Fresh and Hardened Properties of Portland Cement-Slag Concrete Activated Using the By-Product of the Liquid Crystal Display Manufacturing Process

Abstract

1. Introduction

2. Experimental Program

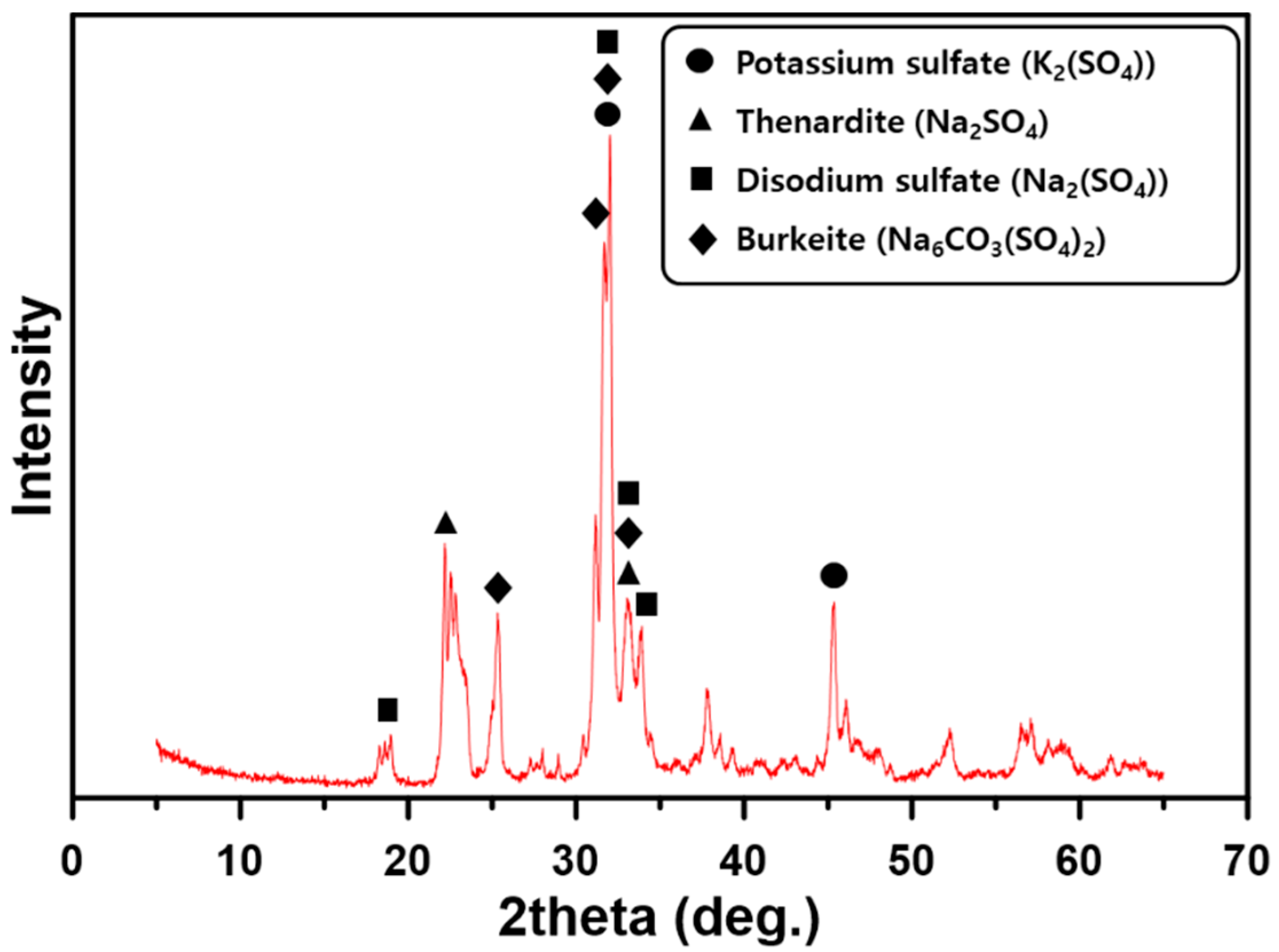

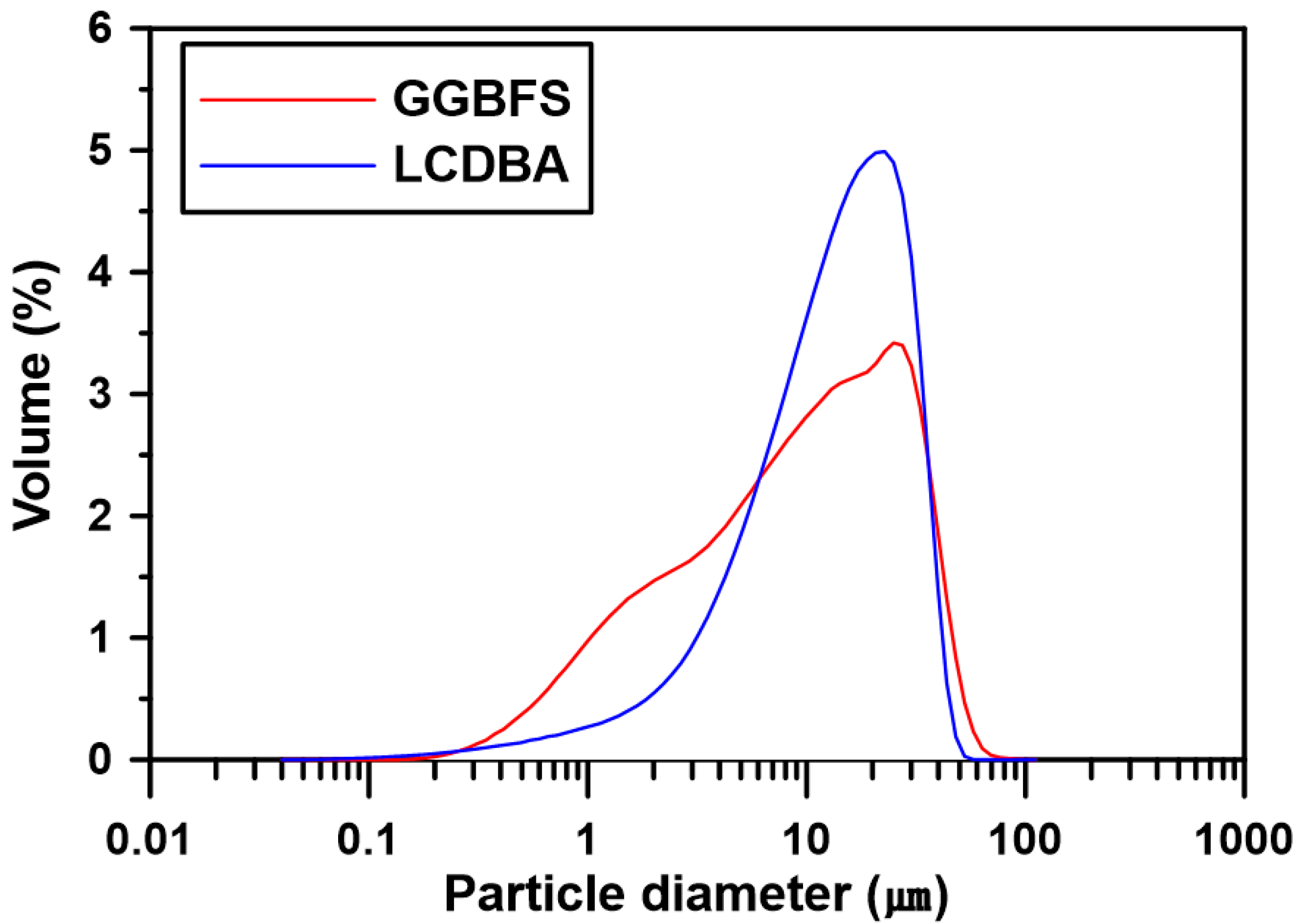

2.1. Raw Materials

2.2. Mix Proportions

2.3. Experimental Methods

3. Test Results and Discussions

