The Effect of Accelerator Dosage on Fresh Concrete Properties and on Interlayer Strength in Shotcrete 3D Printing

Abstract

1. Introduction

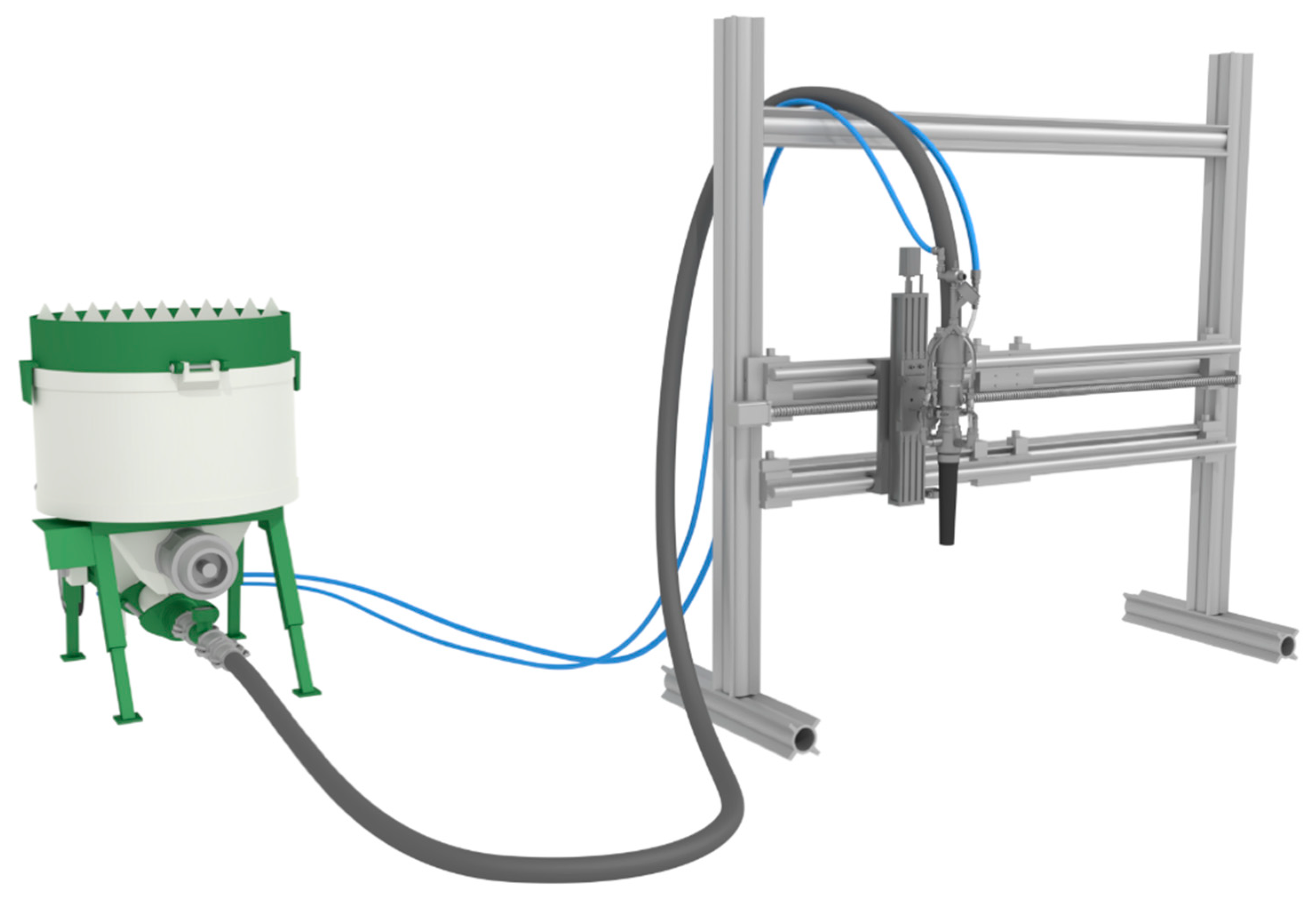

2. Shotcrete 3D Printing (SC3DP) Technology

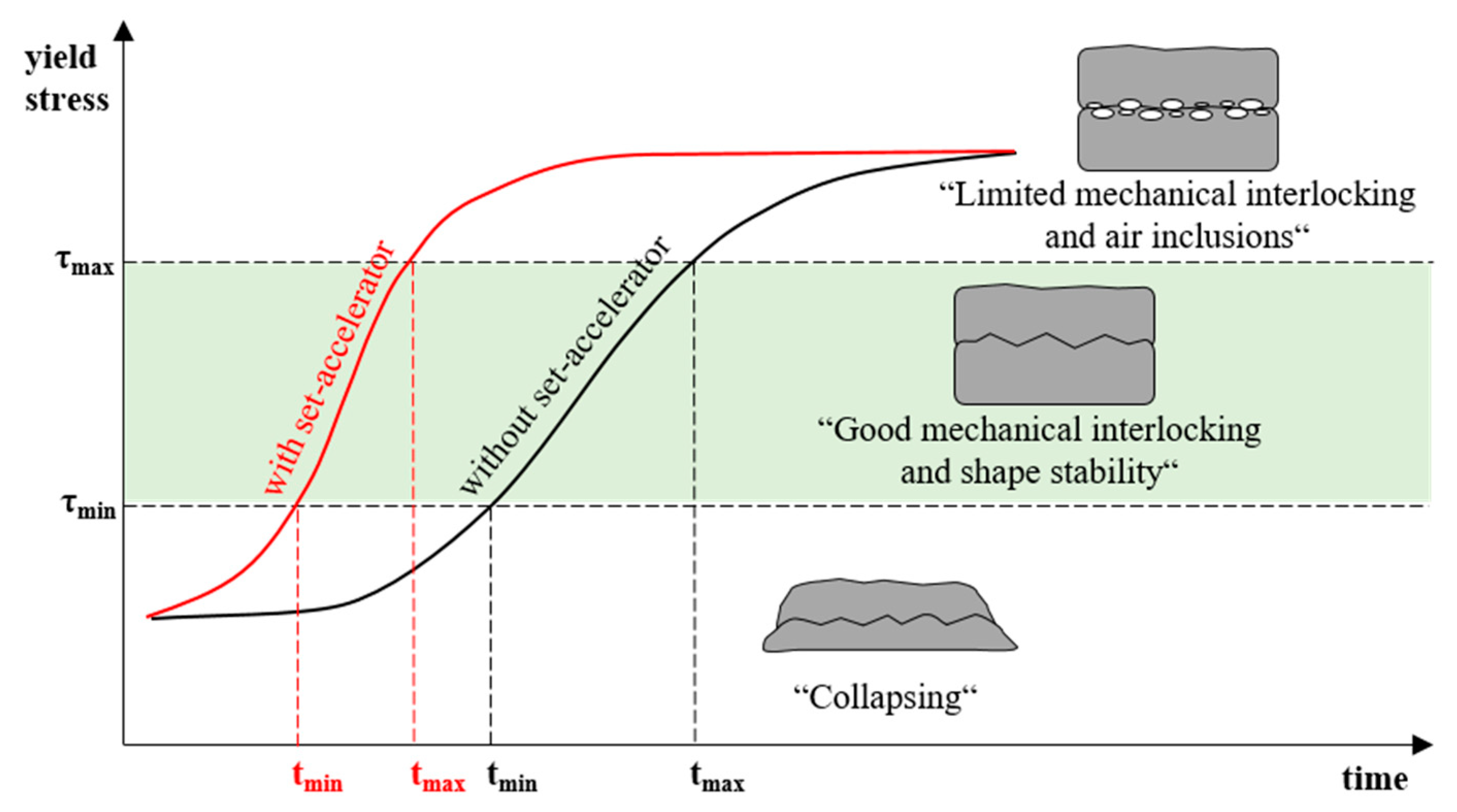

3. Effects on Interlayer Strength

- (a)

- mechanical effect: mechanical bonding relies solely on the physical attributes of the layers, e.g., micro roughness of substrate, cohesion and friction coefficients of the layers and age of the bottom strand as well as rheological properties of the single layers [31,32]. The inability of the layers to interlock lead to a reduced contact area and herewith to a reduced interlayer adhesion.

- (b)

- chemical effect: chemical bonding occurs if the hydration and chemical bonding of particles occurs in between two layers [31].

4. Materials and Methods

4.1. Scope and Concept of Experimental Investigation

4.2. Materials and Mixture Preparation

- Water was put into the mixer. For 2 min, all components are added continuously into the mixing container while the mixing tool was rotating. The order of addition was set as follows: a dry premixed mixture of cement, ground limestone and stabilizer is added, followed by the dry premixed aggregates. Moreover, superplasticizer was added constantly over the entire 2 min.

