Finite Element Simulation of the Machining Process of Boiling Structures in a Novel Radial Heat Sink for High-Power LEDs

Abstract

1. Introduction

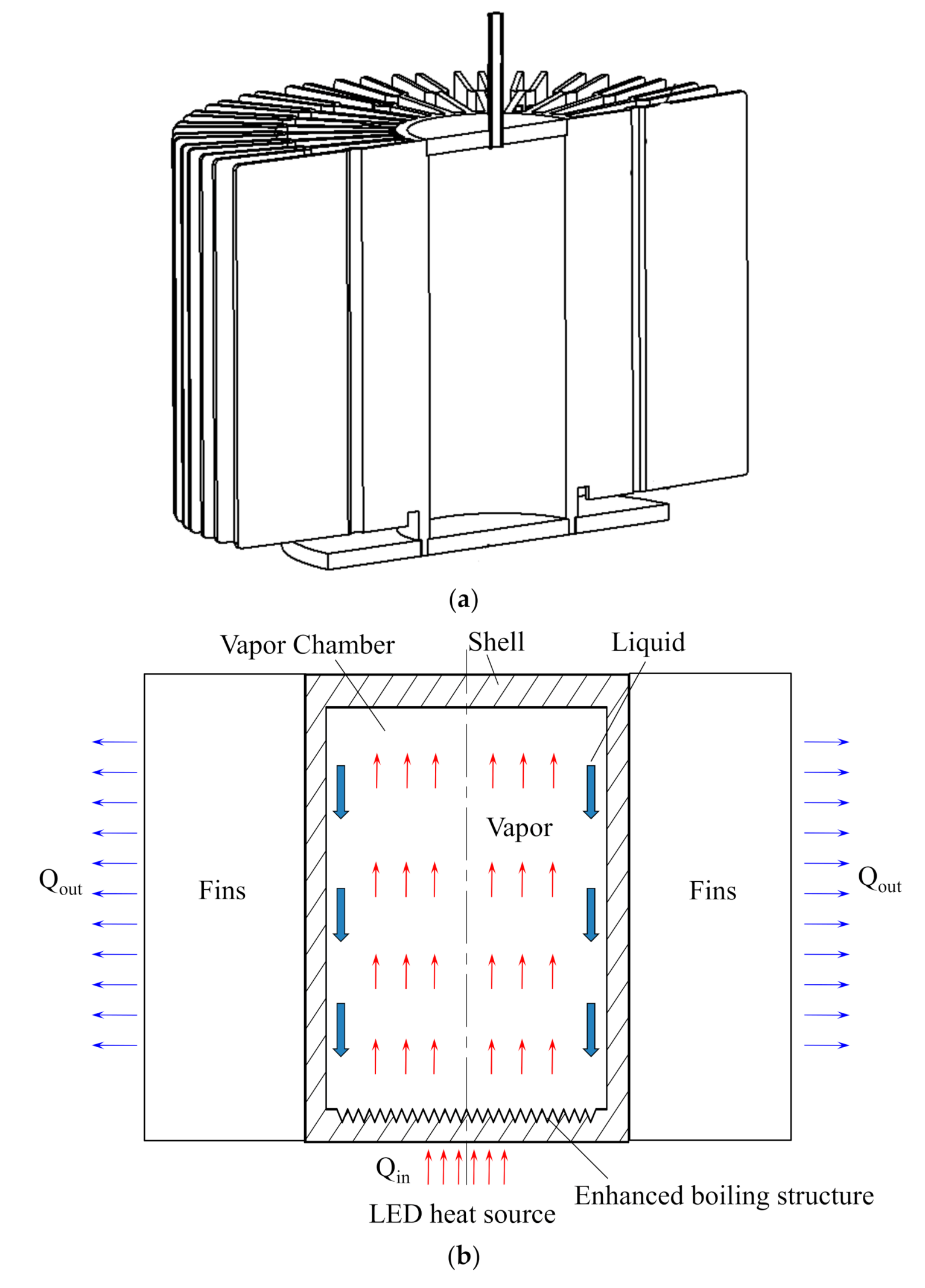

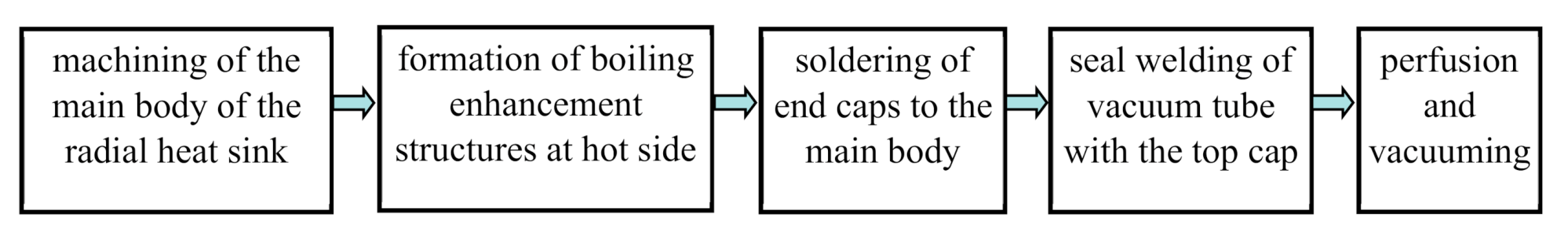

