Laboratory Investigation of Aging Resistance for Rubberized Bitumen Modified by Using Microwave Activation Crumb Rubber and Different Modifiers

Abstract

1. Introduction

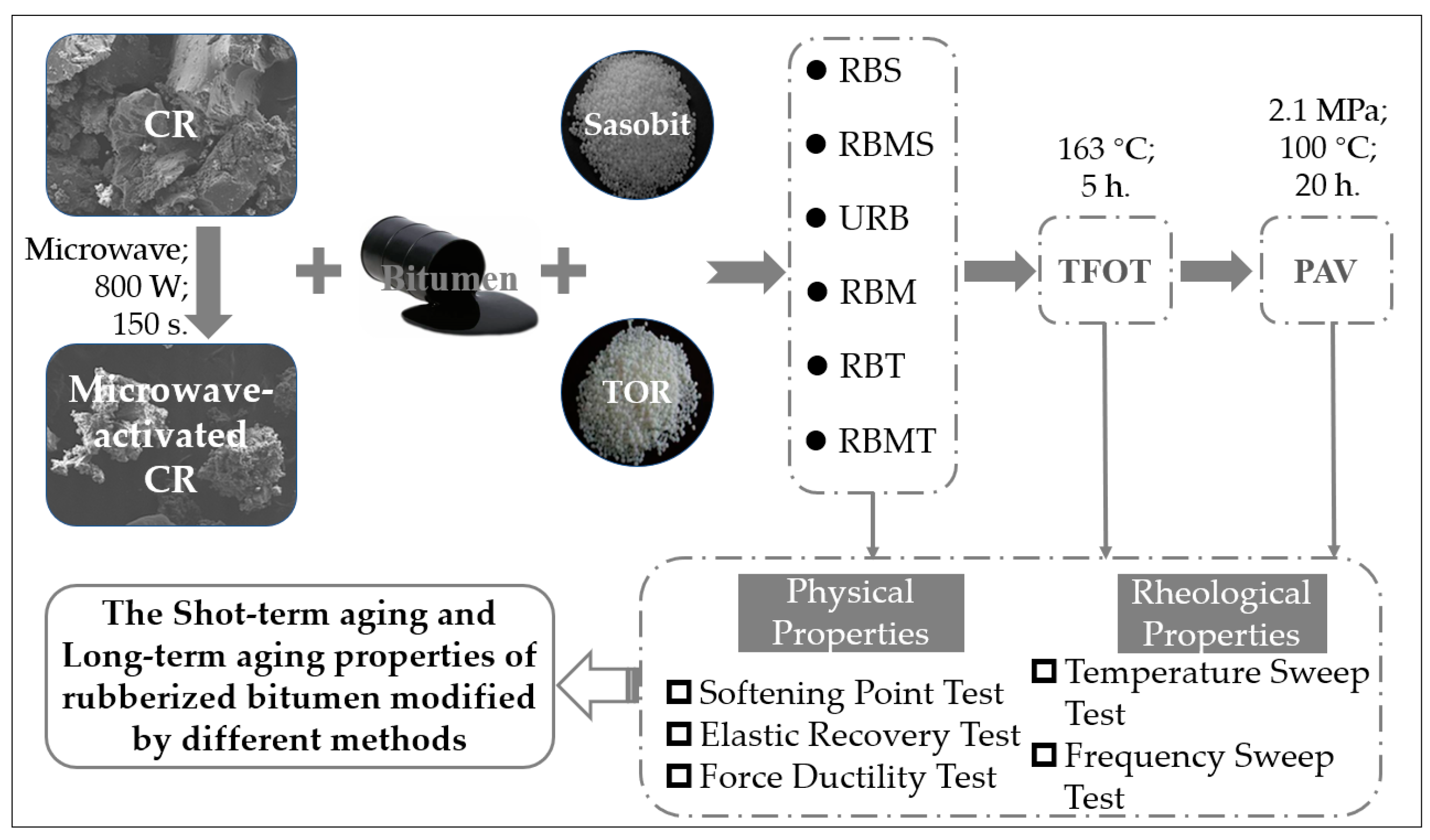

2. Objective and Approach

- ◆

- The TFOT and PAV test were used for the simulations of the aging conditions.

