Influence of Myrrh Extracts on the Properties of PLA Films and Melt-Spun Multifilament Yarns

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation of Myrrh Ethanolic Extract

2.3. Preparation of Myrrh Aqueous Extract

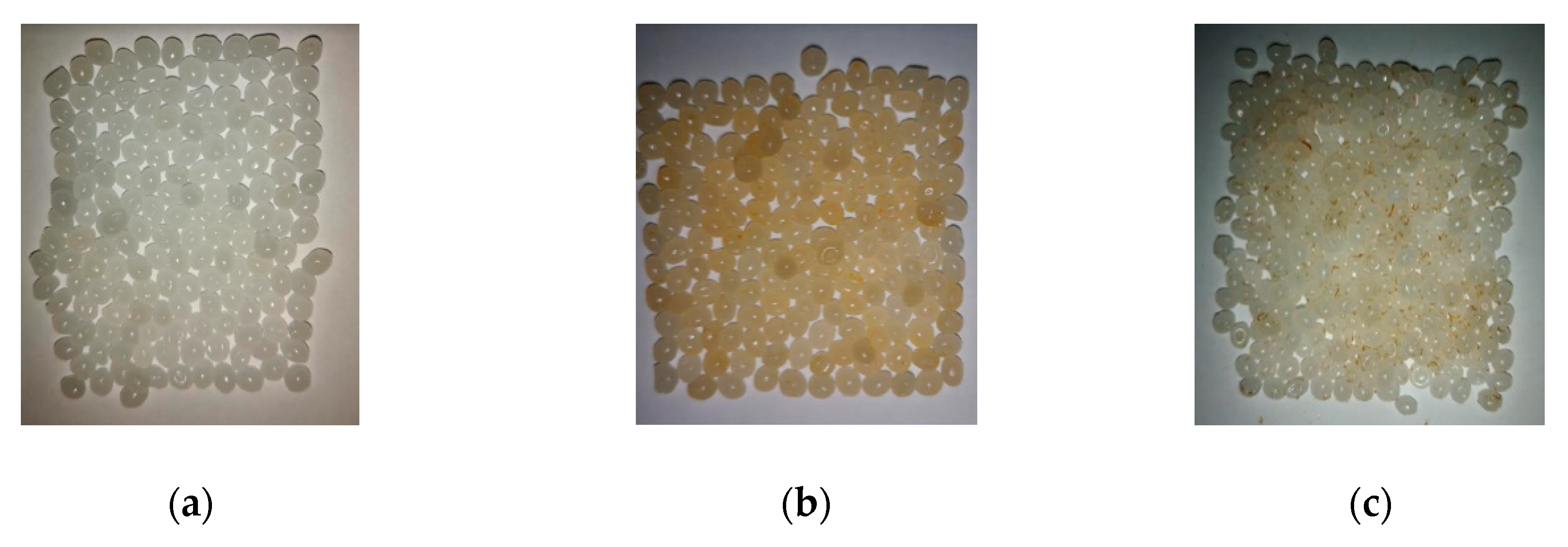

2.4. Modification of PLA Granules with Myrrh Extracts

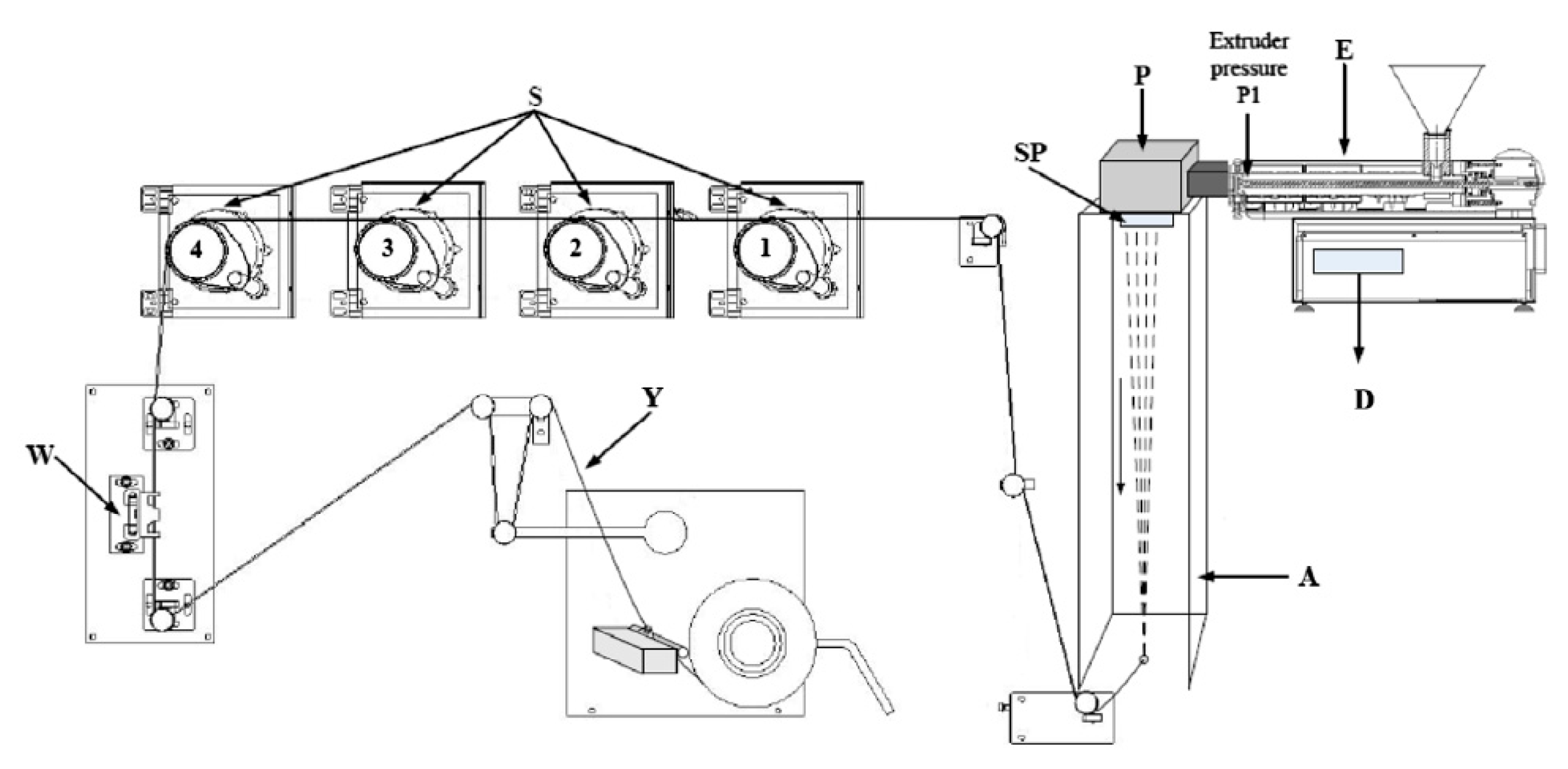

2.5. Melt Spinning of PLA Multifilament Yarns

2.6. Formation of PLA Films

2.7. Linear Density of Yarns

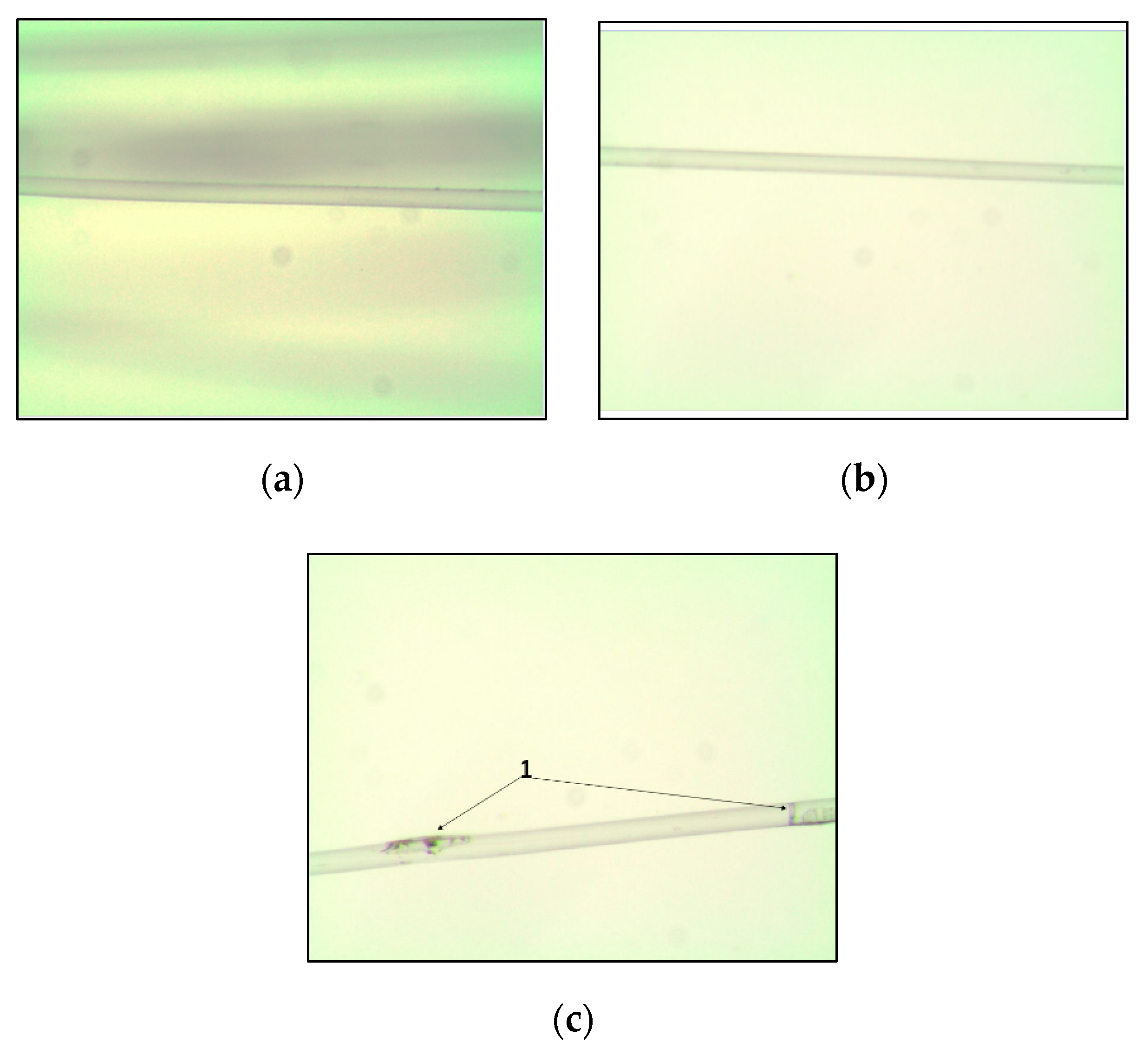

2.8. Structure of PLA Multifilament Yarns

2.9. Mechanical Properties of PLA Films and Multifilament Yarns

2.10. Optical Properties of PLA Films and Multifilament Yarns

