2.1. Characteristics of the Raw Materials Used

Gypsum β-modifications of the grade G-5B II (Belgorod, Russia) was used as a component of the gypsum-cement binder (

Table 2).

Portland cement CEM I 42.5 N (Belgorodsky cement, Belgorod, Russia) with a bulk density of 1150 kg/m

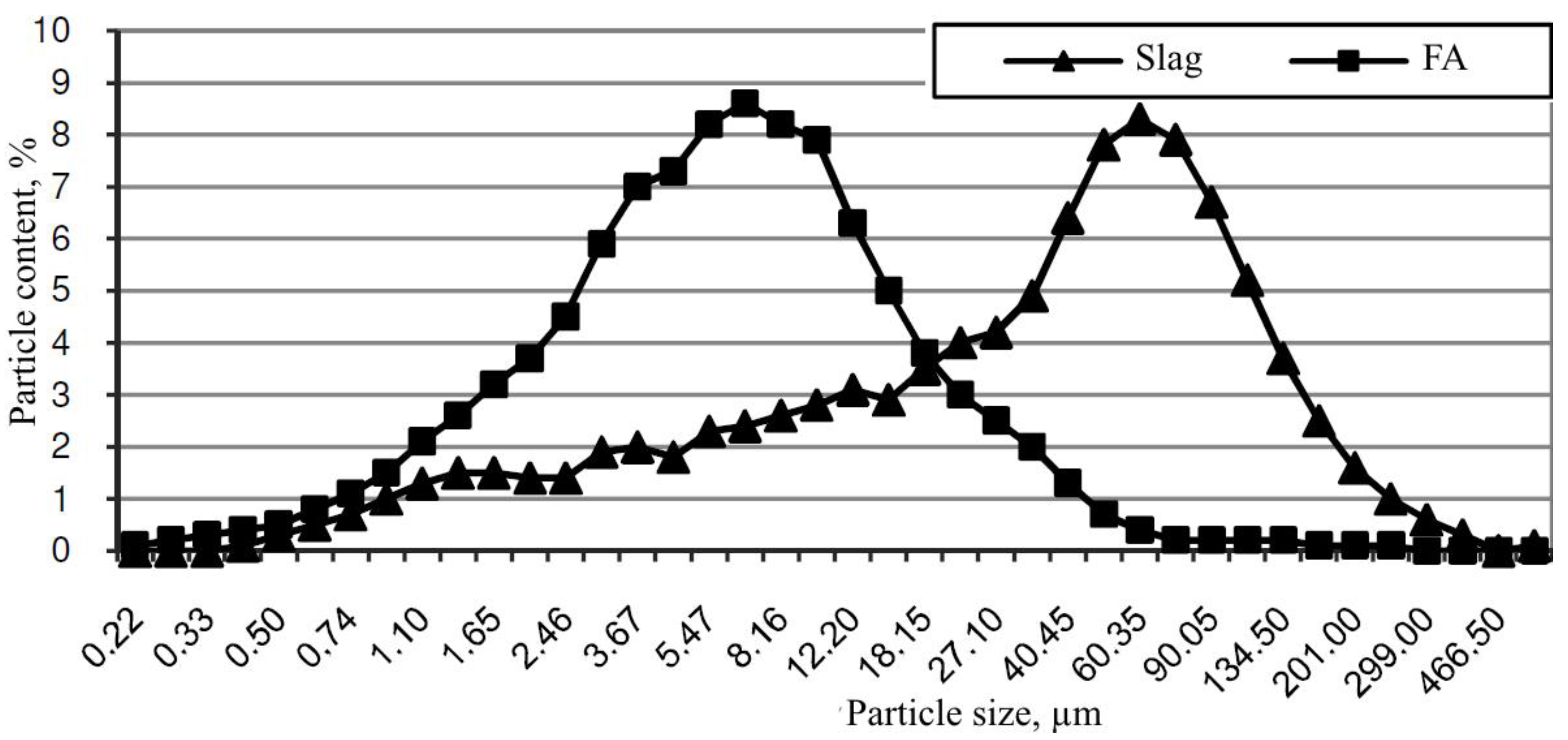

3 was used as a binder material. Fly ash (FA) and slag of the Grozny thermal power plant (TPP) (Grozny, Russia) were used as silica-containing components. The bulk density of fly ash and slag was 900 and 1100 kg/m

