Bond Strength and Flexural Capacity of Normal Concrete Beams Strengthened with No-Slump High-Strength, High-Ductility Concrete

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Test Method

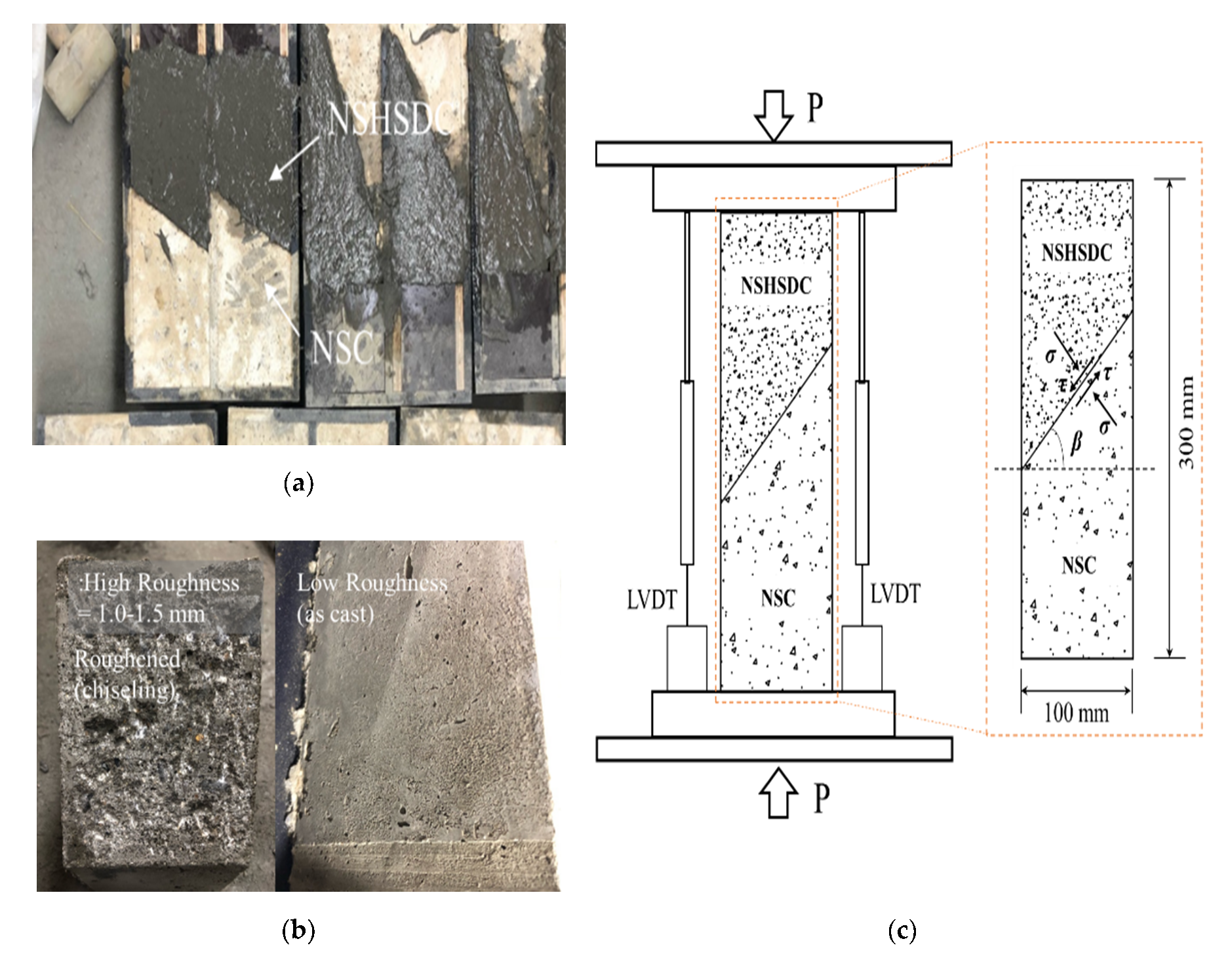

2.2.1. Interface Bond Strength Characterization Test

