Piezoelectric Energy Harvester Based on LiNbO3 Thin Films

Abstract

1. Introduction

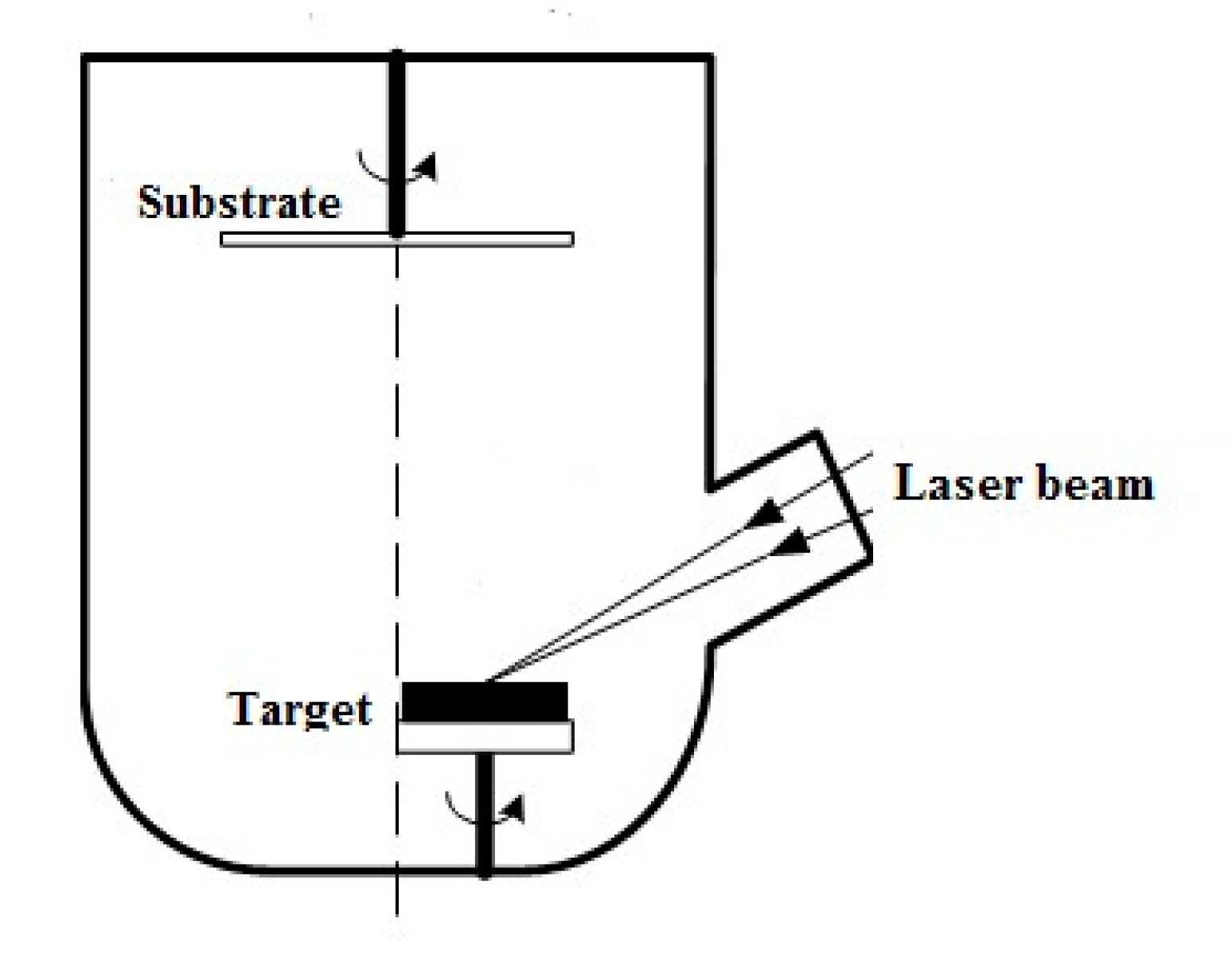

2. Materials and Methods

3. Results

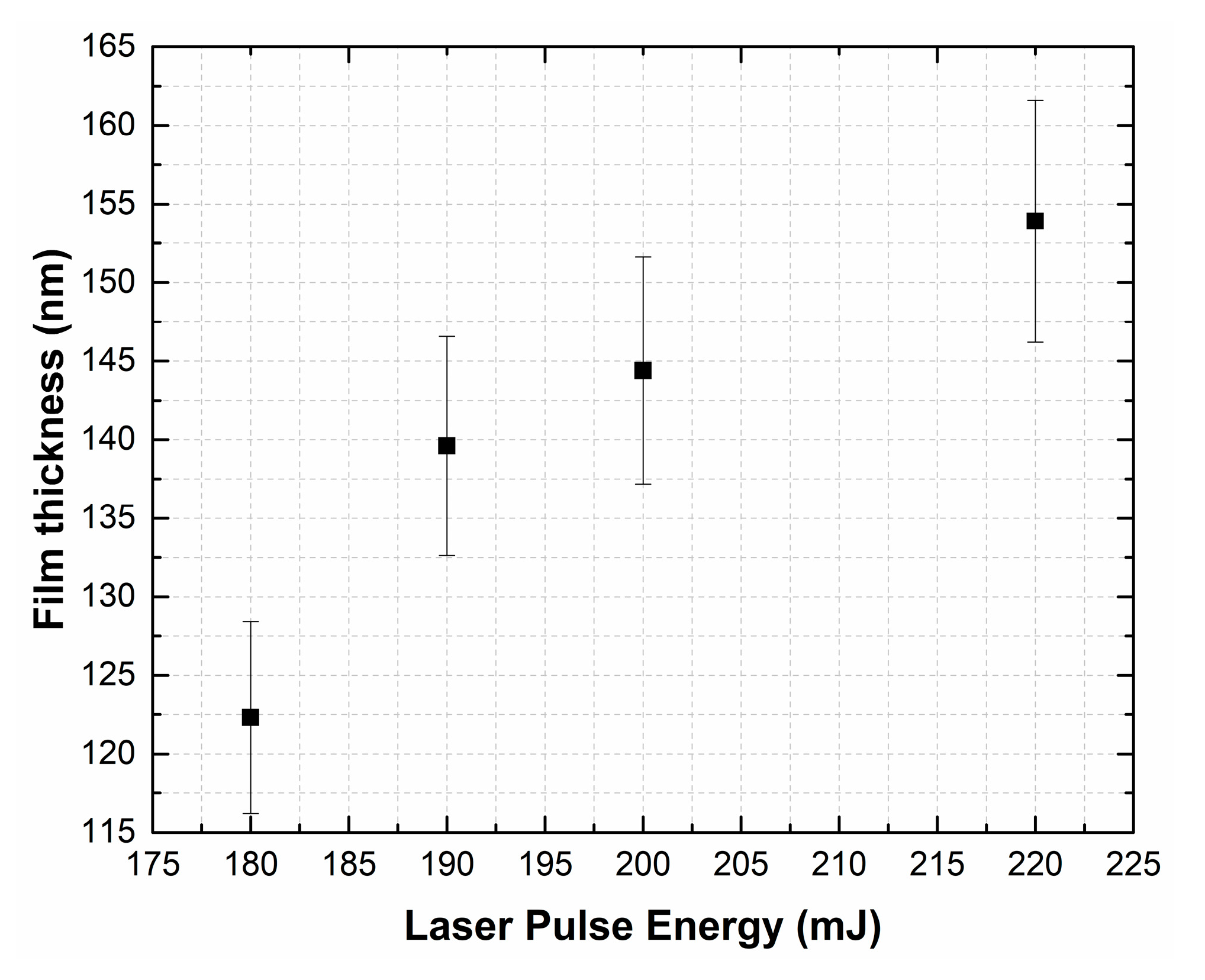

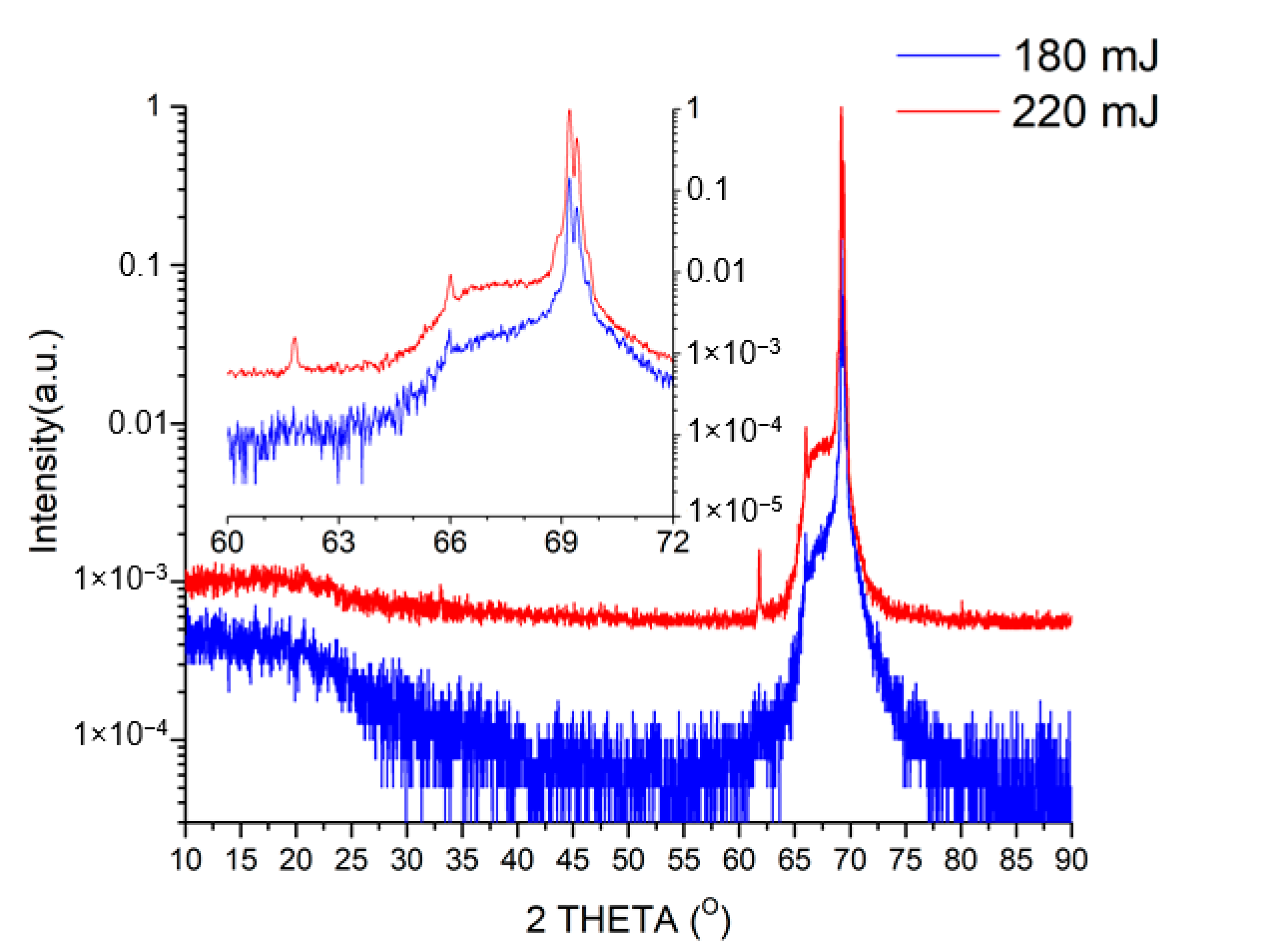

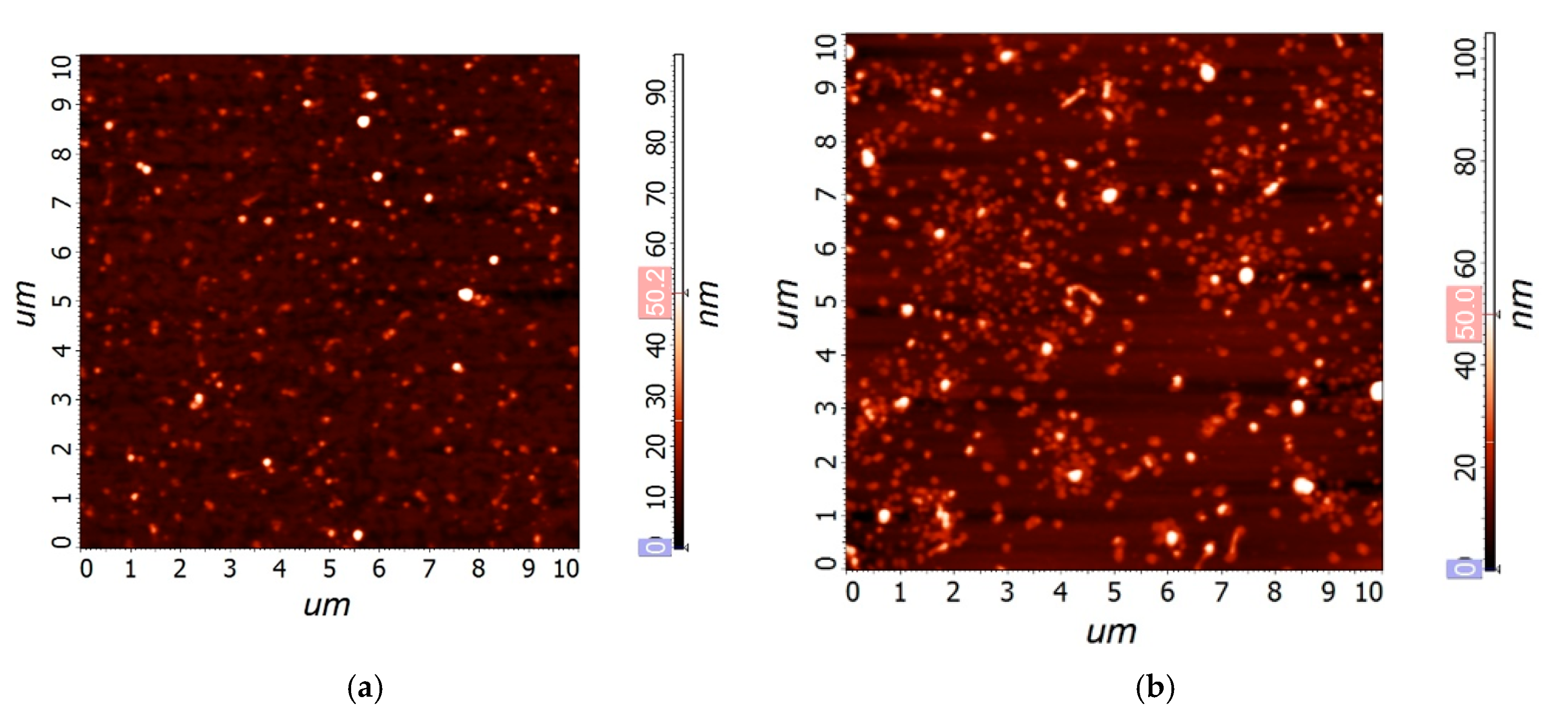

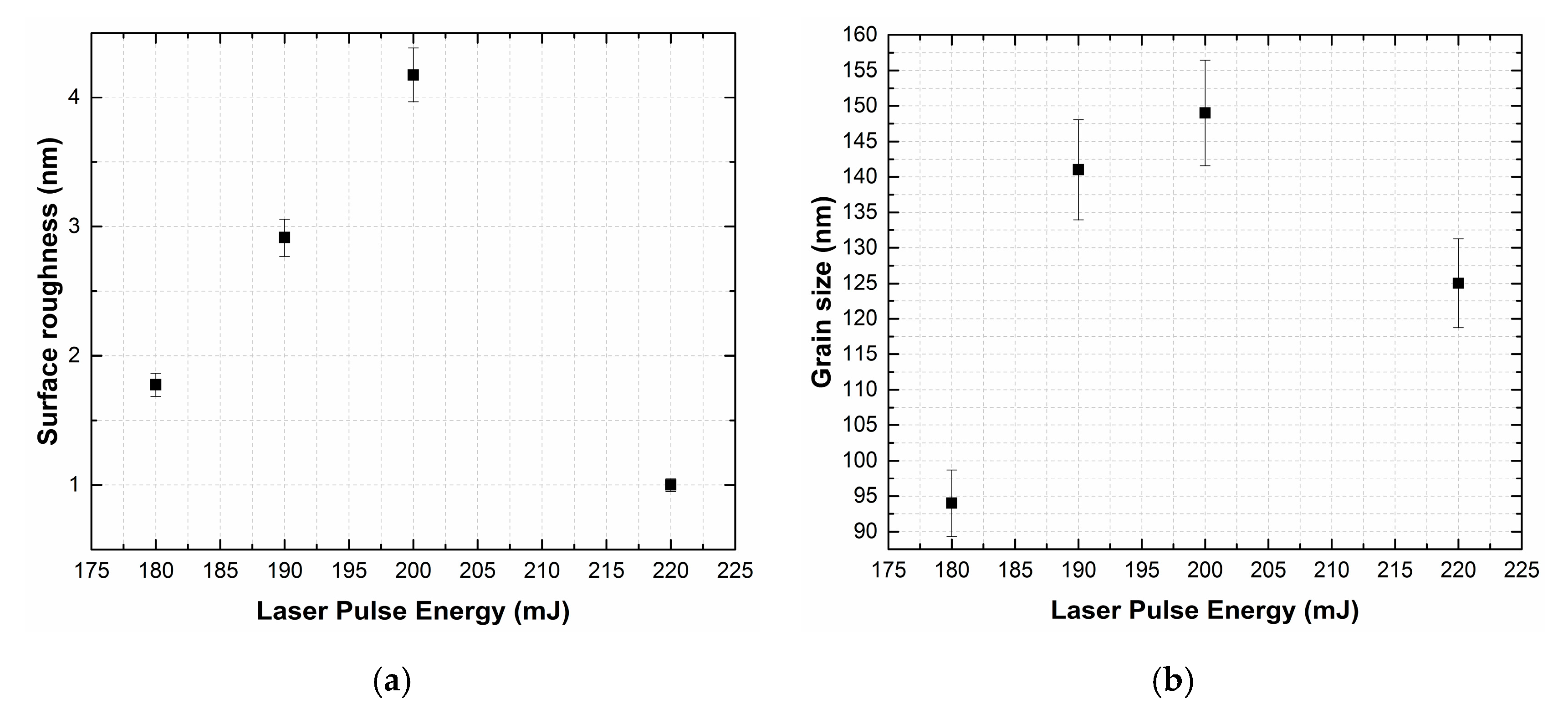

