Powder-in-Tube Reactive Molten-Core Fabrication of Glass-Clad BaO-TiO2-SiO2 Glass–Ceramic Fibers

Abstract

1. Introduction

2. Materials and Methods

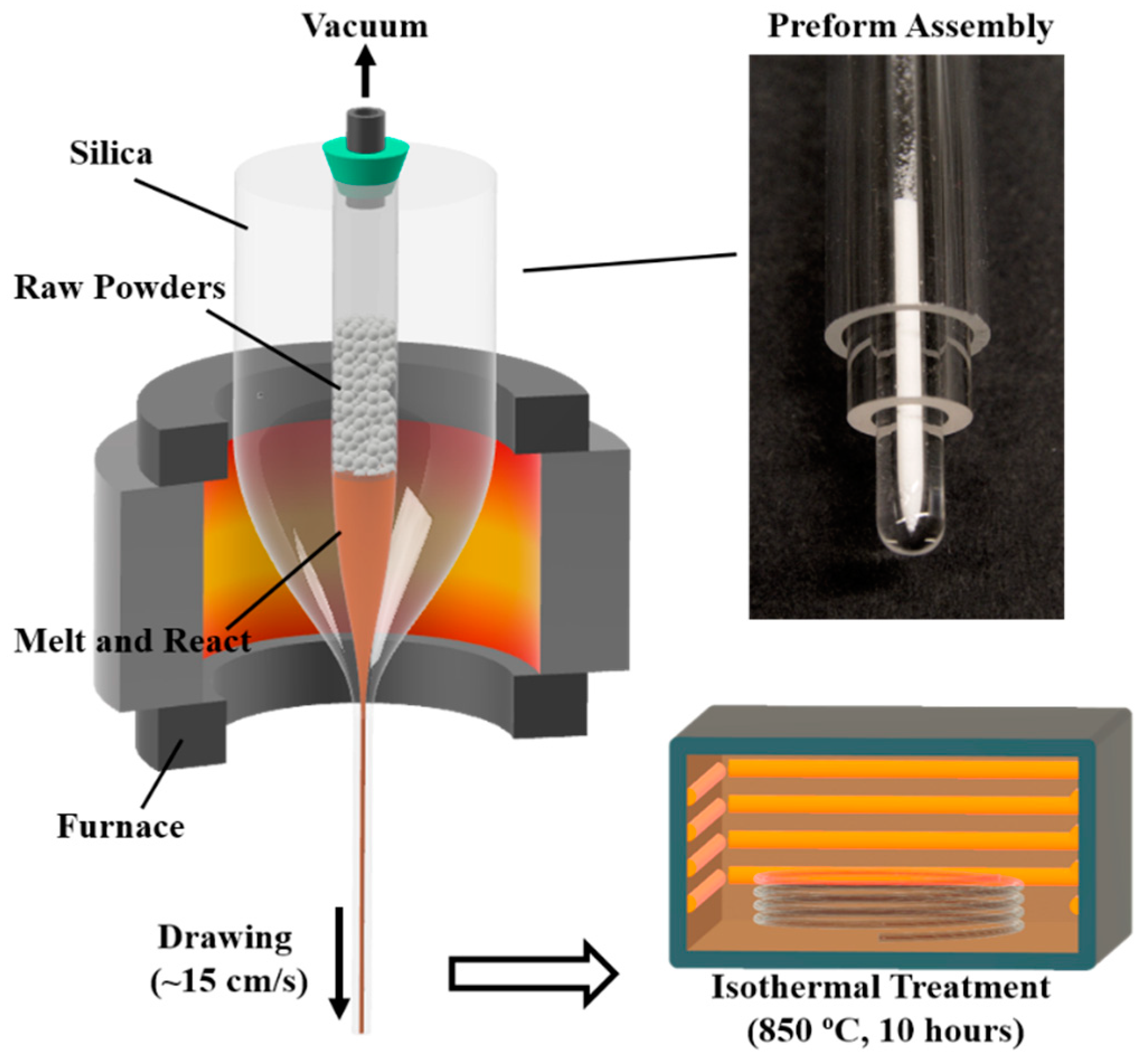

2.1. Preform Assembly and Fiber Fabrication

2.2. Characterization

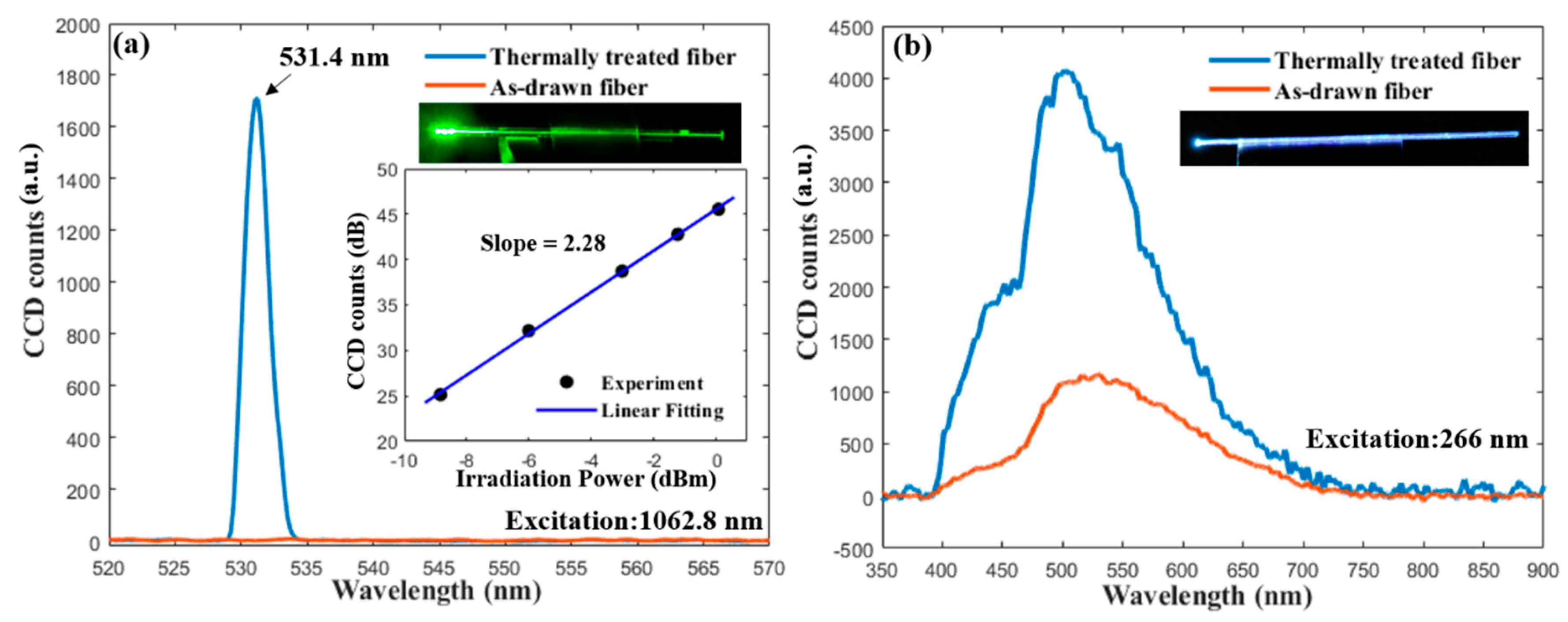

3. Results

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Keiser, G.A. Optical Fiber Communications, 4th ed.; McGraw-Hill Education: New York, NY, USA, 2010. [Google Scholar]

- Santos, J.L.; Farahi, F. Handbook of Optical Sensors; CRC Press: Boca Raton, FL, USA, 2014. [Google Scholar]

- Dong, L.; Samson, B. Fiber Lasers: Basics, Technology, and Applications; CRC Press: Boca Raton, FL, USA, 2016. [Google Scholar]

- Boyd, R.W. Nonlinear Optics; Elsevier: Amsterdam, The Netherlands, 2008. [Google Scholar]

- Myers, R.; Mukherjee, N.; Brueck, S.R. Large second-order nonlinearity in poled fused silica. Opt. Lett. 1991, 16, 1732–1734. [Google Scholar] [CrossRef] [PubMed]