2.11. Thermal Behavior of PLA Films and Multifilament Yarns

2.12. Chemical Interactions between PLA and Myrrh Extracts

2.13. Statistical Analysis

3. Results and Discussion

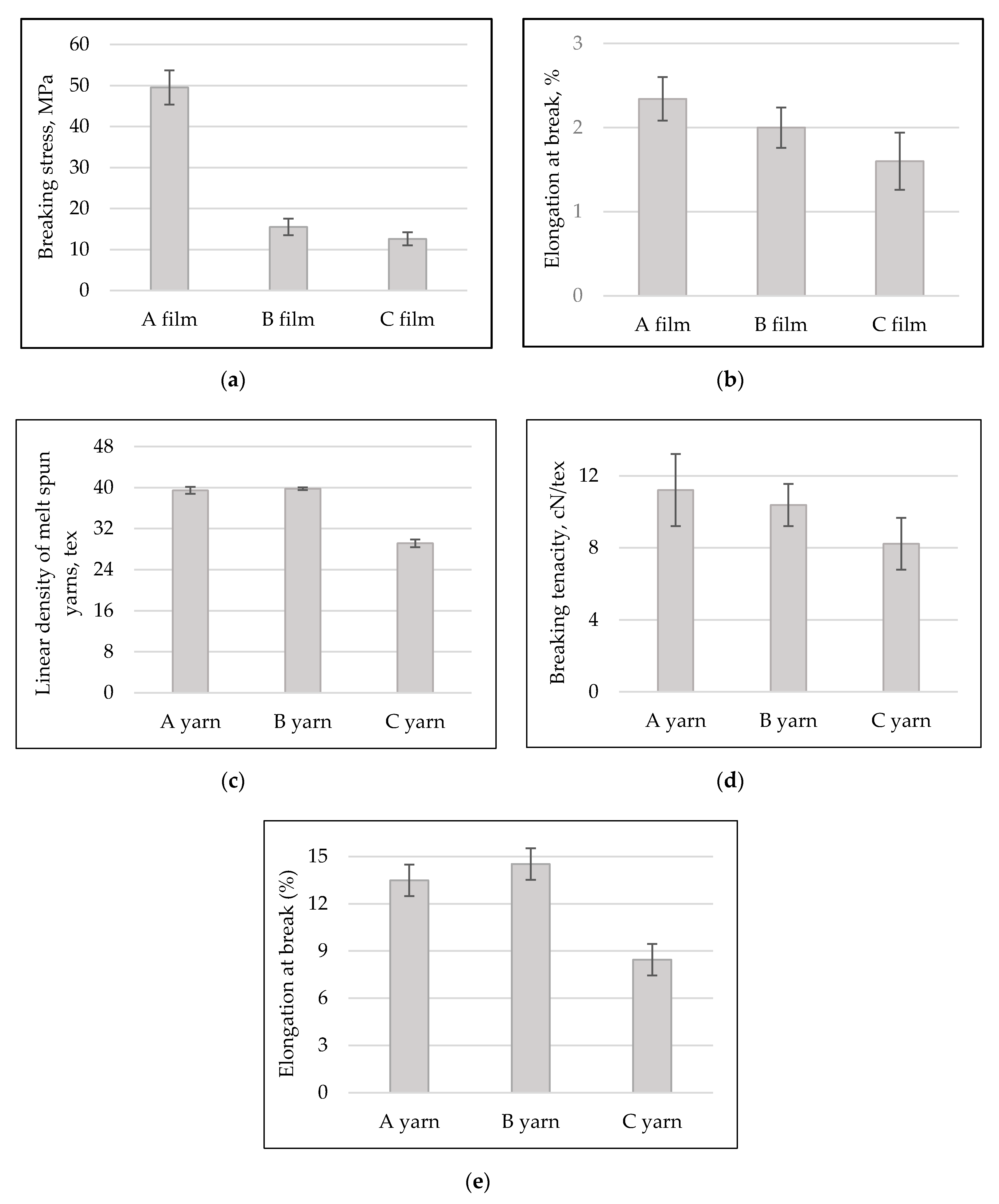

3.1. The Influence of Myrrh Extract on the Structure and Mechanical Properties of Melt-Spun PLA Multifilament Yarns

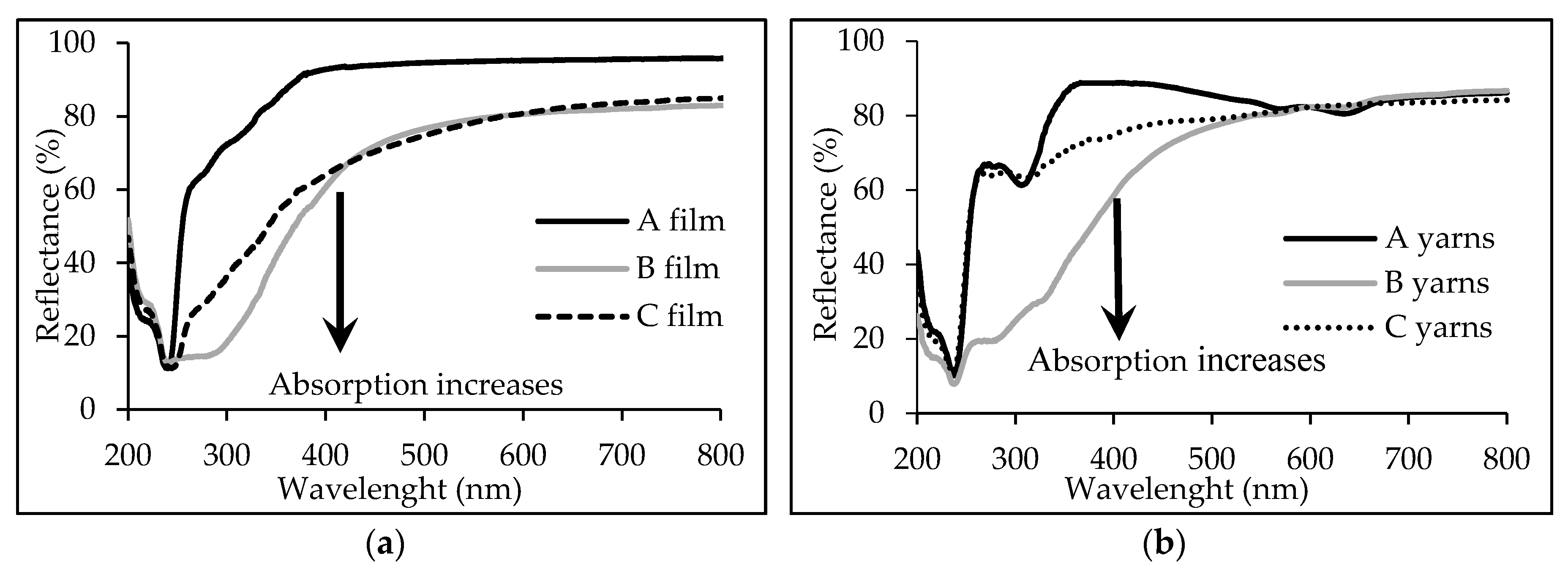

3.2. Optical Analysis of PLA Films and Melt-Spun Multifilament Yarns

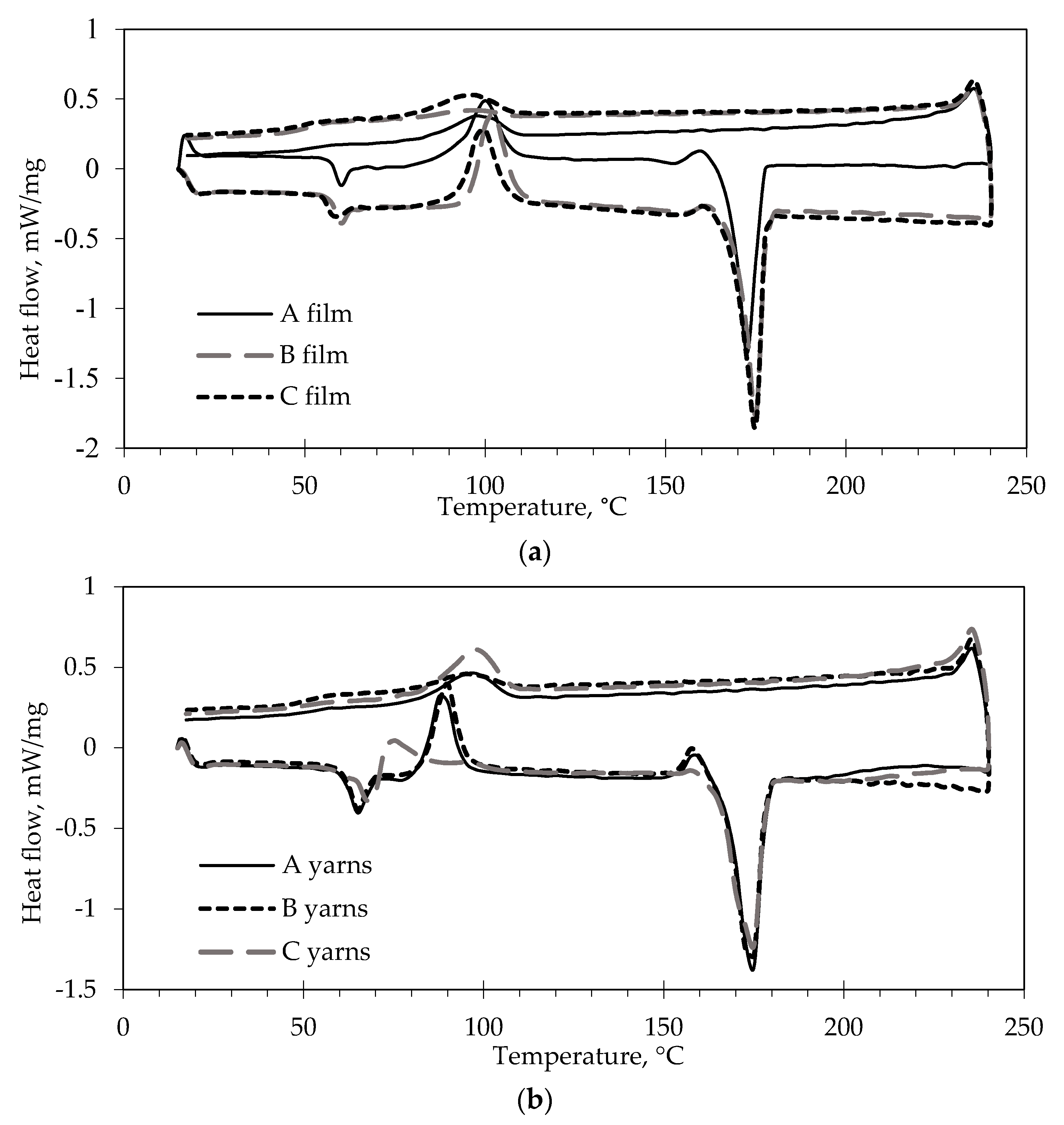

3.3. Thermal Behavior of PLA Films and PLA Melt-Spun Multifilament Yarns

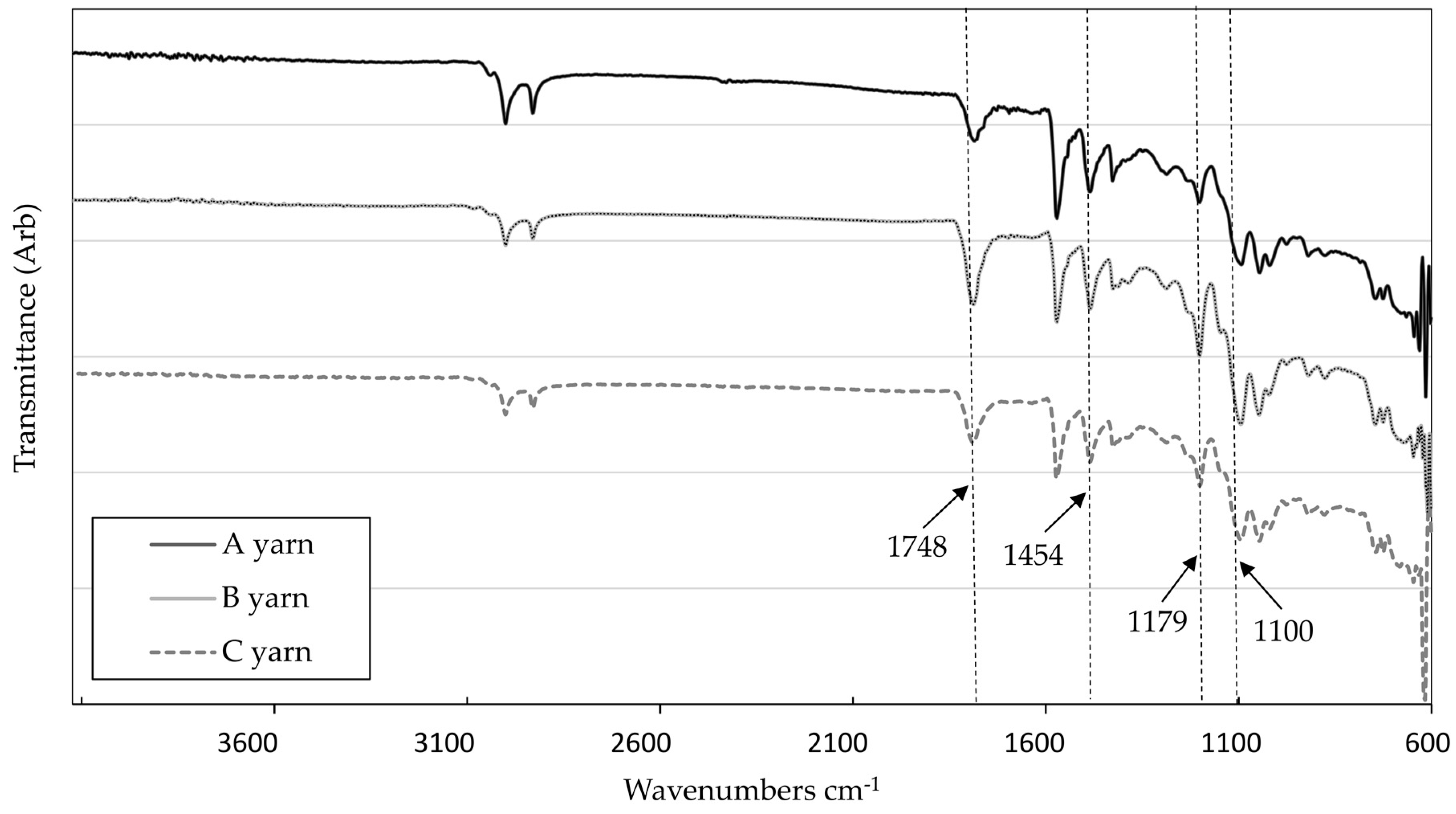

3.4. FTIR Analysis

