Solution Processable CrN Thin Films: Thickness-Dependent Electrical Transport Properties

Abstract

1. Introduction

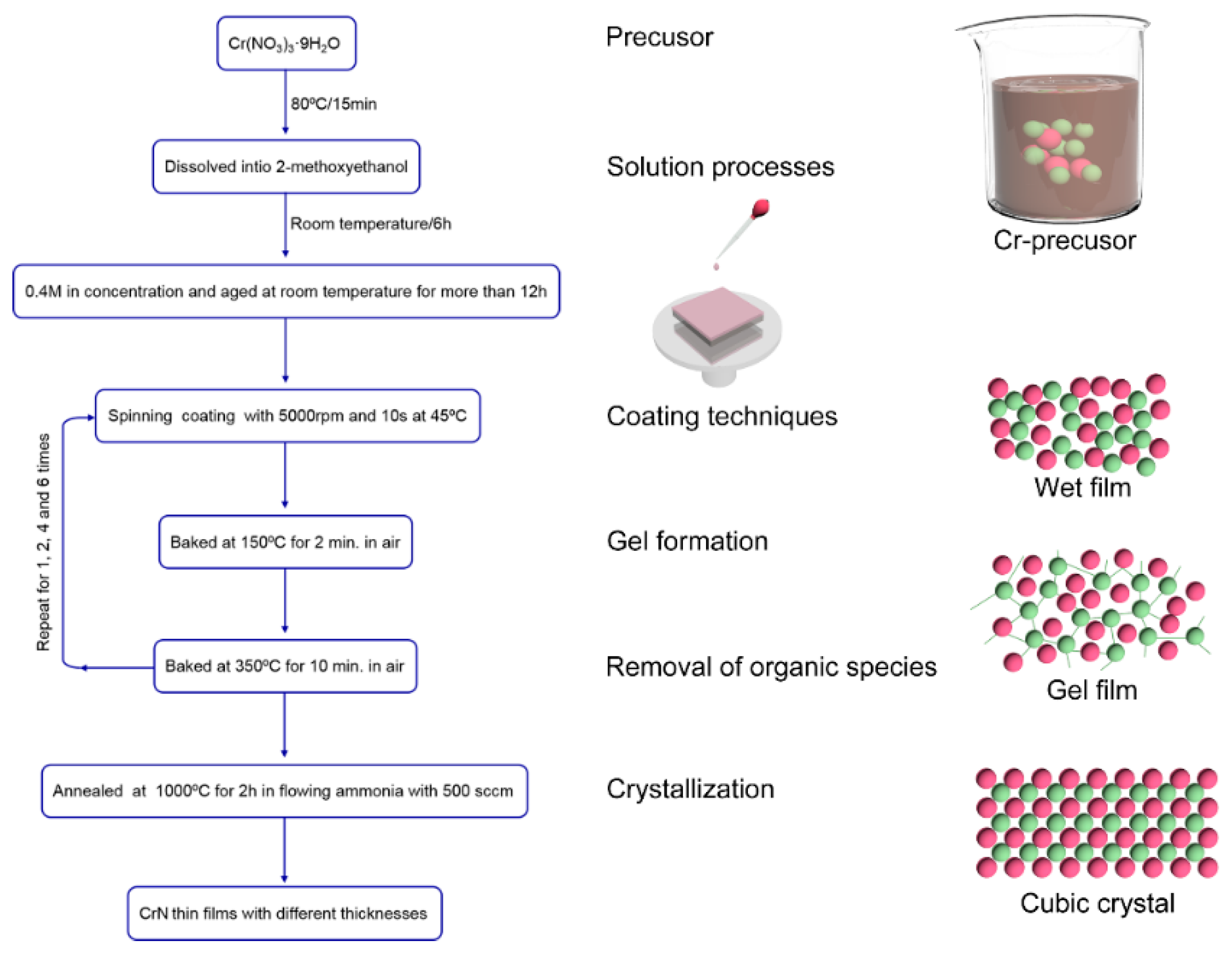

2. Materials and Methods

3. Results and Discussion

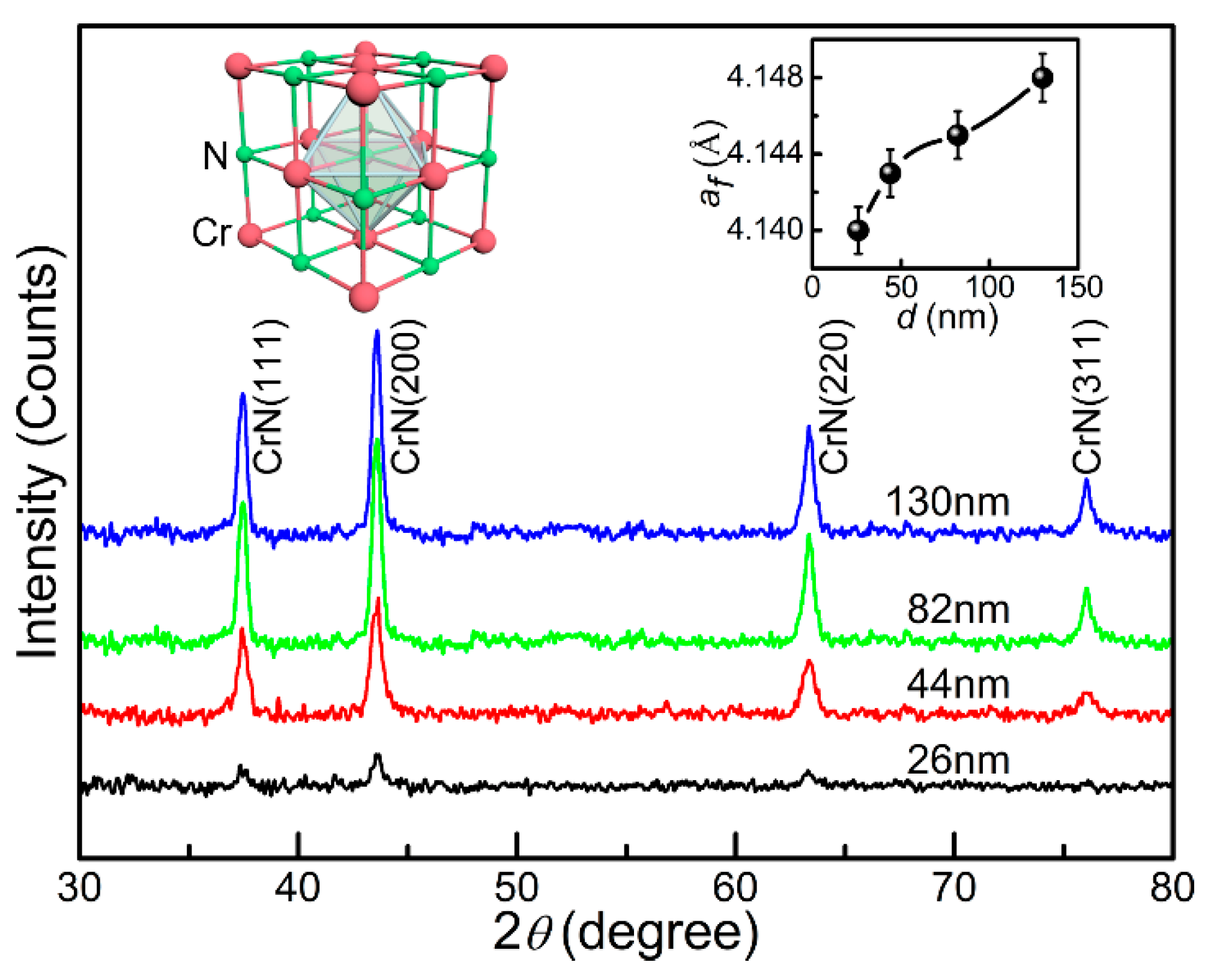

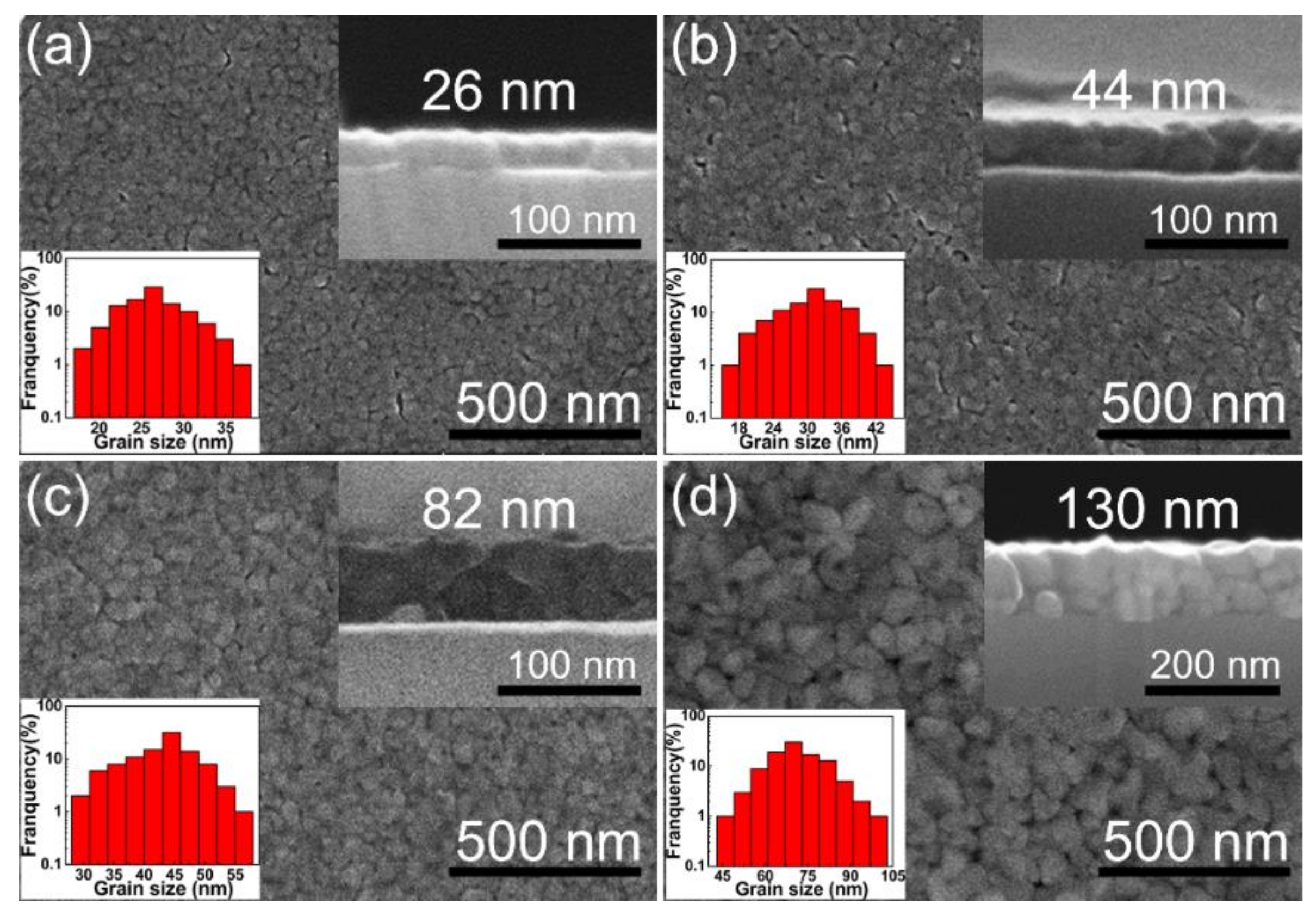