- Fleming, S.C.; An, H. Poled glasses and poled fibre devices. J. Ceram. Soc. Jpn. 2008, 116, 1007–1023. [Google Scholar] [CrossRef]

- Dussauze, M.; Cremoux, T.; Adamietz, F.; Rodriguez, V.; Fargin, E.; Yang, G.; Cardinal, T. Thermal Poling of Optical Glasses: Mechanisms and Second-Order Optical Properties. Int. J. Appl. Glass Sci. 2012, 3, 309–320. [Google Scholar] [CrossRef]

- Wang, J.-S.; Tseng, Y.-H. ITO electrode-embedded double-cladding single-crystal LiNbO3 optical fiber. Opt. Lett. 2013, 38452–38454. [Google Scholar]

- Tang, D.Y.; Route, R.K.; Feigelson, R.S. Growth of barium metaborate (BaB2O4) single crystal fibers by the laser-heated pedestal growth method. J. Cryst. Growth 1988, 91, 81–89. [Google Scholar] [CrossRef]

- Ren, Y.; Zhao, X.; Hagley, E.W.; Deng, L. Ambient-condition growth of high-pressure phase centrosymmetric crystalline KDP microstructures for optical second harmonic generation. Sci. Adv. 2016, 2, e1600404. [Google Scholar] [CrossRef]

- Liu, X.; Zhou, J.; Zhou, S.; Yue, Y.; Qiu, J. Transparent glass-ceramics functionalized by dispersed crystals. Prog. Mater. Sci. 2018, 97, 38–96. [Google Scholar] [CrossRef]

- Holand, W.; Beall, G.H. Glass-Ceramic Technology; John Wiley & Sons: Hoboken, NJ, USA, 2019. [Google Scholar]

- Wisniewski, W.; Thieme, K.; Rüssel, C. Fresnoite glass-ceramics—A review. Prog. Mater. Sci. 2018, 98, 68–107. [Google Scholar] [CrossRef]

- Kim, T.-H.; Kim, Y.-S.; Jeong, Y.-J.; Na, Y.-H.; Lim, H.-H.; Cha, M.-S.; Ryu, B.-K. Optical properties and structure of BaO-TiO2-SiO2 glass ceramics. J. Korean Ceram. Soc. 2008, 45, 821–826. [Google Scholar] [CrossRef]

- Masai, H.; Tsuji, S.; Fujiwara, T.; Benino, Y.; Komatsu, T. Structure and non-linear optical properties of BaO–TiO2–SiO2 glass containing Ba2TiSi2O8 crystal. J. Non-Cryst. Solids 2007, 353, 2258–2262. [Google Scholar] [CrossRef]

- Blasse, G. Fluorescence of compounds with fresnoite (Ba2TiSi2O8) structure. J. Inorg. Nucl. Chem. 1968, 30, 2283–2284. [Google Scholar] [CrossRef]

- Hijiya, H.; Kishi, T.; Yasumori, A. Photoluminescent properties of fresnoite phosphors prepared from phase-separated BaO-TiO2-SiO2 glasses. J. Ceram. Soc. Jpn. 2008, 116, 1255–1259. [Google Scholar] [CrossRef][Green Version]

- Hane, Y.; Komatsu, T.; Benino, Y.; Fujiwara, T. Transparent nonlinear optical crystallized glass fibers with highly oriented Ba2TiGe2O8 crystals. J. Appl. Phys. 2008, 103, 063512. [Google Scholar] [CrossRef]

- Ohara, S.; Masai, H.; Takahashi, Y.; Fujiwara, T.; Kondo, Y.; Sugimoto, N. Fabrication of BaO-TiO2-GeO2-SiO2 based glass fiber. J. Ceram. Soc. Jpn. 2008, 116, 1083–1086. [Google Scholar] [CrossRef][Green Version]

- Fang, Z.; Xiao, X.; Wang, X.; Ma, Z.; Lewis, E.; Farrell, G.; Wang, P.; Ren, J.; Guo, H.; Qiu, J. Glass-ceramic optical fiber containing Ba2TiSi2O8 nanocrystals for frequency conversion of lasers. Sci. Rep. 2017, 7, 44456. [Google Scholar] [CrossRef]