2. Operating Principle and Fabrication Process of the Developed Phase Change Heat Sink

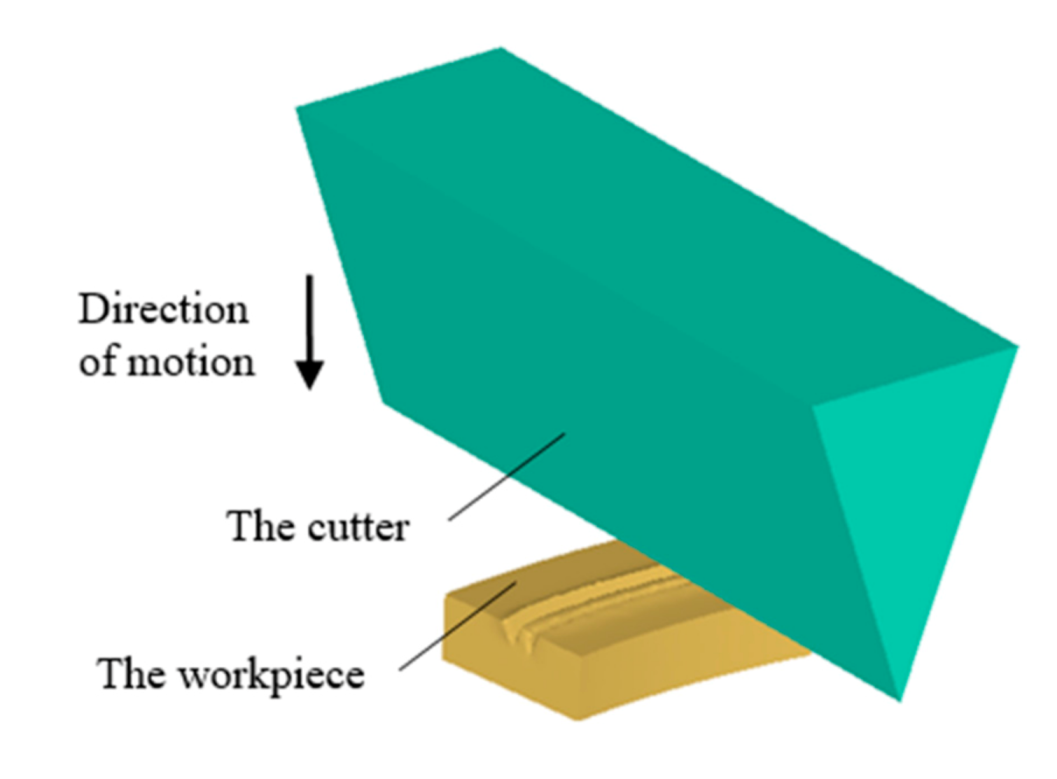

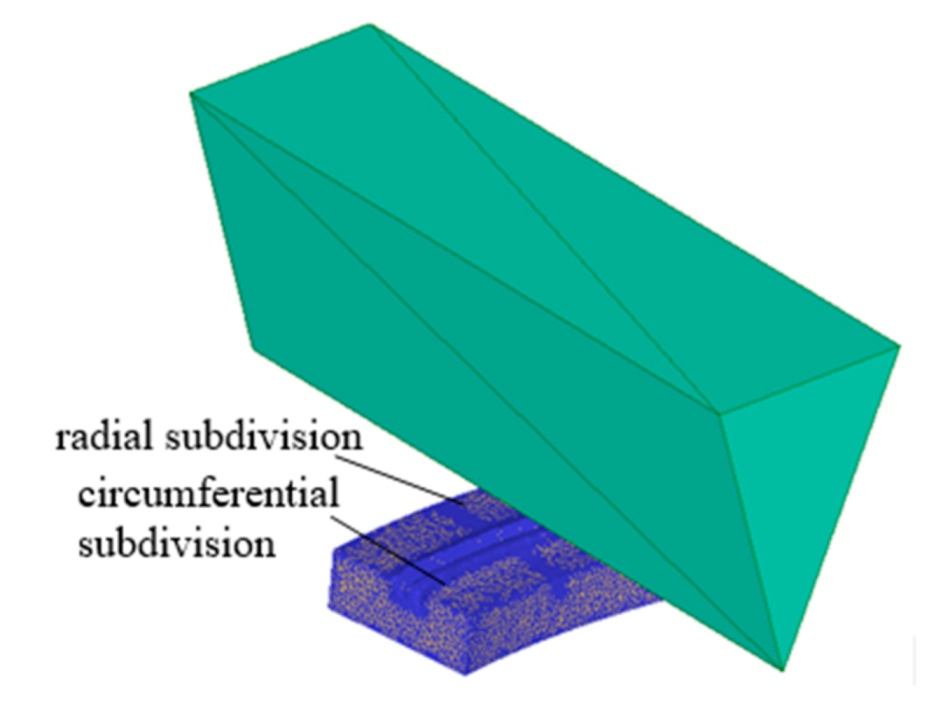

3. Finite Element Simulation