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Shivaji, H.P.; Sonali, S.R.; Jatinder, Y. Organic-inorganic antimicrobial nanostructures for health care applications. Biomater. Tissue Eng. Bulleting 2017, 4, 66–80. [Google Scholar] [CrossRef]

- Reifler, F.A.; Hufenus, R.; Krehel, M.; Zgraggen, E.; Rossi, R.M.; Scherer, L.J. Polymer optical fibers for textile applications—bicomponent melt spinning from cyclic olefin polymer and structural characteristics revealed by wide angle X-ray diffraction. Polymer 2014, 55, 5695–5707. [Google Scholar] [CrossRef]

- Feng, X.; Vo, A.; Patil, H.; Tiwari, R.V.; Alshetaili, A.S.; Pimparade, M.B.; Repka, M.A. The effects of polymer carrier, hot melt extrusion process and downstream processing parameters on the moisture sorption properties of amorphous solid dispersions. J. Pharm. Pharmacol. 2016, 68, 692–704. [Google Scholar] [CrossRef]

- Park, S.J.; Lee, B.K.; Na, M.H.; Kim, D.S. Melt-spun shaped fibers with enhanced surface effects: Fiber fabrication, characterization and application to woven scaffolds. Acta Biomater. 2013, 9, 7719–7726. [Google Scholar] [CrossRef] [PubMed]

- Naeimirad, M.; Zadhoush, A.; Neisiany, R.S.; Salimian, S.; Kotek, R. Melt-spun PLA liquid-filled fibers: Physical, morphological, and thermal properties. J. Text. Inst. 2019, 110, 89–99. [Google Scholar] [CrossRef]