2.2.2. Beam Flexural Strength Test

3. Results and Discussion

3.1. Slant Shear Strength of the Interface

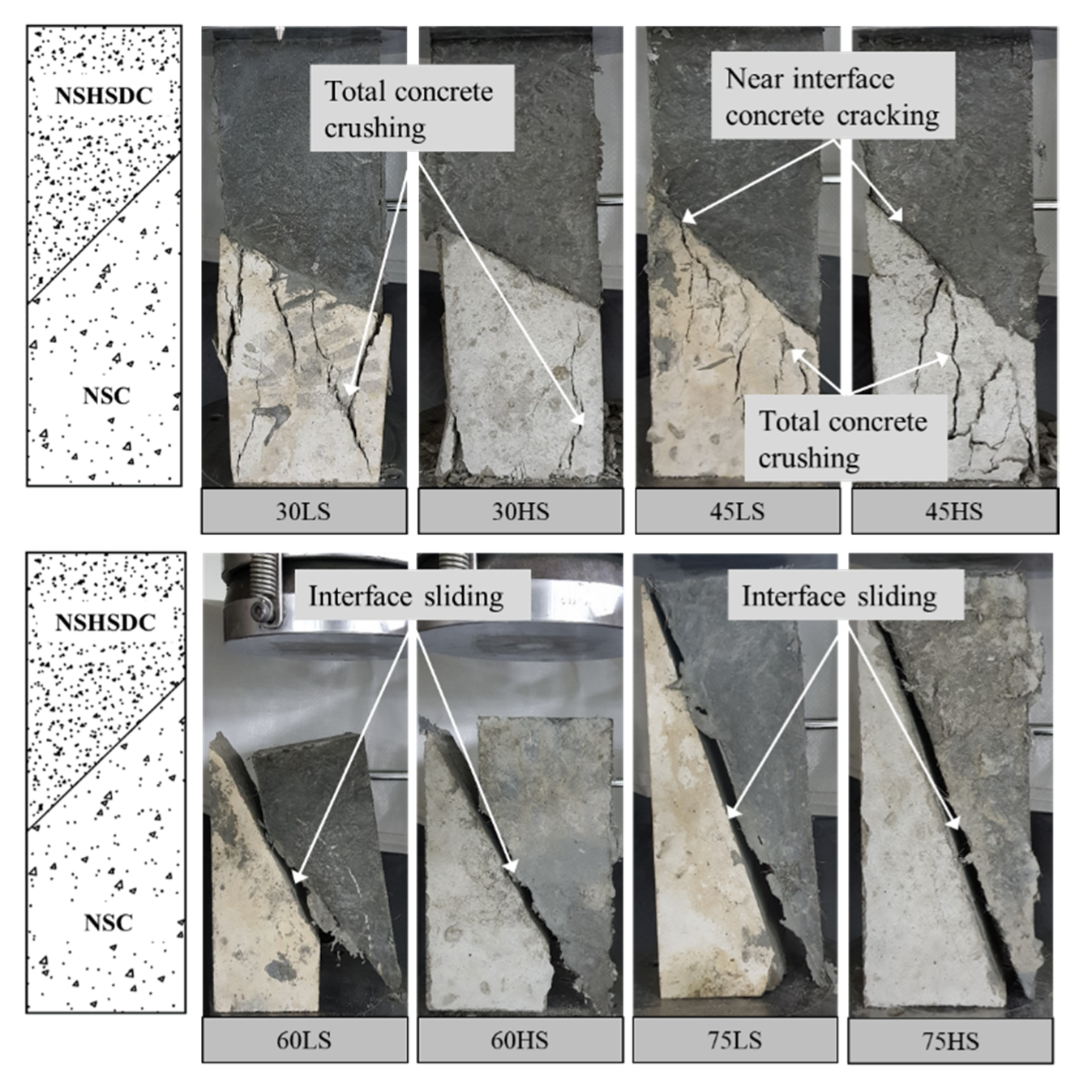

3.1.1. Slant Shear Strength and Failure Mode of Composite NSC and NSHSDC Specimens

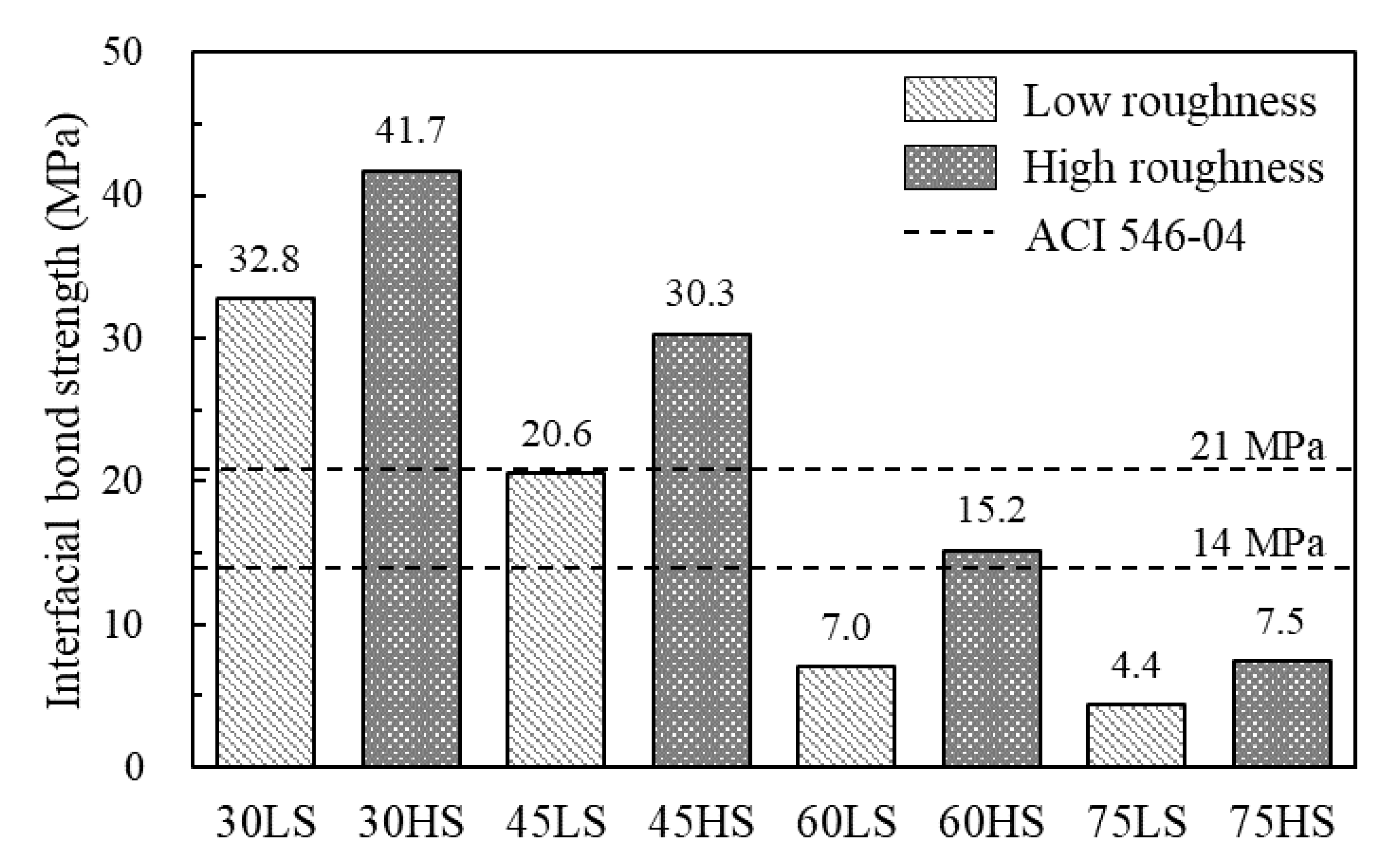

3.1.2. Comparison of Slant Shear Strength with Design Codes