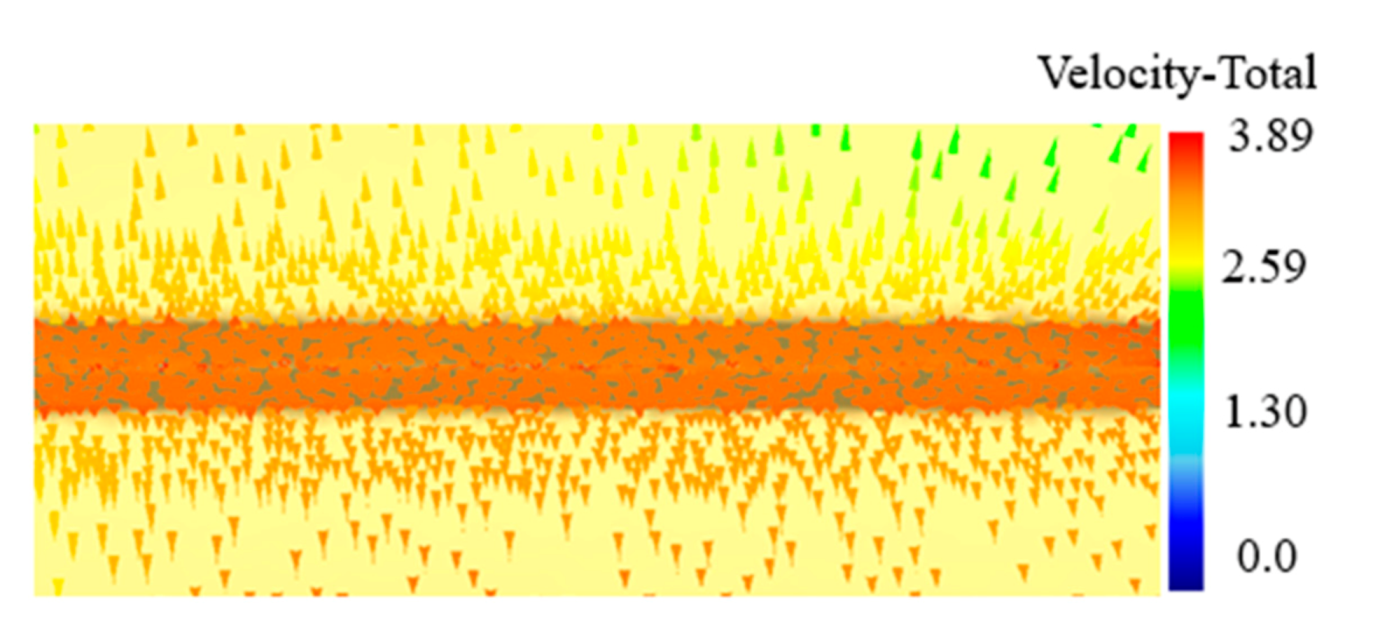

4. Results and Discussion

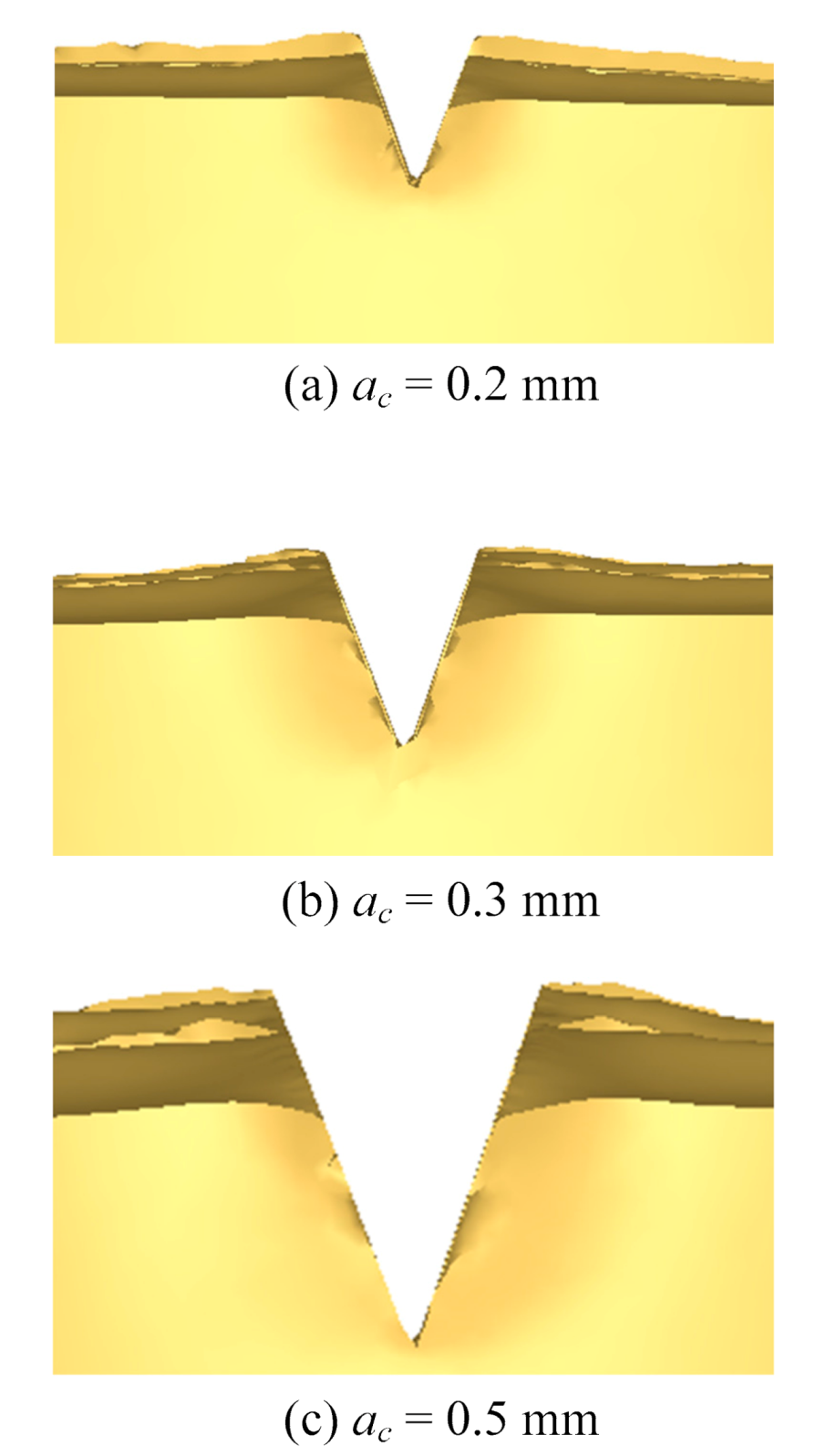

4.1. Effect of Different Stamping Depths on the Morphology of Microgrooves

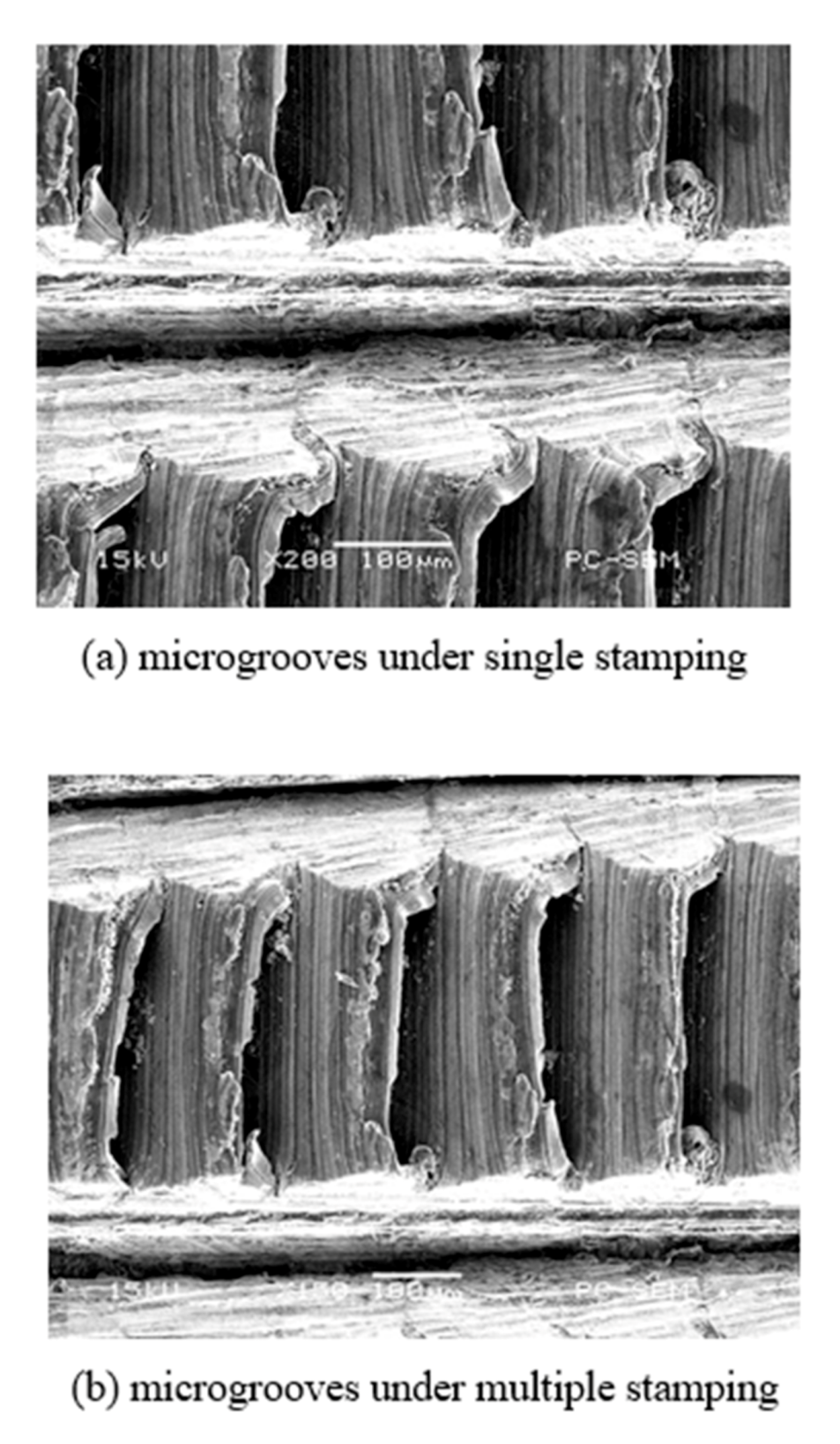

