Implementing FDM 3D Printing Strategies Using Natural Fibers to Produce Biomass Composite

Abstract

1. Introduction

2. Article Structure

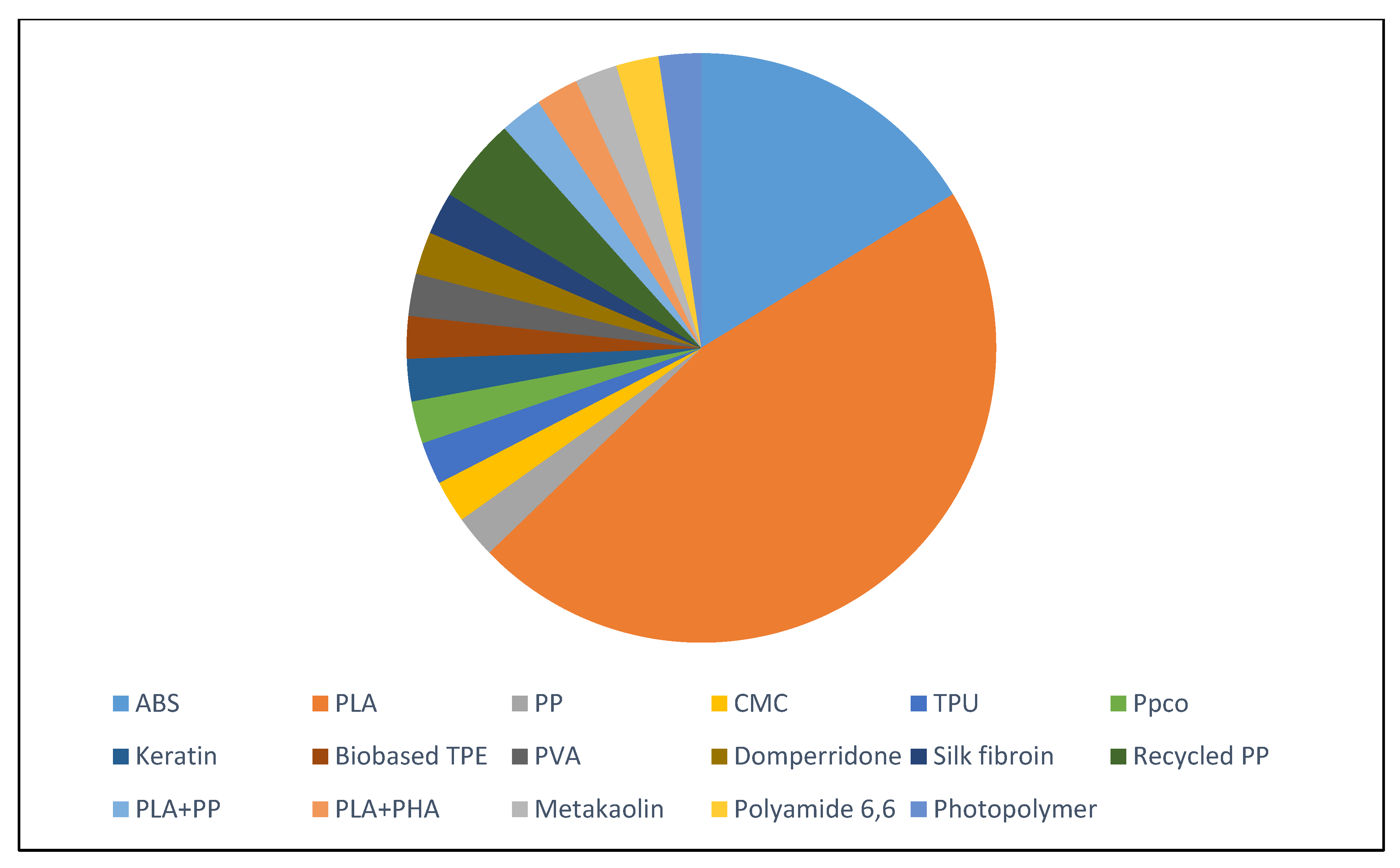

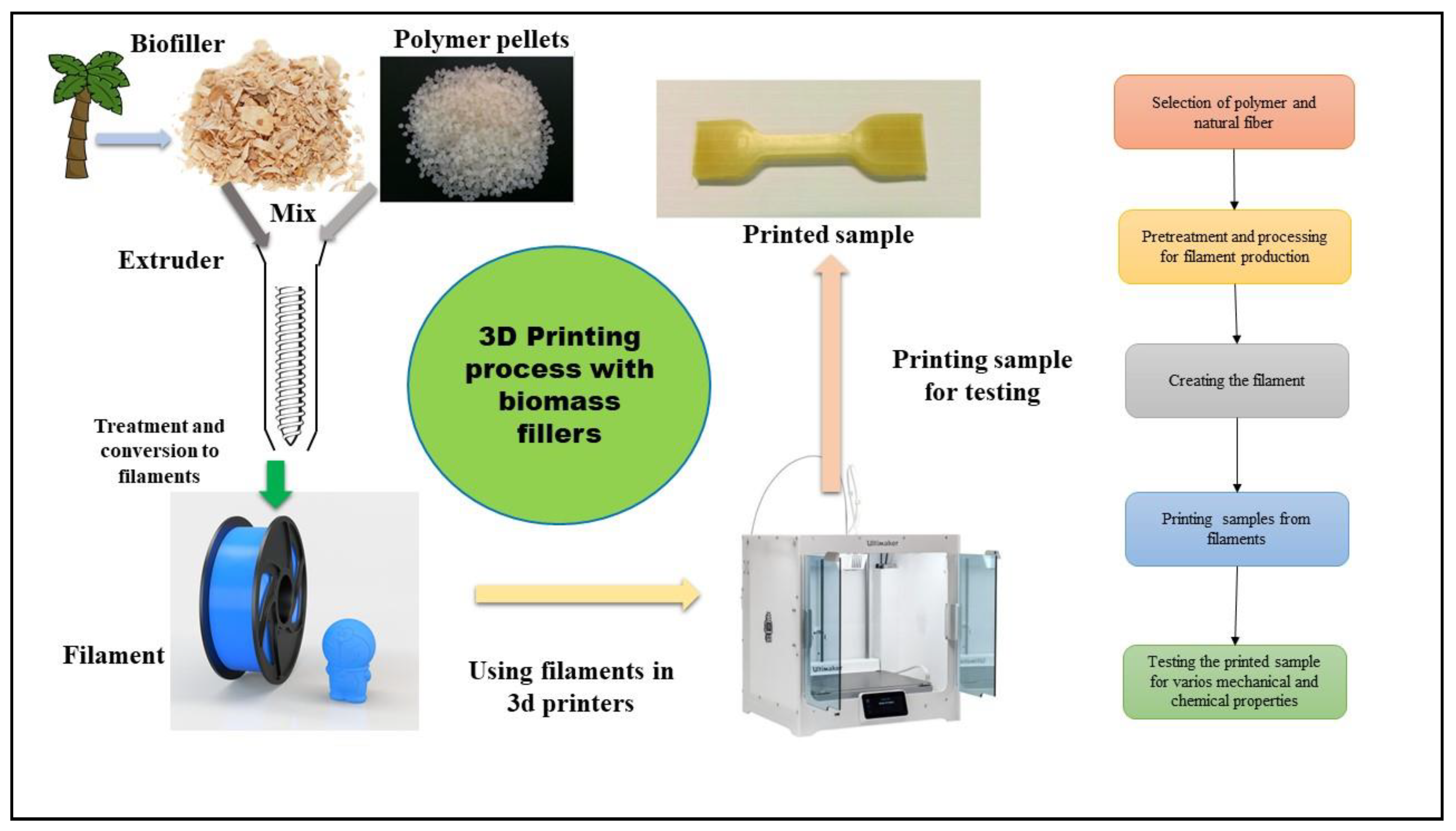

3. Materials

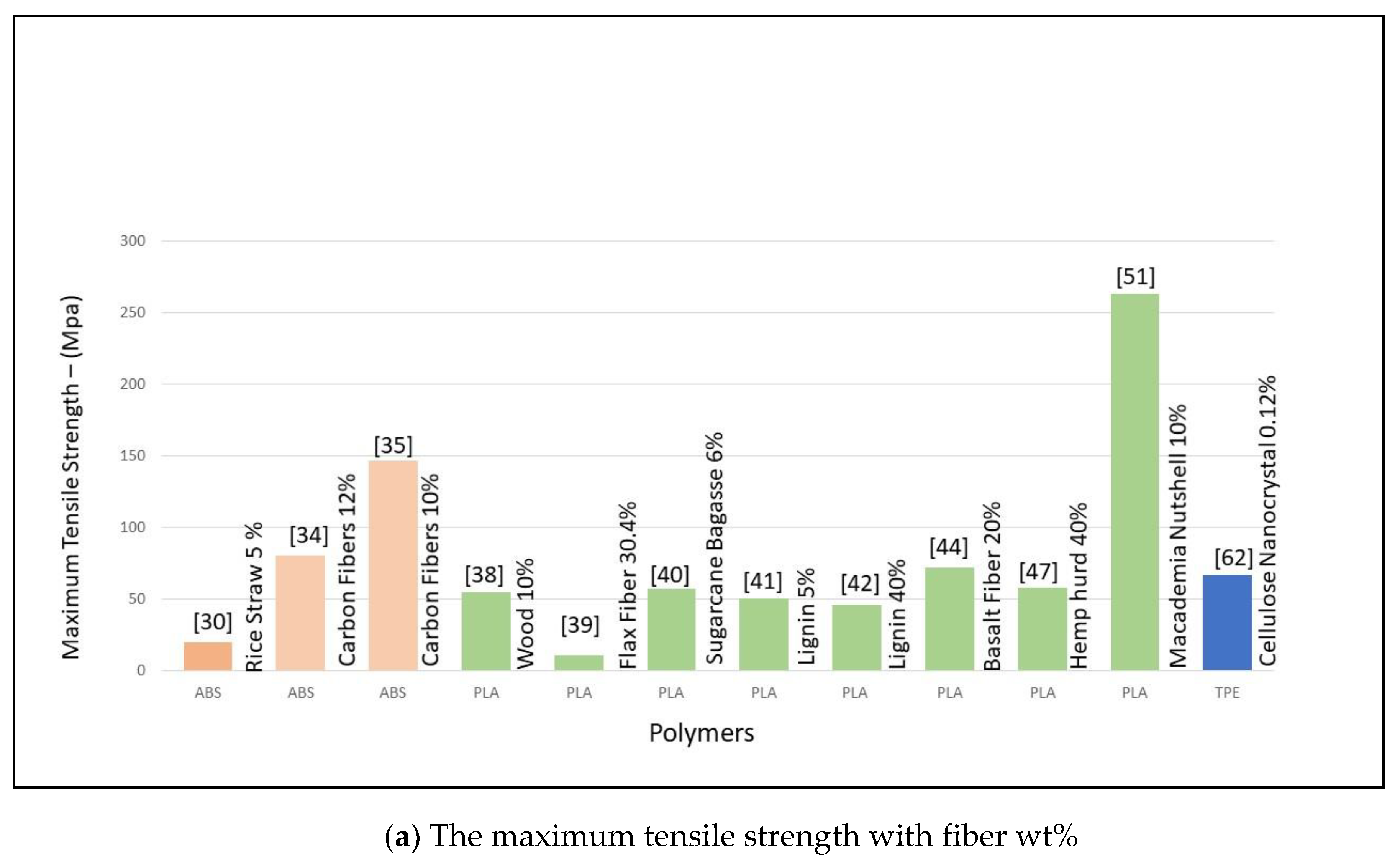

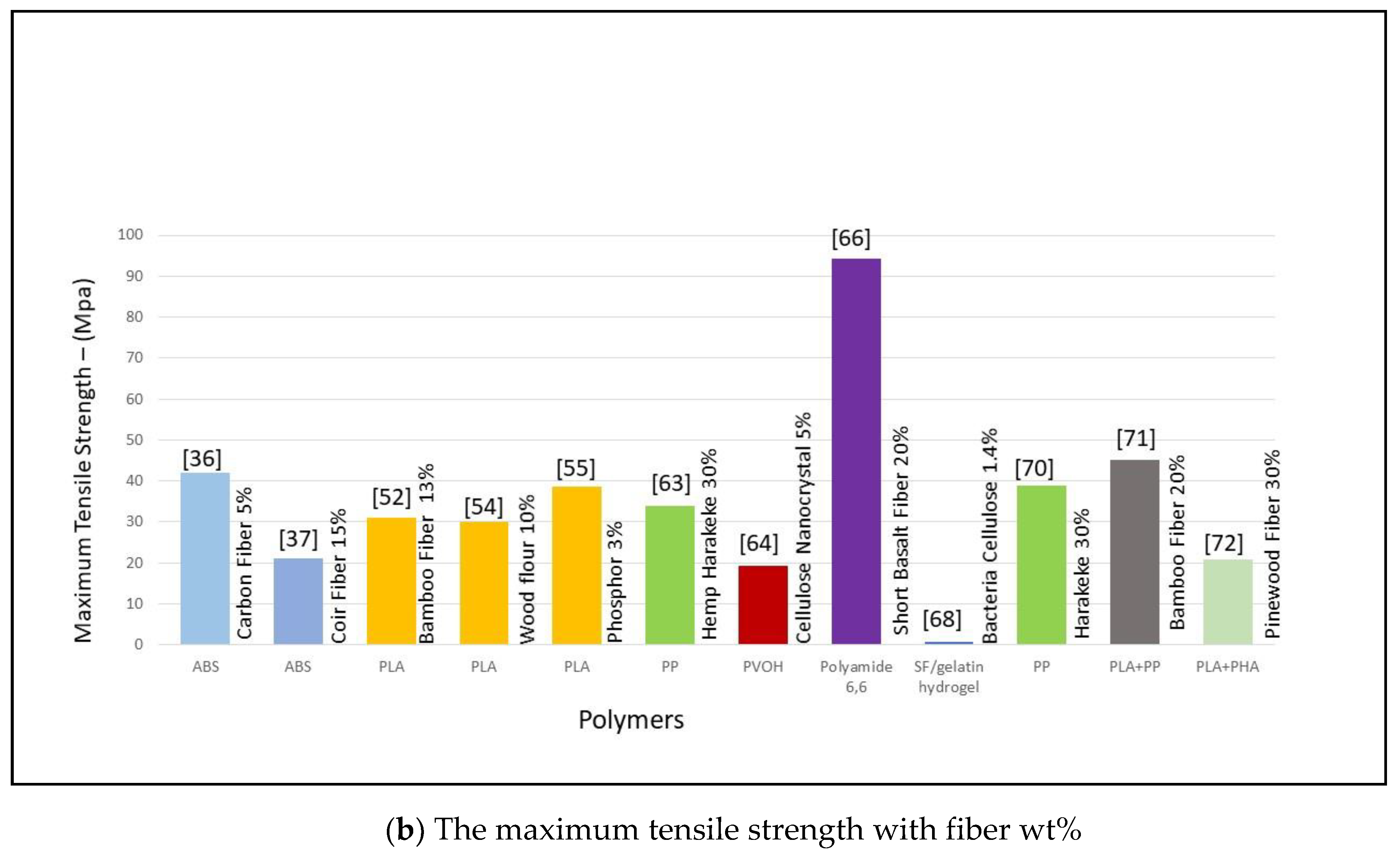

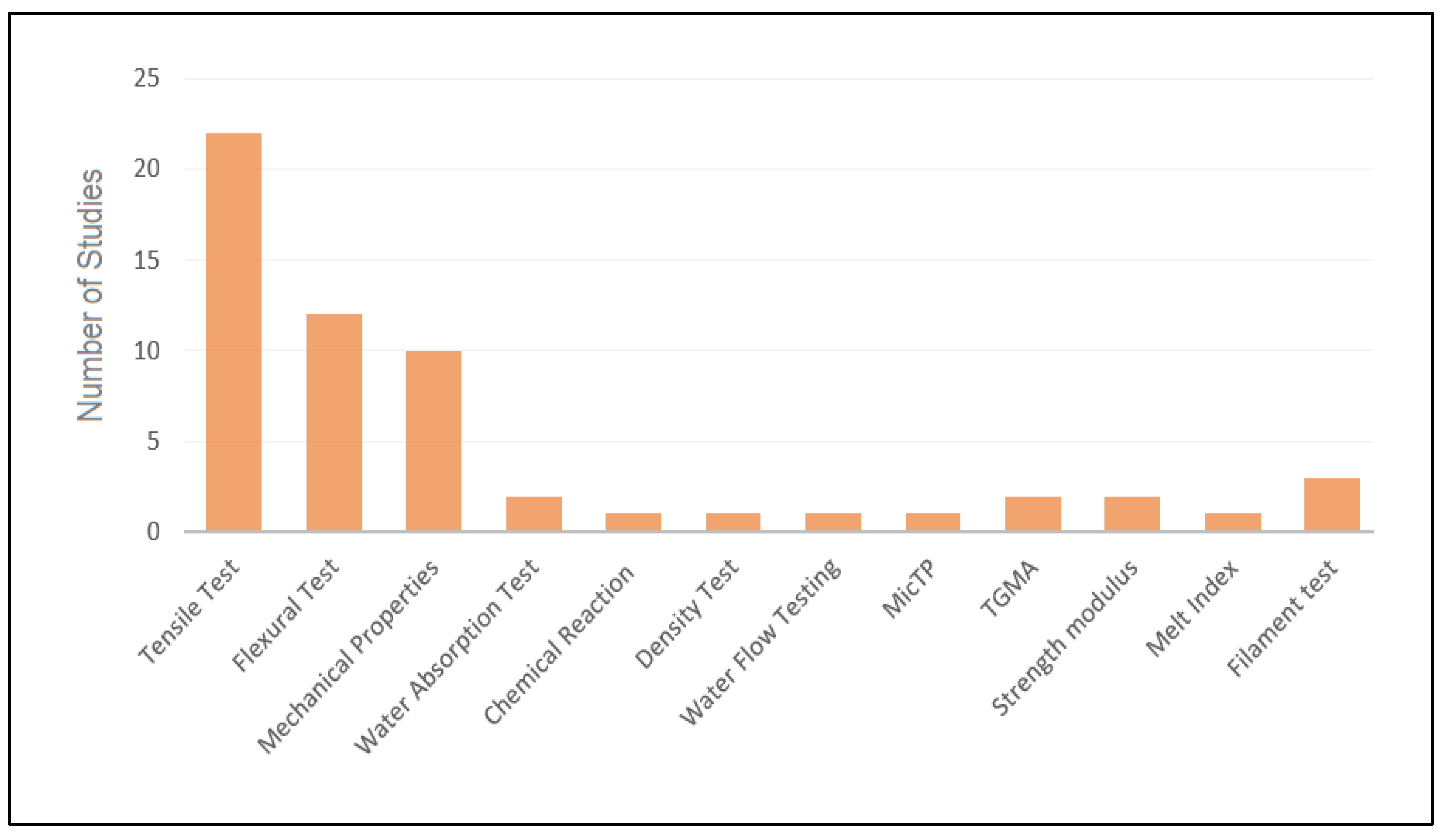

4. Mechanical Properties

5. Printing Failures and Issues

6. Discussion

7. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- 3D Printing Scales up, The Economist. 5 September 2013. Available online: https://www.economist.com/technology-quarterly/2013/09/05/3d-printing-scales-up (accessed on 8 September 2020).

- Hull, C.W. Apparatus for Production of Three-Dimensional Objects by Stereolithography. U.S. Patent 4575330A, 11 March 1986. Available online: https://patents.google.com/patent/US4575330A/en (accessed on 8 September 2020).

- Learning Course: Additive Manufacturing—Additive Fertigung. Tmg-muenchen.de. Available online: https://www.tmg-muenchen.de/training-course/11/Additive-Manufacturing?flang=en (accessed on 8 September 2020).