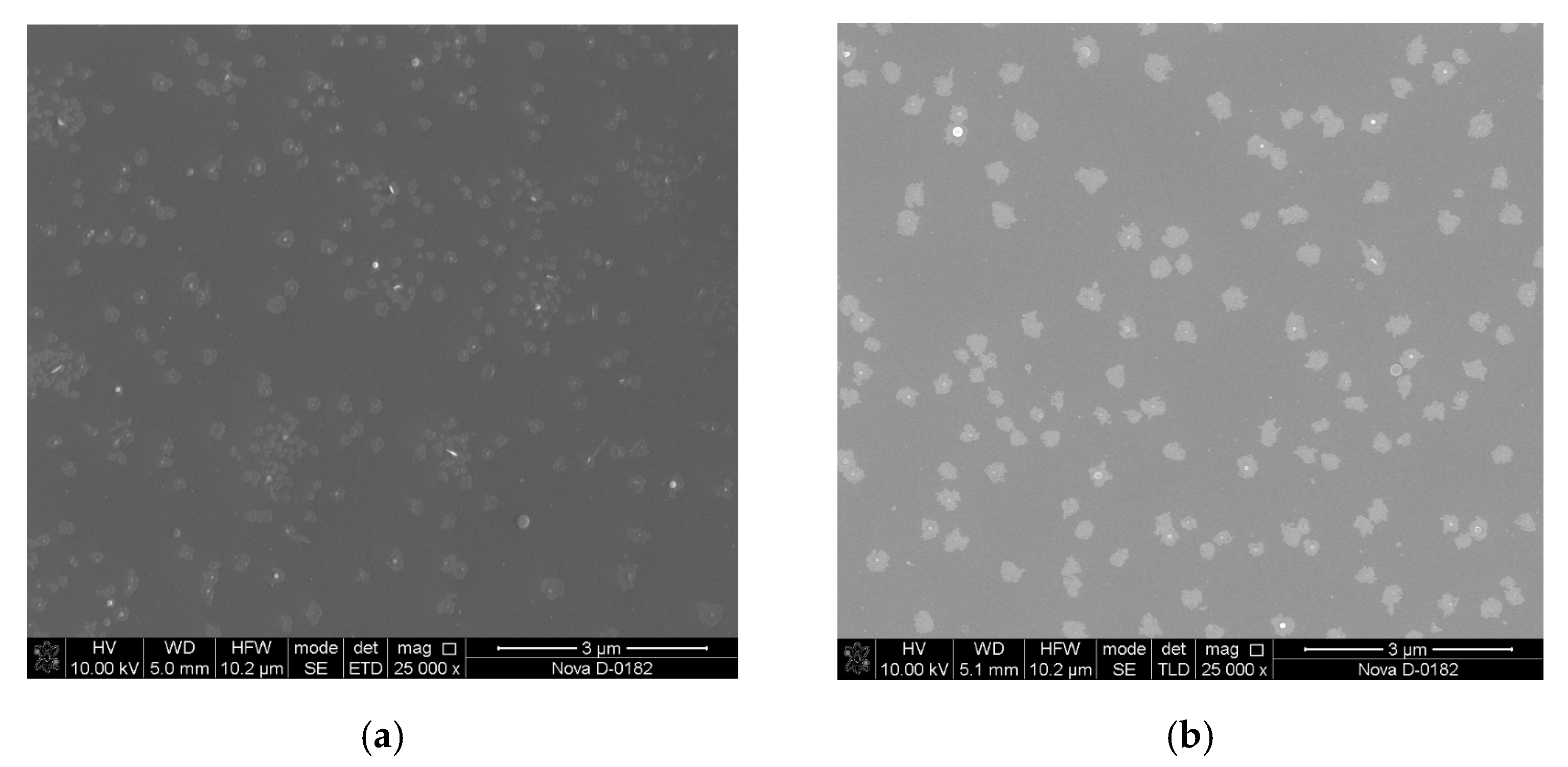

3.1. LiNbO3 Thin Film Growth

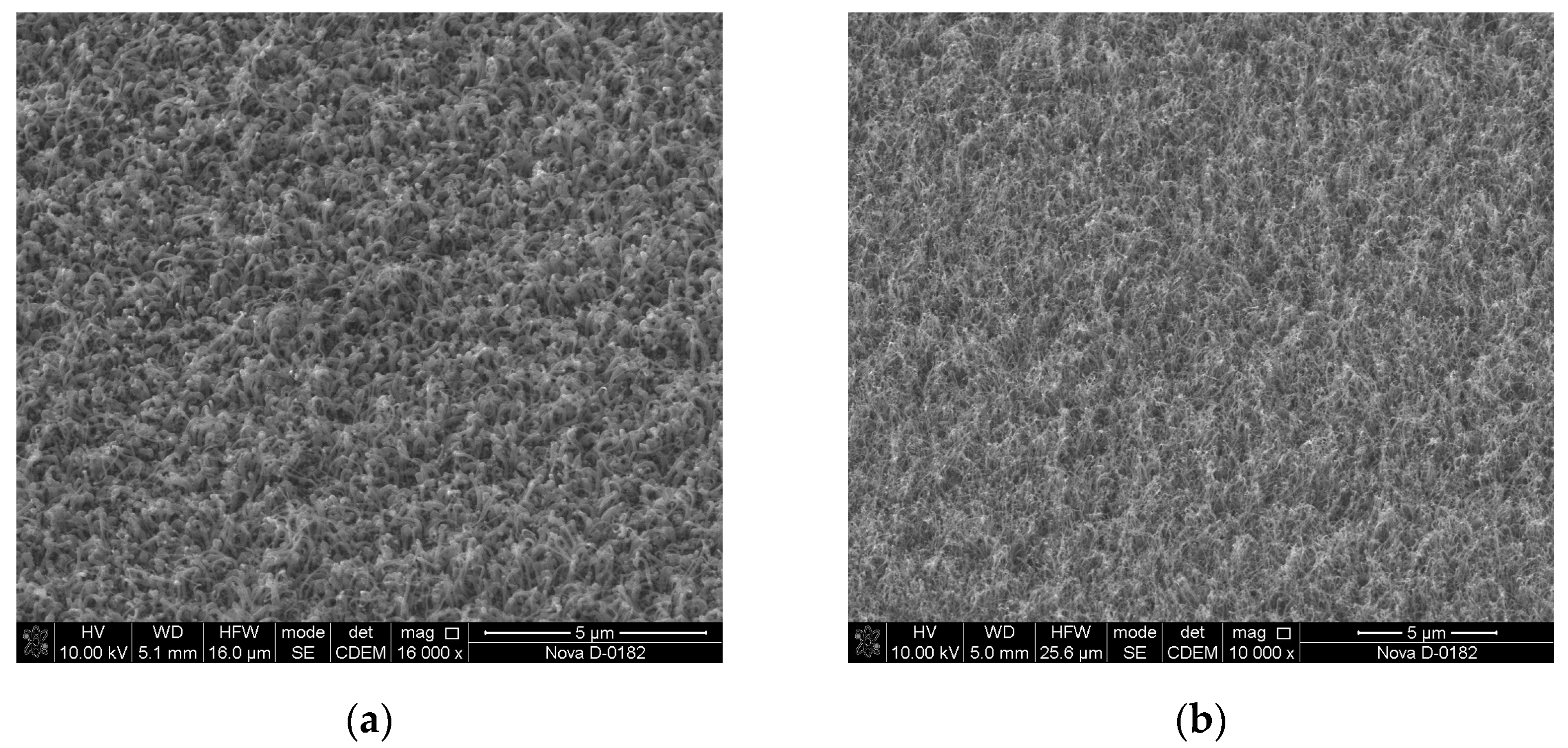

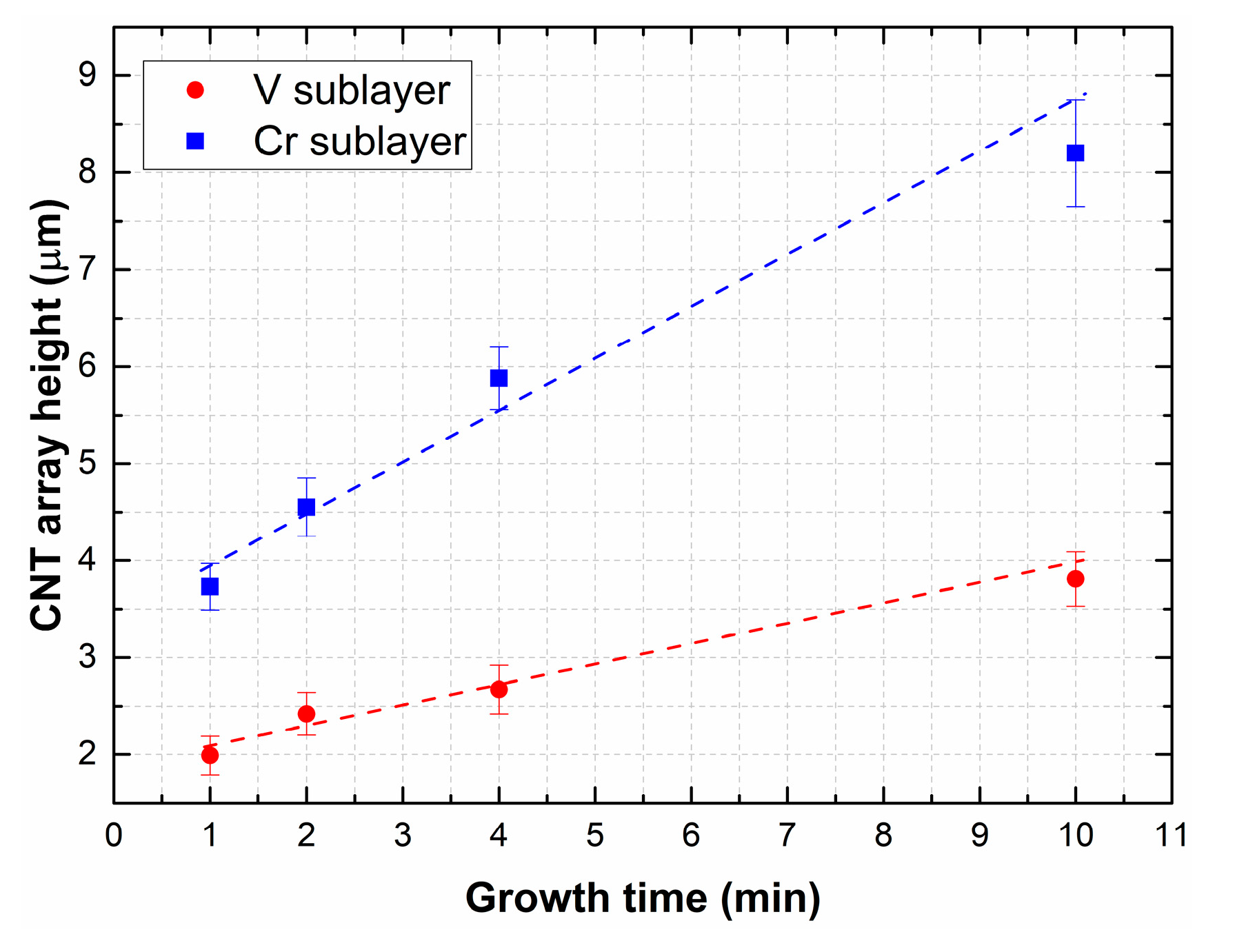

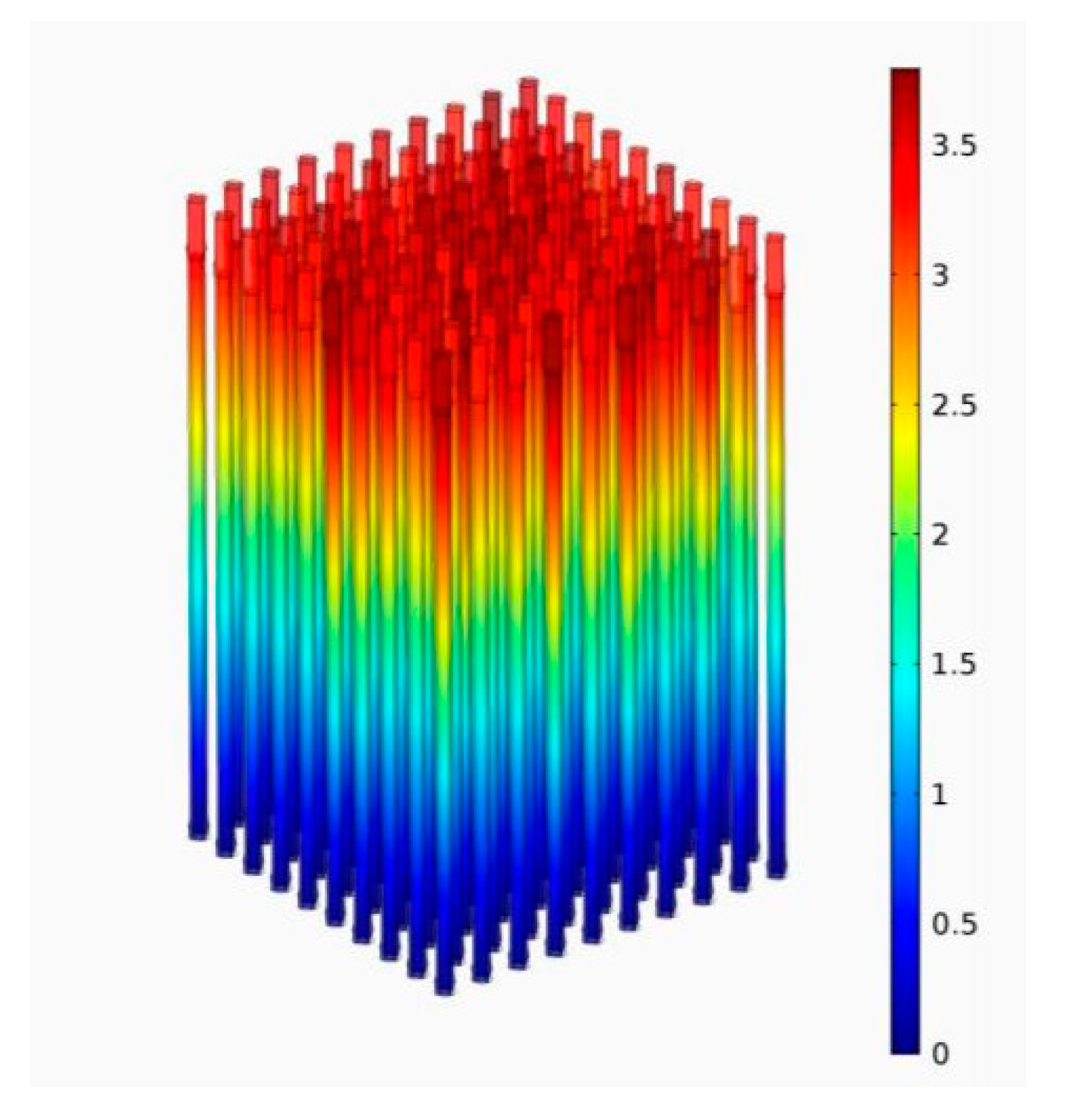

3.2. CNT Growth

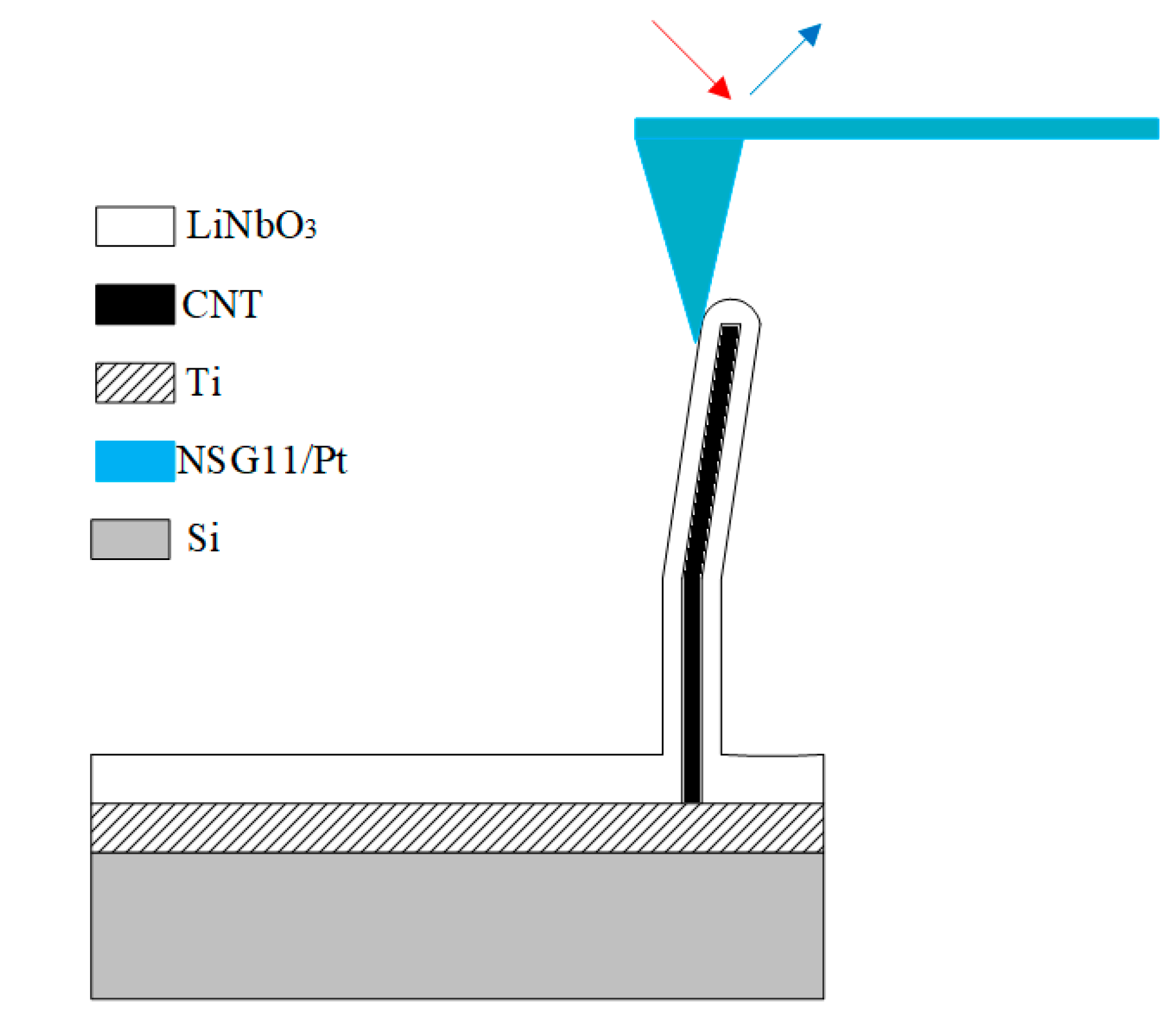

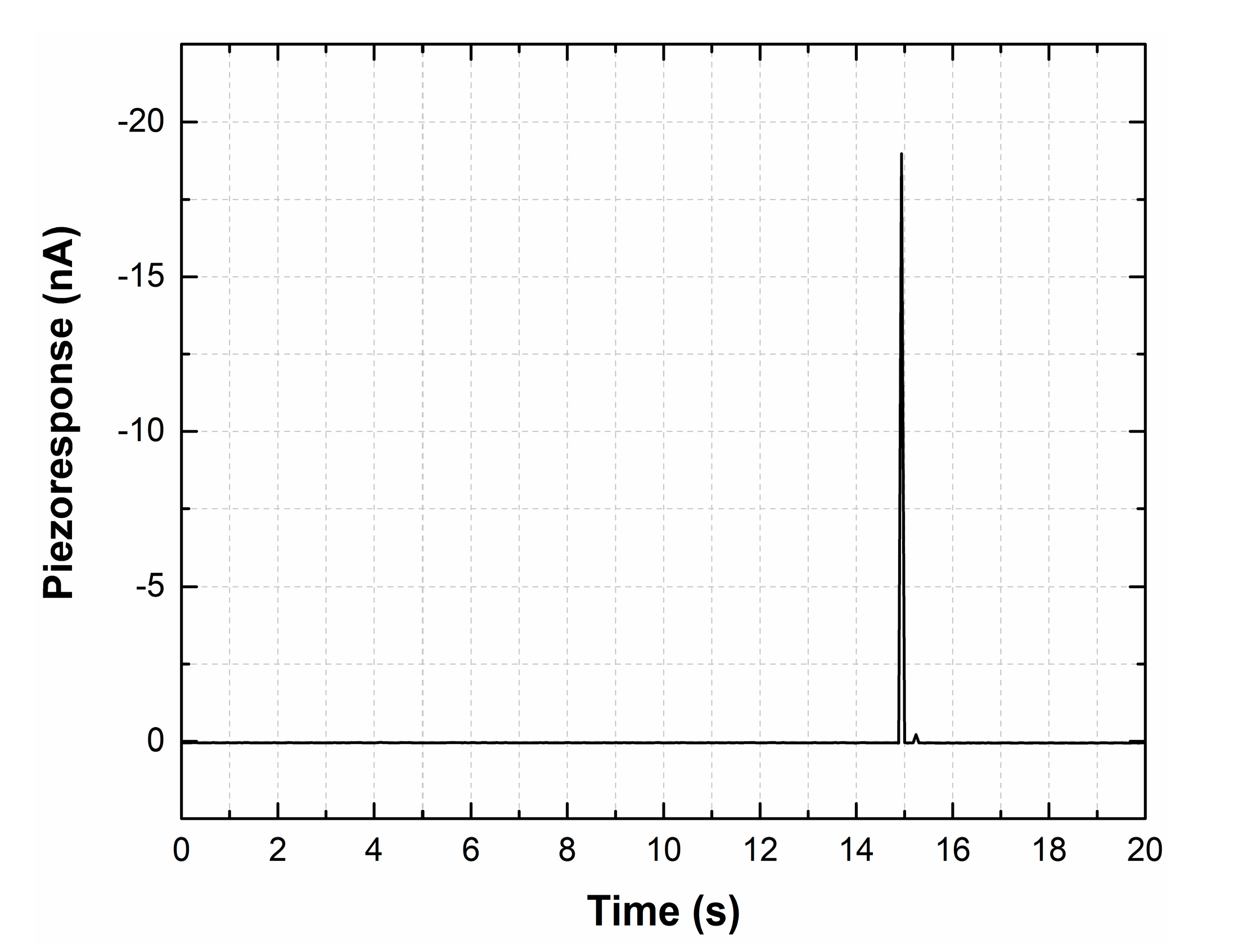

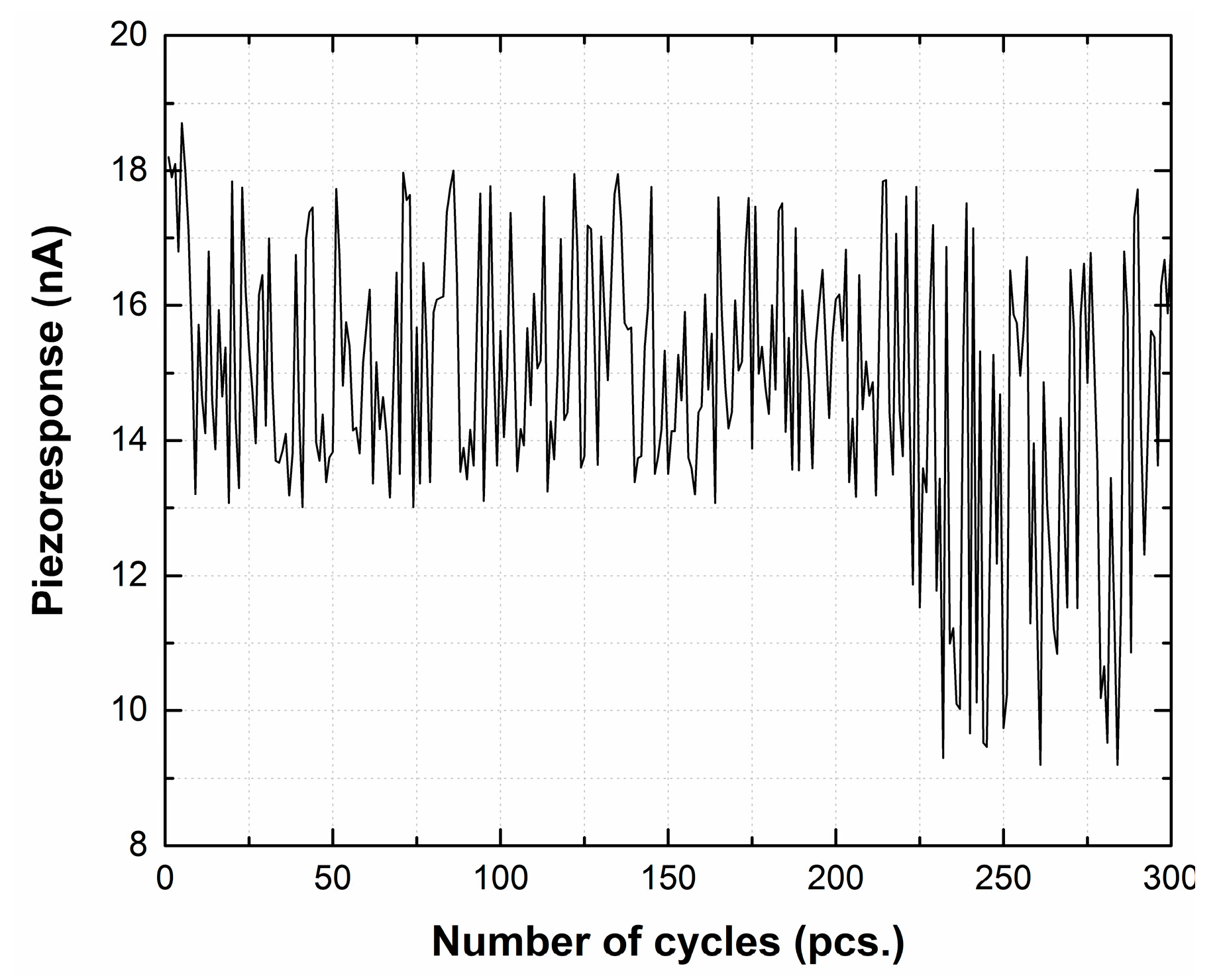