4.1.1. Morphology of Microgrooves under Different Stamping Depths

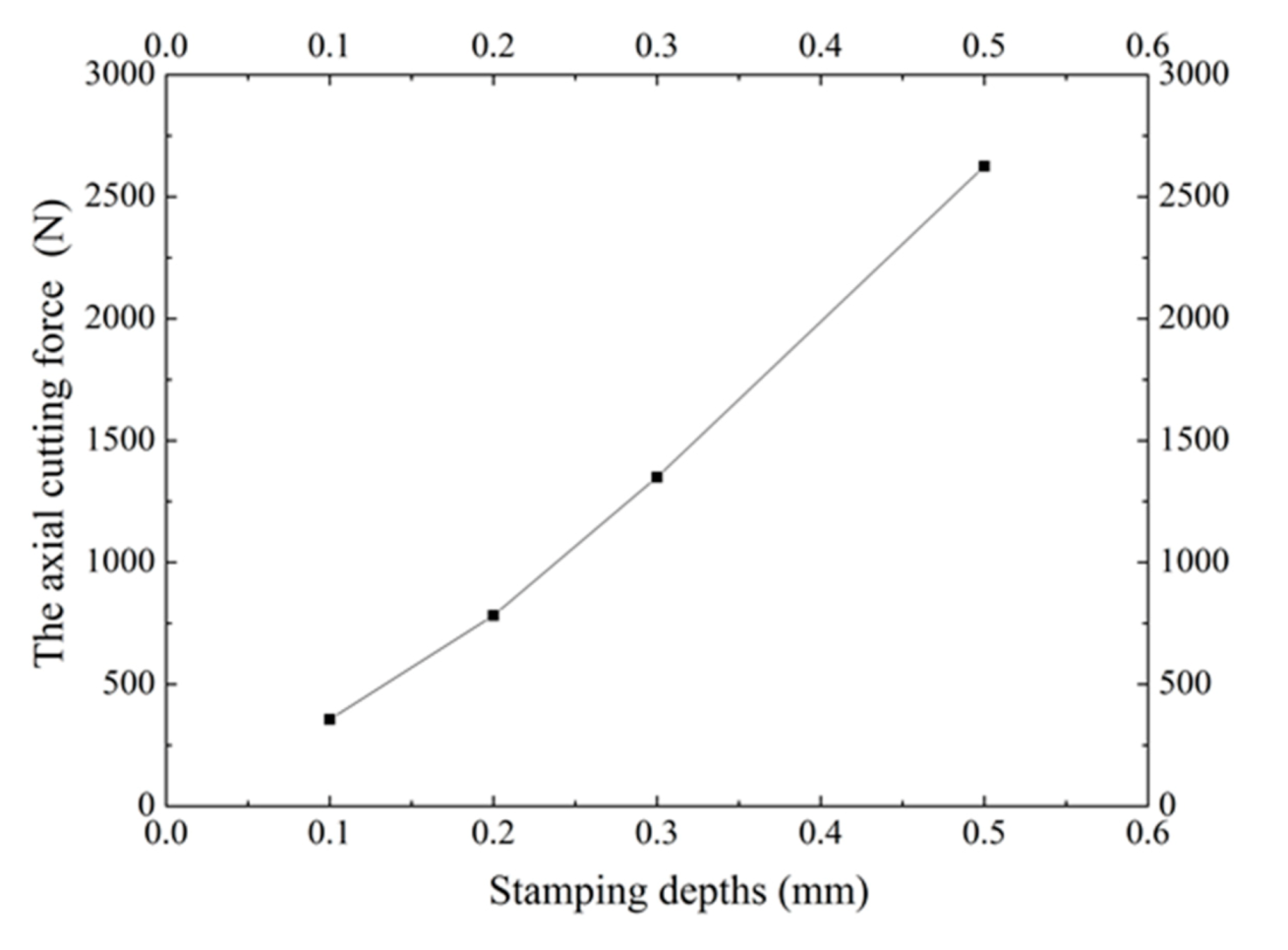

4.1.2. Analysis of Cutting Force

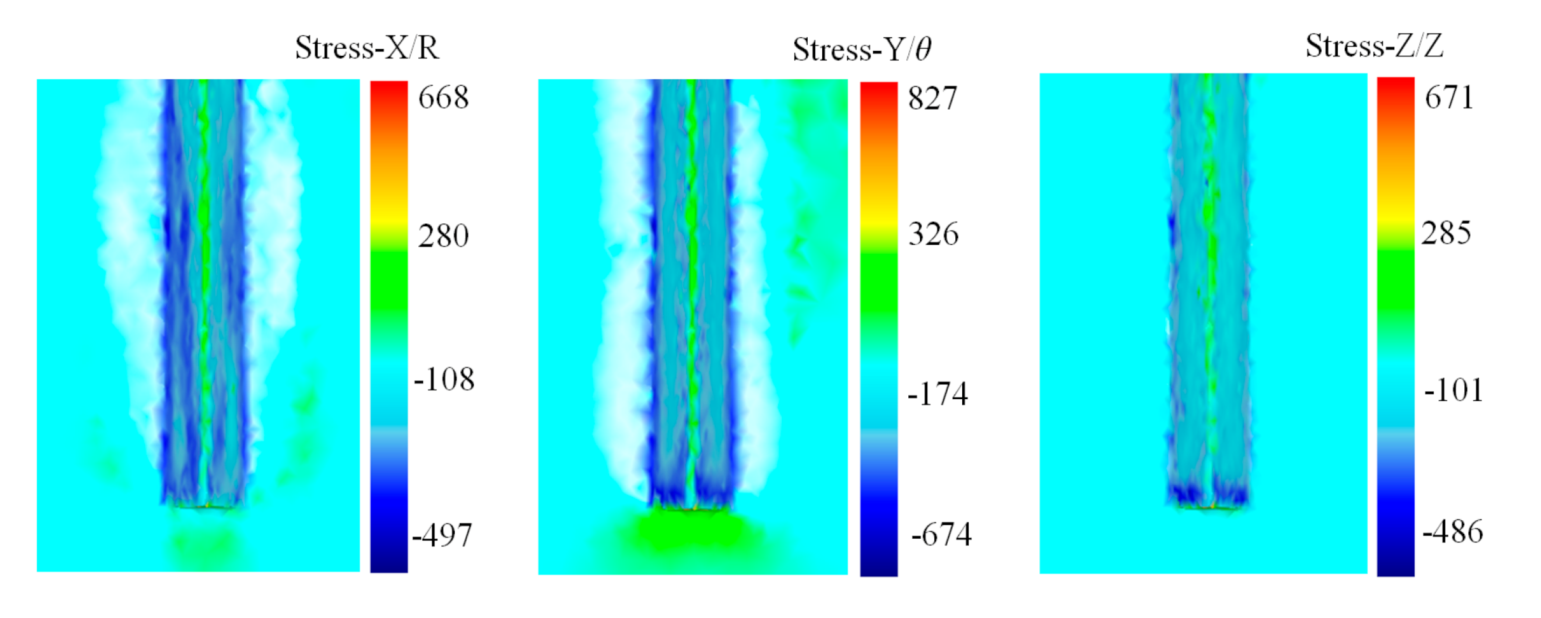

4.1.3. Stress Distribution