- Fu, K.; Yao, Y.; Dai, J.; Hu, L. Progress in 3D Printing of carbon materials for energy-related applications. Adv. Mater. 2017, 29, 1603486. [Google Scholar] [CrossRef] [PubMed]

- Aimar, A.; Palermo, A.; Innocenti, B. The role of 3D printing in medical applications: A state of the art. J. Healthc. Eng. 2019, 2019, 5340616. [Google Scholar] [CrossRef] [PubMed]

- Gunasekera, D.H.; Kuek, S.; Hasanaj, D.; He, Y.; Tuck, C.; Croft, A.K.; Wildman, R.D. Three dimensional ink-jet Printing of biomaterials using ionic liquids and co-solvents. Faraday Discuss. 2016, 190, 509–523. [Google Scholar] [CrossRef] [PubMed]

- Jungst, T.; Smolan, W.; Schacht, K.; Scheibel, T.; Groll, J. Strategies and molecular design criteria for 3D printable hydrogels. Chem. Rev. 2016, 116, 1496–1539. [Google Scholar] [CrossRef] [PubMed]

- Murphy, S.V.; Atala, A. 3D bioprinting of tissues and organs. Nat. Biotechnol. 2014, 32, 773–785. [Google Scholar] [CrossRef] [PubMed]

- Melocchi, A.; Parietti, F.; Maroni, A.; Foppoli, A.; Gazzaniga, A.; Zema, L. Hot-melt extruded filaments based on pharmaceutical grade polymers for 3D Printing by fused deposition modelling. Int. J. Pharm. 2016, 509, 255–263. [Google Scholar] [CrossRef]

- Truby, R.L.; Lewis, J.A. Printing soft matter in three dimensions. Nature 2016, 540, 371–378. [Google Scholar] [CrossRef]

- Mazzanti, V.; Malagutti, L.; Mollica, F. FDM 3D printing of polymers containing natural fillers: A review of their mechanical properties. Polymers 2019, 11, 1094. [Google Scholar] [CrossRef] [PubMed]

- Henke, K.; Treml, S. Wood based bulk material in 3D printing processes for applications in construction. Eur. J. Wood Prod. 2013, 71, 139–141. [Google Scholar] [CrossRef]

- Guvendiren, M.; Molde, J.; Soares, R.M.D.; Kohn, J. Designing biomaterials for 3D Printing. ACS Biomater. Sci. Eng. 2016, 2, 1679–1693. [Google Scholar] [CrossRef]

- Pitt, K.; Lopez-Botello, O.; Lafferty, A.D.; Todd, I.; Mumtaz, K. Investigation into the material properties of wooden composite structures with in-situ fibre reinforcement using additive manufacturing. Compos. Sci. Technol. 2017, 138, 32–39. [Google Scholar] [CrossRef]

- Le Duigou, A.; Castro, M.; Bevan, R.; Martin, N. 3D printing of wood fibre biocomposites: From mechanical to actuation functionality. Mater. Des. 2016, 96, 106–114. [Google Scholar] [CrossRef]

- Tarrés, Q.; Melbø, J.K.; Delgado-Aguilar, M.; Espinach, F.X.; Mutjé, P.; Chinga-Carrasco, G. Bio-polyethylene reinforced with thermomechanical pulp fibers: Mechanical and micromechanical characterization and its application in 3D-printing by fused deposition modelling. Compos. Part B 2018, 153, 70–77. [Google Scholar] [CrossRef]

- Ambrosi, A.; Pumera, M. 3D-printing technologies for electrochemical applications. Chem. Soc. Rev. 2016, 45, 2740–2755. [Google Scholar] [CrossRef]

- Gross, B.C.; Erkal, J.L.; Lockwood, S.Y.; Chen, C.; Spence, D.M. Evaluation of 3D Printing and its potential impact on biotechnology and the chemical sciences. Anal. Chem. 2014, 86, 3240–3253. [Google Scholar] [CrossRef]

- Tran, T.S.; Bayer, I.S.; Heredia-Guerrero, J.A.; Frugone, M.; Lagomarsino, M.; Maggio, F.; Athanassiou, A. Cocoa shell waste biofilaments for 3D printing applications. Macromol. Mater. Eng. 2017, 302, 1700219. Available online: https://onlinelibrary.wiley.com/doi/abs/10.1002/mame.201700219 (accessed on 8 September 2020). [CrossRef]

- Zhao, D.; Cai, X.; Shou, G.; Gu, Y.; Wang, P. Study on the preparation of bamboo plastic composite intend for additive manufacturing. Key Eng. Mater. 2016, 667, 250–258. [Google Scholar] [CrossRef]

- Wang, Q.; Sun, J.; Yao, Q.; Ji, C.; Liu, J.; Zhu, Q. 3D printing with cellulose materials. Cellulose 2018, 25, 4275–4301. [Google Scholar] [CrossRef]

- Rejeski, D.; Zhao, D.; Huang, Y. Research needs and recommendations on environmental implications of additive manufacturing. Addit. Manuf. 2018, 19, 21–28. [Google Scholar] [CrossRef]

- Bhatia, S.K.; Ramadurai, K.W. 3D Printing and Bio-Based Materials in Global Health; Springer International Publishing AG: Cham, Switzerland, 2017. [Google Scholar]

- Liu, J.; Korpinen, R.; Mikkonen, K.S.; Willför, S.; Xu, C. Nanofibrillated cellulose originated from birch sawdust after sequential extractions: A promising polymeric material from waste to films. Cellulose 2014, 21, 2587–2598. [Google Scholar] [CrossRef]

- Zhang, L.; Liu, Z.; Cui, C.; Chen, L. Biomass-derived materials for electrochemical energy storages. Prog. Polym. Sci. 2015, 43, 136–164. [Google Scholar] [CrossRef]

- Wang, X.; Jiang, M.; Zhou, Z.; Gou, J.; Hui, D. 3D printing of polymer matrix composites: A review and prospective. Compos. Part B 2017, 110, 442–458. [Google Scholar] [CrossRef]

- Rauwendaal, C.J. Analysis and experimental evaluation of twin screw extruders. Polym. Eng. Sci. 1981, 21, 1092–1100. [Google Scholar] [CrossRef]

- Gu, D.D.; Meiners, W.; Wissenbach, K.; Poprawe, R. Laser additive manufacturing of metallic components: Materials, processes and mechanisms. Int. Mater. Rev. 2012, 57, 133–164. [Google Scholar] [CrossRef]

- Hofmann, M. 3D printing gets a boost and opportunities with polymer materials. ACS Macro Lett. 2014, 3, 382–386. [Google Scholar] [CrossRef]

- Osman, M.A.; Atia, M.R.A. Investigation of ABS-rice straw composite feedstock filament for FDM. Rapid Prototyp. J. 2018, 24, 1067–1075. [Google Scholar] [CrossRef]

