Influence of Variable Radius of Cutting Head Trajectory on Quality of Cutting Kerf in the Abrasive Water Jet Process for Soda–Lime Glass

Abstract

1. Introduction

2. Methodology of Experimental Studies

2.1. Main Goal

2.2. Characteristics of the Samples

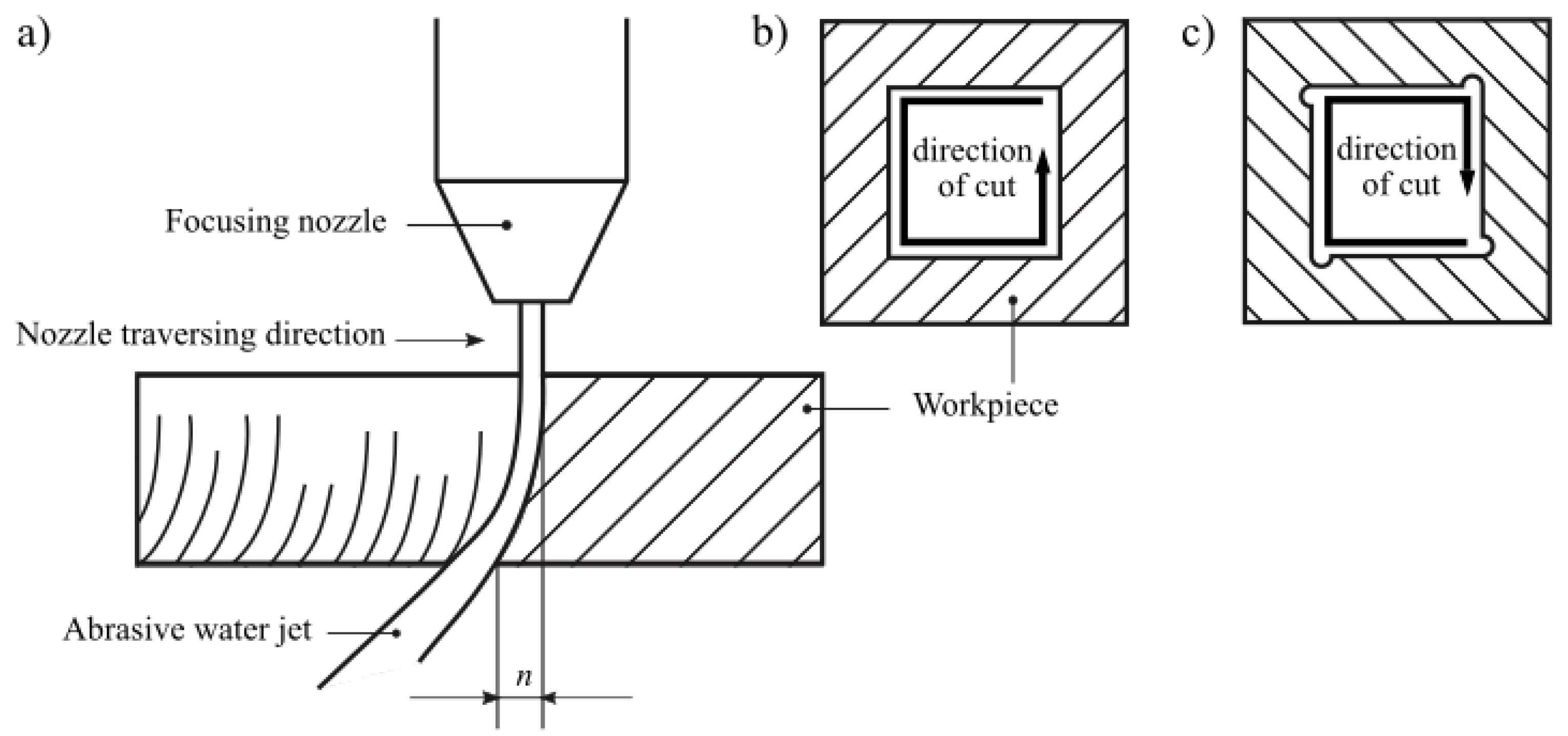

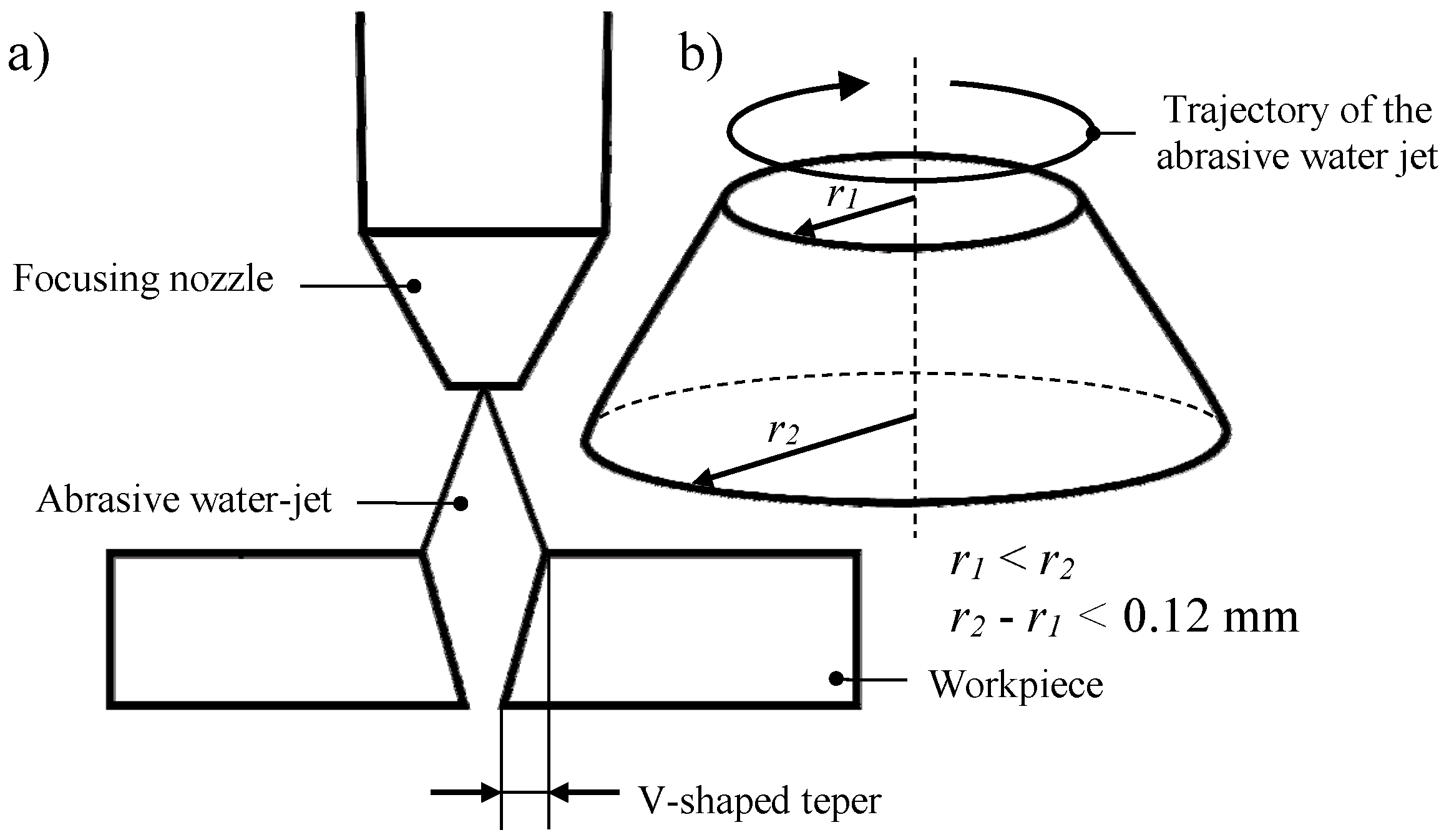

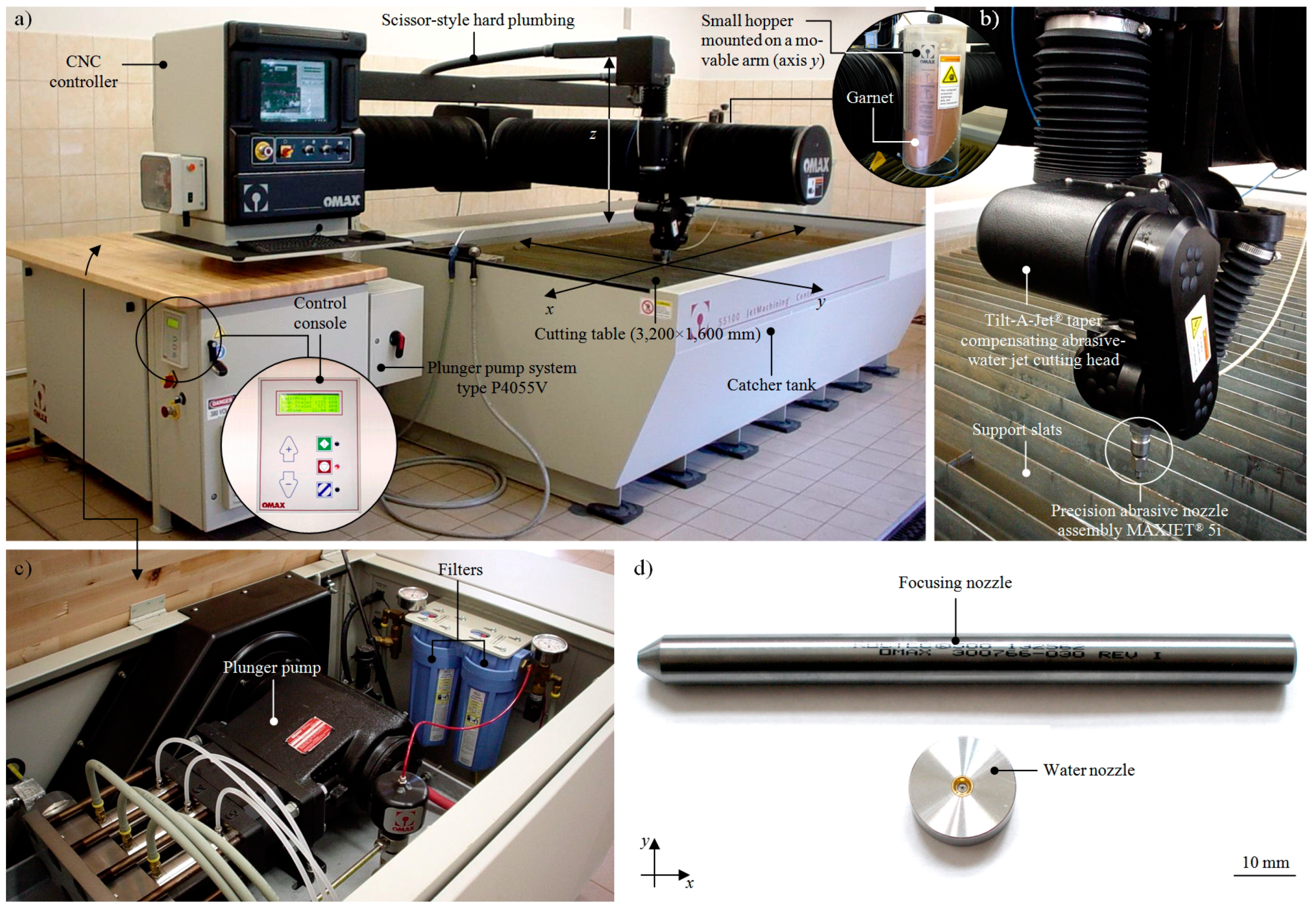

2.3. Conditions and Course of the AWJ Process

2.4. Characteristics of Measurement Systems and Course of Measurement Process

3. Results and Discussion

- A study of the influence of the curvature of the cut out shape on the IS and OS surface texture shaped using an AWJ, carried out on the basis of the calculated values of roughness and waviness parameters characteristic for this type of machining [24] measured by the Talysurf CLI 2000 multisensory optical profilometer (Taylor-Hobson, Leicester, Great Britain) (Section 3.1).