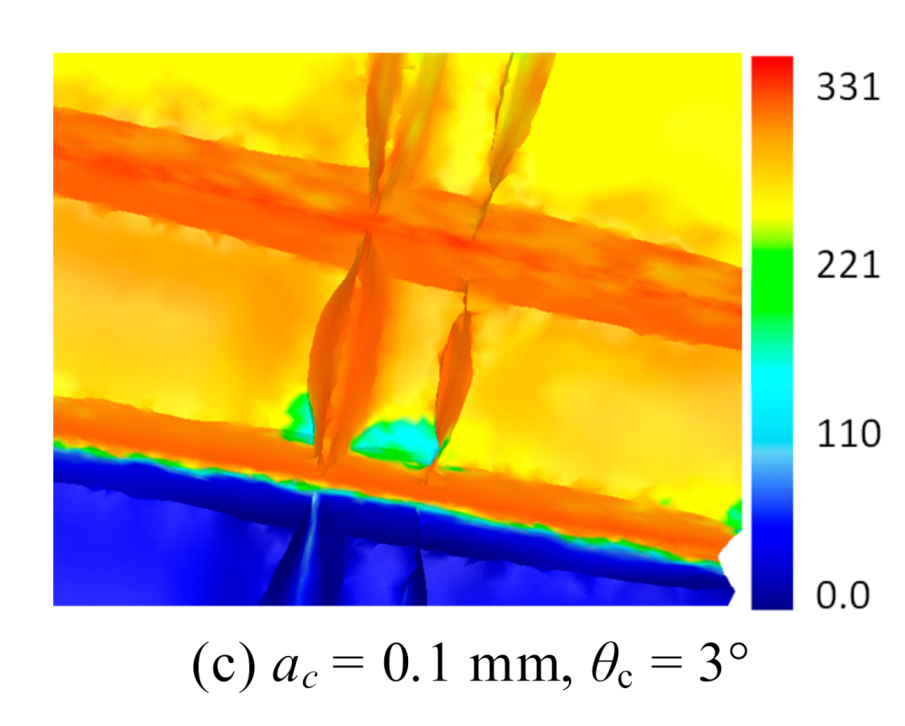

4.2. Effect of Feeding Angles on the Morphology of Microgrooves

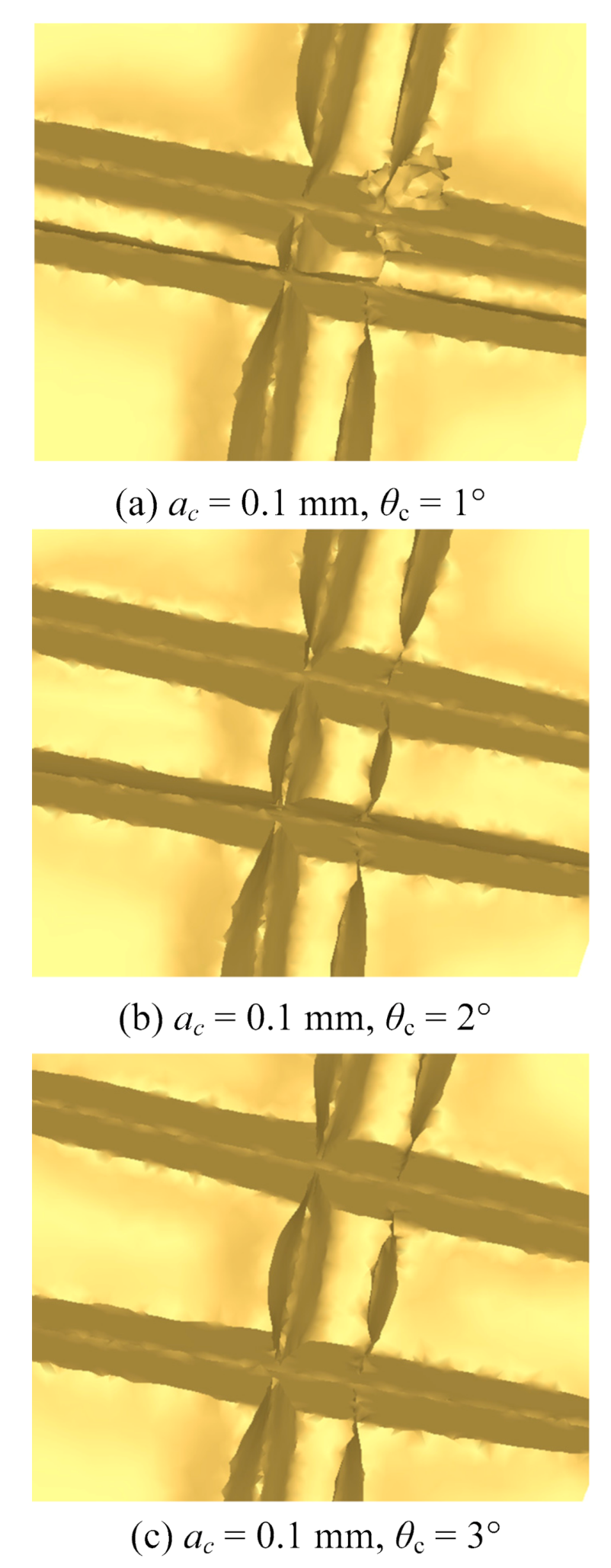

4.2.1. Analysis of Plastic Forming at Different Feeding Angles

