Mechanical Properties and Environmental Evaluation of Ultra-High-Performance Concrete with Aeolian Sand

Abstract

:1. Introduction

2. Materials and Experimental Methods

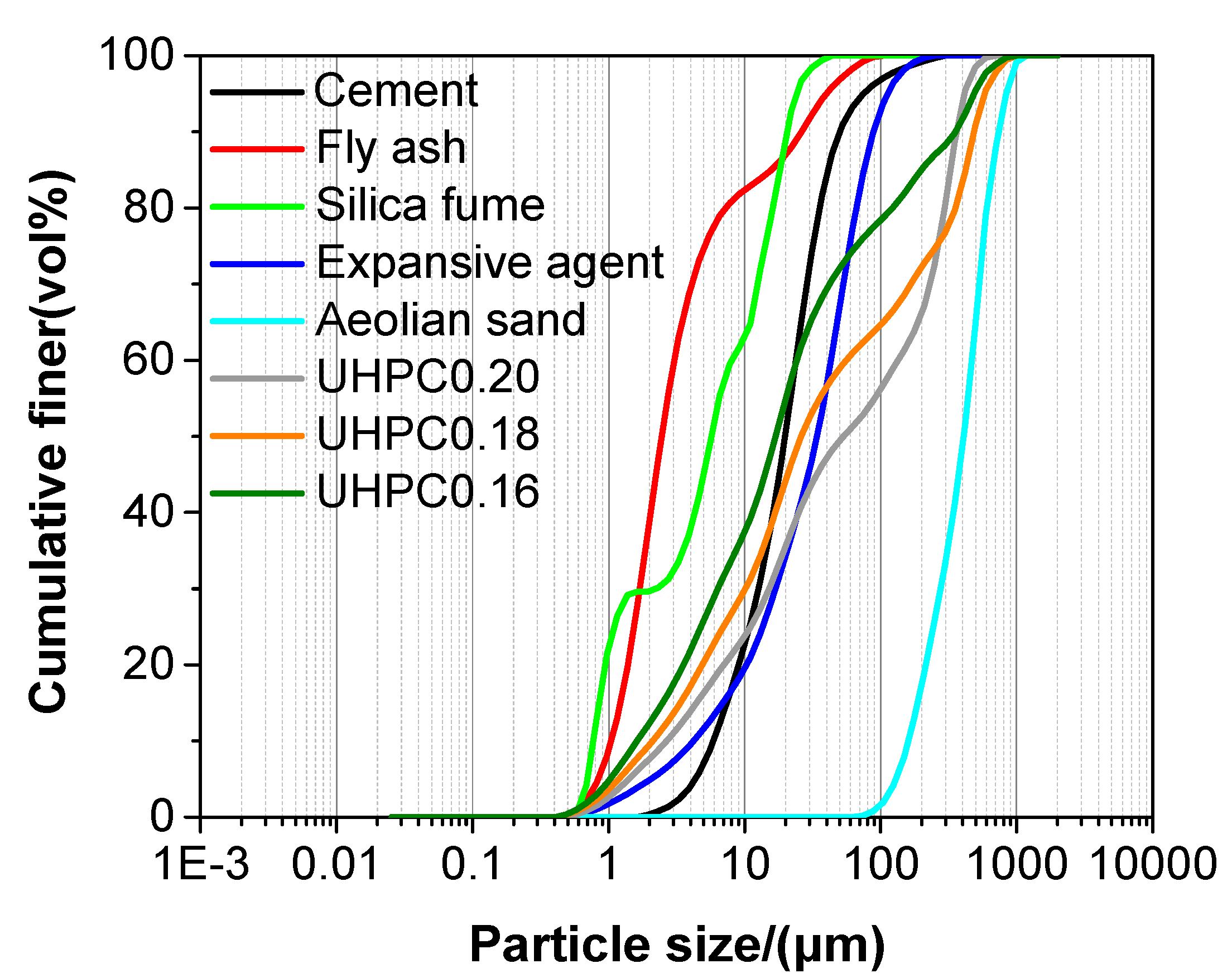

2.1. Raw Materials

2.2. Mix Proportion Design of UHPC

2.3. Specimen Preparation

2.4. Testing Methodology