- ◆

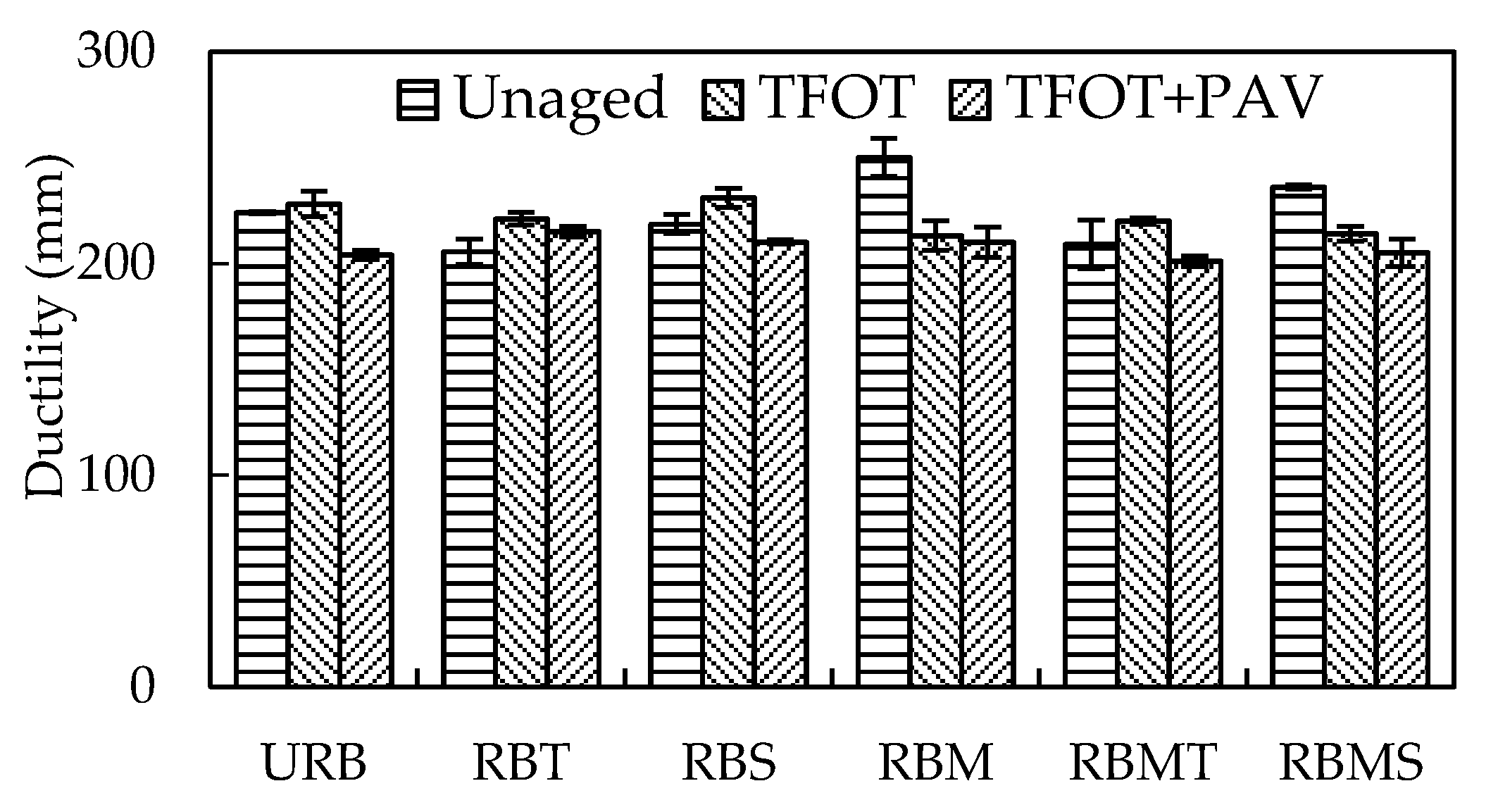

- Indexes including softening point, elastic recovery ratio, maximum load, ductility, and fracture energy were tested before aging, and after STA and LTA to evaluate the physical properties of rubberized bitumen.