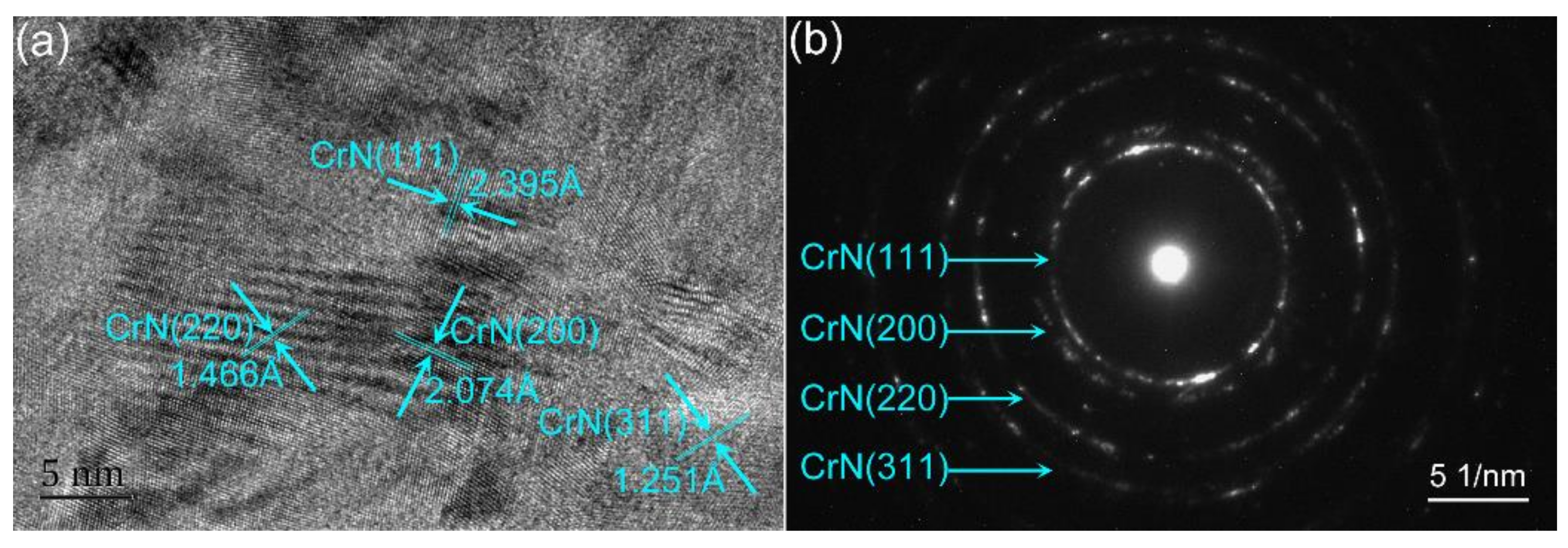

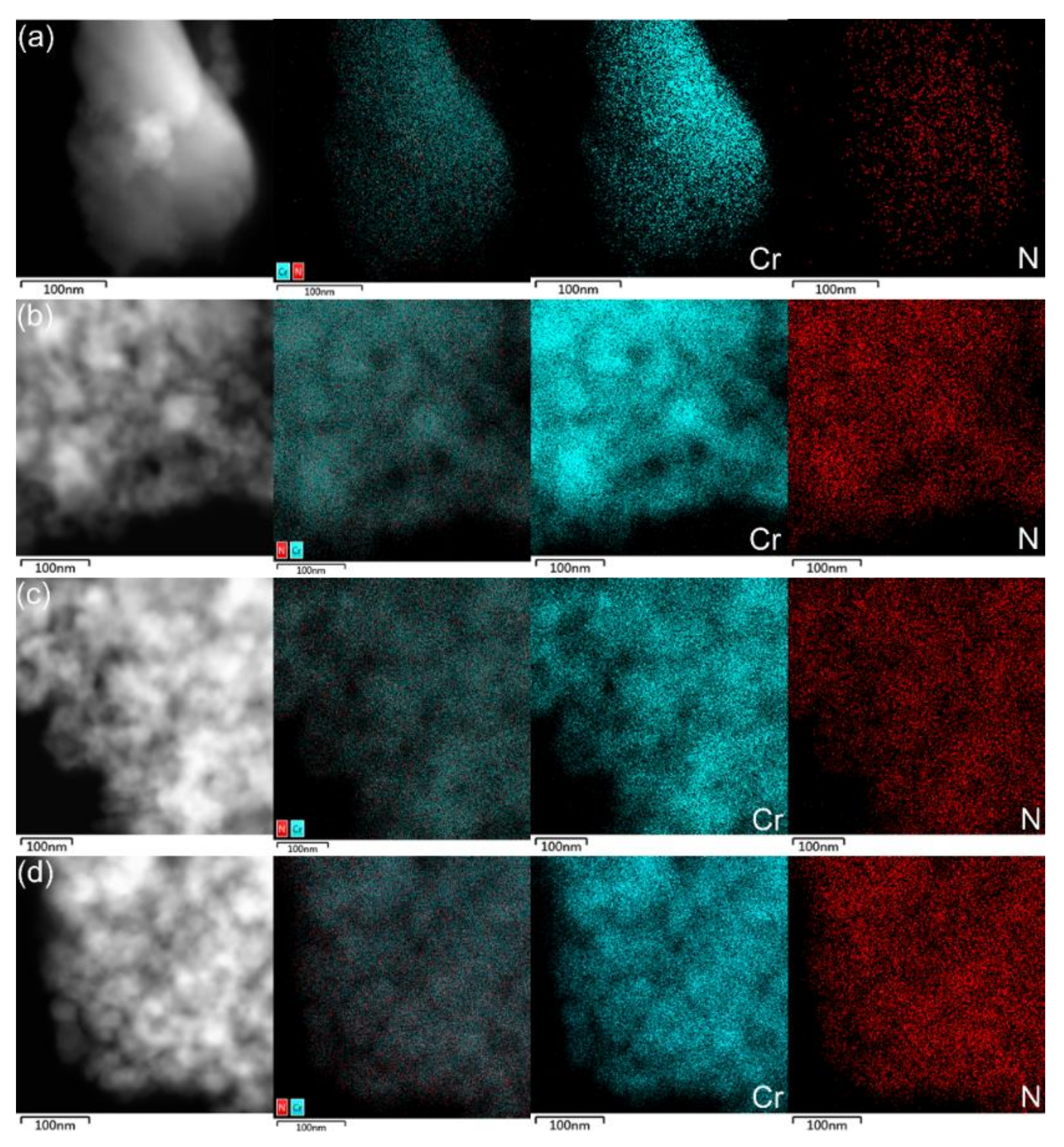

3.1. Structural and Surface Morphology Studies

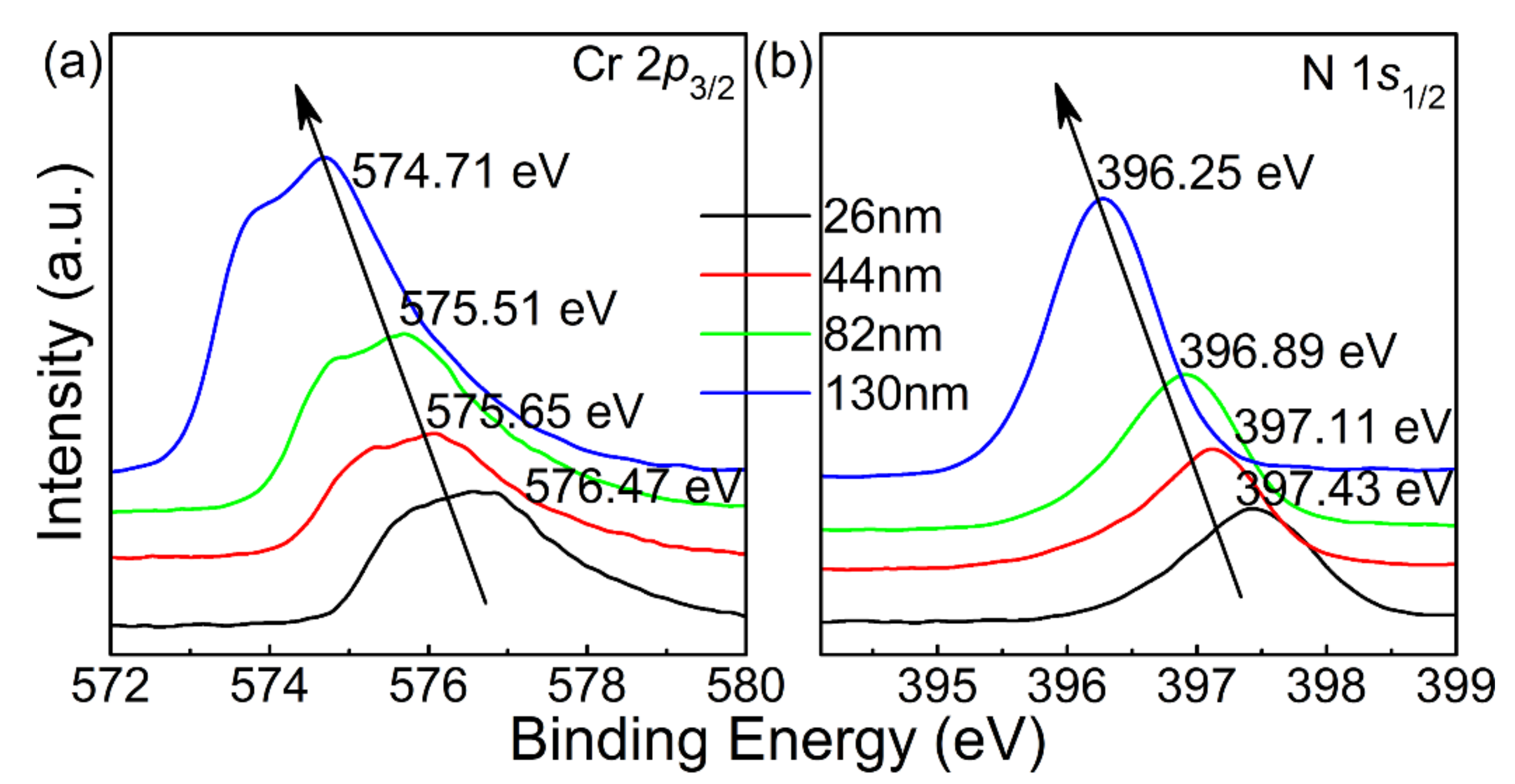

3.2. Nitrogen Content Variations

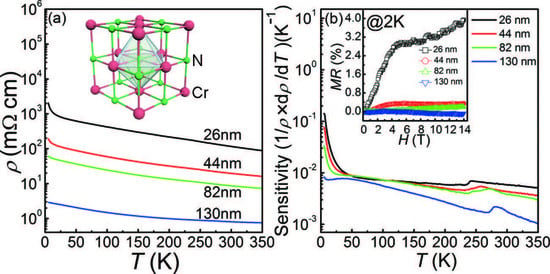