2.5. Environmental Assessment

3. Results and Discussion

3.1. Workability of UHPC

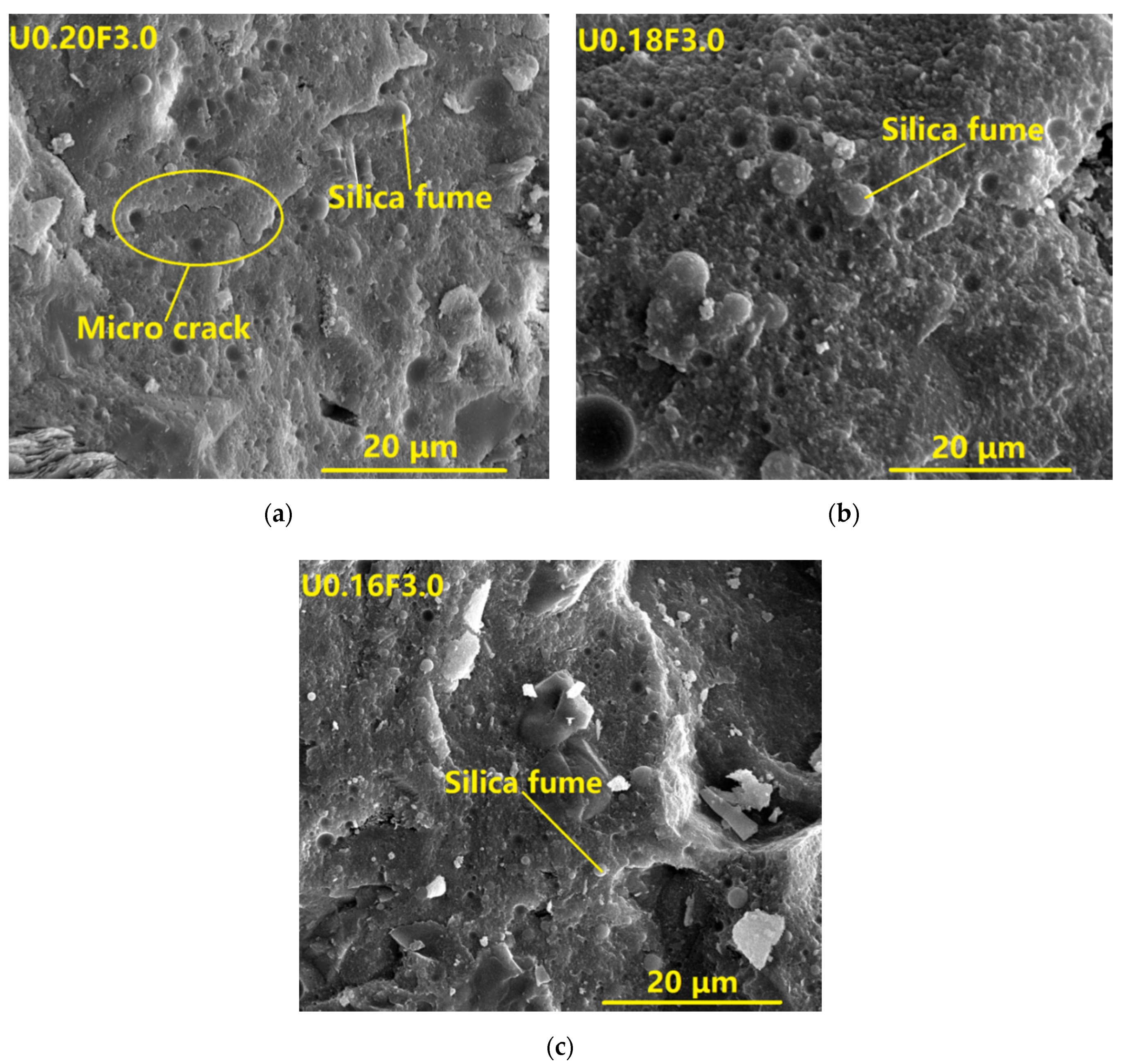

3.2. Microstructure

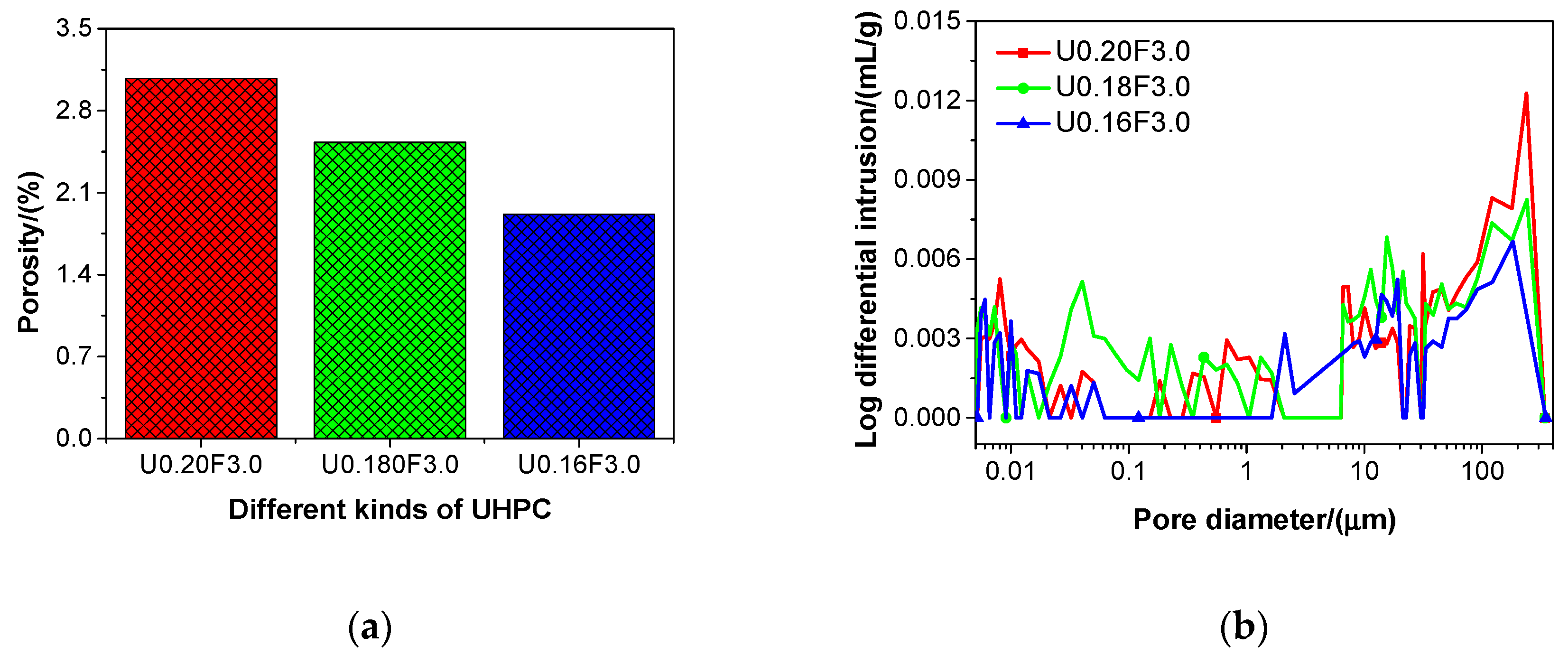

3.3. Porosity

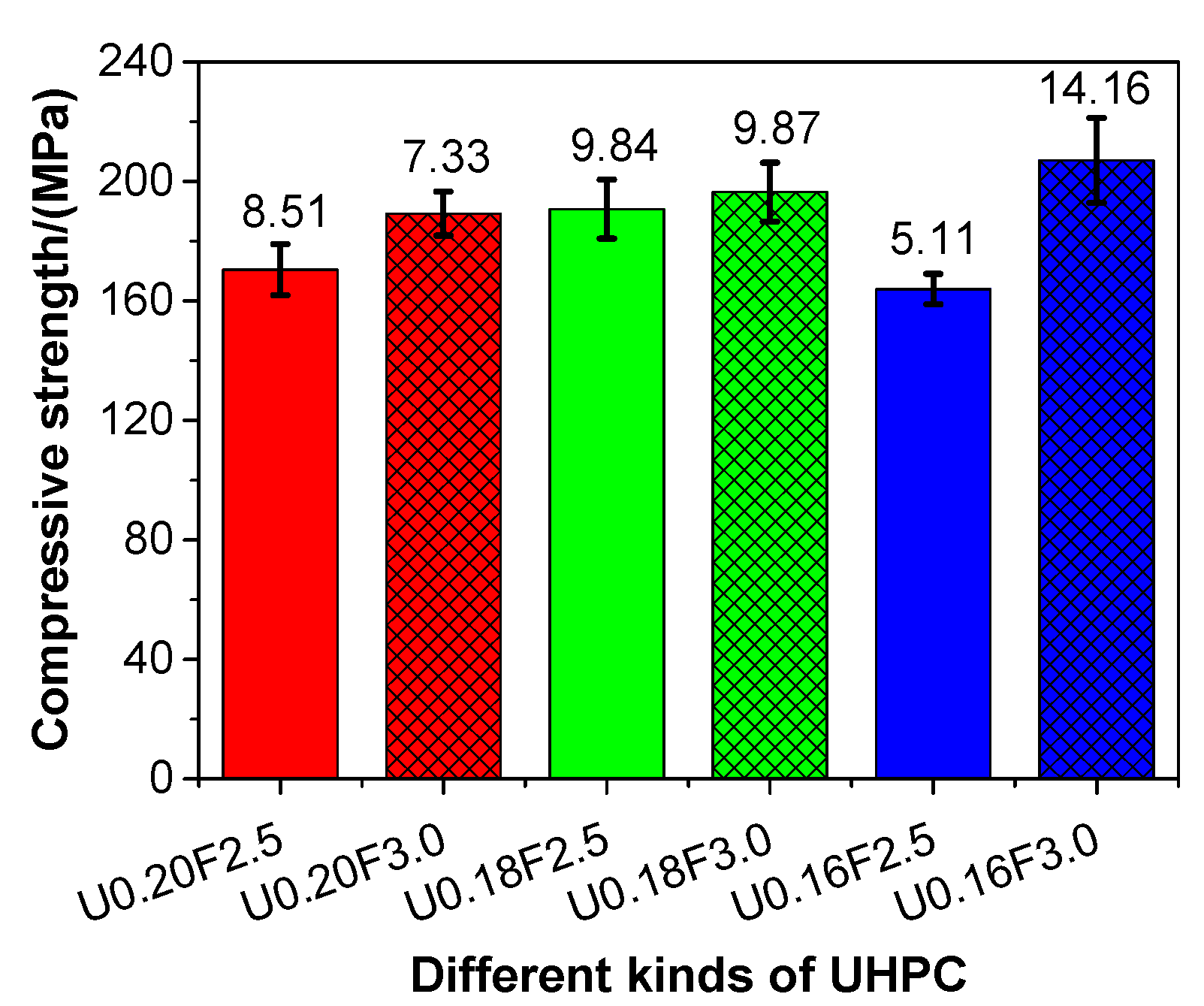

3.4. Compressive Strength

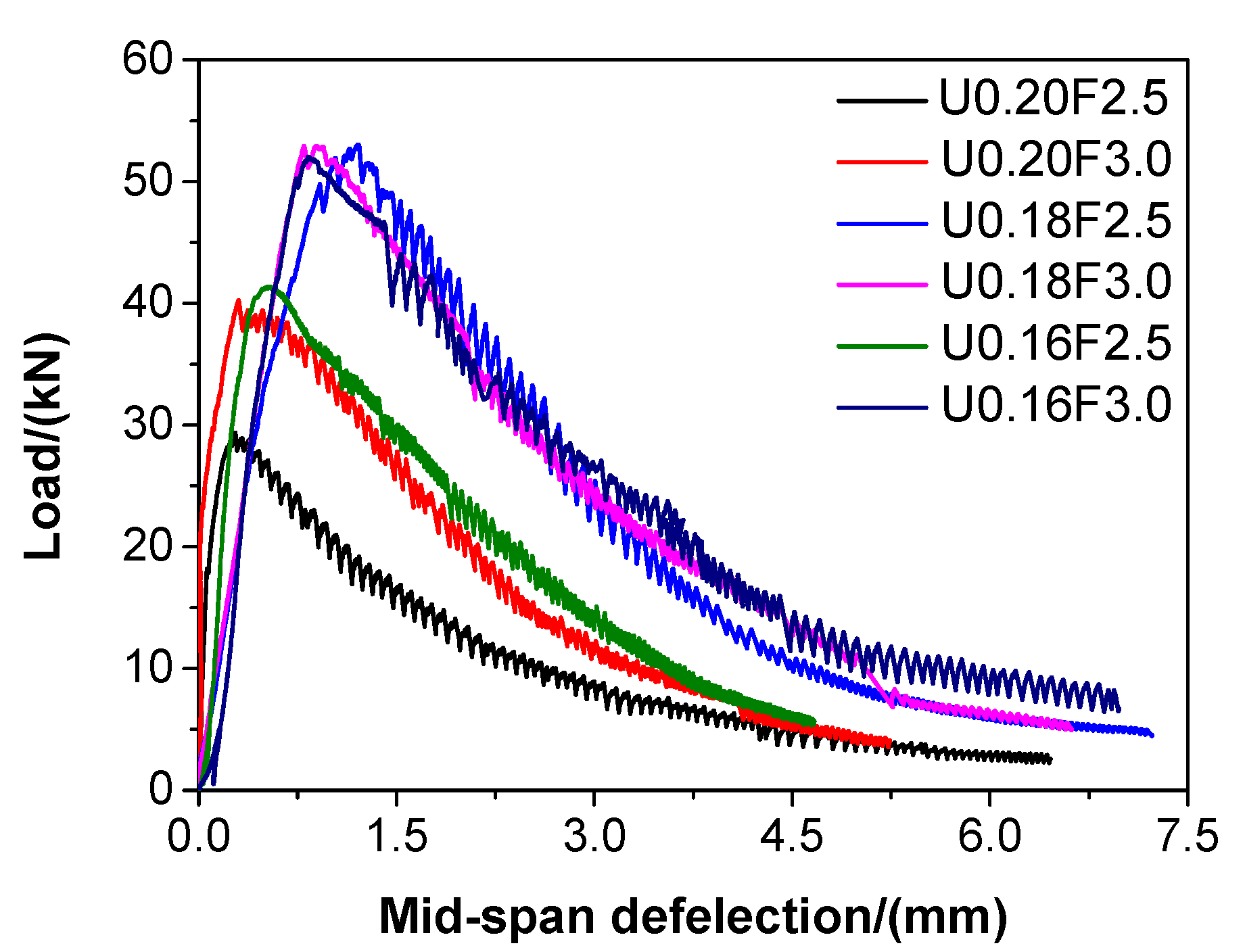

