Preparation and Mechanical Behavior of Ultra-High Strength Low-Carbon Steel

Abstract

1. Introduction

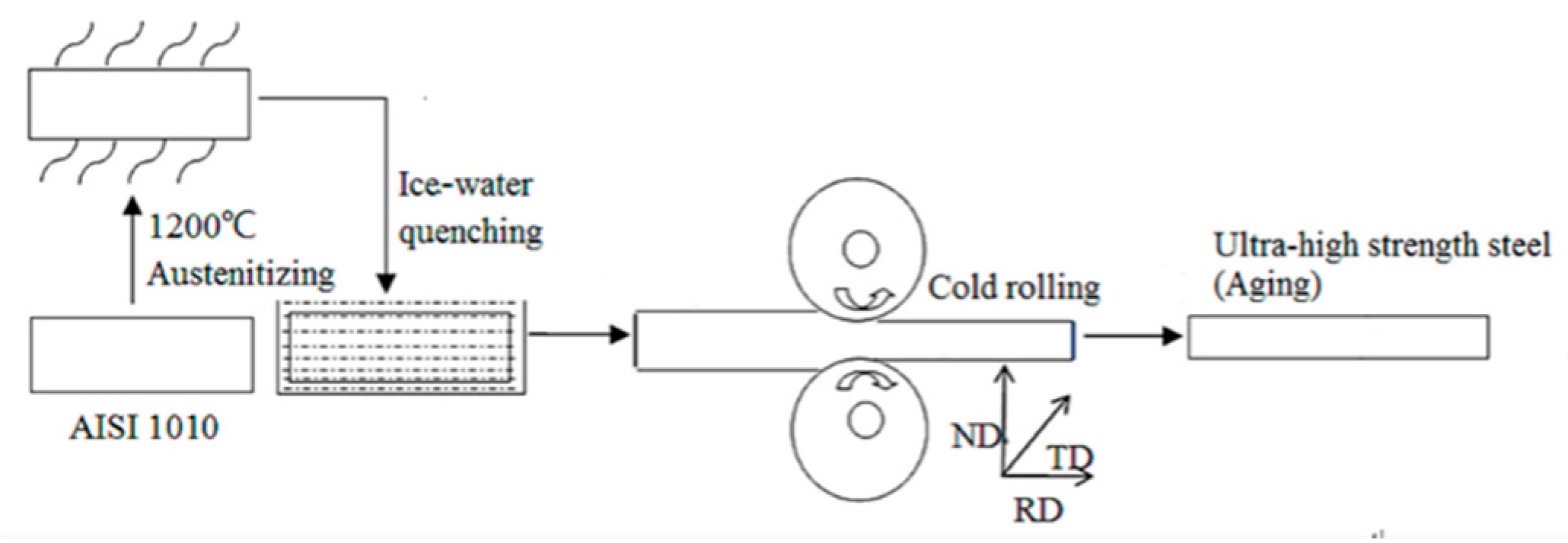

