Wearable Textile UHF-RFID Sensors: A Systematic Review

Abstract

1. Introduction

2. Fundamentals of Textile UHF-RFID Sensor Techniques

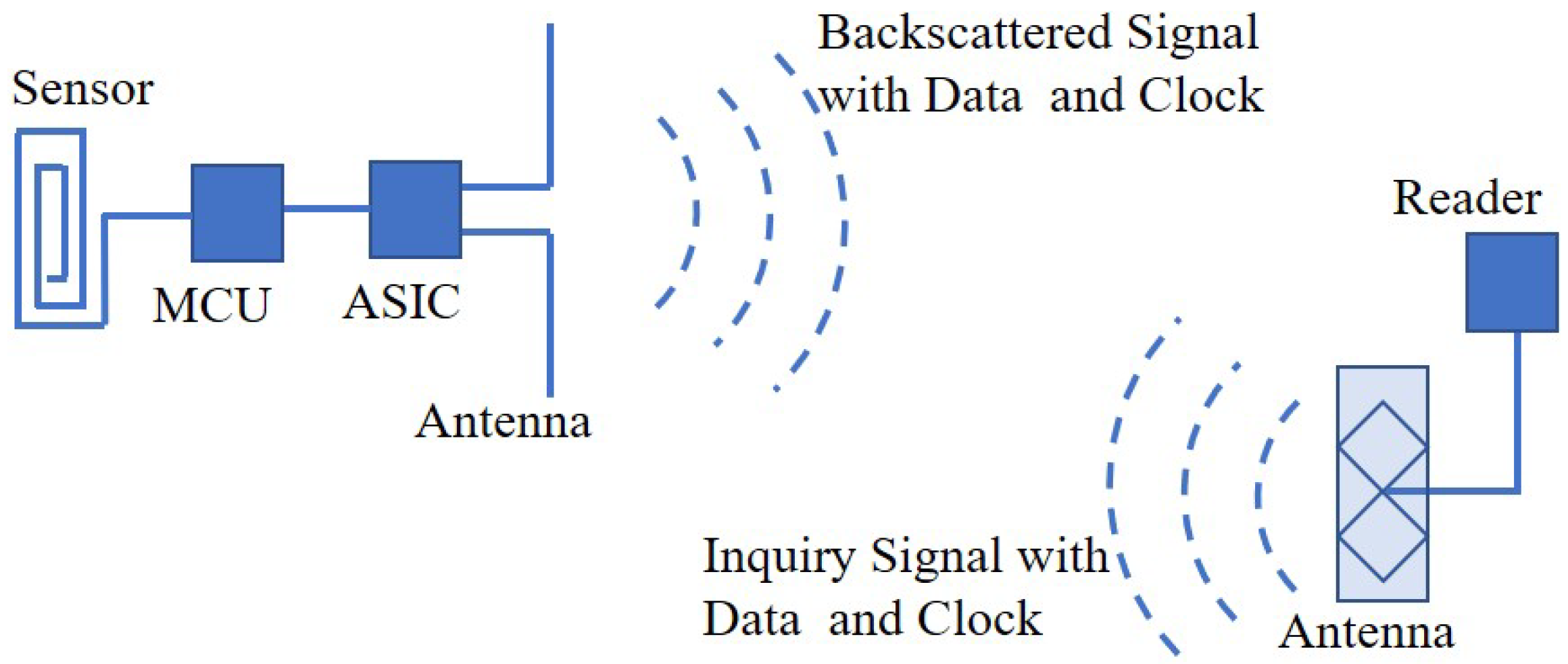

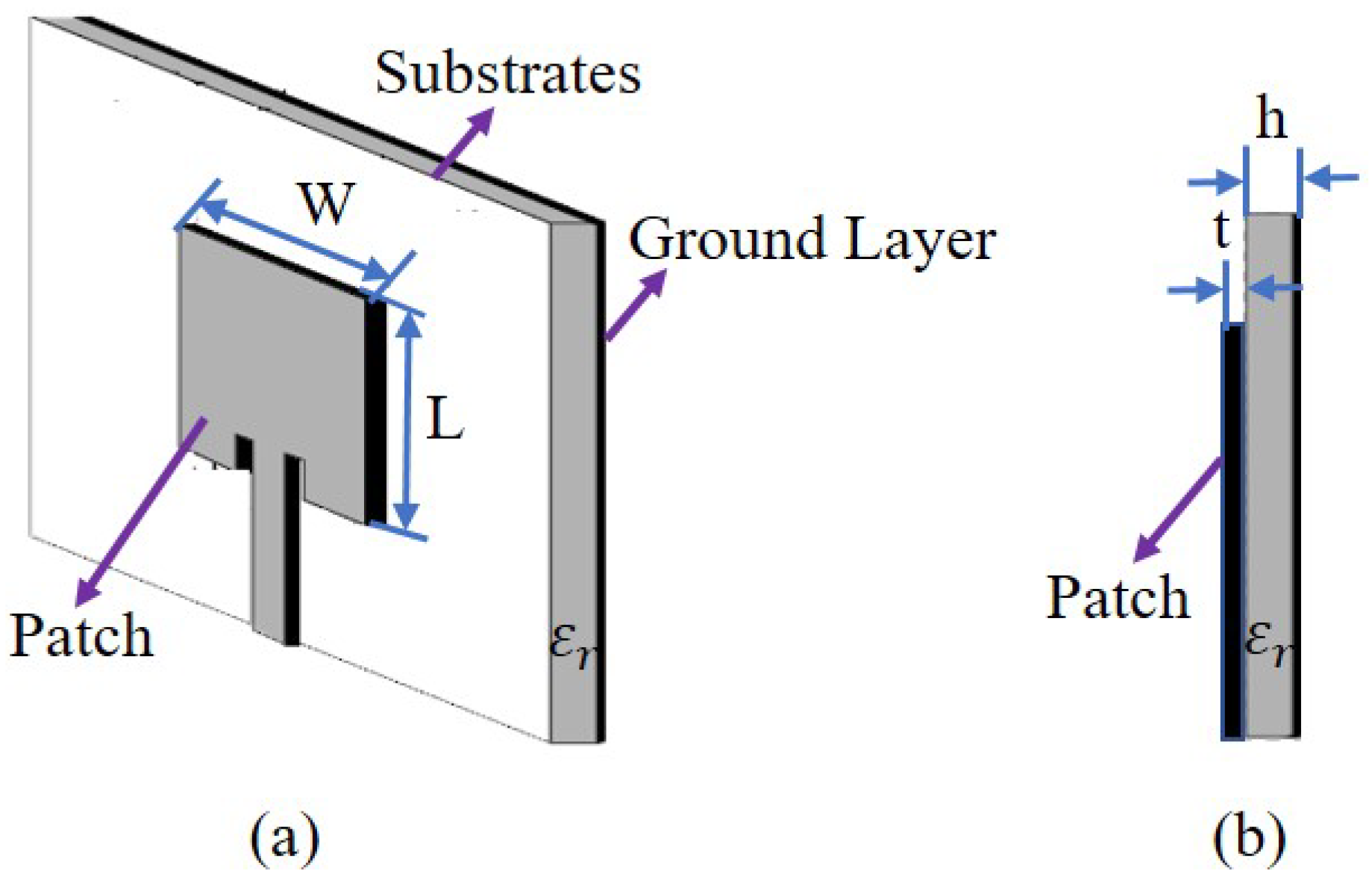

2.1. UHF-RFID Sensor Techniques

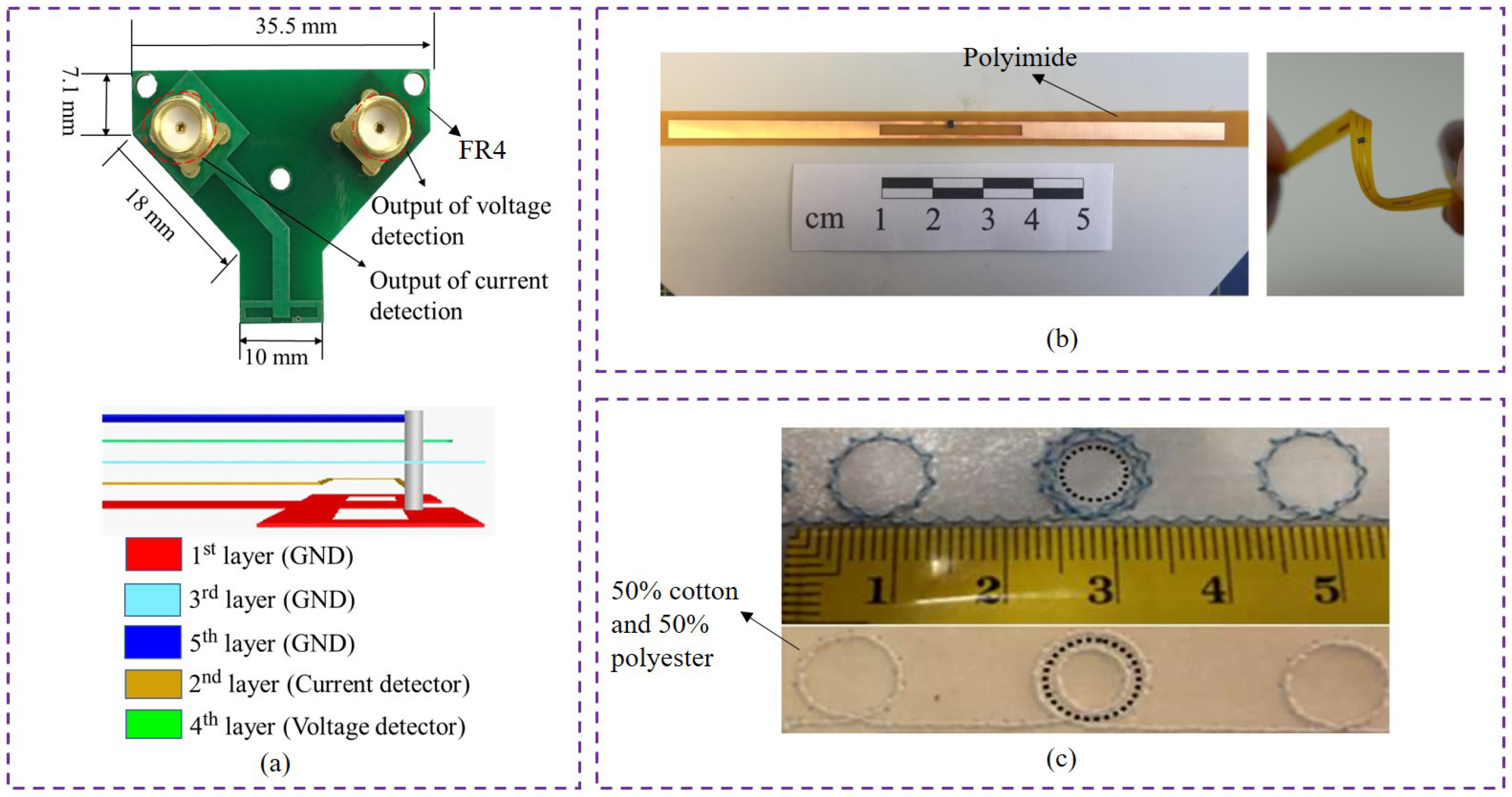

2.2. Electro-Textile Techniques

3. Materials of UHF-RFID Sensors

3.1. Materials of Substrates

3.2. Materials of UHF-RFID Antennas and Sensors

4. Review Search Strategy and Paper Selection

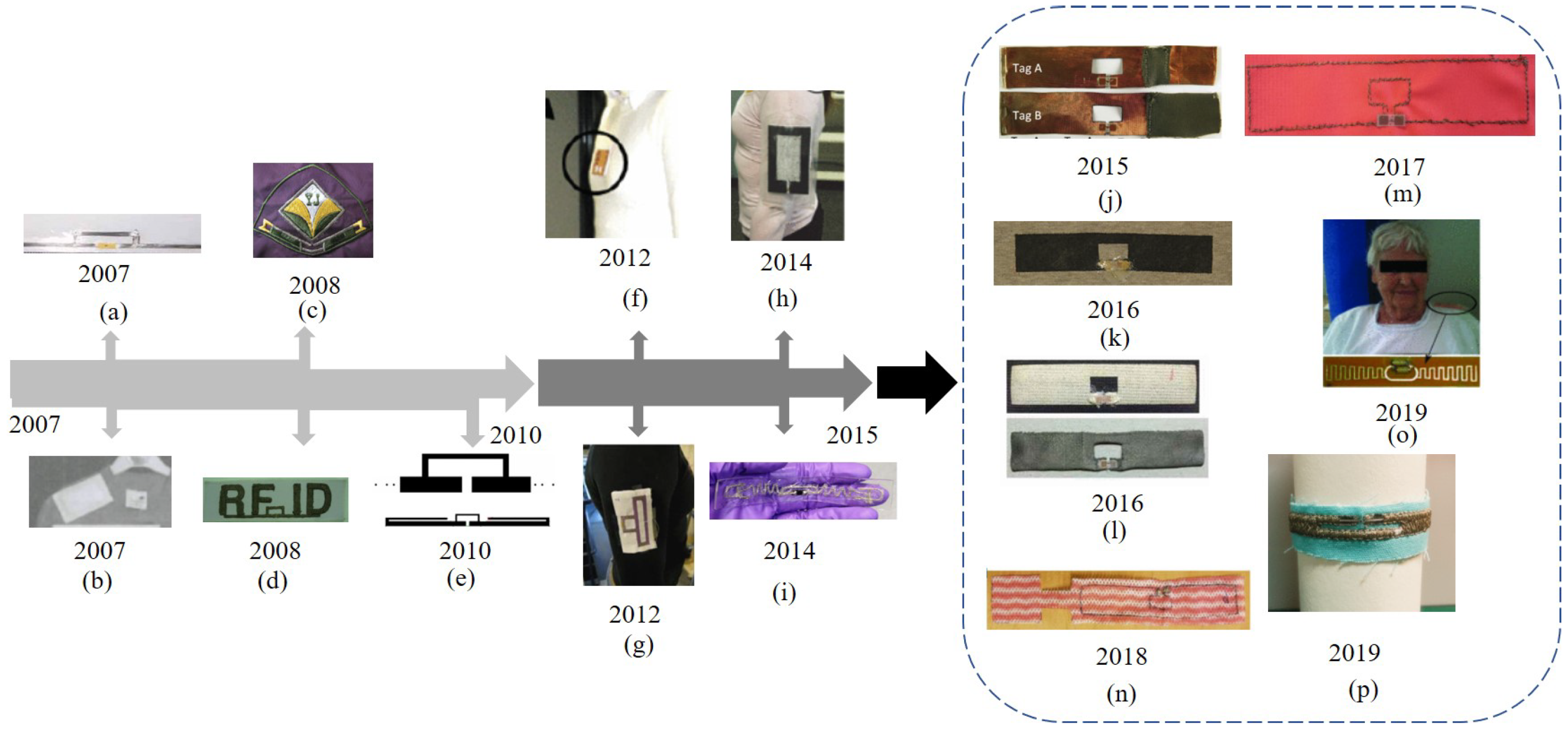

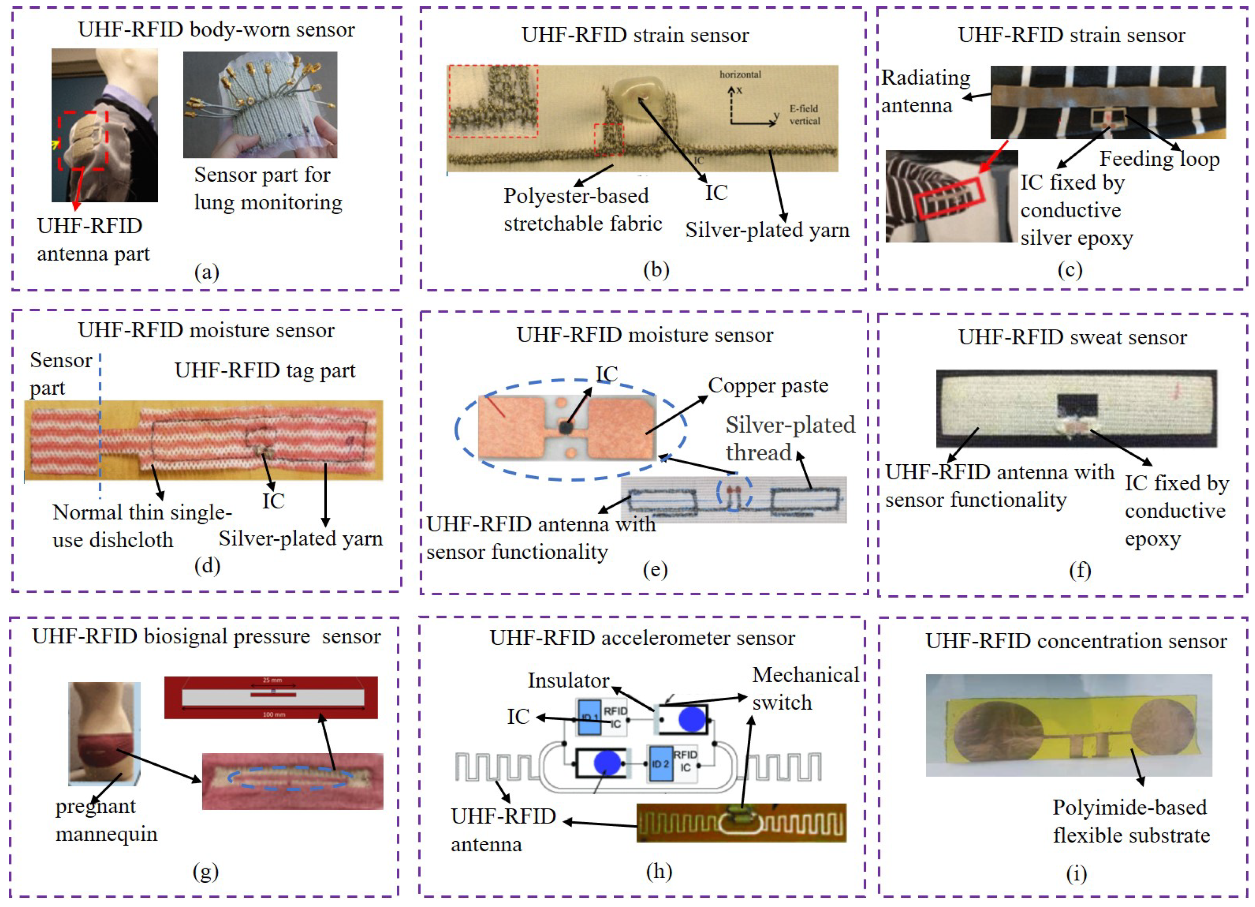

5. Development of Textile UHF-RFID Sensors

5.1. State-of-the-Art of Textile UHF-RFID Sensors Applications

5.2. State of Researches on Reliability of Textile UHF-RFID Sensors

6. Future Prospects