- Masai, H.; Hamaguchi, K.; Suzuki, Y.; Iwasaki, K.; Ihara, R.; Takahashi, Y.; Fujiwara, T. Precipitation of Pt nanocrystallites from BaO-TiO2-GeO2 remelted glass. J. Appl. Phys. 2012, 111, 123513. [Google Scholar] [CrossRef]

- Ballato, J.; McMillen, C.; Hawkins, T.; Foy, P.; Stolen, R.; Rice, R.; Zhu, L.; Stafsudd, O. Reactive molten core fabrication of glass-clad amorphous and crystalline oxide optical fibers. Opt. Mater. Express 2012, 2, 153–160. [Google Scholar] [CrossRef]

- Ballato, J.; Peacock, A.C. Perspective: Molten core optical fiber fabrication—A route to new materials and applications. APL Photonics 2018, 3, 120903. [Google Scholar] [CrossRef]

- Cavillon, M.; Dragic, P.; Faugas, B.; Hawkins, T.W.; Ballato, J. Insights and Aspects to the Modeling of the Molten Core Method for Optical Fiber Fabrication. Materials 2019, 12, 2898. [Google Scholar] [CrossRef]

- Mangognia, A.; Kucera, C.; Guerrier, J.; Furtick, J.; Hawkins, T.; Dragic, P.D.; Ballato, J. Spinel-derived single mode optical fiber. Opt. Mater. Express 2013, 3, 511–518. [Google Scholar] [CrossRef]

- Dragic, P.; Hawkins, T.; Foy, P.; Morris, S.; Ballato, J. Sapphire-derived all-glass optical fibres. Nat. Photonics 2012, 6, 627. [Google Scholar] [CrossRef]

- Faugas, B.; Hawkins, T.; Kucera, C.; Bohnert, K.; Ballato, J. Molten core fabrication of bismuth germanium oxide Bi4Ge3O12 crystalline core fibers. J. Am. Ceram. Soc. 2018, 101, 4340–4349. [Google Scholar] [CrossRef]

- Heyl, H.; Homa, D.; Pickrell, G. Reaction of YBa2Cu3O7-x (YBCO) and fused silica in YBCO glass fibres. Bull. Mater. Sci. 2019, 42, 154. [Google Scholar] [CrossRef]

- Heyl, H.V. Phase Relations in the YBa2Cu3O7-x-SiO2 System and the Impact on Superconducting Fibers. Ph.D. Thesis, Virginia Tech, Blacksburg, VA, USA, 2019. [Google Scholar]

- Heyl, H.; Yang, S.; Homa, D.; Slebodnick, C.; Wang, A.; Pickrell, G. Dissolution and diffusion based reactions within YBa2Cu3O7-x glass fibers. Fibers 2020, 8, 2. [Google Scholar] [CrossRef]

- Boulay, E.; Ragoen, C.; Idrissi, H.; Schryvers, D.; Godet, S. Influence of amorphous phase separation on the crystallization behavior of glass-ceramics in the BaO–TiO2–SiO2 system. J. Non-Cryst. Solids 2014, 384, 61–72. [Google Scholar] [CrossRef]

- Ray, C.S.; Day, D.E. Crystallization of baria-titania-silica glasses. J. Non-Cryst. Solids 1986, 81, 173–183. [Google Scholar] [CrossRef]

- Cabral, A.A.; Fokin, V.M.; Zanotto, E.D.; Chinaglia, C.R. Nanocrystallization of fresnoite glass. I. Nucleation and growth kinetics. J. Non-Cryst. Solids 2003, 330, 174–186. [Google Scholar] [CrossRef]

- Wisniewski, W.; Döhler, F.; Rüssel, C. Oriented Nucleation and Crystal Growth of Ba-Fresnoite (Ba2TiSi2O8) in 2BaO·TiO2·2SiO2 Glasses with Additional SiO2. Cryst. Growth Des. 2018, 18, 3202–3208. [Google Scholar] [CrossRef]

