Stabilized Amorphous Calcium Carbonate as a Precursor of Microcoating on Calcite

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation and Characterization of Stabilized ACC

2.3. Formation of the Coating Layers on Calcite Single Crystals

2.4. Microstructural Analysis of the Coating Layers

3. Results and Discussion

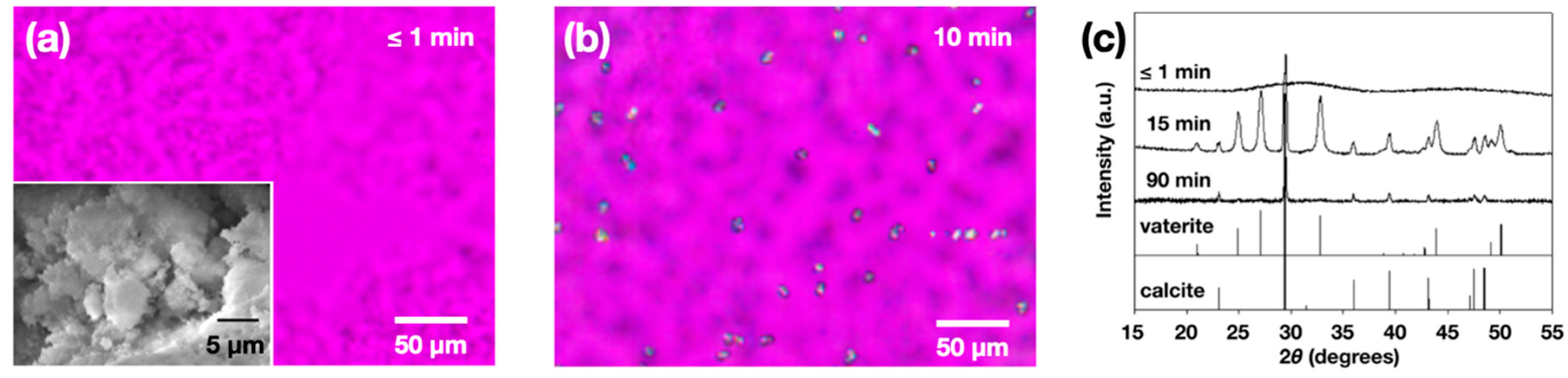

3.1. ACC Formation and Characterization