3.3. Piezoelectric Energy Harvester

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Niroomand, M.; Foroughi, H.R. A rotary electromagnetic microgenerator for energy harvesting from human motions. J. Appl. Res. Technol. 2016, 14, 259–267. [Google Scholar] [CrossRef]

- Waldrop, M.M. The chips are down for Moore’s law. Nat. News 2016, 530, 144. [Google Scholar] [CrossRef] [PubMed]

- Chavez, R.; Vakulov, D.; Gazibegovic, S.; Car, D.; Kendig, D.; Tay, A.A.O.; Shakouri, A.; Bakkers, E.P.A.M. Thermopower characterization of InSb nanowires using thermoreflectance. In Proceedings of the 2017 23rd International Workshop on Thermal Investigations of ICs and Systems (THERMINIC), Amsterdam, The Netherlands, 27–29 September 2017; pp. 1–5. [Google Scholar]

- Shaikh, F.K.; Zeadally, S. Energy harvesting in wireless sensor networks: A comprehensive review. Renew. Sustain. Energy Rev. 2016, 55, 1041–1054. [Google Scholar] [CrossRef]

- Zeadally, S.; Shaikh, F.K.; Talpur, A.; Sheng, Q.Z. Design architectures for energy harvesting in the Internet of Things. Renew. Sustain. Energy Rev. 2020, 128, 109901. [Google Scholar] [CrossRef]

- Orrego, S.; Shoele, K.; Ruas, A.; Doran, K.; Caggiano, B.; Mittal, R.; Kang, S.H. Harvesting ambient wind energy with an inverted piezoelectric flag. Appl. Energy 2017, 194, 212–222. [Google Scholar] [CrossRef]