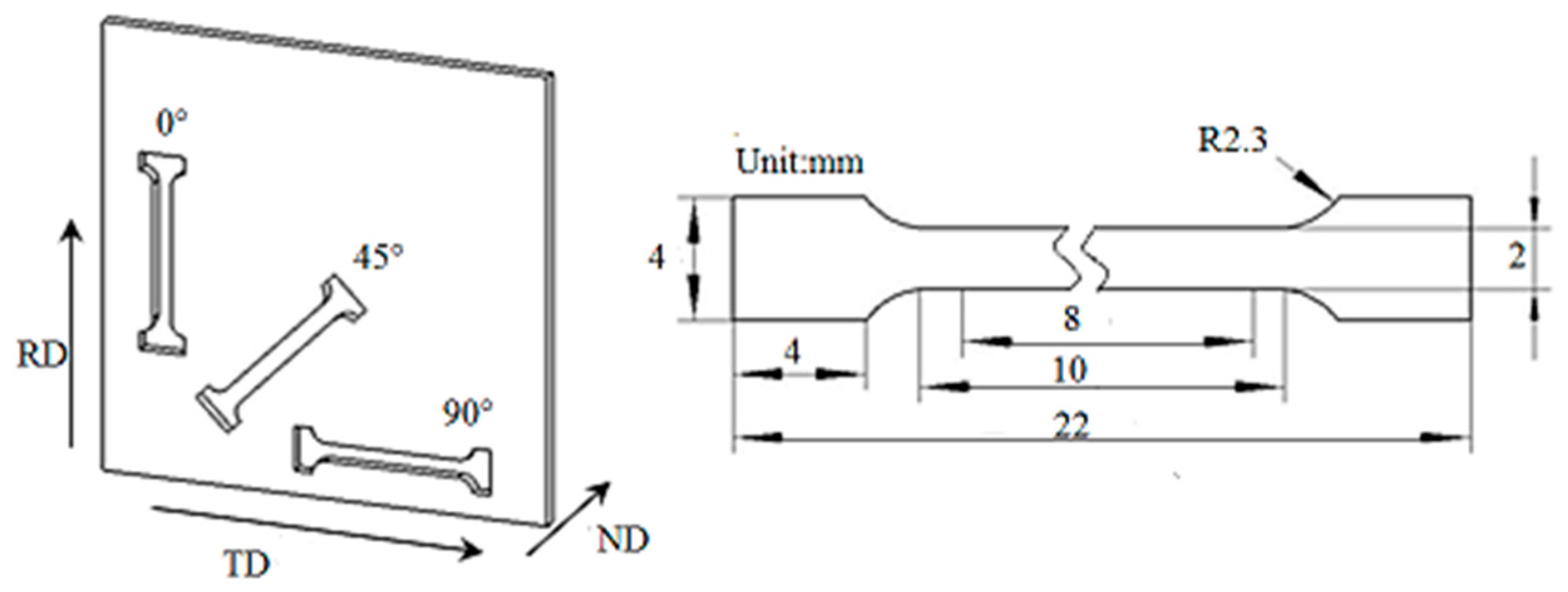

2. Materials and Methods

3. Results

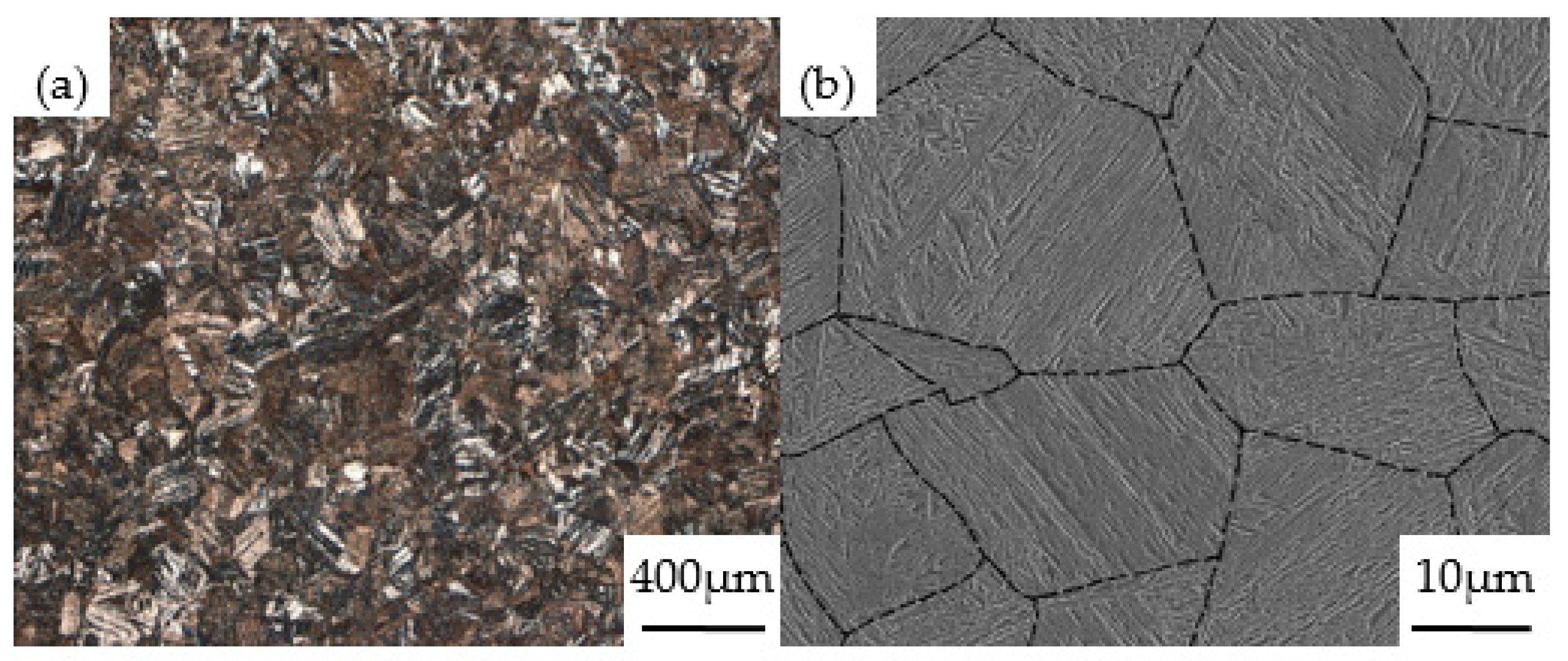

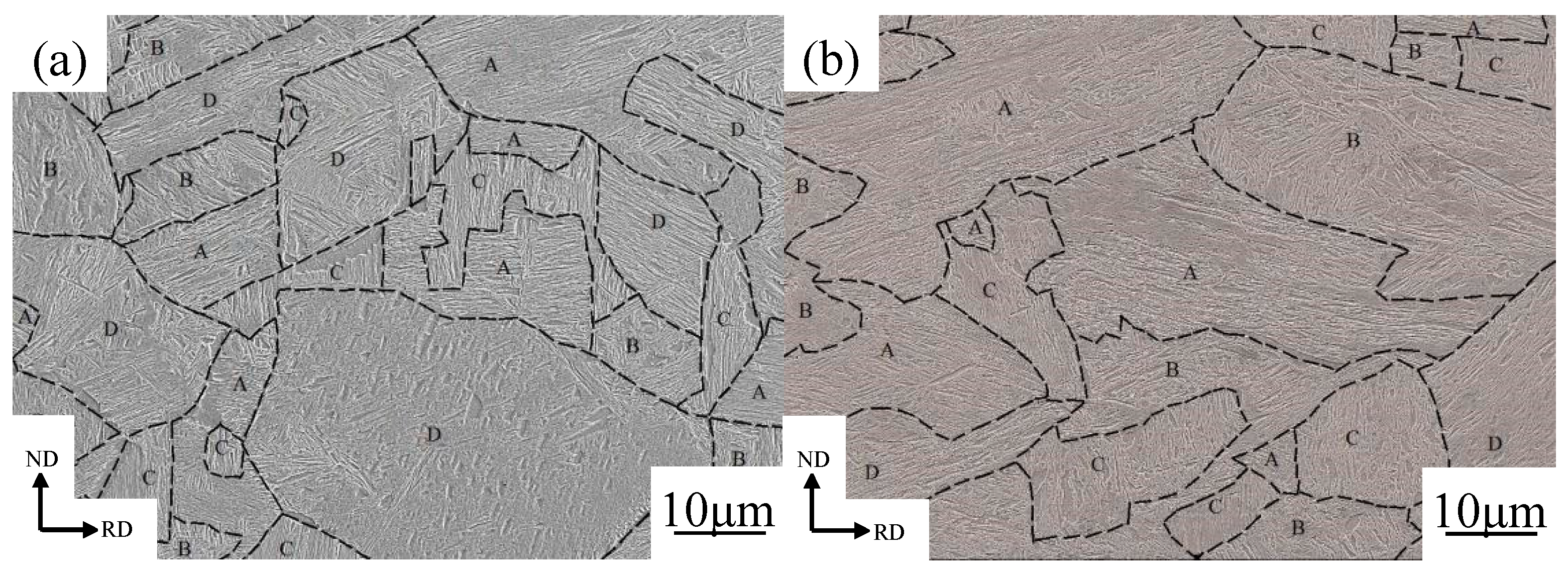