3.2. Effect of Reinforced Method on Flexural Strength Tests

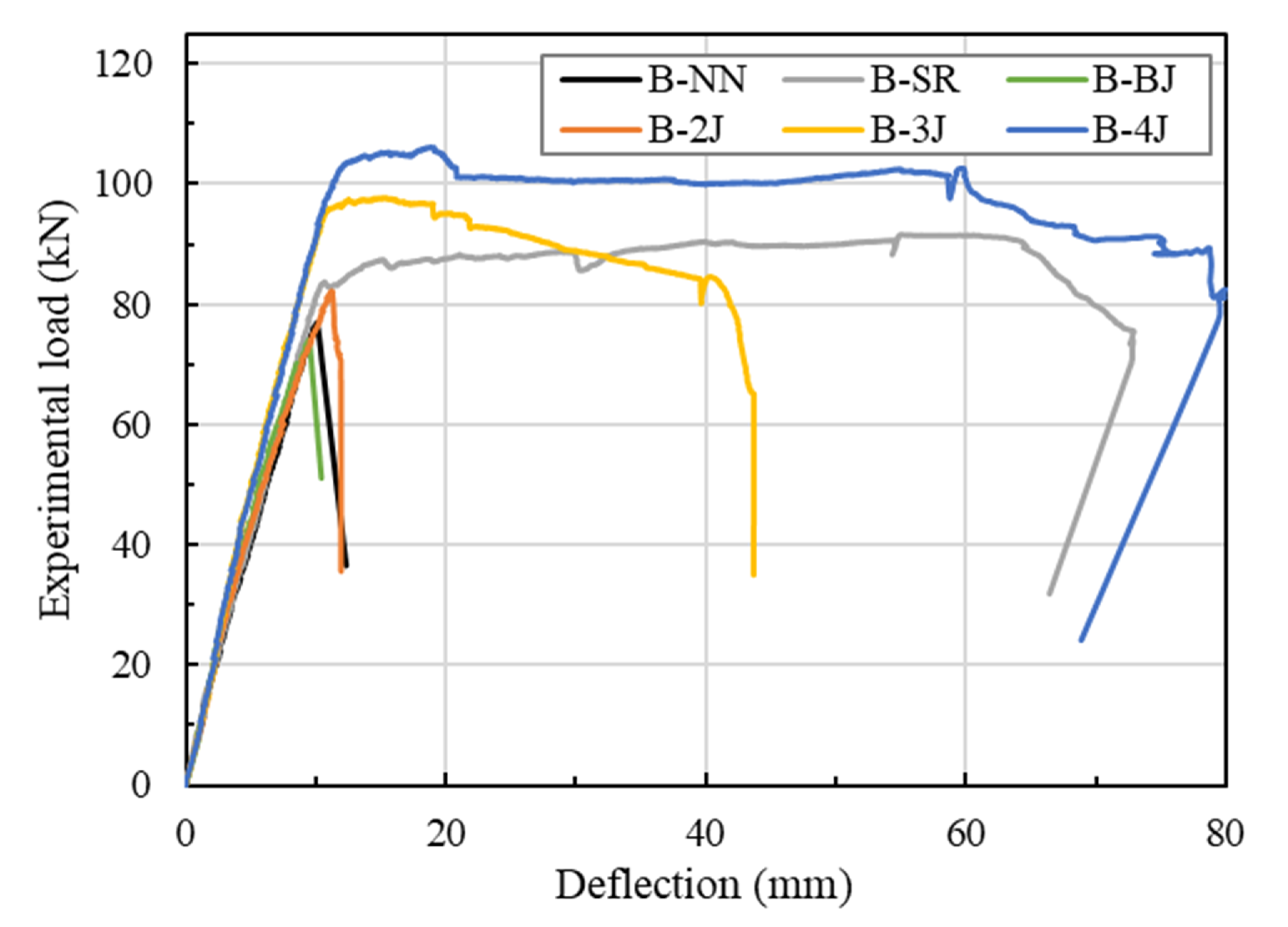

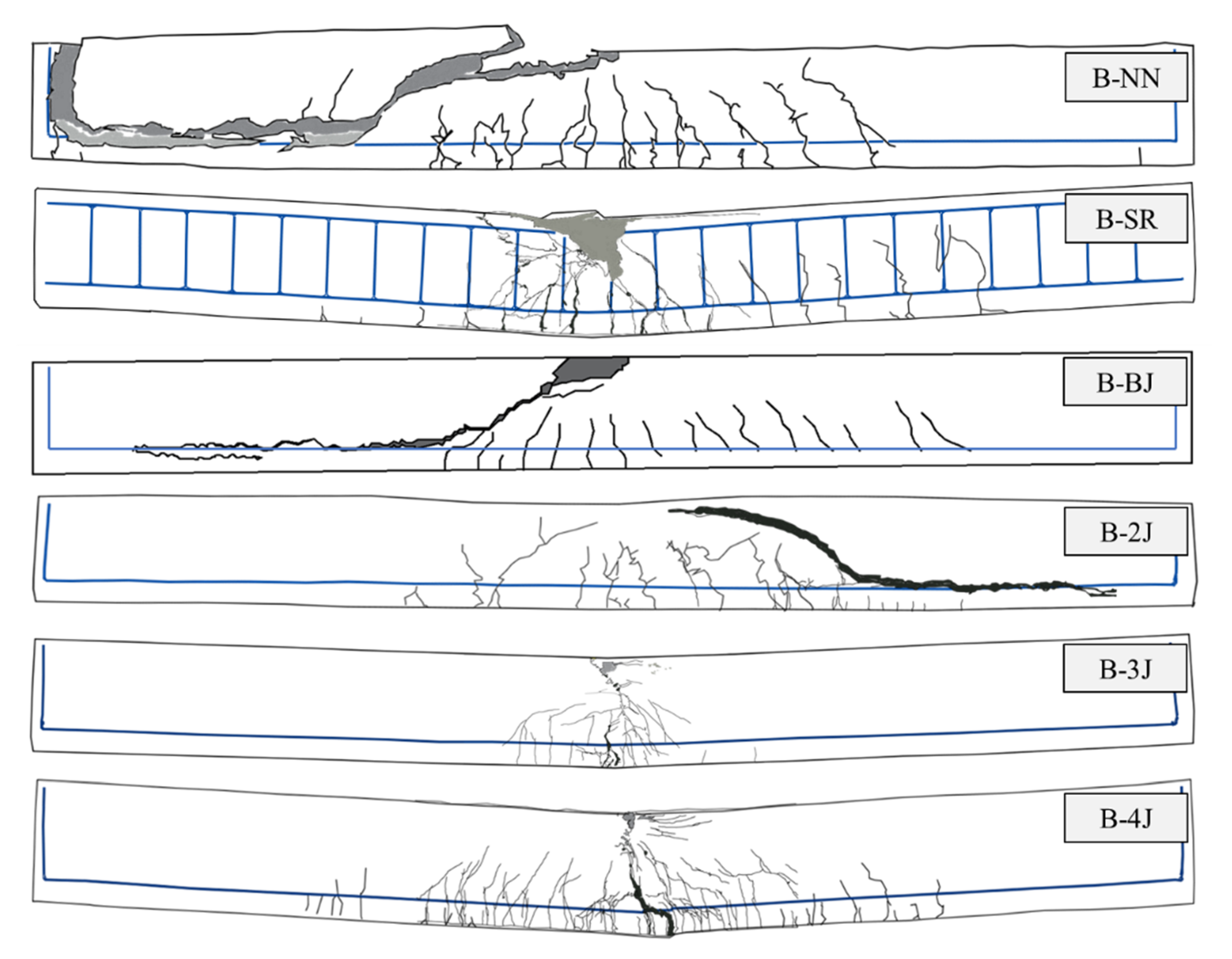

3.2.1. Load Defection Behavior and Failure Mode

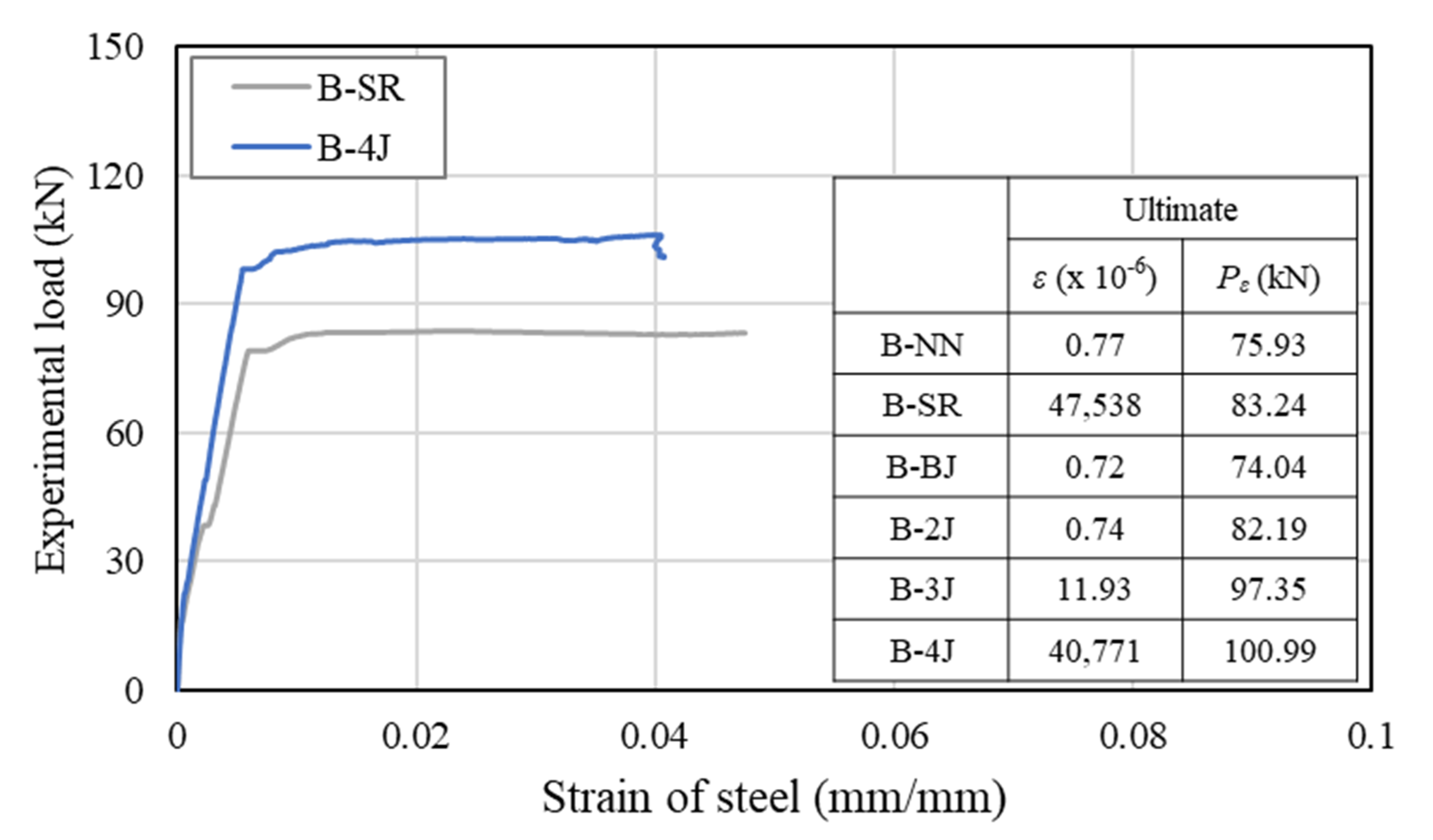

3.2.2. Load–Strain Behavior

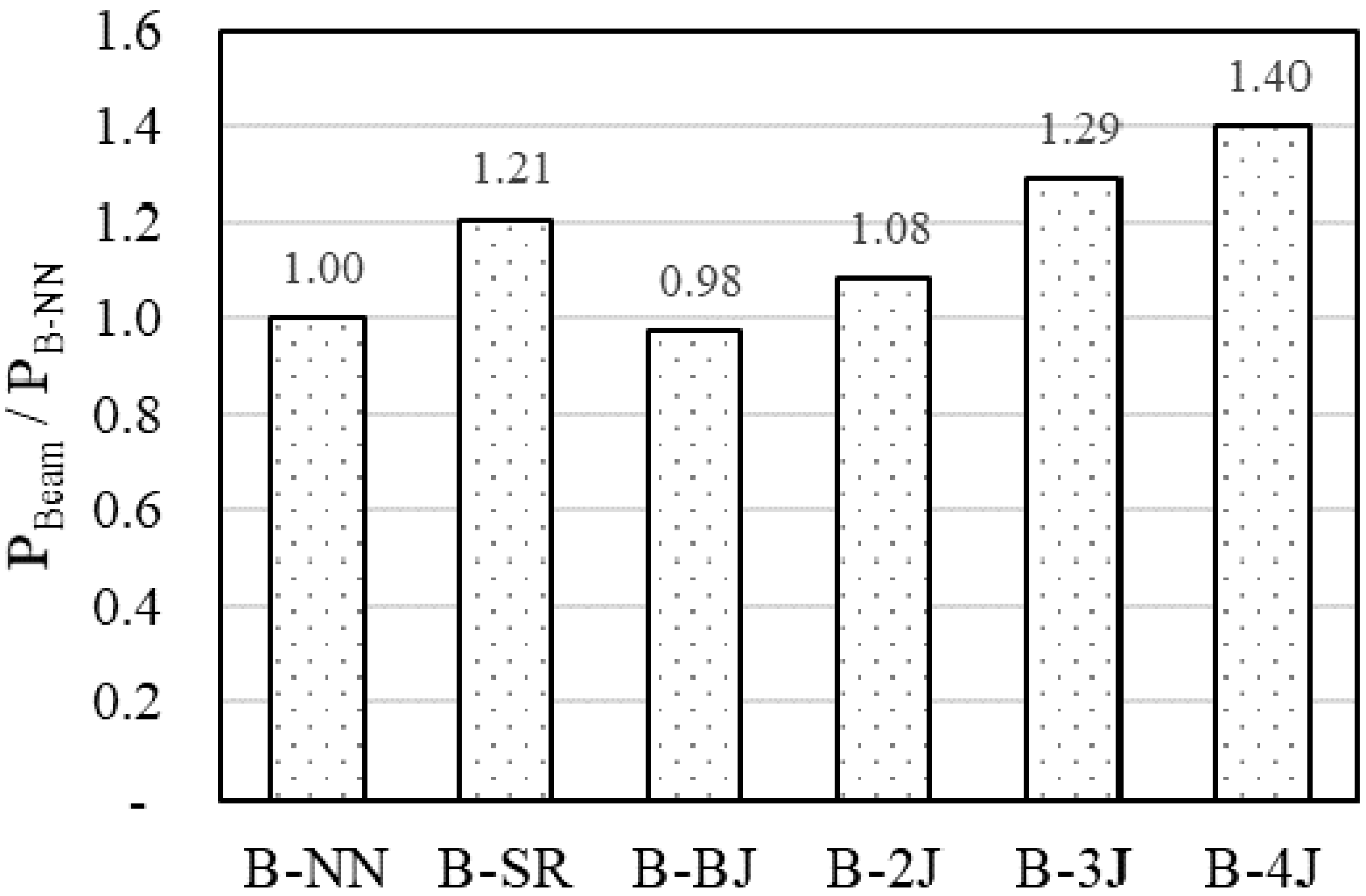

3.2.3. Effect of Strengthening Method

4. Conclusions

- (1)

- Regarding slant shear bond properties, specimens with high roughness conformed to the properties (14–21 MPa for 28 days) of the ACI Committee 546 recommendation, except specimens with 75° of interface angle. For the low roughness specimens, an interface angle of 30–45° conformed to the properties of ACI recommendation. The high roughness specimens exhibited higher interface stresses than those of the low (no) roughness specimens, and the interface shear stress ratios of the test to prediction (τ/τpred) ranged from 1.27 to 2.17.