- ◆

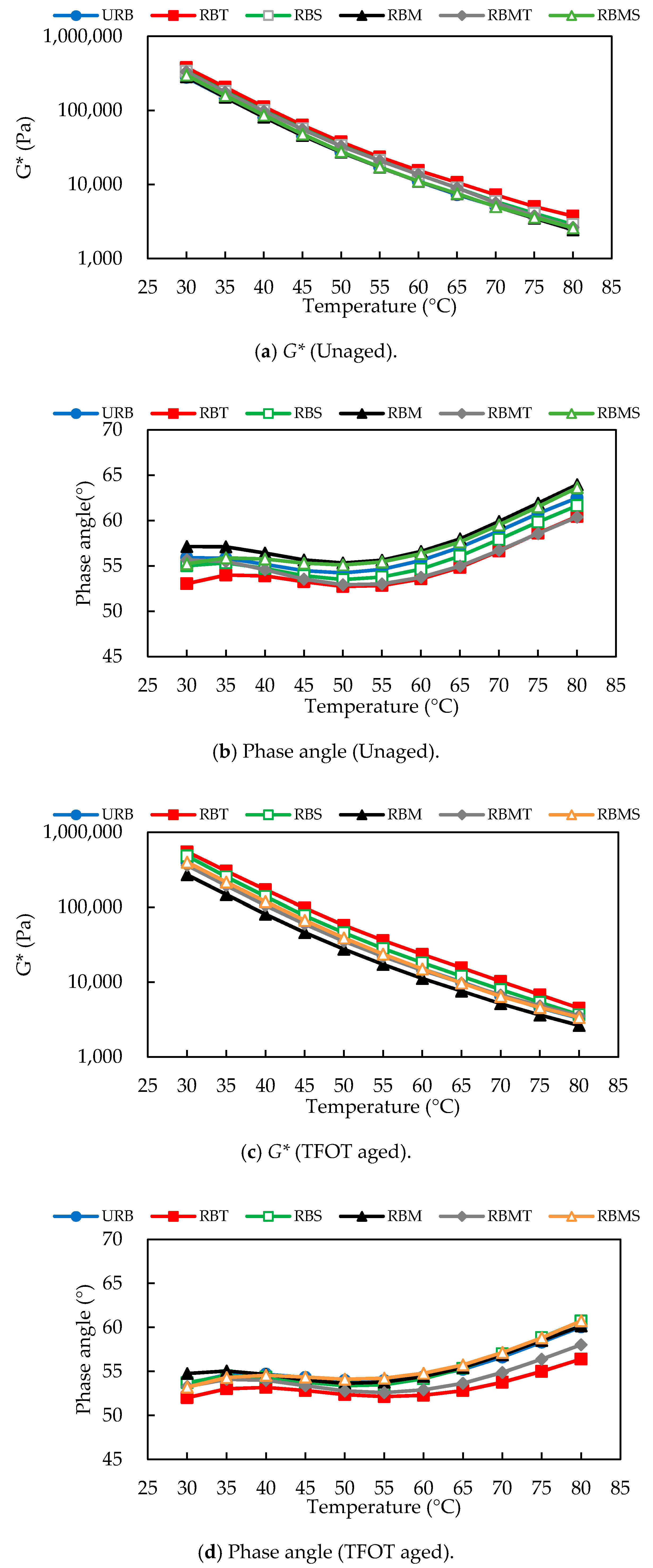

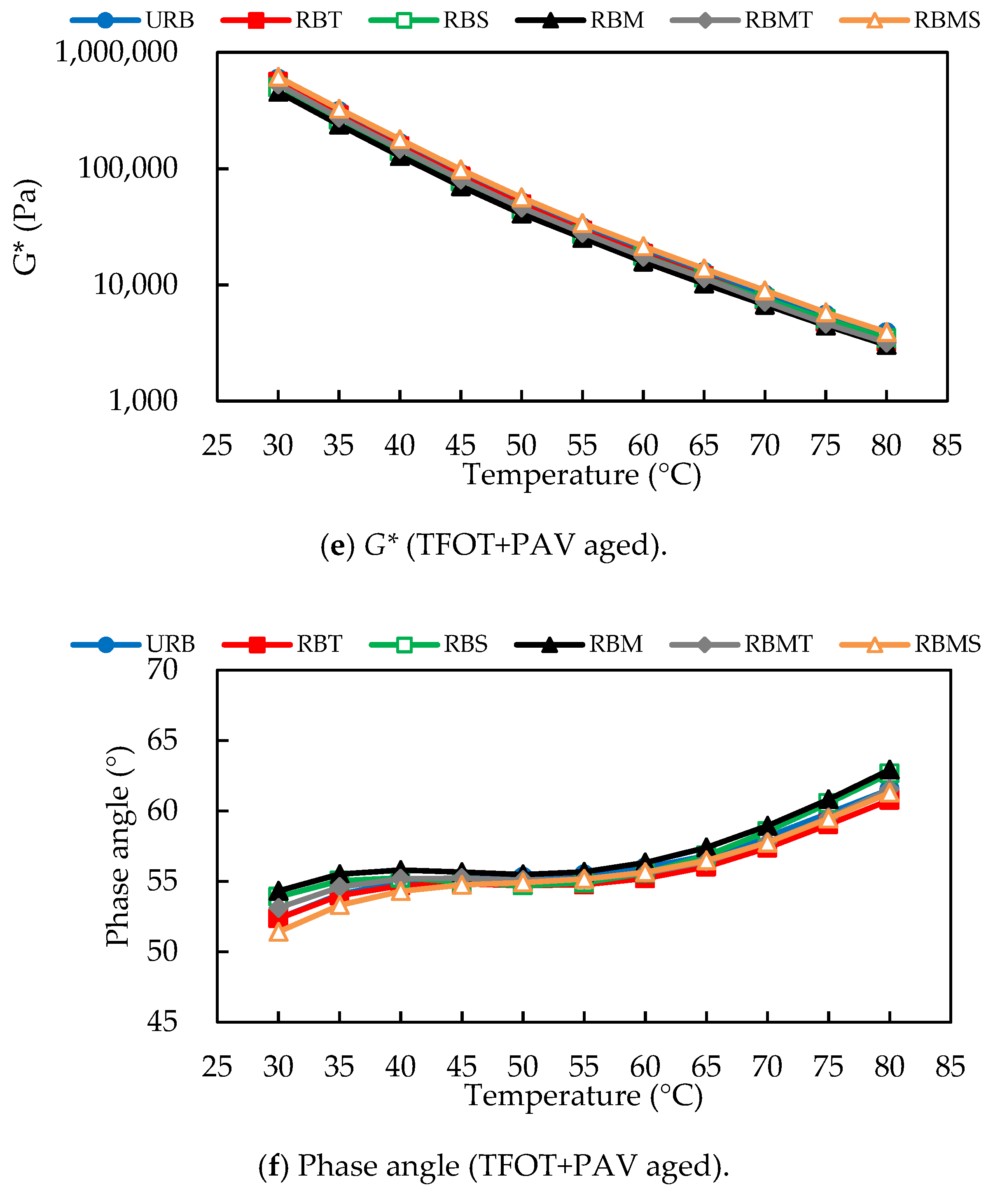

- Dynamic shear rheometer (DSR) tests were conducted on rubberized bitumen samples (before aging, subjected to TFOT, and subjected to TFOT + PAV) to obtain the indexes including phase angle and dynamic modulus.

3. Experimental

3.1. Materials and Samples Preparation

- (1)

- Blend the CR (or pre-treated CR) modifiers with the virgin bitumen previously conditioned at 150 °C by a 300 rpm stirring for 30 min.

- (2)

- Shear the blended mixture at 4000 rpm and 200 °C for 60 min.

- (3)

- Stir the blended mixture at 300 rpm and 180 °C for 60 min.

- (4)

- Condition the prepared rubberized bitumen at 140 °C for 30 min.