- Wei, C.; Jing, X. A comprehensive review on vibration energy harvesting: Modelling and realization. Renew. Sustain. Energy Rev. 2017, 74, 1–18. [Google Scholar] [CrossRef]

- Chai, Z.; Zhang, N.; Sun, P.; Huang, Y.; Zhao, C.; Fan, H.J.; Fan, X.; Mai, W. Tailorable and wearable textile devices for solar energy harvesting and simultaneous storage. ACS Nano 2016, 10, 9201–9207. [Google Scholar] [CrossRef]

- Glynne-Jones, P.; Tudor, M.J.; Beeby, S.P.; White, N.M. An electromagnetic, vibration-powered generator for intelligent sensor systems. Sens. Actuators A Phys. 2004, 110, 344–349. [Google Scholar] [CrossRef]

- Mitcheson, P.D.; Miao, P.; Stark, B.H.; Yeatman, E.M.; Holmes, A.S.; Green, T.C. MEMS electrostatic micropower generator for low frequency operation. Sens. Actuators A Phys. 2004, 115, 523–529. [Google Scholar] [CrossRef]

- Wang, N.; Cui, C.; Guo, H.; Chen, B.; Zhang, X. Advances in dielectric elastomer actuation technology. Sci. China Technol. Sci. 2018, 61, 1512–1527. [Google Scholar] [CrossRef]

- Yang, Z.; Zhou, S.; Zu, J.; Inman, D. High-performance piezoelectric energy harvesters and their applications. Joule 2018, 2, 642–697. [Google Scholar] [CrossRef]

- Kang, M.G.; Jung, W.S.; Kang, C.Y.; Yoon, S.J. Recent progress on PZT based piezoelectric energy harvesting technologies. Actuators 2016, 5, 5. [Google Scholar] [CrossRef]

- Yang, Z.; Erturk, A.; Zu, J. On the efficiency of piezoelectric energy harvesters. Extrem. Mech. Lett. 2017, 15, 26–37. [Google Scholar] [CrossRef]

- Turkmen, A.C.; Celik, C. Energy harvesting with the piezoelectric material integrated shoe. Energy (Oxford) 2018, 150, 556–564. [Google Scholar] [CrossRef]

- Maiti, S.; Karan, S.K.; Kim, J.K.; Khatua, B.B. Nature driven bio-piezoelectric/triboelectric nanogenerator as next-generation green energy harvester for smart and pollution free society. Adv. Energy Mater. 2019, 9, 1803027. [Google Scholar] [CrossRef]

- Bowen, C.R.; Kim, H.A.; Weaver, P.M.; Dunn, S. Piezoelectric and ferroelectric materials and structures for energy harvesting applications. Energy Environ. Sci. 2014, 7, 25–44. [Google Scholar] [CrossRef]

- Lesieutre, G.A. Vibration damping and control using shunted piezoelectric materials. Shock. Vib. 1998, 30, 187–195. [Google Scholar] [CrossRef]

- Narita, F.; Fox, M. A review on piezoelectric, magnetostrictive, and magnetoelectric materials and device technologies for energy harvesting applications. Adv. Eng. Mater. 2018, 20, 1700743. [Google Scholar] [CrossRef]

- Khan, A.; Abas, Z.; Kim, H.S.; Oh, I.K. Piezoelectric thin films: An integrated review of transducers and energy harvesting. Smart Mater. Struct. 2016, 25, 053002. [Google Scholar] [CrossRef]

- Kumar, A.; Sharma, A.; Kumar, R.; Vaish, R.; Chauhan, V.S. Finite element analysis of vibration energy harvesting using lead-free piezoelectric materials: A comparative study. J. Asian Ceram. Soc. 2014, 2, 138–143. [Google Scholar] [CrossRef][Green Version]

- Bedekar, V.; Oliver, J.; Zhang, S.; Priya, S. Comparative study of energy harvesting from high temperature piezoelectric single crystals. Jpn. J. Appl. Phys. 2019, 48, 091406. [Google Scholar] [CrossRef]

- Ageev, O.; Konoplev, B. (Eds.) Nanotechnology in Microelectronics; Nauka: Moscow, Russia, 2019; p. 511. [Google Scholar]

- Tellekamp, M.B.; Shank, J.C.; Goorsky, M.S.; Doolittle, W.A. Molecular beam epitaxy growth of high crystalline quality LiNbO3. J. Electron. Mater. 2016, 45, 6292–6299. [Google Scholar] [CrossRef]

- Morosanu, C.E. Thin Films by Chemical Vapour Deposition, 1st ed.; Elsevier: Amsterdam, The Netherlands, 1990; p. 719. [Google Scholar]

- Sauze, L.C.; Vaxelaire, N.; Rouchon, D.; Pierre, F.; Templier, R.; Remiens, D.; Rodriguez, G. Microstructural and chemical analysis of polycrystalline LiNbO3 films obtained by room-temperature RF sputtering after various annealing durations. J. Vac. Sci. Technol. A 2020, 38, 043205. [Google Scholar] [CrossRef]

- Li, W.; Cui, J.; Wang, W.; Zheng, D.; Jia, L.; Saeed, S.; Liu, H.; Rupp, R.; Kong, Y.; Xu, J. P-type lithium niobate thin films fabricated by nitrogen-doping. Materials 2019, 12, 819. [Google Scholar] [CrossRef] [PubMed]

- Vakulov, Z.; Zamburg, E.; Khakhulin, D.; Geldash, A.; Golosov, D.A.; Zavadski, S.M.; Miakonkikh, A.V.; Rudenko, K.V.; Dostanko, A.P.; He, Z.; et al. Oxygen pressure influence on properties of nanocrystalline LiNbO3 films grown by laser ablation. Nanomaterials 2020, 10, 1371. [Google Scholar] [CrossRef]

- Nakata, Y.; Gunji, S.; Okada, T.; Maeda, M. Fabrication of LiNbO3 thin films by pulsed laser deposition and investigation of nonlinear properties. Appl. Phys. A 2004, 79, 1279–1282. [Google Scholar] [CrossRef]

- Vakulov, Z.E.; Zamburg, E.G.; Golosov, D.A.; Zavadskiy, S.M.; Miakonkikh, A.V.; Clemente, I.E.; Rudenko, K.V.; Dostanko, A.P.; Ageev, O.A. Effect of substrate temperature on the properties of LiNbO3 nanocrystalline films during pulsed laser deposition. Bull. Russ. Acad. Sci. Phys. 2017, 81, 1476–1480. [Google Scholar] [CrossRef]

- Takahashi, M.; Yamauchi, K.; Yagi, T.; Nishiwaki, A.; Wakita, K.; Ohnishi, N.; Hotta, K.; Sahashi, I. Preparation and characterization of high-quality stoichiometric LiNbO3 thick films prepared by the sol-gel method. Thin Solid Film. 2004, 458, 108–113. [Google Scholar] [CrossRef]

- Tominov, R.V.; Vakulov, Z.E.; Avilov, V.I.; Khakhulin, D.A.; Fedotov, A.A.; Zamburg, E.G.; Smirnov, V.A.; Ageev, O.A. Synthesis and memristor effect of a forming-free ZnO nanocrystalline films. Nanomaterials 2020, 10, 1007. [Google Scholar] [CrossRef]

- Vakulov, Z.E.; Varzarev, Y.N.; Gusev, E.Y.; Skrylev, A.V.; Panich, A.E.; Miakonkikh, A.V.; Klemente, I.E.; Rudenko, K.V.; Konoplev, B.G.; Ageev, O.A. Influence of pulsed laser deposition modes on properties of nanocrystalline LiNbO3 films. Russ. Microelectron. 2019, 48, 59–65. [Google Scholar] [CrossRef]