- Continuous mixing for a further 2 min.

4.3. Methods

4.3.1. Material Processing and Test Specimens

- Discharge rate of concrete pump: 0.8 m3/h,

- Hose: 5 m, diameter: 35 mm,

- Volume air flow: 45 m3/h,

- Working distance (nozzle to specimen): 20 cm,

- Gantry speed: 4.5 m/min.

4.3.2. Investigations on Fresh Properties

4.3.3. Investigations on Mechanical Properties

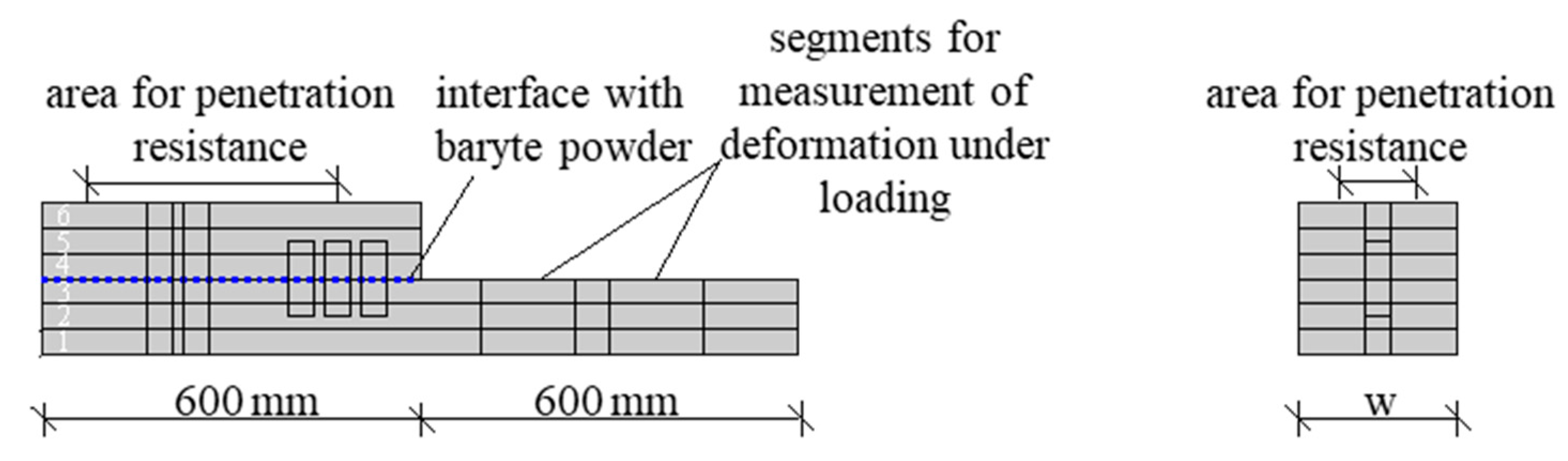

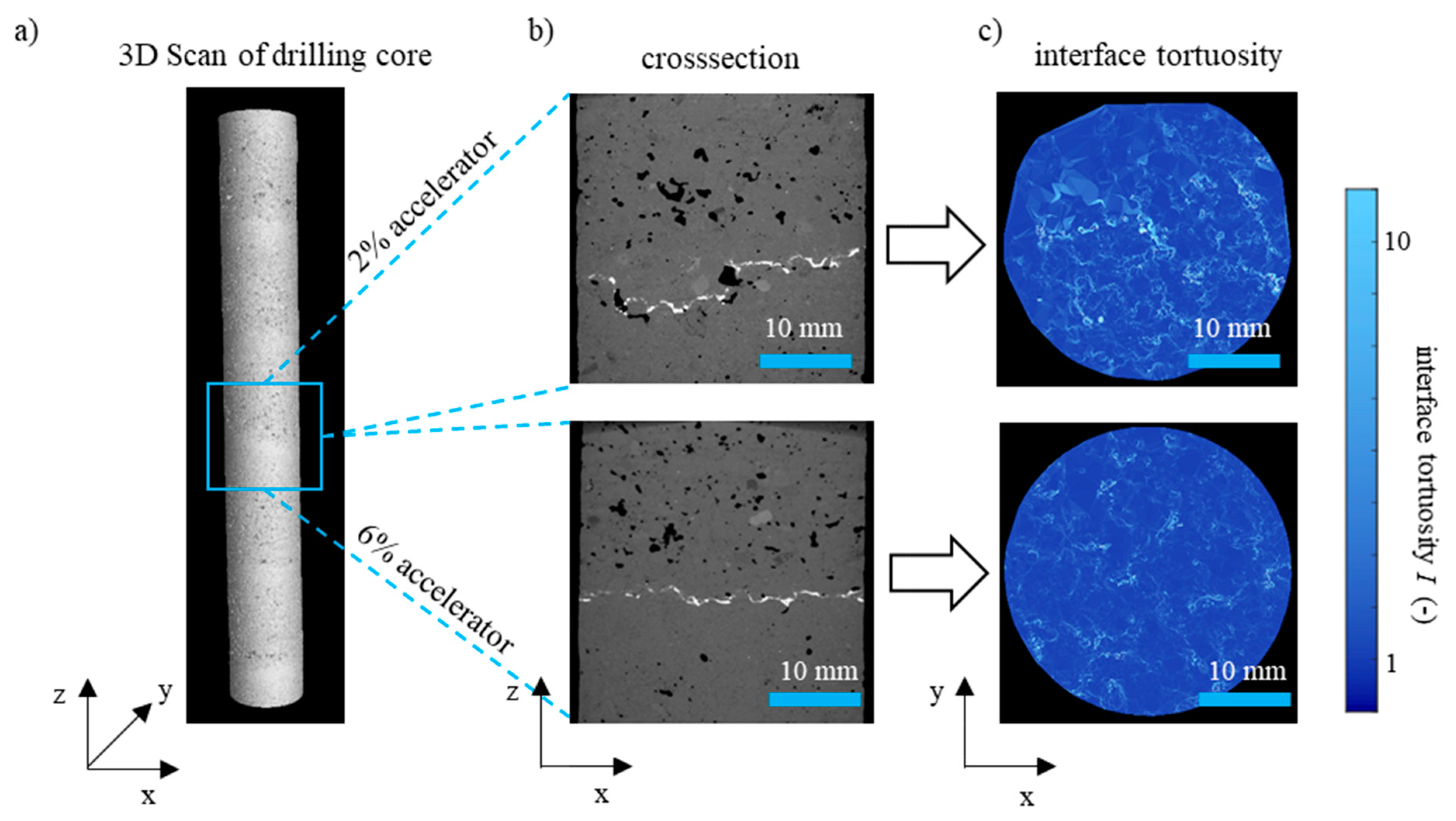

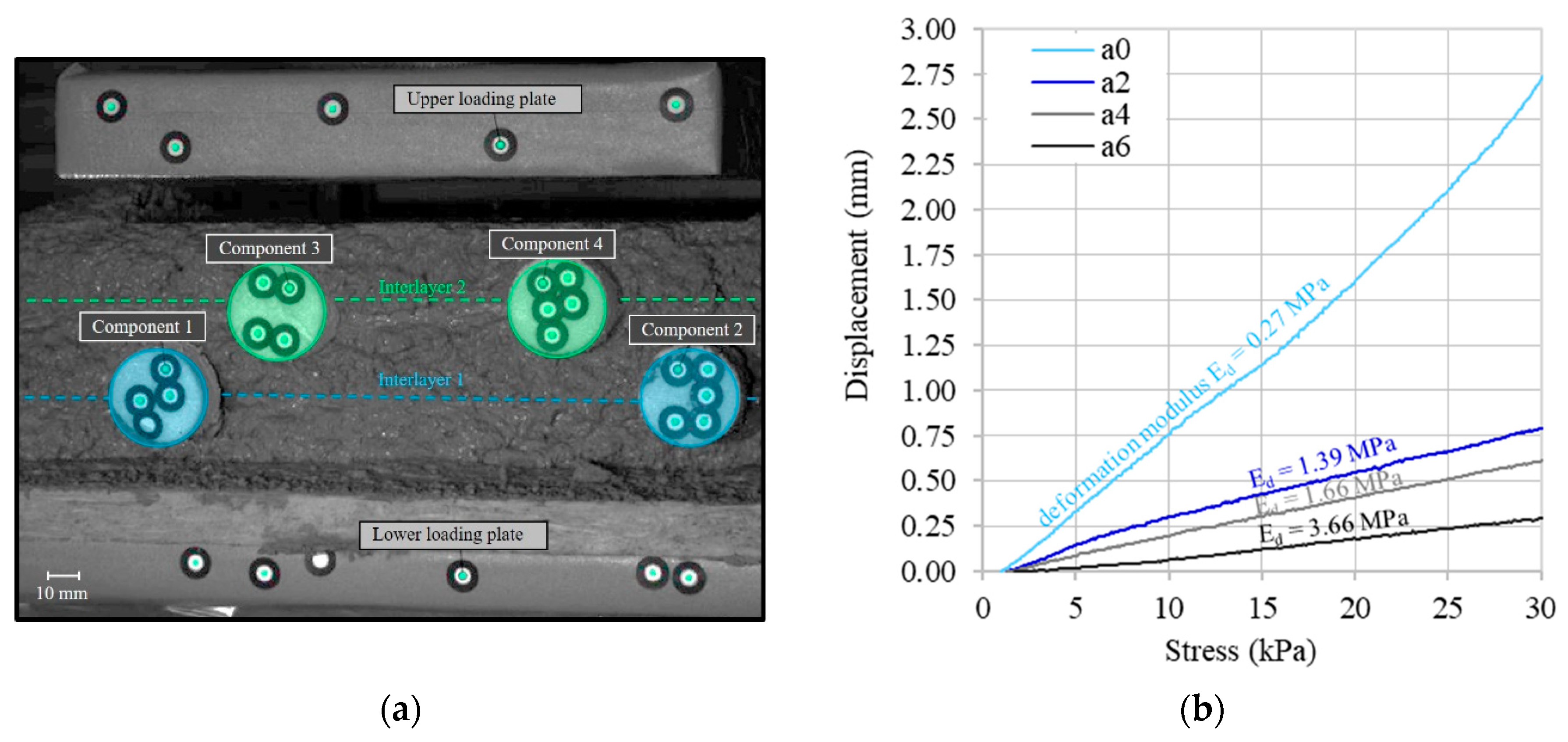

4.3.4. Investigations on Interlayer Characteristics