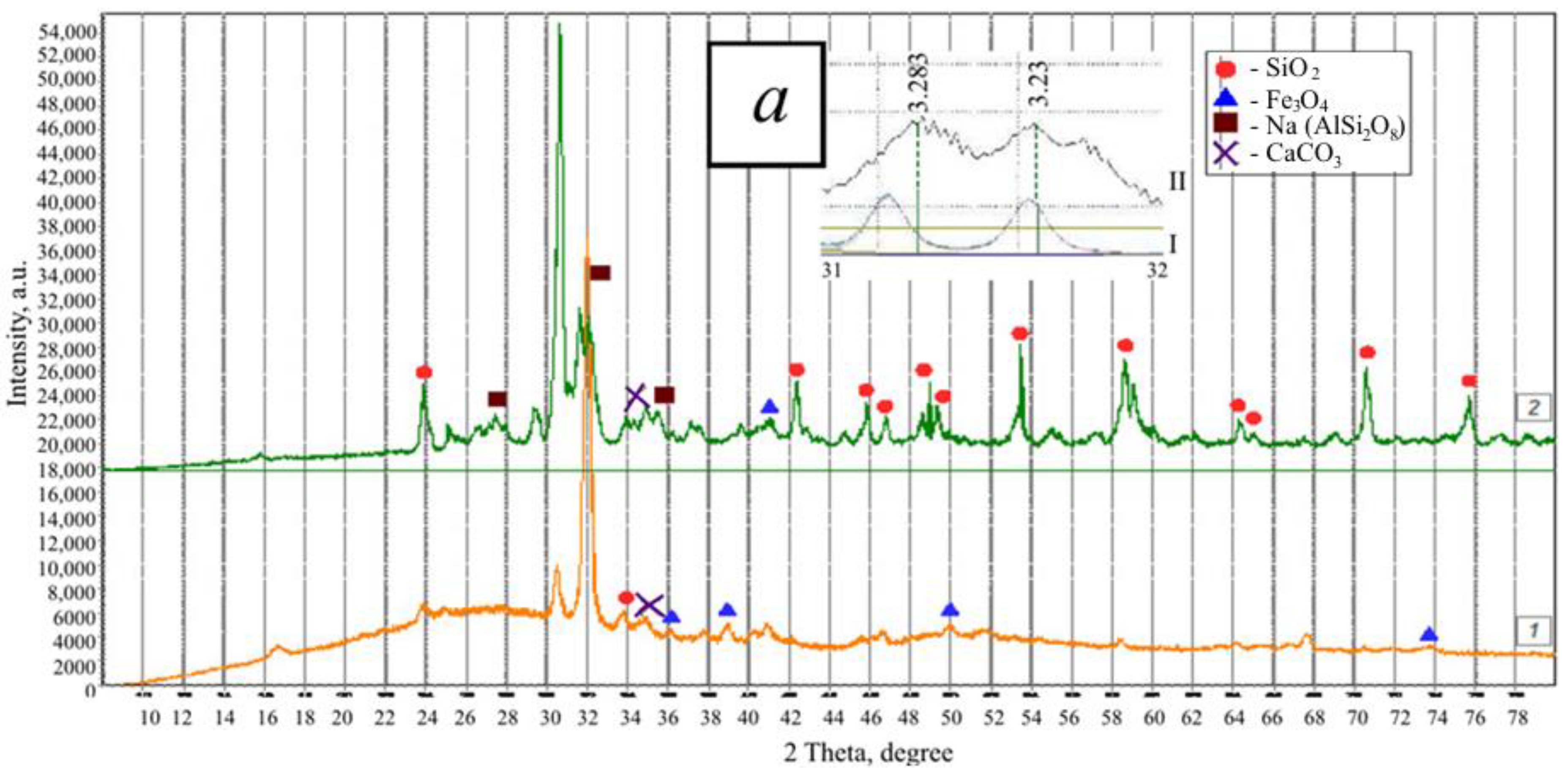

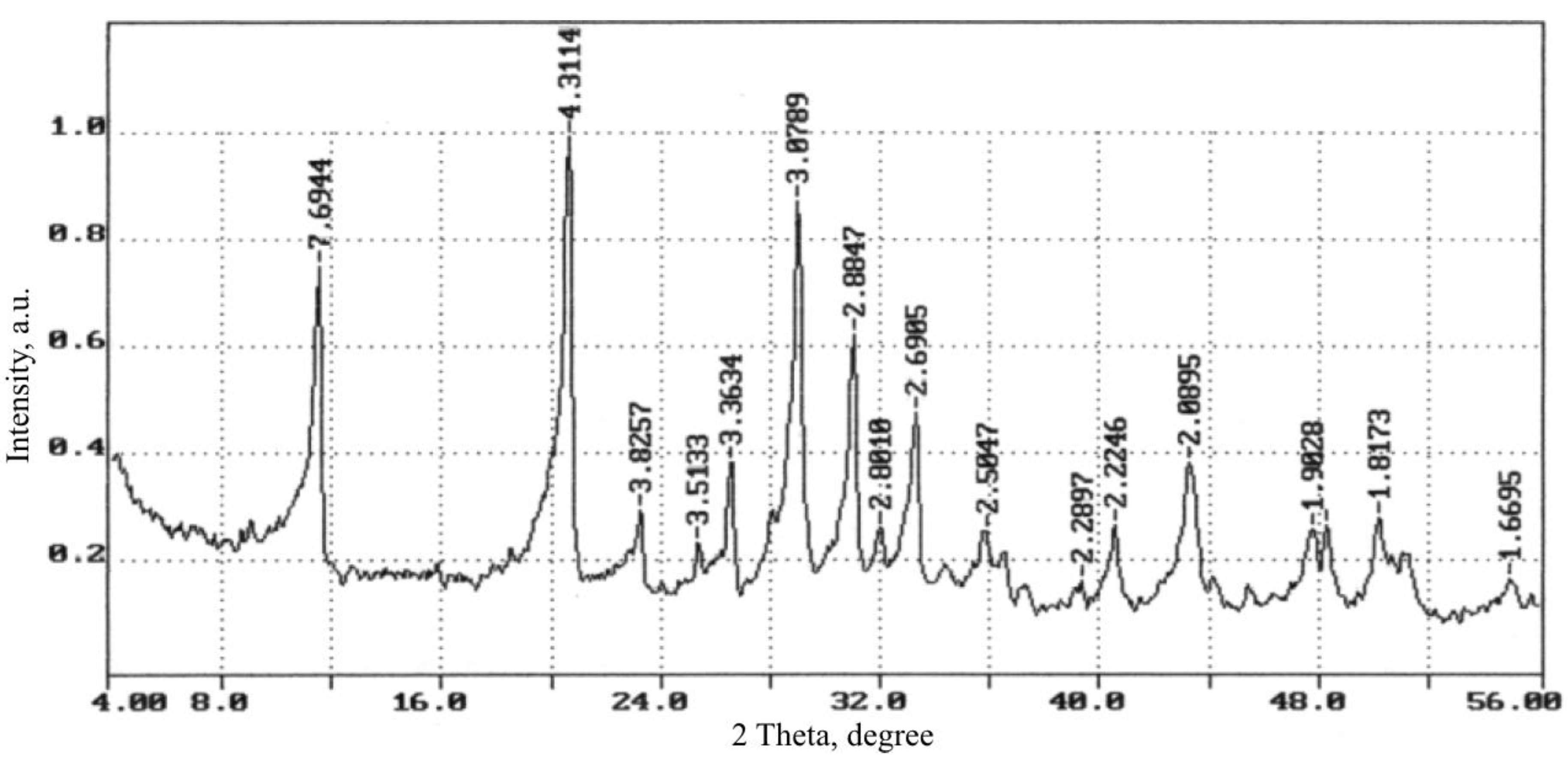

3, respectively. According to the XRD data (

Figure 2), the fly ash of the Grozny TPP consists of two modifications of quartz (d = 3.403, 3.247 A), magnetite Fe