3.2. Aging Methods

3.3. Analysis Methods

4. Results and Analysis

4.1. Physical Properties

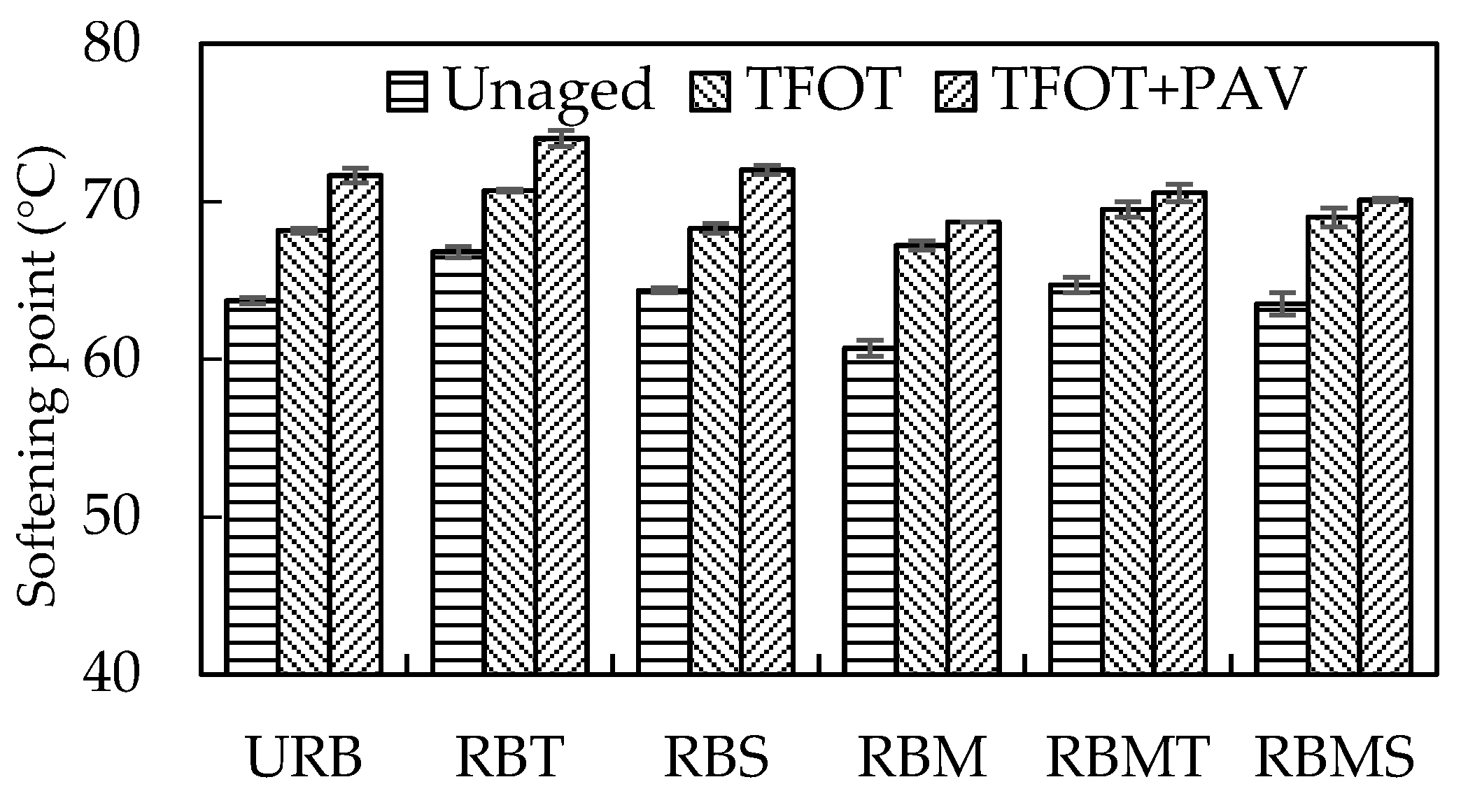

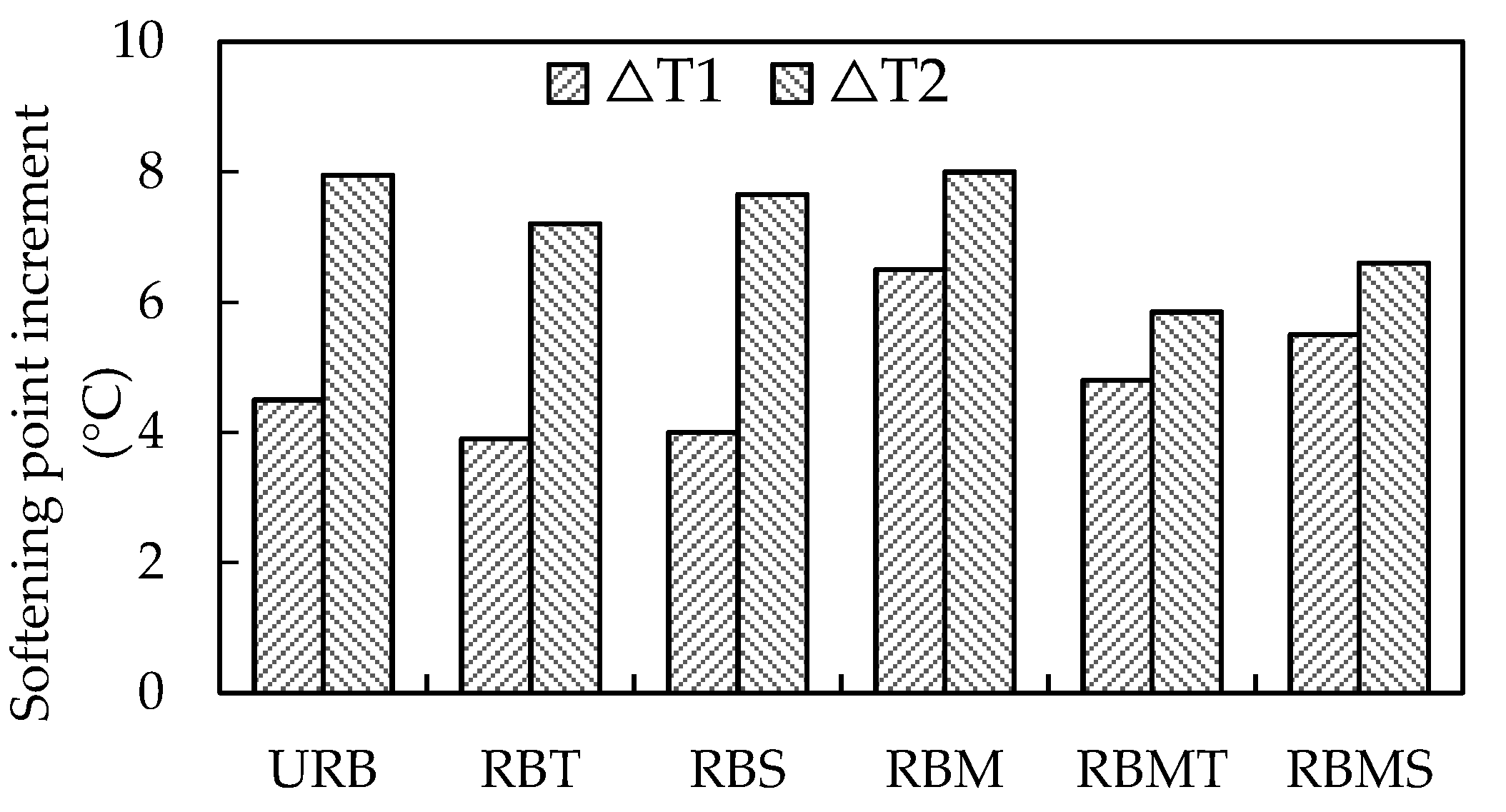

4.1.1. Softening Point

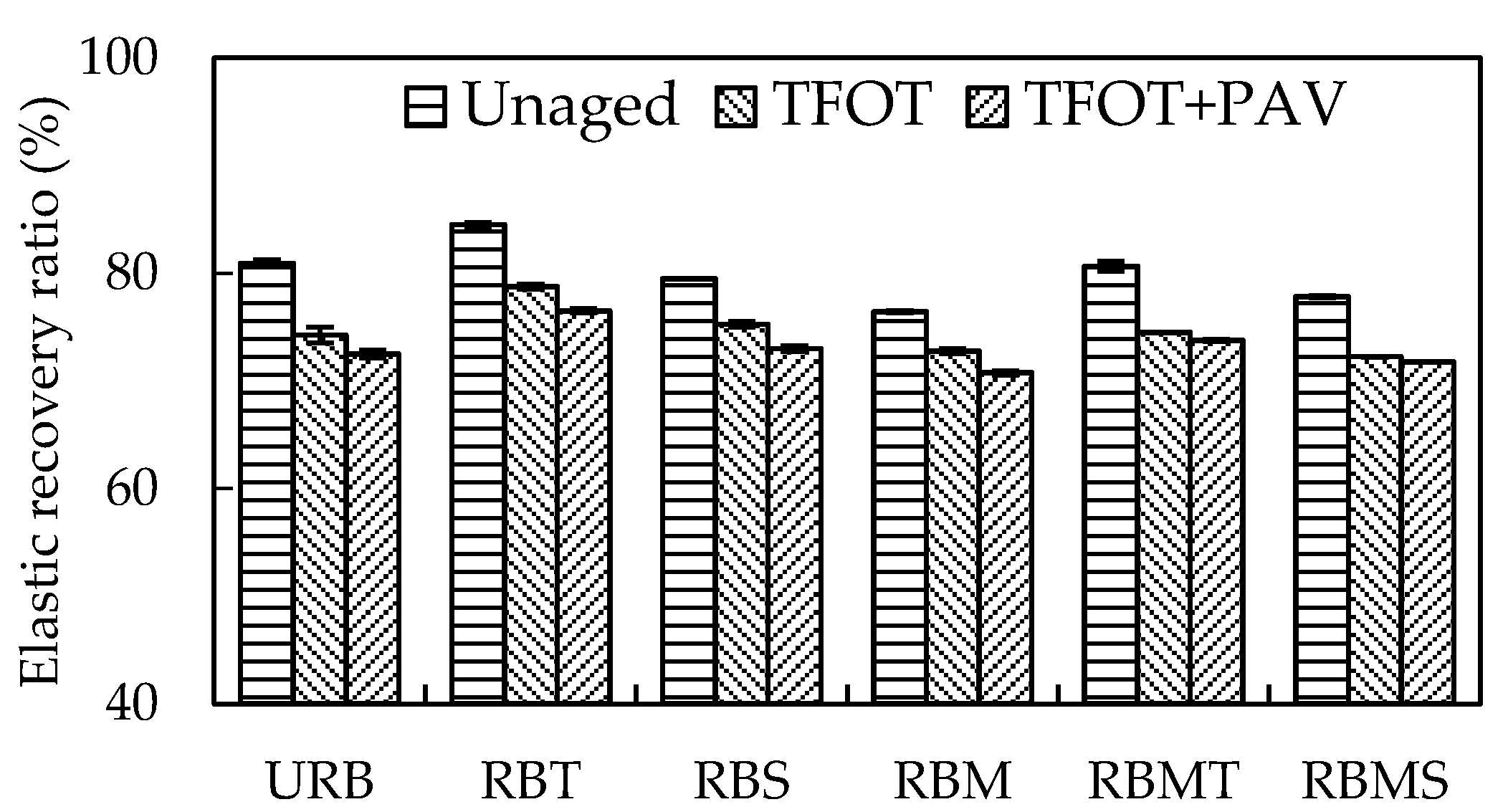

4.1.2. Elastic Recovery Ratio

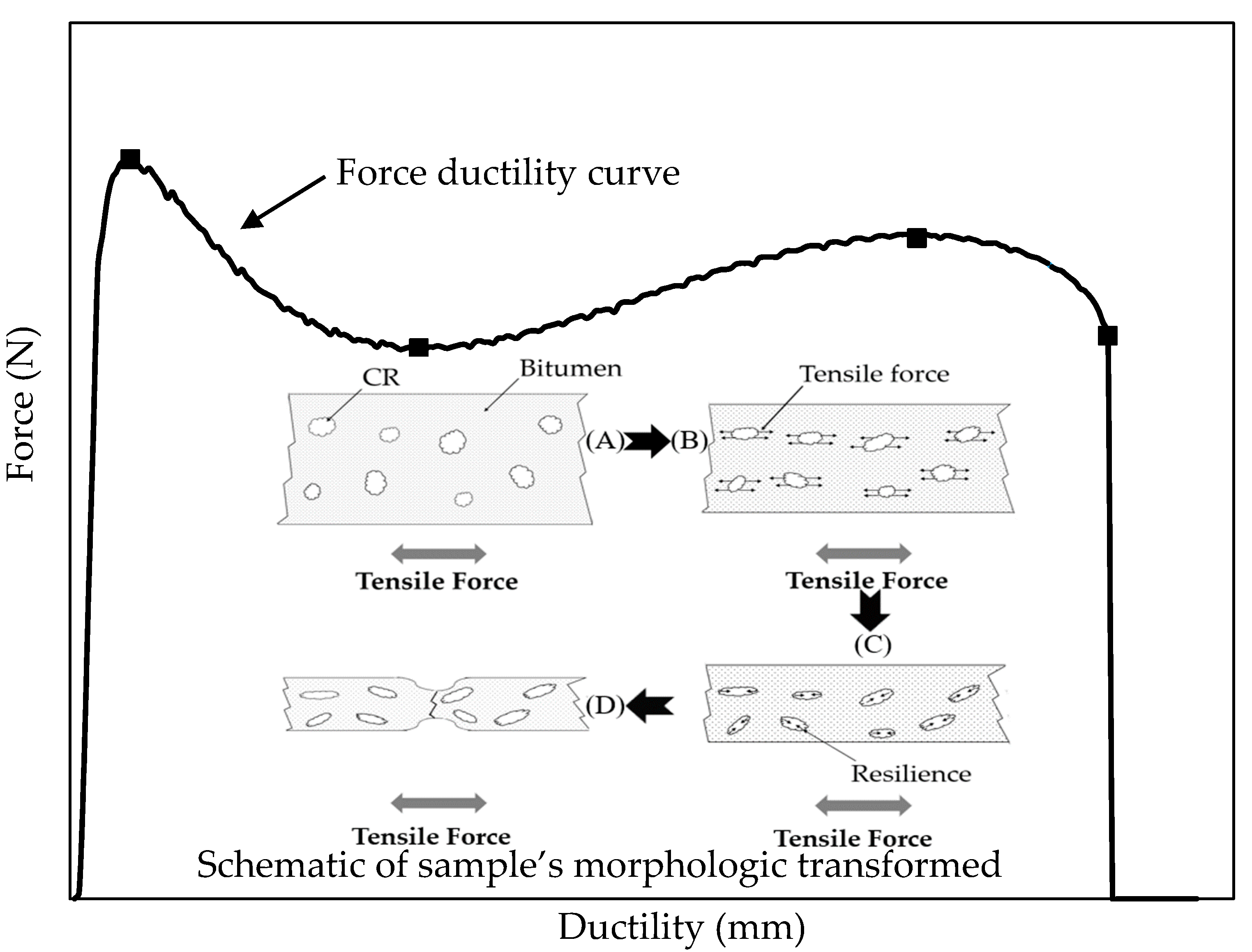

4.1.3. Force Ductility

4.2. Rheological Properties

4.2.1. Temperature Sweep Test

4.2.2. Frequency Sweep Test

5. Conclusions

- (1)

- TOR and Sasobit improved the high-temperature stability and elastic recoverability of rubberized bitumen, but the effect of Sasobit was barely noticeable. However, microwave-activated rubberized bitumen had an adverse effect on these properties.

- (2)

- STA had a significant effect on the high-temperature stability and elastic recoverability of rubberized bitumen. The TOR-modified rubberized bitumen showed the best aging resistance among the six rubberized bitumens. The CR activated by microwave has worse aging resistance compared with other modification methods. From the temperature sweep test and frequency sweep test, it can be seen that compared with unaged binders, the difference between the rheological properties of various rubberized bitumen after STA was reduced.

- (3)

- Among various modification methods, TOR modifier showed the best aging resistance to LTA, while microwave activation resulted in a weaker aging resistance due to the cracking of CR. From the temperature sweep test and frequency sweep test, it can be seen that the difference between the rheological properties of various bitumen after LTA was further reduced.

- (4)