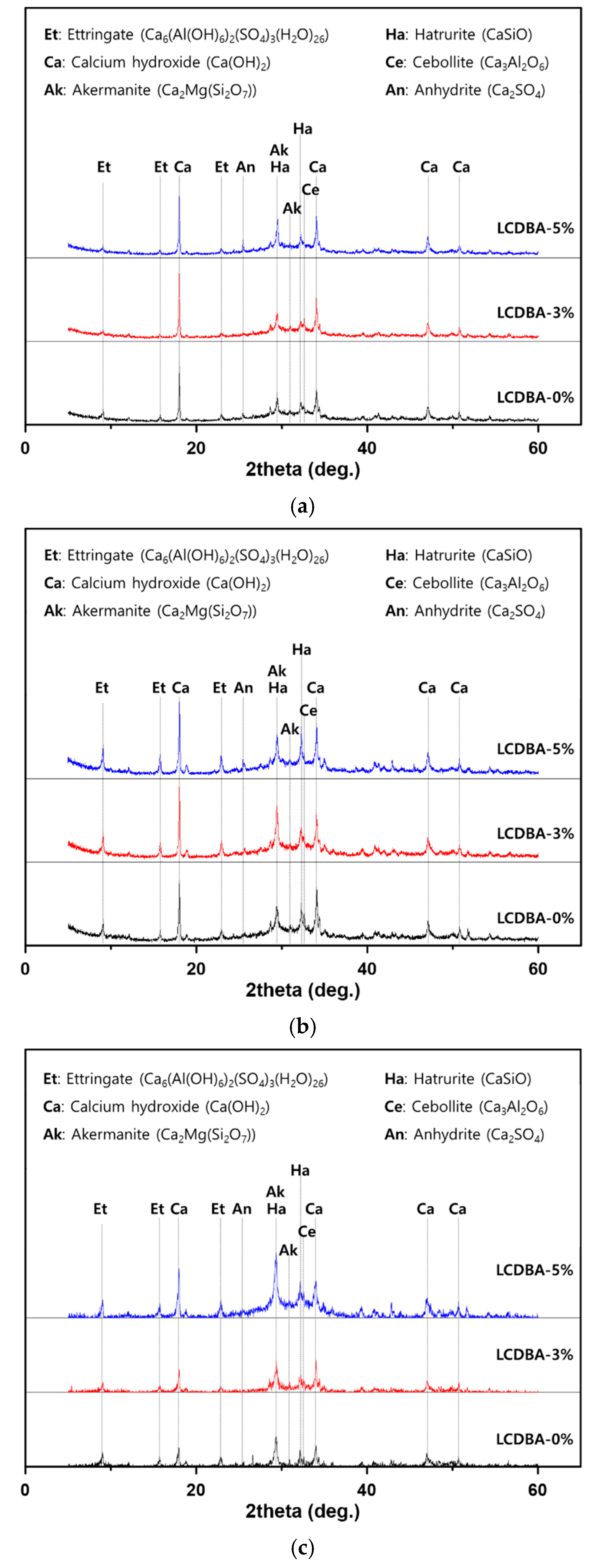

3.1. XRD Analysis

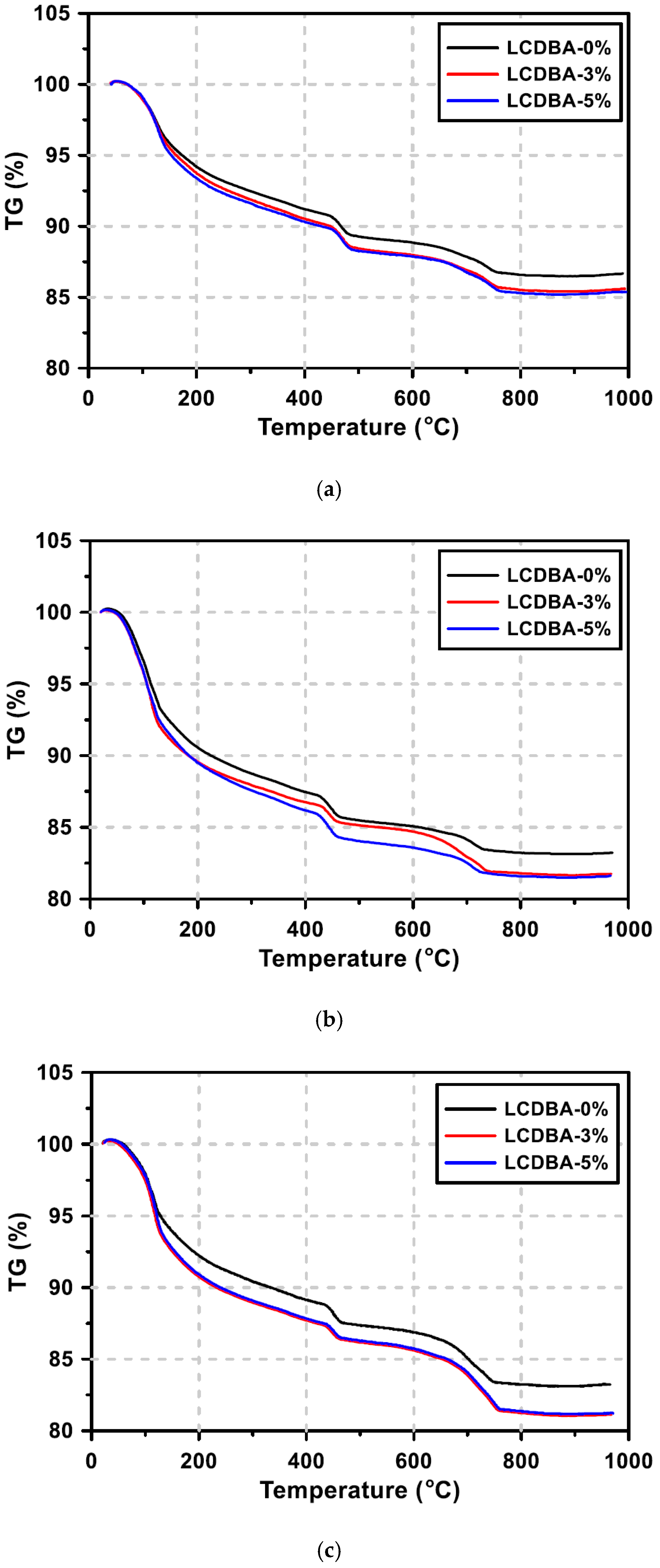

3.2. TG Analysis

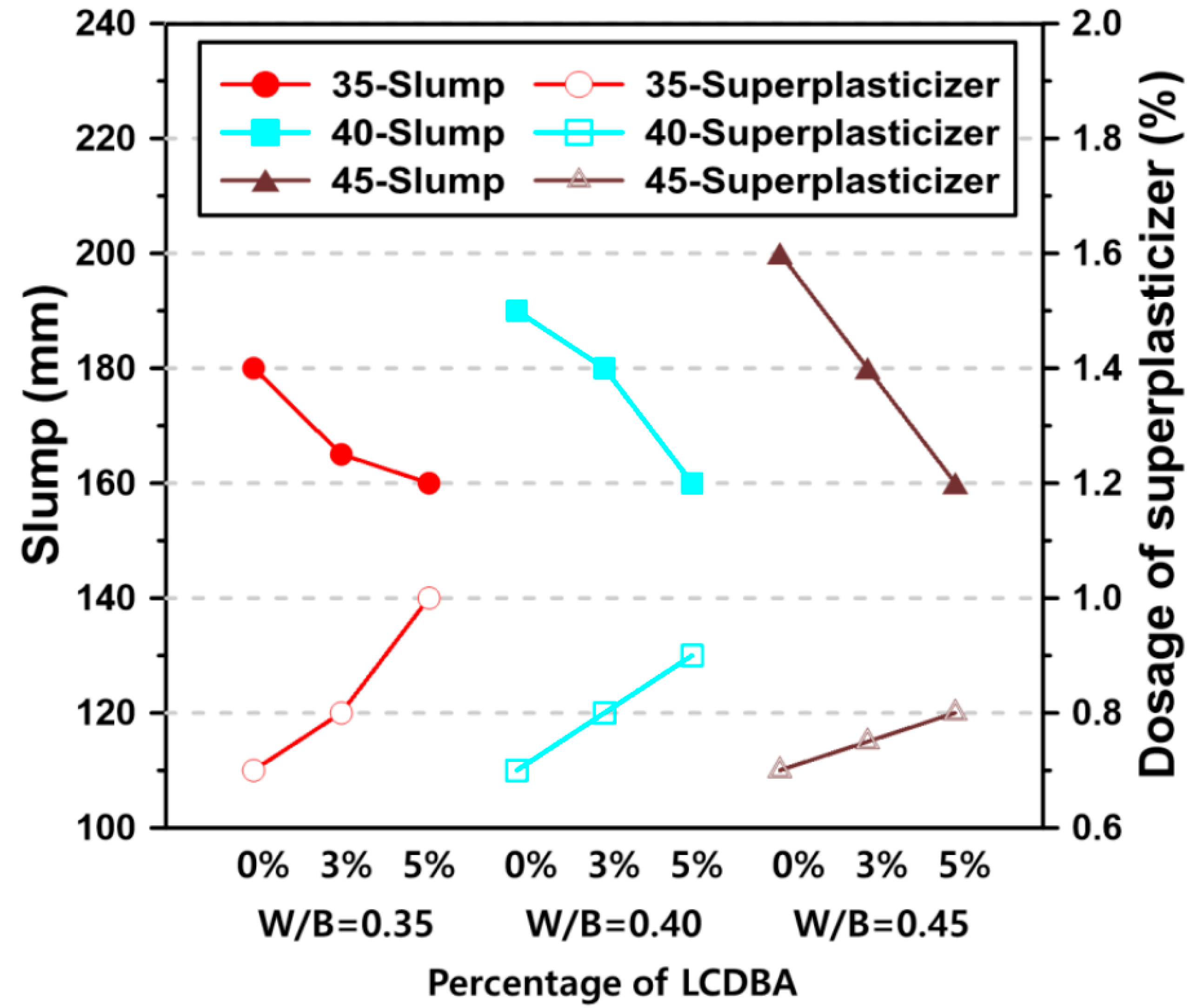

3.3. Workability

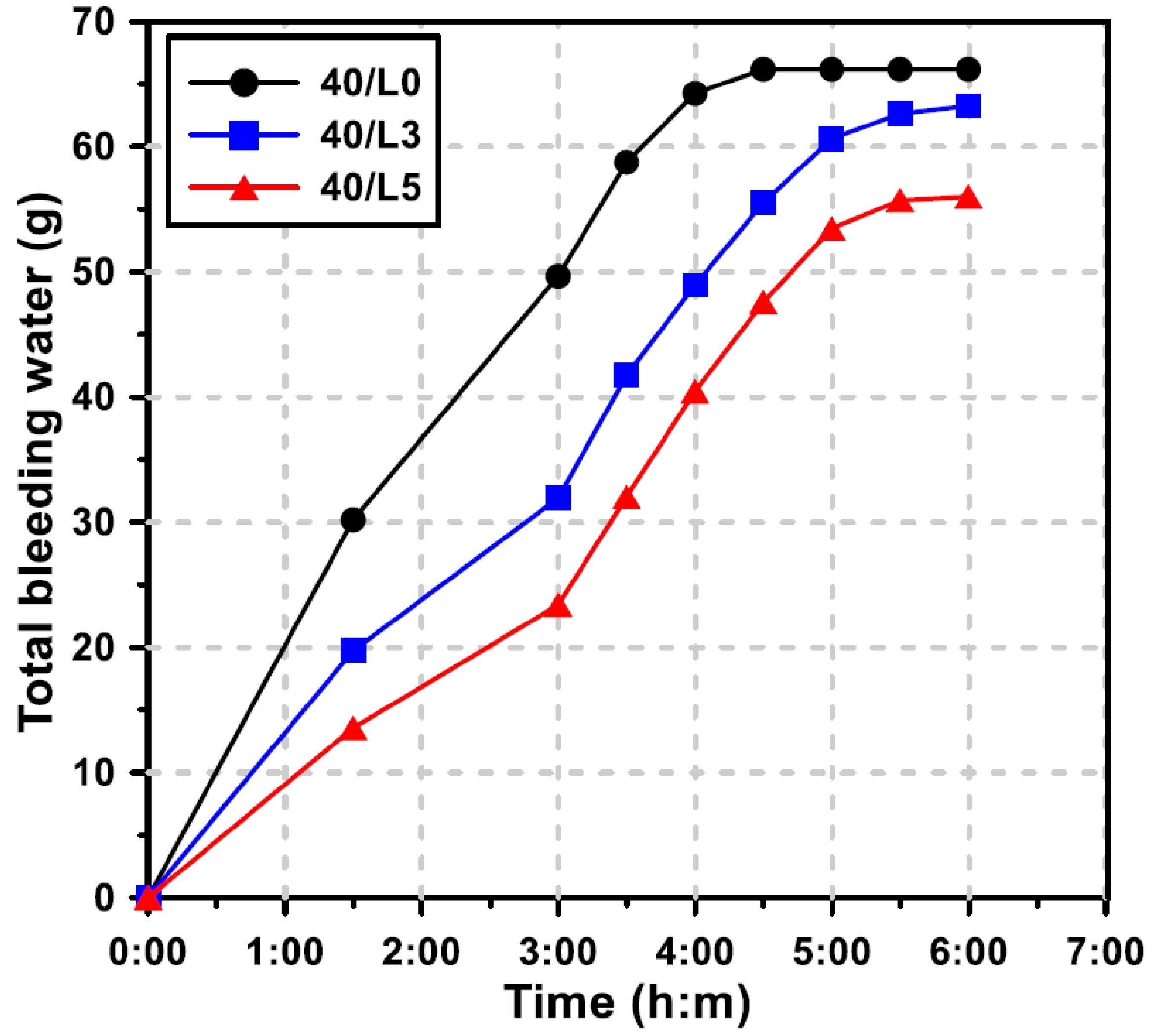

3.4. Bleeding

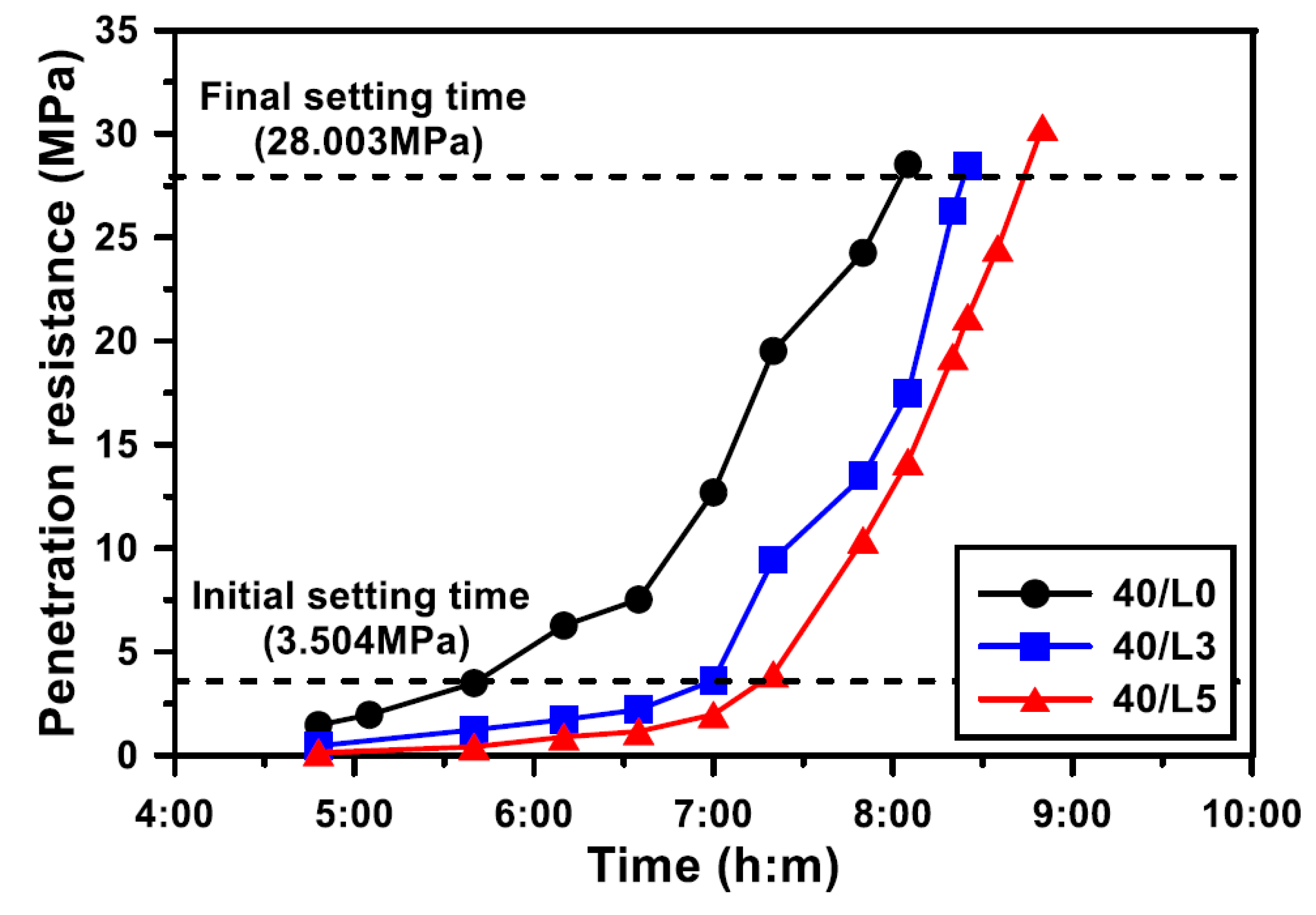

3.5. Setting Time

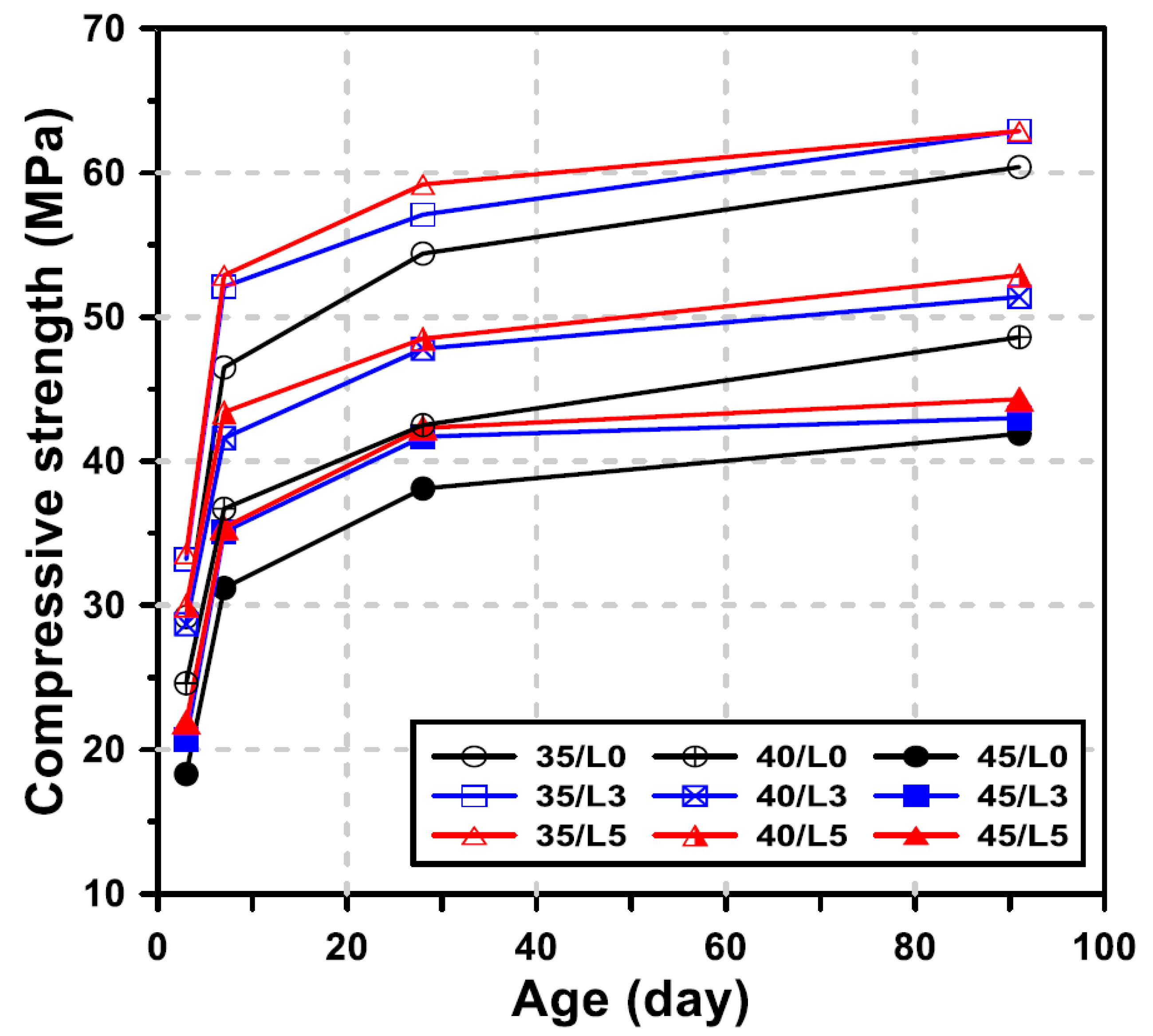

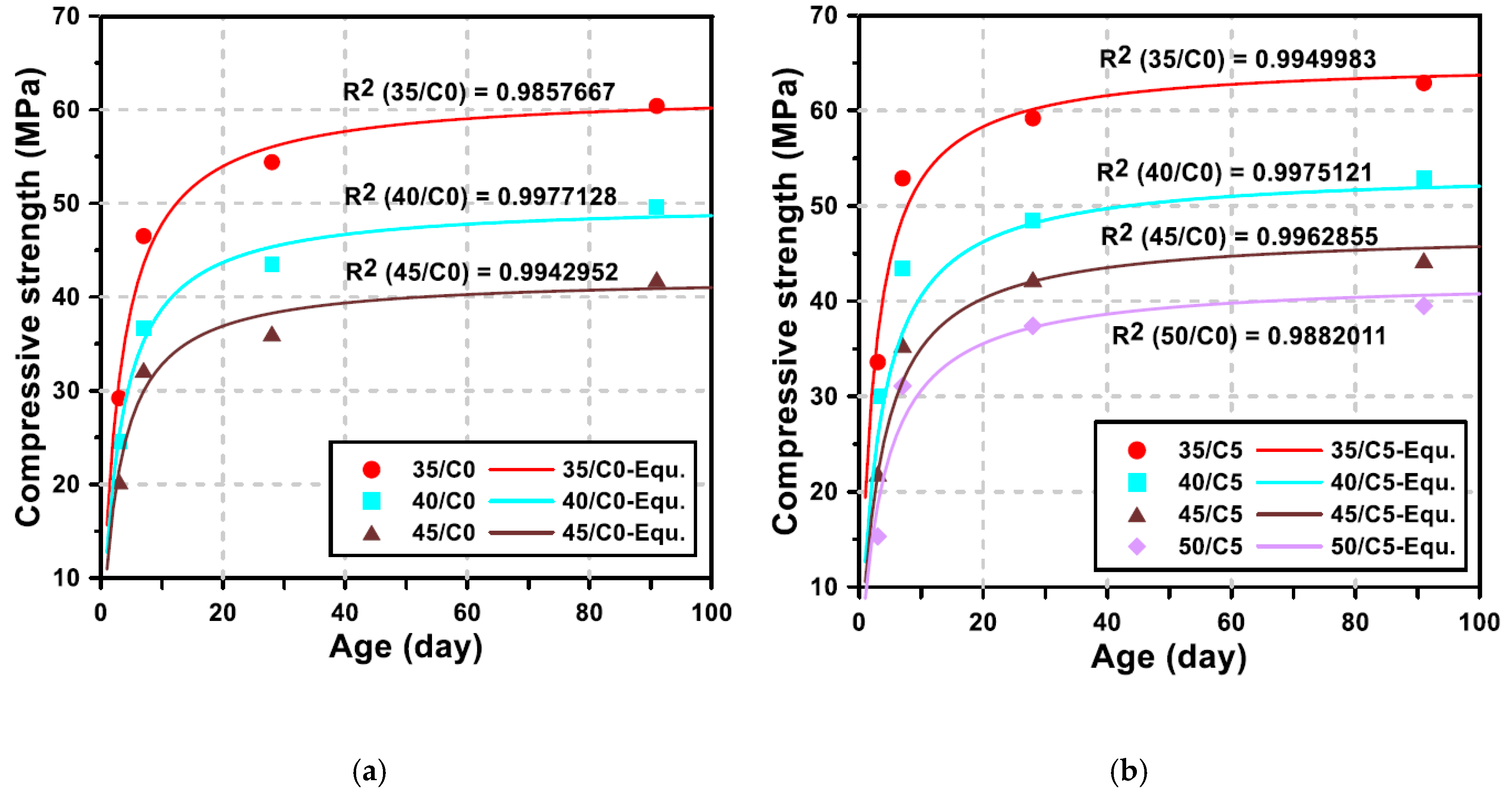