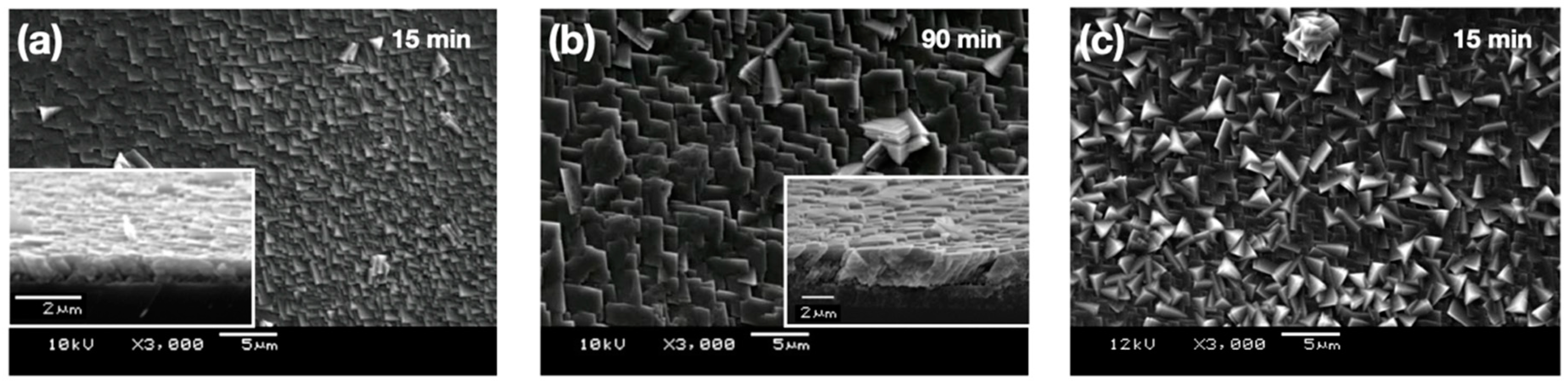

3.2. ACC on Calcite Substrates

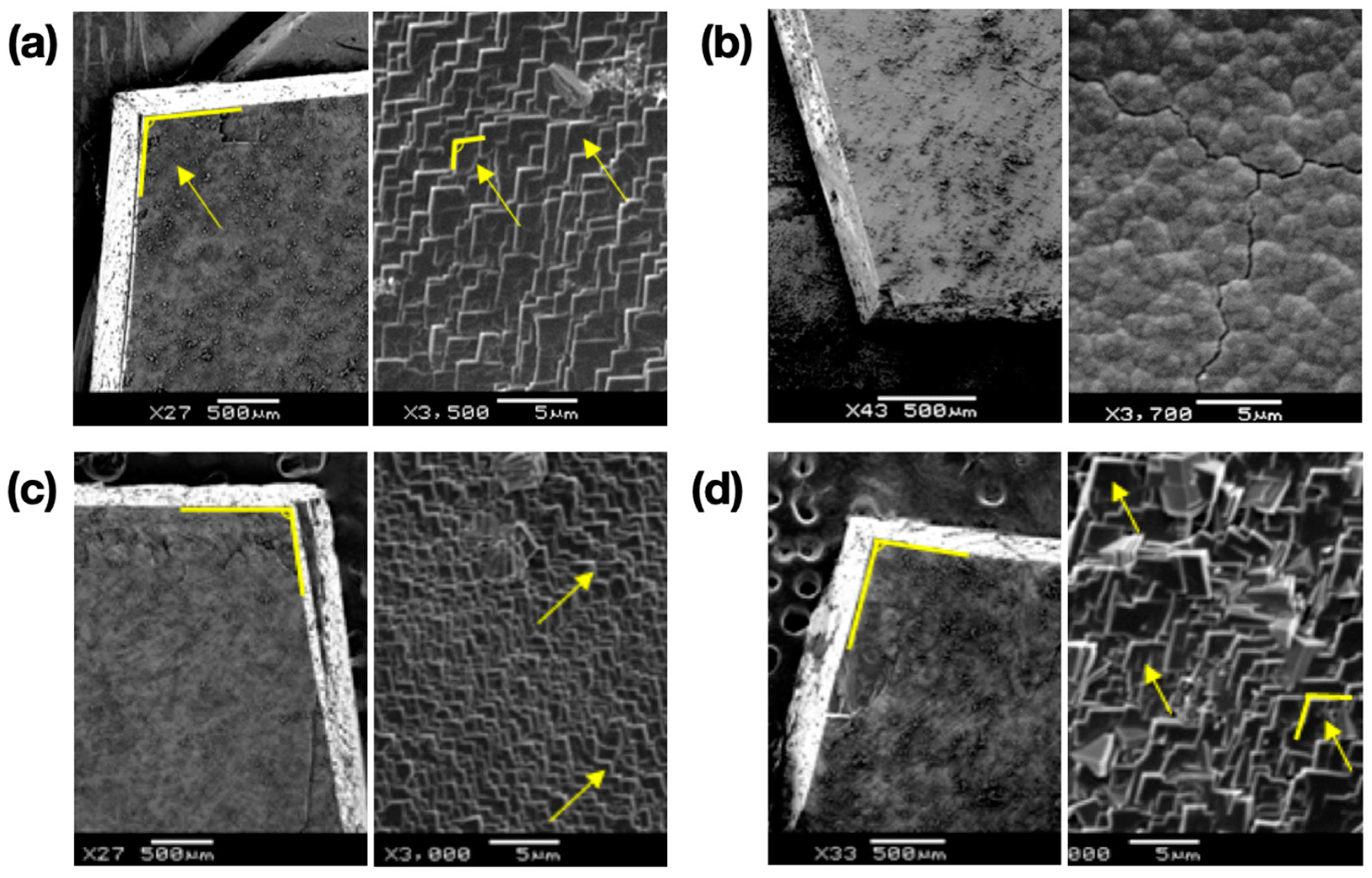

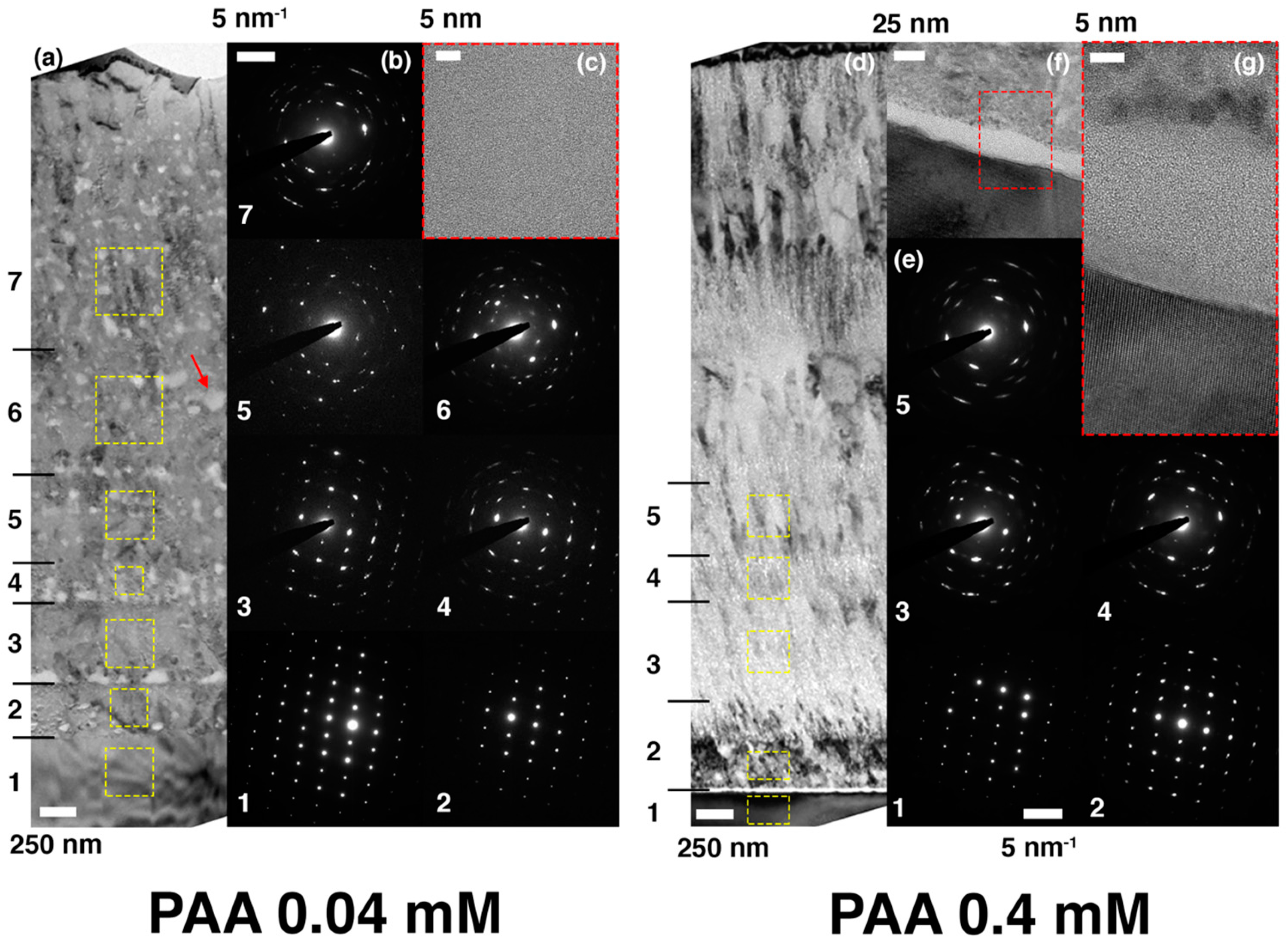

3.3. Effects of Model Macromolecules

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Matthews, F.L.; Rawlings, R.D. Composite Materials: Engineering and Science; CRC Press: Boca Raton, FL, USA, 1999; pp. 1–28. [Google Scholar]

- Lowenstam, H.A.; Weiner, S. On Biomineralization; Oxford University Press: New York, NY, USA, 1989; pp. 88–110, 135–188. [Google Scholar]

- Weiner, S.; Addadi, L. Design strategies in mineralized biological materials. J. Mater. Chem. 1997, 7, 689–702. [Google Scholar] [CrossRef]

- Bradbury, S. Hewer’s Textbook of Histology for Medical Students, 9th ed.; William Heinemann Medical Books: London, UK, 1973; pp. 274–291. [Google Scholar]