- This study evaluated the influence of the modification methods on the aging resistance for rubberized bitumen by analyzing the difference in its properties before and after aging. Future research is suggested to investigate the mechanism of different modification methods before and after aging.

Author Contributions

Funding

Conflicts of Interest

References

- Abdelrahman, M.A. Engineering characterization of the interaction of asphalt with crumb rubber modifier (CRM). FEMS Immunol. Med. Microbiol. 1996, 28, 97–104. [Google Scholar]

- Wang, H.; Liu, X.; Apostolidis, P.; Scarpas, T. Review of warm mix rubberized asphalt concrete: Towards a sustainable paving technology. J. Clean. Prod. 2018, 177, 302–314. [Google Scholar] [CrossRef]

- Subhy, A.; Pires, G.M.; Lo Presti, D.; Airey, G. The effects of laboratory ageing on rheological and fracture characteristics of different rubberised bitumens. Constr. Build. Mater. 2018, 180, 188–198. [Google Scholar] [CrossRef]

- Min, K.E.; Jeong, H.M. Characterization of air-blown asphalt/trans-polyoctenamer rubber blends. J. Ind. Eng. Chem. 2013, 19, 645–649. [Google Scholar] [CrossRef]

- Shatanawi, K.M.; Biro, S.; Geiger, A.; Amirkhanian, S.N. Effects of furfural activated crumb rubber on the properties of rubberized asphalt. Constr. Build. Mater. 2012, 28, 96–103. [Google Scholar] [CrossRef]

- Ghavibazoo, A.; Abdelrahman, M.; Ragab, M. Effect of Crumb Rubber Modifier Dissolution on Storage Stability of Crumb Rubber–Modified Asphalt. Transp. Res. Rec. 2013, 2370, 109–115. [Google Scholar] [CrossRef]

- Liang, M.; Xin, X.; Fan, W.; Ren, S.; Shi, J.; Luo, H. Thermo-stability and aging performance of modified asphalt with crumb rubber activated by microwave and TOR. Mater. Des. 2017, 127, 84–96. [Google Scholar] [CrossRef]