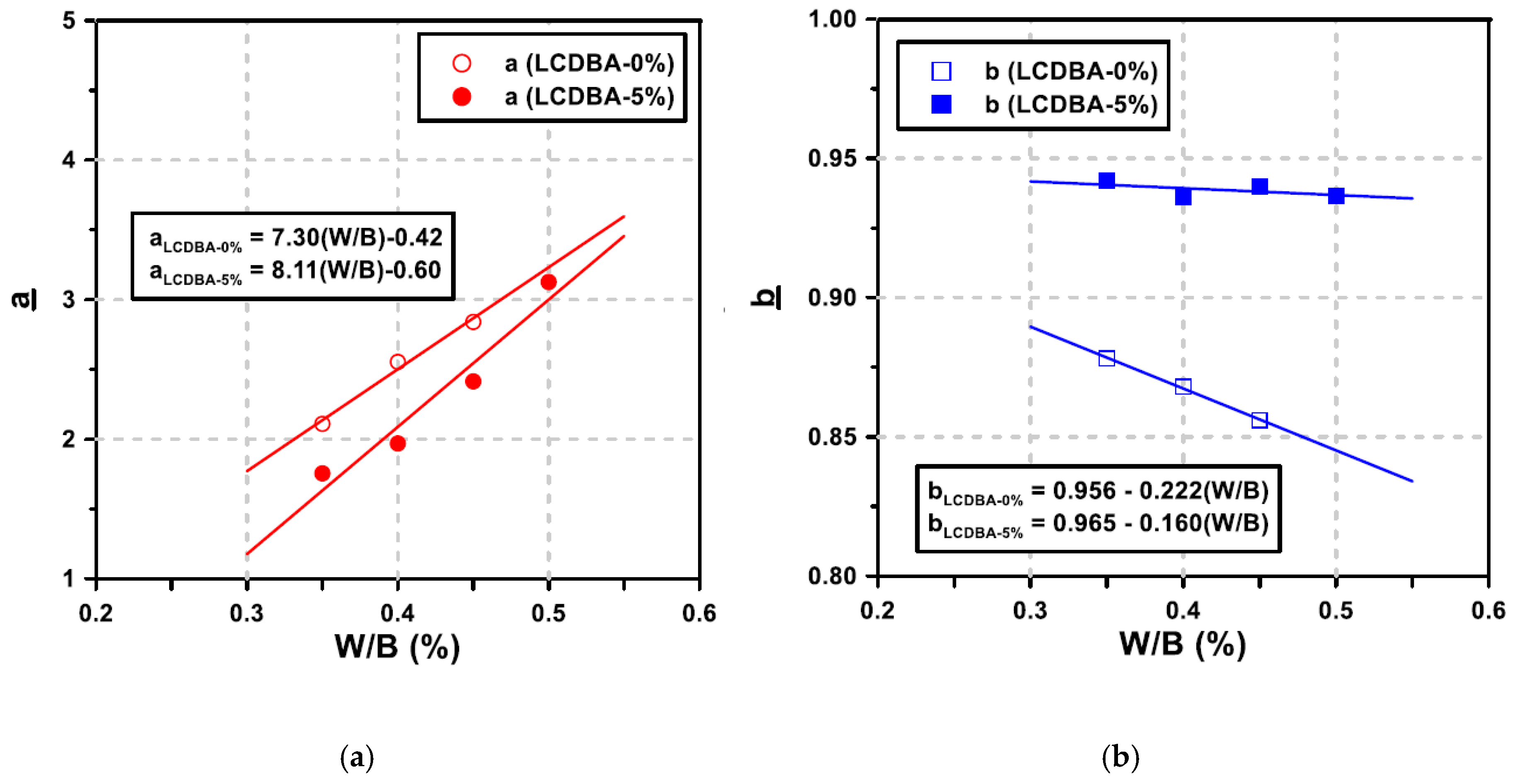

3.6. Compressive Strength

4. Conclusions

- (1)

- The effectiveness of LCDBA as an alternative and sustainable alkaline activator for GGBFS blended cement concrete was demonstrated for the first time in this study. The formations of akermanite and ettringite, as well as the consumption of Ca(OH)2 due to the stimulation of GGBFS hydrations with LCDBA as days of curing increase, were characterized using XRD analysis. This finding highlights the role of LCDBA as an activator for GGBFS blended cement concrete by providing the essential chemical evidence.

- (2)

- The thermogravimetric analysis was employed to evaluate the degrees of hydration. The results highlight that a large amount of C-S-H gel was initially formed and that the cement hydration product, Ca(OH)2, was relatively less consumed due to the incorporation of LCDBA that contains abundant alkali compounds that promote the reactivity of GGBFS. As curing age increased, the remaining amount of Ca(OH)2 in the pastes with LCDBA became similar as to the one in the pastes without LCDBA, which is another implication of the relatively less long-term strength development.

- (3)

- It is identified from this research that by incorporating LCDBA, the fresh GGBFS blended cement concrete showed degraded workability, delayed bleeding ends, reduced bleeding capacity, and delayed setting times, attributed to the porous nature of LCDBA that led to mix water absorption.