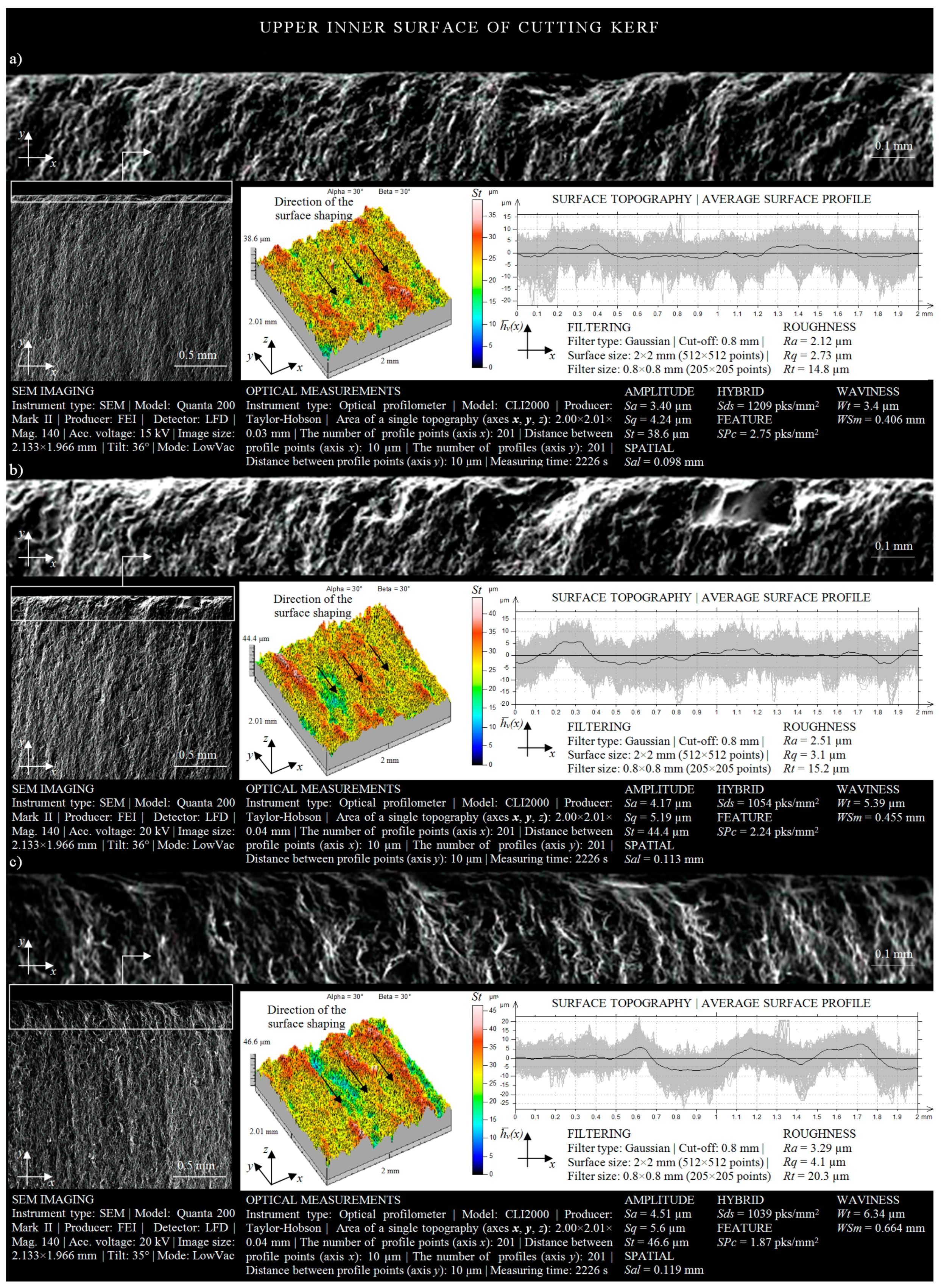

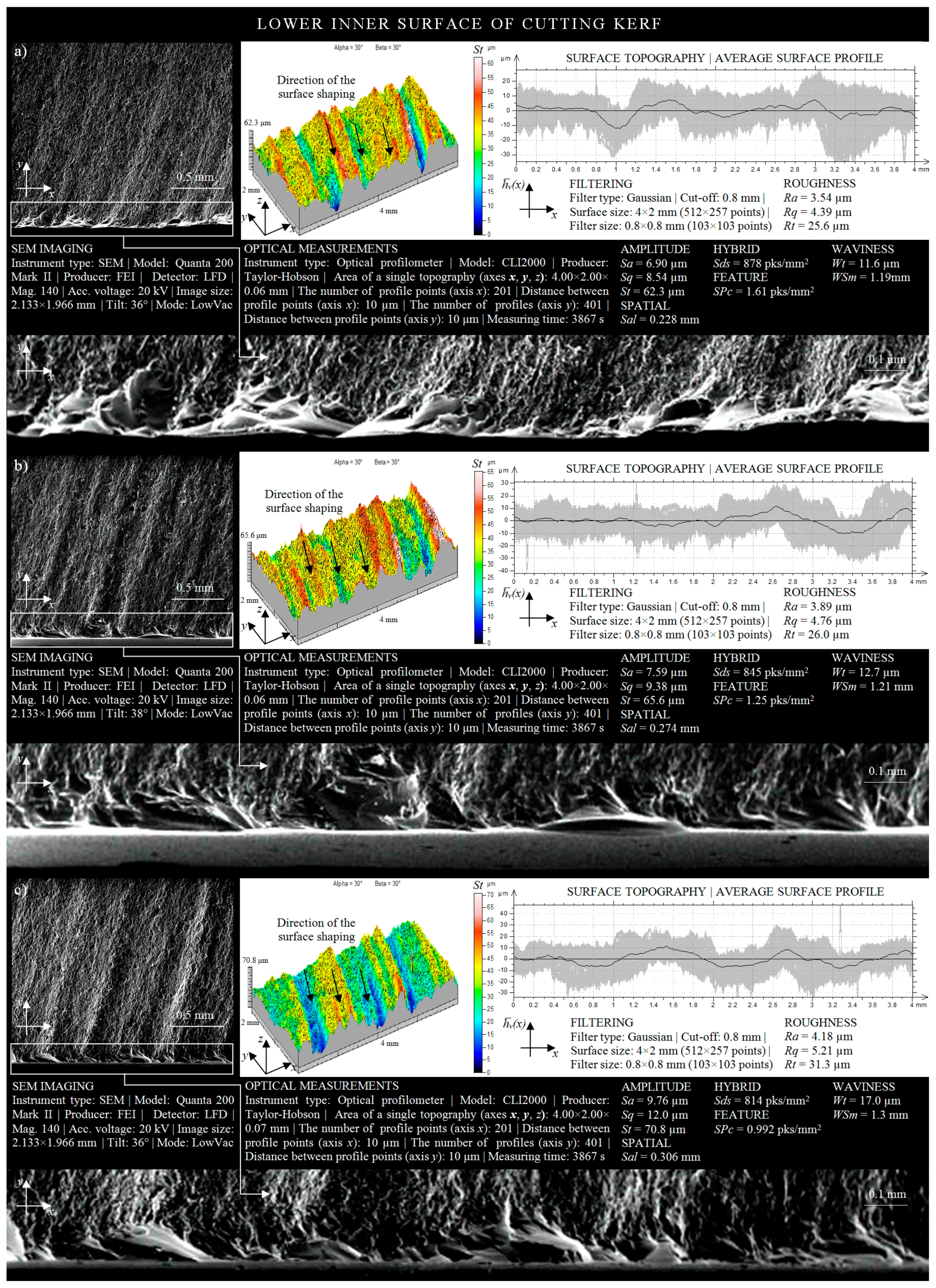

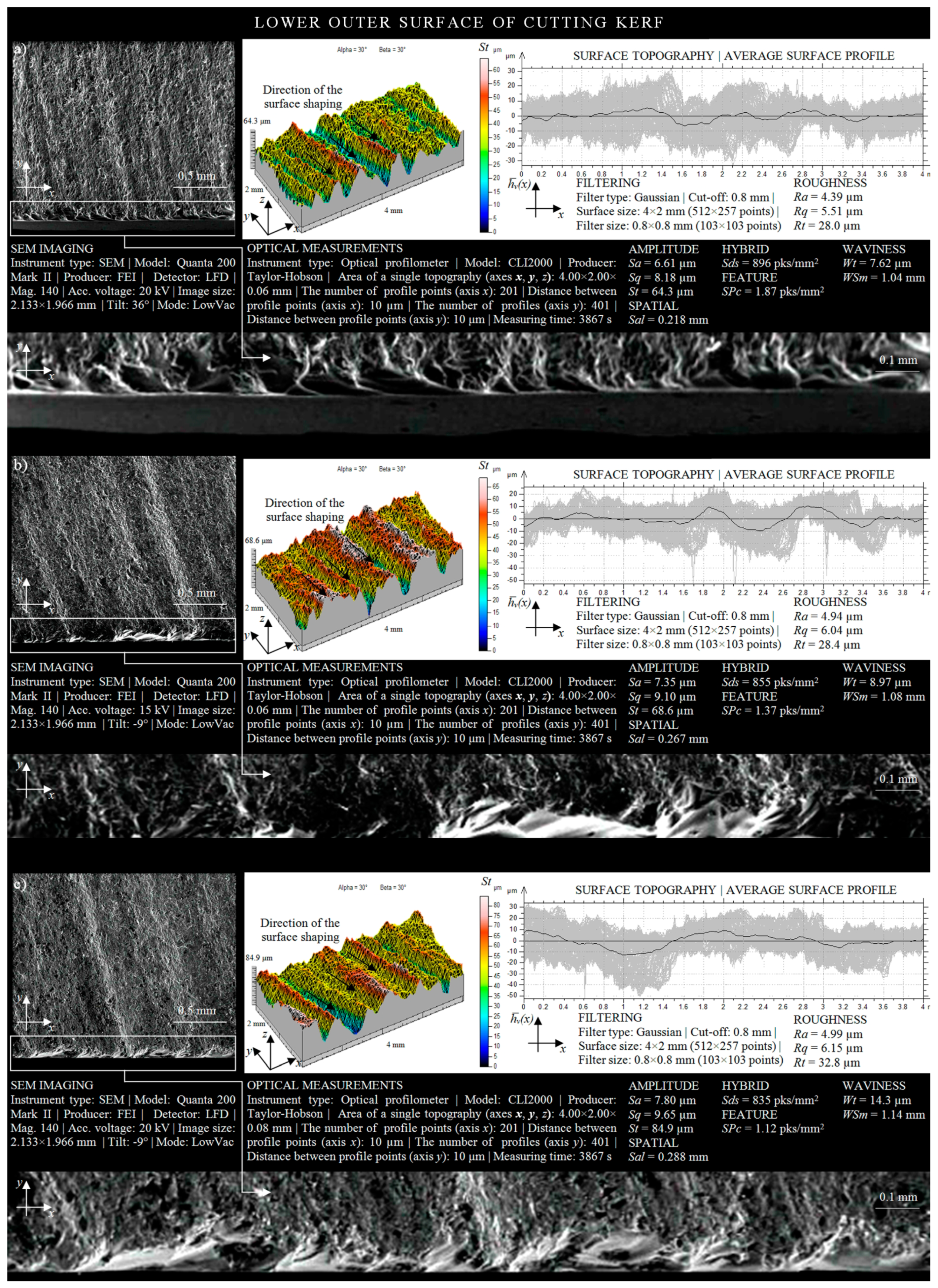

- A study of the surface texture of the OS (Section 3.2), as well as the IS (Section 3.3), shaped with an AWJ, using surface microtopographies measured with an optical method using the Talysurf CLI 2000 multisensory optical profilometer (Taylor-Hobson, Leicester, Great Britain) and SEM-micrographs obtained by a Quanta 200 Mark II SEM microscope (FEI Company, Hillsboro, OR, USA).