3.5. Flexural Strength

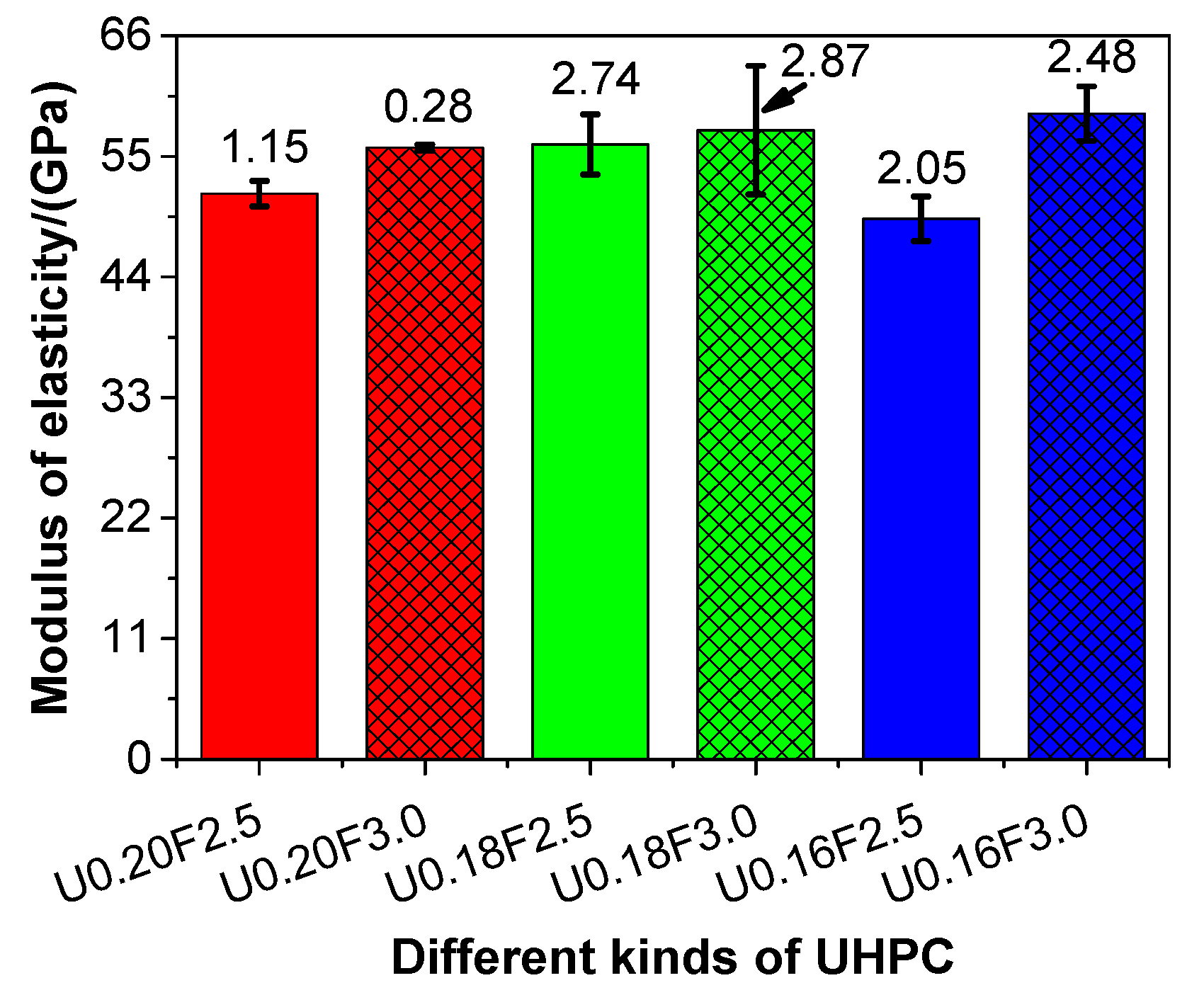

3.6. Young’s Modulus

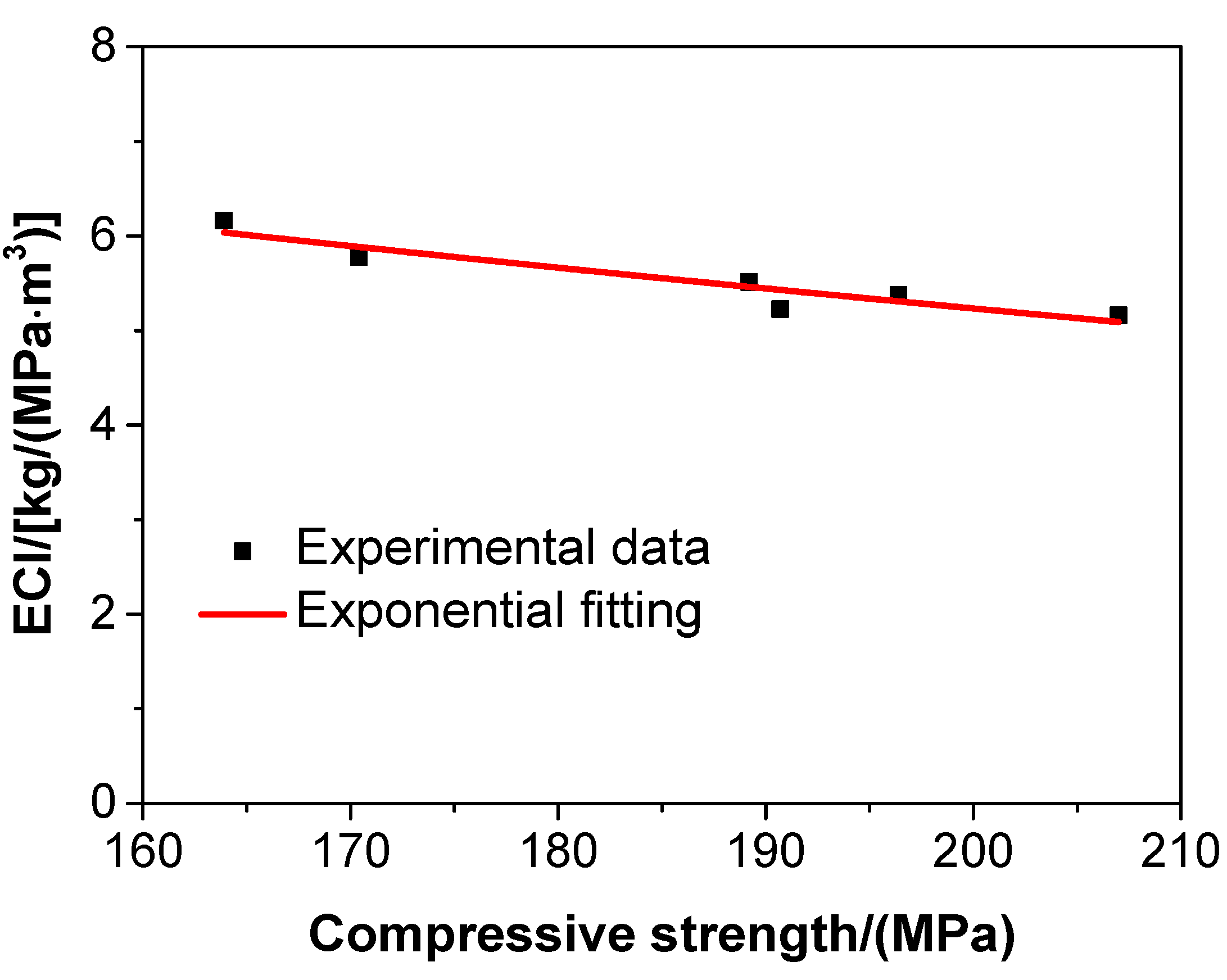

3.7. Compressive Strength—Young’s Modulus Correlation

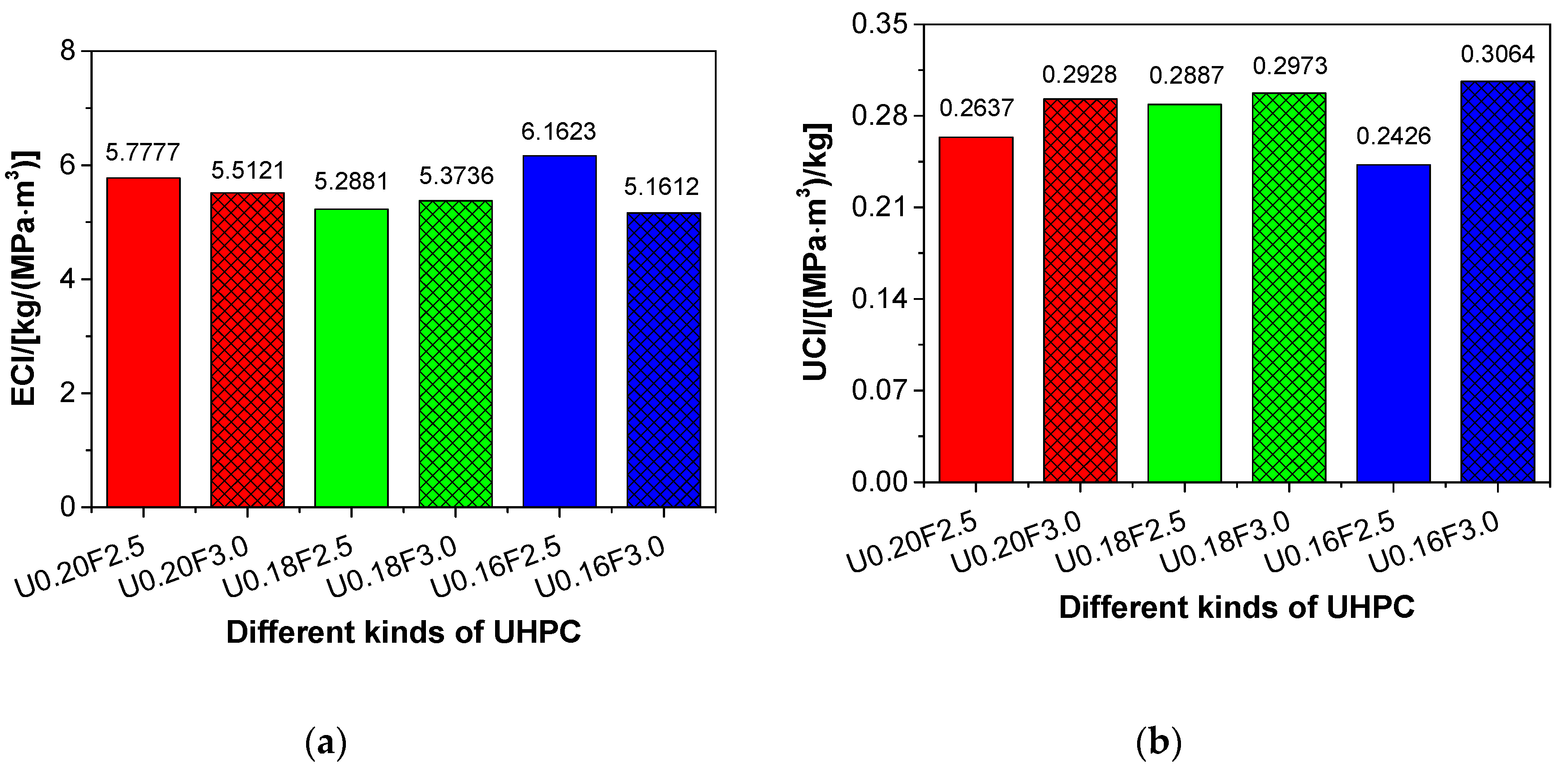

3.8. Environmental Assessment

4. Conclusions

- (1)

- The mix proportions of UHPC with aeolian sand were adequately designed according to the particle packing theory, and it is possible to use aeolian sand to manufacture UHPC.

- (2)

- The slump flow of UHPC decreased with a reduction in the water/binder ratio or an increase in the steel fibre content.

- (3)

- The porosities of U0.18F3.0 and U0.16F3.0 were invariably lower than that of U0.20F3.0, which suggests that the porosity of UHPC decreases if the water/binder ratio is reduced.

- (4)

- The compressive strength, flexural strength, and Young’s modulus of UHPC samples with aeolian sand were in the ranges of 163.9–207.0 MPa, 18.0–32.2 MPa, and 49.3–58.9 GPa, respectively.