7. Discussion and Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Gil, I.; Fernández-García, R.; Tornero, J.A. Embroidery manufacturing techniques for textile dipole antenna applied to wireless body area network. Text. Res. J. 2019, 89, 1573–1581. [Google Scholar] [CrossRef]

- Wang, L. Inheritance and Innovation of Embroidery in Modern Design. In Proceedings of the 3rd International Conference on Art Studies: Science, Experience, Education, Moscow, Russia, 4–5 October 2019; pp. 232–234. [Google Scholar]

- Catrysse, M.; Puers, R.; Hertleer, C. Towards the integration of textile sensors in a wireless monitoring suit. Sens. Actuator A Phys. 2004, 114, 302–311. [Google Scholar] [CrossRef]

- Vieroth, R.; Kallmayer, C.; Aschenbrenner, R. A new package for textile integrated RFID tags. In Proceedings of the 2009 11th Electronics Packaging Technology Conference, Singapore, 9–11 December 2009; pp. 240–243. [Google Scholar]

- Merilampi, S.; Björninen, T.; Sydänheimo, L. Passive Uhf Rfid Strain Sensor Tag for Detecting Limb Movement. Int. J. Smart Sens. Intell. Syst. 2012, 5, 315–328. [Google Scholar] [CrossRef]

- Merilampi, S.; He, H.; Sydänheimo, L. The possibilities of passive UHF RFID textile tags as comfortable wearable sweat rate sensors. In Proceedings of the 2016 Progress in Electromagnetic Research Symposium (PIERS), Shanghai, China, 8–11 August 2016; pp. 3984–3987. [Google Scholar]

- Patron, D. On the Use of Knitted Antennas and Inductively Coupled RFID Tags for Wearable Applications. IEEE Trans. Biomed. Circuits. Syst. 2016, 10, 1047–1057. [Google Scholar] [CrossRef] [PubMed]

- Mongan, W.M.; Rasheed, I.; Ved, K. On the Use of Radio Frequency Identification for Continuous Biomedical Monitoring. In Proceedings of the 2017 IEEE/ACM Second International Conference on Internet-of-Things Design and Implementation (IoTDI), Pittsburgh, PA, USA, 18–21 April 2017; pp. 197–202. [Google Scholar]

- Chesser, M.; Jayatilaka, A.; Visvanathan, R. Super Low Resolution RF Powered Accelerometers for Alerting on Hospitalized Patient Bed Exits. In Proceedings of the IEEE International Conference on Pervasive Computing and Communications, Kyoto, Japan, 11–15 March 2019; pp. 1–10. [Google Scholar]

- Ennasar, M.A.; El Mrabet, O.; Mohamed, K. Design and Characterization of a Broadband Flexible Polyimide RFID Tag Sensor for NaCl and Sugar Detection. Prog. Electromagn. Res. 2019, 94, 273–283. [Google Scholar] [CrossRef]

- Merilampi, S.; Ruuskanen, P.; Björninen, T. Printed passive UHF RFID tags as wearable strain sensors. In Proceedings of the 2010 3rd International Symposium on Applied Sciences in Biomedical and Communication Technologies (ISABEL 2010), Rome, Italy, 7–10 November 2010; pp. 1–5. [Google Scholar]