- (2)

- In the effect of the strengthening method in the flexural loading test, beams B-BJ and B-2J exhibited similar behavior as B-NN, which exhibited typical shear failure mode without significantly improve the peak load. However, it is important to note that strengthened NSHSDC did not delaminate from the NSC surface.

- (3)

- Specimens B-3J and B-4J exhibited similar behavior to B-SR, except that the ductility of B-3J decreased rapidly with more stress up to the failure of the beam structure. B-4J occurred flexure failure similar to minimum shear reinforcement concrete (B-SR). Additionally, the test beam strengthened from three sides slightly increased in stiffness.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Souza, R.H.F.; Appleton, J. Flexural behavior of strengthened reinforced concrete beams. Mater. Struct. 1997, 30, 154–159. [Google Scholar] [CrossRef]

- Tanarslan, H.M. Flexural strengthening of RC beams with prefabricated ultra-high performance fiber reinforced concrete laminates. Eng. Struct. 2017, 151, 337–348. [Google Scholar] [CrossRef]

- AL-Osta, M.A.; Isa, M.N.; Baluch, M.H.; Rahman, M.K. Flexural behavior of reinforced concrete beams strengthened with ultra-high performance fiber reinforced concrete. Constr. Buil. Mater. 2017, 134, 279–296. [Google Scholar] [CrossRef]

- Carbonell Munoz, M.A.; Harris, D.K.; Ahlborn, T.M.; Froster, D.C. Bond performance between ultrahigh-performance concrete and normal-strength concrete. J. Mater. Civ. Eng. 2013, 26, 04014031. [Google Scholar] [CrossRef]

- Lampropoulos, A.P.; Paschalis, S.A.; Tsioulou, O.T.; Dritsos, S.E. Strengthening of reinforced concrete beams using ultra high performance fiber reinforced concrete (UHPFRC). Eng. Struct. 2016, 106, 370–384. [Google Scholar] [CrossRef] [Green Version]

- Hussein, L.; Amleh, L. Structural behavior of ultra-high performance fiber reinforced-concrete normal strength concrete or high strength concrete composite member. Constr. Buil. Mater. 2015, 93, 1105–1116. [Google Scholar] [CrossRef]

- Ghafari, E.; Costa, H.; Julio, E.; Portugal, A.; Duraes, L. The effect of nanosilica addition on flowability, strength and transport properties of ultra-high performance concrete. Mater. Desi. 2014, 59, 1–9. [Google Scholar] [CrossRef] [Green Version]

- Yu, R.; Spiese, P.; Brouwers, H.J.H. Development of an eco-friendly ultra-high performance concrete with efficient cement and mineral admixtures uses. Cem. Concr. Compos. 2015, 55, 383–394. [Google Scholar] [CrossRef] [Green Version]

- Shen, P.; Lu, L.; He, Y.J.; Rao, M.J.; Fu, Z.D.; Wang, F.Z.; Hu, S.G. Experimental investigation on the autogenous shrinkage of steam cured ultra-high performance concrete. Constr. Buil. Mater. 2018, 162, 512–522. [Google Scholar] [CrossRef]

- Hable, K.; Denarié, E.; Bruhwiler, E. Experimental investigation of composite ultra-high performance fiber-reinforced concrete and conventional concrete members. ACI Struct. J. 2007, 104, 10–20. [Google Scholar]

- Mohammed, T.; Abu Bakar, B.H.; Bunnori, N.M. Torsional improvement of reinforced concrete beams using ultra high-performance fiber reinforced concrete (UHPFC) jackets-experimental study. Constr. Buil. Mater. 2016, 106, 533–542. [Google Scholar] [CrossRef]

- Yuan, T.F.; Lee, J.Y.; Min, K.H.; Yoon, Y.S. Experimental investigation on mechanical properties of hybrid steel and polyethylene fiber reinforced no-slump high strength concrete. Inter. J. Polym. Sci. 2019, 2019, 1–11. [Google Scholar] [CrossRef] [Green Version]

- Yuan, T.F.; Lee, J.Y.; Yoon, Y.S. Enhancing the tensile capacity of no-slump high-strength high-ductility concrete. Cem. Concr. Compos. 2020, 106, 103458. [Google Scholar] [CrossRef]

- Choi, J.I.; Koh, K.T.; Lee, B.Y. Tensile behavior of ultra-high performance concrete according to combination of fibers. J. Korea Inst. Struct. Mainten. Inspec. 2015, 19, 49–56. [Google Scholar] [CrossRef]

- Park, S.H.; Kim, D.J.; Ryu, G.S.; Koh, K.T. Tensile behavior of ultra-high performance hybrid fiber reinforced concrete. Cem. Concr. Compos. 2012, 34, 172–184. [Google Scholar] [CrossRef]

- Li, V.C.; Wang, S.X.; Wu, C. Tensile strain-hardening behavior of polyvinyl alcohol engineered cementitious composite (PVA-ECC). ACI Mater. J. 2001, 98, 483–492. [Google Scholar]

- American Society for Testing and Materials (ASTM). ASTM C39/C39M Standard test method for compressive strength of cylindrical concrete specimens. In Annual Book of ASTM Standards; ASTM: West Conshohocken, PA, USA, 2014. [Google Scholar]

- American Society for Testing and Materials (ASTM). ASTM C1609/C1609 M. Standard test method for flexural performance of fiber-reinforced concrete (using beam with third-point loading). In Annual Book of ASTM Standards; ASTM: West Conshohocken, PA, USA, 2012. [Google Scholar]