- Kim, H.H.; Lee, S. Effect of crumb rubber on viscosity of rubberized asphalt binders containing wax additives. Constr. Build. Mater. 2015, 95, 65–73. [Google Scholar] [CrossRef]

- Liu, H.; Chen, Z.; Wang, W.; Wang, H.; Hao, P. Investigation of the rheological modification mechanism of crumb rubber modified asphalt (CRMA) containing TOR additive. Constr. Build. Mater. 2014, 67, 225–233. [Google Scholar] [CrossRef]

- Leng, Z.; Yu, H.Y.; Zhang, Z.Y.; Tan, Z.F. Optimizing the mixing procedure of warm asphalt rubber with wax-based additives through mechanism investigation and performance characterization. Constr. Build. Mater. 2017, 144, 291–299. [Google Scholar] [CrossRef]

- Zhang, B.; Chen, H.; Zhang, H.; Kuang, D.; Wu, J.; Zhang, X. A Study on Physical and Rheological Properties of Rubberized Bitumen Modified by Different Methods. Materials 2019, 12, 3538. [Google Scholar] [CrossRef] [PubMed]

- Lee, S.; Hu, J.; Kim, H.; Amirkhanian, S.N.; Jeong, K. Aging analysis of rubberized asphalt binders and mixes using gel permeation chromatography. Constr. Build. Mater. 2011, 25, 1485–1490. [Google Scholar] [CrossRef]

- Wang, H.; Xueyan, L.; Apostolidis, P.; Ven, M.V.D.; Scarpas, T. Effect of laboratory aging on chemistry and rheology of crumb rubber modified bitumen. Mater. Struct. 2020, 53, 26. [Google Scholar] [CrossRef]

- Nivitha, M.R.; Prasad, E.; Krishnan, J.M. Ageing in modified bitumen using FTIR spectroscopy. Int. J. Pavement Eng. 2016, 17, 565–577. [Google Scholar] [CrossRef]

- Feng, Z.; Wang, S.; Bian, H.; Guo, Q.; Li, X. FTIR and rheology analysis of aging on different ultraviolet absorber modified bitumens. Constr. Build. Mater. 2016, 115, 48–53. [Google Scholar] [CrossRef]