- Akbari, M.; Virkki, J.; Sydänheimo, L. Toward Graphene-Based Passive UHF RFID Textile Tags: A Reliability Study. IEEE Trans. Device Mater. Reliab. 2016, 16, 429–431. [Google Scholar] [CrossRef]

- Rocha, G.S.; Silva, M.K.L.; Cesarino, I. Reduced Graphene Oxide-Based Impedimetric Immunosensor for Detection of Enterotoxin A in Milk Samples. Materials 2020, 13, 1751. [Google Scholar] [CrossRef]

- Björninen, T.; Virkki, J.; Sydänheimo, L. Manufacturing of antennas for passive UHF RFID tags by direct write dispensing of copper and silver inks on textiles. In Proceedings of the 2015 International Conference on Electromagnetics in Advanced Applications (ICEAA), Turin, Italy, 7–11 September 2015; pp. 589–592. [Google Scholar]

- Lugoda, P.; Costa, J.C.; Oliveira, C.; Garcia-Garcia, L.A.; Wickramasinghe, S.D.; Pouryazdan, A.; Roggen, D.; Dias, T.; Münzenrieder, N. Flexible Temperature Sensor Integration into E-Textiles Using Different Industrial Yarn Fabrication Processes. Sensors 2020, 20, 73. [Google Scholar] [CrossRef]

- Gong, Z.; Xiang, Z.; Ouyang, X.; Zhang, J.; Lau, N.; Zhou, J.; Chan, C.C. Wearable Fiber Optic Technology Based on Smart Textile: A Review. Materials 2019, 12, 3311. [Google Scholar] [CrossRef]

- Paret, D. Standards for RFID at UHF and SHF. In RFID at Ultra and Super High Frequencies Theory and Application; Wiley: Hoboken, NJ, USA, 2009; pp. 369–505. [Google Scholar]

- Gaspari, F.; Simone, Q. Nanostructured Materials for RFID Sensors. In Nanomaterials Design for Sensing Applications; Elsevier: Amsterdam, The Netherlands, 2019; pp. 93–128. [Google Scholar]

- Sazonov, E. Wearable Sensors: Fundamentals, Implementation and Applications; Elsevier: Amsterdam, The Netherlands, 2014. [Google Scholar]

- Marian, V.; Allard, B.; Vollaire, C. Strategy for microwave energy harvesting from ambient field or a feeding source. IEEE Trans. Power Electron. 2012, 27, 4481–4491. [Google Scholar] [CrossRef]

- Fuschini, F.; Piersanti, C.; Paolazzi, F. Analytical approach to the backscattering from UHF RFID transponder. IEEE Antenn. Wirel. Pr. 2008, 7, 33–35. [Google Scholar] [CrossRef]

- Loo, C.H.; Elmahgoub, K.; Yang, F. Chip impedance matching for UHF RFID tag antenna design. Prog. Electromagn. Res. 2008, 81, 359–370. [Google Scholar] [CrossRef]

- Kim, Y.; Lee, K.; Kim, Y.; Chung, Y.C. Wearable UHF RFID tag antenna design using flexible electro-thread and textile. In Proceedings of the 2007 IEEE Antennas and Propagation Society International Symposium, Honolulu, HI, USA, 9–15 June 2007; pp. 5487–5490. [Google Scholar]

- Fu, Y.Y.; Chan, Y.L.; Yang, M.H. Experimental study on the washing durability of electro-textile UHF RFID tags. IEEE Antenn. Wirel. Pr. 2014, 14, 466–469. [Google Scholar] [CrossRef]

- Björninen, T.; Virkki, J.; Sydänheimo, L.; Ukkonen, L. Impact of recurrent stretching on the performance of electro-textile UHF RFID tags. In Proceedings of the 5th Electronics System-integration Technology Conference (ESTC), Helsinki, Finland, 16–18 September 2014; pp. 251–255. [Google Scholar]

- Björninen, T.; Virkki, J.; Sydänheimo, L. Impact of recurrent washing on the performance of electro-textile UHF RFID tags. In Proceedings of the 2014 IEEE RFID Technology and Applications Conference (RFID-TA), Tampere, Finland, 8–9 September 2014; pp. 251–255. [Google Scholar]

- Virkki, J.; Björninen, T.; Kellomäki, T. Reliability of washable wearable screen printed UHF RFID tags. Microelectron. Reliab. 2014, 54, 840–846. [Google Scholar] [CrossRef]

- Laschuk, N.O.; Ebralidze, I.I.; Quaranta, S.; Kerr, S.T.; Egan, J.G.; Gillis, S.; Gaspari, F.; Latini, A.; Zenkina, O.V. Rational design of a material for rapid colorimetric Fe2+ detection. Mater. Des. 2016, 107, 18–25. [Google Scholar] [CrossRef]

- Laschuk, N.O.; Obua, A.; Ebralidze, I.I.; Fruehwald, H.M.; Poisson, J.; Egan, J.G.; Gaspari, F.; Naumkin, F.Y.; Easton, E.B.; Zenkina, O.V. Spacer Conjugation and Surface Support Effects in Monolayer Electrochromic Materials. ACS Appl. Electron. Mater. 2019, 8, 1705–1717. [Google Scholar] [CrossRef]

- Quaranta, S.; Giorcelli, M.; Savi, P. Graphene and MWCNT Printed Films: Preparation and RF Electrical Properties Study. J. Nanomater. 2019, 2019, 1–9. [Google Scholar] [CrossRef]

- Ujiie, H. Digital Printing of Textiles; Woodhead Publishing: Sawston, UK, 2006. [Google Scholar]

- Cie, C. Ink Jet Textile Printing; Elsevier: Amsterdam, The Netherlands, 2015. [Google Scholar]