- American Society for Testing and Materials (ASTM). ASTM C496 Standard test method for splitting tensile strength of cylindrical concrete specimens). In Annual Book of ASTM Standards; ASTM: West Conshohocken, PA, USA, 2017. [Google Scholar]

- American Society for Testing and Materials (ASTM). ASTM C882 / C882M-13a Standard Test Method for Bond Strength of Epoxy-Resin Systems used with Concrete by Slant Shear. In Annual Book of ASTM Standards; ASTM: West Conshohocken, PA, USA, 2013. [Google Scholar]

- Zanotti, C.; Banthia, N.; Plizzari, G. A study of some factors affecting bond in cementitious fiber reinforced repairs. Cem. Concr. Res. 2014, 63, 117–126. [Google Scholar] [CrossRef]

- Tayeh, B.A.; Abu Bakar, B.H.; Megat Johari, M.A.; Voo, Y.L. Mechanical and permeability properties of the interface between normal concrete substrate and ultra-high performance fiber concrete overlay. Constr. Buil. Mater. 2012, 36, 538–548. [Google Scholar] [CrossRef]

- Tayeh, B.A.; Abu Baker, B.H.; Megat Johari, M.A.; Ratnam, M.M. The relationship between substrate roughness parameters and bond strength of ultra-high-performance fiber concrete. J. Adhes. Sci. Techn. 2013, 27, 1790–1810. [Google Scholar] [CrossRef]

- Rui, S.; Eduardo, J.; Daniel, D.; Pedro, S. A modified slant shear test designed to enforce adhesive failure. Const. Buil. Mater. 2013, 41, 673–680. [Google Scholar]

- Youm, H.S.; Lim, W.Y.; Hong, S.G.; Jon, C.B. Evaluation of interfacial performance of normal strength concrete strengthened with ultra-high performance fiber reinforced concrete through slant shear test. J. Korea Concr. Inst. 2018, 30, 391–401. [Google Scholar] [CrossRef]

- American Concrete Institute. ACI Committee 318 Building Code Requirements for Structural Concrete (ACI 318M-14) and Commentary; American Concrete Institute: Farmington Hills, MI, USA, 2019. [Google Scholar]

- American Association of State Highway and Transportation Officials. AASHTO-LRFD Bridge Design Specification; American Association of State Highway and Transportation Officials: Washington, DC, USA, 2012. [Google Scholar]

- Canadian Standard Association. CSA Design of Concrete Structures; Canadian Standard Association: Rexdale, ON, Canada, 2014. [Google Scholar]

- The International Federation for Structural Concrete (fib). Fib Bulletin 65 Model Code 2010; The International Federation for Structural Concrete: Lausanne, Switzerland, 2010. [Google Scholar]

- Diab, A.M.; Elmoaty, A.E.M.A.; Eldin, M.R.T. Slant shear bond strength between self compacting concrete and old concrete. Const. Buil. Mater. 2017, 130, 73–82. [Google Scholar] [CrossRef]

- Coasta, H.; Carmo, R.N.F.; Júlio, E. Influence of lightweight aggregates concrete on the bond strength of concrete-to-concrete interfaces. Const. Buil. Mater. 2018, 180, 519–530. [Google Scholar] [CrossRef]

- American Concrete Institute. ACI Committee 546 Concrete Repair Guide. 546R-04; American Concrete Institute: Farmington Hills, MI, USA, 2004. [Google Scholar]

- Espeche, A.D.; Leon, J. Estimation of bond strength envelopes for old-to-new concrete interfaces based on a cylinder splitting test. Constr. Buil. Mater. 2011, 25, 1222–1235. [Google Scholar] [CrossRef]

- Manrtinola, G.; Meda, A.; Plizzarti, G.A.; Rinaldi, Z. Strengthening and repair of RC beams with fiber reinforced concrete. Cem. Concr. Compos. 2010, 32, 731–739. [Google Scholar] [CrossRef]

| Type | w/c | Water | Cement | Fine Aggregate | Coarse Aggregate | SP | Slump |

|---|---|---|---|---|---|---|---|

| NSC | 0.43 | 165 | 380 | 818 | 921 | 0.8% | 175 mm |

| Type | w/b | Water | Cement | Silica Fume | Silica Filler | Silica Sand | Steel Fiber | Polyethylene Fiber | SP |

|---|---|---|---|---|---|---|---|---|---|

| NSHSDC | 0.172 | 0.215 | 1.00 | 0.25 | 0.30 | 1.10 | 1.0% | 0.5% | 3.0% |

| Type | Surface Area (cm2/g) | Density (g/cm3) | Chemical Composition (%) | ||||||

|---|---|---|---|---|---|---|---|---|---|

| SiO2 | Al2O3 | Fe2O3 | CaO | MgO | SO3 | Na2O | |||

| Cement | 3492 | 3.15 | 21.2 | 4.7 | 3.1 | 62.8 | 2.8 | 2.1 | - |

| Silica fume | 200,000 | 2.20 | 96.0 | 0.3 | 0.1 | 0.4 | 0.1 | <0.2 | - |

| Silica filler | 2.65 | 0.75 | 99.6 | 0.3 | 0.03 | 0.01 | 0.006 | - | 0.009 |

| Type | Diameter df, (mm) | Length lf, (mm) | Aspect Ratio (lf/df) | Density (g/cm3) | Tensile Strength (MPa) | Elastic Modulus (GPa) |

|---|---|---|---|---|---|---|

| High strength straight steel fiber | 0.2 | 19.5 | 97.5 | 7.8 | 2650 | 200 |

| High strength polyethylene fiber | 31 μm | 12 | 387 | 0.97 | 2900 | 100 |

| Hooked-end steel fiber | 0.55 | 35 | 65 | 7.9 | 1400 | 200 |

| Type | Compressive Strength (MPa/CV) | Flexural Strength (MPa/CV) | Tensile Strength (MPa/CV) | Remarks |