- Xiao, P.; Zheng, J.; Kang, A.; Sun, L.; Wang, Y. Aging Characteristics of Rubber Modified Asphalts in Different Environmental Factors Combinations. Appl. Sci. 2017, 7, 806. [Google Scholar] [CrossRef]

- Huang, S. Rubber Concentrations on Rheology of Aged Asphalt Binders. J. Mater. Civ. Eng. 2008, 20, 221–229. [Google Scholar] [CrossRef]

- Huang, S. Rheological characteristics of crumb rubber-modified asphalts with long-term aging. Road Mater. Pavement Des. 2006, 7, 37–56. [Google Scholar] [CrossRef]

- Ali, A.H.; Mashaan, N.S.; Karim, M.R. Investigations of Physical and Rheological Properties of Aged Rubberised Bitumen. Adv. Mater. Sci. Eng. 2013, 2013, 239036. [Google Scholar] [CrossRef]

- Yang, X.; Shen, A.; Li, B.; Wu, H.; Lyu, Z.; Wang, H.; Lyu, Z. Effect of microwave-activated crumb rubber on reaction mechanism, rheological properties, thermal stability, and released volatiles of asphalt binder. J. Clean. Prod. 2020, 248, 119230. [Google Scholar] [CrossRef]

- Wang, S.; Wang, Q.; Li, S. Thermooxidative aging mechanism of crumb-rubber-modified asphalt. J. Appl. Polym. Sci. 2016, 133, 43323. [Google Scholar] [CrossRef]

- Pouranian, M.R.; Shishehbor, M. Sustainability assessment of green asphalt mixtures: A review. Environments 2019, 6, 73. [Google Scholar] [CrossRef]

- Yu, H.Y.; Leng, Z.; Dong, Z.J.; Tan, Z.F.; Guo, F.; Yan, J.H. Workability and mechanical property characterization of asphalt rubber mixtures modified with various warm mix asphalt additives. Constr. Build. Mater. 2018, 175, 392–401. [Google Scholar] [CrossRef]

- Kim, H.H.; Mazumder, M.; Lee, S.; Lee, M. Characterization of recycled crumb rubber modified binders containing wax warm additives. J. Traffic Transp. Eng. 2018, 5, 197–206. [Google Scholar] [CrossRef]

- Akpolat, M.; Kok, B.V. Effect of Using Crumb Rubber with Warm-Mix-Asphalt Additive in Laboratory and Field Aging. World Acad. Sci. Eng. Technol. Int. J. Civ. Environ. Struct. Constr. Archit. Eng. 2018, 12, 157–161. [Google Scholar]

- Xu, O.; Xiao, F.; Han, S.; Amirkhanian, S.; Wang, Z. High temperature rheological properties of crumb rubber modified asphalt binders with various modifiers. Constr. Build. Mater. 2016, 112, 49–58. [Google Scholar] [CrossRef]

- Xie, Z.; Shen, J. Effect of cross-linking agent on the properties of asphalt rubber. Constr. Build. Mater. 2014, 67, 234–238. [Google Scholar] [CrossRef]

- Padhan, R.K.; Gupta, A.A.; Mohanta, C.S.; Badoni, R.P.; Bhatnagar, A.K. Performance improvement of a crumb rubber modified bitumen using polyoctenamer and cross linking agent. Road Mater. Pavement Des. 2017, 18, 999–1006. [Google Scholar] [CrossRef]

- Puga, K.L.N.N. Rheology and Performance Evaluation of Polyoctenamer as Asphalt Rubber Modifier in Hot Mix Asphalt. Master’s Thesis, Iowa State University, Ames, IA, USA, 2013. [Google Scholar]

- Han, L.; Zheng, M.; Li, J.; Li, Y.; Zhu, Y.; Ma, Q. Effect of nano silica and pretreated rubber on the properties of terminal blend crumb rubber modified asphalt. Constr. Build. Mater. 2017, 157, 277–291. [Google Scholar] [CrossRef]

- Li, B.; Shen, J.; Xie, Z. Influence of trans-polyoctenamer on rheological properties of rubberised asphalt binders after short term aging procedures. Mater. Res. Innov. 2014, 18, 39–41. [Google Scholar] [CrossRef]

- Yu, G.; Li, Z.M.; Zhou, X.L.; Li, C. Crumb Rubber—Modified Asphalt: Microwave Treatment Effects. Pet. Sci. Technol. 2011, 29, 411–417. [Google Scholar] [CrossRef]

- Zhang, Z.; Li, B.; Li, P.; Yang, J. Influence of Surface Area of Microwave Activated Crumb Rubber on Rheological Properties of Rubber Asphalt. Pet. Process. Petrochem. 2018, 49, 79–83. [Google Scholar]

- Yin, J.; Wang, S.; Lv, F. Improving the short-term aging resistance of asphalt by addition of crumb rubber radiated by microwave and impregnated in epoxidized soybean oil. Constr. Build. Mater. 2013, 49, 712–719. [Google Scholar] [CrossRef]

- Ibrahim, I.M.; Fathy, E.S.; Elshafie, M.; Elnaggar, M.Y. Impact of incorporated gamma irradiated crumb rubber on the short-term aging resistance and rheological properties of asphalt binder. Constr. Build. Mater. 2015, 81, 42–46. [Google Scholar] [CrossRef]

- Li, B.; Zhou, J.; Zhang, Z.; Yang, X.; Wu, Y. Effect of Short-Term Aging on Asphalt Modified Using Microwave Activation Crumb Rubber. Materials 2019, 12, 1039. [Google Scholar] [CrossRef] [PubMed]

- Xiao, F.; Punith, V.S.; Amirkhanian, S.N. Effects of non-foaming WMA additives on asphalt binders at high performance temperatures. Fuel 2012, 94, 144–155. [Google Scholar] [CrossRef]

- China Ministry of Transport JTG E20. Standard Test Methods of Bitumen and Bitumious Mixtures for Highway Engineering; Research Institute of Highway Ministry of Transport: Beijing, China, 2011.