3O

4 (d = 2.987, 2.600, 2.119, 1.493 A), calcite CaCO

3 (d = 3.081 A), calcium-iron silicate CaFeSi

2O

6. The excess of the background in the region of 20–40° is mainly due to the high iron content.

Mostly (up to 95%) glass phase is present in the slag. The crystalline phase is represented by albite, NaAl-silicates and Al-silicates, several different modifications of quartz, which differ from the natural modifications by the crystal lattice parameters (d = 4.327, 4.106, 3.386, 3.283, 2.477, 2.351, 2.255, 2.140, 1.990, 1.788, 1.681, 1.660, 1. 549, 1.458 A), which is associated with its technogenic origin. The XRD pattern contains peaks of two fairly strong varieties of silicate (albite and anorthoclase K, Na (AlSi

3O

8) (d = 3.888, 3.283, 3.23, 2.983 A), except in addition, there are peaks of mica-hydronosodium aluminosilicates (d = 3.527), magnetite Fe

3O

4 (d = 3.00, 2.55 A) and calcite CaCO

3 (d = 3.03, 3.065 A). In the range of 31–32°, the interplanar spacings of sodium aluminum silicates are broadened (AlSi

3O

8), and there is also a significant background increase under these interplanar distances (d = 3.383–3.23 A), which indicates the partial presence of their amorphized state (a in

Figure 2). As a result of calculations based on the maximum intensity of interplanar distances, of minerals SiO

2 and K, Na (AlSi

3O

8) and the background value, it was found that the content of crystalline SiO

2 is 56.9%, amorphous SiO

2—3.7%, amorphous K, Na (AlSi

3O

8)—39.4%.