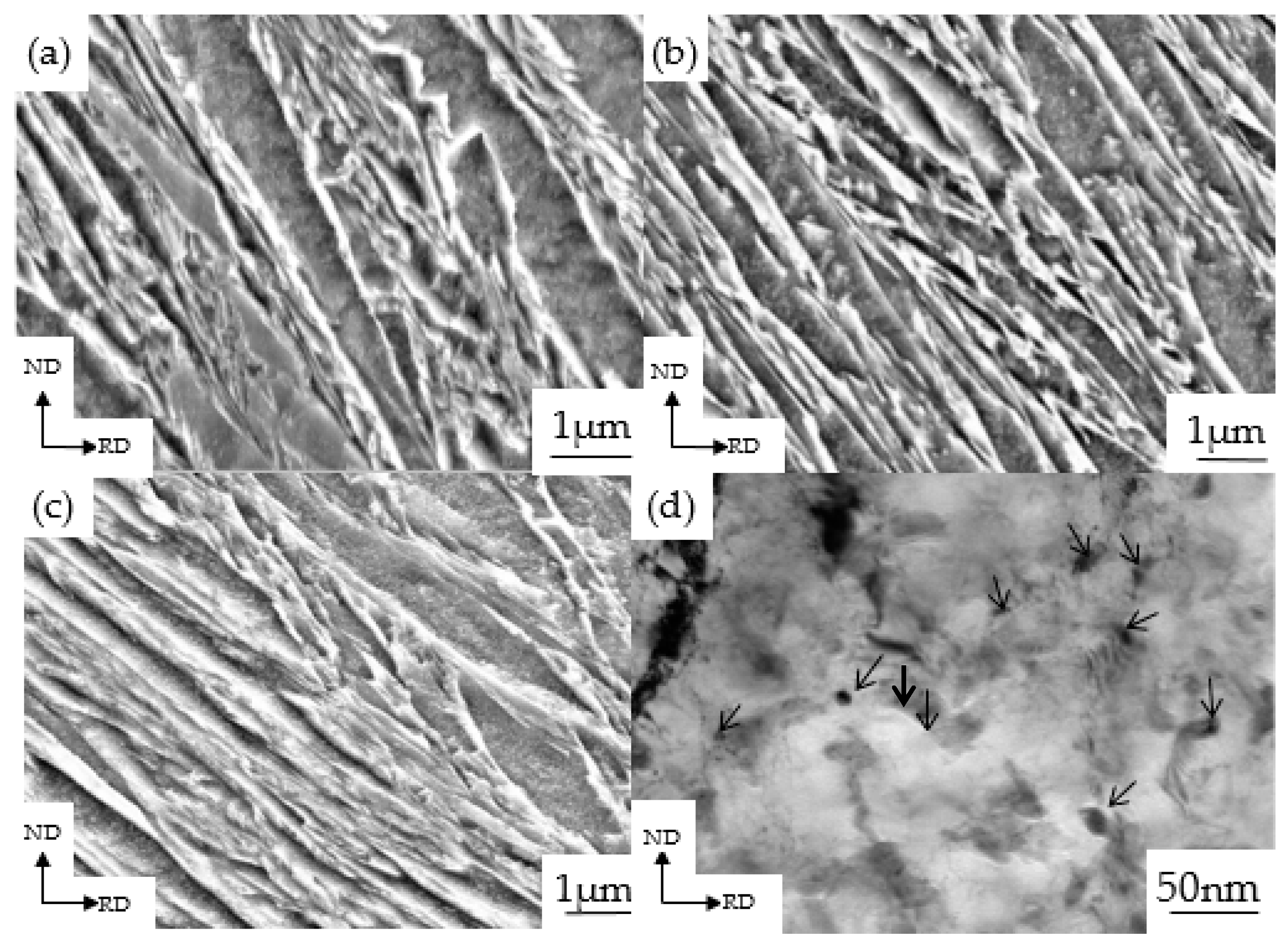

3.1. Microstructure after Cold Rolling

- A

- Very fine lamellar structure mainly elongated parallel to the RD.