- Girdis, J.; Gaudion, L.; Proust, G.; Löschke, S.; Dong, A. Rethinking timber: Investigation into the use of waste macadamia nut shells for additive manufacturing. JOM 2017, 69, 575–579. [Google Scholar] [CrossRef]

- Ahmad, M.N.; Wahid, M.K.; Maidin, N.A.; Ab Rahman, M.A.H.; Osman, M.H.; Alis, I.F. Mechanical characteristics of oil palm fiber reinforced thermoplastics as filament for fused deposition modeling (FDM). Adv. Manuf. 2020, 8, 72–81. [Google Scholar] [CrossRef]

- Xie, G.; Zhang, Y.; Lin, R. Plasticizer combinations and performance of wood flour–poly (lactic acid) 3D printing filaments. BioResources 2017, 12, 6736–6748. [Google Scholar] [CrossRef]

- Nguyen, N.A.; Barnes, S.H.; Bowland, C.C.; Meek, K.M.; Littrell, K.C.; Keum, J.K.; Naskar, A.K. A path for lignin valorization via additive manufacturing of high-performance sustainable composites with enhanced 3D printability. Sci. Adv. 2015, 4, eaat4967. [Google Scholar] [CrossRef]

- Yang, C.; Tian, X.; Liu, T.; Cao, Y.; Li, D. 3D printing for continuous fiber reinforced thermoplastic composites: Mechanism and performance. Rapid Prototyp. J. 2017, 23, 209–215. [Google Scholar] [CrossRef]

- Ning, F.; Cong, W.; Qiu, J.; Wei, J.; Wang, S. Additive manufacturing of carbon fiber reinforced thermoplastic composites using fused deposition modelling. Compos. B Eng. 2015, 80, 369–378. [Google Scholar] [CrossRef]

- Šafka, J.; Ackermann, M.; Bobek, J.; Seidl, M.; Habr, J.; Bĕhálek, L. Use of composite materials for FDM 3D print technology. Trans. Tech. Publ. Ltd. Mater. Sci. Forum 2016, 862, 174–181. [Google Scholar] [CrossRef]

- Kariz, M.; Sernek, M.; Obućina, M.; Kuzman, M.K. Effect of wood content in FDM filament on properties of 3D printed parts, Mater. Today Commun. 2018, 14, 135–140. [Google Scholar] [CrossRef]

- Le Duigou, A.; Barbé, A.; Guillou, E.; Castro, M. 3D printing of continuous flax fibre reinforced biocomposites for structural applications. Mater. Des. 2019, 180, 107884. [Google Scholar] [CrossRef]

- Liu, H.; He, H.; Peng, X.; Huang, B.; Li, J. Three-dimensional printing of poly (lactic acid) bio-based composites with sugarcane bagasse fiber: Effect of printing orientation on tensile performance. Polym. Adv. Technol. 2019, 30, 910–922. [Google Scholar] [CrossRef]

- Gkartzou, E.; Koumoulos, E.P.; Charitidis, C.A. Production and 3D printing processing of bio-based thermoplastic filament. Manuf. Rev. 2017, 4, 1. [Google Scholar] [CrossRef]

- Tanase-Opedal, M.; Espinosa, E.; Rodríguez, A.; Chinga-Carrasco, G. Lignin: A biopolymer from forestry biomass for biocomposites and 3D printing. Materials 2019, 12, 3006. [Google Scholar] [CrossRef]

- Tao, Y.; Wang, H.; Li, Z.; Li, P.; Shi, S.Q. Development and application of wood flour-filled polylactic acid composite filament for 3D Printing. Materials 2017, 10, 339. [Google Scholar] [CrossRef]

- Sang, L.; Han, S.; Li, Z.; Yang, X.; Hou, W. Development of short basalt fiber reinforced polylactide composites and their feasible evaluation for 3D printing applications. Compos. B Eng. 2019, 164, 629–639. [Google Scholar] [CrossRef]

- Ma, S.; Kou, L.; Zhang, X.; Tan, T. Energy grass/polylactic acid composites and pretreatments for additive manufacturing. Cellulose 2020, 27, 2669–2683. [Google Scholar] [CrossRef]

- Le Guen, M.J.; Hill, S.; Smith, D.; Theobald, B.; Gaugler, E.; Barakat, A.; Mayer-Laigle, C. Influence of rice husk and wood biomass on the manufacture of filaments for Fused Deposition Modelling. Front. Chem. 2019, 7, 735. [Google Scholar] [CrossRef] [PubMed]

- Xiao, X.; Chevali, V.S.; Song, P.; He, D.; Wang, H. Polylactide/hemp Hurd biocomposites as sustainable 3D printing feedstock. Compos. Sci. Technol. 2019, 184, 107887. [Google Scholar] [CrossRef]

- Daver, F.; Lee, K.P.M.; Brandt, M.; Shanks, R. Cork–PLA composite filaments for fused deposition modelling. Compos. Sci. Technol. 2018, 168, 230–237. [Google Scholar] [CrossRef]

- Liu, Z.; Lei, Q.; Xing, S. Mechanical characteristics of wood, ceramic, metal and carbon fiber-based PLA composites fabricated by FDM. J. Mater. Res. Technol. 2019, 8, 3741–3751. [Google Scholar] [CrossRef]

- Hinchcliffe, S.A.; Hess, K.M.; Srubar, W.V., III. Experimental and theoretical investigation of prestressed natural fiber-reinforced polylactic acid (PLA) composite materials. Compos. B Eng. 2016, 95, 346–354. [Google Scholar] [CrossRef]

- Song, X.; He, W.; Qin, H.; Yang, S.; Wen, S. Fused Deposition Modeling of poly (lactic acid)/Macadamia Composites—Thermal, Mechanical Properties and Scaffolds. Materials 2020, 13, 258. [Google Scholar] [CrossRef]

- Depuydt, D.; Balthazar, M.; Hendrickx, K.; Six, W.; Ferraris, E.; Desplentere, F.; Ivens, J.; Van Vuure, A.W. Production and characterization of bamboo and flax fiber reinforced polylactic acid filaments for fused deposition modeling (FDM). Polym. Compos. 2019, 40, 1951–1963. [Google Scholar] [CrossRef]

- Kearns, A.J. Cotton Cellulose Fibers in 3D Print Material. Master’s Thesis, North Carolina State University, Raleigh, NC, USA, 2017. [Google Scholar]

- Chansoda, K.; Suwanjamrat, C.; Chookaew, W. Study on processability and mechanical properties of parawood-powder filled PLA for 3D printing material. MSE 2020, 773, 012053. [Google Scholar] [CrossRef]

- Wan, M.; Jiang, X.; Nie, J.; Cao, Q.; Zheng, W.; Dong, X.; Fan, Z.H.; Zhou, W. Phosphor powders-incorporated polylactic acid polymeric composite used as 3D printing filaments with green luminescence properties. J. Appl. Polym. Sci. 2020, 137, 48644. [Google Scholar] [CrossRef]

