Percussion Drilling of Deep Holes Using Picosecond Ultrashort Pulse Laser in Ni-Based Superalloy Coated with Ceramic Thermal Barrier Coatings

Abstract

1. Introduction

2. Experiments and Samples

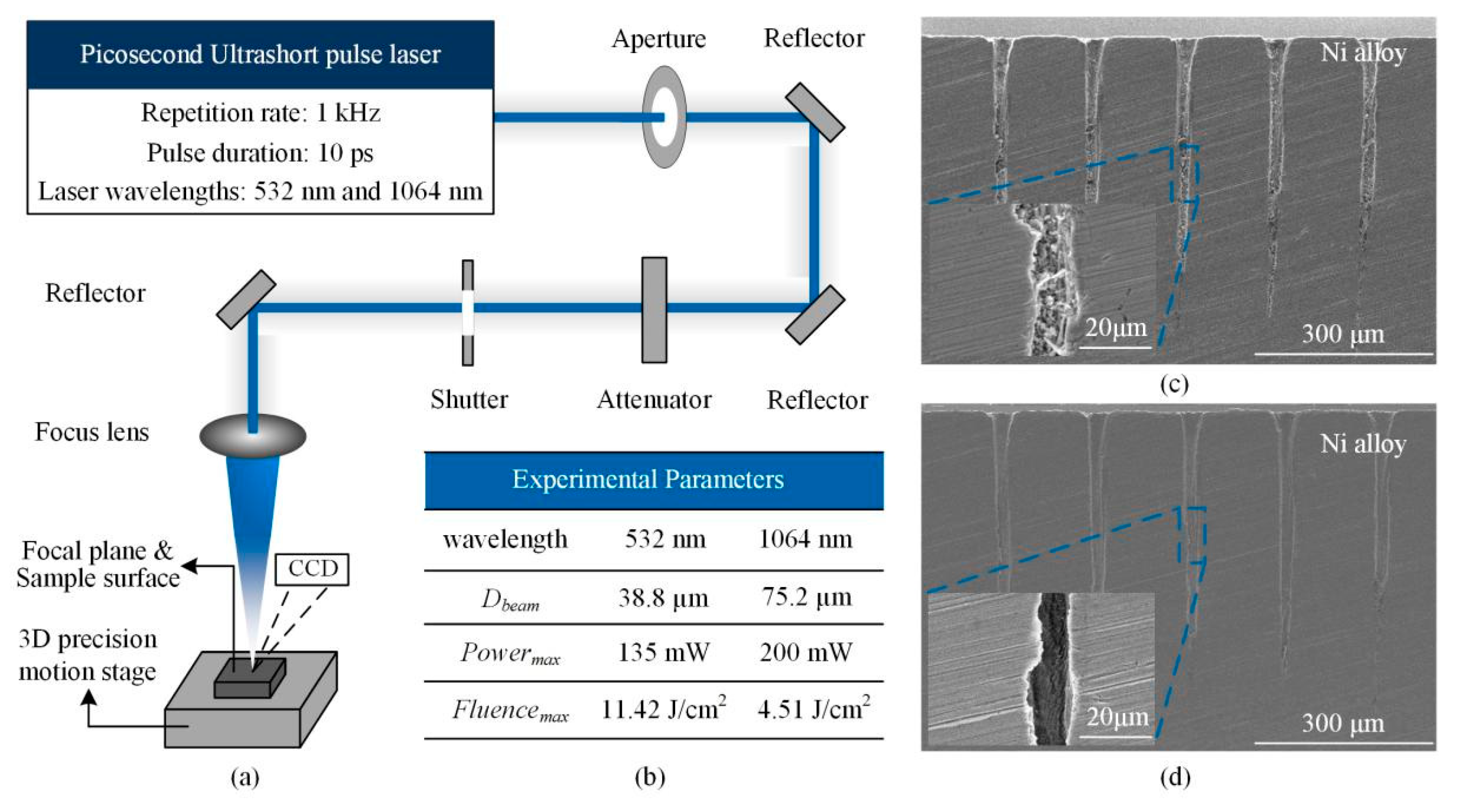

2.1. Experimental Setups and Parameters

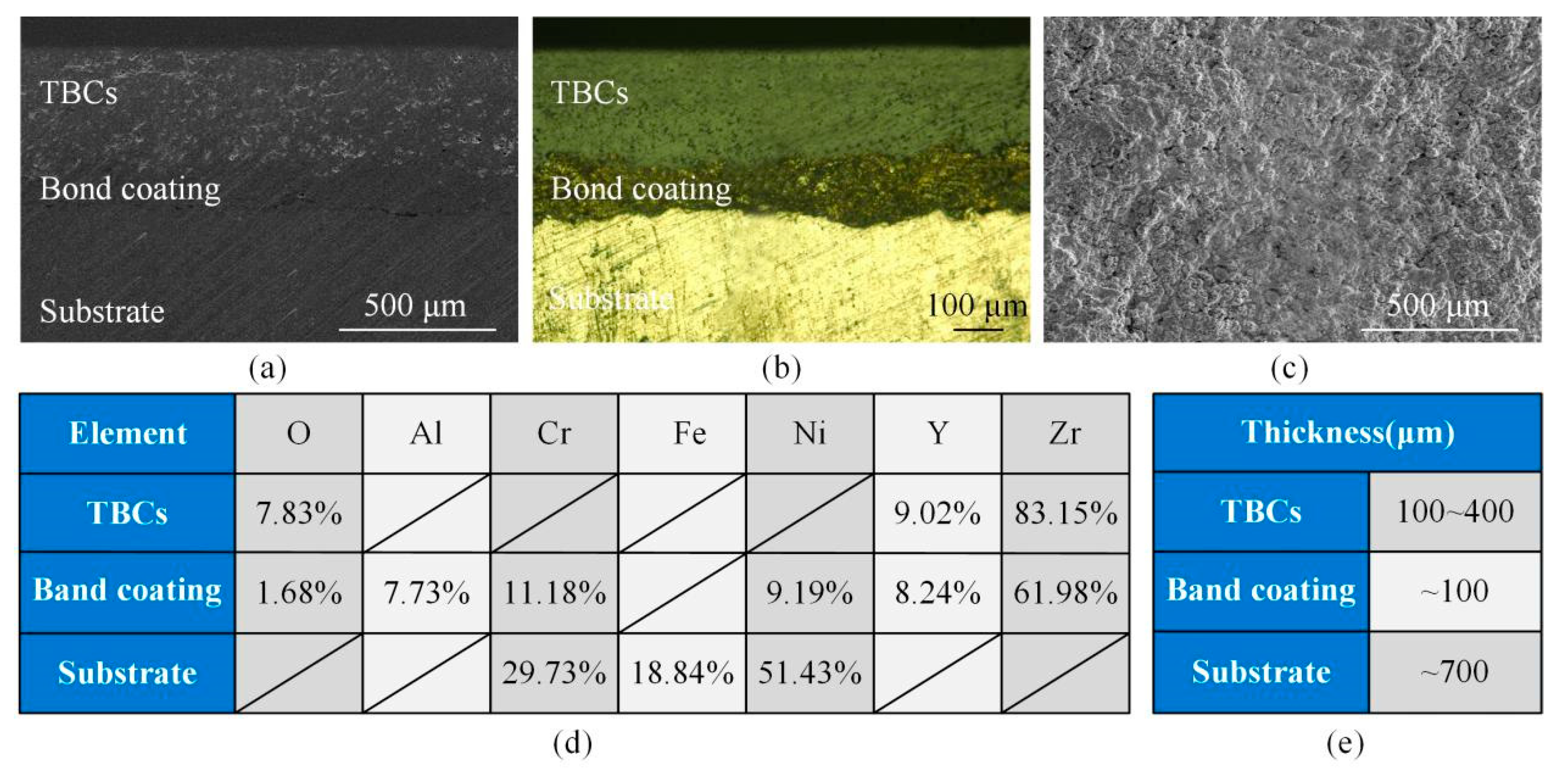

2.2. Samples

3. Results and Discussions

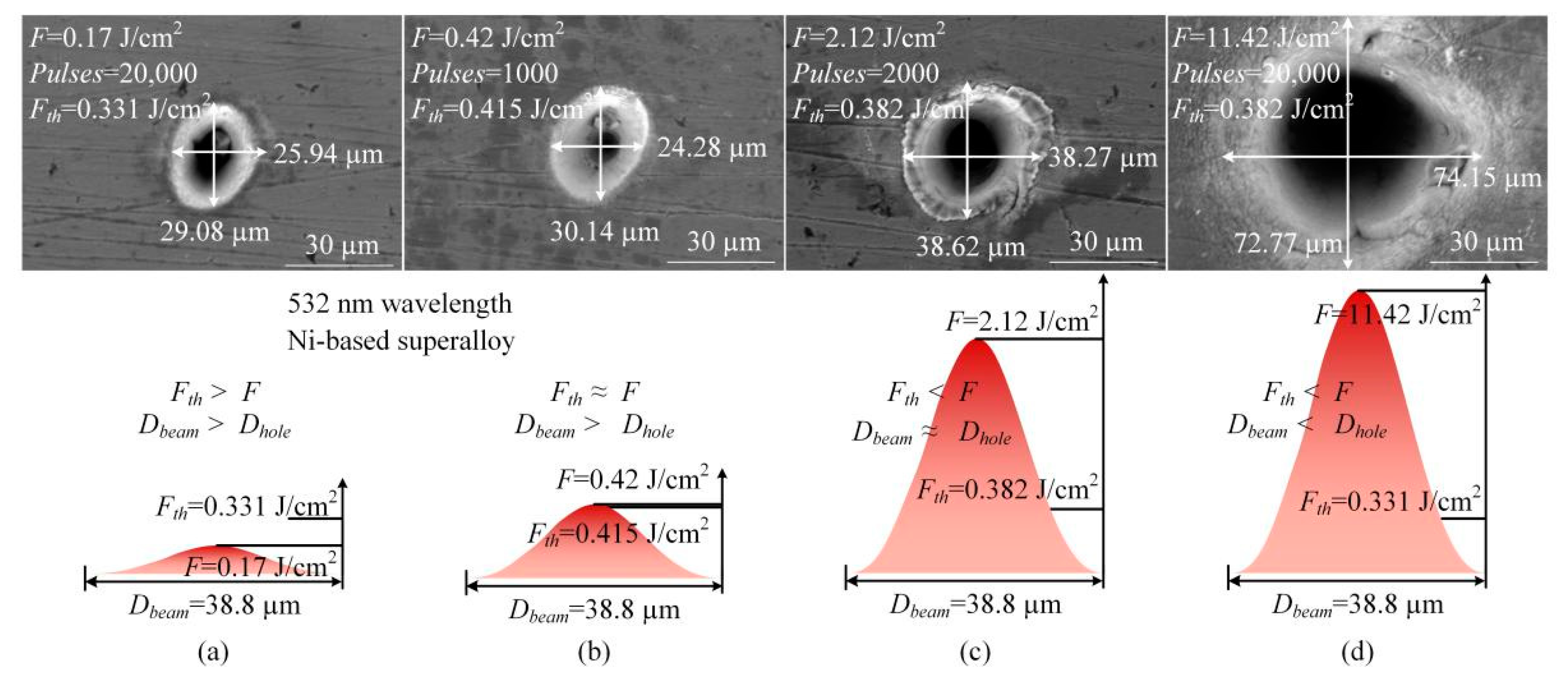

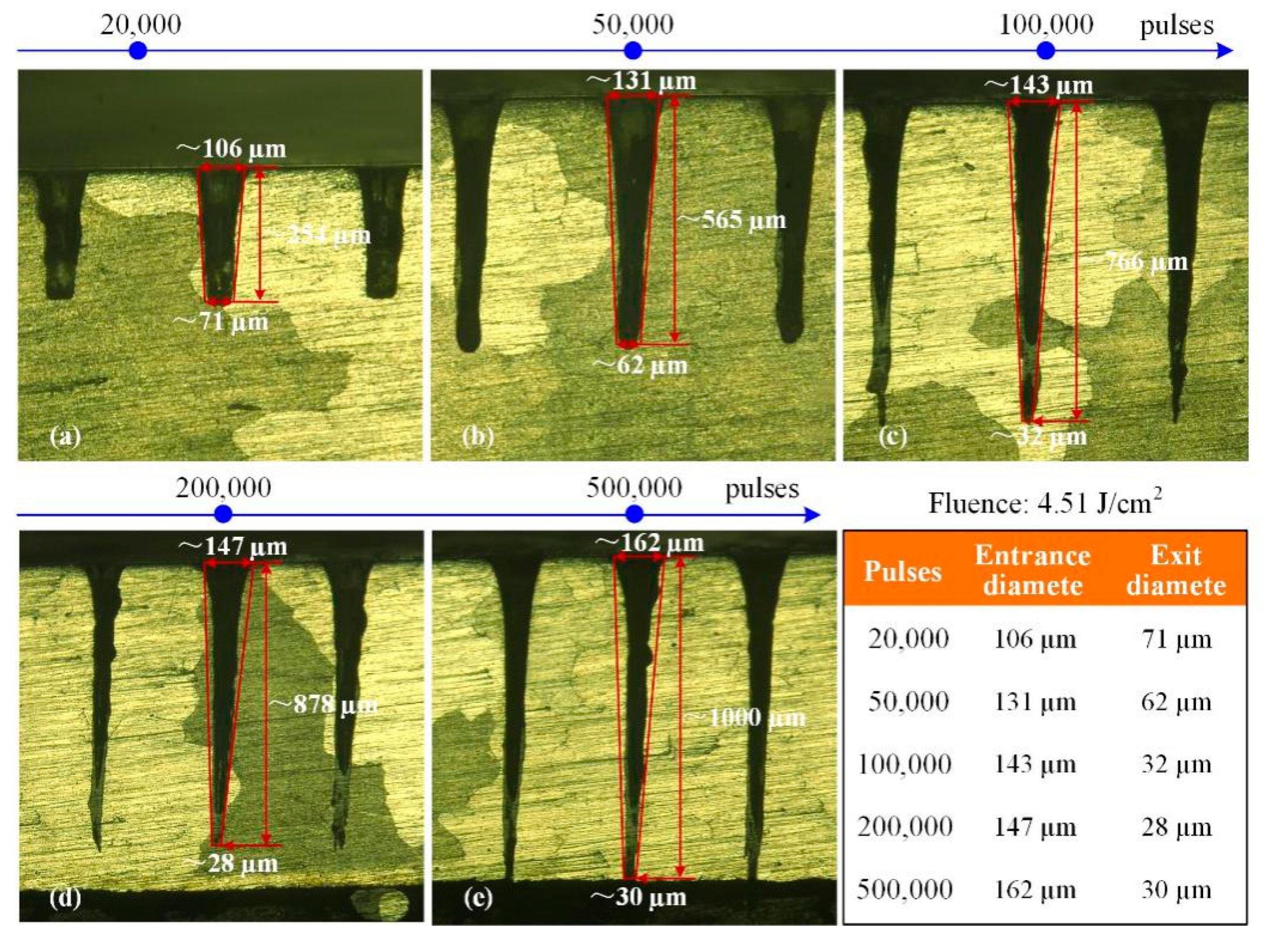

3.1. Hole Diameter Versus Pulses and Threshold of Material with 532 nm Wavelength

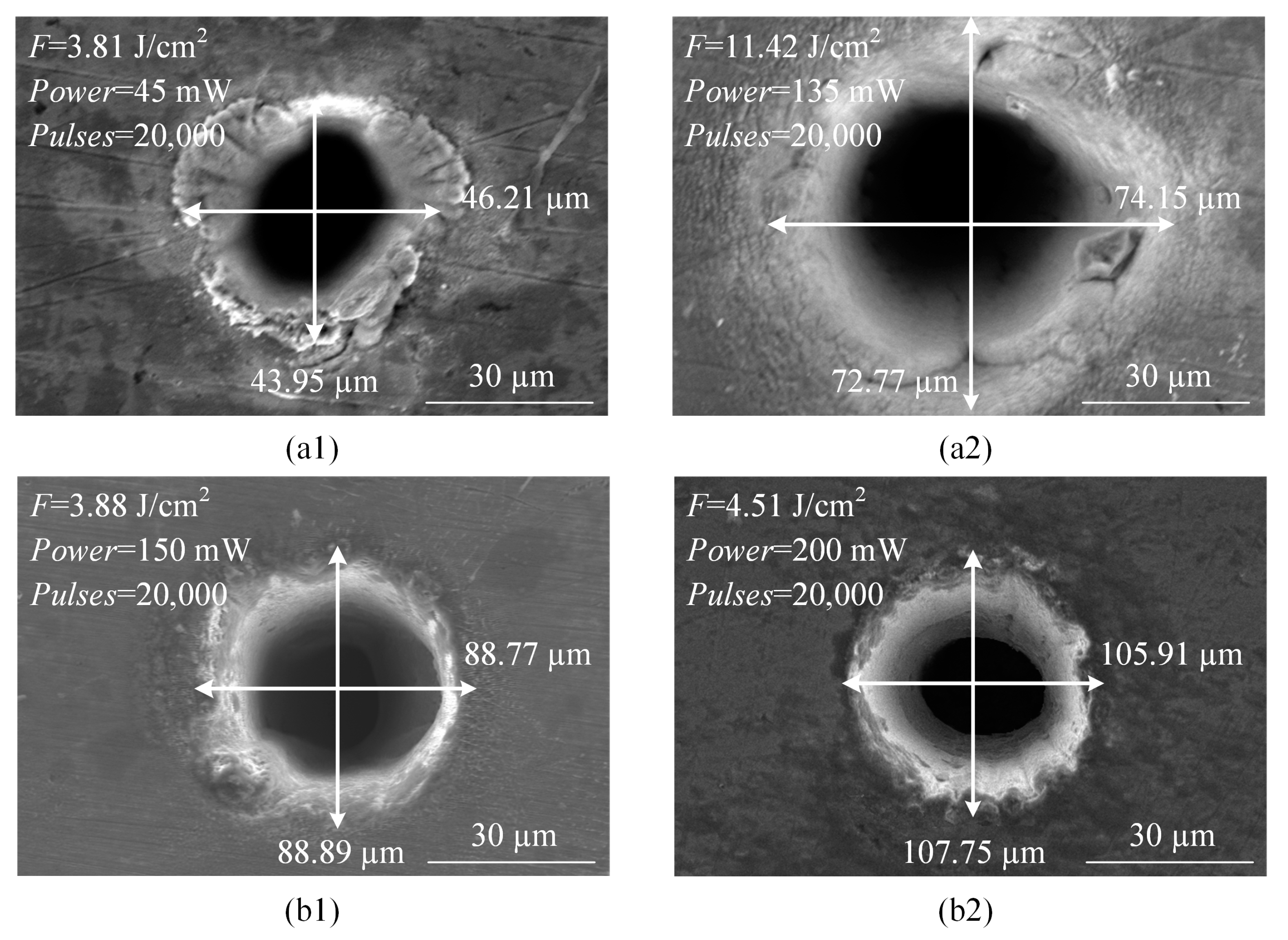

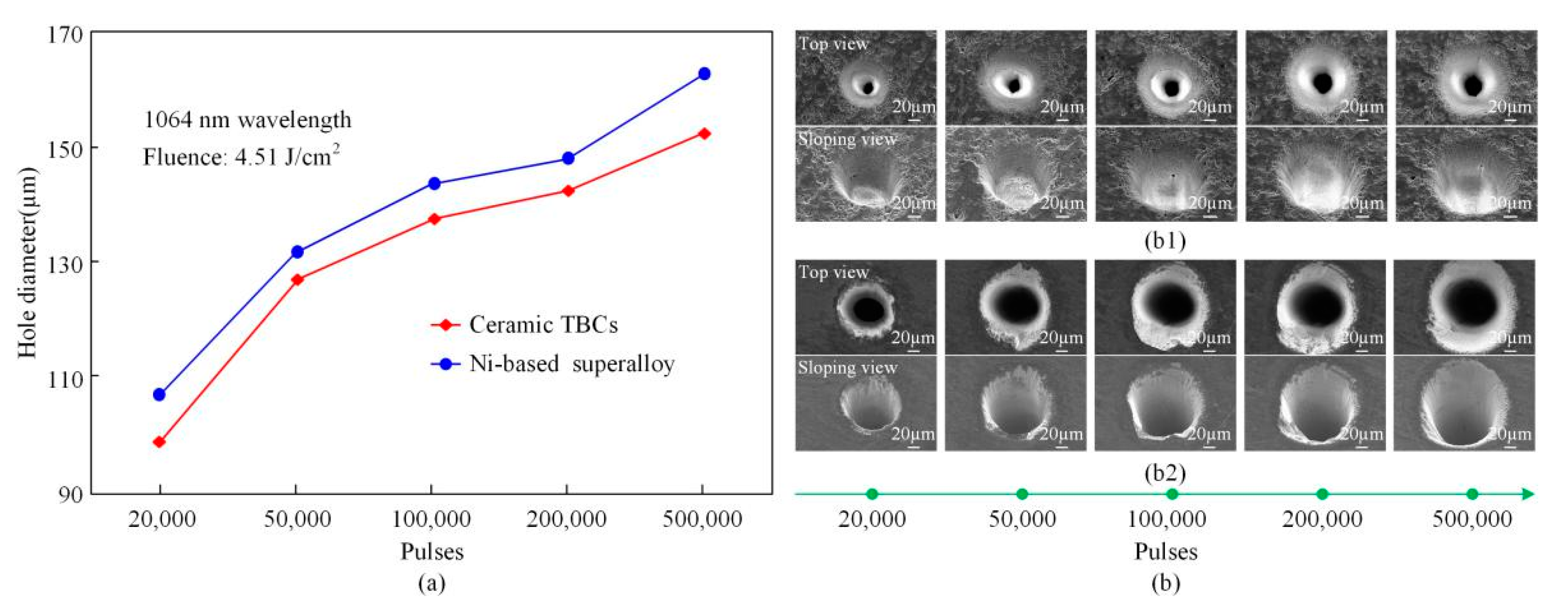

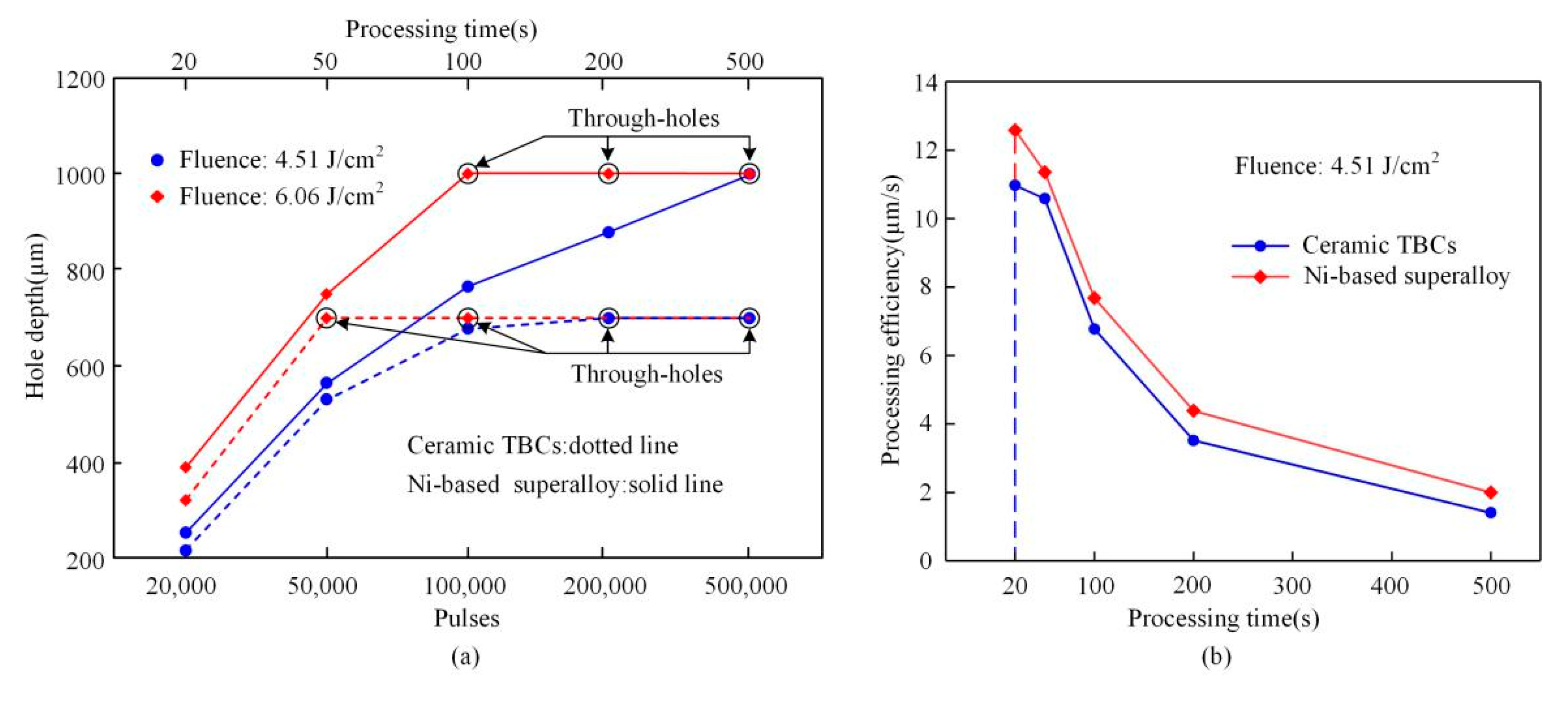

