Surface Characteristics of Milled and 3D Printed Denture Base Materials Following Polishing and Coating: An In-Vitro Study

Abstract

:1. Introduction

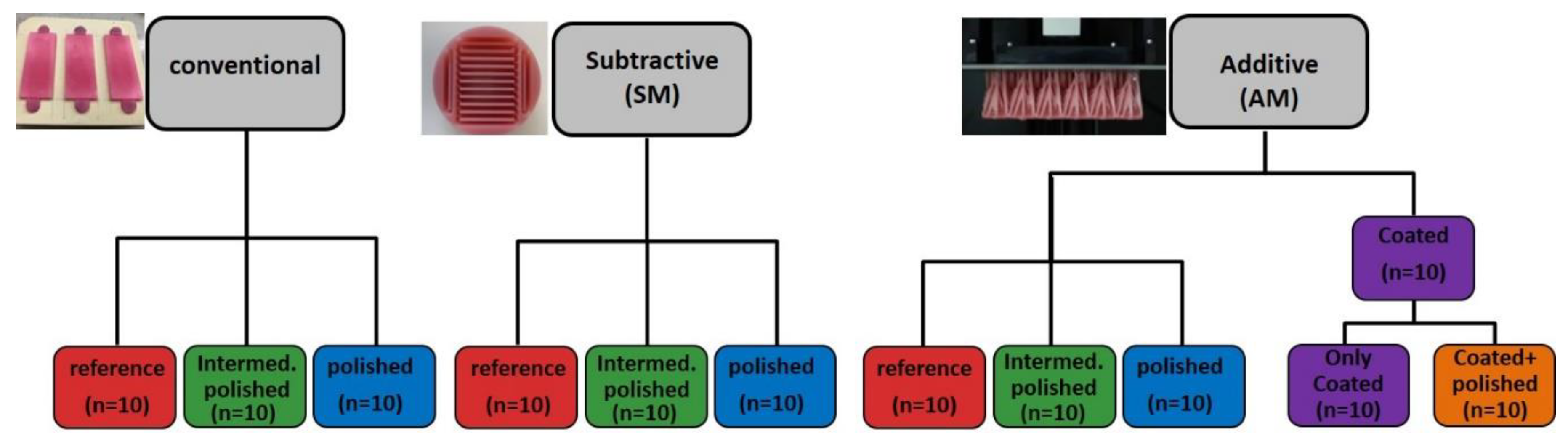

2. Experimental Section

2.1. Specimens Manufacturing

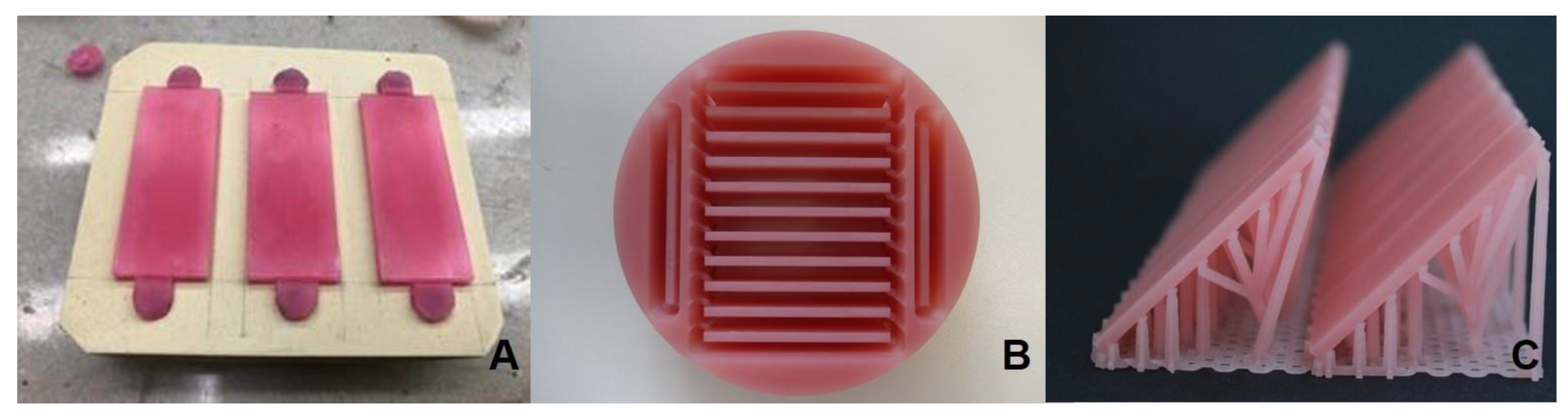

2.1.1. Conventional

2.1.2. Subtractive

2.1.3. Additive

2.2. Polishing

2.3. Coating

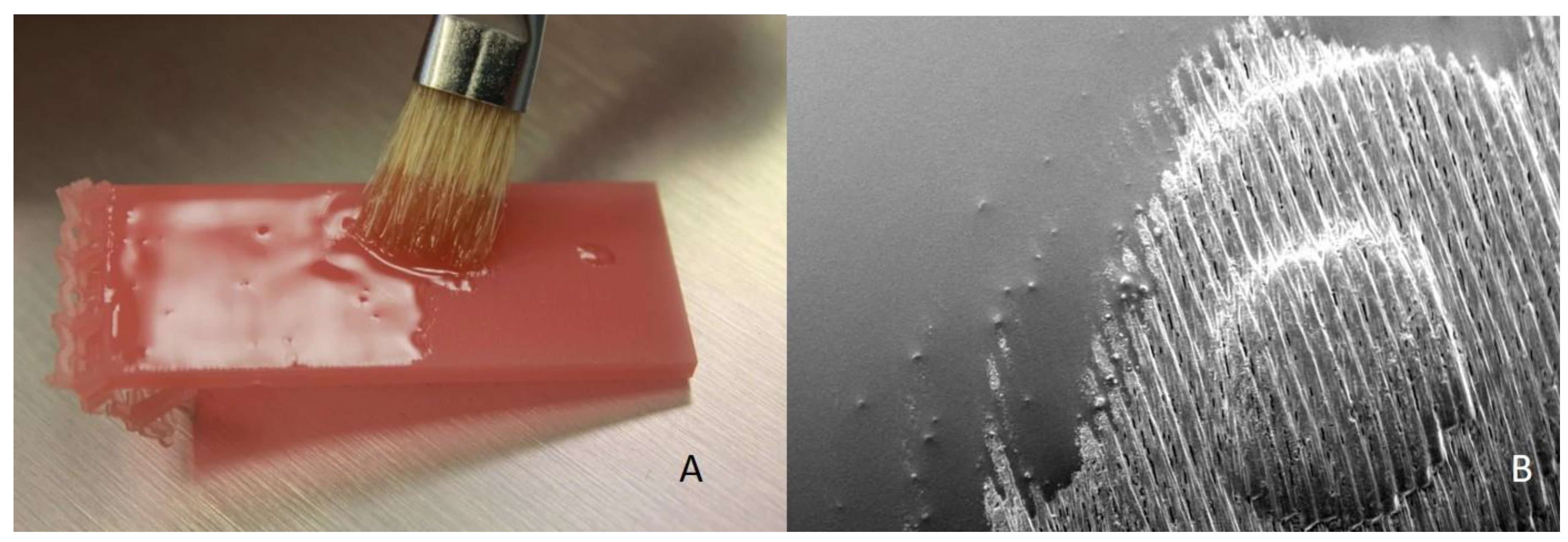

2.4. Surface Roughness

2.5. Gloss

2.6. REM

2.7. Statistical Analysis

3. Results