5. Results and Discussion

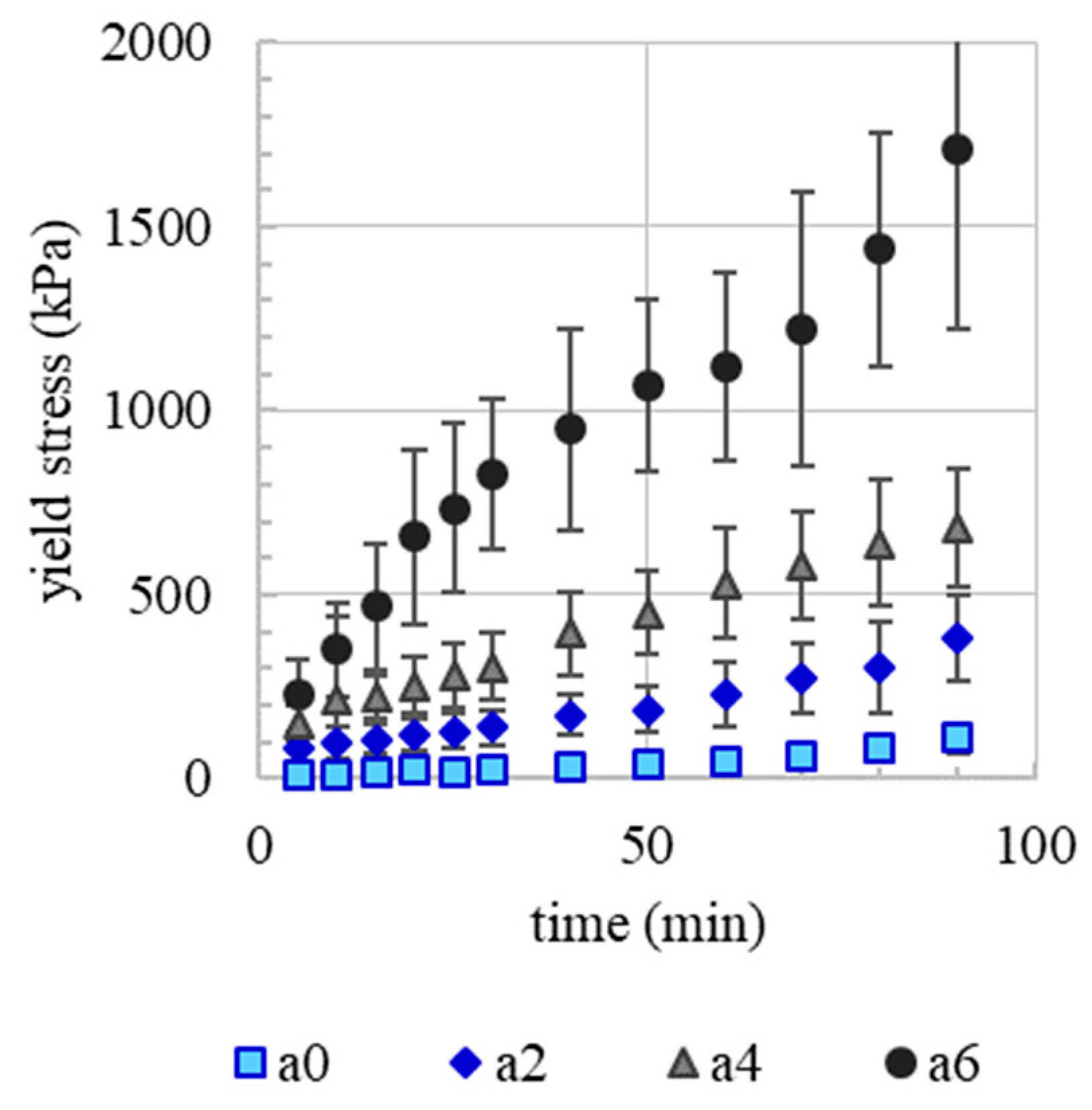

5.1. Fresh Properties

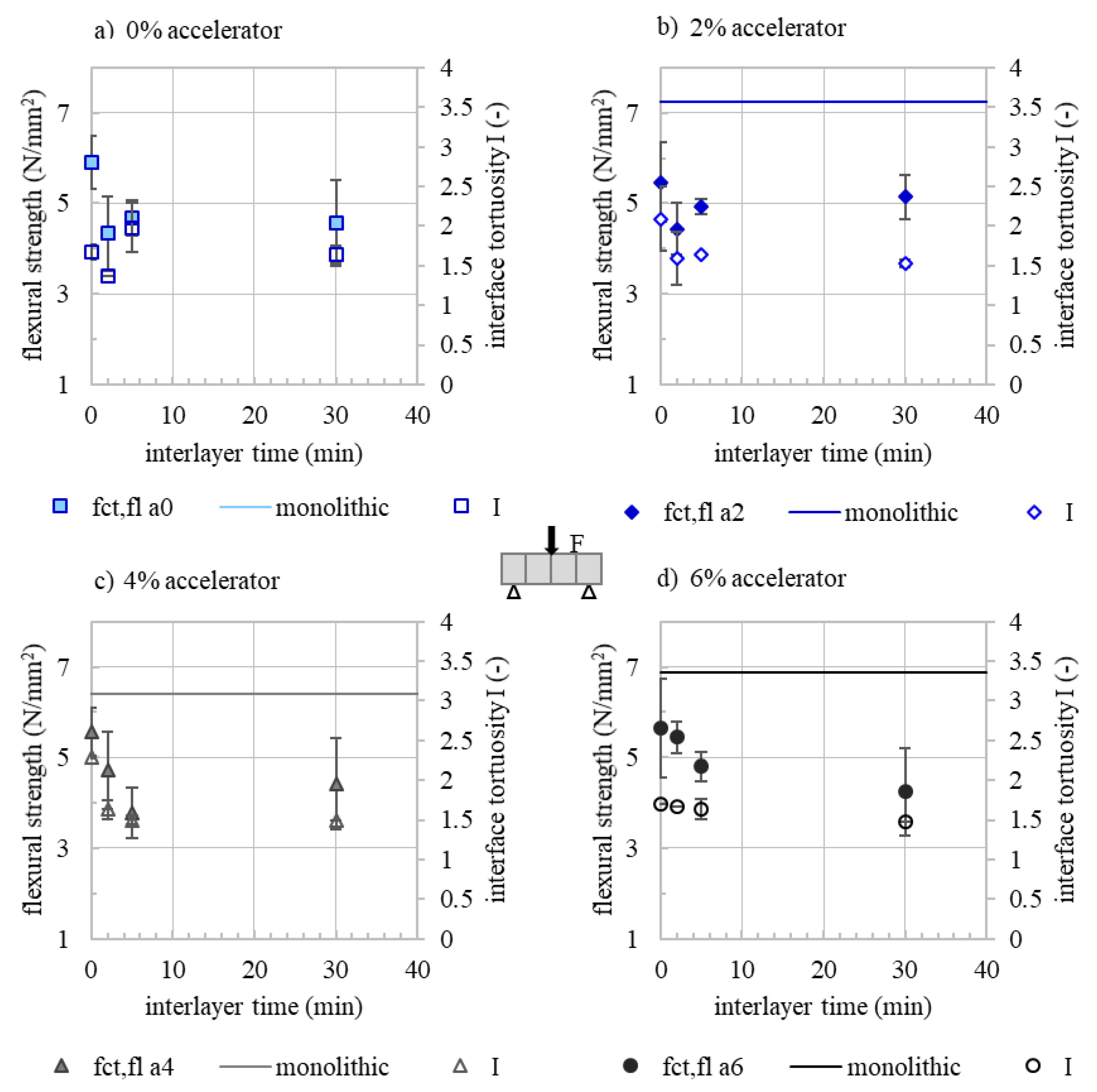

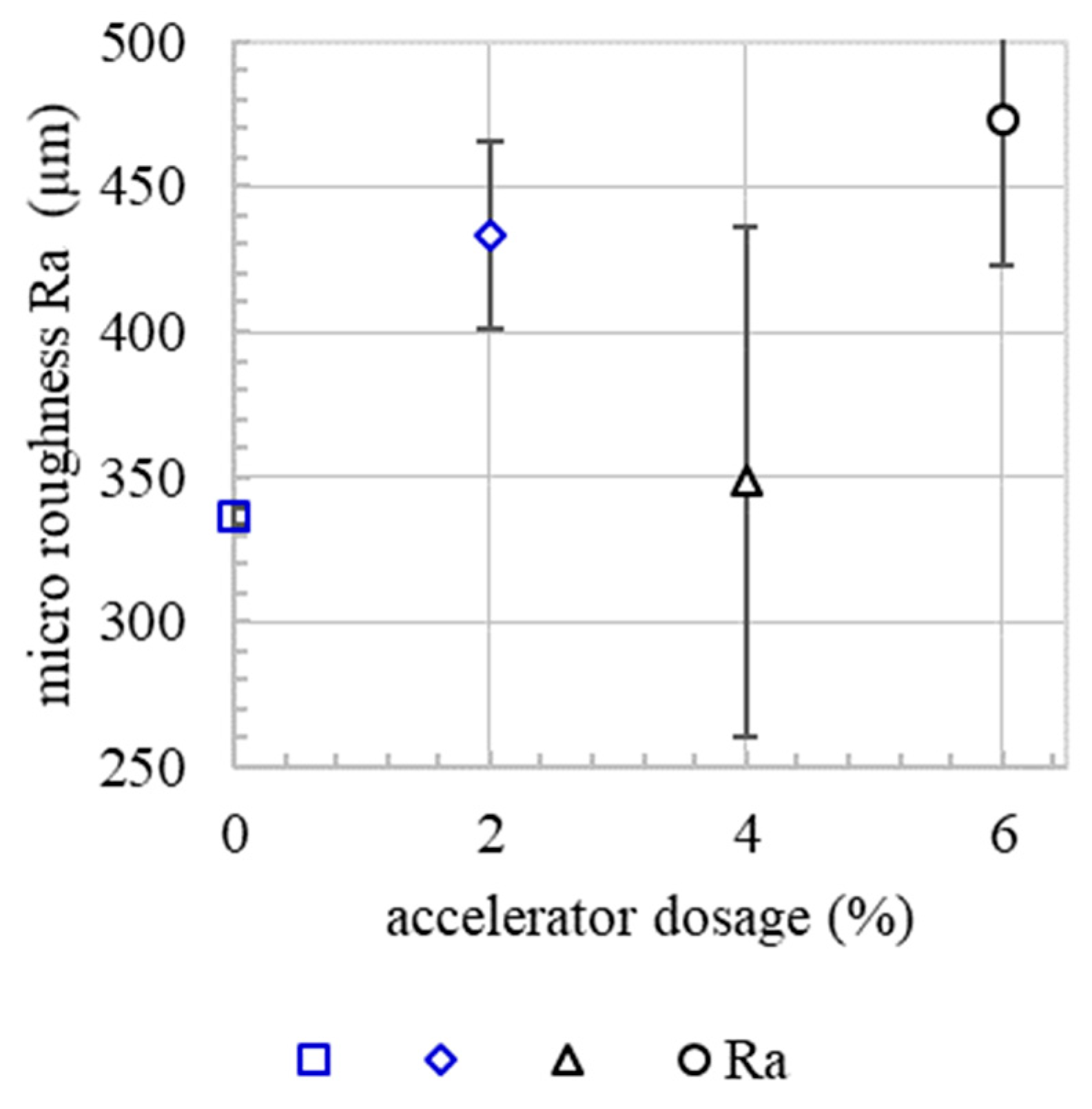

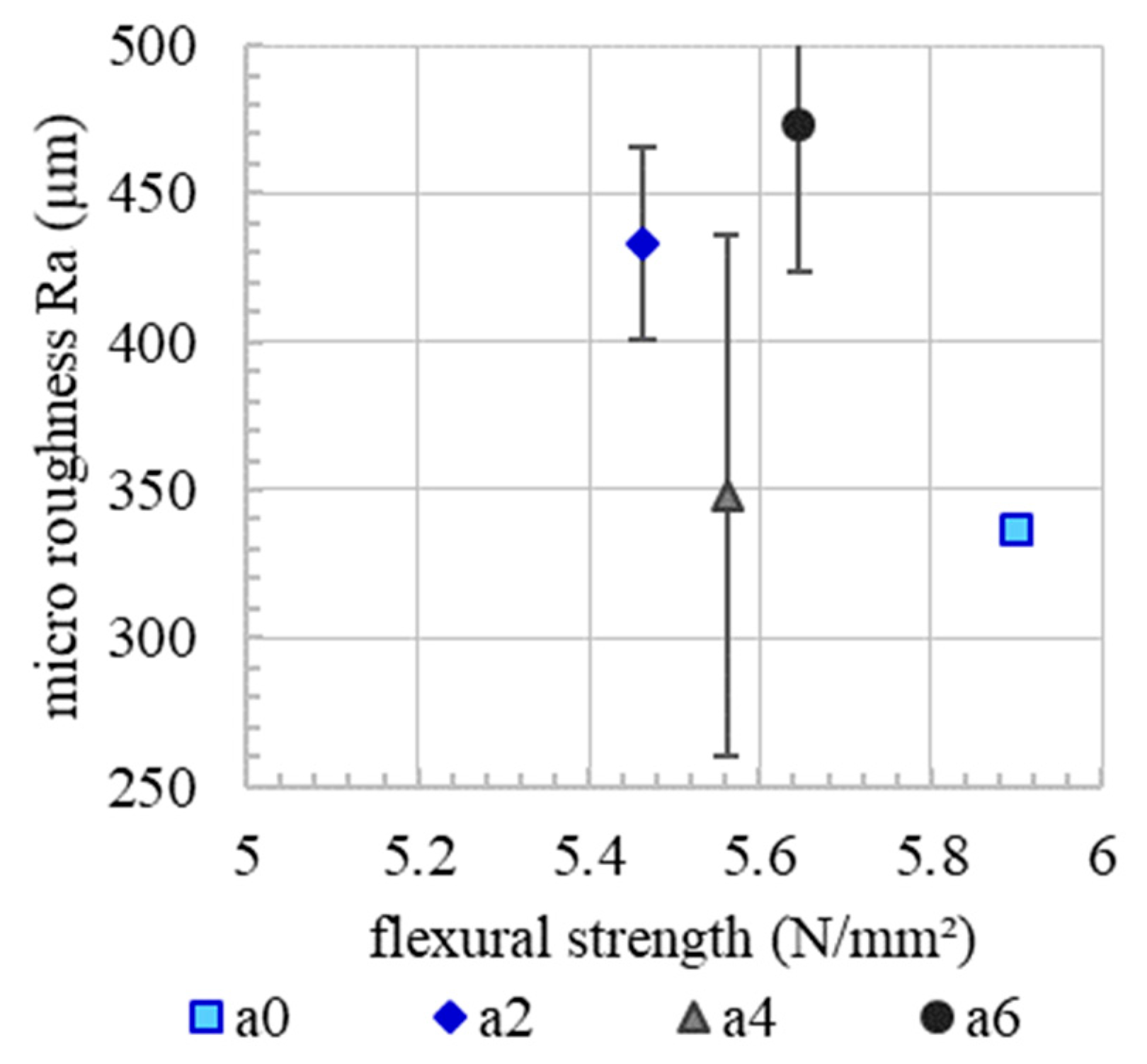

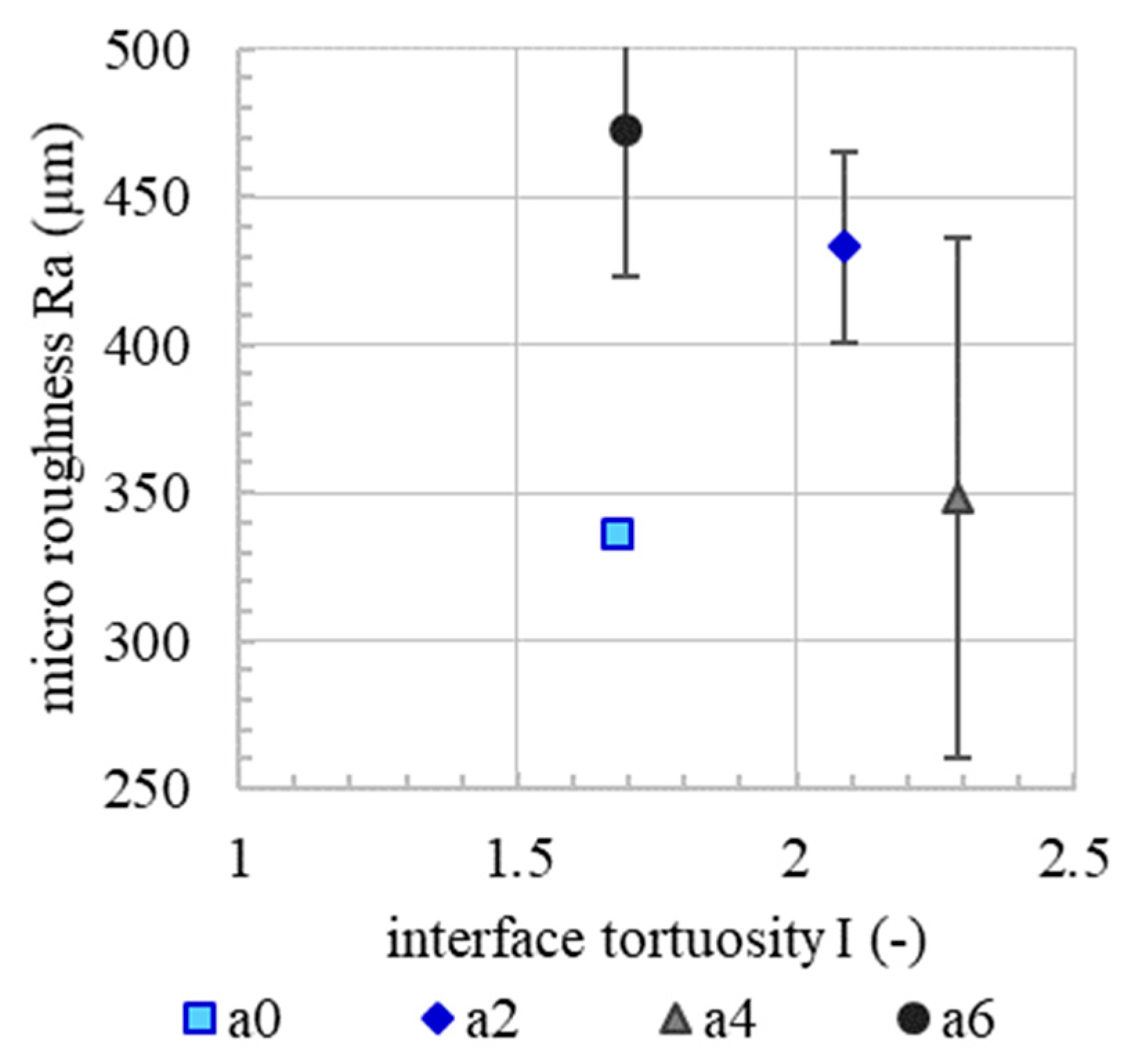

5.2. Interlayer Characteristics and Mechanical Properties

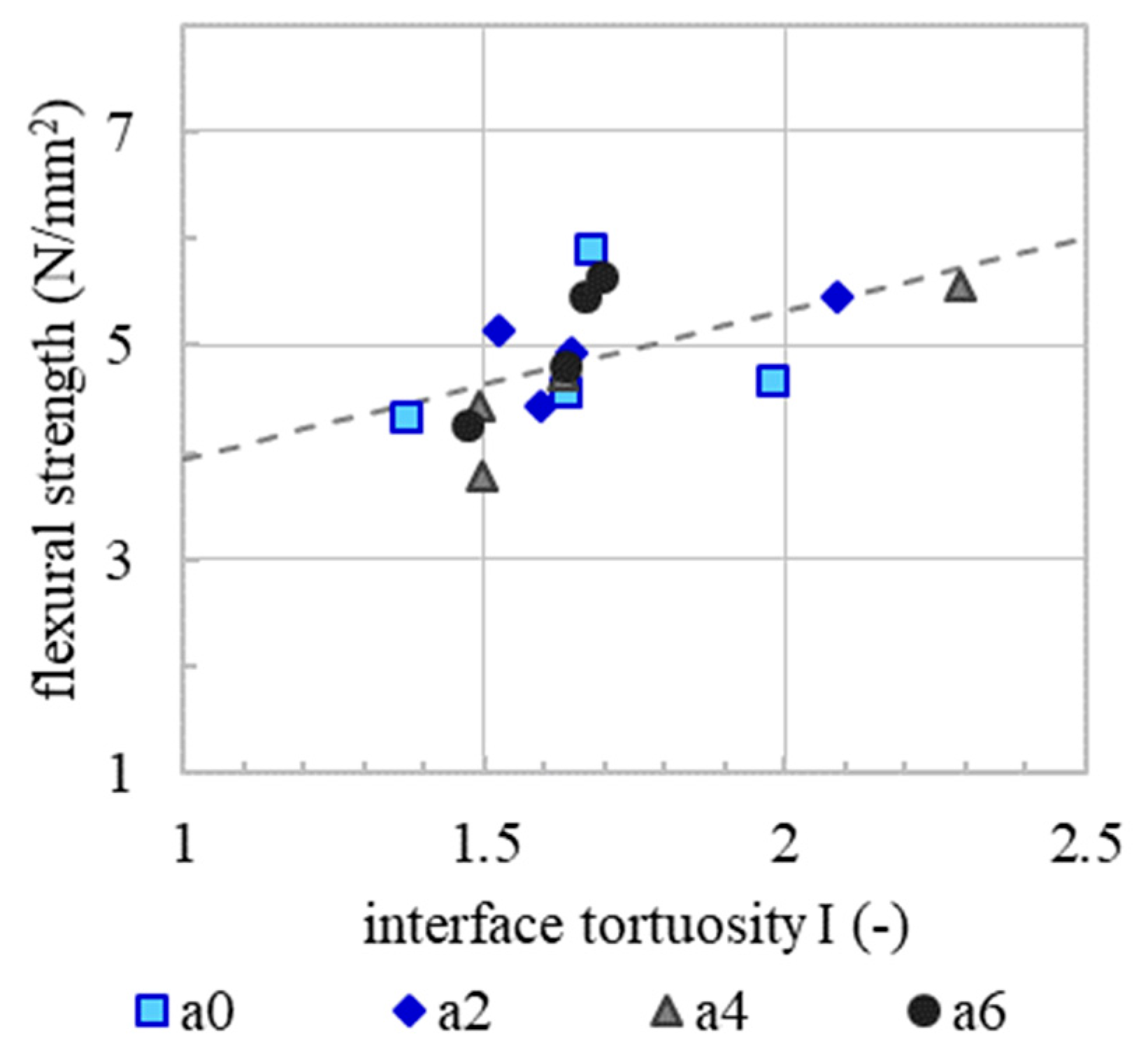

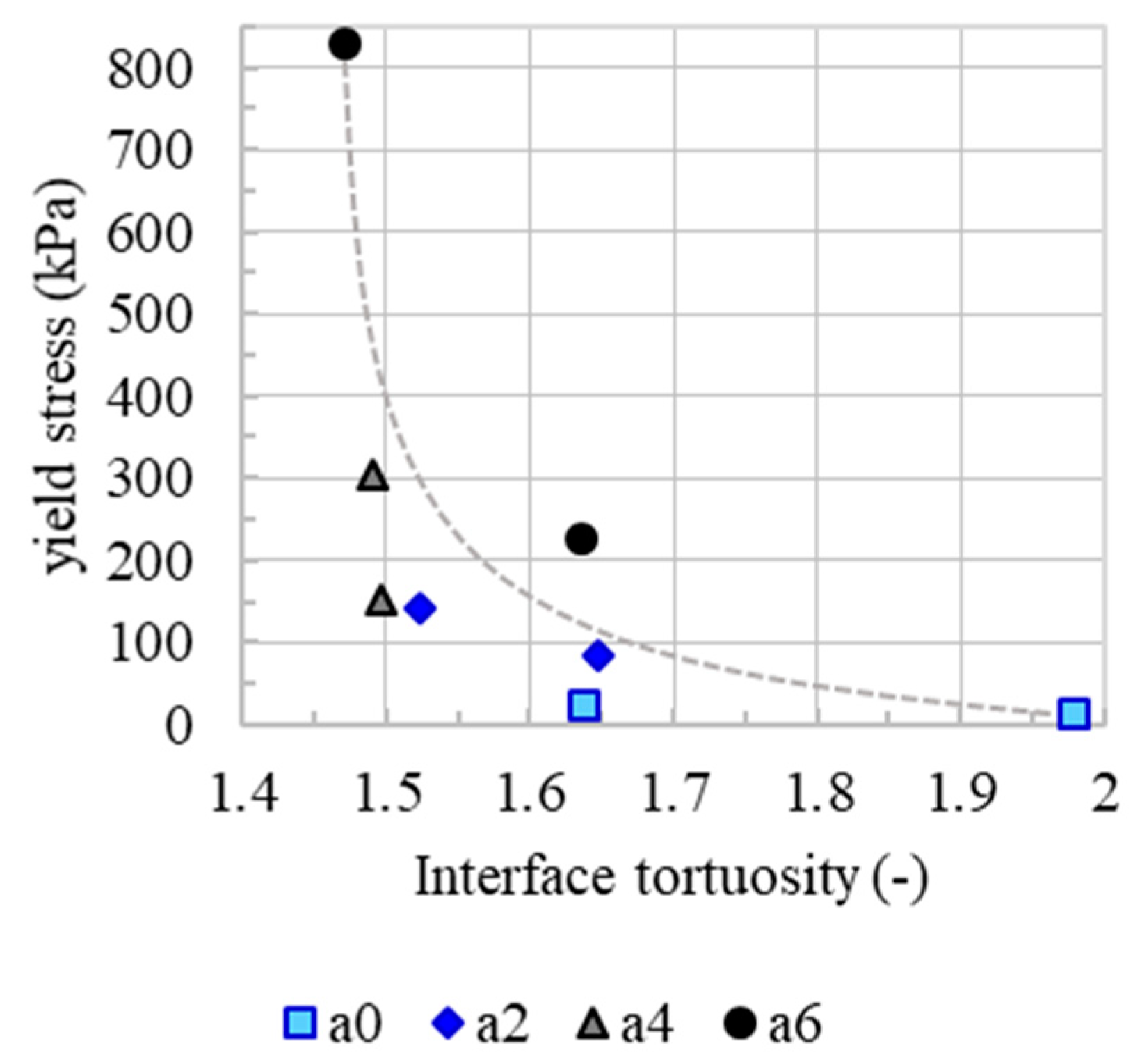

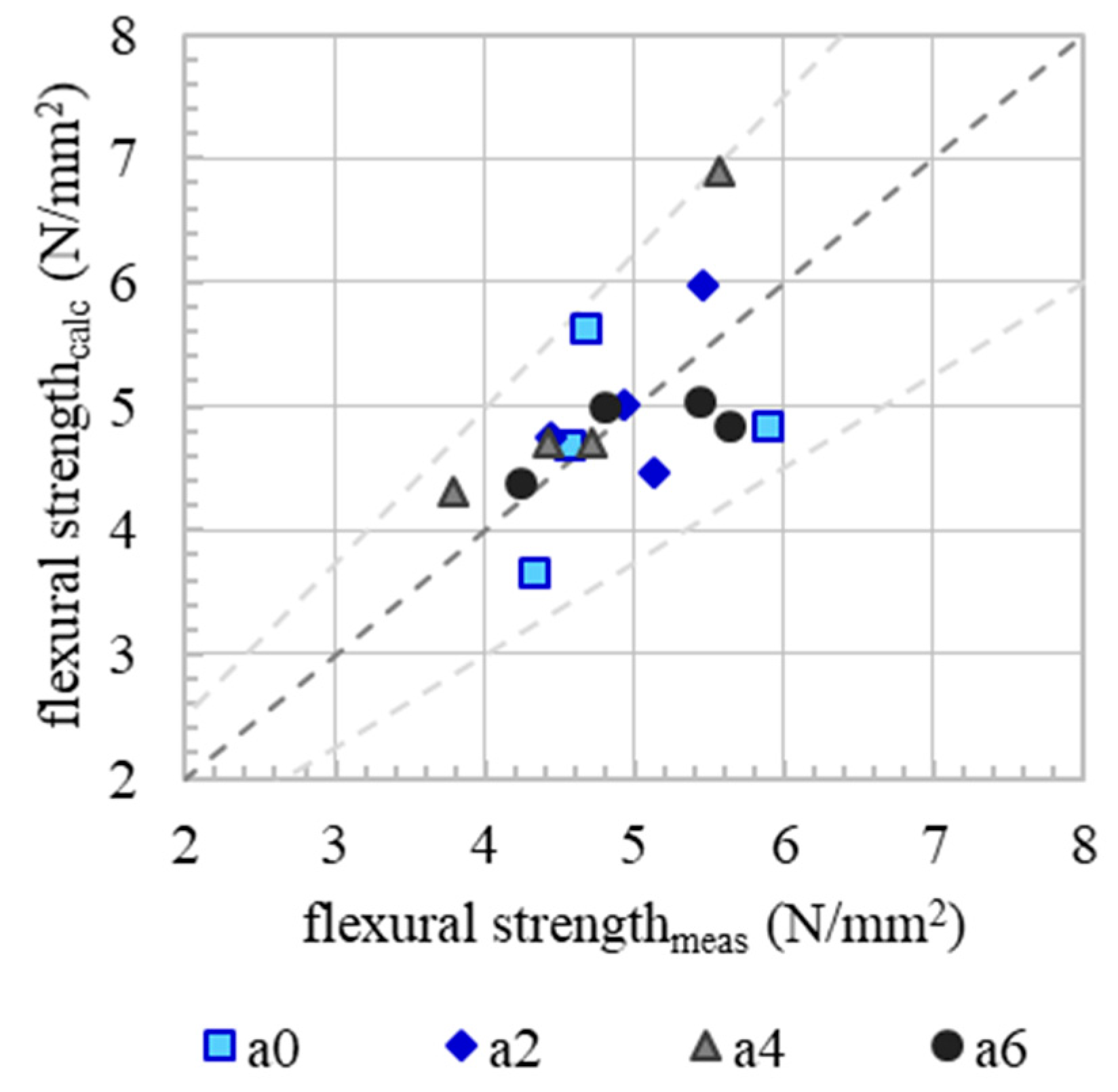

5.3. Modeling Interlayer Strength

6. Conclusions and Outlook