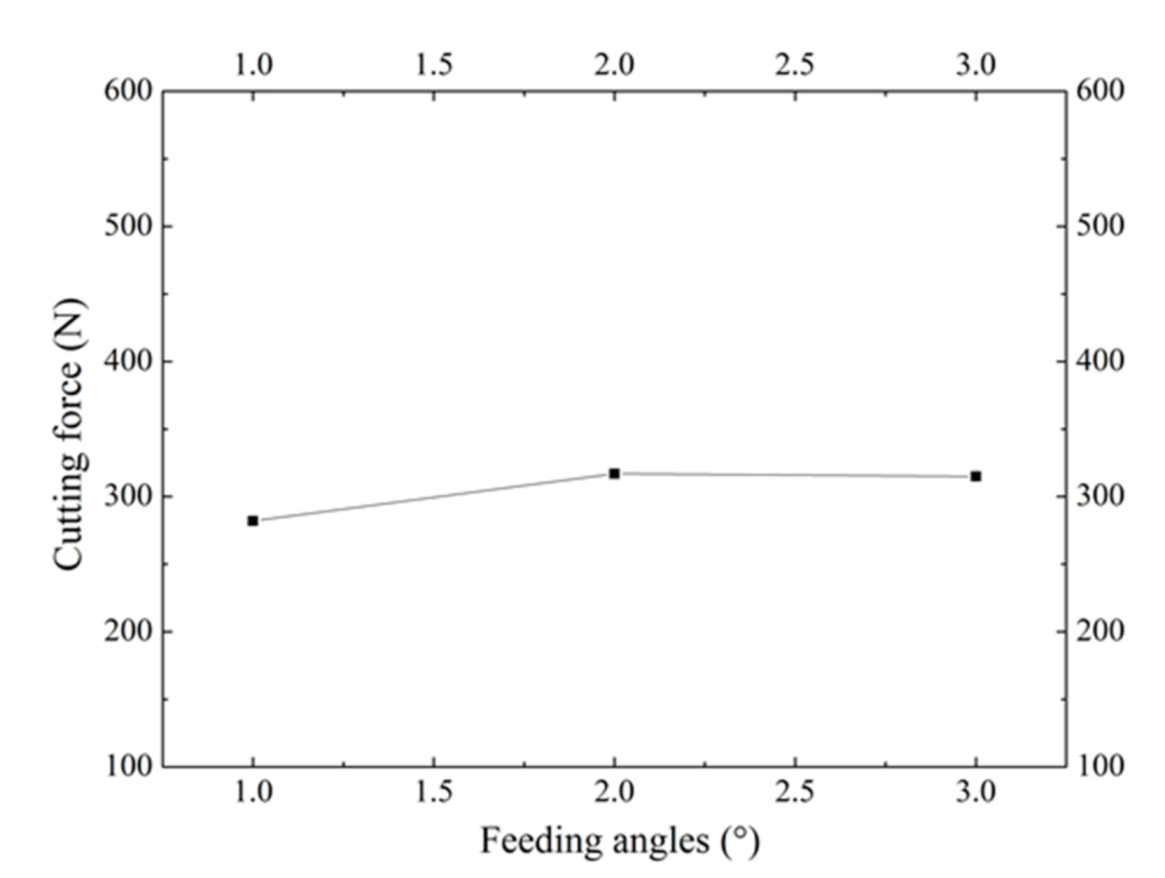

4.2.2. Analysis of Cutting Force

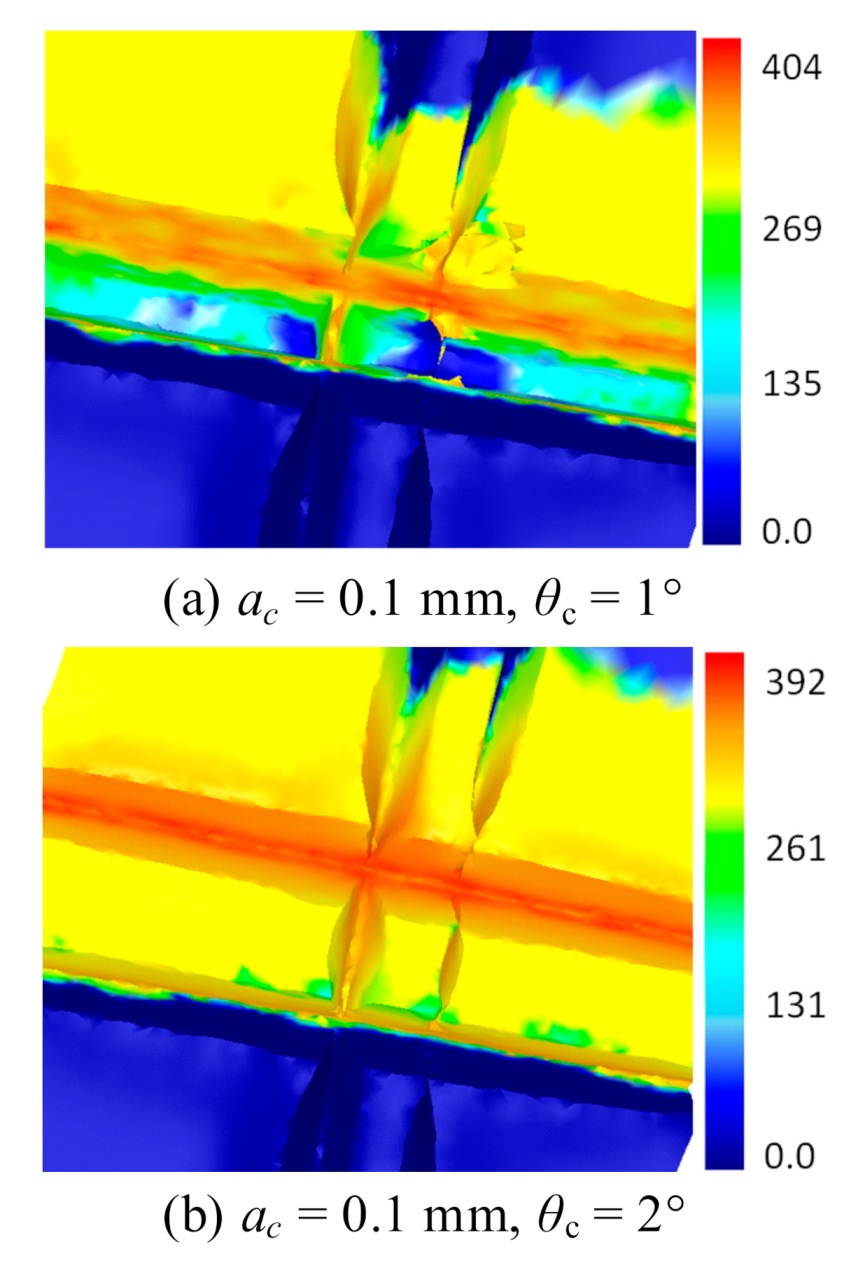

4.2.3. Stress Distribution

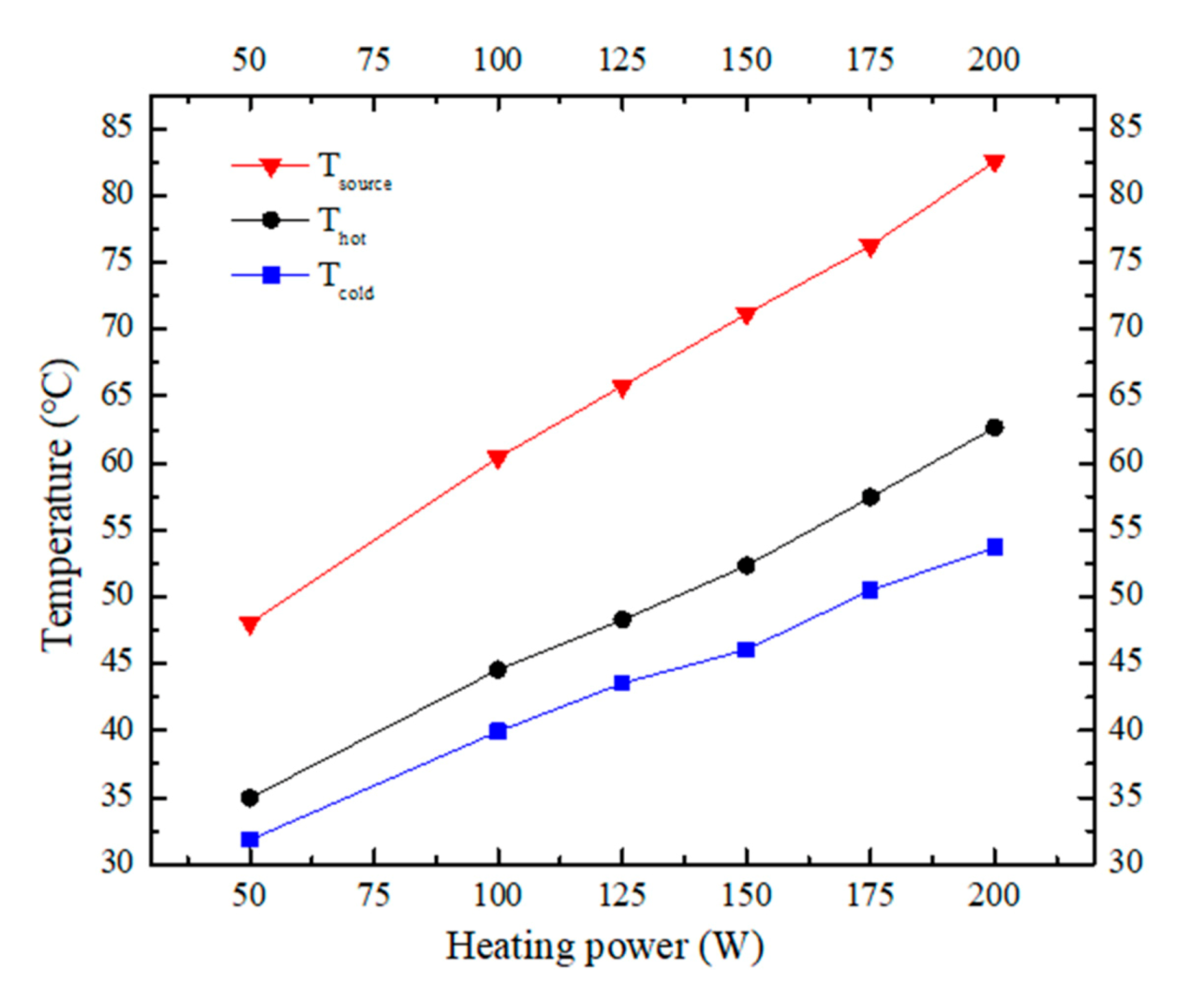

5. Heat Transfer Performance Testing

6. Conclusions

- (1)

- This paper proposed a novel phase change radial heat sink for high-power LED heat dissipation. The working principle and the fabrication process of the heat sink were introduced.