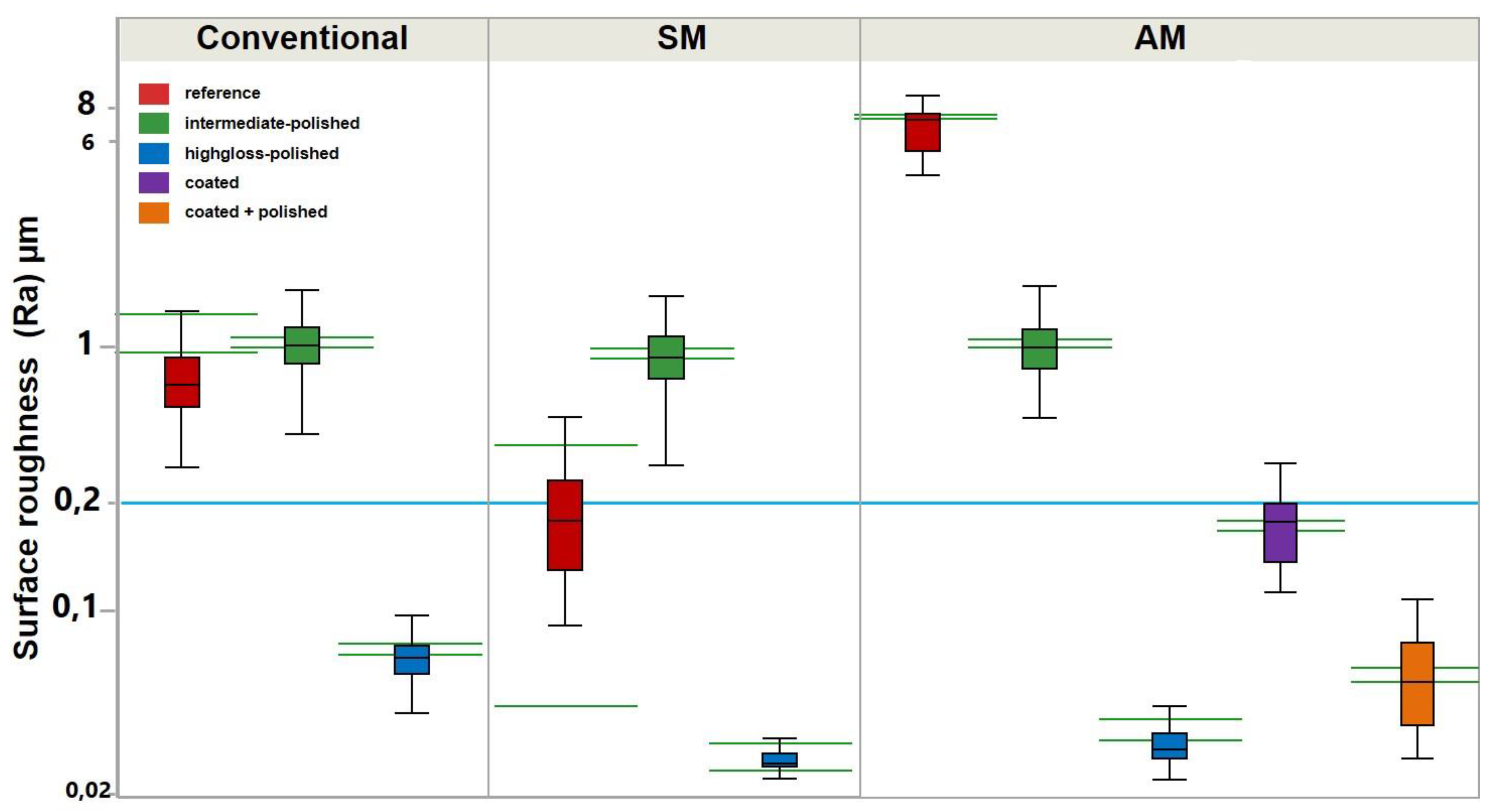

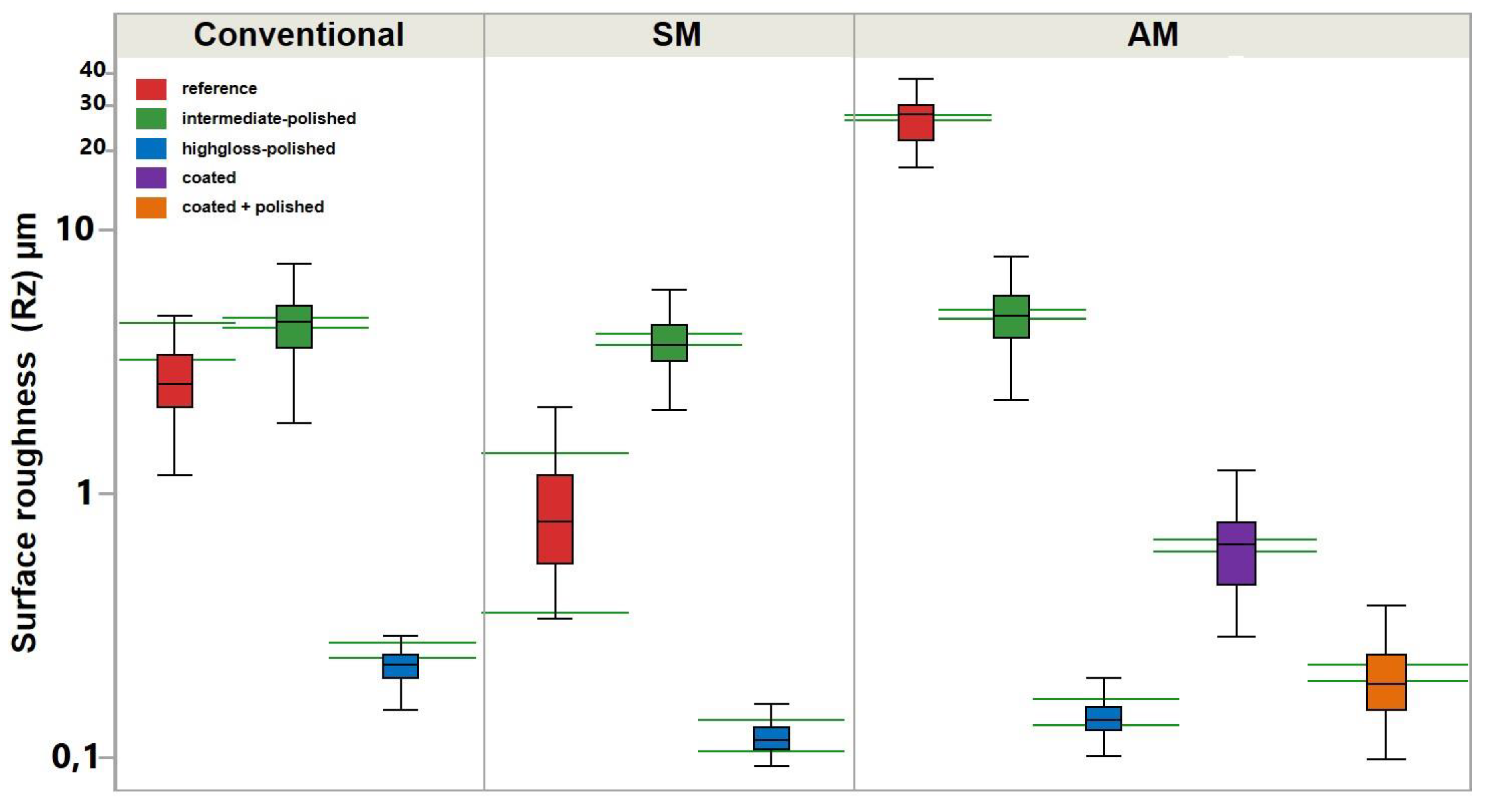

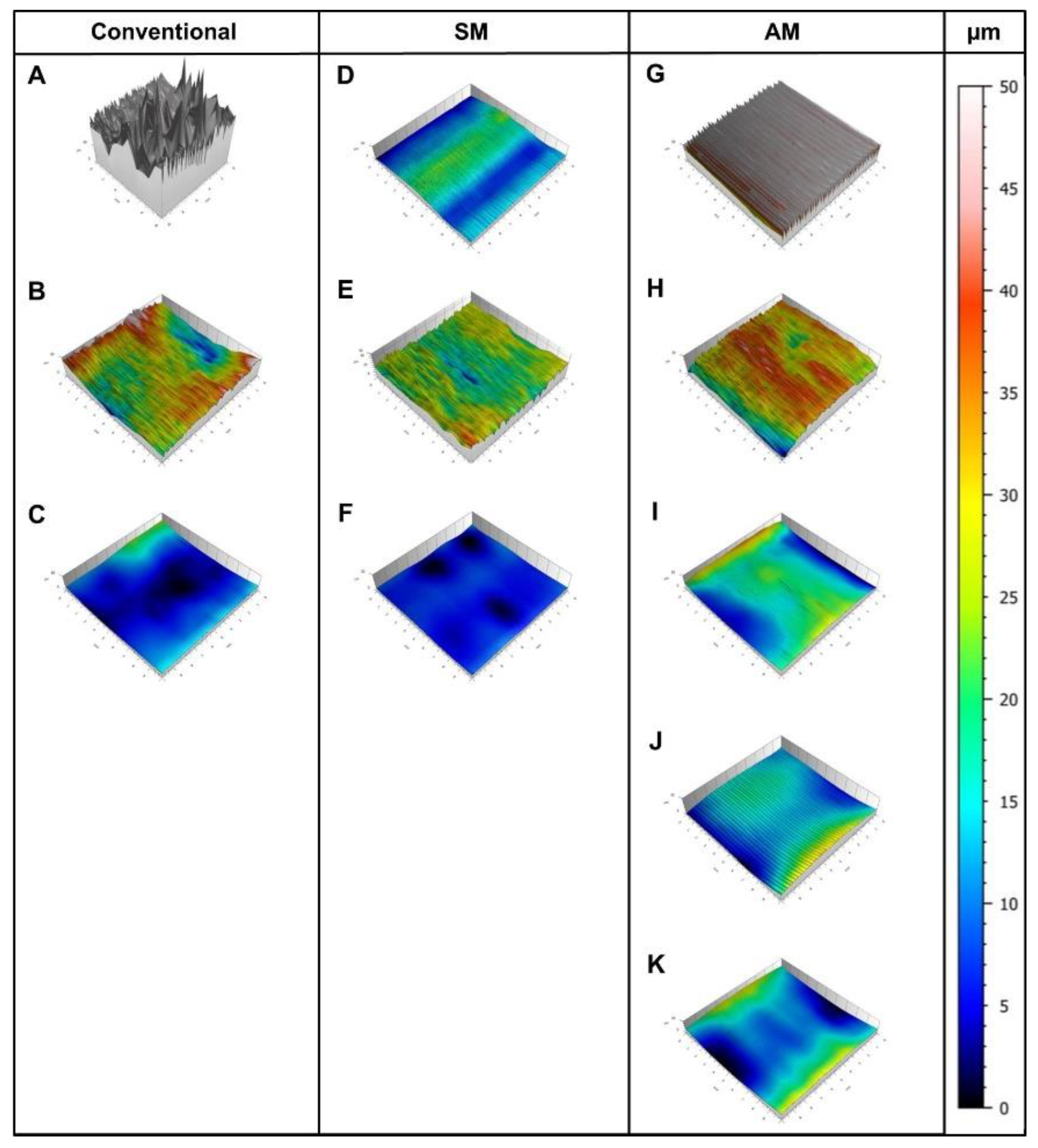

3.1. Surface Roughness

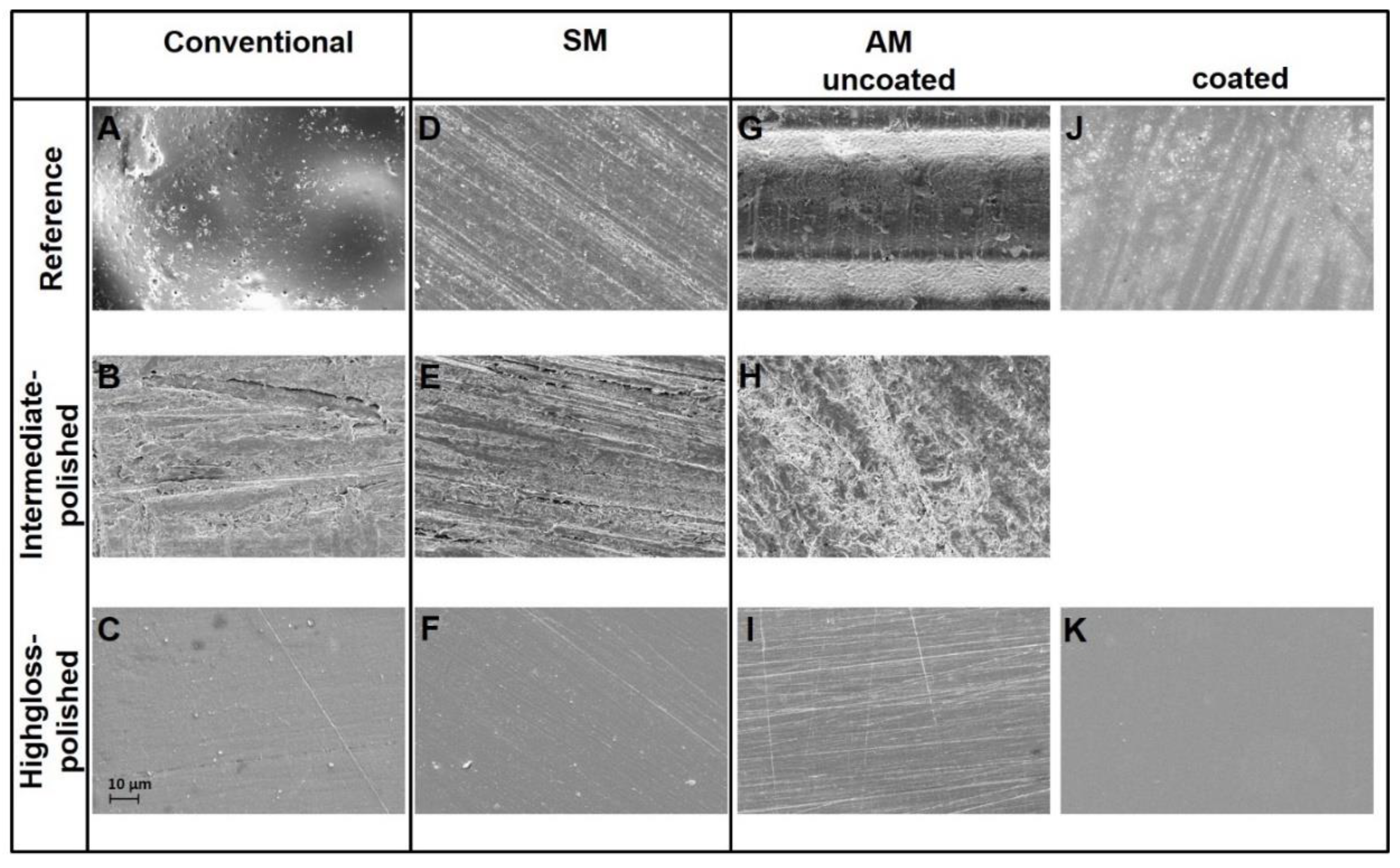

3.2. REM

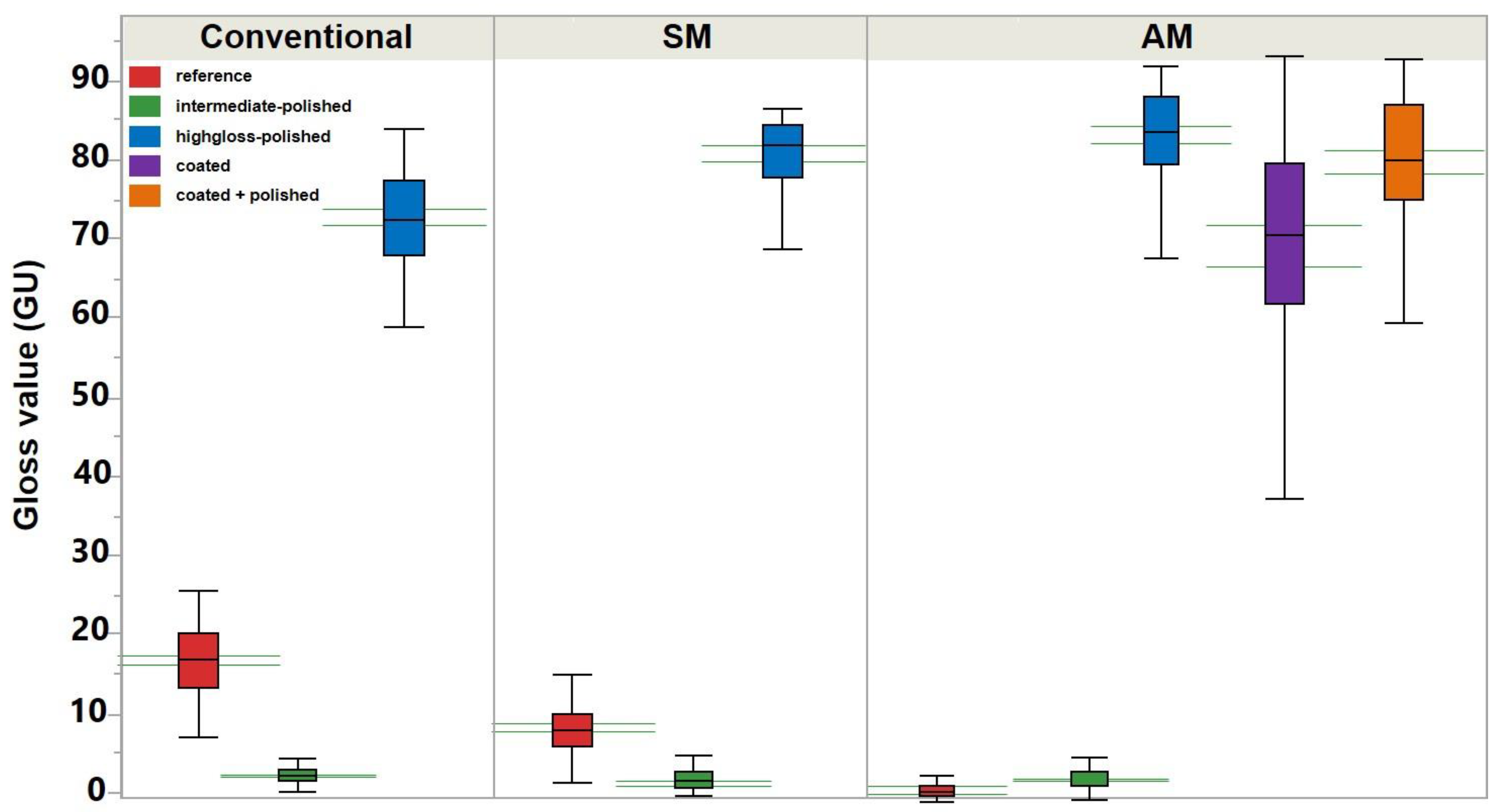

3.3. Gloss

4. Discussion

5. Conclusions

- The milled specimens demonstrated superiors surface characteristics than 3D printed and conventionally produced after polishing, whereby all groups showed the Ra values within the clinically relevant threshold of 0.2 µm.