- B

- Irregularly bent lamellar structure.

- C

- Lump of martensite laths with shear bands that is parallel to the ND.

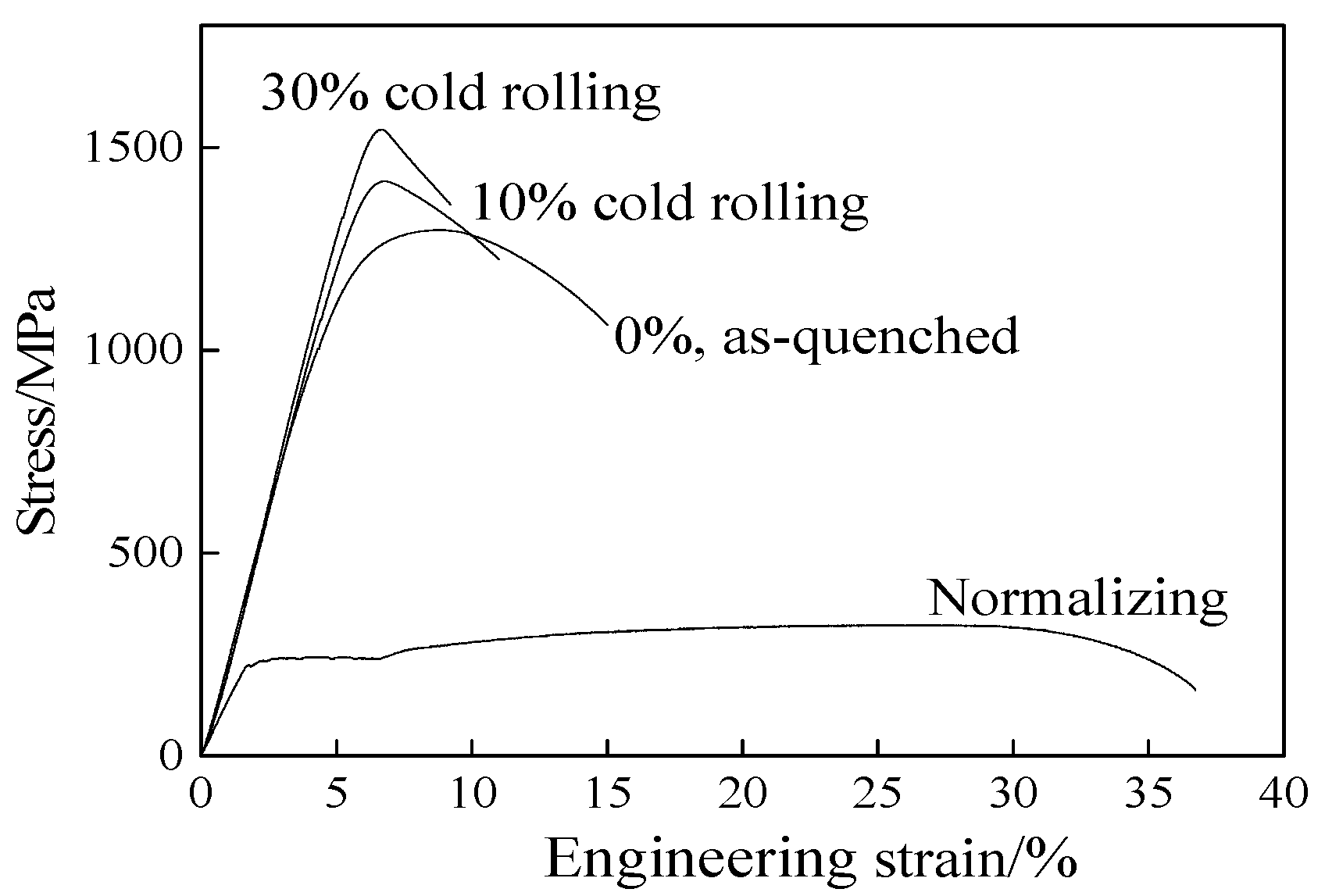

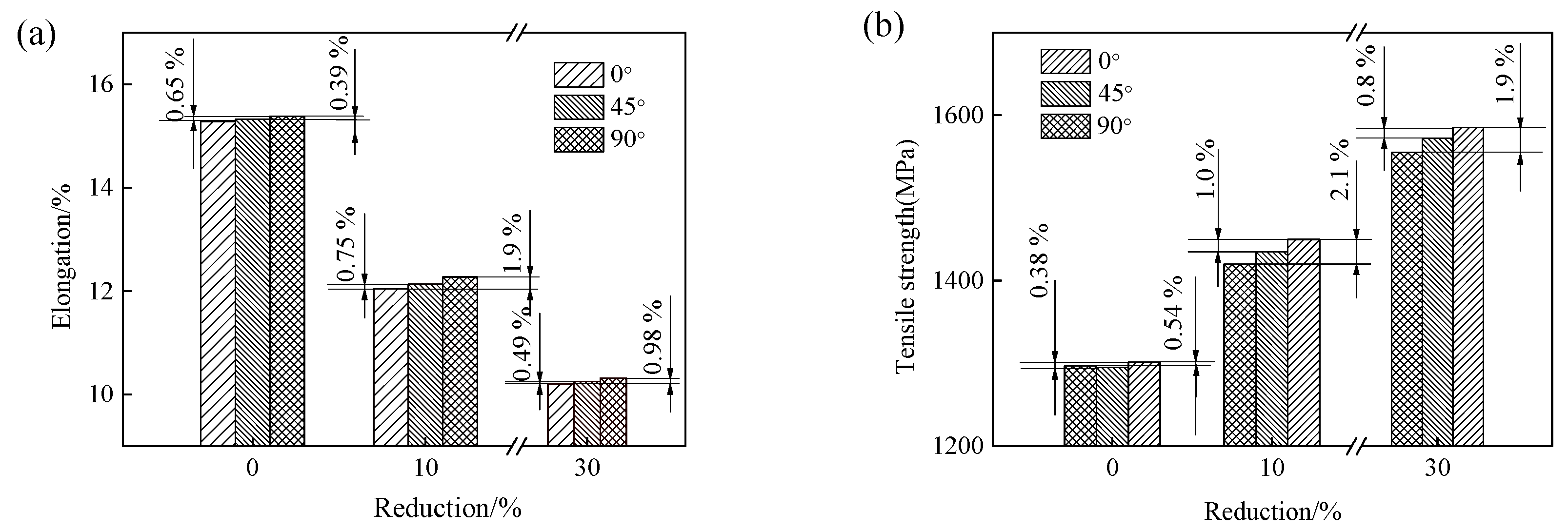

3.2. Mechanical Properties after Cold Rolling

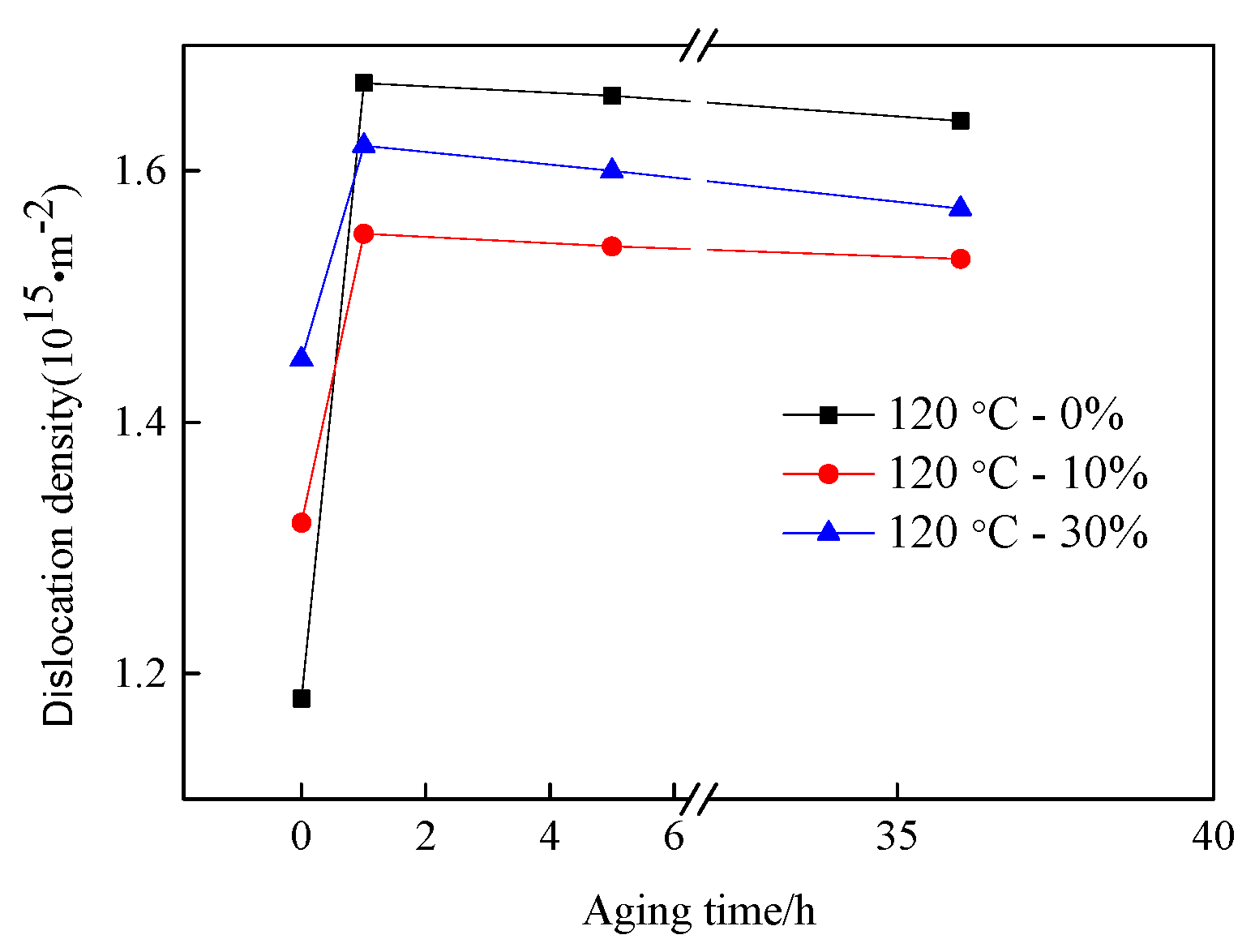

3.3. Effects of Aging

4. Discussion

5. Conclusions

- (1)

- The deformed structures (LDC, IBL, and KL) were present in the 10% and 30% cold rolled specimens and fairly large amount of the martensite structure remained the same. The area occupied by the LDC, IBL and KL structure increased from 24, 14, and 13% to 40, 31, and 17% with increasing rolling reductions. The martensite lath began to be elongated along the RD and the martensite structure was gradually refined.