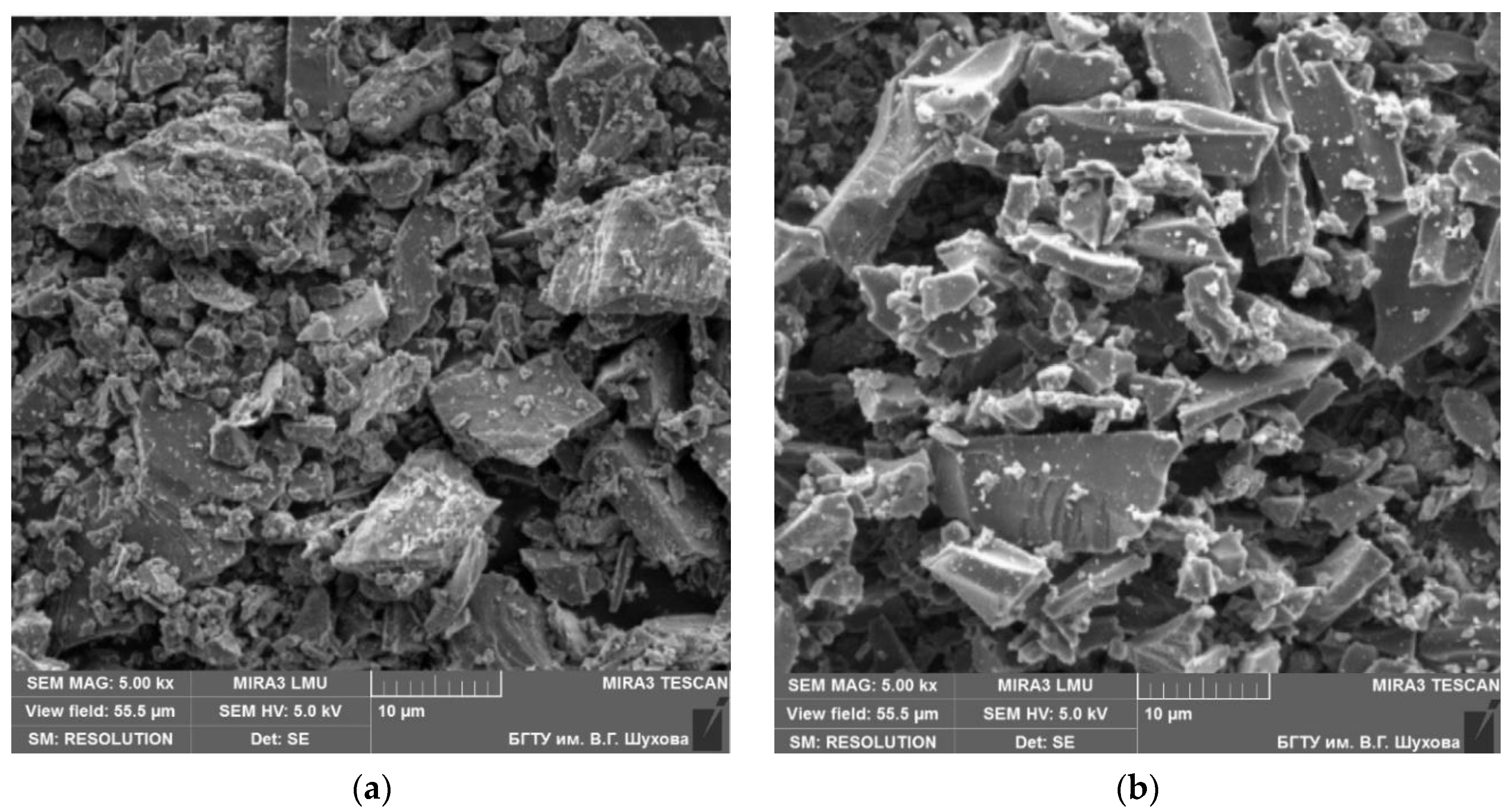

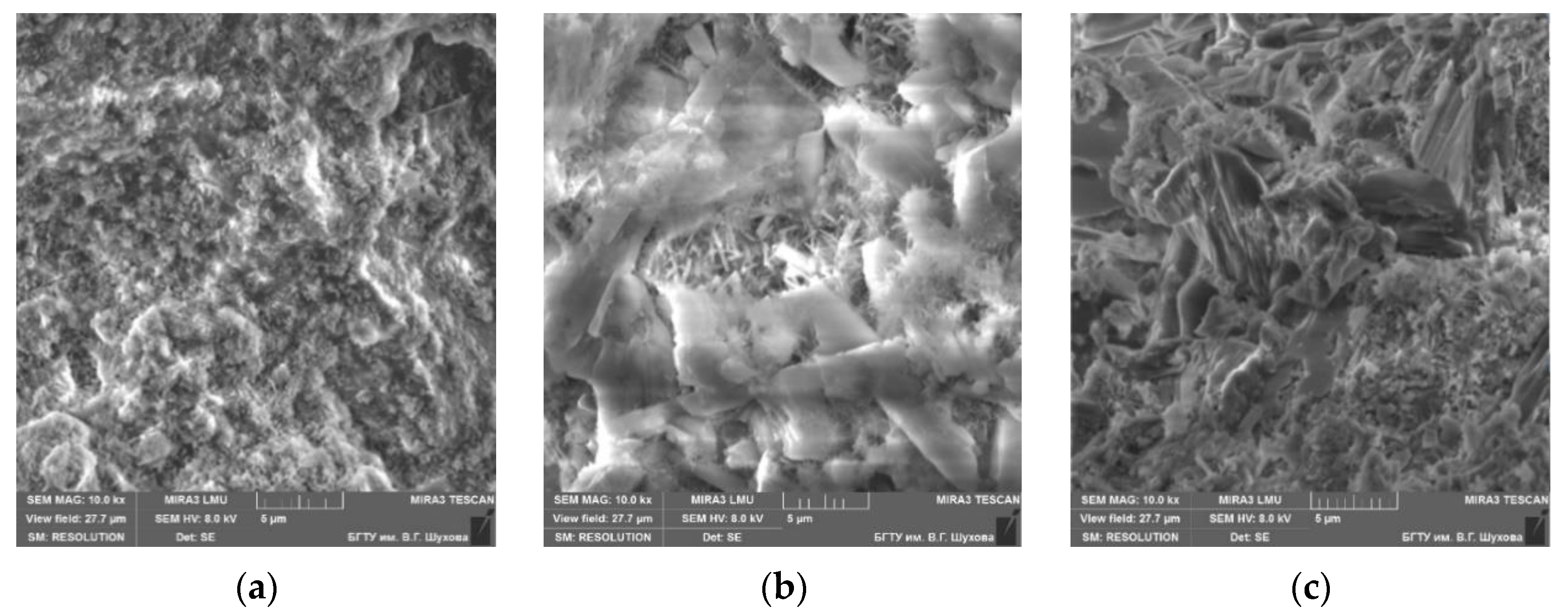

Thus, both in fly ash and in slag, a large number of X-ray amorphous phases are noted. This characterizes the pozzolanic activity necessary for the binding of calcium hydroxide released during the hydration of clinker minerals into secondary hydrosilicates of calcium. The slag particles are layered and consist of dense glassy particles of various sizes of cubic or rounded shape (

Figure 3a).

Most of the ash consists of porous glassy particles of various sizes, which have a lamellar, irregular, and angular shape (

Figure 3b). Porous, relatively large particles with a concave surface are observed, as well as small particles of a flaky structure. The chemical compositions of the used Portland cement, fly ash, and slag are listed in

Table 3.

To improve the rheology, the superplasticizer SP Melment F10 (BASF, Ludwigshafen, Germany) with a bulk density of 550 kg/m

3 was used. It is optimized to plasticize and reduce water consumption for cement-gypsum mixtures. High modulus basalt and low modulus polyamide fibers were used for micro reinforcing (

Table 4). Basalt and polyamide fibers have a density of 2800 and 1100 kg/m

3, respectively. They are chopped thin fibers with a length of about 10 mm and a diameter of 30–100 µm.

2.2. Laboratory Equipment and Research Methods

The ARL X’TRA device (Thermo Fisher Scientific, Waltham, MA, USA) was used for the X-ray diffraction analysis. The microstructure of raw materials and synthesized composites were studied using a Tescan Mira 3 electron microscope (Brno, Czech), which allows not only to obtain SEM images, but also to carry out X-ray fluorescence analysis.