- The polished specimens demonstrated superior surface characteristics compared to coated specimens, whereby all groups showed the Ra values within the clinically relevant threshold of 0.2 µm.

- The polished specimens showed superior gloss value in the AM group, followed by SM and conventional.

- The coating of additively produced dentures with the same unpolymerized material may be regarded as an alternative to conventional polishing.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Emami, E.; Kabawat, M.; Rompre, P.H.; Feine, J.S. Linking evidence to treatment for denture stomatitis: A meta-analysis of randomized controlled trials. J. Dent. 2014, 42, 99–106. [Google Scholar] [CrossRef] [PubMed]

- Sahin, O.; Koroglu, A.; Dede, D.O.; Yilmaz, B. Effect of surface sealant agents on the surface roughness and color stability of denture base materials. J. Prosthet. Dent. 2016, 116, 610–616. [Google Scholar] [CrossRef] [PubMed]

- Alammari, M.R. The influence of polishing techniques on pre-polymerized CAD\CAM acrylic resin denture bases. Electron. Physician 2017, 9, 5452–5458. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Koroglu, A.; Sahin, O.; Dede, D.O.; Yilmaz, B. Effect of different surface treatment methods on the surface roughness and color stability of interim prosthodontic materials. J. Prosthet. Dent. 2016, 115, 447–455. [Google Scholar] [CrossRef]

- Choi, S.Y.; Habimana, O.; Flood, P.; Reynaud, E.G.; Rodriguez, B.J.; Zhang, N.; Casey, E.; Gilchrist, M.D. Material- and feature-dependent effects on cell adhesion to micro injection moulded medical polymers. Colloids Surf. B Biointerfaces 2016, 145, 46–54. [Google Scholar] [CrossRef]

- Gendreau, L.; Loewy, Z.G. Epidemiology and etiology of denture stomatitis. J. Prosthodont. 2011, 20, 251–260. [Google Scholar] [CrossRef]

- Verran, J.; Jackson, S.; Coulthwaite, L.; Scallan, A.; Loewy, Z.; Whitehead, K. The effect of dentifrice abrasion on denture topography and the subsequent retention of microorganisms on abraded surfaces. J. Prosthet. Dent. 2014, 112, 1513–1522. [Google Scholar] [CrossRef]