- Arvanitidis, I.; Siche, D.; Seetharaman, S. A study of the thermal decomposition of BaCO3. Metall. Mater. Trans. B 1996, 27, 409–416. [Google Scholar] [CrossRef]

- Ballato, J.; Hawkins, T.; Foy, P.; Kokuoz, B.; Stolen, R.; McMillen, C.; Daw, M.; Su, Z.; Tritt, T.M.; Dubinskii, M.; et al. On the fabrication of all-glass optical fibers from crystals. J. Appl. Phys. 2009, 105, 053110. [Google Scholar] [CrossRef]

- Mezeix, P.; Célarié, F.; Houizot, P.; Gueguen, Y.; Muñoz, F.; Rouxel, T. Elasticity and viscosity of BaO-TiO2-SiO2 glasses in the 0.9 to 1.2Tg temperature interval. J. Non-Cryst. Solids 2016, 445–446, 45–52. [Google Scholar] [CrossRef]

- Senz, S.; Graff, A.; Hesse, D.; Abicht, H.P. Formation of an amorphous product phase during the solid state reaction between a vitreous SiO2 thin film and a (001) BaTiO3 substrate. J. Eur. Ceram. Soc. 2000, 20, 2469–2475. [Google Scholar] [CrossRef]

- Stolyarova, V.L.; Lopatin, S.I. Mass spectrometric study of the vaporization and thermodynamic properties of components in the BaO-TiO2-SiO2 system. Glass Phys. Chem. 2005, 31, 132–137. [Google Scholar] [CrossRef]

- Takahashi, Y.; Yamazaki, Y.; Ihara, R.; Fujiwara, T. Perfect surface crystallization and parasitic structures in nonstoichiometric glass-ceramics: Micro-/nanoscopic aspects. Appl. Phys. Lett. 2013, 102, 191903. [Google Scholar] [CrossRef]