- (5)

- The compressive strength, flexural strength, and Young’s modulus of UHPC increased with a decrease in the water/binder ratio, except for U0.16F2.5. This indicates that the compressive strength, flexural strength, and Young’s modulus of UHPC are improved when the water/binder ratio is reduced.

- (6)

- The compressive strength, flexural strength, fracture energy, and Young’s modulus of UHPC raised when the steel fibre content increased from 2.5 to 3.0 vol%. This demonstrated that the adoption of steel fibre contributes to enhancing the compressive strength, flexural strength, plasticity, and Young’s modulus of UHPC.

- (7)

- The compressive strength—Young’s modulus correlation of UHPC can be described by an exponential formula. This is a convenient practical method of assessing the Young’s modulus of UHPC in terms of its compressive strength via the empirical formula.

- (8)

- The environmental impact of UHPC was improved by decreasing the water/binder ratio, and the compressive strength–ECI correlation of UHPC displayed a significant negative correlation.

- (9)

- The recommended value of steel fibre was 3.0 vol%, considering the mechanical properties and the environmental impact of UHPC produced in the paper.

Author Contributions

Funding

Conflicts of Interest

References

- Khan, I.H. Soil studies for highway construction in arid zones. Eng. Geol. 1982, 19, 47–62. [Google Scholar] [CrossRef]

- Al-Sanad, H.; Ismael, N.; Nayfeh, A. Geotechnical properties of dune sands in Kuwait. Eng. Geol. 1993, 34, 45–52. [Google Scholar] [CrossRef]

- Yuan, Y.; Wang, X.; Zhou, X. Experimental research on compaction characteristics of aeolian sand. Front. Arch. Civ. Eng. China 2008, 2, 359–365. [Google Scholar] [CrossRef]

- Al-Taie, A.J.; Al-Shakarchi, Y.J.; Mohammed, A.A. Investigation of geotechnical specifications of sand dune soil: A case study around baiji in iraq. IIUM Eng. J. 2013, 14, 208–215. [Google Scholar] [CrossRef] [Green Version]

- Zhang, G.; Song, J.; Yang, J.; Liu, X. Performance of mortar and concrete made with a fine aggregate of desert sand. Build. Environ. 2006, 41, 1478–1481. [Google Scholar] [CrossRef]

- Al-Harthy, A.S.; Halim, M.A.; Taha, R.; Al-Jabri, K. The properties of concrete made with fine dune sand. Constr. Build. Mater. 2007, 21, 1803–1808. [Google Scholar] [CrossRef]

- Dong, W.; Shen, X.-D.; Xue, H.-J.; He, J.; Liu, Y. Research on the freeze-thaw cyclic test and damage model of Aeolian sand lightweight aggregate concrete. Constr. Build. Mater. 2016, 123, 792–799. [Google Scholar] [CrossRef]

- Lopez-Querol, S.; Arias-Trujillo, J.; Gm-Elipe, M.; Matias-Sanchez, A.; Cantero, B. Improvement of the bearing capacity of confined and unconfined cement-stabilized aeolian sand. Constr. Build. Mater. 2017, 153, 374–384. [Google Scholar] [CrossRef]

- Farzampour, A. Compressive behavior of concrete under environmental effects. In Compressive Strength of Concrete; IntechOpen: London, UK, 2019. [Google Scholar]

- Farzampour, A. Temperature and humidity effects on behavior of grouts. Adv. Concr. Constr. 2017, 5, 659–669. [Google Scholar]

- Mansouri, I.; Shahheidari, F.S.; Hashemi, S.M.A.; Farzampour, A. Investigation of steel fiber effects on concrete abrasion resistance. Adv. Concr. Constr. 2020, 9, 367–374. [Google Scholar]

- Jiang, J.-Y.; Zhou, W.; Gao, Y.; Wang, L.; Wang, F.; Chu, H.-Y.; Xu, G.; Vandevyvere, B.; Sierens, Z.; Li, J. Feasibility of manufacturing ultra-high performance cement-based composites (UHPCCs) with recycled sand: A preliminary study. Waste Manag. 2018, 83, 104–112. [Google Scholar] [CrossRef] [PubMed]

- Damineli, B.L.; Kemeid, F.M.; Aguiar, P.S.; John, V.M. Measuring the eco-efficiency of cement use. Cem. Concr. Compos. 2010, 32, 555–562. [Google Scholar] [CrossRef]

- Rossi, P. Influence of fibre geometry and matrix maturity on the mechanical performance of ultra high-performance cement-based composites. Cem. Concr. Compos. 2013, 37, 246–248. [Google Scholar] [CrossRef]

- El-Dieb, A.S. Mechanical, durability and microstructural characteristics of ultra-high-strength self-compacting concrete incorporating steel fibers. Mater. Des. 2009, 30, 4286–4292. [Google Scholar] [CrossRef]

- Habert, G.; Denarié, E.; Šajna, A.; Rossi, P. Lowering the global warming impact of bridge rehabilitations by using Ultra High Performance Fibre Reinforced Concretes. Cem. Concr. Compos. 2013, 38, 1–11. [Google Scholar] [CrossRef] [Green Version]

- Bornemann, R.; Schmidt, M. The role of powders in concrete. In Proceedings of the 6th International Symposium on Utilisation of High Strength/High Performance Concrete, Leipzig, Germany, 2 June 2002; pp. 863–872. [Google Scholar]

- Huang, W.; Kazemi-Kamyab, H.; Sun, W.; Scrivener, K. Effect of replacement of silica fume with calcined clay on the hydration and microstructural development of eco-UHPFRC. Mater. Des. 2017, 121, 36–46. [Google Scholar] [CrossRef]

- Brouwers, H.; Radix, H. Self-Compacting Concrete: Theoretical and experimental study. Cem. Concr. Res. 2005, 35, 2116–2136. [Google Scholar] [CrossRef]

- Li, J.; Wu, C.; Hao, H. An experimental and numerical study of reinforced ultra-high performance concrete slabs under blast loads. Mater. Des. 2015, 82, 64–76. [Google Scholar] [CrossRef]

- Hassan, A.; Jones, S.; Mahmud, G. Experimental test methods to determine the uniaxial tensile and compressive behaviour of ultra high performance fibre reinforced concrete (UHPFRC). Constr. Build. Mater. 2012, 37, 874–882. [Google Scholar] [CrossRef]