- Vakulov, Z.E.; Klimin, V.S.; Rezvan, A.A.; Tominov, R.V.; Korzun, K.; Kots, I.N.; Polyakova, V.V.; Ageev, O.A. Formation of SiO2 buffer layer for LiNbO3 thin films growth. J. Phys. Conf. Ser. 2019, 1410, 012042. [Google Scholar] [CrossRef]

- Vakulov, Z.; Ivonin, M.; Zamburg, E.G.; Klimin, V.S.; Volik, D.P.; Golosov, D.A.; Zavadskiy, S.M.; Dostanko, A.P.; Miakonkikh, A.V.; Clemente, I.E.; et al. Size effects in LiNbO3 thin films fabricated by pulsed laser deposition. J. Phys. Conf. Ser. 2018, 1124, 022032. [Google Scholar] [CrossRef]

- Wicklein, S.; Sambri, A.; Amoruso, S.; Wang, X.; Bruzzese, R.; Koehl, A.; Dittmann, R. Pulsed laser ablation of complex oxides: The role of congruent ablation and preferential scattering for the film stoichiometry. Appl. Phys. Lett. 2012, 101, 131601. [Google Scholar] [CrossRef]

- He, H.; Xiao, M.; Zhong, Q.; Fu, Y.C.; Shen, X.M.; Zeng, J.M. Influence of laser pulse energy on the microstructure and optical properties of Cu2ZnSnS4 films by one-step pulsed laser deposition. Ceram. Int. 2014, 40, 13263–13267. [Google Scholar] [CrossRef]

- Il’in, O.I.; Il’ina, M.V.; Rudyk, N.N.; Fedotov, A.A.; Ageev, O.A. Vertically Aligned Carbon Nanotubes Production by PECVD. In Perspective of Carbon Nanotubes, 1st ed.; El-Din, S.H., Moawad, M.E.-S.S., Eds.; IntechOpen: London, UK, 2019. [Google Scholar]

- Il’in, O.I.; Rudyk, N.N.; Fedotov, A.A.; Il’ina, M.V.; Cherednichenko, D.I.; Ageev, O.A. Modeling of catalytic centers formation processes during annealing of multilayer nanosized metal films for carbon nanotubes growth. Nanomaterials 2020, 10, 554. [Google Scholar] [CrossRef] [PubMed]

- Bartasyte, A.; Plausinaitiene, V.; Abrutis, A.; Stanionyte, S.; Margueron, S.; Boulet, P.; Kobata, T.; Uesu, Y.; Gleize, J. Identification of LiNbO3, LiNb3O8 and Li3NbO4 phases in thin films synthesized with different deposition techniques by means of XRD and Raman spectroscopy. J. Phys. Condens. Matter 2013, 25, 205901. [Google Scholar] [CrossRef]

- Prapitpongwanich, P.; Harizanova, R.; Pengpat, K.; Rüssel, C. Nanocrystallization of ferroelectric lithium niobate in LiNbO3-SiO2 glasses. Mater. Lett. 2009, 63, 1027–1029. [Google Scholar] [CrossRef]

- Lee, T.H.; Hwang, F.T.; Lee, C.T.; Lee, H.Y. Investigation of LiNbO3 thin films grown on Si substrate using magnetron sputter. Mater. Sci. Eng. B 2007, 136, 92–95. [Google Scholar] [CrossRef]

- Gamaly, E.G.; Rode, A.V.; Luther-Davies, B. Ultrafast ablation with high-pulse-rate lasers. Part I: Theoretical considerations. J. Appl. Phys. 1999, 85, 4213–4221. [Google Scholar] [CrossRef]

- Chen, J.; Döbeli, M.; Stender, D.; Conder, K.; Wokaun, A.; Schneider, C.W.; Lippert, T. Plasma interactions determine the composition in pulsed laser deposited thin films. Appl. Phys. Lett. 2014, 105, 114104. [Google Scholar]

- Il’ina, M.V.; Il’in, O.I.; Blinov, Y.F.; Konshin, A.A.; Konoplev, B.G.; Ageev, O.A. Piezoelectric response of multi-walled carbon nanotubes. Materials 2018, 11, 638. [Google Scholar] [CrossRef] [PubMed]

- Kubasov, I.V.; Kislyuk, A.M.; Malinkovich, M.D.; Temirov, A.A.; Ksenich, S.V.; Kiselev, D.A.; Bykov, A.S.; Parkhomenko, Y.N. Vibrational power harvester based on lithium niobate bidomain plate. Acta Phys. Pol. 2018, 134, 90–92. [Google Scholar] [CrossRef]

- Hu, C.J.; Lin, Y.H.; Tang, C.W.; Tsai, M.Y.; Hsu, W.K.; Kuo, H.F. ZnO-coated carbon nanotubes: Flexible piezoelectric generators. Adv. Mater. 2011, 23, 2941–2945. [Google Scholar] [CrossRef] [PubMed]

- Yan, J.; Jeong, Y.G. Roles of carbon nanotube and BaTiO3 nanofiber in the electrical, dielectric and piezoelectric properties of flexible nanocomposite generators. Compos. Sci. Technol. 2017, 144, 1–10. [Google Scholar] [CrossRef]

- Balpande, S.S.; Pande, R.S.; Patrikar, R.M. Design and low cost fabrication of green vibration energy harvester. Sens. Actuators A Phys. 2016, 251, 134–141. [Google Scholar] [CrossRef]

- Cui, Y.; Yu, M.; Gao, S.; Kong, X.; Gu, W.; Zhang, R.; Liu, B. Fabrication and characterization of a piezoelectric energy harvester with clamped-clamped beams. AIP Adv. 2018, 8, 055028. [Google Scholar] [CrossRef]

- Zhang, Y.; Wang, T.; Luo, A.; Hu, Y.; Li, X.; Wang, F. Micro electrostatic energy harvester with both broad bandwidth and high normalized power density. Appl. Energy 2018, 212, 362–371. [Google Scholar] [CrossRef]

- Woo, M.S.; Ahn, J.H.; Eom, J.H.; Hwang, W.S.; Kim, J.H.; Yang, C.H.; Song, G.J.; Hong, S.D.; Jhun, J.P.; Sung, T.H. Study on increasing output current of piezoelectric energy harvester by fabrication of multilayer thick film. Sens. Actuators A Phys. 2018, 269, 524–534. [Google Scholar] [CrossRef]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Vakulov, Z.; Geldash, A.; Khakhulin, D.; Il’ina, M.V.; Il’in, O.I.; Klimin, V.S.; Dzhuplin, V.N.; Konoplev, B.G.; He, Z.; Ageev, O.A. Piezoelectric Energy Harvester Based on LiNbO3 Thin Films. Materials 2020, 13, 3984. https://doi.org/10.3390/ma13183984

Vakulov Z, Geldash A, Khakhulin D, Il’ina MV, Il’in OI, Klimin VS, Dzhuplin VN, Konoplev BG, He Z, Ageev OA. Piezoelectric Energy Harvester Based on LiNbO3 Thin Films. Materials. 2020; 13(18):3984. https://doi.org/10.3390/ma13183984

Chicago/Turabian StyleVakulov, Zakhar, Andrey Geldash, Daniil Khakhulin, Marina V. Il’ina, Oleg I. Il’in, Viktor S. Klimin, Vladimir N. Dzhuplin, Boris G. Konoplev, Zhubing He, and Oleg A. Ageev. 2020. "Piezoelectric Energy Harvester Based on LiNbO3 Thin Films" Materials 13, no. 18: 3984. https://doi.org/10.3390/ma13183984

APA StyleVakulov, Z., Geldash, A., Khakhulin, D., Il’ina, M. V., Il’in, O. I., Klimin, V. S., Dzhuplin, V. N., Konoplev, B. G., He, Z., & Ageev, O. A. (2020). Piezoelectric Energy Harvester Based on LiNbO3 Thin Films. Materials, 13(18), 3984. https://doi.org/10.3390/ma13183984