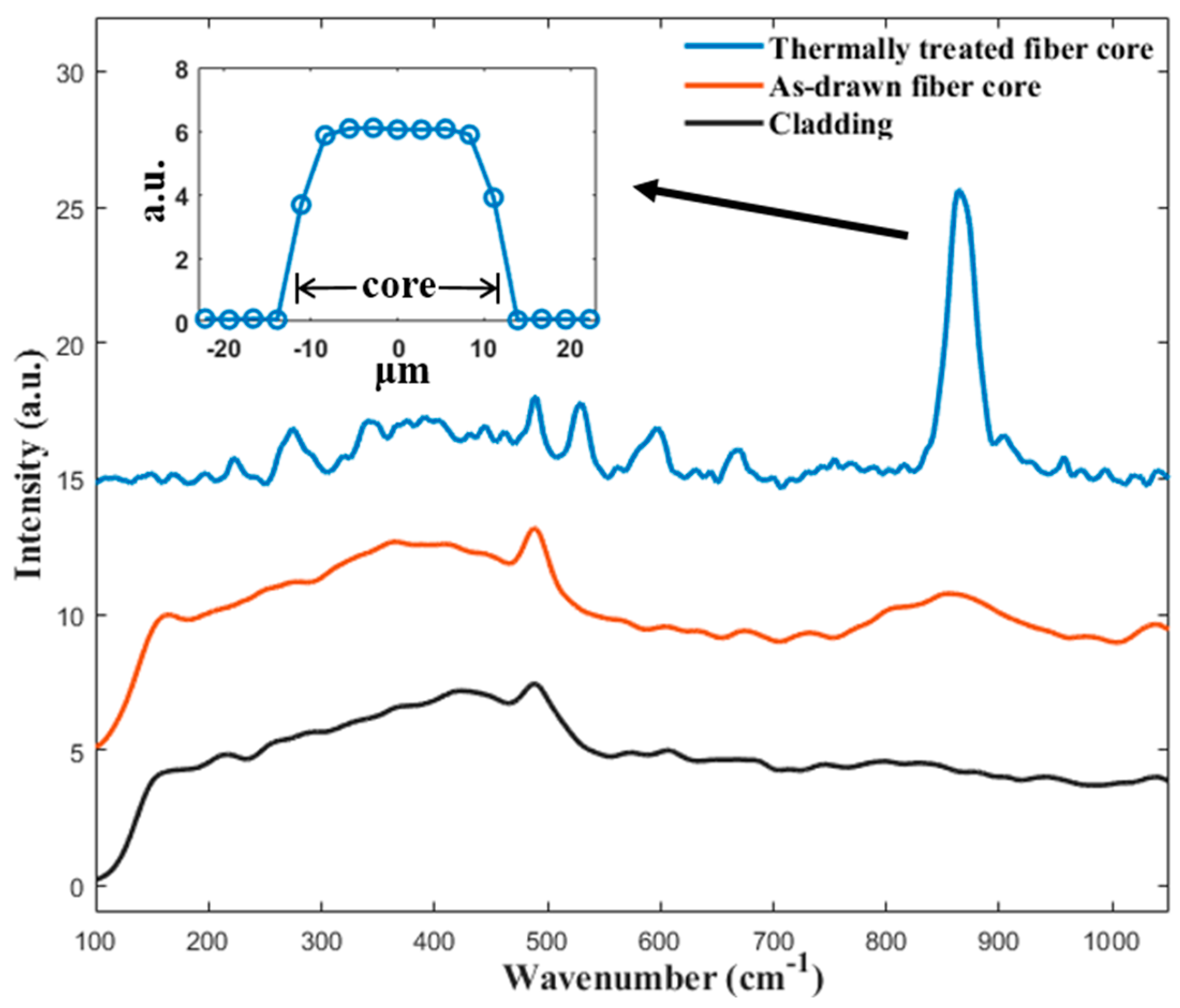

- Markgraf, S.A.; Sharma, S.K.; Bhalla, A.S. Raman study of fresnoite-type materials: Polarized single crystal, crystalline powders, and glasses. J. Mater. Res. Technol. 1993, 8, 635–648. [Google Scholar] [CrossRef]

- Zhu, B.; Dai, Y.; Ma, H.; Zhang, S.; Lin, G.; Qiu, J. Femtosecond laser induced space-selective precipitation of nonlinear optical crystals in rare-earth-doped glasses. Opt. Express 2007, 15, 6069–6074. [Google Scholar] [CrossRef]

- Dai, W.; Zhu, M.; Hou, Y.D.; Wang, H.; Yan, H.; Shao, M.; Chen, X.; Xu, J.B. Preparation and characterization of Ba2TiSi2O8 ferroelectric films produced by sol–gel method. Mater. Lett. 2004, 58, 2927–2931. [Google Scholar] [CrossRef]

- Takahashi, Y.; Kitamura, K.; Benino, Y.; Fujiwara, T.; Komatsu, T. Second-order optical nonlinear and luminescent properties of Ba2TiSi2O8 nanocrystallized glass. Appl. Phys. Lett. 2005, 86, 091110. [Google Scholar] [CrossRef]

- Ehrt, D.; Herrmann, A.; Tiegel, M. Glasses and glass ceramics with blue, green and red photoluminescence. Phys. Chem. Glasses B 2011, 52, 68–76. [Google Scholar]

- Takahashi, Y.; Iwasaki, K.; Fujiwara, T. Photoluminescence in mineral-derived titanosilicates with various Ti-polyhedral types for rare-earth free phosphor. Phys. Status Solidi C 2012, 9, 2336–2339. [Google Scholar] [CrossRef]

- Blasse, G. Fresnoite (Ba2TiSi2O8): A luminescent compound with a long decay time. J. Inorg. Nucl. Chem. 1979, 41, 639–641. [Google Scholar] [CrossRef]