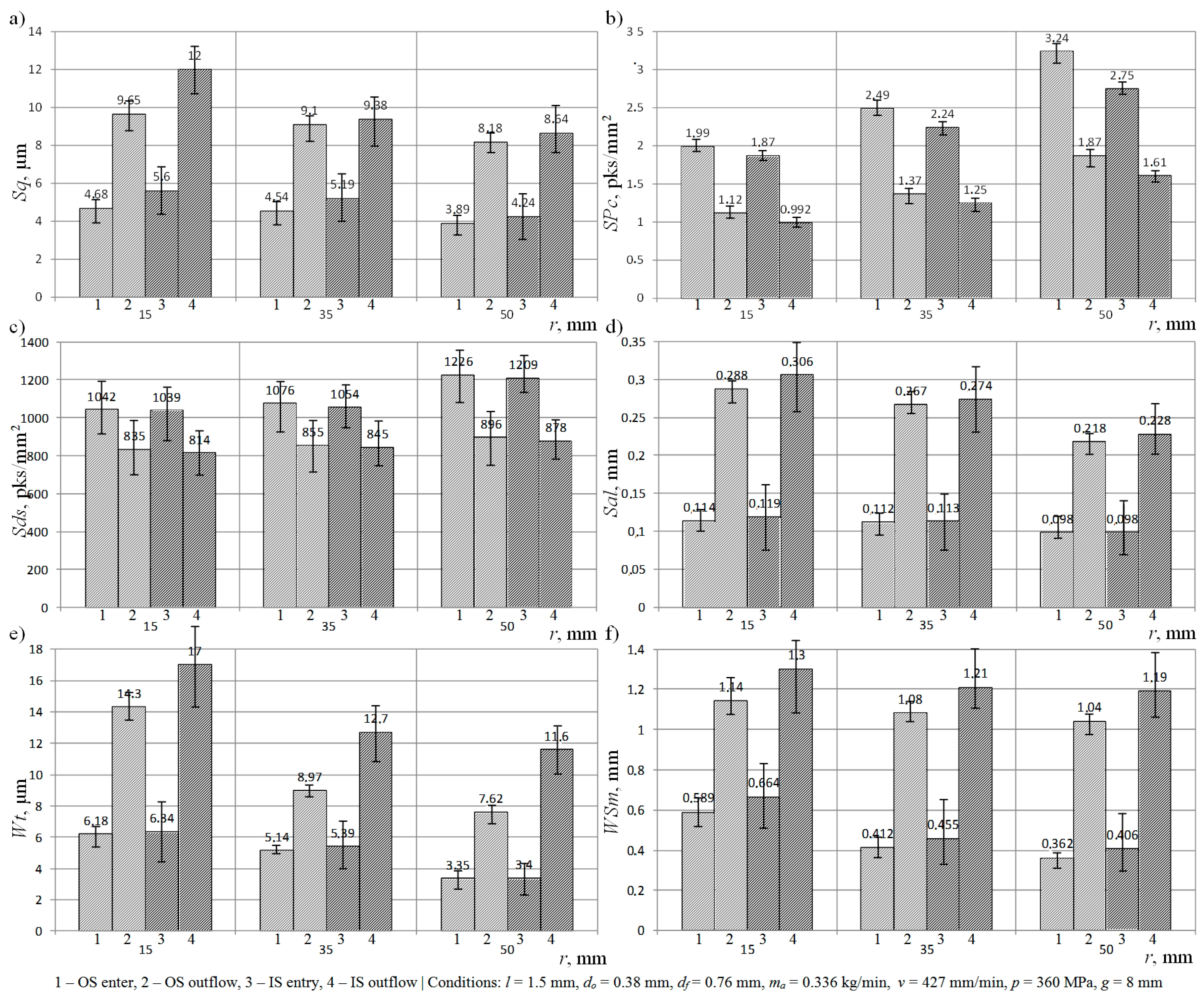

3.1. Study of the Influence of the Curvature of the Cut Out Shape on the IS and OS Surface Texture

3.2. The Shaping Quality of Inner Surface of Cutting Kerf

3.3. Shaping Quality of Outer Surface of Cutting Kerf

4. Conclusions

- The obtained results of the experimental studies confirmed that the effect of the curvature of the cut shape is important from the point of view of the efficiency of the glass-based brittle materials cutting process using the AWJ. On the basis of the obtained experimental results, it may be concluded that the feed speed should be limited when r < 35 mm.

- The determined mathematical model in Equation (1), which describes the influence of the cutting head trajectory on the surface quality of the soda–lime glass, describes with approximately 95% accuracy the relationships occurring between the trajectory radius of the cutting head and the amplitude Sq (surface) parameter. This means that the model was adequate for the experimental data and could be successfully used to predict the quality of both surfaces of the cutting kerf. The model ran properly in the range of radius variation r = 15–50 mm.

- The determined values of the surface texture parameters for the inner and outer surfaces of cutting kerf (Figure 5, Figure 6, Figure 7, Figure 8 and Figure 9) clearly indicate that these surfaces were characterized by worse technological quality than cylindrical surfaces. The maximum difference in the total height of the surface (St) existing between the considered surfaces (for r = 15 mm) was almost 20%, which should be a sufficient condition for planning cutting operations, so that the workpiece is shaped mainly by internal surfaces.

- The results of experimental studies presented in this article do not exhaust all the issues related to the problem of curvilinear cutting of brittle materials (glass) using AWJ, particularly the aspects of their surface quality inspection. The authors see a strong need to continue this interesting and promising subject, especially in the context of AWJ process optimization for industrial applications planning subsequent publications in this area in the near future.

Author Contributions

Funding

Conflicts of Interest

Nomenclature

| AWJ | Abrasive water jet |

| BEI | Backscattered electron imaging |

| BSED | Solid-state secondary electron detector |

| CAD | Computer-aided design |

| ESEM | Environmental scanning electron microscope |

| GSED | Gaseous secondary electron detector |

| IS | Inner surface of cutting kerf |

| LFD | Low-vacuum secondary electron detector |

| OS | Outer surface of cutting kerf |

| RMS | Root mean square |

| SED | Secondary electron detector |

| SEI | Secondary electron image |

| SEM | Scanning electron microscope |

| df | Focusing tube diameter, mm |

| do | Water jet orifice diameter, mm |

| g | Material thickness, mm |

| (x) | Average waviness profile, μm |

| l | Standoff distance, mm |

| ma | Abrasive feed rate, kg/min |

| n | Jet lag distance, mm |

| p | Water jet pressure, MPa |

| pmax | Nominal pressure, MPa |

| r | Machining radius, mm |

| v | Traverse speed, mm/min |

| Qmax | Maximum water flow rate, dm3/min |

| Ra | Arithmetical mean deviation of the roughness profile, μm |

| Rq | Root-mean-square deviation of the roughness profile, μm |

| Rt | Total height of the profile on the evaluation length, μm |

| Sa | Arithmetic mean deviation of the surface, μm |

| Sal | Fastest decay autocorrelation length, mm |

| Sds | Density of summits of the surface, pks/mm2 |

| SPc | Arithmetic mean peak curvature, pks/mm2 |

| Sq | Root-mean-square deviation of the surface, μm |

| St | Total height of the surface, μm |

| Ua | Accelerating voltage, kV |

| WSm | Mean width of profile elements, within a sampling length, mm |

| Wt | Maximum height of waviness profile, μm |

References

- Liu, X.; Liang, Z.; Wen, G.; Yuan, X. Waterjet machining and research developments: A review. Int. J. Adv. Manuf. Technol. 2019, 102, 1257–1335. [Google Scholar] [CrossRef]