- Li, X.; Chang, W.-C.; Chao, Y.J.; Wang, R.; Chang, M. Nanoscale structural and mechanical characterization of a natural nanocomposite materials: The shell of red abalone. Nano Lett. 2004, 4, 613–617. [Google Scholar] [CrossRef]

- Li, X.; Xu, Z.-H.; Wang, R. In situ observation of nanograin rotation and deformation in nacre. Nano Lett. 2006, 6, 2301–2304. [Google Scholar] [CrossRef] [PubMed]

- Addadi, L.; Joester, D.; Nudelman, F.; Weiner, S. Mollusk shell formation: A source of new concepts for understanding biomineralization processes. Chem. Eur. J. 2006, 12, 980–987. [Google Scholar] [CrossRef]

- Mann, S. Biomineralization: Principles and Concepts in Bioinorganic Materials Chemistry; Oxford University Press: New York, NY, USA, 2001; pp. 38–124. [Google Scholar]

- Cölfen, H.; Antonietti, M. Mesocrystals and Nonclassical Crystallization; Wiley: Chichester, UK, 2008. [Google Scholar]

- Kim, Y.-Y.; Schenk, A.S.; Ihli, J.; Kulak, A.N.; Hetherington, N.B.J.; Tang, C.C.; Schmahl, W.W.; Griesshaber, E.; Hyett, G.; Meldrum, F.C. A critical analysis of calcium carbonate mesocrystals. Nat. Commun. 2014, 5, 4341. [Google Scholar] [CrossRef]

- De Yoreo, J.J.; Gilbert, P.U.P.A.; Sommerdijk, N.A.J.M.; Penn, R.L.; Whitelam, S.; Joester, D.; Zhang, H.; Rimer, J.D.; Navrotsky, A.; Banfield, J.F.; et al. Crystallization by particle attachment in synthetic, biogenic, and geologic environments. Science 2015, 349, aaa6760. [Google Scholar] [CrossRef]

- Evans, J.S. Composite materials design: Biomineralization proteins and the guided assembly and organization of biomineral nanoparticles. Materials 2019, 12, 581. [Google Scholar] [CrossRef]

- Sommerdijk, N.A.J.M.; de With, G. Biomimetic CaCO3 mineralization using designer molecules and interfaces. Chem. Rev. 2008, 108, 4499–4550. [Google Scholar] [CrossRef]

- Falini, G.; Albeck, S.; Weiner, S.; Addadi, L. Control of aragonite or calcite polymorphism by mollusk shell macromolecules. Science 1996, 271, 67–69. [Google Scholar] [CrossRef]

- Aizenberg, J.; Lambert, G.; Weiner, S.; Addadi, L. Factors involved in the formation of amorphous and crystalline calcium carbonate: A study of an ascidian skeleton. J. Am. Chem. Soc. 2002, 124, 32–39. [Google Scholar] [CrossRef]

- Orme, C.A.; Noy, A.; Wierzbicki, A.; McBride, M.T.; Grantham, M.; Teng, H.H.; Dove, P.M.; DeYoreo, J.J. Formation of chiral morphologies through selective binding of amino acids to calcite surface steps. Nature 2001, 411, 775–779. [Google Scholar] [CrossRef] [PubMed]

- Kim, I.W.; Robertson, R.E.; Zand, R. Selected polymorphs of CaCO3 through epitaxy with inorganic substrates aligned with an electric field. Adv. Mater. 2003, 15, 709–712. [Google Scholar] [CrossRef]

- Lee, H.S.; Ha, T.H.; Kim, K. Fabrication of unusually stable amorphous calcium carbonate in an ethanol medium. Mater. Chem. Phys. 2005, 93, 376–382. [Google Scholar] [CrossRef]

- Chen, S.-F.; Cölfen, H.; Antonietti, M.; Yu, S.-H. Ethanol assisted synthesis of pure and stable amorphous calcium carbonate nanoparticles. Chem. Commun. 2013, 49, 9564–9566. [Google Scholar] [CrossRef]

- Tobler, D.J.; Rodriguez-Blanco, J.D.; Dideriksen, K.; Bovet, N.; Sand, K.K.; Stipp, S.L.S. Citrate effects on amorphous calcium carbonate (ACC) structure, stability, and crystallization. Adv. Funct. Mater. 2015, 25, 3081–3090. [Google Scholar] [CrossRef]