- Zhang, H.; Liu, D.; Huang, T.; Hu, Q.; Lammer, H. 3D Printing Method of Spatial Curved Surface by Continuous Natural Fiber Reinforced Composite. MSE 2020, 782, 022059. [Google Scholar] [CrossRef]

- Bi, H.; Ren, Z.; Guo, R.; Xu, M.; Song, Y. Fabrication of flexible wood flour/thermoplastic polyurethane elastomer composites using fused deposition molding. Ind. Crops Prod. 2018, 122, 76–84. [Google Scholar] [CrossRef]

- Thibaut, C.; Denneulin, A.; Rolland du Roscoat, S.R.; Beneventi, D.; Orgéas, L.; Chaussy, D. A fibrous cellulose paste formulation to manufacture structural parts using 3D Printing by extrusion. Carbohydr. Polym. 2019, 212, 119–128. [Google Scholar] [CrossRef] [PubMed]

- Wang, L.; Palmer, J.; Tajvidi, M.; Gardner, D.J.; Han, Y. Thermal properties of spray-dried cellulose nanofibril-reinforced polypropylene composites from extrusion-based additive manufacturing. J. Therm. Anal. Calorim. 2019, 136, 1069–1077. [Google Scholar] [CrossRef]

- Grigsby, W.J.; Scott, S.M.; Plowman-Holmes, M.I.; Middlewood, P.G.; Recabar, K. Combination and processing keratin with lignin as biocomposite materials for additive manufacturing technology. Acta Biomater. 2020, 104, 95–103. [Google Scholar] [CrossRef]

- Selvaraj, D.K.; Silva, F.J.G.; Campilho, R.D.S.G.; Baptista, A.; Pinto, G.F.L. Influence of the natural additive on natural fiber reinforced thermoplastic composite. Procedia Manuf. 2019, 38, 1121–1129. [Google Scholar] [CrossRef]

- Koo, J.M.; Kang, J.; Shin, S.H.; Jegal, J.; Cha, H.G.; Choy, S.; Hakkarainen, S.; Park, J.; Oh, D.X.; Hwang, S.Y. Biobased thermoplastic elastomer with seamless 3D-Printability and superior mechanical properties empowered by in-situ polymerization in the presence of nanocellulose. Compos. Sci. Technol. 2020, 185, 107885. [Google Scholar] [CrossRef]

- Milosevic, M.; Stoof, D.; Pickering, K.L. Characterizing the mechanical properties of fused deposition modelling natural fiber recycled polypropylene composites. J. Compos. Sci. 2017, 1, 7. [Google Scholar] [CrossRef]

- Cataldi, A.; Rigotti, D.; Nguyen, V.D.H.; Pegoretti, A. Polyvinyl alcohol reinforced with crystalline nanocellulose for 3D printing application. Mater. Today Commun. 2018, 15, 236–244. [Google Scholar] [CrossRef]

- Chai, X.; Chai, H.; Wang, X.; Yang, J.; Li, J.; Zhao, Y.; Cai, W.; Tao, T.; Xiang, X. Fused deposition modeling (FDM) 3D printed tablets for intragastric floating delivery of domperidone. Sci. Rep. 2017, 7, 2829. [Google Scholar] [CrossRef]

- Yu, S.; Hwang, J.Y.; Hong, S.H. 3D microstructural characterization and mechanical properties determination of short basalt fiber-reinforced polyamide 6, 6 composites. Compos. Part B Eng. 2020, 187, 107839. [Google Scholar] [CrossRef]

- Rocha-Hoyos, J.C.; Llanes-Cedeño, E.A.; Peralta-Zurita, D.; Pucha-Tambo, M. Mechanical Flexural Characterization of Composite Materials with Photopolymer Matrix Reinforced with Abaca and Cabuya Fibers Using 3D Printing. Ingenius 2019, 22, 100. [Google Scholar] [CrossRef]

- Huang, L.; Du, X.; Fan, S.; Yang, G.; Shao, H.; Li, D.; Cao, C.; Zhu, Y.; Zhu, M.; Zhan, Y. Bacterial cellulose nanofibers promote stress and fidelity of 3D-printed silk based hydrogel scaffold with hierarchical pores. Carbohydr. Polym. 2019, 221, 146–156. [Google Scholar] [CrossRef] [PubMed]

- Zander, N.E.; Park, J.H.; Boelter, Z.R.; Gillan, M.A. Recycled cellulose polypropylene composite feedstocks for Material Extrusion Additive Manufacturing. ACS Omega 2019, 4, 13879–13888. [Google Scholar] [CrossRef]

- Stoof, D.; Pickering, K. Sustainable composite fused deposition modelling filament using recycled pre-consumer polypropylene. Compos. B Eng. 2018, 135, 110–118. [Google Scholar] [CrossRef]

- Long, H.; Wu, Z.; Dong, Q.; Shen, Y.; Zhou, W.; Luo, Y.; Zhang, C.; Dong, X. Mechanical and thermal properties of bamboo fiber reinforced polypropylene/polylactic acid composites for 3D Printing. Polym. Eng. Sci. 2019, 59, E247–E260. [Google Scholar] [CrossRef]

- Guessasma, S.; Belhabib, S.; Nouri, H. Microstructure and mechanical performance of 3D printed wood-PLA/PHA using fused deposition modelling: Effect of printing temperature. Polymers 2019, 11, 1778. [Google Scholar] [CrossRef]

- Agnoli, E.; Ciapponi, R.; Levi, M.; Turri, S. Additive manufacturing of geopolymers modified with microalgal biomass biofiller from wastewater treatment plants. Materials 2019, 12, 1004. [Google Scholar] [CrossRef]

- Al Jassmi, H.; Alnajjar, F.S.; Ahmed, W.K. Qatar University, Compound Nozzle for Cement 3D Printer to Produce Thermally Insulated Composite Cement. U.S. Patent 10399247, 3 September 2019. [Google Scholar]

- Liu, S.; Li, Y.; Li, N. A novel free-hanging 3D printing method for continuous carbon fiber reinforced thermoplastic lattice truss core structures. Mater. Des. 2018, 137, 235–244. [Google Scholar] [CrossRef]

- Skorski, M.R.; Esenther, J.M.; Ahmed, Z.; Miller, A.E.; Hartings, M.R. The chemical, mechanical, and physical properties of 3D printed materials composed of TiO2-ABS nanocomposites. Sci. Technol. Adv. Mater. 2016, 17, 89–97. [Google Scholar] [CrossRef]