- Balanis, C.A. Antenna Theory: Analysis and Design; John Wiley and Sons: Hoboken, NJ, USA, 2016. [Google Scholar]

- Gravas, I.P.; Zaharis, Z.D.; Lazaridis, P.I.; Yioultsis, T.V.; Kantartzis, N.V.; Antonopoulos, C.S.; Chochliouros, I.P.; Xenos, T.D. Optimal Design of Aperiodic Reconfigurable Antenna Array Suitable for Broadcasting Applications. Electronics 2020, 9, 818. [Google Scholar] [CrossRef]

- Korošak, Ž.; Suhadolnik, N.; Pleteršek, A. The implementation of a low power environmental monitoring and soil moisture measurement system based on UHF RFID. Sensors 2019, 19, 5527. [Google Scholar] [CrossRef]

- Strangfeld, C.; Johann, S.; Bartholmai, M. Smart RFID Sensors Embedded in Building Structures for Early Damage Detection and Long-Term Monitoring. Sensors 2019, 19, 5514. [Google Scholar] [CrossRef]

- Rossi, M.; Liberati, R.M.; Frasca, M.; Richardson, J. Experimental Implementation of a Low-Cost, Fully-Analog Self-Jamming Canceller for UHF RFID Devices. Electronics 2020, 9, 786. [Google Scholar] [CrossRef]

- Zradziński, P.; Karpowicz, J.; Gryz, K.; Ramos, V. An Evaluation of Electromagnetic Exposure While Using Ultra-High Frequency Radiofrequency Identification (UHF RFID) Guns. Sensors 2020, 20, 202. [Google Scholar] [CrossRef] [PubMed]

- El Khamlichi, M.; Alvarez Melcon, A.; El Mrabet, O.; Ennasar, M.A.; Hinojosa, J. Flexible UHF RFID Tag for Blood Tubes Monitoring. Sensors 2019, 19, 4903. [Google Scholar] [CrossRef] [PubMed]

- Wagih, M.; Wei, Y.; Komolafe, A.; Torah, R.; Beeby, S. Reliable UHF Long-Range Textile-Integrated RFID Tag Based on a Compact Flexible Antenna Filament. Sensors 2020, 20, 3435. [Google Scholar] [CrossRef] [PubMed]

- Islam, M.T.; Alam, T.; Yahya, I.; Cho, M. Flexible radio-frequency identification (RFID) tag antenna for sensor applications. Sensors 2018, 18, 4212. [Google Scholar] [CrossRef] [PubMed]

- Chen, X.; Li, B.; Qiao, Y.; Lu, Z. Preparing polypyrrole-coated stretchable textile via low-temperature interfacial polymerization for highly sensitive strain sensor. Micromachines 2019, 10, 788. [Google Scholar] [CrossRef]

- Abbas, B.; Khamas, S.K.; Ismail, A.; Sali, A. Full Embroidery Designed Electro-Textile Wearable Tag Antenna for WBAN Application. Sensors 2019, 19, 2470. [Google Scholar] [CrossRef]

- Yang, T.; Xiong, X.; Petrů, M.; Tan, X.; Kaneko, H.; Militký, J.; Sakuma, A. Theoretical and Experimental Studies on Thermal Properties of Polyester Nonwoven Fibrous Material. Materials 2020, 13, 2882. [Google Scholar] [CrossRef]

- Luo, C.; Fang, W.; Shen, Y.; Qiu, H.; Shao, W.; Hong, Z.; Wang, L.; He, Z.; En, Y. Collocated and simultaneous measurements of RF current and voltage on a trace in a noncontact manner. IEEE Trans. Microw. Theory. Tech. 2019, 67, 2406–2415. [Google Scholar] [CrossRef]

- Liu, Q.; Li, H.; Yu, Y.F.; Zhao, W.S.; Zhang, S. A Novel Finger-Controlled Passive RFID Tag Design for Human–Machine Interaction. Sensors 2019, 19, 5125. [Google Scholar] [CrossRef]

- Hu, J.; Yu, J.; Li, Y.; Liao, X.; Yan, X.; Li, L. Nano Carbon Black-Based High Performance Wearable Pressure Sensors. Nanomaterials 2020, 10, 664. [Google Scholar] [CrossRef] [PubMed]

- Hu, Q.; Memon, H.; Qiu, Y.; Liu, W.; Wei, Y. A Comprehensive Study on the Mechanical Properties of Different 3D Woven Carbon Fiber-Epoxy Composites. Materials 2020, 13, 2765. [Google Scholar] [CrossRef] [PubMed]

- Cho, H.S.; Yang, J.H.; Lee, J.H.; Lee, J.H. Evaluation of Joint Motion Sensing Efficiency According to the Implementation Method of SWCNT-Coated Fabric Motion Sensor. Sensors 2020, 20, 284. [Google Scholar] [CrossRef]

- Ojstršek, A.; Virant, N.; Fox, D.; Krishnan, L.; Cobley, A. The Efficacy of Polymer Coatings for the Protection of Electroless Copper Plated Polyester Fabric. Polymers 2020, 12, 1277. [Google Scholar] [CrossRef] [PubMed]

- Gaubert, V.; Gidik, H.; Koncar, V. Boxer Underwear Incorporating Textile Moisture Sensor to Prevent Nocturnal Enuresis. Sensor 2020, 20, 3546. [Google Scholar] [CrossRef] [PubMed]

- García, P.A.; Khoshnam, M.; Menon, C. Wearable Device to Monitor Back Movements Using an Inductive Textile Sensor. Sensors 2020, 20, 905. [Google Scholar] [CrossRef] [PubMed]