|---|---|---|---|---|

| NSC | 46.2/0.1 | 26.5/0.6 | 3.9/0.5 | Splitting tensile strength test |

| NSHDC | 123.4/0.3 | 21.9/8.5 | 9.7/1.6 | Direct tensile strength |

| Specimen | Test Type | Roughness | Angle of Interface (β) | Remarks |

|---|---|---|---|---|

| NSC | Compression | - | - | - |

| 30LS | Slant shear | As cast | 30° | Low roughness |

| 30HS | Slant shear | Chiseling | 30° | High roughness |

| 45LS | Slant shear | As cast | 45° | Low roughness |

| 45HS | Slant shear | Chiseling | 45° | High roughness |

| 60LS | Slant shear | As cast | 60° | Low roughness |

| 60HS | Slant shear | Chiseling | 60° | High roughness |

| 75LS | Slant shear | As cast | 75° | Low roughness |

| 75HS | Slant shear | Chiseling | 75° | High roughness |

| Specimen | Failure Mode | fck, s (MPa) | σ (MPa) | τ (MPa) | Shear Strength Ratio, τ/τpred | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Primary | Secondary | Mean | Norm | CV | τ/τACI | τ/τASH | τ/τCSA | τ/τfib | |||

| NSC | CC | - | 48.6 | 1 | 0.05 | - | - | - | - | - | - |

| 30LS | CC | - | 37.9 | 0.78 | 0.43 | 28.4 | 16.4 | 29.3 | 0.6 | 1.5 | 0.8 |

| 30HS | CC | - | 48.2 | 0.99 | 0.10 | 36.2 | 20.9 | 37.3 | 0.9 | 1.6 | 0.9 |

| 45LS | NI | CC | 29.1 | 0.60 | 0.24 | 14.6 | 14.5 | 26.0 | 0.9 | 2.5 | 1.3 |

| 45HS | NI | CC | 42.9 | 0.88 | 0.49 | 21.5 | 21.4 | 38.3 | 1.6 | 2.7 | 1.6 |

| 60LS | NI | IS | 14.0 | 0.29 | 0.78 | 3.5 | 6.1 | 10.8 | 1.4 | 4.0 | 2.1 |

| 60HS | NI | IS | 30.4 | 0.63 | 0.61 | 7.6 | 13.2 | 23.5 | 2.3 | 4.5 | 2.3 |

| 75LS | NI | IS | 10.4 | 0.21 | 1.62 | 1.0 | 3.1 | 5.5 | 1.6 | 5.5 | 2.3 |

| 75HS | NI | IS | 17.7 | 0.36 | 0.58 | 1.7 | 5.3 | 9.4 | 2.7 | 6.5 | 2.7 |

| Mean | 22.5 | 1.5 | 3.6 | 1.7 | |||||||

| COV | 0.53 | 0.46 | 0.48 | 0.37 | |||||||

| Specimen | Initial Crack | Ultimate | Failure | Initial Stiffness (kN·mm) | Deflection Ductility (δp/δcr) | Energy Absorption (kN·m) | |||

|---|---|---|---|---|---|---|---|---|---|

| Pcr (kN) | δcr (mm) | Pp (kN) | δp (mm) | Pf (kN) | δf (mm) | ||||

| B-NN | 11.81 | 1.30 | 75.93 | 10.17 | 75.93 | 10.17 | 9.08 | 7.82 | 0.39 |

| B-SR | 12.88 | 1.43 | 91.58 | 55.08 | 91.17 | 62.40 | 9.01 | 38.82 | 5.73 |

| B-BJ | 12.37 | 1.43 | 74.04 | 9.48 | 74.04 | 9.48 | 8.65 | 6.63 | 0.35 |

| B-2J | 13.41 | 1.57 | 82.19 | 11.21 | 82.19 | 11.21 | 8.54 | 7.14 | 0.46 |

| B-3J | 13.67 | 1.55 | 97.71 | 15.36 | 82.44 | 41.43 | 8.82 | 9.91 | 3.32 |

| B-4J | 13.70 | 1.51 | 106.12 | 18.80 | 89.21 | 79.24 | 9.07 | 12.45 | 7.11 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yuan, T.-F.; Hong, S.-H.; Shin, H.-O.; Yoon, Y.-S. Bond Strength and Flexural Capacity of Normal Concrete Beams Strengthened with No-Slump High-Strength, High-Ductility Concrete. Materials 2020, 13, 4218. https://doi.org/10.3390/ma13194218

Yuan T-F, Hong S-H, Shin H-O, Yoon Y-S. Bond Strength and Flexural Capacity of Normal Concrete Beams Strengthened with No-Slump High-Strength, High-Ductility Concrete. Materials. 2020; 13(19):4218. https://doi.org/10.3390/ma13194218

Chicago/Turabian StyleYuan, Tian-Feng, Se-Hee Hong, Hyun-Oh Shin, and Young-Soo Yoon. 2020. "Bond Strength and Flexural Capacity of Normal Concrete Beams Strengthened with No-Slump High-Strength, High-Ductility Concrete" Materials 13, no. 19: 4218. https://doi.org/10.3390/ma13194218

APA StyleYuan, T.-F., Hong, S.-H., Shin, H.-O., & Yoon, Y.-S. (2020). Bond Strength and Flexural Capacity of Normal Concrete Beams Strengthened with No-Slump High-Strength, High-Ductility Concrete. Materials, 13(19), 4218. https://doi.org/10.3390/ma13194218