- Von Fraunhofer, J.A.; Loewy, Z.G. Factors involved in microbial colonization of oral prostheses. Gen. Dent. 2009, 57, 136–143. [Google Scholar]

- Quirynen, M.; van der Mei, H.C.; Bollen, C.M.; Schotte, A.; Marechal, M.; Doornbusch, G.I.; Naert, I.; Busscher, H.J.; van Steenberghe, D. An in vivo study of the influence of the surface roughness of implants on the microbiology of supra- and subgingival plaque. J. Dent. Res. 1993, 72, 1304–1309. [Google Scholar] [CrossRef]

- Bollen, C.M.; Papaioanno, W.; Van Eldere, J.; Schepers, E.; Quirynen, M.; van Steenberghe, D. The influence of abutment surface roughness on plaque accumulation and peri-implant mucositis. Clin. Oral Implants Res. 1996, 7, 201–211. [Google Scholar] [CrossRef]

- Srinivasan, M.; Kalberer, N.; Naharro, M.; Marchand, L.; Lee, H.; Müller, F. CAD-CAM milled dentures: The Geneva protocols for digital dentures. J. Prosthet. Dent. 2020, 123, 27–37. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Schweiger, J.; Stumbaum, J.; Edelhoff, D.; Guth, J.F. Systematics and concepts for the digital production of complete dentures: Risks and opportunities. Int. J. Comput. Dent. 2018, 21, 41–56. [Google Scholar] [PubMed]

- Millet, C.; Virard, F.; Dougnac-Galant, T.; Ducret, M. CAD-CAM immediate to definitive complete denture transition: A digital dental technique. J. Prosthet. Dent. 2020. [Google Scholar] [CrossRef]

- Bidra, A.S.; Taylor, T.D.; Agar, J.R. Computer-aided technology for fabricating complete dentures: Systematic review of historical background, current status, and future perspectives. J. Prosthet. Dent. 2013, 109, 361–366. [Google Scholar] [CrossRef]

- Alp, G.; Johnston, W.M.; Yilmaz, B. Optical properties and surface roughness of prepolymerized poly(methyl methacrylate) denture base materials. J. Prosthet. Dent. 2019, 121, 347–352. [Google Scholar] [CrossRef] [PubMed]

- Al-Dwairi, Z.N.; Tahboub, K.Y.; Baba, N.Z.; Goodacre, C.J.; Özcan, M. A Comparison of the Surface Properties of CAD/CAM and Conventional Polymethylmethacrylate (PMMA). J. Prosthodont. 2019, 28, 452–457. [Google Scholar] [CrossRef] [Green Version]

- Srinivasan, M.; Gjengedal, H.; Cattani-Lorente, M.; Moussa, M.; Durual, S.; Schimmel, M.; Müller, F. CAD/CAM milled complete removable dental prostheses: An in vitro evaluation of biocompatibility, mechanical properties, and surface roughness. Dent. Mat. J. 2018, 37, 526–533. [Google Scholar] [CrossRef] [Green Version]

- Murat, S.; Alp, G.; Alatali, C.; Uzun, M. In Vitro Evaluation of Adhesion of Candida albicans on CAD/CAM PMMA-Based Polymers. J. Prosthodont. 2019, 28, e873–e879. [Google Scholar] [CrossRef] [PubMed]

- Al-Fouzan, A.F.; Al-Mejrad, L.A.; Albarrag, A.M. Adherence of Candida to complete denture surfaces in vitro: A comparison of conventional and CAD/CAM complete dentures. J. Adv. Prosthodont. 2017, 9, 402–408. [Google Scholar] [CrossRef] [Green Version]

- Lin, W.S.; Harris, B.T.; Pellerito, J.; Morton, D. Fabrication of an interim complete removable dental prosthesis with an in-office digital light processing three-dimensional printer: A proof-of-concept technique. J. Prosthet. Dent. 2018, 120, 331–334. [Google Scholar] [CrossRef]

- Unkovskiy, A.; Wahl, E.; Zander, A.T.; Huettig, F.; Spintzyk, S. Intraoral scanning to fabricate complete dentures with functional borders: A proof-of-concept case report. BMC Oral Health 2019, 19, 46. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Cristache, C.M.; Totu, E.E.; Iorgulescu, G.; Pantazi, A.; Dorobantu, D.; Nechifor, A.C.; Isildak, I.; Burlibasa, M.; Nechifor, G.; Enachescu, M. Eighteen Months Follow-Up with Patient-Centered Outcomes Assessment of Complete Dentures Manufactured Using a Hybrid Nanocomposite and Additive CAD/CAM Protocol. J. Clin. Med. 2020, 9, 324. [Google Scholar] [CrossRef] [Green Version]

- Choi, J.J.E.; Uy, C.E.; Ramani, R.S.; Waddell, J.N. Evaluation of surface roughness, hardness and elastic modulus of nanoparticle containing light-polymerized denture glaze materials. J. Mech. Behav. Biomed. Mat. 2020, 103, 103601. [Google Scholar] [CrossRef] [PubMed]