- Gower, L.B.; Odom, D.J. Deposition of calcium carbonate films by a polymer-induced liquid-precursor (PILP) process. J. Cryst. Growth 2000, 210, 719–734. [Google Scholar] [CrossRef]

- Liu, J.; Pancera, S.; Boyko, V.; Gummel, J.; Nayuk, R.; Huber, K. Impact of sodium polyacrylate on the amorphous calcium carbonate formation from supersaturated solution. Langmuir 2012, 28, 3593–3605. [Google Scholar] [CrossRef]

- Noel, E.H.; Kim, Y.-Y.; Charnock, J.M.; Meldrum, F.C. Solid state crystallization of amorphous calcium carbonate nanoparticles leads to polymorph selectivity. CrystEngComm 2013, 15, 697–705. [Google Scholar] [CrossRef]

- Rodriquez-Blanco, J.D.; Shaw, S.; Benning, L.G. The kinetics and mechanisms of amorphous calcium carbonate (ACC) crystallization to calcite, via vaterite. Nanoscale 2011, 3, 265–271. [Google Scholar] [CrossRef]

- Koga, N.; Nakagoe, Y.; Tanaka, H. Crystallization of amorphous calcium carbonate. Thermochim. Acta 1998, 318, 239–244. [Google Scholar] [CrossRef]

- Rodriquez-Navarro, C.; Cara, A.B.; Elert, K.; Putnis, C.V.; Ruiz-Agudo, E. Direct nanoscale imaging reveals the growth of calcite crystals via amorphous nanoparticles. Cryst. Growth Des. 2016, 16, 1850–1860. [Google Scholar] [CrossRef]

- Kawano, J.; Shimobayashi, N.; Kitamura, M.; Shinoda, K.; Aikawa, N. Formation of calcium carbonate from highly supersaturated solution. J. Cryst. Growth. 2002, 237–239, 419–423. [Google Scholar] [CrossRef]

- Kim, I.W.; Robertson, R.E.; Zand, R. Effects of some nonionic polymeric additives on the crystallization of calcium carbonate. Cryst. Growth Des. 2005, 5, 513–522. [Google Scholar] [CrossRef]

- Perdikouri, C.; Putnis, C.V.; Kasioptas, A.; Putnis, A. An atomic force microscopy study of the growth of a calcite surface as a function of calcium/total carbonate concentration ratio in solution at constant supersaturation. Cryst. Growth Des. 2009, 9, 4344–4350. [Google Scholar] [CrossRef]

- Gebrehiwet, T.A.; Redden, G.D.; Fujita, Y.; Beig, M.S.; Smith, R.W. The effect of the CO32− to Ca2+ ion activity ratio on calcite precipitation kinetics and Sr2+ partitioning. Geochem. Trans. 2012, 13, 1. [Google Scholar] [CrossRef]

- Kwak, S.-Y.; DiMasi, E.; Han, Y.-J.; Aizenberg, J.; Kuzmenko, I. Orientation and Mg incorporation of calcite grown on functionalized self-assembled monolayers: A synchrotron X-ray study. Cryst. Growth Des. 2005, 5, 2139–2145. [Google Scholar] [CrossRef]

- Yu, J.; Lei, M.; Cheng, B.; Zhao, X. Effects of PAA additive and temperature on morphology of calcium carbonate particles. J. Solid. State Chem. 2004, 177, 681–689. [Google Scholar] [CrossRef]

- Yang, T.; Kim, D.; Huh, E.; Jho, J.Y.; Kim, I.W. Regulating the morphology of calcite through selective binding of polymers with carboxylic acids. Polym. Korea 2016, 40, 813–817. [Google Scholar] [CrossRef]

- Kim, H.Y.; Yang, T.; Huh, W.; Kwark, Y.-J.; Lee, Y.; Kim, I.W. The combined effects of Sr(II) and poly(acrylic acid) on the morphology of calcite. Materials 2019, 12, 3339. [Google Scholar] [CrossRef]

- Cai, G.-B.; Zhao, G.-X.; Wang, X.-K.; Yu, S.-H. Synthesis of polyacrylic acid stabilized amorphous calcium carbonate nanoparticles and their application for removal of toxic heavy metal ions in water. J. Phys. Chem. C 2010, 114, 12948–12954. [Google Scholar] [CrossRef]