- Krikštanavičienė, K.; Stanys, S.; Jonaitienė, V. Dependence of polypropylene yarn mechanical properties on manufacturing parameters. materials science. Medziagotyra 2014, 20, 295–300. [Google Scholar] [CrossRef][Green Version]

- Kawahara, Y.; Takarada, W.; Yamamoto, M.; Kondo, Y.; Tashiro, K.; Kikutani, T. Fiber structure, tensile behavior and antibacterial activity of polylactide/poly(butylene terephthalate) bicomponent fibers produced by high-speed melt-spinning. J. Macromol. Sci. 2020, 59, 440–456. [Google Scholar] [CrossRef]

- Maqsood, M.; Langensiepen, F.; Seide, G. Investigation of melt spinnability of plasticized polylactic acid biocomposites-containing intumescent flame retardant. J. Therm. Anal. Calorim. 2020, 139, 305–318. [Google Scholar] [CrossRef]

- Yuan, X.; Mak, A.F.T.; Kwok, K.W.; Yung, B.K.O.; Yao, K. Characterization of poly (L -lactic acid) fibers produced by melt spinning. J. Appl. Polym. Sci. 2001, 81, 251–260. [Google Scholar] [CrossRef]

- Güzdemir, Ö.; Bermudez, V.; Kanhere, S.; Ogale, A.A. Melt-spun poly(lactic acid) fibers modified with soy fillers: Toward environment-friendly disposable nonwovens. Polym. Eng. Sci. 2020, 60, 1158–1168. [Google Scholar] [CrossRef]

- Mujica-Garcia, A.; Hooshmand, S.; Skrifvars, M.; Kenny, J.M.; Oksmanc, K.; Peponi, L. Poly (lactic acid) melt-spun fibers reinforced with functionalized cellulose nanocrystals. RSC Adv. 2016, 6, 9221–9231. [Google Scholar] [CrossRef]

