrossRef]

- Li, S.D.; Yuan, Z.R.; Lü, L.Y.; Liu, M.M.; Huang, Z.G.; Zhang, F.M.; Du, Y.W. Effect of annealing on the magnetic entropy change of CoMnSb alloy. Mater. Sci. Eng. A 2006, 428, 332–335. [Google Scholar] [CrossRef]

- Huang, C.H.; Wang, Y.; Tang, Z.; Liao, X.Q.; Yang, S.; Song, X.P. Influence of atomic ordering on elastocaloric and magnetocaloric effects of a Ni-Cu-Mn-Ga ferromagnetic shape memory alloy. J. Alloys Compd. 2015, 630, 244–249. [Google Scholar] [CrossRef]

- Gallardo, M.C.; Manchado, J.; Romero, F.J.; del Cerro, J.; Salje, E.K.H.; Planes, A.; Vives, E.; Romero, R.; Stipcich, M. Avalanche criticality in the martensitic transition of Cu67.64Zn16.71Al15.65 shape-memory alloy: A calorimetric and acoustic emission study. Phys. Rev. B 2010, 81, 174102. [Google Scholar] [CrossRef]

- Diestel, A.; Backen, A.; Rößler, U.K.; Schultz, L.; Fähler, S. Twin boundary energy of hierarchically twinned magnetic shape memory alloys. Appl. Phys. Lett. 2011, 99, 092512. [Google Scholar] [CrossRef]

- Overholser, R.W.; Wuttig, M.; Neumann, D.A. Chemical ordering in Ni-Mn-Ga Heusler alloys. Scr. Mater. 1999, 40, 1095–1102. [Google Scholar] [CrossRef]

- Toby, B.H. EXPGUI, a graphical user interface for GSAS. J. Appl. Cryst. 2001, 34, 210–213. [Google Scholar] [CrossRef]

- Larson, A.C.; Von Dreele, R.B. General Structure Analysis System (GSAS); Los Alamos National Laboratory LAUR: Santa Fe, NM, USA, 2004; pp. 86–748. [Google Scholar]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liao, X.; Xu, X.; Gao, L.; Khan, M.T.; Hao, C.; Cheng, F.; He, Y.; Wang, Y. Influence of Annealing on the Damping Behavior of Ni-Cu-Mn-Ga Ferromagnetic Shape Memory Alloys. Materials 2020, 13, 480. https://doi.org/10.3390/ma13020480

Liao X, Xu X, Gao L, Khan MT, Hao C, Cheng F, He Y, Wang Y. Influence of Annealing on the Damping Behavior of Ni-Cu-Mn-Ga Ferromagnetic Shape Memory Alloys. Materials. 2020; 13(2):480. https://doi.org/10.3390/ma13020480

Chicago/Turabian StyleLiao, Xiaoqi, Xin Xu, Lumei Gao, Muhammad Tahir Khan, Chunxi Hao, Fei Cheng, Yuewei He, and Yu Wang. 2020. "Influence of Annealing on the Damping Behavior of Ni-Cu-Mn-Ga Ferromagnetic Shape Memory Alloys" Materials 13, no. 2: 480. https://doi.org/10.3390/ma13020480

APA StyleLiao, X., Xu, X., Gao, L., Khan, M. T., Hao, C., Cheng, F., He, Y., & Wang, Y. (2020). Influence of Annealing on the Damping Behavior of Ni-Cu-Mn-Ga Ferromagnetic Shape Memory Alloys. Materials, 13(2), 480. https://doi.org/10.3390/ma13020480