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- The Economist. The Third Industrial Revolution. 2012. Available online: https://www.economist.com/leaders/2012/04/21/the-third-industrial-revolution (accessed on 31 August 2018).

- Lowke, D.; Dini, E.; Perrot, A.; Weger, D.; Gehlen, C.; Dillenburger, B. Particle-bed 3D printing in concrete construction—Possibilities and challenges. Cem. Concr. Res. 2018, 112, 50–65. [Google Scholar] [CrossRef]

- Wörner, M.; Schmeer, D.; Schuler, B.; Pfinder, J.; Garrecht, H.; Sawodny, O.; Sobek, W. The technology of graded concrete—From the development of concrete mixtures and the conceptual design to the automatized manufacturing (in German). Beton Und Stahlbetonbau 2016, 111, 794–805. [Google Scholar] [CrossRef]

- Lim, S.; Le, T.; Webster, J.; Buswell, R.; Austin, A.; Gibb, A.; Thorpe, T. Fabrication Construction Components using Layered Manufacturing Technology; Lim, S., Thanh Le, J., Webster, J., Buswell, R., Austin, S., Gibb, A., Thorpe, T., Eds.; Loughborough University: Leicestershire, UK, 2009. [Google Scholar]

- Buswell, R.A.; Leal de Silva, W.R.; Jones, S.Z.; Dirrenberger, J. 3D printing using concrete extrusion: A roadmap for research. Cem. Concr. Res. 2018, 112, 37–49. [Google Scholar] [CrossRef]

- Asprone, D.; Auricchio, F.; Menna, C.; Mercuri, V. 3D printing of reinforced concrete elements: Technology and design approach. Constr. Build. Mater. 2018, 165, 218–231. [Google Scholar] [CrossRef]

- Asprone, D.; Menna, C.; Bos, F.P.; Salet, T.A.M.; Mata-Falcón, J.; Kaufmann, W. Rethinking reinforcement for digital fabrication with concrete. Cem. Concr. Res. 2018, 112, 111–121. [Google Scholar] [CrossRef]