- Doumbia, A.F.; Vezin, H.; Ferreira, M.; Campagne, C.; Devaux, E. Studies of polylactide/zinc oxide nanocomposites: Influence of surface treatment on zinc oxide antibacterial activities in textile nanocomposites. J. Appl. Polym. Sci. 2015, 132, 41776. [Google Scholar] [CrossRef]

- Wang, L.F.; Rhim, J.W. Grapefruit seed extract incorporated antimicrobial LDPE and PLA films: Effect of type of polymer matrix. LWT—Food Sci. Technol. 2016, 74, 338–345. [Google Scholar] [CrossRef]

- Ramos, M.; Jiménez, A.; Peltzer, M.; Garrigós, M.C. Development of novel nano-biocomposite antioxidant films based on poly (lactic acid) and thymol for active packaging. Food Chem. 2014, 162, 149–155. [Google Scholar] [CrossRef] [PubMed]

- Qin, Y.; Li, W.; Liu, D.; Yuan, M.; Li, L. Development of active packaging film made from poly (lactic acid) incorporated essential oil. Prog. Org. Coat. 2017, 103, 76–82. [Google Scholar] [CrossRef]

- Llana-Ruiz-Cabello, M.; Pichardo, S.; Bermúdez, J.M.; Baños, A.; Núñez, C.; Guillamón, E.; Aucejo, S.; Cameán, A.M. Development of PLA films containing oregano essential oil (Origanum vulgare L. virens) intended for use in food packaging. Food Addit. Contam. Part A 2016, 33, 1374–1386. [Google Scholar] [CrossRef]

- Ahmed, J.; Mulla, M.Z.; Arfat, Y.A. Thermo-mechanical, structural characterization and antibacterial performance of solvent casted polylactide/cinnamon oil composite films. Food Control 2016, 69, 196–204. [Google Scholar] [CrossRef]

- Adomavičiūtė, E.; Baltušnikaitė-Guzaitienė, J.; Juškaitė, V.; Žilius, M.; Briedis, V.; Stanys, S. Formation and characterization of melt-spun polypropylene fibers with propolis for medical applications. J. Text. Inst. 2018, 109, 278–284. [Google Scholar] [CrossRef]

- Bhouri, N.; Debbabi, F.; Snoussi, M.; Abdessalem, S.B. Exploitation of essential oil extracted from Tunisian Laurus nobilis for the development of PET antibacterial sutures. J. Text. Inst. 2018, 109, 1282–1292. [Google Scholar] [CrossRef]

- Kanerva, M.; Puolakka, A.; Takala, T.M.; Elert, A.M.; Mylläri, V.; Jönkkäri, I.; Sarlin, E.; Seitsonen, J.; Roukolainen, J.; Saris, P.; et al. Antibacterial polymer fibres by rosin compounding and melt-spinning. Mater. Today Commun. 2019, 20, 100527. [Google Scholar] [CrossRef]

- Al Alamoudi, H.A.A.; Salem, A.A. Application of myrrh extract as an eco-friendly dye and antimicrobial agent on wool and silk fabrics part 1: Dyeing with myrrh extract. J. Nat. Fibers 2019, 16, 1006–1014. [Google Scholar] [CrossRef]

- El-Sherbiny, I.M.; Salih, E.; Reicha, F.M. Green synthesis of densely dispersed and stable silver nanoparticles using myrrh extract and evaluation of their antibacterial activity. J. Nanostructure Chem. 2013, 3, 8. [Google Scholar] [CrossRef]

- Auda, S.H.; Salem-Bekhit, M.M.; Alanazi, F.K.; Alsarra, I.A.; Shakeel, F. Antimicrobial evaluation of novel buccoadhesive films containing Myrrh extract. Polym. Bull 2017, 74, 4041–4054. [Google Scholar] [CrossRef]

- Alminderej, F.M. Study of new cellulosic dressing with enhanced antibacterial performance grafted with a biopolymer of chitosan and myrrh polysaccharide extract. Arab. J. Chem. 2020, 13, 3672–3681. [Google Scholar] [CrossRef]

- Ingeo™ Biopolymer 6100D Technical Data Sheet. Available online: https://www.natureworksllc.com/~/media/Files/NatureWorks/Technical-Documents/Technical-Data-Sheets/TechnicalDataSheet_6100D_fiber-melt-spinning_pdf.pdf (accessed on 15 July 2020).

- Krikštanavičienė, K.; Stanys, S.; Jonaitienė, V. Relation between mathematically simulated and experimental results of polyhidroxybutyrate-co-valerate yarns. Fibres Text. East. Eur. 2013, 6, 27–32. Available online: http://yadda.icm.edu.pl/baztech/element/bwmeta1.element.baztech-81d7583c-7470-46df-9db1-b76e7af949d2 (accessed on 24 August 2020).