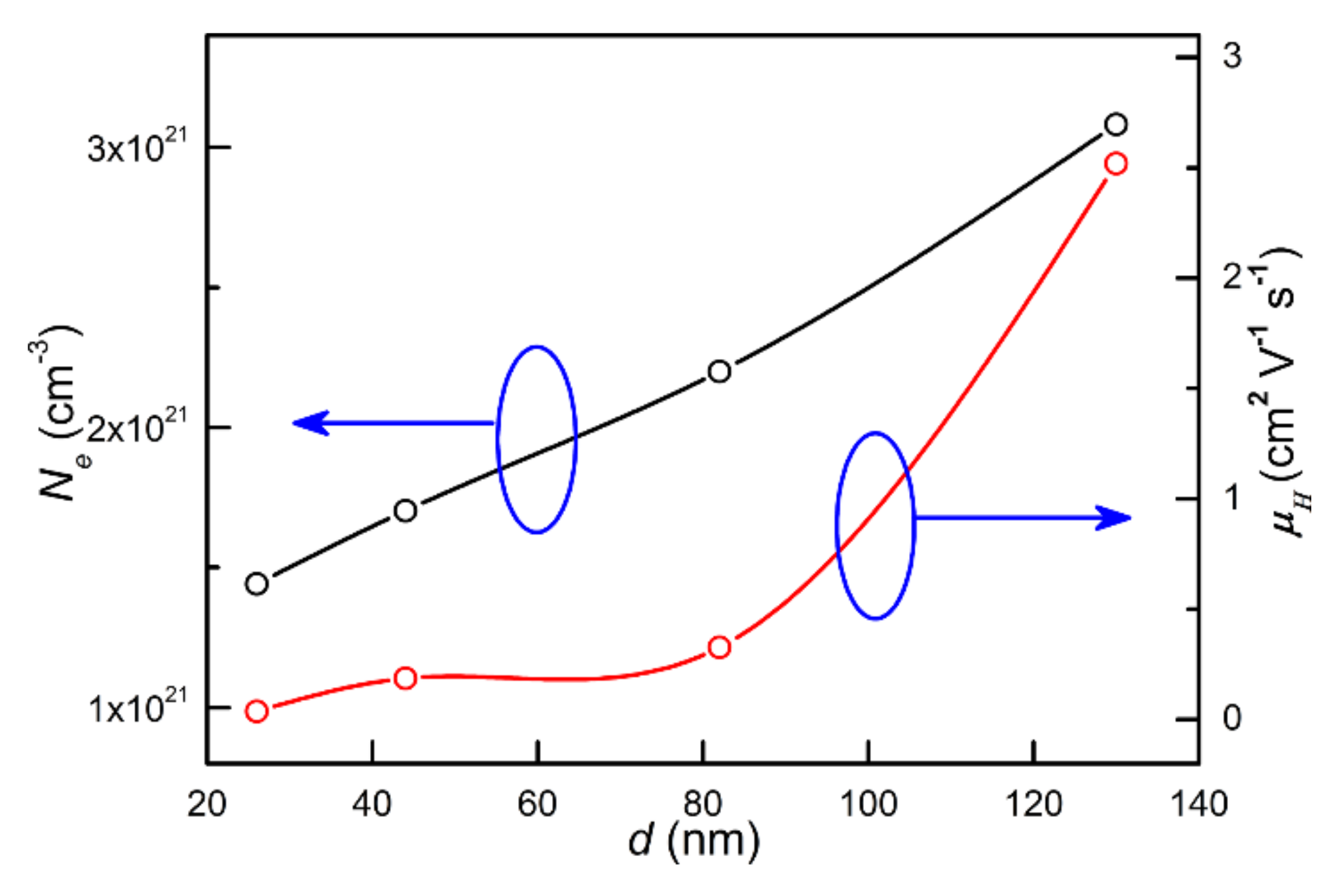

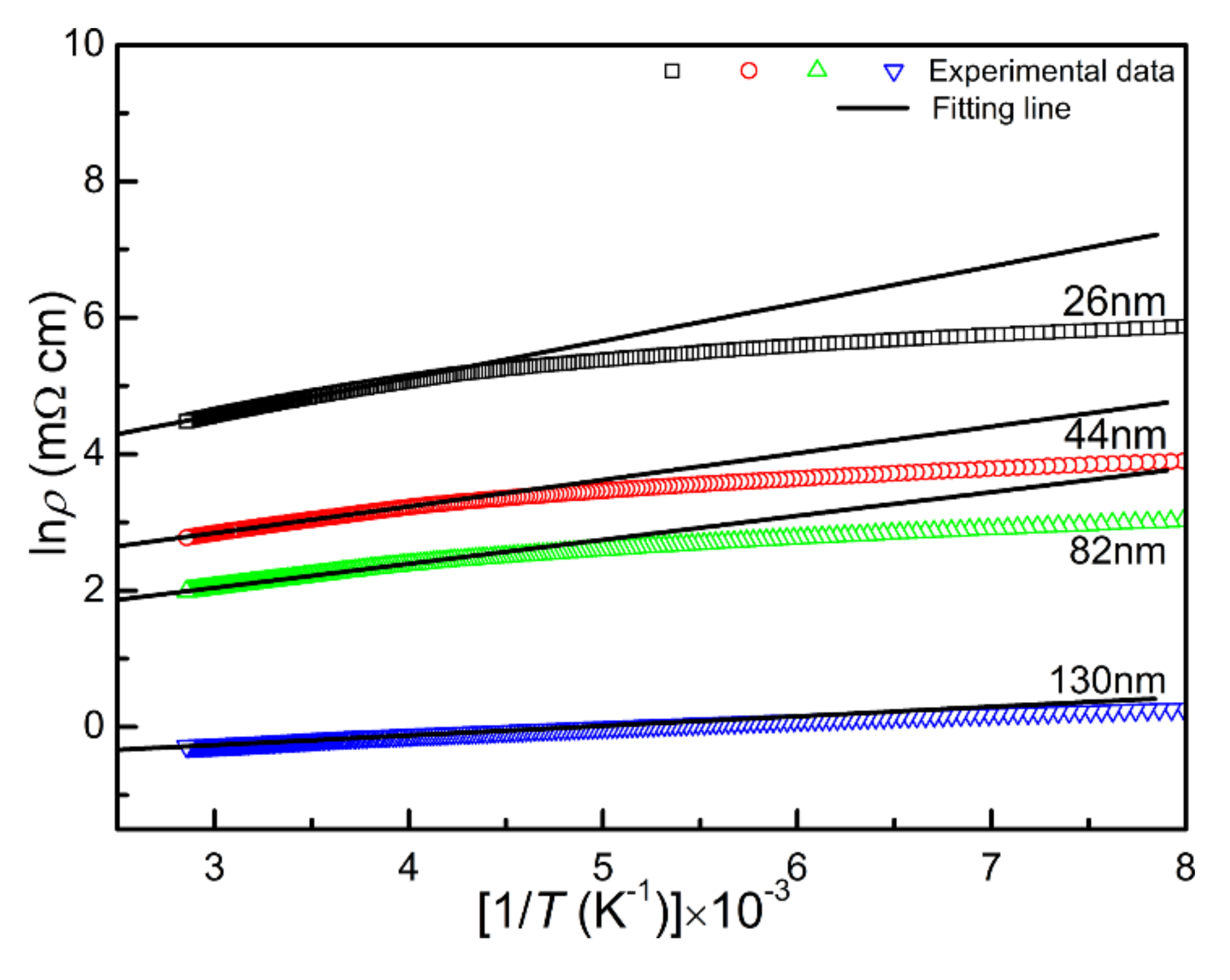

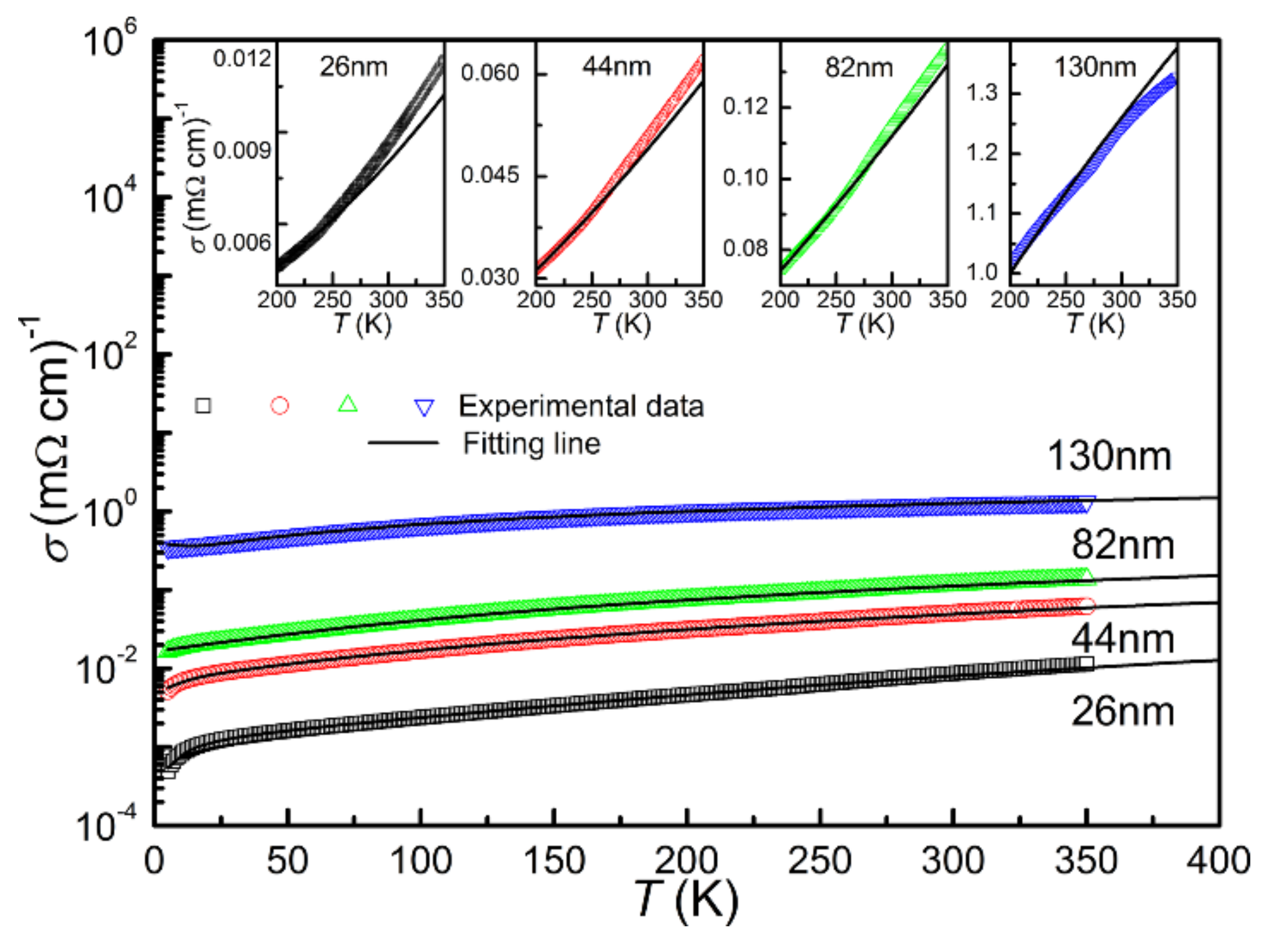

3.3. Electrical Transport Properties

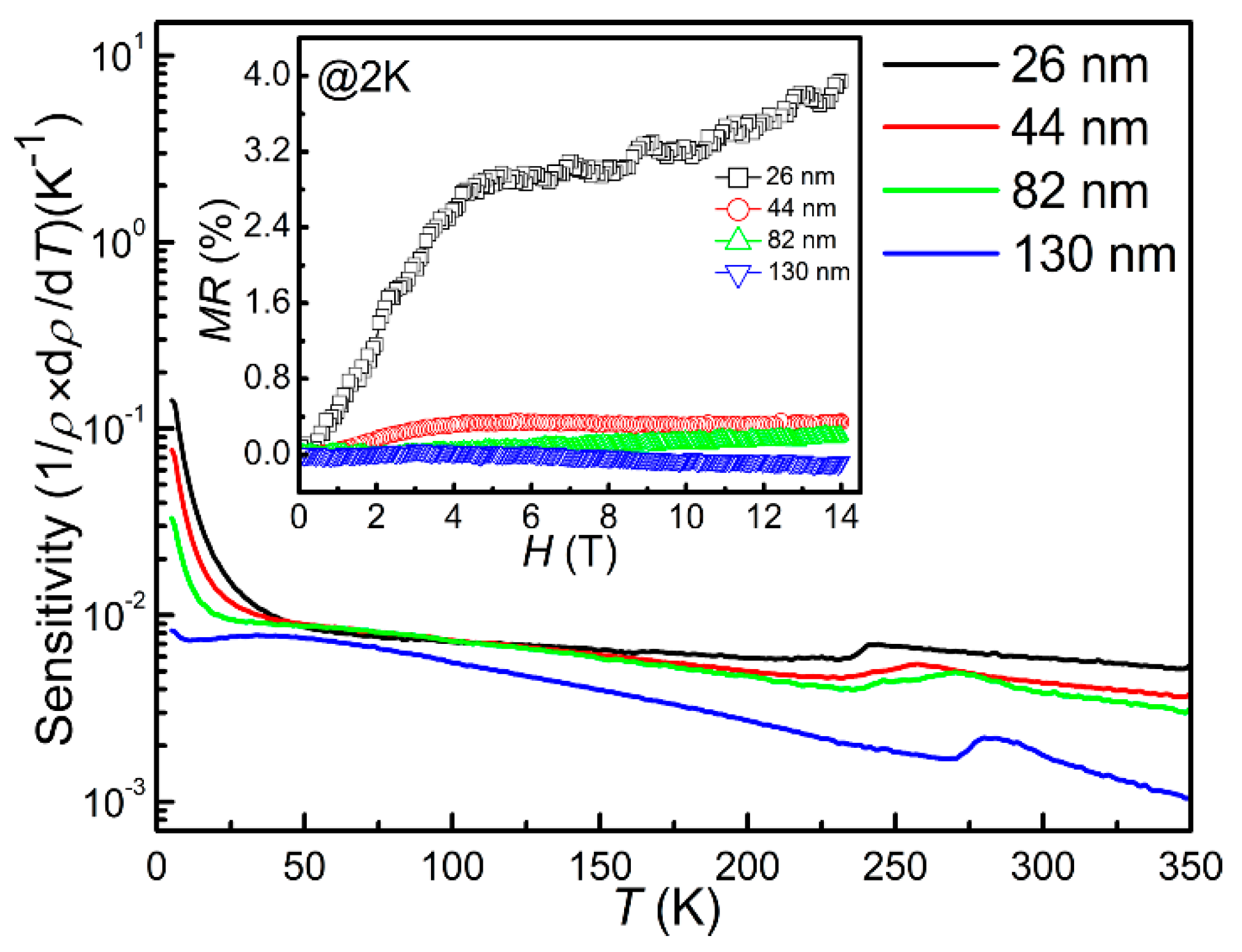

3.4. The Zero-Field Sensitivity and Magnetoresistance Under High Magnetic Fields

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Corliss, L.M.; Elliott, N.; Hastings, J.M. Antiferromagnetic structure of CrN. Phys. Rev. 1960, 117, 929–935. [Google Scholar] [CrossRef]

- Rivadulla, F.; Bañobre-López, M.; Quintela, C.X.; Piñeiro, A.; Pardo, V.; Baldomir, D.; López-Quintela, M.A.; Rivas, J.; Ramos, C.A.; Salva, H.; et al. Reduction of the bulk modulus at high pressure in CrN. Nat. Mater. 2009, 8, 947–951. [Google Scholar] [CrossRef] [PubMed]

- Wei, B.B.; Liang, H.F.; Zhang, D.F.; Wu, Z.T.; Qi, Z.B.; Wang, Z.C. CrN thin films prepared by reactive DC magnetron sputtering for symmetric supercapacitors. J. Mater. Chem. A 2017, 5, 2844–2851. [Google Scholar] [CrossRef]

- Lou, B.S.; Chang, Y.C.; Lee, J.W. High Temperature Oxidation Behaviors of CrNx and Cr-Si-N Thin Films at 1000 °C. Coatings 2019, 9, 540. [Google Scholar] [CrossRef]