- Xia, M.; Nematollahi, B.; Sanjayan, J.G. Compressive Strength and Dimensional Accuracy of Portland Cement Mortar Made Using Powder-Based 3D Printing for Construction Applications. In First RILEM International Conference on Concrete and Digital Fabrication: Digital Concrete 2018; Wangler, T., Flatt, R.J., Eds.; Springer: Cham, Switzerland, 2019; pp. 245–254. [Google Scholar]

- Panda, B.; Mohamed, N.; Tay, Y.; Tan, M. Bond Strength in 3D Printed Geopolymer Mortar. In First RILEM International Conference on Concrete and Digital Fabrication: Digital Concrete 2018; Wangler, T., Flatt, R.J., Eds.; Springer: Cham, Switzerland, 2019; pp. 200–206. [Google Scholar]

- Marchment, T.; Sanjayan, J.G. Method of Enhancing Interlayer Bond Strength in 3D Concrete Printing. In First RILEM International Conference on Concrete and Digital Fabrication: Digital Concrete 2018; Wangler, T., Flatt, R.J., Eds.; Springer: Cham, Switzerland, 2019; pp. 148–156. [Google Scholar]

- Khoshnevis, B. Automated construction by contour crafting—Related robotics and information technologies. Autom. Constr. 2004, 13, 5–19. [Google Scholar] [CrossRef]

- Khoshnevis, B.; Dutton, R. Innovative Rapid Prototyping Process Makes Large Sized, Smooth Surfaced Complex Shapes in a Wide Variety of Materials. Mater. Technol. 2016, 13, 53–56. [Google Scholar] [CrossRef]

- Khoshnevis, B.; Hwang, D.; Yao, K.T.; Yeh, Z. Mega-scale fabrication by Contour Crafting. IJISE 2006, 1, 301. [Google Scholar] [CrossRef]

- Khoshnevis, B.; Bukkapatnam, S.; Kwon, H.; Saito, J. Experimental investigation of contour crafting using ceramics materials. Rapid Prototyp. J. 2001, 7, 32–42. [Google Scholar] [CrossRef]

- Nerella, V.N.; Mechtcherine, V. Studying Printability of Fresh Concrete on-Site 3D Printing Technology (CONPrint3D); Nerella, V.N., Krause, M., Näther, M., Mechtcherine, V., Eds.; Rheologische Messungen an Baustoffen: Regensburg, Germany, 2016. [Google Scholar]

- Mechtcherine, V.; Nerella, V. Bewehrungskonzepte beim 3D-Druck mit Beton; IAB-Wissenschaftstage: Weimar, Germany, 2018; pp. 54–55. [Google Scholar]

- De Schutter, G.; Lesage, K.; Mechtcherine, V.; Nerella, V.N.; Habert, G.; Agusti-Juan, I. Vision of 3D printing with concrete—Technical, economic and environmental potentials. Cem. Concr. Res. 2018, 112, 25–36. [Google Scholar] [CrossRef]

- Nolte, N.; Heidmann-Ruhz, M.; Krauss, H.-W.; Varady, P.; Budelmann, H.; Wolter, A. Entwicklung von Spritzbetonrezepturen mit steuerbaren Eigenschaften für die robotergestützte additive Fertigung von Betonbauteilen: Development of shotcrete mixtures with controllable properties for the additive manufacturing of concrete structures. In Proceedings of the 2018—Spritzbetontagung, Alpbach, Austria, 11–12 January 2018. [Google Scholar]

- Roussel, N. Rheological requirements for printable concretes. Cem. Concr. Res. 2018, 112, 76–85. [Google Scholar] [CrossRef]

- Reiter, L.; Wangler, T.; Roussel, N.; Flatt, R.J. The role of early age structural build-up in digital fabrication with concrete. Cem. Concr. Res. 2018, 112, 86–95. [Google Scholar] [CrossRef]

- Hosseini, E.; Zakertabrizi, M.; Korayem, A.; Xu, G. A novel method to enhance the interlayer bonding of 3D printing concrete: An experimental and computational investigation. Cem. Concr. Compos. 2019, 99, 112–119. [Google Scholar] [CrossRef]

- Wangler, T.; Lloret, E.; Reiter, L.; Hack, N.; Gramazio, F.; Kohler, M.; Bernhard, M.; Dillenburger, B.; Buchli, J.; Roussel, N.; et al. Digital Concrete: Opportunities and Challenges. Rilem Tech. Lett. 2016, 1, 67–75. [Google Scholar] [CrossRef]

- Wangler, T.; Roussel, N.; Bos, F.P.; Salet, T.A.M.; Flatt, R.J. Digital Concrete: A Review. Cem. Concr. Res. 2019, 123, 105780. [Google Scholar] [CrossRef]

- Lindemann, H.; Gerbers, R.; Ibrahim, S.; Dietrich, F.; Dröder, K.; Raatz, A.; Kloft, H. Development of a Shotcrete 3D-Printing (SC3DP) Technology for Additive Manufacturing of Reinforced Freeform Concrete Structures. In Proceedings of the 1st International Conference on Concrete and Digital Fabrication, Zürich, Switzerland, 10–12 September 2018. [Google Scholar]

- Kloft, H.; Lowke, D.; Hack, N. Shotcrete 3D Printing (SC3DP)—An innovative and efficient technology for 3D printing of large-scale concrete components. In Drymix Mortar Yearbook 3D Special; Drymix.info: München, Germany, 2019; pp. 38–43. [Google Scholar]

- Kloft, H.; Hack, N.; Mainka, J.; Lowke, D. Large Scale 3D Concrete Printing. Constr. Print. Technol. 2019, 1, 17–24. [Google Scholar]

- Krauss, H.-W.; Nolte, N.; Budelmann, H.; Kloft, H.; Lowke, D. Additive Fertigung mit Beton—Herausforderungen und Lösungswege am Beispiel des SC3DP-Verfahrens. In Proceedings of the 20th Internationale Baustofftagung: ibausil, Weimar, Germany, 12–14 September 2018. [Google Scholar]

- Nolte, N.; Varady, P.; Krauss, H.-W.; Lowke, D. Schichtenverbund bei der additiven Fertigung—Einflussgrößen und Verfahrensvergleich. In Proceedings of the 20th Internationale Baustofftagung: ibausil, Weimar, Germany, 12–14 September 2018; pp. 1331–1338. [Google Scholar]

- Lindemann, H.; Kloft, H.; Hack, N. Gradual Transition Shotcrete 3D Printing. Advances in Architectural Geometry; Chalmers University of Technology: Gothenburg, Sweden, 2018. [Google Scholar]

- Sanjayan, J.G.; Nematollahi, B.; Xia, M.; Marchment, T. Effect of surface moisture on inter-layer strength of 3D printed concrete. Constr. Build. Mater. 2018, 172, 468–475. [Google Scholar] [CrossRef]

- Nerella, V.; Hempel, S.; Mechtcherine, V. Effects of layer-interface properties on mechanical performance of concrete elements produced by extrusion-based 3D-printing. Constr. Build. Mater. 2019, 205, 586–601. [Google Scholar] [CrossRef]

- Zareiyan, B.; Khoshnevis, B. Effects of interlocking on interlayer adhesion and strength of structures in 3D printing of concrete. Autom. Constr. 2017, 83, 212–221. [Google Scholar] [CrossRef]

- Marchment, T.; Sanjayan, J.; Xia, M. Method of enhancing interlayer bond strength in construction scale 3D printing with mortar by effective bond area amplification. Mater. Des. 2019, 169, 107684. [Google Scholar] [CrossRef]

- Wolfs, R.J.M.; Bos, F.P.; Salet, T.A.M. Hardened properties of 3D printed concrete: The influence of process parameters on interlayer adhesion. Cem. Concr. Res. 2019, 119, 132–140. [Google Scholar] [CrossRef]

- Le, T.T.; Austin, S.A.; Lim, S.; Buswell, R.A.; Law, R.; Gibb, A.G.F.; Thorpe, T. Hardened properties of high-performance printing concrete. Cem. Concr. Res. 2012, 42, 558–566. [Google Scholar] [CrossRef]

- Paul, S.C.; Tay, Y.W.D.; Panda, B.; Tan, M.J. Fresh and hardened properties of 3D printable cementitious materials for building and construction. Arch. Civ. Mech. Eng. 2018, 18, 311–319. [Google Scholar] [CrossRef]

- Feng, P.; Meng, X.; Chen, J.-F.; Ye, L. Mechanical properties of structures 3D printed with cementitious powders. Constr. Build. Mater. 2015, 93, 486–497. [Google Scholar] [CrossRef]