- Zhang, H.; Mao, X.; Du, Z.; Jiang, W.; Han, X.; Zhao, D.; Han, D.; Li, Q. Three dimensional printed macroporous polylactic acid/hydroxyapatite composite scaffolds for promoting bone formation in a critical-size rat calvarial defect model. Sci. Technol. Adv. Mater. 2016, 17, 136–148. [Google Scholar] [CrossRef] [PubMed]

- Shirazi, S.F.S.; Gharehkhani, S.; Mehrali, M.; Yarmand, H.; Metselaar, H.S.C.; Kadri, N.A.; Osman, N.A.A. A review on powder-based additive manufacturing for tissue engineering: Selective laser sintering and inkjet 3D printing. Sci. Technol. Adv. Mater. 2015, 16, 033502. [Google Scholar] [CrossRef] [PubMed]

- El-Hassan, H.; Alnajjar, F.; Al Jassmi, H.; Ahmed, W. Fresh and Hardened Properties of 3D-Printed Concrete Made with Dune Sand. In RILEM International Conference on Concrete and Digital Fabrication; Springer: Cham, Switzerland, 2020; pp. 225–234. [Google Scholar]

- Al Khawaja, H.; Alabdouli, H.; Alqaydi, H.; Mansour, A.; Ahmed, W.; Al Jassmi, H. Investigating the Mechanical Properties of 3D Printed Components. In Proceedings of the 2020 Advances in Science and Engineering Technology International Conferences (ASET), Dubai, UAE, 4 February–9 April 2020; pp. 1–7. [Google Scholar] [CrossRef]

- Ahmed, W.; Alabdouli, H.; Alqaydi, H.; Mansour, A.; Al, K.H.; Al, J.H. Open source 3d printer: A case study. In Proceedings of the International Conference on Industrial Engineering and Operations Management, 10th Annual International IEOM Conference, Dubai, UAE, 10–12 March 2020; pp. 2995–3004. [Google Scholar]

- Mansour, A.; Alabdouli, H.; Alqaydi, H.; Al, K.H.; Ahmed, W.; Al, J.H. Evaluating the 3d printing capabilities. In Proceedings of the International Conference on Industrial Engineering and Operations Management, 10th Annual International IEOM Conference, Dubai, UAE, 10–12 March 2020; pp. 2618–2629. [Google Scholar]

- Ahmed, W.K.; Al-Douri, Y. Three-dimensional printing of ceramic powder technology. Met. Oxide Powder Technol. 2020, 351–383. [Google Scholar] [CrossRef]

| Polymer Type | Polymer Name | References |

|---|---|---|

| Virgin | PCL | [19] |

| ABS | [30,31,32,33,34,35,36,37] | |

| PLA | [38,39,40,41,42,43,44,45,46,47,48,49,50,51,52,53,54,55,56] | |

| TPU | [57] | |

| CMC | [58] | |

| PPco | [59] | |

| Keratin | [60] | |

| Resin | [61] | |

| Biobased TPE | [62] | |

| PP | [63] | |

| PVA | [64] | |

| Domperidone | [65] | |

| Polyamide 6,6 | [66] | |

| Photopolymer | [67] | |

| Recycled | Silk fibroin (SF)/gelatin composite hydrogel scaffolds | [68] |

| Recycled PP using cellulose waste materials | [69] | |

| Recycled PP | [70] | |

| Hybrid | PLA + PP | [71] |

| PLA + PHA | [72] | |

| Metakaolin, bentonite, and distilled water | [73] |

| Polymer Name | Biomass Name | Biomass Type | Biomass Size | Biomass % | Chemical Agent | Nozzle Diameter (mm) | Filament Diameter (mm) | Printing Temperature (°C) | Filament Process | Tests | Ref. |

|---|---|---|---|---|---|---|---|---|---|---|---|

| PCL | Cocoa shell waste | Ground | 50 mm | 0–50 wt% | - | 0.5–0.9 | 100 200 | - | LDM extruder | FT | [19] |

| ABS | Rice straw | Grounded | 0.149 mm, 0.105 mm | 0, 5, 10, 15, and 20 wt% | - | 0.5 | 1.75 | 230 | Single-screw extruder | T, F, A, | [30] |

| ABS | Macadamia nutshell | Grounded | Macrosize (MSZ) | 19–29 wt% | - | 1 | 0.3, 1.75, 6 | 250 | Single-screw extruder | T, F, WFT | [31] |

| ABS | Oil palm fiber | Fibers | MSZ | 5 wt% | - | 0.5 | 2.5 | 210 | Single shot extruder | T | [32] |

| PLA | Poplar wood flour | Powder form | MSZ | - | 4% glycerol 2& glycerol 2% 4-tert-Butylcatechol | - | 1.75 | 170 | Twin-screw extruder | T, MI | [33] |

| ABS | Lignin and carbon fibers | Hot-pressed | MSZ | 40–60 wt. % lignin 4–16 wt% carbon fibers | - | 0.4 | 1.75 | 190 | Twin-screw extruder | MP, MicTP | [34] |

| ABS | Carbon fiber | Fiber | Diameter of 7.2 mm | 3, 5, 7.5, 10, 15 wt% | - | 0.35 | - | 230 | - | T, F | [35] |

| PLA | Poplar wood flour | Powder form | MSZ | glycerol tributyl citrate | 0.4 | 1.75 | 220 | Single-screw extruder | MP, MI | [36] | |

| ABS | Coir fibers | Powder | MSZ | 15 wt% | - | 0.4 | 1.75 | 230–245 | - | T | [37] |

| PLA | Wood | Powder form | 0.237 mm | 0–50 wt% | - | 2 | 1.75 | 80–100 | Single-screw extruder | T, ST | [38] |

| PLA | Continuous flax fiber | Yarn form | MSZ | - | - | - | 1.75 | 140–165 | Double screw extruder | T, SM | [39] |

| PLA | Sugarcane | Cellulose fiber | MSZ | 3–15 wt% | - | 0.2–0.4 | 1.75 | 80–100 | Single-screw extruder | T | [40] |

| PLA | Pine lignin | Powder form | MSZ | 5–20 wt% | - | 0.4 | 1.75 | 200–210 | Screw extruder | T, SM | [41] |

| PLA | Lignin | Liquid form | MSZ | 0, 20, 40 wt% | - | 1.75 | 1.75 | 230 | Single-screw extruder | T, F | [42] |

| PLA | Wood flour | Powder form | MSZ | 5 wt% | - | 0.4 | 1.75 | 210 | Single-screw extruder | T, F, SM | [43] |

| PLA | Basalt fiber and carbon fiber | Fiber form | 1–3 mm | 5–20 wt% | - | 1.8 | 40.4 | 195 | Flat-head nozzle | T | [44] |

| PLA | Grass biomass | - | MSZ | - | Pretreatment: 1 alkali- H2O2, 3% (v/v) H2O2, 1.5% (w/v) NaOH and 12.5 g/L Na2SiO3 2. acid treatment: silvergrass was pretreated with 1.5% (w/v) of H2SO4 PLA was mixed with biomass and coupling agents | 0.75 | 1.75 | 190–200 | Co-rotating twin-screw extruder | MP, CR | [45] |