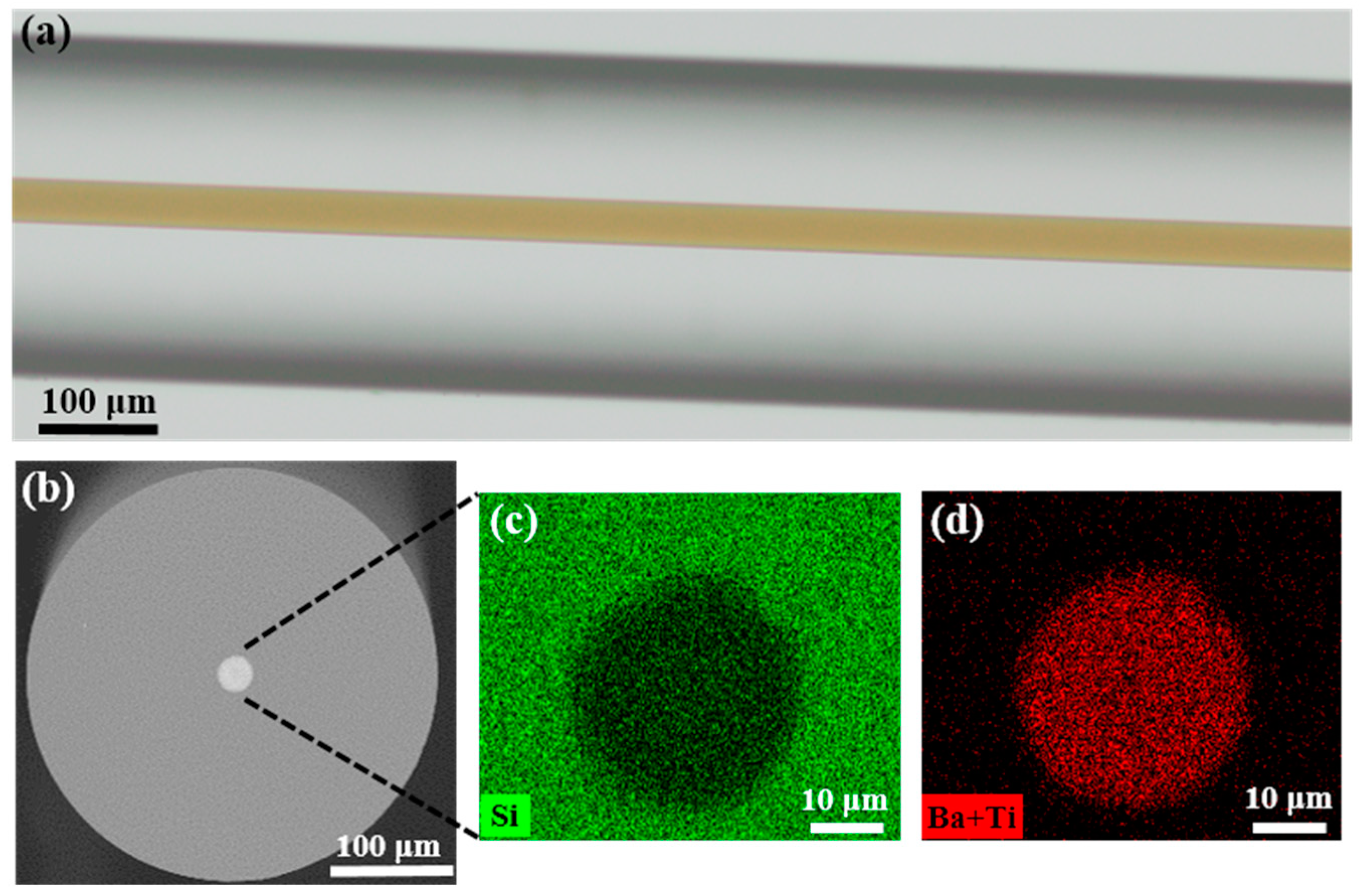

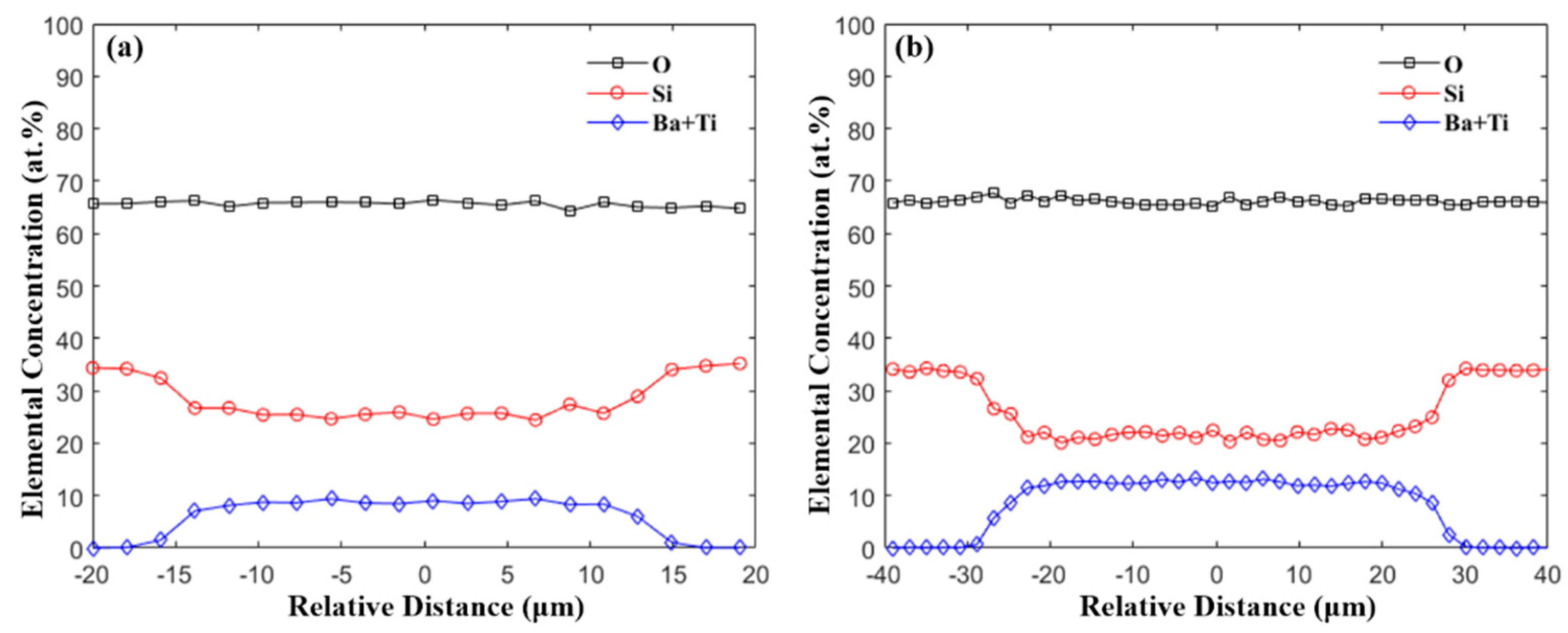

| Core Diameter (μm) | Ba + Ti (at.%) | Si (at.%) |

|---|---|---|

| 24.6 | 8.7 ± 0.4 | 25.6 ± 0.8 |

| 50.8 | 12.3 ± 0.6 | 21.6 ± 0.8 |

| 113.8 | 11.8 ± 0.6 | 21.8 ± 0.7 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, S.; Heyl, H.; Homa, D.; Pickrell, G.; Wang, A. Powder-in-Tube Reactive Molten-Core Fabrication of Glass-Clad BaO-TiO2-SiO2 Glass–Ceramic Fibers. Materials 2020, 13, 395. https://doi.org/10.3390/ma13020395

Yang S, Heyl H, Homa D, Pickrell G, Wang A. Powder-in-Tube Reactive Molten-Core Fabrication of Glass-Clad BaO-TiO2-SiO2 Glass–Ceramic Fibers. Materials. 2020; 13(2):395. https://doi.org/10.3390/ma13020395

Chicago/Turabian StyleYang, Shuo, Hanna Heyl, Daniel Homa, Gary Pickrell, and Anbo Wang. 2020. "Powder-in-Tube Reactive Molten-Core Fabrication of Glass-Clad BaO-TiO2-SiO2 Glass–Ceramic Fibers" Materials 13, no. 2: 395. https://doi.org/10.3390/ma13020395

APA StyleYang, S., Heyl, H., Homa, D., Pickrell, G., & Wang, A. (2020). Powder-in-Tube Reactive Molten-Core Fabrication of Glass-Clad BaO-TiO2-SiO2 Glass–Ceramic Fibers. Materials, 13(2), 395. https://doi.org/10.3390/ma13020395