- (4)

- The series of compressive strength tests conducted in this research concluded that LCDBA was an effective alkaline activator for GGBFS blended cement concrete, showing early-age strength developing characteristics, especially for mixtures with lower water/binder ratios. The compressive strength model, suggested by the ACI Committee 209, also highlighted the early-age strength developing characteristics of the blended concrete activated with LCDBA.

Author Contributions

Funding

Conflicts of Interest

References

- Maraghechi, H.; Salwocki, S.; Rajabipour, F. Utilisation of alkali activated glass powder in binary mixtures with Portland cement, slag, fly ash and hydrated lime. Mater. Struct. 2017, 50, 16. [Google Scholar] [CrossRef]

- Sajedi, F.; Razak, H.A. The effect of chemical activators on early strength of ordinary Portland cement-slag mortars. Constr. Build. Mater. 2010, 24, 1944–1951. [Google Scholar] [CrossRef]

- Ding, Y.; Dai, J.G.; Shi, C.J. Mechanical properties of alkali-activated concrete: A state-of-the-art review. Constr. Build. Mater. 2016, 127, 68–79. [Google Scholar] [CrossRef]

- Kim, H.; Koh, T.; Pyo, S. Enhancing flowability and sustainability of ultra high performance concrete incorporating high replacement levels of industrial slags. Constr. Build. Mater. 2016, 123, 153–160. [Google Scholar] [CrossRef]

- Kang, H.; Kang, S.H.; Jeong, Y.; Moon, J. Quantitative analysis of hydration reaction of GGBFS using X-ray diffraction methods. J. Korea Concr. Inst. 2020, 32, 241–250. [Google Scholar] [CrossRef]

- Lee, H.K.; Jeon, S.M.; Lee, B.Y.; Kim, H.K. Use of circulating fluidized bed combustion bottom ash as a secondary activator in high-volume slag cement. Constr. Build. Mater. 2020, 234, 117240. [Google Scholar] [CrossRef]

- Lee, B.Y.; Jeon, S.M.; Cho, C.G.; Kim, H.K. Evaluation of time to shrinkage-induced crack initiation in OPC and slag cement matrices incorporating circulating fluidized bed combustion bottom ash. Constr. Build. Mater. 2020, 257, 119507. [Google Scholar] [CrossRef]

- Kang, C.; Kim, T. The strength properties of alkali-activated cement with blended ground granulated blast furnace slag. J. Korea Concr. Inst. 2018, 30, 315–324. [Google Scholar]

- Suh, J.I.; Yum, W.S.; Song, H.; Park, H.G.; Oh, J.E. Influence of calcium nitrate and sodium nitrate on strength development and properties in quicklime (CaO)-activated Class F fly ash system. Mater. Struct. 2019, 52, 115. [Google Scholar] [CrossRef]

- Humad, A.M.; Provis, J.L.; Cwirzen, A. Alkali activation of a high MgO GGBS–fresh and hardened properties. Mag. Concr. Res. 2018, 70, 1256–1264. [Google Scholar] [CrossRef]

- Mohamed, O.A. A review of durability and strength characteristics of alkali-activated slag concrete. Materials 2019, 12, 1198. [Google Scholar] [CrossRef] [PubMed]

- Qureshi, M.N.; Ghosh, S. Workability and setting time of alkali activated blast furnace slag paste. Adv. Civ. Eng. Mater. 2013, 2, 62–77. [Google Scholar] [CrossRef]

- Turner, L.K.; Collins, F.G. Carbon dioxide equivalent (CO2-e) emissions: A comparison between geopolymer and OPC cement concrete. Constr. Build. Mater. 2013, 43, 125–130. [Google Scholar] [CrossRef]

- Liu, Y.; Shi, C.; Zhang, Z.; Li, N. An overview on the reuse of waste glasses in alkali-activated materials. Resour. Conserv. Recycl. 2019, 144, 297–309. [Google Scholar] [CrossRef]

- Lin, K.L.; Huang, W.J.; Shie, J.L.; Lee, T.C.; Wang, K.S.; Lee, C.H. The utilization of thin film transistor liquid crystal display waste glass as a pozzolanic material. J. Hazard. Mater. 2009, 163, 916–921. [Google Scholar] [CrossRef] [PubMed]

- Jang, H.S.; Jeon, S.H.; So, H.S.; So, S.Y. A study of the possibility of using TFT-LCD waste glass as an admixture for steam-cured PHC piles. Mag. Concr. Res. 2014, 66, 196–208. [Google Scholar] [CrossRef]

- Wang, H.Y.; Zeng, H.H.; Wu, J.Y. A study on the macro and micro properties of concrete with LCD glass. Constr. Build. Mater. 2014, 50, 664–670. [Google Scholar] [CrossRef]

- Kim, S.K.; Kang, S.T.; Kim, J.K.; Jang, I.Y. Effects of particle size and cement replacement of LCD glass powder in concrete. Adv. Mater. Sci. Eng. 2017, 2017, 3928047. [Google Scholar] [CrossRef]

- Chang, J.J. A study on the setting characteristics of sodium silicate-activated slag pastes. Cem. Concr. Res. 2003, 33, 1005–1011. [Google Scholar] [CrossRef]

- ASTM International. ASTM C94/C94M-19a. Standard Specification for Ready-Mixed Concrete; ASTM International: West Conshohocken, PA, USA, 2019. [Google Scholar]

- ASTM International. ASTM C232/C232M-14. Standard Test Method for Bleeding of Concrete; ASTM International: West Conshohocken, PA, USA, 2019. [Google Scholar]

- ASTM International. ASTM C803/C803M-18. Standard Test Method for Penetration Resistance of Hardened Concrete; ASTM International: West Conshohocken, PA, USA, 2018. [Google Scholar]

- ASTM International. ASTM C39/C39M-18. Standard Test Method for Compressive Strength of Cylindrical Concrete Specimens; ASTM International: West Conshohocken, PA, USA, 2018. [Google Scholar]

- Kim, M.S.; Jun, Y.; Lee, C.; Oh, J.E. Use of CaO as an activator for producing a price-competitive non-cement structural binder using ground granulated blast furnace slag. Cem. Concr. Res. 2013, 54, 208–214. [Google Scholar] [CrossRef]

- Yum, W.S.; Suh, J.I.; Jeon, D.; Oh, J.E. Strength enhancement of CaO-activated slag system through addition of calcium formate as a new auxiliary activator. Cem. Concr. Compos. 2020, 109, 103572. [Google Scholar] [CrossRef]