- Alsalman, A.; Dang, C.; Hale, W.M. Development of ultra-high performance concrete with locally available materials. Constr. Build. Mater. 2017, 133, 135–145. [Google Scholar] [CrossRef]

- Verma, M.; Prem, P.R.; Rajasankar, J.; Bharatkumar, B. On low-energy impact response of ultra-high performance concrete (UHPC) panels. Mater. Des. 2016, 92, 853–865. [Google Scholar] [CrossRef]

- Tafraoui, A.; Escadeillas, G.; Vidal, T. Durability of the Ultra High Performances Concrete containing metakaolin. Constr. Build. Mater. 2016, 112, 980–987. [Google Scholar] [CrossRef]

- Shafieifar, M.; Farzad, M.; Azizinamini, A. Experimental and numerical study on mechanical properties of Ultra High Performance Concrete (UHPC). Constr. Build. Mater. 2017, 156, 402–411. [Google Scholar] [CrossRef]

- Hüsken, G.; Brouwers, H.J.H. Erratum to: A new mix design concept for earth-moist concrete: A theoretical and experimental study. Cem. Concr. Res. 2008, 38, 1246–1259. [Google Scholar] [CrossRef]

- Yu, R.; Spiesz, P.; Brouwers, H. Effect of nano-silica on the hydration and microstructure development of Ultra-High Performance Concrete (UHPC) with a low binder amount. Constr. Build. Mater. 2014, 65, 140–150. [Google Scholar] [CrossRef] [Green Version]

- Yu, R.; Spiesz, P.; Brouwers, H. Mix design and properties assessment of Ultra-High Performance Fibre Reinforced Concrete (UHPFRC). Cem. Concr. Res. 2014, 56, 29–39. [Google Scholar] [CrossRef]

- Pyo, S.; Kim, H.-K.; Lee, B.Y. Effects of coarser fine aggregate on tensile properties of ultra high performance concrete. Cem. Concr. Compos. 2017, 84, 28–35. [Google Scholar] [CrossRef]

- Wang, X.; Yu, R.; Shui, Z.; Song, Q.; Zhang, Z. Mix design and characteristics evaluation of an eco-friendly Ultra-High Performance Concrete incorporating recycled coral based materials. J. Clean. Prod. 2017, 165, 70–80. [Google Scholar] [CrossRef]

- Funk, J.E.; Dinger, D.R. Predictive Process Control of Crowded Particulate Suspensions Applied to Ceramic Manufacturing; Kluwer Academic Publishers: Boston, MA, USA, 1994. [Google Scholar]

- Kim, H.; Koh, T.; Pyo, S. Enhancing flowability and sustainability of ultra high performance concrete incorporating high replacement levels of industrial slags. Constr. Build. Mater. 2016, 123, 153–160. [Google Scholar] [CrossRef]

- Wille, K.; Boisvert-Cotulio, C. Material efficiency in the design of ultra-high performance concrete. Constr. Build. Mater. 2015, 86, 33–43. [Google Scholar] [CrossRef]

- Park, S.H.; Kim, D.-J.; Ryu, G.-S.; Koh, K.T. Tensile behavior of Ultra High Performance Hybrid Fiber Reinforced Concrete. Cem. Concr. Compos. 2012, 34, 172–184. [Google Scholar] [CrossRef]

- GB 50204. In Code for Quality Acceptance of Concrete Structure Construction; China Architecture & Building Press: Beijing, China, 2014.

- GB 50119. In Code for Concrete Admixture Application; China Architecture & Building Press: Beijing, China, 2014.

- GB/T 17671. In Method of Testing Cements-Determination of Strength; Standards Press of China: Beijing, China, 1999.

- Long, G.; Gao, Y.; Xie, Y. Designing more sustainable and greener self-compacting concrete. Constr. Build. Mater. 2015, 84, 301–306. [Google Scholar] [CrossRef]

- Chiaia, B.; Fantilli, A.P.; Guerini, A. Eco-mechanical index for structural concrete. Constr. Build. Mater. 2014, 67, 386–392. [Google Scholar] [CrossRef]

- Wang, R.; Gao, X.; Huang, H.; Han, G. Influence of rheological properties of cement mortar on steel fiber distribution in UHPC. Constr. Build. Mater. 2017, 144, 65–73. [Google Scholar] [CrossRef]

- Alsalman, A.; Dang, C.N.; Prinz, G.S.; Hale, W.M. Evaluation of modulus of elasticity of ultra-high performance concrete. Constr. Build. Mater. 2017, 153, 918–928. [Google Scholar] [CrossRef]

- Wu, Z.; Shi, C.; He, W.; Wu, L. Effects of steel fiber content and shape on mechanical properties of ultra high performance concrete. Constr. Build. Mater. 2016, 103, 8–14. [Google Scholar] [CrossRef]

- Chu, H.-Y.; Jiang, J.-Y.; Sun, W.; Zhang, M. Effects of graphene sulfonate nanosheets on mechanical and thermal properties of sacrificial concrete during high temperature exposure. Cem. Concr. Compos. 2017, 82, 252–264. [Google Scholar] [CrossRef]

- Meng, W.; Khayat, K.H. Mechanical properties of ultra-high-performance concrete enhanced with graphite nanoplatelets and carbon nanofibers. Compos. Part B Eng. 2016, 107, 113–122. [Google Scholar] [CrossRef]

- Chu, H.-Y.; Ge, X.; Jiang, J.-Y.; Tang, J.; Zhang, Z. Mechanical properties and ablation behaviour of nuclear sacrificial materials containing graphene sulfonate nanosheets. Constr. Build. Mater. 2018, 191, 69–79. [Google Scholar] [CrossRef]

- Wang, L.-G.; Ju, S.-Y.; Chu, H.-Y.; Liu, Z.-Y.; Yang, Z.-Q.; Wang, F.-J.; Jiang, J. Hydration process and microstructure evolution of low exothermic concrete produced with urea. Constr. Build. Mater. 2020, 248, 118640. [Google Scholar] [CrossRef]

- Jiang, J.-Y.; Zhou, W.; Chu, H.; Wang, F.; Wang, L.; Feng, T.; Guo, D. Design of Eco-friendly Ultra-high Performance Concrete with Supplementary Cementitious Materials and Coarse Aggregate. J. Wuhan Univ. Technol. Sci. Ed. 2019, 34, 1350–1359. [Google Scholar] [CrossRef]