- (2)

- As the reduction increased, the hardness and the tensile strength gradually increased, and the elongation decreased. When the reduction reached to 30%, the hardness and tensile strength increased to 466 HV and 1585 MPa, respectively. However, the elongation decreased to 10.2%. When the tensile specimens were selected at 0°, 45°, and 90° in the RD, the specimens exhibited different strength and elongation. The deviation was calculated to be within 3%. The anisotropy of the material properties was not obvious for the martensitic steel and the cold rolled martensitic steel at low strain (below 30% reduction).

- (3)

- The strength of the initial martensite and deformed martensite showed an increasing trend at first, and then a decreasing trend with increasing aging time, the tensile strength reached to a maximum value after aging for 5 h. The tensile strength of the as-quenched martensitic steel and 30% cold rolled martensitic steel increased to 1339 and 1625 MPa after aging treatment for 5 h, respectively. The elongation of the initial martensite and deformed martensite increased with increasing aging time. When the aging treatment time reached to 36 h, the elongation of the as-quenched martensitic steel and 30% cold rolled specimen increased to 17 and 11%, respectively.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Dong, H.S.; Kim, B.C.; Park, K.T.; Choo, W.Y. Microstructural changes in equal channel angular pressed low carbon steel by static annealing. Acta Mater. 2000, 48, 3245–3252. [Google Scholar] [CrossRef]

- Kaibyshev, O.A. Grain refinement in commercial alloys due to high plastic deformations and phase transformations. J Mater. Process. Technol. 2001, 117, 300–306. [Google Scholar] [CrossRef]

- Morovvati, M.R.; Mollaei-Dariani, B. The formability investigation of CNT-reinforced aluminum nano-composite sheets manufactured by accumulative roll bonding. Int. J. Adv. Manu. Technol. 2018, 95, 3523–3533. [Google Scholar] [CrossRef]

- Sauvage, X.; Ganeev, A.; Ivanisenko, Y.; Enikeev, N.; Murashkin, M.; Valiev, R.Z. Grain Boundary Segregation in UFG Alloys Processed by Severe Plastic Deformation. Adv. Eng. Mat. 2012, 14, 968–974. [Google Scholar] [CrossRef]

- Ghassemali, E.; Kermanpur, A.; Najafizadeh, A. Microstructural Evolution in a Low Carbon Steel During Cold Rolling and Subsequent Annealing. J. Nanosci. Nanotechnol. 2010, 10, 6177–6181. [Google Scholar] [CrossRef] [PubMed]

- Lv, Z.; Jiang, P.; Wang, Z.; Zhang, W.; Sun, S.; Fu, W. XRD analyses on dissolution behavior of cementite in eutectoid pearlitic steel during cold rolling. Mater. Lett. 2008, 62, 2825–2827. [Google Scholar] [CrossRef]

- Fukuda, Y.; Oh-Ishi, K.; Horita, Z.; Langdon, T.G. Processing of a low-carbon steel by equal-channel angular pressing. Acta Mater. 2002, 50, 1359–1368. [Google Scholar] [CrossRef]

- He, T.; Xiong, Y.; Ren, F.; Guo, Z.; Volinsky, A.A. Microstructure of ultra-fine-grained high carbon steel prepared by equal channel angular pressing. Mat. Sci. Eng. A-Struct. 2012, 535, 306–310. [Google Scholar] [CrossRef]

- Xu, J.; Li, J.; Zhu, X.; Fan, G.; Shan, D.; Guo, B. Microstructural Evolution at Micro/Meso-Scale in, an Ultrafine-Grained Pure Aluminum Processed by Equal-Channel Angular Pressing with Subsequent Annealing Treatment. Materials 2015, 8, 7447–7460. [Google Scholar] [CrossRef]

- Dobathin, S.V.; Shagalina, S.V.; Sleptsov, O.I.; Krasil’nikov, N.A. Effect of the initial state of a low-carbon steel on nanostructure formation during high-pressure torsion at high strains and pressures. Russ. Metall. 2006, 5, 445–452. [Google Scholar] [CrossRef]

- Song, R.; Pong, D.; Raabe, D.; Speera, J.G.; Matlocka, D.K. Overview of processing, microsture and mechanical properties of ultrafine grained bcc steels. Mater. Sci. Eng. A-Struct. 2006, 441, 1–17. [Google Scholar] [CrossRef]

- Kwan, C.; Wang, Z. Cyclic Deformation of Ultra-Fine Grained Commercial Purity Aluminum Processed by Accumulative Roll-Bonding. Materials 2013, 6, 3469–3481. [Google Scholar] [CrossRef] [PubMed]

- Su, L.; Lu, C.; Tieu, K.; Deng, G. Annealing Behavior of Accumulative Roll Bonding Processed Aluminum Composites. Steel Res. Int. 2013, 84, 1241–1245. [Google Scholar] [CrossRef]

- Saito, Y.; Utsunomiya, H.; Tsuji, N.; Sakai, T. Novel ultra-high straining process for bulk materials—development of the accumulative roll-bonding (ARB) process. Acta Mater. 1999, 47, 579–583. [Google Scholar] [CrossRef]

- Kobayashi, C.; Sakai, T.; Belyakov, A.; Miura, H. Ultrafine grain development in copper during multidirectional forging at 195 K. Philos. Mag. Lett. 2007, 87, 16. [Google Scholar] [CrossRef]