- Obrosov, A.; Sutygina, A.N.; Volinsky, A.A.; Manakhov, A.; 4 Weiß, S.; Kashkarov, E.B. Effect of Hydrogen Exposure on Mechanical and Tribological Behavior of CrxN Coatings Deposited at Different Pressures on IN718. Materials 2017, 10, 563. [Google Scholar] [CrossRef]

- Quintela, C.X.; Podkaminer, J.P.; Luckyanova, M.N.; Paudel, T.R.; Thies, E.L.; Hillsberry, D.A.; Tenne, D.A.; Tsymbal, E.Y.; Chen, G.; Eom, C.B.; et al. Epitaxial CrN thin films with high thermoelectric figure of merit. Adv. Mater. 2015, 27, 3032–3037. [Google Scholar] [CrossRef]

- Sanjinés, R.; Banakh, O.; Rojas, C.; Schmid, P.E.; Lévy, F. Electronic properties of Cr1-xAlxN thin films deposited by reactive magnetron sputtering. Thin Solid Films 2002, 420, 312–317. [Google Scholar] [CrossRef]

- Inumaru, K.; Koyama, K.; Imo-oka, N.; Yamanaka, S. Controlling the structural transition at the Néel point of CrN epitaxial thin films using epitaxial growth. Phys. Rev. B 2007, 75, 054416. [Google Scholar] [CrossRef]

- Mitin, V.F.; McDonald, P.C.; Pavese, F.; Boltovets, N.S.; Kholevchuk, V.V.; Nemish, I.Y.; Basanets, V.V.; Dugaev, V.K.; Sorokin, P.V.; Konakova, R.V.; et al. Ge-on-GaAs film resistance thermometers for cryogenic applications. Cryogenics 2007, 47, 474–482. [Google Scholar] [CrossRef]

- Süßer, M.; Wüchner, F. Behavior of CERNOX temperature sensors at static magnetic fields up to 15 T. Cryogenics 2000, 40, 413–415. [Google Scholar] [CrossRef]

- Heinet, G.; Lang, W. Magnetoresistance of the new ceramic “Cernox” thermometer from 4.2 K to 300 K in magnetic fields up to 13 T. Cryogenics 1998, 38, 377–379. [Google Scholar] [CrossRef]

- Courts, S.S. Standardized CernoxTM cryogenic temperature sensor for aerospace applications. Cryogenics 2014, 64, 248–254. [Google Scholar] [CrossRef]

- Ramsbottom, H.D.; Ali, S.; Hampshire, D.P. Response of a new ceramic-oxynitride (Cernox) resistance temperature sensor in high magnetic fields. Cryogenics 1996, 36, 61–63. [Google Scholar] [CrossRef]

- Khojier, K.; Savaloni, H.; Zolghadr, S.; Amani, E. Study of Electrical, Mechanical, and Tribological Properties of CrNx Thin Films as a Function of Sputtering Conditions. J. Mater. Eng. Perform. 2014, 23, 3444–3448. [Google Scholar] [CrossRef]

- Pedrosa, P.; Rodrigues, M.S.; Neto, M.A.; Oliveira, F.J.; Silva, R.F.; Borges, J.; Amaral, M.; Ferreira, A.; Godinho, L.H.; Carvalho, S.; et al. Properties of CrN thin films deposited in plasma-activated ABS by reactive magnetron sputtering. Surf. Coat. Technol. 2018, 349, 858–866. [Google Scholar] [CrossRef]

- Jimeneza, M.J.M.; Antunesa, V.; Cucattia, S.; RiulJra, A.; Zagonela, L.F.; Figueroab, C.A.; Wisniveskya, D.; Alvarez, F. Physical and micro-nano-structure properties of chromium nitride coating deposited by RF sputtering using dynamic glancing angle deposition. Surf. Coat. Technol. 2019, 372, 268–277. [Google Scholar] [CrossRef]

- Song, G.H.; Yang, X.P.; Xiong, G.L.; Lou, Z.; Chen, L.J. The corrosive behavior of Cr/CrN multilayer coatings with different modulation periods. Vacuum 2013, 89, 136–141. [Google Scholar] [CrossRef]

- Lange, F.F. Chemical solution routes to single-crystal thin films. Science 1996, 273, 903–909. [Google Scholar] [CrossRef]

- Subramanyam, G.; Cole, M.W.; Sun, N.X.; Kalkur, T.S.; Sbrockey, N.M.; Tompa, G.S.; Guo, X.M.; Chen, C.L.; Alpay, S.P.; Rossetti, G.A.; et al. Challenges and opportunities for multi-functional oxide thin films for voltage tunable radio frequency/microwave components. J. Appl. Phys. 2013, 114, 191301. [Google Scholar] [CrossRef]

- Hui, Z.Z.; Tang, X.W.; Shao, D.F.; Lei, H.C.; Yang, J.; Song, W.H.; Luo, H.M.; Zhu, X.B.; Sun, Y.P. Epitaxial antiperovskite superconducting CuNNi3 thin films synthesized by chemical solution deposition. Chem. Commun. 2014, 50, 12734–12737. [Google Scholar] [CrossRef]

- Hui, Z.Z.; Tang, X.W.; Shao, D.F.; Wei, R.H.; Yang, J.; Tong, P.; Song, W.H.; Zhu, X.B.; Sun, Y.P. Self-assembled c-axis oriented antiperovskite soft-magnetic CuNCo3 thin films by chemical solution deposition. J. Mater. Chem. C 2015, 3, 4438. [Google Scholar] [CrossRef]

- Tang, X.W.; Wei, R.H.; Hu, L.; Yang, J.; Song, W.H.; Dai, J.M.; Zhu, X.B.; Sun, Y.P. Annealing Effects on the Grain Growth and Electrical Properties of ZrO2 Buffered Chromium Nitride Thin Films. Cryst. Growth Des. 2019, 19, 5737–5742. [Google Scholar] [CrossRef]

- Cen, S.L.; Lv, X.G.; Xu, B.B.; Xu, Y. The Effect of Gradient Bias Design on Electrochemistry and Tribology Behaviors of PVD CrN Film in a Simulative Marine Environment. Materials 2018, 11, 1753. [Google Scholar] [CrossRef] [PubMed]

- Schwartz, R.W. Chemical Solution Deposition of Perovskite Thin Films. Chem. Mater. 1997, 9, 2325–2329. [Google Scholar] [CrossRef]