- (2)

- The machining process of the boiling structures was simulated using DEFORM-3D v11.0. Plastic deformation generated during the formation was analyzed. Key parameters related to the morphology of the boiling structures were discussed including feeding angles and machining depths. When the stamping depth changes from 0.1 mm to 0.5 mm, the axial cutting force increases from 350 N to 2500 N. The maximum equivalent stress can reach around 672 MPa. Considering the interference effect and the number of radial grooves, the optimal feeding angle is 2°.

- (3)

- The FE simulation results were compared with those of experiments. Results show that they coincide well with each other.

Author Contributions

Funding

Conflicts of Interest

References

- Wu, Y.; Tang, Y.; Li, Z.; Ding, X.; Yuan, W.; Zhao, X.; Yu, B. Experimental investigation of a PCM-HP heat sink on its thermal performance and anti-thermal-shock capacity for high-power LEDs. Appl. Therm. Eng. 2016, 108, 192–203. [Google Scholar] [CrossRef]

- Tang, Y.; Qiu, S.; Li, M.; Zhao, K. Fabrication of alumina/copper heat dissipation substrates by freeze tape casting and melt infiltration for high-power LED. J. Alloys Compd. 2017, 690, 469–477. [Google Scholar] [CrossRef]

- Park, D.H.; Lee, D.B.; Seo, E.R.; Park, Y.J. A parametric study on heat dissipation from a LED-lamp. Appl. Therm. Eng. 2016, 108, 1261–1267. [Google Scholar] [CrossRef]

- Park, S.J.; Jang, D.; Lee, K.S. Thermal performance improvement of a radial heat sink with a hollow cylinder for LED downlight applications. Int. J. Heat Mass Transf. 2015, 89, 1184–1199. [Google Scholar] [CrossRef]

- Li, B.; Byon, C. Orientation effects on thermal performance of radial heat sinks with a concentric ring subject to natural convection. Int. J. Heat Mass Transf. 2015, 90, 102–108. [Google Scholar] [CrossRef]

- Arshad, A.; Ali, H.M.; Khushnood, S.; Jabbal, M. Experimental investigation of PCM based round pin-fin heat sinks for thermal management of electronics: Effect of pin-fin diameter. Int. J. Heat Mass Transf. 2018, 117, 861–872. [Google Scholar] [CrossRef]

- Li, B.; Baik, Y.J.; Byon, C. Enhanced natural convection heat transfer of a chimney-based radial heat sink. Energy Convers. Manag. 2016, 108, 422–428. [Google Scholar] [CrossRef]

- Schmid, G.; Valladares-Rendón, L.G.; Yang, T.H.; Chen, S.L. Numerical analysis of the effect of a central cylindrical opening on the heat transfer of radial heat sinks for different orientations. Appl. Therm. Eng. 2017, 125, 575–583. [Google Scholar] [CrossRef]

- Xiang, J.; Zhou, C.; Zhang, C.; Liu, G.; N, C.C.H.E.; Zhou, W. Optimization of three-dimensional boiling enhancement structure at evaporation surface for high power light emitting diode. Trans. Nonferrous Met. Soc. China 2018, 28, 1404–1412. [Google Scholar] [CrossRef]

- Klamecki, B.E. Incipient Chip Formation in Metal Cutting—A Three Dimension Finite Element Analysis. Ph.D. Thesis, Department of Mechanical and Industrial Engineering, University of Illinois, Urbana, IL, USA, 1973. [Google Scholar]

- Zhou, Q.; Wierzbicki, T. A tension zone model of blanking and tearing of ductile metal plates. Int. J. Mech. Sci. 1996, 38, 303–324. [Google Scholar] [CrossRef]

- Breitling, J.; Chernauskas, V.; Taupin, E.; Altan, T. Precision shearing of billets—Special equipment and process simulation. J. Mater. Process. Technol. 1997, 71, 119–125. [Google Scholar] [CrossRef]

- Hambli, R.; Guerin, F. Application of a neural network for optimum clearance prediction in sheet metal blanking processes. Finite Elem. Anal. Des. 2003, 39, 1039–1052. [Google Scholar] [CrossRef]

- Kim, C.; Mayor, R.; Ni, J. Molecular dynamics simulations of plastic material deformation in machining with a round cutting edge. Int. J. Precis. Eng. Manuf. 2012, 13, 1303–1309. [Google Scholar] [CrossRef]

- Atlati, S.; Haddag, B.; Nouari, M.; Moufki, A. Effect of the local friction and contact nature on the Built-Up Edge formation process in machining ductile metals. Tribol. Int. 2015, 90, 217–227. [Google Scholar] [CrossRef]

- Oliaei, S.N.B.; Karpat, Y. Investigating the influence of friction conditions on finite element simulation of microscale machining with the presence of built-up edge. Int. J. Adv. Manuf. Technol. 2017, 90, 819–829. [Google Scholar] [CrossRef]

- Zang, J.; Zhao, J.; Li, A.; Pang, J. Serrated chip formation mechanism analysis for machining of titanium alloy Ti-6Al-4V based on thermal property. Int. J. Adv. Manuf. Technol. 2018, 98, 119–127. [Google Scholar] [CrossRef]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xiang, J.; Liu, Z.; Zhang, C.; Zhou, C.; Chen, C. Finite Element Simulation of the Machining Process of Boiling Structures in a Novel Radial Heat Sink for High-Power LEDs. Materials 2020, 13, 3958. https://doi.org/10.3390/ma13183958

Xiang J, Liu Z, Zhang C, Zhou C, Chen C. Finite Element Simulation of the Machining Process of Boiling Structures in a Novel Radial Heat Sink for High-Power LEDs. Materials. 2020; 13(18):3958. https://doi.org/10.3390/ma13183958

Chicago/Turabian StyleXiang, Jianhua, Zeyu Liu, Chunliang Zhang, Chao Zhou, and Conggui Chen. 2020. "Finite Element Simulation of the Machining Process of Boiling Structures in a Novel Radial Heat Sink for High-Power LEDs" Materials 13, no. 18: 3958. https://doi.org/10.3390/ma13183958

APA StyleXiang, J., Liu, Z., Zhang, C., Zhou, C., & Chen, C. (2020). Finite Element Simulation of the Machining Process of Boiling Structures in a Novel Radial Heat Sink for High-Power LEDs. Materials, 13(18), 3958. https://doi.org/10.3390/ma13183958