- Wang, B.; Wang, X.; Li, J. Formation and Microstructure of Ultrafine-Grained Titanium Processed by Multi-Directional Forging. J. Mater. Eng. Perform. 2016, 25, 2521–2527. [Google Scholar] [CrossRef]

- Salishchev, G.; Zaripov, R.; Galeev, R.; Valiakhmetov, O. Nanocrystalline structure formation during severe plastic deformation in metals and their deformation behaviour. Nanostruct. Mater. 1999, 56, 913–916. [Google Scholar] [CrossRef]

- Valiev, R.Z.; Islamgaliev, R.K.; Alexandrov, I.V. Bulk nanostructured materials from severe plastic deformation. Prog. Mater. Sci. 2000, 45, 103–189. [Google Scholar] [CrossRef]

- Valiev, R.Z.; Ivanisenko, Y.V.; Rauch, E.F.; Baudelet, B. Structure and deformaton behaviour of Armco iron subjected to severe plastic deformation. Acta Mater. 1996, 44, 4705–4712. [Google Scholar] [CrossRef]

- Astafurova, E.G.; Dobatkin, S.V.; Naydenkin, E.V.; Shagalina, S.V.; Zakharova, G.G.; Ivanov, Y.F. Structural and phase transformations in nanostructured 0.1% C-Mn-V-Ti steel during cold deformation by high pressure torsion and subsequent heating. Nanotechnol. Russ. 2009, 4, 109–120. [Google Scholar] [CrossRef]

- Mousavi, A.S.H.; Jafarian, H.R.; Park, N. The effect of severe plastic deformation and annealing conditions on mechanical properties and restoration phenomena in an ultrafine-grains Fe-28.5%Ni steel. Philos. Mag. 2018, 98, 1–24. [Google Scholar] [CrossRef]

- Wang, J.T.; Xu, C.; Du, Z.Z.; Qu, G.Z.; Langdon, T.G. Microstructure and properties of a low-carbon steel processed by equal-channel angular pressing. Mat. Sci. Eng. A-Struct. 2005, 410, 312–315. [Google Scholar] [CrossRef]

- Senuma, T. Advances in Physical Metallurgy and Processing of Steels. Physical Metallurgy of Modern High Strength Steel Sheets. ISIJ Int. 2001, 41, 520–532. [Google Scholar] [CrossRef]

- Morito, S.; Yoshida, H.; Maki, T.; Huang, X. Effect of block size on the strength of lath martensite in low carbon steels. Mater. Sci. Eng. 2006, 438, 237–240. [Google Scholar] [CrossRef]

- Galindo-Nava, E.I.; Rivera-Díaz-del-Castillo, P.E.J. A model for the microstructure behaviour and strength evolution in lath martensite. Acta Mater. 2015, 98, 81–93. [Google Scholar] [CrossRef]

- Hutchinson, B.; Hagström, J.; Karlsson, O.; Lindell, D.; Tornberg, M.; Lindberg, F.; Thuvander, M. Microstructures and hardness of as-quenched martensites (0.1–0.5%C). Acta Mater. 2011, 59, 5845–5858. [Google Scholar] [CrossRef]

- Morito, S.; Nishikawa, J.; Maki, T. Dislocation density within lath martensite in Fe-C and Fe-Ni alloy. ISIJ Int. 2003, 43, 1475. [Google Scholar] [CrossRef]

- Christien, F.; Telling, M.T.F.; Knight, K.S. Neutron diffraction in situ monitoring of the dislocation density during martensitic transformation in a stainless steel. Scr. Mater. 2013, 68, 506–509. [Google Scholar] [CrossRef]

- Krauss, G. Steels: Processing, Structure, and Performance; ASM International: Materials Park, OH, USA, 2005. [Google Scholar]

- Huang, X.; Morito, S.; Hansen, N.; Maki, T. Ultrafine Structure and High Strength in Cold-Rolled Martensite. Metall. Mater. Trans. 2012, 43, 3517–3531. [Google Scholar] [CrossRef]

- Li, B.L.; Godfrey, A.; Meng, Q.C.; Liu, Q.; Hansen, N. Microstructural evolution of IF-steel during cold rolling. Acta Mater. 2004, 52, 1069–1081. [Google Scholar] [CrossRef]

- Ueji, R.; Tsuji, N.; Minamino, Y.; Koizumi, Y. Ultragrain refinement of plain low carbon steel by cold-rolling and annealing of martensite. Acta Mater. 2002, 50, 4177–4189. [Google Scholar] [CrossRef]

- Ueji, R.; Tsuji, N.; Minamino, Y.; Koizumi, Y. Effect of rolling reduction on ultrafine grained structure and mechanical properties of low-carbon steel thermomechanically processed from martensite starting structure. Sci. Technol. Adv. Mater. 2004, 5, 153–162. [Google Scholar] [CrossRef]

- Maki, T. The Morphology of Micro-structure Composed of Lath Martensites in Steels. Trans. ISIJ 1980, 20, 207–214. [Google Scholar] [CrossRef]

- Morito, S.; Tanaka, H.; Furuhara, T.; Maki, T. Recovery and Recrystallization of Lath Martensite in an Ultra-low Carbon Steel. In Proceedings of the 4th International Conference on Recrystallization and Related Phenomena (RECRYSTALLIZATION 99), Tsukuba City, Japan, 13–16 July 1999; JIM: Sendai, Japan; pp. 295–300. [Google Scholar]