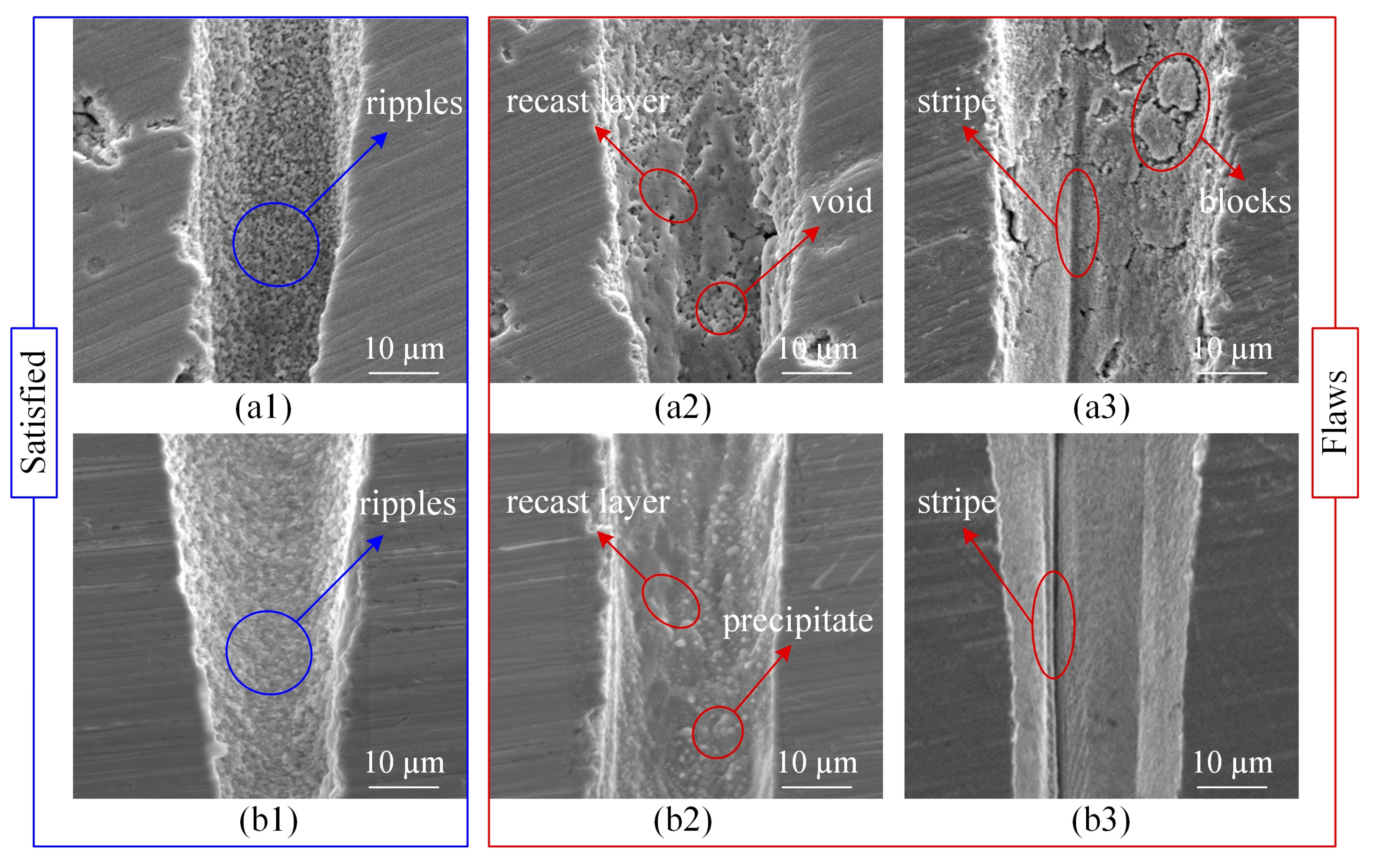

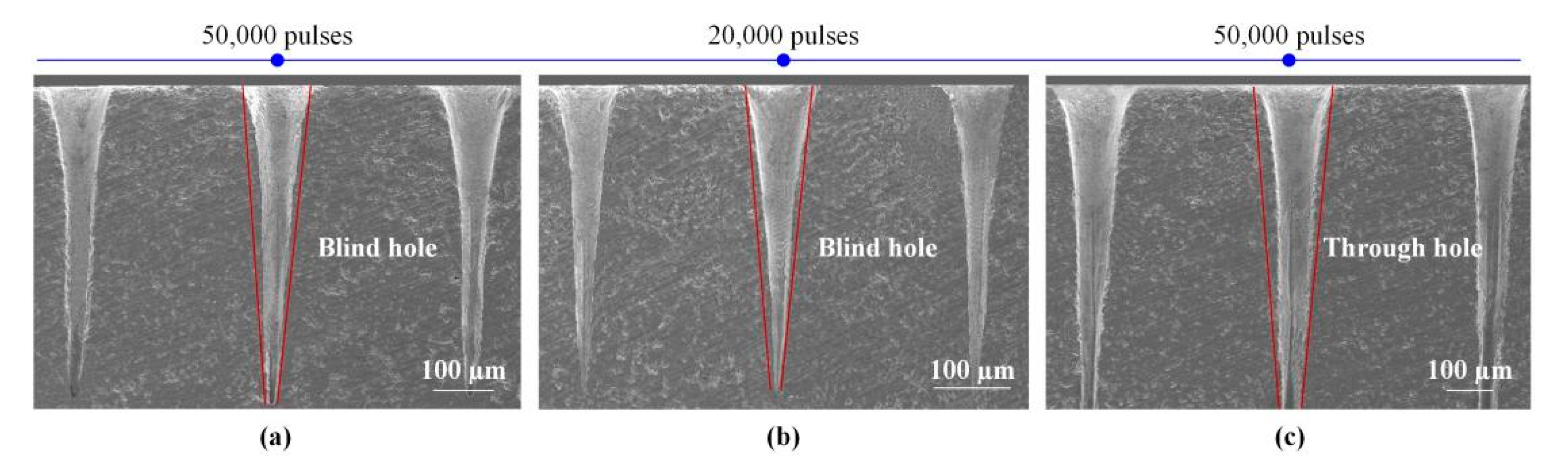

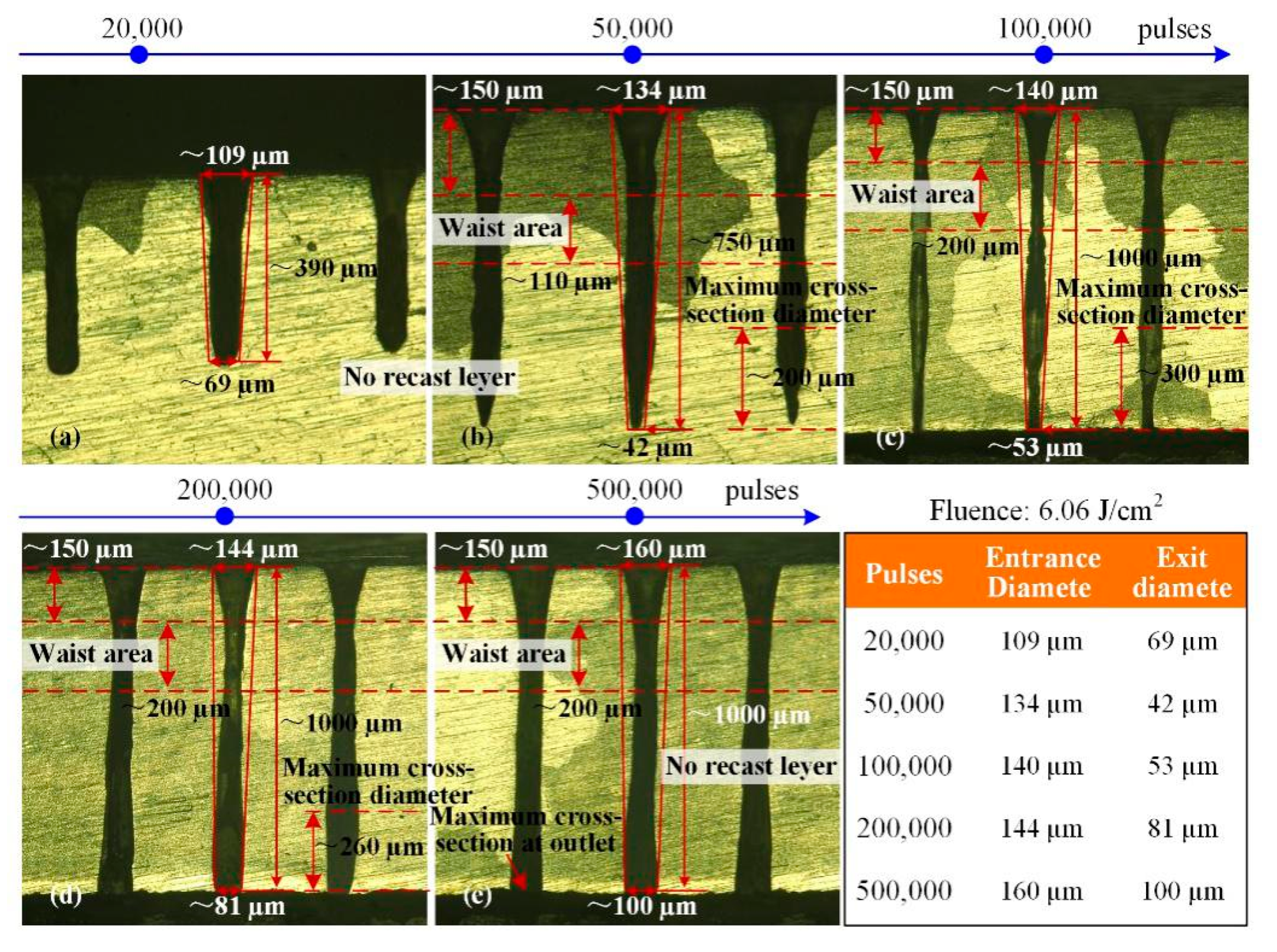

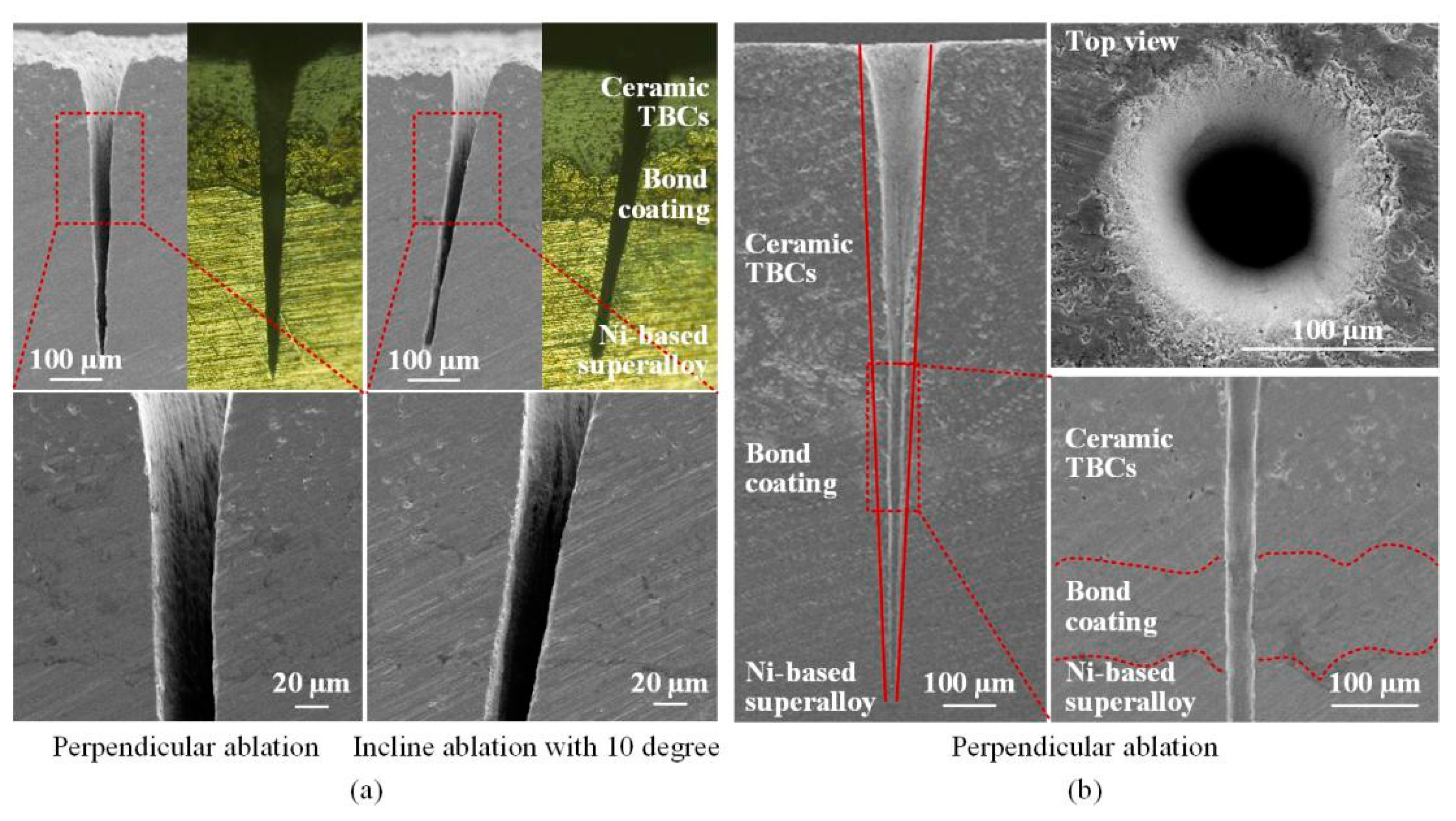

3.2. Deep Holes Ablation with 1064 nm Wavelength

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Ghosh, S. Thermal Barrier Ceramic Coatings—A Review. In Advanced Ceramic Processing; Adel Mohamed IntechOpen: London, UK, 2015; pp. 111–138. [Google Scholar] [CrossRef]

- Goswami, B.; Ray, A.; Sahay, S. Thermal Barrier Coating System for Gas Turbine Application–A Review. High Temp. Mater. Process. 2004, 23, 73–92. [Google Scholar] [CrossRef]