- Colombo, A.; Geiker, M.; Justnes, H.; Lauten, R.A.; De Weerdt, K. The effect of calcium lignosulfonate on ettringite formation in cement paste. Cem. Concr. Res. 2018, 107, 188–205. [Google Scholar] [CrossRef]

- Mohammed, S.; Safiullah, O. Optimization of the SO3 content of an Algerian Portland cement: Study on the effect of various amounts of gypsum on cement properties. Constr. Build. Mater. 2018, 164, 362–370. [Google Scholar] [CrossRef]

- Song, H.; Jeong, Y.; Bae, S.; Jun, Y.; Yoon, S.; Oh, J.E. A study of thermal decomposition of phases in cementitious systems using HT-XRD and TG. Constr. Build. Mater. 2018, 169, 648–661. [Google Scholar] [CrossRef]

- Mirghiasi, Z.; Bakhtiari, F.; Darezereshki, E.; Esmaeilzadeh, E. Preparation and characterization of CaO nanoparticles from Ca(OH)2 by direct thermal decomposition method. J. Ind. Eng. Chem. 2014, 20, 113–117. [Google Scholar] [CrossRef]

- Siddique, R.; Bennacer, R. Use of iron and steel industry by-product (GGBS) in cement paste and mortar. Res. Conserv. Recycl. 2012, 69, 29–34. [Google Scholar] [CrossRef]

- Barnett, S.J.; Soutsos, M.N.; Millard, S.G.; Bungey, J.H. Strength development of mortars containing ground granulated blast-furnace slag: Effect of curing temperature and determination of apparent activation energies. Cem. Concr. Res. 2006, 36, 434–440. [Google Scholar] [CrossRef]

- Deb, P.S.; Nath, P.; Sarker, P.K. The effects of ground granulated blast-furnace slag blending with fly ash and activator content on the workability and strength properties of geopolymer concrete cured at ambient temperature. Mater. Des. 2014, 62, 32–39. [Google Scholar] [CrossRef]

- Fang, G.; Ho, W.K.; Tu, W.; Zhang, M. Workability and mechanical properties of alkali-activated fly ash-slag concrete cured at ambient temperature. Constr. Build. Mater. 2018, 172, 476–487. [Google Scholar] [CrossRef]

- American Concrete Institute (ACI). ACI Committee 209.2R-08. Guide for Modeling and Calculating Shrinkage and Creep in Hardened Concrete; American Concrete Institute (ACI): Farmington Hills, MI, USA, 2008. [Google Scholar]

- Yang, K.H.; Song, J.K.; Ashour, A.F.; Lee, E.T. Properties of cementless mortars activated by sodium silicate. Constr. Build. Mater. 2008, 22, 1981–1989. [Google Scholar] [CrossRef]

| Element | SiO2 | Al2O3 | Fe2O3 | CaO | MgO | SO3 | K2O | Na2O | LOI |

|---|---|---|---|---|---|---|---|---|---|

| OPC | 19.5 | 5.6 | 3.5 | 61.5 | 3.8 | 2.5 | 1.1 | 0.1 | 2.5 |

| GGBFS | 32.6 | 15.5 | 0.5 | 42.2 | 4.6 | 3.3 | 0.5 | 0.2 | - |

| LCDBA | 4.3 | - | 0.2 | 10.0 | 0.5 | 47.4 | 4.3 | 30.4 | 3.0 |

| Mixture | W/B (%) | s/a (%) | Unit Weight (kg/m3) | Super-Plasticizer (%) | |||||

|---|---|---|---|---|---|---|---|---|---|

| Water | Binder | Fine Aggregate | Coarse Aggregate | ||||||

| OPC | GGBFS | LCDBA | |||||||

| 35/L0 | 35 | 47.5 | 160 | 251 | 206 | - | 814 | 903 | 0.70 |

| 35/L3 | 35 | 46.0 | 160 | 244 | 200 | 14 | 788 | 929 | 0.80 |

| 35/L5 | 35 | 45.0 | 160 | 239 | 195 | 23 | 770 | 945 | 1.00 |

| 40/L0 | 40 | 49.0 | 160 | 220 | 180 | - | 864 | 903 | 0.70 |

| 40/L3 | 40 | 48.0 | 160 | 213 | 175 | 12 | 846 | 920 | 0.80 |

| 40/L5 | 40 | 47.5 | 160 | 209 | 171 | 20 | 837 | 928 | 0.97 |

| 45/L0 | 45 | 50.0 | 160 | 196 | 160 | - | 901 | 904 | 0.70 |

| 45/L3 | 45 | 49.0 | 160 | 190 | 155 | 11 | 882 | 922 | 0.75 |

| 45/L5 | 45 | 48.0 | 160 | 186 | 152 | 18 | 864 | 940 | 0.80 |

| 50/L5 | 50 | 49.0 | 160 | 167 | 137 | 16 | 897 | 937 | 0.70 |

| Mixture | Curing Age (%) | |||

|---|---|---|---|---|

| 3 Days | 7 Days | 28 Days | 91 Days | |

| 35/L3 | 13.7 | 12.0 | 5.0 | 4.1 |

| 35/L5 | 15.1 | 13.8 | 8.8 | 4.1 |

| 40/L3 | 16.7 | 13.4 | 12.5 | 5.8 |

| 40/L5 | 22.0 | 18.3 | 14.1 | 8.8 |

| 45/L3 | 13.1 | 9.0 | 1.5 | 1.4 |

| 45/L5 | 19.7 | 9.9 | 2.9 | 4.5 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Choi, S.; Pyo, S. Fresh and Hardened Properties of Portland Cement-Slag Concrete Activated Using the By-Product of the Liquid Crystal Display Manufacturing Process. Materials 2020, 13, 4354. https://doi.org/10.3390/ma13194354

Choi S, Pyo S. Fresh and Hardened Properties of Portland Cement-Slag Concrete Activated Using the By-Product of the Liquid Crystal Display Manufacturing Process. Materials. 2020; 13(19):4354. https://doi.org/10.3390/ma13194354

Chicago/Turabian StyleChoi, Sung, and Sukhoon Pyo. 2020. "Fresh and Hardened Properties of Portland Cement-Slag Concrete Activated Using the By-Product of the Liquid Crystal Display Manufacturing Process" Materials 13, no. 19: 4354. https://doi.org/10.3390/ma13194354

APA StyleChoi, S., & Pyo, S. (2020). Fresh and Hardened Properties of Portland Cement-Slag Concrete Activated Using the By-Product of the Liquid Crystal Display Manufacturing Process. Materials, 13(19), 4354. https://doi.org/10.3390/ma13194354