- Unkovskiy, A.; Bui, P.H.; Schille, C.; Geis-Gerstorfer, J.; Huettig, F.; Spintzyk, S. Objects build orientation, positioning, and curing influence dimensional accuracy and flexural properties of stereolithographically printed resin. Dent. Mat. 2018, 34, e324–e333. [Google Scholar] [CrossRef] [PubMed]

- Shim, J.S.; Kim, J.E.; Jeong, S.H.; Choi, Y.J.; Ryu, J.J. Printing accuracy, mechanical properties, surface characteristics, and microbial adhesion of 3D-printed resins with various printing orientations. J. Prosthet. Dent. 2019. [Google Scholar] [CrossRef]

- Steinmassl, O.; Dumfahrt, H.; Grunert, I.; Steinmassl, P.A. Influence of CAD/CAM fabrication on denture surface properties. J. Oral Rehabil. 2018, 45, 406–413. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Rao, D.C.; Kalavathy, N.; Mohammad, H.S.; Hariprasad, A.; Kumar, C.R. Evaluation of the surface roughness of three heat-cured acrylic denture base resins with different conventional lathe polishing techniques: A comparative study. J. Indian Prosthodont. Soc. 2015, 15, 374–380. [Google Scholar] [CrossRef]

- Gungor, H.; Gundogdu, M.; Yesil Duymus, Z. Investigation of the effect of different polishing techniques on the surface roughness of denture base and repair materials. J. Prosthet. Dent. 2014, 112, 1271–1277. [Google Scholar] [CrossRef]

- Zhang, Z.-C.; Li, P.-L.; Chu, F.-T.; Shen, G. Influence of the three-dimensional printing technique and printing layer thickness on model accuracy. J. Orofac. Orthop. 2019, 80, 194–204. [Google Scholar] [CrossRef]

- Reymus, M.; Lümkemann, N.; Stawarczyk, B. 3D-printed material for temporary restorations: Impact of print layer thickness and post-curing method on degree of conversion. Int. J. Comput. Dent. 2019, 22, 231–237. [Google Scholar] [PubMed]

| Conventional | SM | AM | ||

|---|---|---|---|---|

| Mean ± SD | Mean ± SD | Mean ± SD | ||

| Ra (µm) | Reference | 0.83 ± 0.92 a | 0.17 ± 0.08 b | 6.61 ± 1.18 c |

| Intermediate-polished | 0.76 ± 0.19 a | 0.69 ± 0.19 a | 0.84 ± 0.2 a | |

| Highgloss-polished | 0.05 ± 0.02 a | 0.02 ± 0 b | 0.03 ± 0.01 c | |

| Coated | 0.16 ± 0.04 c | |||

| Coated + polished | 0.04 ± 0.02 c | |||

| Rz (µm) | Reference | 3.61 ± 3.15 a | 0.95 ± 0.38 b | 27.64 ± 4.76 c |

| Intermediate-polished | 4.13 ± 1 a | 3.63 ± 0.91 a | 4.44 ± 1.12 b | |

| Highgloss-polished | 0.31 ± 0.2 a | 0.16 ± 0.03 b | 0.19 ± 0.05 c | |

| Coated | 0.73 ± 0.22 c | |||

| Coated + polished | 0.26 ± 0.1 c | |||

| Gloss value (GU) | Reference | 16.93 ± 4.29 a | 8.69 ± 3.19 b | 1.10 ± 0.82 c |

| Intermediate-polished | 2.77 ± 0.6 a | 2.37 ± 0.82 a | 1.77 ± 0.66 a | |

| Highgloss-polished | 70.78 ± 5.81 a | 78.55 ± 3.93 b | 80.84 ± 7.94 c | |

| Coated | 67.25 ± 13.65 c | |||

| Coated + polished | 77.39 ± 7.84 c |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kraemer Fernandez, P.; Unkovskiy, A.; Benkendorff, V.; Klink, A.; Spintzyk, S. Surface Characteristics of Milled and 3D Printed Denture Base Materials Following Polishing and Coating: An In-Vitro Study. Materials 2020, 13, 3305. https://doi.org/10.3390/ma13153305

Kraemer Fernandez P, Unkovskiy A, Benkendorff V, Klink A, Spintzyk S. Surface Characteristics of Milled and 3D Printed Denture Base Materials Following Polishing and Coating: An In-Vitro Study. Materials. 2020; 13(15):3305. https://doi.org/10.3390/ma13153305

Chicago/Turabian StyleKraemer Fernandez, Pablo, Alexey Unkovskiy, Viola Benkendorff, Andrea Klink, and Sebastian Spintzyk. 2020. "Surface Characteristics of Milled and 3D Printed Denture Base Materials Following Polishing and Coating: An In-Vitro Study" Materials 13, no. 15: 3305. https://doi.org/10.3390/ma13153305