| PLA | Rice husks Wood flour | Both in powder form | MSZ | 10 wt% | - | 2.7 | - | 200 | Co-rotating twin-screw extruder | MP, TGMA | [46] |

| PLA | Hemp hurd | Powder form | 50 μm | - | Poly butylene adipate-co-terephthalate)(PBAT), ethylene-methyl acrylate-glycidyl methacrylate terpolymer (EGMA) | 0.8 | 1.75 | 230 | Single-screw extruder | T, DT | [47] |

| PLA | Cork | Powder form | MSZ | 5 wt% | TBC | 0.30 | - | >130 | Twin-screw extruder | MP | [48] |

| PLA | 1.Wood 2. Ceramic 3. Copper 4. Aluminum 5. Carbon fiber | - | MSZ | - | - | 0.4 | 1.75 | 200 | - | T, F | [49] |

| PLA | Jute fiber Flax fiber | - | Jute fiber 2 mm Flax fiber 0.5 mm | - | - | 0.2 | - | 215 | - | T, F | [50] |

| PLA | Macadamia nutshell | Powder | MSZ | 0, 5, 10, 15 wt% | Zirconium balls | 0.4–0.6 | 1.75–0.3 | 210 | Single-screw extruder | MP | [51] |

| PLA | Bamboo Flax | - | MSZ | 15 wt% | - | - | 2.85 | - | - | FT | [52] |

| PLA | Cellulose fiber | - | MSZ | 0–20 wt% | - | 0.5 | 2.85 | 210 | Two step extruder | [53] | |

| PLA | Commercial grade wood powder waste | Powder | - | 5–20 wt% | MAH NaOH | - | 1.5 mm | - | Twin and single screw extruder | MT, T | [54] |

| PLA | Phosphor | Powder | 500 μm | 2 wt% | Toughening agent | 1.75mm | 1.75 + 0.05 mm | 170–180 | Singe screw extruder | T, F | [55] |

| PLA | Continuous flax fiber | Yarn | - | - | - | - | 1.0 mm | 190 | - | Compressive strength | [56] |

| TPU | Poplar wood flour | Powder form | 150 μm | 10–40 wt.% | EPDM-g-MAH, POE-g-MAH, chitosan, MDI 5wt. % | 0.4 | 1.45–1.75 | 180–200 | - | FT, F | [57] |

| CMC | Natural cellulose | Fibers | 100–200 μm | 35–50 wt.% | Distilled water | 0.4 | 1.75 | 210 | - | T, ST, TGMA | [58] |

| PPco | Cellulose nano-fibers | Suspension form | MSZ | 0–15 wt.% | MAPP | 0.4 | 1.75 | 200 | Single-screw extruder | MP, ST | [59] |

| Keratin | Lignin | Aqueous solution | MSZ | 15, 20, 30 wt.% | polyethylene gly- col (PEG) | - | - | - | - | T, F, A | [60] |

| Elium® liquid thermoplastic resin | Flax natural fiber | - | MSZ | 5 to 15 wt.% of matrix | tamarind seed powder | 0.8 | - | 230 | Novel extruder | 3PT Test, T | [61] |

| Biobased TPE | Cellulose nanocrystals | Spray dried | MSZ | - | - | 0.4 | - | 178 | - | T | [62] |

| PP | Hemp | Fiber | MSZ | 10–30 wt.% | Alkaline | 3 | 2.4–3.1 | 174–18 | Twin-screw extruder | T, FFT | [63] |

| PVA | Cellulose nanocrystals | Microcrystals | MSZ | 2–10 wt.% | - | 0.35 | 230 | Single-screw extruder | T | [64] | |

| Domperidone | Hydroxypropyl Cellulose | - | MSZ | 80–90 wt.% | - | 0.2 | 1.76 | 210 | Twin-screw extruder | MP | [65] |

| Polyamide 6,6 | Short basalt fiber | Fiber | 137 μm | 20 wt.% | Portland cement | - | - | 270–290 | Tein screw extruder | T | [66] |

| Photopolymer | Abaca & Cabuya | - | - | 20 wt.% | - | - | - | - | - | - | [67] |

| SF/gelatin composite hydrogel scaffolds | Bacteria cellulose nano-fibers | - | MSZ | 1:2 ratio | - | 0.3 | 1.77 | - | - | MP | [68] |

| Recycled PP using cellulose waste materials | Wood flour Cardboard Wastepaper | Powder form | MSZ | 5, 10, 20 wt.% | - | 0.8 | 2.2 | 220 | Twin-screw extruder | T | [69] |

| Recycled PP | Hemp+harakeke | Fiber | MSZ | 10–50 wt.% | Alkaline | 1 | 3 | 230 | - | T, F | [70] |

| PLA + PP | Bamboo fiber | Dried fiber | MSZ | 20 wt.% | MAPP | - | - | 150–170 | Co-rotating twin-screw extruder | MP | [71] |

| Metakaolin, bentonite, and distilled water | Microalgal biomass species and lignin | Freeze-dried powders | MSZ | 1, 3, 5 wt.% | Bentonite | 2.25 | - | - | Piston-type extruder | ST | [71] |

| PLA+PHA | Pinewood fiber | - | MSZ | 30 wt.% | - | 0.4 | 1.75 | 210–250 | - | T | [73] |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ahmed, W.; Alnajjar, F.; Zaneldin, E.; Al-Marzouqi, A.H.; Gochoo, M.; Khalid, S. Implementing FDM 3D Printing Strategies Using Natural Fibers to Produce Biomass Composite. Materials 2020, 13, 4065. https://doi.org/10.3390/ma13184065

Ahmed W, Alnajjar F, Zaneldin E, Al-Marzouqi AH, Gochoo M, Khalid S. Implementing FDM 3D Printing Strategies Using Natural Fibers to Produce Biomass Composite. Materials. 2020; 13(18):4065. https://doi.org/10.3390/ma13184065

Chicago/Turabian StyleAhmed, Waleed, Fady Alnajjar, Essam Zaneldin, Ali H. Al-Marzouqi, Munkhjargal Gochoo, and Sumayya Khalid. 2020. "Implementing FDM 3D Printing Strategies Using Natural Fibers to Produce Biomass Composite" Materials 13, no. 18: 4065. https://doi.org/10.3390/ma13184065

APA StyleAhmed, W., Alnajjar, F., Zaneldin, E., Al-Marzouqi, A. H., Gochoo, M., & Khalid, S. (2020). Implementing FDM 3D Printing Strategies Using Natural Fibers to Produce Biomass Composite. Materials, 13(18), 4065. https://doi.org/10.3390/ma13184065