- Chu, H.-Y.; Jiang, J.-Y.; Sun, W.; Zhang, M. Thermal behavior of siliceous and ferro-siliceous sacrificial concrete subjected to elevated temperatures. Mater. Des. 2016, 95, 470–480. [Google Scholar] [CrossRef]

- Yu, R.; Spiesz, P.; Brouwers, H. Development of an eco-friendly Ultra-High Performance Concrete (UHPC) with efficient cement and mineral admixtures uses. Cem. Concr. Compos. 2015, 55, 383–394. [Google Scholar] [CrossRef] [Green Version]

- Yoo, D.-Y.; Banthia, N.; Lee, J.-Y.; Yoon, Y.-S. Effect of fiber geometric property on rate dependent flexural behavior of ultra-high-performance cementitious composite. Cem. Concr. Compos. 2018, 86, 57–71. [Google Scholar] [CrossRef]

- Siddique, R. Effect of fine aggregate replacement with Class F fly ash on the mechanical properties of concrete. Cem. Concr. Res. 2003, 33, 539–547. [Google Scholar] [CrossRef]

- Su, Y.; Wu, C.; Li, J.; Li, Z.-X.; Li, W. Development of novel ultra-high performance concrete: From material to structure. Constr. Build. Mater. 2017, 135, 517–528. [Google Scholar] [CrossRef]

- Bazant, Z.P. Fracture mechanics of concrete structures. In Proceedings of the First International Conference on Fracture Mechanics of Concrete Structures (FraMCoS1), held at Beaver Run Resort, Breckenridge, CO, USA, 1–5 June 1992; Taylor & Francis: London, UK. [Google Scholar]

- Harsh, S.; Shen, Z.; Darwin, D. Strain-rate sensitive behavior of cement paste and mortar in compression. ACI Mater. J. 1990, 87, 508–516. [Google Scholar]

- Shi, Y.; Long, G.; Ma, C.; Xie, Y.; He, J. Design and preparation of ultra-high performance concrete with low environmental impact. J. Clean. Prod. 2019, 214, 633–643. [Google Scholar] [CrossRef]

| Materials | Cement | Fly Ash | Aeolian Sand |

|---|---|---|---|

| CaO | 64.70 | 8.38 | 2.07 |

| SiO2 | 20.40 | 47.96 | 81.72 |

| Al2O3 | 4.70 | 30.46 | 8.19 |

| Fe2O3 | 3.38 | 5.91 | 1.49 |

| MgO | 0.87 | 2.60 | 0.84 |

| SO3 | 1.88 | 1.32 | 0.08 |

| K2O | 0.83 | 1.61 | 2.12 |

| Na2O | - | 1.76 | 1.67 |

| Loss | 3.24 | - | 1.82 |

| Mixture | U0.20F2.5 | U0.20F3.0 | U0.18F2.5 | U0.18F3.0 | U0.16F2.5 | U0.16F3.0 |

|---|---|---|---|---|---|---|

| Cement | 646.2 | 646.2 | 660.6 | 660.6 | 675.6 | 675.6 |

| Fly ash | 323.1 | 323.1 | 330.3 | 330.3 | 337.8 | 337.8 |

| Silica fume | 107.7 | 107.7 | 110.1 | 110.1 | 112.6 | 112.6 |

| Aeolian sand | 861.8 | 861.8 | 880.8 | 880.8 | 900.6 | 900.6 |

| Water | 215.4 | 215.4 | 198.2 | 198.2 | 180.2 | 180.2 |

| Superplasticizer | 21.5 | 21.5 | 22.0 | 22.0 | 22.5 | 22.5 |

| Expensive agent | 32.3 | 32.3 | 33.0 | 33.0 | 33.8 | 33.8 |

| Steel fibre | 195.0 | 234.0 | 195.0 | 234.0 | 195.0 | 234.0 |

| Aggregate/cement ratio (in weight) | 1.33 | 1.33 | 1.33 | 1.33 | 1.33 | 1.33 |

| Items | Unit | Embedded CO2 (kg) | Reference |

|---|---|---|---|

| Cement | kg | 0.8324 | [39] |

| Fly ash | kg | 0.0090 | [38] |

| Silica fume | kg | 0 | [39] |

| Aeolian sand | kg | 0.0010 | |

| Water | kg | 0.0003 | [38] |

| Superplasticizer | kg | 0.7200 | [38] |

| Expensive agent | kg | 0.0810 | |

| Steel fibre | kg | 1.4965 | [39] |

| Mixture | U0.20F2.5 | U0.20F3.0 | U0.18F2.5 | U0.18F3.0 | U0.16F2.5 | U0.16F3.0 |

|---|---|---|---|---|---|---|

| Slump flow | 900 | 840 | 775 | 700 | 630 | 570 |

| Mixture | U0.20F2.5 | U0.20F3.0 | U0.18F2.5 | U0.18F3.0 | U0.16F2.5 | U0.16F3.0 |

|---|---|---|---|---|---|---|

| Fracture energy | 60.3 | 90.1 | 132.6 | 133.8 | 94.1 | 135.2 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chu, H.; Wang, F.; Wang, L.; Feng, T.; Wang, D. Mechanical Properties and Environmental Evaluation of Ultra-High-Performance Concrete with Aeolian Sand. Materials 2020, 13, 3148. https://doi.org/10.3390/ma13143148

Chu H, Wang F, Wang L, Feng T, Wang D. Mechanical Properties and Environmental Evaluation of Ultra-High-Performance Concrete with Aeolian Sand. Materials. 2020; 13(14):3148. https://doi.org/10.3390/ma13143148

Chicago/Turabian StyleChu, Hongyan, Fengjuan Wang, Liguo Wang, Taotao Feng, and Danqian Wang. 2020. "Mechanical Properties and Environmental Evaluation of Ultra-High-Performance Concrete with Aeolian Sand" Materials 13, no. 14: 3148. https://doi.org/10.3390/ma13143148

APA StyleChu, H., Wang, F., Wang, L., Feng, T., & Wang, D. (2020). Mechanical Properties and Environmental Evaluation of Ultra-High-Performance Concrete with Aeolian Sand. Materials, 13(14), 3148. https://doi.org/10.3390/ma13143148