- Bos, F.; Wolfs, R.; Ahmed, Z.; Salet, T. Additive manufacturing of concrete in construction: Potentials and challenges of 3D concrete printing. Virtual Phys. Prototyp. 2016, 11, 209–225. [Google Scholar] [CrossRef]

- Nerella, V.; Hempel, S.; Mechtcherine, V. Micro- and Macroscopic Investigations on the Interface between Layers of 3D-printed Cementitious Elements. In Proceedings of the International Conference on Advances in Construction Materials and Systems, Chennai, India, 3–8 September 2017. [Google Scholar]

- Marchment, T.; Sanjayan, J.G.; Nematollahi, B.; Xia, M. Interlayer Strength of 3D Printed Concrete. In 3D Concrete Printing Technology; Butterworth-Heinemann: Hawthorn, Victoria, Australia, 2019; pp. 241–264. [Google Scholar] [CrossRef]

- Van der Putten, J.; de Schutter, G.; van Tittelboom, K. The Effect of Print Parameters on the (Micro) structure of 3D Printed Cementitious Materials. In First RILEM International Conference on Concrete and Digital Fabrication—Digital Concrete 2018; Wangler, T., Flatt, R.J., Eds.; Springer: Cham, Switzerland, 2019. [Google Scholar]

- Keita, E.; Bessaies-Bey, H.; Zuo, W.; Belin, P.; Roussel, N. Weak bond strength between successive layers in extrusion-based additive manufacturing: Measurement and physical origin. Cem. Concr. Res. 2019, 123, 105787. [Google Scholar] [CrossRef]

- Marchment, T.; Xia, M.; Dodd, E.; Sanjayan, J.G.; Nematollahi, B. Effect of Delay Time on the Mechanical Properties of Extrusion-based 3D Printed Concrete. In Proceedings of the 34th International Symposium on automation and Rovotics in Construction, Taipei, Taiwan, 28 June–1 July 2017. [Google Scholar]

- Zareiyan, B.; Khoshnevis, B. Effects of mixture ingredients on interlayer adhesion of concrete in Contour Crafting. Rapid Prototyp. J. 2018, 24, 584–592. [Google Scholar] [CrossRef]

- Zareiyan, B.; Khoshnevis, B. Interlayer adhesion and strength of structures in Contour Crafting—Effects of aggregate size, extrusion rate, and layer thickness. Autom. Constr. 2017, 81, 112–121. [Google Scholar] [CrossRef]

- Roussel, N.; Cussigh, F. Distinct-layer casting of SCC: The mechanical consequences of thixotropy. Cem. Concr. Res. 2008, 38, 624–632. [Google Scholar] [CrossRef]

- Lowke, D. Thixotropy of SCC—A model describing the effect of particle packing and superplasticizer adsorption on thixotropic structural build-up of the mortar phase based on interparticle interactions. Cem. Concr. Res. 2018, 104, 94–104. [Google Scholar] [CrossRef]

- Wallevik, J.E. Rheological properties of cement paste: Thixotropic behavior and structural breakdown. Cem. Concr. Res. 2009, 39, 14–29. [Google Scholar] [CrossRef]

- Panda, B.; Paul, S.C.; Mohamed, N.A.N.; Tay, Y.W.D.; Tan, M.J. Measurement of tensile bond strength of 3D printed geopolymer mortar. Measurement 2018, 113, 108–116. [Google Scholar] [CrossRef]

- Kloft, H.; Krauss, H.-W.; Hack, N.; Herrmann, E.; Neudecker, S.; Varady, P.; Lowke, D. Shotcrete 3D Printing (SC3DP): A robot-guided technology for Additive Manufacturing of large-scale reinforced concrete components. Cem. Concr. Res. (Spec. Issue) 2020. submitted for publication. [Google Scholar]

- DIN EN 12350-2: Testing Fresh Concrete—Part 2: Slump Test; British Standards Institution: London, UK, September 2019.

- Lootens, D.; Jousset, P.; Martinie, L.; Roussel, N.; Flatt, R.J. Yield stress during setting of cement pastes from penetration tests. Cem. Concr. Res. 2009, 39, 401–408. [Google Scholar] [CrossRef]

- Mettler, L.K.; Wittel, F.K.; Flatt, R.J.; Herrmann, H.J. Evolution of strength and failure of SCC during early hydration. Cem. Concr. Res. 2016, 89, 288–296. [Google Scholar] [CrossRef]

- Gom mbH. Aquisition with Aramis (Manual); Gom mbH: Braunschweig, Germany, 2015. [Google Scholar]

- Carrara, P.; Kruse, R.; Bentz, D.; Lunardelli, M.; Leusmann, T.; Varady, P.; de Lorenzis, L. Improved mesoscale segmentation of concrete from 3D X-ray images using contrast enhancers. Cem. Concr. Compos. 2018, 93, 30–42. [Google Scholar] [CrossRef]

- Mengel, L.; Krauss, H.-W.; Lowke, D. Fluid Transport Through Cracks in Plain and Reinforced Concrete—Influencing Factors and Open Questions. Constr. Build. Mater. 2019. Submitted for publication. [Google Scholar]

- DIN EN ISO 4287: Geometrical Product Specifications (GPS)—Surface Texture: Profile Method—Terms, Definitions and Surface Texture Parameters; British Standards Institution: London, UK, July 2010.

- Myrdal, R. Accelerating Admixtures for Concrete; SINTEF: Trondheim, Norway, 2007. [Google Scholar]

- Bravo, A.; Cerulli, T.; Maltese, C.; Pistolesi, C.; Salvioni, D. Effects of Increasing Dosages of an Alkali-Free Accelerator on the Physical and Chemical Properties of a Hydrating Cement Paste. ACI 2003, 217, 211–226. [Google Scholar]

- Salvador, R.P.; Cavalaro, S.H.P.; Cano, M.; Figueiredo, A.D. Influence of spraying on the early hydration of accelerated cement pastes. Cem. Concr. Res. 2016, 88, 7–19. [Google Scholar] [CrossRef]

- Walraven, J.C. Aggregate Interlock: A Theoretical and Experimental Analysis. Ph.D. Thesis, TU Delft, Delft, The Netherlands, 1980. [Google Scholar]

| Accelerator Dosage | Interlayer Time | |||

|---|---|---|---|---|

| 0. Min | 2. Min | 5. Min | 30. Min | |

| 0% Accelerator | a0t0 | a0t2 | a0t5 | a0t30 |

| 2% Accelerator | a2t0 | a2t2 | a2t5 | a2t30 |

| 4% Accelerator | a4t0 | a4t2 | a4t5 | a4t30 |

| 6% Accelerator | a6t0 | a6t2 | a6t5 | a6t30 |

| Components | Value | Unit |

|---|---|---|

| Portland Cement (CEM I 52.5) | 600 | kg/m3 |

| Ground limestone | 97 | kg/m3 |

| Aggregate, d = 0–3.15 mm | 1258 | kg/m3 |

| Water | 270 | kg/m3 |

| Stabilizer | 0.1 | M.-% |

| PCE superplasticizer | 0.3 | M.-%/cement |

| Alkali-free set accelerator | 0–6 | M.-%/cement |

| Accelerator Dosage | Total Deformation of Lowest Layer at a Load of 1000 N |

|---|---|

| 0% | 2.9 mm |

| 2% | 1.2 mm |

| 4% | 0.8 mm |

| 6% | 0.5 mm |

| Accelerator Dosage | Averaged Compressive Strength fc | Standard Deviation σfc |

|---|---|---|

| 0% | 59.9 N/mm2 | 3.4 N/mm2 |

| 2% | 64.8 N/mm2 | 2.8 N/mm2 |

| 4% | 66.0 N/mm2 | 4.6 N/mm2 |

| 6% | 65.7 N/mm2 | 3.0 N/mm2 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dressler, I.; Freund, N.; Lowke, D. The Effect of Accelerator Dosage on Fresh Concrete Properties and on Interlayer Strength in Shotcrete 3D Printing. Materials 2020, 13, 374. https://doi.org/10.3390/ma13020374

Dressler I, Freund N, Lowke D. The Effect of Accelerator Dosage on Fresh Concrete Properties and on Interlayer Strength in Shotcrete 3D Printing. Materials. 2020; 13(2):374. https://doi.org/10.3390/ma13020374

Chicago/Turabian StyleDressler, Inka, Niklas Freund, and Dirk Lowke. 2020. "The Effect of Accelerator Dosage on Fresh Concrete Properties and on Interlayer Strength in Shotcrete 3D Printing" Materials 13, no. 2: 374. https://doi.org/10.3390/ma13020374

APA StyleDressler, I., Freund, N., & Lowke, D. (2020). The Effect of Accelerator Dosage on Fresh Concrete Properties and on Interlayer Strength in Shotcrete 3D Printing. Materials, 13(2), 374. https://doi.org/10.3390/ma13020374