- Roberson, D.A.; Wicker, R.B.; Murr, L.E.; Church, K.; MacDonald, E. Microstructural and process characterization of conductive traces printed from Ag particulate inks. Materials 2011, 4, 963–979. [Google Scholar] [CrossRef]

- Ma, Z.; Jiang, Y. High-density 3D printable chipless RFID tag with structure of passive slot rings. Sensors 2019, 19, 2535. [Google Scholar] [CrossRef]

- Liu, S.; Li, Y.; Xing, S.; Liu, L.; Zou, G.; Zhang, P. Structure inheritance in nanoparticle ink direct-writing processes and crack-free nano-copper interconnects printed by a single-run approach. Materials 2019, 12, 1559. [Google Scholar] [CrossRef]

- Nayak, R.; Chatterjee, K.N.; Khurana, G.K.; Khandual, A. RFID: Tagging the new ERA. Man-Made Text. India 2007, 50, 174–177. [Google Scholar]

- Choi, J.; Kim, Y.; Lee, L.; Chung, Y.C. Various wearable embroidery RFID tag antenna using electro-thread. In Proceedings of the 2008 IEEE Antennas and Propagation Society International Symposium, San Diego, CA, USA, 5–11 July 2008; pp. 1–4. [Google Scholar]

- Kim, G. Design of a UHF RFID fiber tag antenna with electric-thread using a sewing machine. In Proceedings of the Asia-Pacific Microwave Conference (APMC), Macau, China, 16–20 December 2008; pp. 1–4. [Google Scholar]

- Manzari, S.; Occhiuzzi, C.; Marrocco, G. Feasibility of Body-Centric Systems Using Passive Textile RFID Tags. IEEE Antennas Propagat. Mag. 2012, 54, 49–62. [Google Scholar] [CrossRef]

- Ukkonen, L.; Sydänheimo, L.; Rahmat-Samii, Y. Sewed textile RFID tag and sensor antennas for on-body use. In Proceedings of the 2012 6th European Conference on Antennas and Propagation (EUCAP), Prague, Czech Republic, 26–30 March 2012; pp. 3450–3454. [Google Scholar]

- Koski, K.; Lohan, E.S.; Sydänheimo, L. Electro-textile UHF RFID patch antennas for positioning and localization applications. In Proceedings of the 2014 IEEE RFID Technology and Applications Conference (RFID-TA), Tampere, Finland, 8–9 September 2014; pp. 246–250. [Google Scholar]

- Shao, S.; Kiourti, A.; Burkholder, R. Broadband and flexible textile RFID tags for tires. In Proceedings of the 2014 IEEE Antennas and Propagation Society International Symposium (APSURSI), Memphis, TN, USA, 6–11 July 2014; p. 1507. [Google Scholar]

- Long, F.Y. Implementation and wireless readout of passive UHF RFID strain sensor tags based on electro-textile antennas. In Proceedings of the 2015 9th European Conference on Antennas and Propagation (EuCAP), Lisbon, Portugal, 13–17 April 2015; pp. 1–5. [Google Scholar]

- Shuaib, D.; Ukkonen, L.; Virkki, J. The possibilities of embroidered passive UHF RFID textile tags as wearable moisture sensors. In Proceedings of the 2017 IEEE 5th International Conference on Serious Games and Applications for Health (SeGAH), Perth, WA, USA, 2–4 April 2017; pp. 1–5. [Google Scholar]

- Chen, X.; He, H.; Ukkonen, L. Embroidered UHF RFID Moisture Sensor Tag on Dishcloth Substrate. In Proceedings of the 2018 IEEE International Symposium on Antennas and Propagation USNC/URSI National Radio Science Meeting, Boston, MA, USA, 8–13 July 2018; pp. 2009–2010. [Google Scholar]

- Yu, M.; Shang, X.; Wang, M. Deformation Sensitivity Study of Embroidered UHF RFID Antennas. In Proceedings of the 2019 IEEE International Conference on RFID Technology and Applications (RFID-TA), Pisa, Italy, 25–27 September 2019; pp. 322–326. [Google Scholar]

- Zhang, L.; Wang, Z.; Volakis, J.L. Textile antennas and sensors for body-worn applications. IEEE Antennas Wirel. Propag. Lett. 2012, 11, 1690–1693. [Google Scholar] [CrossRef]

- Hasani, M.; Vena, A.; Sydänheimo, L. Implementation of a dual-interrogation-mode embroidered RFID-enabled strain sensor. IEEE Antennas Wirel. Propag. Lett. 2013, 12, 1272–1275. [Google Scholar] [CrossRef]

- He, H.; Chen, X.; Ukkonen, L. Clothing-Integrated Passive RFID Strain Sensor Platform for Body Movement-Based Controlling. In Proceedings of the 2019 IEEE International Conference on RFID Technology and Applications (RFID-TA), Pisa, Italy, 25–27 September 2019; pp. 236–239. [Google Scholar]

- Chen, X.; He, H.; Khan, Z. Textile-Based Batteryless Moisture Sensor. IEEE Antennas Wirel. Propag. Lett. 2019, 19, 198–202. [Google Scholar] [CrossRef]

- Moraru, A.; Ursachi, C.; Helerea, E. A New Washable UHF RFID Tag: Design, Fabrication, and Assessment. Sensors 2020, 20, 3451. [Google Scholar] [CrossRef]

- Guibert, M.; Massicart, A.; Chen, X. Washing reliability of painted, embroidered, and electro-textile wearable RFID tags. In Proceedings of the 2017 Progress in Electromagnetics Research Symposium—Fall (PIERS—FALL), Singapore, 19–22 November 2017; pp. 828–831. [Google Scholar]