- Tang, F.; Ajdelsztajn, L.; Kim, G.E.; Provenzano, V.; Schoenung, J.M. Effects of variations in coating materials and process conditions on the thermal cycle properties of NiCrAlY/YSZ thermal barrier coatings. Mater. Sci. Eng. A 2006, 425, 94–106. [Google Scholar] [CrossRef]

- Meier, S.M.; Gupta, D.K.; Sheffler, K.D. Ceramic thermal barrier coatings for commercial gas turbine engines. JOM 1991, 43, 50–53. [Google Scholar] [CrossRef]

- Teng, S.; Han, J.-C.; Poinsatte, P.E. Effect of Film-Hole Shape on Turbine-Blade Film-Cooling Performance. J. Thermophys. Heat Transf. 2001, 15, 257–265. [Google Scholar] [CrossRef]

- Beck, T. Laser drilling in gas turbine blades. Laser Tech. J. 2011, 8, 40–43. [Google Scholar] [CrossRef]

- Girardot, J.; Schneider, M.; Berthe, L.; Favier, V. Investigation of delamination mechanisms during a laser drilling on a cobalt-base superalloy. J. Mater. Process. Technol. 2013, 213, 1682–1691. [Google Scholar] [CrossRef]

- Sun, X.; Wang, W.; Mei, X.; Pan, A.; Liu, B.; Li, M. Controllable dot-matrix marking on titanium alloy with anti-reflective micro-structures using defocused femtosecond laser. Opt. Laser Technol. 2019, 115, 298–305. [Google Scholar] [CrossRef]

- Corcoran, A.; Sexton, L.; Seaman, B.; Ryan, P.; Byrne, G. The laser drilling of multi-layer aerospace material systems. J. Mater. Process. Technol. 2002, 123, 100–106. [Google Scholar] [CrossRef]