- Twarowska-Schmidt, K. Influence of drawing parameters on the properties of melt spun poly(Lactic Acid) fibres. Fibres Text. East. Eur. 2012, 96, 58–63. [Google Scholar]

- Liu, S.; Wu, G.; Chen, X.; Zhang, X.; Yu, J.; Liu, M.; Zhang, Y.; Wang, P. Degradation behavior In Vitro of carbon nanotubes (CNTs)/Poly(lactic acid) (PLA) composite suture. Polymers 2019, 11, 1015. [Google Scholar] [CrossRef]

- Ali, A.; El-Dessouky, H. An insight on the process—Property relationships of melt spun polylactic acid fibers. Text. Res. J. 2019, 89, 4959–4966. [Google Scholar] [CrossRef]

- Vargas, A.F.; Orozco, V.H.; Rault, F.; Giraud, S.; Devaux, E.; López, B.L. Influence of fiber-like nanofillers on the rheological, mechanical, thermal and fire properties of polypropylene: An application to multifilament yarn. Compos. Part A Appl. Sci. Manuf. 2010, 41, 1797–1806. [Google Scholar] [CrossRef]

- Biomax® Thermal 300 Technical Datasheet. Available online: https://polymer-additives.specialchem.com/product/a-dupont-biomax-thermal-300 (accessed on 28 June 2020).

- Maqsood, M.; Seide, G. Improved thermal processing of polylactic acid/oxidized starch composites and flame-retardant behavior of intumescent non-wovens. Coatings 2020, 10, 291. [Google Scholar] [CrossRef]

- Garcia-Garcia, D.; Carbonell-Verdu, A.; Arrieta, M.P.; López-Martínez, J.; Samper, M.D. Improvement of PLA film ductility by plasticization with epoxidized karanja oil. Polym. Degrad. Stab. 2020, 179, 109259. [Google Scholar] [CrossRef]

- Hossain, K.M.Z.; Parsons, A.J.; Rudd, C.D.; Ahmed, I.; Thielemans, W. Mechanical, crystallisation and moisture absorption properties of melt drawn polylactic acid fibres. Eur. Polym. J. 2014, 53, 270–281. [Google Scholar] [CrossRef]

- Solarski, S.; Ferreira, M.; Devaux, E. Thermal and mechanical characteristics of polylactide filaments drawn at different temperatures. J. Text. Inst. 2007, 98, 227–236. [Google Scholar] [CrossRef]

- Yu, W.; Wang, X.; Ferraris, E.; Zhang, J. Melt crystallization of PLA/Talc in fused filament fabrication. Mater. Des. 2019, 182, 108013. [Google Scholar] [CrossRef]

- Sharifah, I.S.S.; Qairol, A.A.B.; Azlina, H.N.; Nor Khairusshima, M.K. Thermal, structural and mechanical properties of melt drawn cur-loaded poly(lactic acid) fibers. Procedia Eng. 2017, 184, 544–551. [Google Scholar] [CrossRef]

- Abdulbary, M. Study of turmeric plant (Curcuma longa L.) rhizomes and myrrh (Commiphora myrrha L.) gums methanolic extracts effect on Candida albicans isolated from mouth. Plant Arch. 2018, 18, 665–668. [Google Scholar]

| Code of Sample | Tg (°C) | Tc1 (°C) | Tc2 (°C) | ∆Hc (J/g) | Tcc (°C) | Tm (°C) | Crystallinity Xc (wt%) |

|---|---|---|---|---|---|---|---|

| A film | 59.8 | 100.0 | 159.6 | 27.1 | 97.7 | 173 | 28.1 |

| B film | 59.7 | 101.7 | 161.7 | 34.2 | 96 | 174.9 | 18.1 |

| C film | 58.7 | 99.2 | 160.7 | 30.3 | 96.3 | 174.5 | 27.9 |

| A yarn | 65.6 | 88.5 | 158.8 | 23.9 | 96.9 | 174.5 | 39.5 |

| B yarn | 65.3 | 89.6 | 158.1 | 25.0 | 95.3 | 174.0 | 40.4 |

| C yarn | 68.6 | 74.5 | – | 16.7 | 97.7 | 174.9 | 44.3 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bolskis, E.; Adomavičiūtė, E.; Griškonis, E.; Norvydas, V. Influence of Myrrh Extracts on the Properties of PLA Films and Melt-Spun Multifilament Yarns. Materials 2020, 13, 3824. https://doi.org/10.3390/ma13173824

Bolskis E, Adomavičiūtė E, Griškonis E, Norvydas V. Influence of Myrrh Extracts on the Properties of PLA Films and Melt-Spun Multifilament Yarns. Materials. 2020; 13(17):3824. https://doi.org/10.3390/ma13173824

Chicago/Turabian StyleBolskis, Evaldas, Erika Adomavičiūtė, Egidijus Griškonis, and Valdas Norvydas. 2020. "Influence of Myrrh Extracts on the Properties of PLA Films and Melt-Spun Multifilament Yarns" Materials 13, no. 17: 3824. https://doi.org/10.3390/ma13173824

APA StyleBolskis, E., Adomavičiūtė, E., Griškonis, E., & Norvydas, V. (2020). Influence of Myrrh Extracts on the Properties of PLA Films and Melt-Spun Multifilament Yarns. Materials, 13(17), 3824. https://doi.org/10.3390/ma13173824