- Hashish, M. Waterjet machining process. In Handbook of Manufacturing Engineering and Technology; Nee, A.Y.C., Ed.; Springer: London, UK, 2015. [Google Scholar]

- Valíček, J.; Harničárová, M.; Hlavatý, I.; Grznárik, R.; Kušnerová, M.; Hutyrová, Z.; Panda, A. A new approach for the determination of technological parameters for hydroabrasive cutting of materials. Mater. Werkst. 2016, 47, 462–471. [Google Scholar] [CrossRef]

- Krajcarz, D.; Bańkowski, D.; Młynarczyk, P. The effect of traverse speed on kerf width in AWJ cutting of ceramic tiles. Procedia Eng. 2017, 192, 469–473. [Google Scholar] [CrossRef]

- Wang, S.; Zhang, S.; Wu, Y.; Yang, F. Exploring kerf cut by abrasive waterjet. Int. J. Adv. Manuf. Technol. 2017, 93, 2013–2020. [Google Scholar] [CrossRef]

- Hlaváč, L.M.; Hlaváčová, I.M.; Geryk, V.; Plančár, Š. Investigation of the taper of kerfs cut in steels by AWJ. Int. J. Adv. Manuf. Technol. 2015, 77, 1811–1818. [Google Scholar] [CrossRef]

- Hashish, M. Enhanced Abrasive Waterjet Cutting Accuracy with Dynamic Tilt Compensation. In Proceedings of the CRIP 2nd International Conference on High Performance Cutting, Vancouver, BC, Canada, 12–13 June 2006; pp. 12–13. [Google Scholar]

- Zagórski, I.; Kłonica, M.; Kulisz, M.; Łoza, K. Effect of the AWJM method on the machined surface layer of AZ91D magnesium alloy and simulation of roughness parameters using neural networks. Materials 2018, 11, 2111. [Google Scholar] [CrossRef]

- Chen, M.; Zhang, S.; Zeng, J.; Chen, B. Correcting shape error located in cut-in/cut-out region in abrasive water jet cutting proces. Int. J. Adv. Manuf. Technol. 2018, 102, 1165–1178. [Google Scholar] [CrossRef]

- Wang, S.; Zhang, S.; Wu, Y.; Yang, F. A key parameter to characterize the kerf profile error generated by abrasive water-jet. Int. J. Adv. Manuf. Technol. 2017, 90, 1265–1275. [Google Scholar] [CrossRef]

- Hlaváč, L.M.; Hlaváčová, I.M.; Geryk, V. Taper of kerfs made in rocks by abrasive water jet (AWJ). Int. J. Adv. Manuf. Technol. 2017, 88, 443–449. [Google Scholar] [CrossRef]

- Kechagias, J.; Petropoulos, G.; Vaxevanidis, N. Application of Taguchi design for quality characterization of abrasive water jet machining of TRIP sheet steels. Int. J. Adv. Manuf. Technol. 2012, 62, 635–643. [Google Scholar] [CrossRef]

- Wu, Y.; Zhang, S.; Wang, S.; Yang, F.; Tao, H. Method of obtaining accurate jet lag information in abrasive water-jet machining process. Int. J. Adv. Manuf. Technol. 2015, 76, 1827–1835. [Google Scholar] [CrossRef]

- Sutowski, P.; Sutowska, M.; Kapłonek, W. The use of high-frequency acoustic emission analysis for in-process assessment of the surface quality of aluminium alloy 5251 in abrasive waterjet machining. Proc. Inst. Mech. Eng. B. 2018, 232, 2547–2565. [Google Scholar] [CrossRef]

- Perec, A. Experimental research into alternative abrasive material for the abrasive water-jet cutting of titanium. Int. J. Adv. Manuf. Technol. 2018, 97, 1529–1540. [Google Scholar] [CrossRef]

- Trivedi, P.; Dhanawade, A.; Kumar, S. An experimental investigation on cutting performance of abrasive water jet machining of austenite steel (AISI 316L). Adv. Mater. Res. 2015, 1, 263–274. [Google Scholar] [CrossRef]

- Phokane, T.; Gupta, K.; Gupta, M.K. Investigations on surface roughness and tribology of miniature brass gears manufactured by abrasive water jet machining. Proc. Inst. Mech. Eng. C 2018, 232, 4193–4202. [Google Scholar] [CrossRef]

- Supriya, S.B.; Srinivas, S. Machinability studies on stainless steel by abrasive water jet-Review. Mater. Today Proc. 2018, 5, 2871–2876. [Google Scholar] [CrossRef]

- Niranjan, C.A.; Srinivas, S.; Ramachandra, M. An experimental study on depth of cut of AZ91 magnesium alloy in abrasive water jet cutting. Mater. Today Proc. 2018, 5, 2884–2890. [Google Scholar] [CrossRef]

- Aich, U.; Banerjee, S.; Bandyopadhyay, A.; Das, P.K. Abrasive water jet cutting of borosilicate glass. Procedia. Mater. Sci. 2014, 6, 775–785. [Google Scholar] [CrossRef][Green Version]

- Dhanawade, A.; Kumar, S. Experimental study of delamination and kerf geometry of carbon epoxy composite machined by abrasive water jet. J. Compos. Mater. 2017, 51, 3373–3390. [Google Scholar] [CrossRef]

- Sasikumar, K.S.K.; Arulshri, K.P.; Ponappa, K.; Uthayakumar, M. A study on kerf characteristics of hybrid aluminium 7075 metal matrix composites machined using abrasive water jet machining technology. Proc. Inst. Mech. Eng. B 2018, 232, 690–704. [Google Scholar] [CrossRef]

- Abdullah, R.; Mahrous, A.; Barakat, A.; Zhou, Z. Surface quality of marble machined by abrasive water jet. Cogent Eng. 2016, 3, 1178626. [Google Scholar] [CrossRef]

- Nadolny, K.; Plichta, J.; Sutowski, P. Regeneration of grinding wheel active surface using high-pressure hydro-jet. J. Cent. South Univ. Technol. 2014, 21, 3107–3118. [Google Scholar] [CrossRef]

- Hloch, S.; Srivastava, M.; Krolczyk, J.B.; Chattopadhyaya, S.; Lehocká, D.; Simkulet, V.; Krolczyk, G.M. Strengthening effect after disintegration of stainless steel using pulsating water jet. Teh. Vjesn. 2018, 25, 1075–1079. [Google Scholar]