- ASTM D36. Standard Test Method for Softening Point of Bitumen (Ring-and-Ball Apparatus); ASTM International: West Conshohocken, PA, USA, 2020. [Google Scholar]

- ASTM D6084. Standard Test Method for Elastic Recovery of Asphalt Materials by Ductilometer; ASTM International: West Conshohocken, PA, USA, 2018. [Google Scholar]

- ASTM D7175-15. Standard Test Method for Determining the Rheological Properties of Asphalt Binder Using a Dynamic Shear Rheometer; ASTM International: West Conshohocken, PA, USA, 2015. [Google Scholar]

- Yao, H.; Shuai, Z.; Wang, S. Structural evolution of recycled tire rubber in asphalt. J. Appl. Polym. Sci. 2016, 133, 6. [Google Scholar] [CrossRef]

- Liu, W.; Yan, K.; Ge, D.; Chen, M. Effect of APAO on the aging properties of waste tire rubber modified asphalt binder. Constr. Build. Mater. 2018, 175, 333–341. [Google Scholar] [CrossRef]

- Ghavibazoo, A.; Abdelrahman, M.; Ragab, M. Evaluation of Oxidization of Crumb Rubber–Modified Asphalt during Short-Term Aging. Transp. Res. Rec. 2015, 2505, 84–91. [Google Scholar] [CrossRef]

- Senise, S.; Carrera, V.; Navarro, F.J.; Partal, P. Thermomechanical and microstructural evaluation of hybrid rubberised bitumen containing a thermoplastic polymer. Constr. Build. Mater. 2017, 157, 873–884. [Google Scholar] [CrossRef]

- Mturi, G.A.J.; Nkgapele, M. Force Ductility—A 5 Year Feedback of Performance Results. In Proceedings of the 32nd Southern African Transport Conference, Pretoria, South Africa, 8–11 July 2013. [Google Scholar]

- Zoorob, S.E.; Castrogomes, J.; De Oliveira, L.A.P.; Oconnell, J. Investigating the Multiple Stress Creep Recovery bitumen characterisation test. Constr. Build. Mater. 2012, 30, 734–745. [Google Scholar] [CrossRef]

- Shuler, T.S.; Collins, J.H.; Kirkpatrick, J.P. Polmer-Modified Asphalt Properties Related to Asphalt Concrete Performance. Asphalt Rheology: Relationship to Mixture. A Symposium Sponsored by Astm Committee d-4 on Road and Paving Materials, Nashville, Tennessee, 11 December 1985. Astm Special Technical Publication 941; American Society for Testing and Materials: West Conshohocken, PA, USA, 1987. [Google Scholar]

- Ruan, Y.; Davison, R.R.; Glover, C.J. The effect of long-term oxidation on the rheological properties of polymer modified asphalts. Fuel 2003, 82, 1763–1773. [Google Scholar] [CrossRef]

- Zhang, F.; Hu, C. The research for structural characteristics and modification mechanism of crumb rubber compound modified asphalts. Constr. Build. Mater. 2015, 76, 330–342. [Google Scholar] [CrossRef]

| Test Items | Unit | Results | Specification | |

|---|---|---|---|---|

| Penetration (25 °C, 100 g, 5 s) | 0.1 mm | 94.5 | T0604 | |

| Ductility (15 °C, 5 cm/min) | cm | >150 | T0605 | |

| Softening point | °C | 45.9 | T0606 | |

| RTFOT aging | Mass change | % | +0.4 | T0610 |

| Residual ductility (10 °C) | cm | 12 | T0605 | |

| Residual penetration ratio (25 °C) | % | 57.8 | T0604 | |

| Samples | Details | Labels |

|---|---|---|

| Un-modification rubberized bitumen | CR: 24% by weight of bitumen | URB |

| Rubberized bitumen modified with TOR | CR: 24% by weight of bitumen TOR: 4.5% by weight of CR | RBT |

| Rubberized bitumen modified with WMA | CR: 24% by weight of bitumen WMA: 1% by weight of bitumen | RBS |

| Rubberized bitumen contained microwave pretreated CR | Pre-treated CR: 24% by weight of bitumen | RBM |

| Rubberized bitumen contained microwave pretreated CR and WMA | Pre-treated CR: 24% by weight of bitumen WMA: 1% by weight of bitumen | RBMS |

| Rubberized bitumen contained microwave pretreated CR and TOR | Pre-treated CR: 24% by weight of bitumen TOR: 4.5% by weight of CR | RBMT |

| Test | Standard | Details | |

|---|---|---|---|

| Softening point | ASTM D36 | - | |

| Elastic recovery | ASTM D6084 | Temperature: 25 °C | |

| Force-ductility | - | Temperature: 5 °C | |

| Temperature sweep | ASTM D 7175 | Plates diameter: 25 mm Gap: 1 mm | Temperature: 30~80 °C Frequency: 0.1 Hz |

| Frequency sweep | Temperature: 60 °C Frequency: 0.1~10 Hz | ||

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, B.; Chen, H.; Zhang, H.; Wu, Y.; Kuang, D.; Guo, F. Laboratory Investigation of Aging Resistance for Rubberized Bitumen Modified by Using Microwave Activation Crumb Rubber and Different Modifiers. Materials 2020, 13, 4230. https://doi.org/10.3390/ma13194230

Zhang B, Chen H, Zhang H, Wu Y, Kuang D, Guo F. Laboratory Investigation of Aging Resistance for Rubberized Bitumen Modified by Using Microwave Activation Crumb Rubber and Different Modifiers. Materials. 2020; 13(19):4230. https://doi.org/10.3390/ma13194230

Chicago/Turabian StyleZhang, Ben, Huaxin Chen, Honggang Zhang, Yongchang Wu, Dongliang Kuang, and Fengjun Guo. 2020. "Laboratory Investigation of Aging Resistance for Rubberized Bitumen Modified by Using Microwave Activation Crumb Rubber and Different Modifiers" Materials 13, no. 19: 4230. https://doi.org/10.3390/ma13194230

APA StyleZhang, B., Chen, H., Zhang, H., Wu, Y., Kuang, D., & Guo, F. (2020). Laboratory Investigation of Aging Resistance for Rubberized Bitumen Modified by Using Microwave Activation Crumb Rubber and Different Modifiers. Materials, 13(19), 4230. https://doi.org/10.3390/ma13194230