- Tsuji, N.; Ueji, R.; Minamino, Y.; Saito, Y. A new and simple process to obtain nano-structured bulk low-carbon steel with superior mechanical property. Scr. Mater. 2002, 46, 305–310. [Google Scholar] [CrossRef]

- Saha, D.C.; Biro, E.; Gerlich, A.P.; Zhou, Y. Effects of tempering mode on the structural changes of martensite. Mater. Sci. Eng. A. 2016, 673, 467–475. [Google Scholar] [CrossRef]

- Thomson, R.C.; Miller, M.K. Carbide precipitation in martensite during the early stages of tempering Cr- and Mo-containing low alloy steels. Acta Mater. 1998, 46, 2203–2213. [Google Scholar] [CrossRef]

- Jung, M.; Lee, S.J.; Lee, Y.K. Microstructural and Dilatational Changes during Tempering and Tempering Kinetics in Martensitic Medium-Carbon Steel. Metal. Mater. Trans. A 2009, 40, 551–559. [Google Scholar] [CrossRef]

- Gay, P.; Hirsch, P.B.; Kelly, A. The estimation of dislocation densities in metals from X-ray data. Acta Metal. 1953, 1, 315–319. [Google Scholar] [CrossRef]

- Williamson, G.K.; Smallman, R.E., III. Dislocation densities in some annealed and cold-worked metals from measurements on the X-ray debye-scherrer spectrum. Philos. Mag. 1956, 1, 34–46. [Google Scholar] [CrossRef]

- Wilde, J.; Cerezo, A.; Smith, G.D.W. Three-dimensional atomic-scale mapping of a cottrell atmosphere around a dislocation in iron. Scr. Mater. 2000, 43, 39–48. [Google Scholar] [CrossRef]

- Speich, G.R. Tempering of low-carbon martensite. Trans. TMS-AIME 1969, 245, 2553–2564. [Google Scholar]

- Taylor, K.A.; Olson, G.B.; Cohen, M.; Sande, J.B.V. Carbide precipitation during stage Ⅰ tempering of Fe-Ni-C martensites. Metall. Mater. Trans. A 1989, 20, 2749–2765. [Google Scholar] [CrossRef]

- Krauss, G. Tempering of Lath Martensite in Low and Medium Carbon Steels. Assessment and Challenges. Steel Res. Int. 2017, 88, 1700038. [Google Scholar] [CrossRef]

- Yang, G.W.; Yong, Q.L.; Sun, X.J.; Li, Z. Effects of process on microstructure and mechanical properties of 1500 MPa grade low carbon Nb-Ti low alloy steel. Cailiao Rechuli Xuebao/Trans. Mater Heat Treat. 2013, 34, 65–72. [Google Scholar]

- Caron, R.N.; Krauss, G. The tempering of Fe-C lath martensite. Metall. Trans. 1972, 3, 2381–2389. [Google Scholar] [CrossRef]

- Saeglitz, M.; Krauss, G. Deformation, fracture, and mechanical properties of low-temperature-tempered martensite in SAE 43xx steel. Metall. Mater. Trans. A 1997, 28, 377–387. [Google Scholar] [CrossRef]

- Krauss, G. Deformation and fracture inmartensitic carbon steels tempered at low temperatures. Metall. Mater. Trans. B 2001, 32, 205–221. [Google Scholar] [CrossRef]

- Cahn, R.W.; Haasen, P. Physical Metallurgy, 3rd ed.; Part II; North-Holland Physics Publishing: Amsterdam, The Netherlands, 1983; p. 1599. [Google Scholar]

- Huang, X.; Kamikawa, N.; Tsuji, N.; Hansen, N. Nanostructured Aluminum and IF Steel Produced by Rolling-a Comparative Study. ISIJ Int. 2008, 48, 1080–1087. [Google Scholar] [CrossRef]

- Huang, X.; Hansen, N.; Tsuji, N. Hardening by annealing and softening by deformation in nanostructured metals. Science 2006, 312, 249–251. [Google Scholar] [CrossRef]

- Greer, J.R.; Oliver, W.C.; Nix, W.D. Size dependence of mechanical properties of gold at the micron scale in the absence of strain gradients. Acta Mater. 2005, 80, 1821–1830. [Google Scholar] [CrossRef]

- Schiotz, J.; Jacobsen, K.W. A maximum in the strength of nanocrystalline copper. Jacobsen Sci. 2003, 301, 1357. [Google Scholar] [CrossRef] [PubMed]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lv, Z.; Qian, L.; Liu, S.; Zhan, L.; Qin, S. Preparation and Mechanical Behavior of Ultra-High Strength Low-Carbon Steel. Materials 2020, 13, 459. https://doi.org/10.3390/ma13020459

Lv Z, Qian L, Liu S, Zhan L, Qin S. Preparation and Mechanical Behavior of Ultra-High Strength Low-Carbon Steel. Materials. 2020; 13(2):459. https://doi.org/10.3390/ma13020459

Chicago/Turabian StyleLv, Zhiqing, Lihua Qian, Shuai Liu, Le Zhan, and Siji Qin. 2020. "Preparation and Mechanical Behavior of Ultra-High Strength Low-Carbon Steel" Materials 13, no. 2: 459. https://doi.org/10.3390/ma13020459

APA StyleLv, Z., Qian, L., Liu, S., Zhan, L., & Qin, S. (2020). Preparation and Mechanical Behavior of Ultra-High Strength Low-Carbon Steel. Materials, 13(2), 459. https://doi.org/10.3390/ma13020459