- Hardy, D.A.; Rahemtulla, Z.; Satharasinghe, A.; Shahidi, A.; Oliveira, C.; Anastasopoulos, I.; Nashed, M.N.; Kgatuke, M.; Komolafe, A.; Torah, R.; et al. Wash Testing of Electronic Yarn. Materials 2020, 13, 1228. [Google Scholar] [CrossRef] [PubMed]

- Gaubert, V.; Gidik, H.; Bodart, N.; Koncar, V. Investigating the Impact of Washing Cycles on Silver-Plated Textile Electrodes: A Complete Study. Sensors 2020, 20, 1739. [Google Scholar] [CrossRef] [PubMed]

- Simorangkir, R.B.V.B.; Le, D.; Björninen, T. Washing Durability of PDMS-Conductive Fabric Composite: Realizing Washable UHF RFID Tags. IEEE Antennas Wirel. Propag. Lett. 2019, 18, 2572–2576. [Google Scholar] [CrossRef]

- Kazmi, A.; Rizwan, M.; Sydänheimo, L. A reliability study of coating materials for brush-painted washable textile RFID tags. In Proceedings of the 2016 6th Electronic System-Integration Technology Conference (ESTC), Grenoble, France, 13–15 September 2016; pp. 1–4. [Google Scholar]

- Kazmi, A.; Virkki, J.; Björninen, T. Performance of silver-based textile UHF passive RFID tags after recurrent washing. In Proceedings of the 2016 IEEE International Symposium on Antennas and Propagation (APSURSI), Fajardo, Puerto Rico, 26 June–1 July 2016; pp. 939–940. [Google Scholar]

- Sharma, P.; Kan, E.C. Sleep scoring with a UHF RFID tag by near field coherent sensing. In Proceedings of the 2018 IEEE/MTT-S International Microwave Symposium—IMS, Philadelphia, PA, USA, 10–15 June 2018; pp. 1419–1422. [Google Scholar]

- Chen, X.; Liu, A.; Wei, Z. Experimental study on strain reliability of embroidered passive UHF RFID textile tag antennas and interconnections. J. Eng. Technol. 2017, 2017, 8493405. [Google Scholar] [CrossRef]

- Bai, Q.; Swaisaenyakorn, S.; Lee, H.-J.; Ford, K.L.; Batchelor, J.C.; Langley, R.J. Investigation of a Switchable Textile Communication System on the Human Body. Electronics 2014, 3, 491–503. [Google Scholar] [CrossRef]

- Van Baelen, D.; Lemey, S.; Verhaevert, J.; Rogier, H. A Novel Manufacturing Process for Compact, Low-Weight and Flexible Ultra-Wideband Cavity Backed Textile Antennas. Materials 2018, 11, 67. [Google Scholar] [CrossRef] [PubMed]

- Cheng, S.; Wang, S.; Guan, W.; Xu, H.; Li, P. 3DLRA: An RFID 3D Indoor Localization Method Based on Deep Learning. Sensors 2020, 20, 2731. [Google Scholar] [CrossRef] [PubMed]

- Puruncajas, B.; Vidal, Y.; Tutivén, C. Vibration-Response-Only Structural Health Monitoring for Offshore Wind Turbine Jacket Foundations via Convolutional Neural Networks. Sensors 2020, 20, 3429. [Google Scholar] [CrossRef]

- Vu, C.C.; Kim, J. Highly Sensitive E-Textile Strain Sensors Enhanced by Geometrical Treatment for Human Monitoring. Sensors 2020, 20, 2383. [Google Scholar] [CrossRef] [PubMed]

- Liu, C.; Liao, X.; Shao, W.; Liu, F.; Ding, B.; Ren, G.; Chu, Y.; He, J. Hot-melt Adhesive Bonding of Polyurethane/Fluorinated Polyurethane/Alkylsilane-Functionalized Graphene Nanofibrous Fabrics with Enhanced Waterproofness, Breathability, and Mechanical Properties. Polymers 2020, 12, 836. [Google Scholar] [CrossRef]

| Band | Range | Regulations | Typical Use |

|---|---|---|---|

| 120–150 kHz (LF) | 10 cm | Unregulated | Animal identification, factory data collection |

| 13.56 MHz (HF) | 10 cm–1 m | ISM band worldwide | Smart cards |

| 433 MHz (UHF) | 1–100 m | Short range devices | Defense applications |

| 433 MHz (UHF) | 1–100 m | Short range devices | Defense applications |

| 865–868 MHz (Europe) and 902–928 MHz (North America) (UHF) | 1–12 m | ISM band | staff identification, logistic tracking |

| 2.45–5.8 GHz (microwave band) | 1–2 m | ISM band | 802.11 WLAN, Bluetooth standards |

| 3.1–10 GHz (microwave band) | Up to 200 m | Ultra wide band | Active tags |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Luo, C.; Gil, I.; Fernández-García, R. Wearable Textile UHF-RFID Sensors: A Systematic Review. Materials 2020, 13, 3292. https://doi.org/10.3390/ma13153292

Luo C, Gil I, Fernández-García R. Wearable Textile UHF-RFID Sensors: A Systematic Review. Materials. 2020; 13(15):3292. https://doi.org/10.3390/ma13153292

Chicago/Turabian StyleLuo, Chengyang, Ignacio Gil, and Raúl Fernández-García. 2020. "Wearable Textile UHF-RFID Sensors: A Systematic Review" Materials 13, no. 15: 3292. https://doi.org/10.3390/ma13153292

APA StyleLuo, C., Gil, I., & Fernández-García, R. (2020). Wearable Textile UHF-RFID Sensors: A Systematic Review. Materials, 13(15), 3292. https://doi.org/10.3390/ma13153292