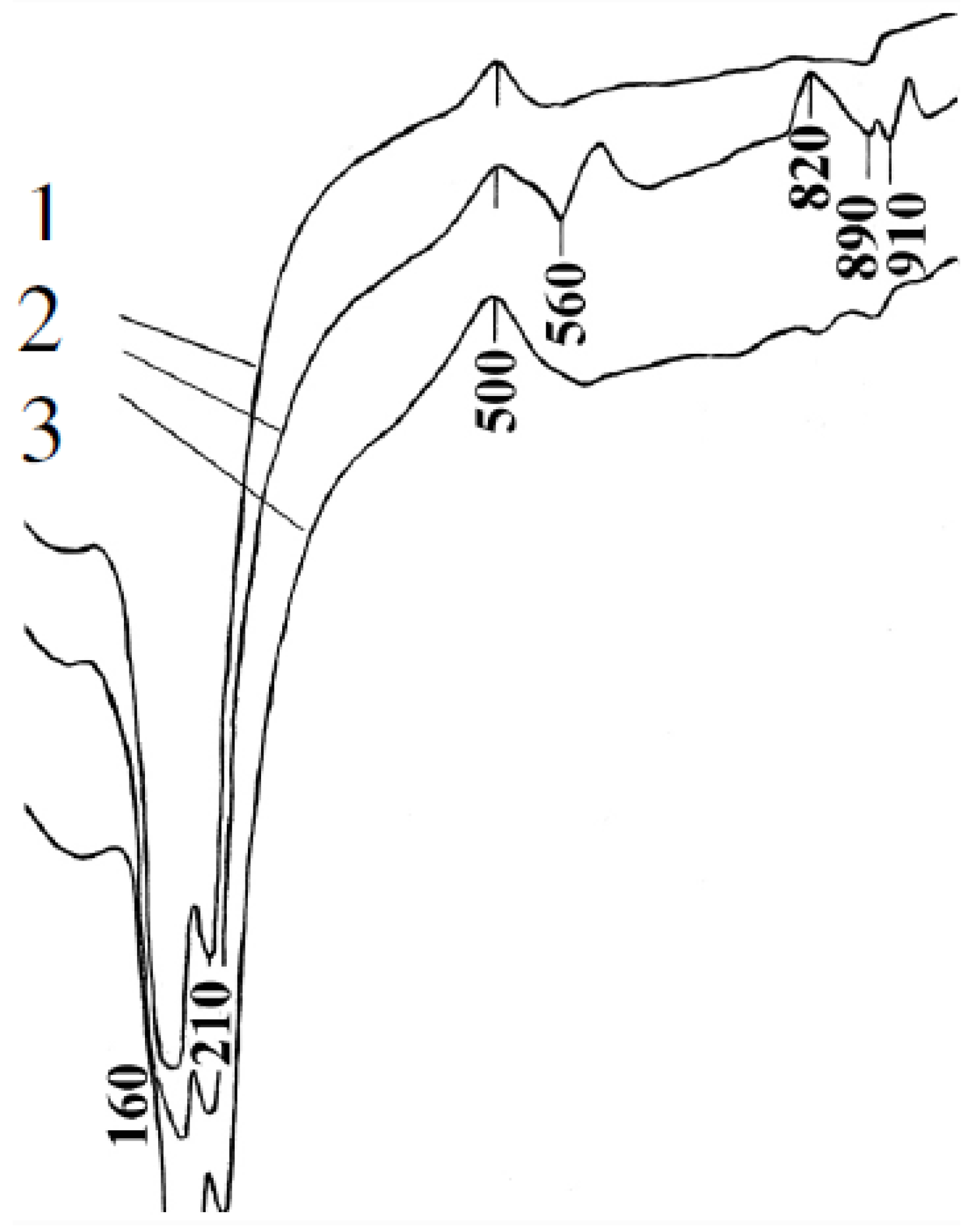

Studies of the composition of hydration products by differential-thermal analysis (DTA) at the age of 28 days were carried out on by the Q600 synchronous thermal analyzer (SDT, Waltham, MA, USA).