- Thompson, C.V. Structure evolution during processing of polycrystalline films. Ann. Rev. Mater. 2000, 30, 159. [Google Scholar] [CrossRef]

- Browne, J.D.; Liddell, P.R.; Street, R.; Mills, T. An investigation of the antiferromagnetic transition of CrN. Phys. Stat. Sol. 1970, 1, 715–723. [Google Scholar] [CrossRef]

- Thompson, C.V. Grain growth in thin films. Annu. Rev. Mater. Sci. 1990, 20, 245–268. [Google Scholar] [CrossRef]

- Palmer, J.E.; Thompson, C.V.; Smith, H.I. Grain growth and grain size distributions in thin germanium films. J. Appl. Phys. 1987, 62, 2492–2497. [Google Scholar] [CrossRef]

- Sacher, E. Asymmetries in transition metal XPS spectra: Metal nanoparticle structure, and interaction with the graphene-structured substrate surface. Langmuir 2010, 26, 3807–3814. [Google Scholar] [CrossRef]

- Chen, M.; Wang, S.; Zhang, J.Z.; He, D.W.; Zhao, Y.S. Synthesis of Stoichiometric and Bulk CrN through a Solid-State Ion-Exchange Reaction. Chem. Eur. J. 2012, 18, 15459–15463. [Google Scholar] [CrossRef]

- Bertoti, I.; Mohai, M.; Mayrhofer, P.H.; Mitterer, C. Surface chemical changes induced by low-energy ion bombardment in chromium nitride layers. Surf. Interface Anal. 2002, 34, 740–743. [Google Scholar] [CrossRef]

- Emerya, C.; Chourasia, A.R.; Yashar, P. A study of CrNx thin films by X-ray photoelectron spectroscopy. J. Electron Spectrosc. Relat. Phenom. 1999, 104, 91–97. [Google Scholar] [CrossRef]

- Merey, R.A.; Karajou, J.; Issa, H. X-ray fluorescence analysis of geological samples: Exploring the effect of sample thickness on the accuracy of results. Appl. Radiat. Isot. 2005, 62, 501–508. [Google Scholar] [CrossRef] [PubMed]

- Constantin, C.; Haider, M.B.; Ingram, D.; Smith, A.R. Metal/semiconductor phase transition in chromium nitride (001) grown by rf-plasma-assisted molecular-beam epitaxy. Appl. Phys. Lett. 2004, 85, 6371–6373. [Google Scholar] [CrossRef]

- Zhang, X.Y.; Chawla, J.S.; Deng, R.P.; Gall, D. Epitaxial suppression of the metal-insulator transition in CrN. Phys. Rev. B 2011, 84, 073101. [Google Scholar] [CrossRef]

- Bhobe, P.A.; Chainani, A.; Taguchi, M.; Takeuchi, T.; Eguchi, R.; Matsunami, M.; Ishizaka, K.; Takata, Y.; Oura, M.; Senba, Y.; et al. Evidence for a correlated insulator to antiferromagnetic metal transition in CrN. Phys. Rev. Lett. 2010, 104, 236404. [Google Scholar] [CrossRef]

- Altshuler, B.L.; Aronov, A.G. Zero bias anomaly in tunnel resistance and electron-electron interaction. Solid State Commun. 1979, 30, 115–117. [Google Scholar] [CrossRef]

- Sajitha, E.P.; Prasad, V.; Subramanyam, S.V. Low temperature electrical transport properties of carbon matrix containing iron nanoparticles. J. Appl. Phys. 2009, 105, 073708. [Google Scholar] [CrossRef]

- Lee, P.A.; Ramakrishnan, T.V. Disordered electronic systems. Rev. Mod. Phys. 1985, 57, 287–337. [Google Scholar] [CrossRef]

- Lindelof, P.E.; Norregaard, J.; Hansen, J.B. Magnetoresistance in two-dimensional magnesium films of various thicknesses. Condens. Matter. 1985, 59, 423–428. [Google Scholar] [CrossRef]

- Hui, Z.Z.; Meng, Q.M.; Wei, R.H.; Tang, X.W.; Zhu, X.D.; Ouyang, Z.R.; Dai, J.M.; Song, W.H.; Luo, H.M.; Zhu, X.B.; et al. CrN thin films with ultra-low magnetoresistance prepared via solution processing for large-area applications. J. Alloys. Comp. 2017, 696, 844. [Google Scholar] [CrossRef]

| CrN | af (Å) | Average Grain Size (nm) | Binding Energy of Cr 2p3/2 (eV) | Binding Energy of N 1s1/2 (eV) |

|---|---|---|---|---|

| T26 | 4.140 | 26 | 576.47 | 397.43 |

| T44 | 4.143 | 31 | 575.65 | 397.11 |

| T82 | 4.145 | 44 | 575.51 | 396.89 |

| T130 | 4.148 | 73 | 574.71 | 396.25 |

| CrN | Ne (cm−3) | μH (cm2V−1s−1) | ρ300K (mΩ·cm) | TK (K) | S5K (K−1) | MR at 2K Under 14 T (%) |

|---|---|---|---|---|---|---|

| T26 | 1.44 × 1021 | 0.037 | 116.55 | 241 | 0.14 | 3.94 |

| T44 | 1.70 × 1021 | 0.186 | 19.28 | 255 | 7.7 × 10−2 | 0.34 |

| T82 | 2.20 × 1021 | 0.326 | 8.62 | 271 | 3.3 × 10−2 | 0.20 |

| T130 | 3.08 × 1021 | 2.520 | 0.79 | 280 | 8.3 × 10−3 | −0.10 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hui, Z.; Zuo, X.; Ye, L.; Wang, X.; Zhu, X. Solution Processable CrN Thin Films: Thickness-Dependent Electrical Transport Properties. Materials 2020, 13, 417. https://doi.org/10.3390/ma13020417

Hui Z, Zuo X, Ye L, Wang X, Zhu X. Solution Processable CrN Thin Films: Thickness-Dependent Electrical Transport Properties. Materials. 2020; 13(2):417. https://doi.org/10.3390/ma13020417

Chicago/Turabian StyleHui, Zhenzhen, Xuzhong Zuo, Longqiang Ye, Xuchun Wang, and Xuebin Zhu. 2020. "Solution Processable CrN Thin Films: Thickness-Dependent Electrical Transport Properties" Materials 13, no. 2: 417. https://doi.org/10.3390/ma13020417

APA StyleHui, Z., Zuo, X., Ye, L., Wang, X., & Zhu, X. (2020). Solution Processable CrN Thin Films: Thickness-Dependent Electrical Transport Properties. Materials, 13(2), 417. https://doi.org/10.3390/ma13020417