- Volkmer, D.; Harms, M.; Gower, L.; Ziegler, A. Morphosynthesis of nacre-type laminated CaCO3 thin films and coatings. Angew. Chem. Int. Ed. 2005, 44, 639–644. [Google Scholar] [CrossRef] [PubMed]

- Giocondi, J.L.; El-Dasher, B.S.; Nancollas, G.H.; Orme, C.A. Molecular mechanisms of crystallization impacting calcium phosphate cements. Phil. Trans. R. Soc. A 2010, 368, 1937–1961. [Google Scholar] [CrossRef] [PubMed]

- Henisch, H.K. Crystal Growth in Gels; Pennsylvania State University Press: University Park, PA, USA, 1973. [Google Scholar]

- Schäffer, T.E.; Ionescu-Zanetti, C.; Proksch, R.; Fritz, M.; Walters, D.A.; Almqvist, N.; Zaremba, C.M.; Belcher, A.M.; Smith, B.L.; Stucky, G.D.; et al. Does Abalone nacre form by heteroepitaxial nucleation or by growth through mineral bridges? Chem. Mater. 1997, 9, 1731–1740. [Google Scholar] [CrossRef]

- Kim, R.; Kim, C.; Lee, S.; Kim, J.; Kim, I.W. In situ atomic force microscopy study on the crystallization of calcium carbonate modulated by poly(vinyl alcohol)s. Cryst. Growth Des. 2009, 9, 4584–4587. [Google Scholar] [CrossRef]

- Kislenko, V.N.; Oliynyk, L.P. Complex formation of polyethyleneimine with copper(II), nickel(II), and cobalt(II) ions. J. Polym. Sci. Part A Polym. Chem. 2002, 40, 914–922. [Google Scholar] [CrossRef]

- Kim, Y.W.; Yang, D.H.; Kim, Y.H. Preparation of electroconductive cotton fibers by polyethyleneimine pretreatment and electroless plating of copper sulfide. Polym. Korea 2020, 44, 349–358. [Google Scholar] [CrossRef]

- Rao, A.; Vásquez-Quitral, P.; Fernández, M.S.; Berg, J.K.; Sánchez, M.; Drechsler, M.; Neira-Carrillo, A.; Arias, J.L.; Gebauer, D.; Cölfen, H. pH-dependent schemes of calcium carbonate formation in the presence of alginates. Cryst. Growth Des. 2016, 16, 1349–1359. [Google Scholar] [CrossRef]

- Dhami, N.K.; Reddy, M.S.; Mukherjee, A. Biomineralization of calcium carbonates and their engineered applications: A review. Front. Microbio. 2013, 4, 314. [Google Scholar] [CrossRef]

- Snook, J.D.; Chesson, C.B.; Peniche, A.G.; Dann, S.M.; Paulucci, A.; Pinchuk, I.V.; Rudra, J.S. Peptide nanofiber–CaCO3 composite microparticles as adjuvant-free oral vaccine delivery vehicles. J. Mater. Chem. B 2016, 4, 1640–1649. [Google Scholar] [CrossRef]

- Tewes, F.; Gobbo, O.L.; Ehrhardt, C.; Healy, A.M. Amorphous calcium carbonate based-microparticles for peptide pulmonary delivery. ACS Appl. Mater. Interfaces 2016, 8, 1164–1175. [Google Scholar] [CrossRef] [PubMed]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jeon, T.; Na, Y.-E.; Jang, D.; Kim, I.W. Stabilized Amorphous Calcium Carbonate as a Precursor of Microcoating on Calcite. Materials 2020, 13, 3762. https://doi.org/10.3390/ma13173762

Jeon T, Na Y-E, Jang D, Kim IW. Stabilized Amorphous Calcium Carbonate as a Precursor of Microcoating on Calcite. Materials. 2020; 13(17):3762. https://doi.org/10.3390/ma13173762

Chicago/Turabian StyleJeon, Taeyoung, Ye-Eun Na, Dongchan Jang, and Il Won Kim. 2020. "Stabilized Amorphous Calcium Carbonate as a Precursor of Microcoating on Calcite" Materials 13, no. 17: 3762. https://doi.org/10.3390/ma13173762

APA StyleJeon, T., Na, Y.-E., Jang, D., & Kim, I. W. (2020). Stabilized Amorphous Calcium Carbonate as a Precursor of Microcoating on Calcite. Materials, 13(17), 3762. https://doi.org/10.3390/ma13173762