- Lehocka, D.; Klich, J.; Foldyna, J.; Hloch, S.; Krolczyk, J.B.; Caracha, J.; Krolczyk, G.M. Copper alloys disintegration using pulsating water jet. Measurement 2016, 82, 375–383. [Google Scholar] [CrossRef]

- Hreha, P.; Radvanská, A.; Hloch, S.; Peržel, W.; Królczyk, G.M.; Monková, K. Determination of vibration frequency depending on abrasive mass flow rate during abrasive water jet cutting. Int. J. Adv. Manuf. Technol. 2015, 77, 763–774. [Google Scholar] [CrossRef]

- Matuszewski, M.; Mikolajczyk, T.; Pimenov, D.Y.; Styp-Rekowski, M. Influence of structure isotropy of machined surface on the wear process. Int. J. Adv. Manuf. Technol. 2017, 88, 2477–2483. [Google Scholar] [CrossRef]

- Bustillo, A.; Pimenov, D.Y.; Matuszewski, M.; Mikolajczyk, T. Using artificial intelligence models for the prediction of surface wear based on surface isotropy levels. Robot. Comput. Integr. Manuf. 2018, 53, 215–227. [Google Scholar] [CrossRef]

- Borkowski, J.; Sutowska, M.; Borkowski, P. Jakościowy model procesu cięcia wybranych materiałów metalowych wysokociśnieniową strugą wodno-ścierną. Mechanik 2014, 9, 255–258. (In Polish) [Google Scholar]

- VDI 2906-5:1994. Quality of Cut Faces of (Sheet) Metal Parts after Cutting, Blanking, Trimming or Piercing—Fine Blanking; Verlag des Vereins Deutscher Ingenieure: Düsseldorf, Germany, 1994. [Google Scholar]

- Löschner, P.; Jarosz, K.; Niesłony, P. Investigation of the effect of cutting speed on surface quality in abrasive water jet cutting of 316l stainless steel. Procedia Eng. 2016, 149, 276–282. [Google Scholar] [CrossRef]

- Hreha, P.; Radvanska, A.; Knapcikova, L.; Królczyk, G.M.; Legutko, S.; Królczyk, J.B.; Hloch, S.; Monka, P. Roughness parameters calculation by means of on-line vibration monitoring emerging from AWJ interaction with material. Metrol. Meas. Syst. 2015, 22, 315–326. [Google Scholar] [CrossRef]

- Klichova, D.; Klich, J. Study of the effect of material machinability on quality of surface created by abrasive water jet. Procedia Eng. 2016, 149, 177–182. [Google Scholar] [CrossRef]

- ISO 4287:1997. Geometrical Product Specifications (GPS)—Surface Texture: Profile Method: Terms, Definitions and Surface Texture Parameters; International Organization for Standardization: Geneva, Switzerland, 1997. [Google Scholar]

- ISO 25178-2:2012. Geometrical Product Specifications (GPS)—Surface Texture: Areal—Part 2: Terms, Definitions and Surface Texture Parameters; International Organization for Standardization: Geneva, Switzerland, 2012. [Google Scholar]

- Stout, K.J.; Sullivan, P.J.; Dong, W.P.; Mainsah, E.; Luo, N.; Mathia, T.; Zahouani, H. The Development of Methods for the Characterization of Roughness in Three Dimensions; Publication No. EUR 15178 EN (Final Report); BCR: Brussels, Belgium, 1993. [Google Scholar]

- Sutowska, M. Jakościowy model procesu cięcia AWJ wybranych materiałów konstrukcyjnych. PAK 2014, 60, 901–903. (In Polish) [Google Scholar]

- Blateyron, F. The areal field parameters. In Characterisation of Areal Surface Texture; Leach, R., Ed.; Springer: Berlin/Heidelberg, Germany, 2013. [Google Scholar]

- Nair, A.; Kumanan, S. Multi-performance optimization of abrasive water jet machining of Inconel 617 using WPCA. Mater. Manuf. Process. 2017, 32, 693–699. [Google Scholar] [CrossRef]

- Zhao, W.; Guo, C. Topography and microstructure of the cutting surface machined with abrasive waterjet. Int. J. Adv. Manuf. Technol. 2014, 73, 941–947. [Google Scholar] [CrossRef]

- Linke, B.; Garretson, I.; Jan, F.; Hafez, M. Integrated design, manufacturing and analysis of airfoil and nozzle shapes in an undergraduate course. Procedia Manuf. 2017, 10, 1077–1086. [Google Scholar] [CrossRef]

- Saurabh, S.; Tiwari, T.; Nag, A.; Dixit, A.R.; Mandal, N.; Das, A.K.; Mandal, A.; Srivastava, A.K. Processing of alumina ceramics by abrasive waterjet—An experimental study. Mater. Today Proc. 2018, 5, 18061–18069. [Google Scholar] [CrossRef]

- Kapłonek, W.; Sutowska, M.; Ungureanu, M.; Çetinkaya, K. Optical profilometer with confocal chromatic sensor forhigh-accuracy 3D measurements of the uncirculated and circulated coins. J. Mech. Energy Eng. 2018, 2, 181–192. [Google Scholar] [CrossRef]

- Yuan, Z.; Zheng, P.; Wen, Q.; He, Y. Chemical kinetics mechanism for chemical mechanical polishing diamond and its related hard-inert materials. Int. J. Adv. Manuf. Technol. 2018, 95, 1715–1727. [Google Scholar] [CrossRef]

- Nadolny, K.; Kapłonek, W.; Królczyk, G.; Ungureanu, N. The effect of active surface morphology of grinding wheel with zone-diversified structure on the form of chips in traverse internal cylindrical grinding of 100Cr6 steel. Proc. Inst. Mech. Eng. B. 2018, 232, 965–978. [Google Scholar] [CrossRef]

- Fan, W.C.; Cao, P.; Long, L. Degradation of joint surface morphology, shear behavior and closure characteristics during cyclic loading. J. Cent. South Univ. Technol. 2018, 25, 653–661. [Google Scholar] [CrossRef]

- Chen, S.; Carlson, M.A.; Zhang, Y.S.; Hu, Y.; Xie, J. Fabrication of injectable and superelastic nanofiber rectangle matrices (“peanuts”) and their potential applications in hemostasis. Biomaterials 2018, 179, 46–59. [Google Scholar] [CrossRef] [PubMed]