- Zhao, W.; Wang, L. Microdrilling of Through-Holes in Flexible Printed Circuits Using Picosecond Ultrashort Pulse Laser. Polym. 2018, 10, 1390. [Google Scholar] [CrossRef]

- Gautam, G.D.; Pandey, A.K. Pulsed Nd:YAG laser beam drilling: A review. Opt. Laser Technol. 2018, 100, 183–215. [Google Scholar] [CrossRef]

- Dausinger, F.; Hügel, H.; Konov, V.I. Micromachining with ultrashort laser pulses: From basic understanding to technical applications. SPIE Proc. 2003, 5147, 106–115. [Google Scholar] [CrossRef]

- Sun, R.; Zhang, X.; Cao, W.; Gong, S.; Zhang, X. Characteristic of Hole Wall Trepanning by Picosecond Laser in Superalloy. Rare Metal Mat. Eng. 2013, 42, 128–131. [Google Scholar]

- Sun, R.; Zhang, X.; Cao, W.; Gong, S. Laser Drilling of Ni-Base Single-Crystal Superalloy through Thermal Barrier Coatings. Rare Metal Mat. Eng. 2014, 43, 1193–1198. [Google Scholar]

- Wang, R.; Duan, W.; Wang, K.; Dong, X.; Fan, Z.; Mei, X.; Wang, W.; Zhang, S. Computational and experimental study on hole evolution and delamination in laser drilling of thermal barrier coated nickel superalloy. Opt. Lasers Eng. 2018, 107, 161–175. [Google Scholar] [CrossRef]

- Qi, H.; Lai, H. Micromachining of Metals and Thermal Barrier Coatings using a 532nm Nanosecond Fiber Laser. Phys. Procedia 2012, 39, 603–612. [Google Scholar] [CrossRef]

- Fan, Z.; Duan, W.; Zhang, X.; Mei, X.; Wang, W.; Cui, J. Influence of Preheating on the Microstructure Evolution of Laser Re-Melting Thermal Barrier Coatings/Ni-Based Single Crystal Superalloy Multilayer System. Materials 2019, 12, 3088. [Google Scholar] [CrossRef]

- Zhang, J.; Long, Y.; Liao, S.; Lin, H.-T.; Wang, C. Effect of laser scanning speed on geometrical features of Nd:YAG laser machined holes in thin silicon nitride substrate. Ceram. Int. 2017, 43, 2938–2942. [Google Scholar] [CrossRef]