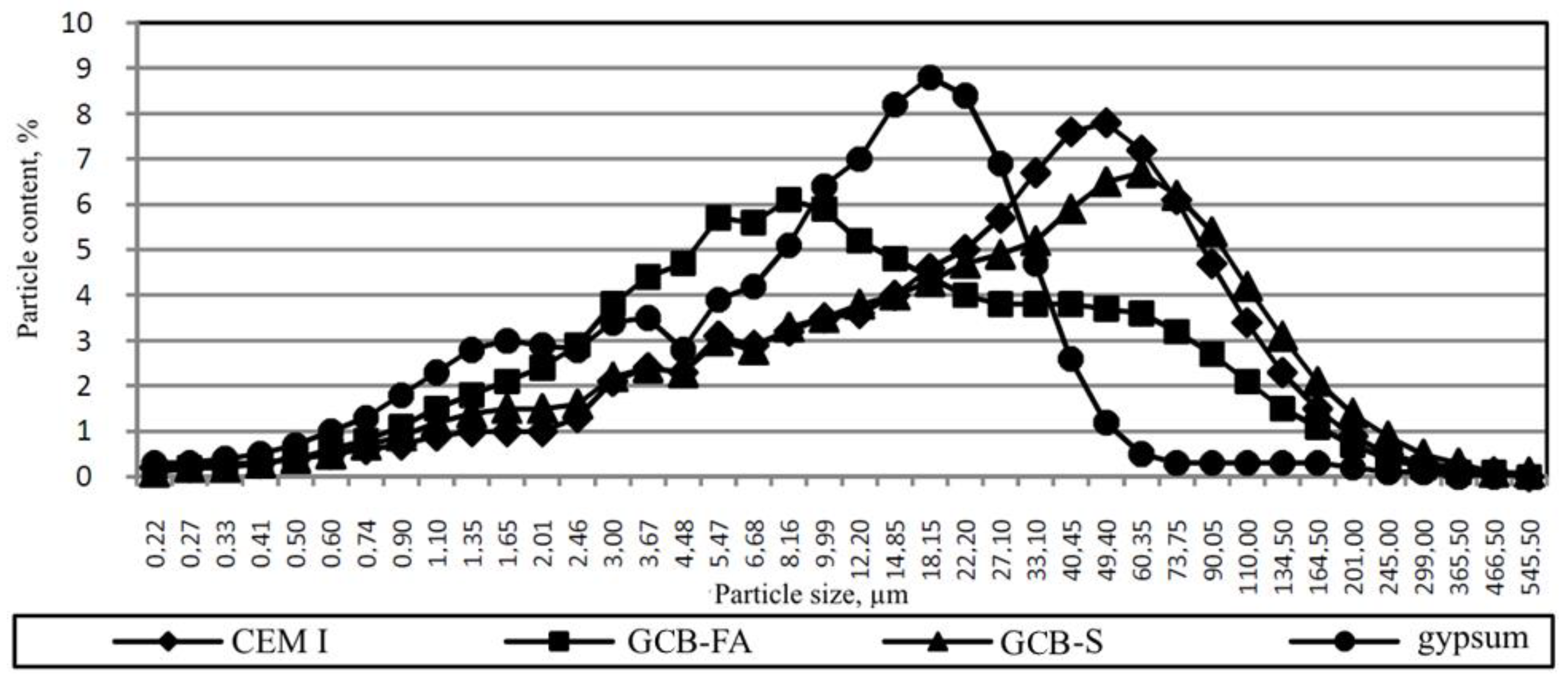

The binder components were ground in a LSM ball mill (Moscow, Russia). The specific surface area of the powders was determined on a PSH-2 device (Moscow, Russia). The BET (Brunauer Emmett Teller) area was determined on a Sorbi-M device(Moscow, Russia). Particle size distribution was performed on a MicroSizer 201 device (Moscow, Russia).

The determination of a standard consistency and setting time of the gypsum-cement paste was carried out using the Vik device (Moscow, Russia).

The slump flow of the paste of standard consistency should correspond to 120 ± 5 mm.

To study the physicomechanical characteristics of the obtained gypsum-cement binders, 6 specimens were molded for each composition. The determination of the compressive strength of the GCB was carried out on sample cubes measuring 100 × 100 × 100 mm3. Upon reaching the age of 2, 7, and 28 days, as well as after drying to constant weight, the specimens were tested according to EN 12,390-3:2009. Flexural strength of the GCB was determined on beams with a size of 40 × 40 × 160 mm3 after 7 and 28 days following EN 1015-11.

The softening coefficient was determined as the ratio of the compressive strength of water-saturated specimens to the compressive strength of dried specimens. In other words, a softening coefficient is actually a coefficient of water resistance, which for gypsum materials is one of the most important indicators of durability.

2.3. Mix Design

The preparation of mixes included 3 stages: crushing and drying of a mineral additive (1), mixing of the mineral additive with Portland cement and superplasticizer (2) and the addition of a gypsum binder with short-term grinding of the mix (3). The proportions of the mixtures are gypsum—70%, cement—15%, mineral additive—15%. The amount of superplasticizer 1% by weight of the mix. The amount of water was selected for each composition individually, taking into account the achievement of a standard consistency.

In terms of calcium oxide, the concentration of calcium hydroxide in the liquid phase of the solidifying suspension, regulated by the Russian standard TU 21-31-62-89, on days 5 and 7, respectively, should not exceed 1.1 and 0.85 g/L. For this purpose, two batches of preparations were prepared from 12 samples (6 samples each), with different amounts of mineral additives (

Table 5).

The filtered solution was titrated with 0.1 N hydrochloric acid solution in the presence of phenolphthalein. The concentration of CaO (g/L) was determined by the formula:

where

A is the amount of hydrochloric acid used for titration, mL;

T is the titer of hydrochloric acid (HCl content, g/mL);

B is the amount of the test solution, mL.

As a result of the studies carried out, the concentration of CaO in the solutions was established:

- -

with fly ash (GCB-FA): after 5 days 0.75–1.1 g/L, after 7 days 0.82–0.85 g/L with a cement/additive ratio of 1:1–1:1.5.

- -

with slag (GCB-S): after 5 days 1.04–1.1 g/L, after 7 days 0.64–0.85 g/L with a cement/additive ratio of 1:1–1:1.5.

In the technology of preparing gypsum-cement composites, uniform distribution of fiber is difficult. Therefore, fiber was introduced to the dry mixture of GCB, and then water with the superplasticizer was added, followed by continuous stirring for 5 min until a homogeneous mass was obtained.