- Nadolny, K.; Sutowski, P.; Herman, D. Analysis of aluminum oxynitride AlON (Abral®) abrasive grains during the brittle fracture process using stress-wave emission techniques. Int. J. Adv. Manuf. Technol. 2015, 81, 1961–1976. [Google Scholar] [CrossRef]

- Kapłonek, W.; Ungureanu, M. SEM-based imaging and analysis of surface morphology of the Trizact™ advanced structured abrasives. J. Mech. Energy Eng. 2018, 2, 17–26. [Google Scholar] [CrossRef]

| Group of Parameters | Symbol | Unit | Description |

|---|---|---|---|

| Roughness (profile) | Ra | µm | Arithmetical mean deviation of the roughness profile |

| Rq | µm | Root-mean-square deviation of the roughness profile | |

| Rt | µm | Total height of the profile on the evaluation length | |

| Amplitude (surface) | Sa | µm | Arithmetic mean deviation of the surface |

| Sq | µm | Root-mean-square (RMS) deviation of the surface | |

| St | µm | Total height of the surface | |

| Spatial (surface) | Sal | mm | Fastest decay autocorrelation length |

| Areal (surface) 1 | Sds | pks/mm2 | Density of summits |

| Feature (surface) | SPc | pks/mm2 | Arithmetic mean peak curvature |

| Waviness (profile) | Wt | µm | Maximum height of waviness profile |

| WSm | mm | Mean width of profile elements, within a sampling length |

| Chemical Composition | |||||||||||||

| SiO2, % | Na2O, % | CaO, % | MgO, % | Al2O3, % | K2O, % | SO2, % | Fe203, % | ||||||

| 72.60 | 13.90 | 8.40 | 3.90 | 1.10 | 0.60 | 0.20 | 0.11 | ||||||

| Strength | |||||||||||||

| Flexural | Compressive | ||||||||||||

| Annealed, MPa | Heat-strengthened, MPa | Toughened, MPa | Annealed, MPa | Heat-strengthened, MPa | Toughened, MPa | ||||||||

| 41 | 83 | 165 | 19 | 39 | 77 | ||||||||

| Physical Properties | |||||||||||||

| Density, kg/m3 1 | Mohs hardness | Modulus of elasticity, GPa | Shear modulus, GPa | Poisson’s ratio | Coeff. of thermal stress, MPa/°C | ||||||||

| 2500 | 5–6 | 72 | 30 | 0.23 | 0.62 | ||||||||

| Thermal conductivity, W/m·K | Specific heat, kJ/kg·K | Coeff. of linear expansion, °C | Index of refraction 2 | Softening point, °C | Annealing point, °C | ||||||||

| 0.937 | 0.88 | 8.3 × 10−6 | 1.5 | 715 | 548 | ||||||||

| Max. working temperature, °C | Thermal shock Δ, °C | ||||||||||||

| Not Toughened | Toughened | Not Toughened | Toughened | ||||||||||

| 110 | 150 | 50 | 118 | ||||||||||

| No. | Instrument Type | Model | Producer | Configuration and Features |

|---|---|---|---|---|

| 1. | Multisensory optical profilometer | CLI2000 | Taylor-Hobson (Leicester, Great Britain) | Components: laser triangulation sensor LK-031 (Keyence Corp., Osaka, Japan) Features (sensor): scanning frequency: 2000 Hz, measuring range: 10 mm, resolution: 1 μm (vertical), 30 µm (lateral), measuring slope: 40°, speed: 30 mm/s Features (instrument): measuring capacity: 200 × 200 × 200 mm, axis traverse length: 200 mm, axis resolution: 0.5 μm, dimensions: 800 × 800 × 800 mm, measuring speed: 0.5, 1, 5, 10, 15, and 30 mm/s, positioning speed: 30 mm/s |

| Software: Talyscan CLI 2000 2.6.1+ TalyMap Silver 4.1.2 (Digital Surf, Besançon, France) | ||||

| 2. | SEM microscope | Quanta 200 Mark II | FEI Company, (Hillsboro, OR, USA) | Components: detectors: SEI (Everhart-Thornley SED, low-vacuum SED (LFD), gaseous SED (GSED)), BEI (solid-state (BSED), gaseous SED (GSED)), specimen stage: eucentric goniometer stage (four-axis motorized) Features: magnification range: 30 × to ~1,000,000 ×, vacuum pressure in the specimen chamber: < 0.0006 Pa (HVM), 10–130 Pa (LVM), accelerating voltage: 0.2–30 kV, resolution (using HVM): 3.0 nm at 30 kV SEI, 4.0 nm at 30 kV BSE, 10 nm at 3 kV SEI, (using LVM): 3.0 nm at 30 kV SEI, 4.0 nm at 30 kV BSE, < 12 nm at 3 kV SEI |

| Software: dedicated FEI software |

| Area location | γ1 | γ2 |

|---|---|---|

| IS enter | 1 | 0 |

| IS outflow | 1 | 1 |

| OS enter | 0 | 0 |

| OS outflow | 0 | 1 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sutowska, M.; Kapłonek, W.; Pimenov, D.Y.; Gupta, M.K.; Mia, M.; Sharma, S. Influence of Variable Radius of Cutting Head Trajectory on Quality of Cutting Kerf in the Abrasive Water Jet Process for Soda–Lime Glass. Materials 2020, 13, 4277. https://doi.org/10.3390/ma13194277

Sutowska M, Kapłonek W, Pimenov DY, Gupta MK, Mia M, Sharma S. Influence of Variable Radius of Cutting Head Trajectory on Quality of Cutting Kerf in the Abrasive Water Jet Process for Soda–Lime Glass. Materials. 2020; 13(19):4277. https://doi.org/10.3390/ma13194277

Chicago/Turabian StyleSutowska, Marzena, Wojciech Kapłonek, Danil Yurievich Pimenov, Munish Kumar Gupta, Mozammel Mia, and Shubham Sharma. 2020. "Influence of Variable Radius of Cutting Head Trajectory on Quality of Cutting Kerf in the Abrasive Water Jet Process for Soda–Lime Glass" Materials 13, no. 19: 4277. https://doi.org/10.3390/ma13194277

APA StyleSutowska, M., Kapłonek, W., Pimenov, D. Y., Gupta, M. K., Mia, M., & Sharma, S. (2020). Influence of Variable Radius of Cutting Head Trajectory on Quality of Cutting Kerf in the Abrasive Water Jet Process for Soda–Lime Glass. Materials, 13(19), 4277. https://doi.org/10.3390/ma13194277