- Wang, M.; Yang, L.; Zhang, S.; Wang, Y. Experimental investigation on the spiral trepanning of K24 superalloy with femtosecond laser. Opt. Laser Technol. 2018, 101, 284–290. [Google Scholar] [CrossRef]

- Das, D.K.; Pollock, T.M. Femtosecond laser machining of cooling holes in thermal barrier coated CMSX4 superalloy. J. Mater. Process. Technol. 2009, 209, 5661–5668. [Google Scholar] [CrossRef]

- Feng, Q.; Picard, Y.N.; McDonald, J.; Van Rompay, P.; Yalisove, S.; Pollock, T. Femtosecond laser machining of single-crystal superalloys through thermal barrier coatings. Mater. Sci. Eng. A 2006, 430, 203–207. [Google Scholar] [CrossRef]

- Zhao, W.; Wang, W.; Jiang, G.; Li, B.Q.; Mei, X. Ablation and morphological evolution of micro-holes in stainless steel with picosecond laser pulses. Int. J. Adv. Manuf. Technol. 2015, 80, 1713–1720. [Google Scholar] [CrossRef]

- Semaltianos, N.; Perrie, W.; French, P.; Sharp, M.; Dearden, G.; Logothetidis, S.; Watkins, K.G. Femtosecond laser ablation characteristics of nickel-based superalloy C263. Appl. Phys. A 2008, 94, 999–1009. [Google Scholar] [CrossRef]

- Tan, B.; Dalili, A.; Venkatakrishnan, K. High repetition rate femtosecond laser nano-machining of thin films. Appl. Phys. A 2008, 95, 537–545. [Google Scholar] [CrossRef]

- Sivayoganathan, M.; Tan, B.; Venkatakrishnan, K. Effect of mega-hertz repetition rate on the agglomerated particle size of femtosecond synthesized nanostructures. Opt. Mater. Express 2012, 2, 987–995. [Google Scholar] [CrossRef]

- Zhao, W.; Yu, Z. Self-cleaning effect in high quality percussion ablating of cooling hole by picosecond ultra-short pulse laser. Opt. Lasers Eng. 2018, 105, 125–131. [Google Scholar] [CrossRef]

- Chien, W.-T.; Hou, S.-C. Investigating the recast layer formed during the laser trepan drilling of Inconel 718 using the Taguchi method. Int. J. Adv. Manuf. Technol. 2006, 33, 308–316. [Google Scholar] [CrossRef]

- Li, C.; Wang, W. Quantitative characterization of lamellar microstructure of plasma-sprayed ceramic coatings through visualization of void distribution. Mater Sci. Eng. A 2004, 386, 10–19. [Google Scholar] [CrossRef]

- Wang, X.; Lim, G.; Zheng, H.; Ng, F.; Liu, W.; Chua, S. Femtosecond pulse laser ablation of sapphire in ambient air. Appl. Surf. Sci. 2004, 228, 221–226. [Google Scholar] [CrossRef]

- Garofano, J.K.; Marcus, H.L.; Aindow, M. Nanoscale carbide precipitation in the recast layer of a percussion laser-drilled superalloy. Scr. Mater. 2009, 61, 943–946. [Google Scholar] [CrossRef]

- Leitz, K.-H.; Redlingshöfer, B.; Reg, Y.; Otto, A.; Schmidt, M. Metal Ablation with Short and Ultrashort Laser Pulses. Phys. Procedia 2011, 12, 230–238. [Google Scholar] [CrossRef]

- Luft, A.; Franz, U.A. Emsermann, J. Kaspar, A study of thermal and mechanical effects on materials induced by pulsed laser drilling. Appl. Phys. A 1996, 6, 93–101. [Google Scholar] [CrossRef]

- Sun, X.; Dong, X.; Wang, K.; Wang, R.; Fan, Z.; Duan, W. Experimental investigation on thermal effects in picosecond laser drilling of thermal barrier coated In718. Opt. Laser Technol. 2019, 113, 150–158. [Google Scholar] [CrossRef]

- Wang, R.; Wang, K.; Dong, X.; Fan, Z.; Duan, W.; Me, X.; Wang, W.; Cui, J.; Zhang, S. An experimental investigation into the defects of laser-drilled holesin thermal barrier coated Inconel 718 superalloys. Int. J. Adv. Manuf. Tech. 2018, 96, 1467–1481. [Google Scholar] [CrossRef]

- Fan, Z.; Dong, X.; Wang, K.; Duan, W.; Wang, R.; Mei, X.; Wang, W.; Cui, J.; Yuan, X.; Xu, C. Effect of drilling allowance on TBC delamination, spatter and re-melted cracks characteristics in laser drilling of TBC coated superalloys. Int. J. Mach. Tools Manuf. 2016, 106, 1–10. [Google Scholar] [CrossRef]

- Lv, J.; Dong, X.; Wang, K.; Duan, W.; Fan, Z.; Mei, X. Study on process and mechanism of laser drilling in water and air. Int. J. Adv. Manuf. Technol. 2016, 86, 1443–1451. [Google Scholar] [CrossRef]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, H.; Zhao, W.; Wang, L.; Shen, X.; Wang, N.; Wang, X. Percussion Drilling of Deep Holes Using Picosecond Ultrashort Pulse Laser in Ni-Based Superalloy Coated with Ceramic Thermal Barrier Coatings. Materials 2020, 13, 3570. https://doi.org/10.3390/ma13163570

Liu H, Zhao W, Wang L, Shen X, Wang N, Wang X. Percussion Drilling of Deep Holes Using Picosecond Ultrashort Pulse Laser in Ni-Based Superalloy Coated with Ceramic Thermal Barrier Coatings. Materials. 2020; 13(16):3570. https://doi.org/10.3390/ma13163570

Chicago/Turabian StyleLiu, Haodong, Wanqin Zhao, Lingzhi Wang, Xiaowei Shen, Ning Wang, and Xu Wang. 2020. "Percussion Drilling of Deep Holes Using Picosecond Ultrashort Pulse Laser in Ni-Based Superalloy Coated with Ceramic Thermal Barrier Coatings" Materials 13, no. 16: 3570. https://doi.org/10.3390/ma13163570

APA StyleLiu, H., Zhao, W., Wang, L., Shen, X., Wang, N., & Wang, X. (2020). Percussion Drilling of Deep Holes Using Picosecond Ultrashort Pulse Laser in Ni-Based Superalloy Coated with Ceramic Thermal Barrier Coatings. Materials, 13(16), 3570. https://doi.org/10.3390/ma13163570