Green and Durable Lightweight Aggregate Concrete: The Role of Waste and Recycled Materials

Abstract

:1. Introduction

2. Green Cementitious Binders

2.1. Special Type Cementitious Binders

2.2. Recycling Materials as Cementitious Binders

3. Green Aggregates

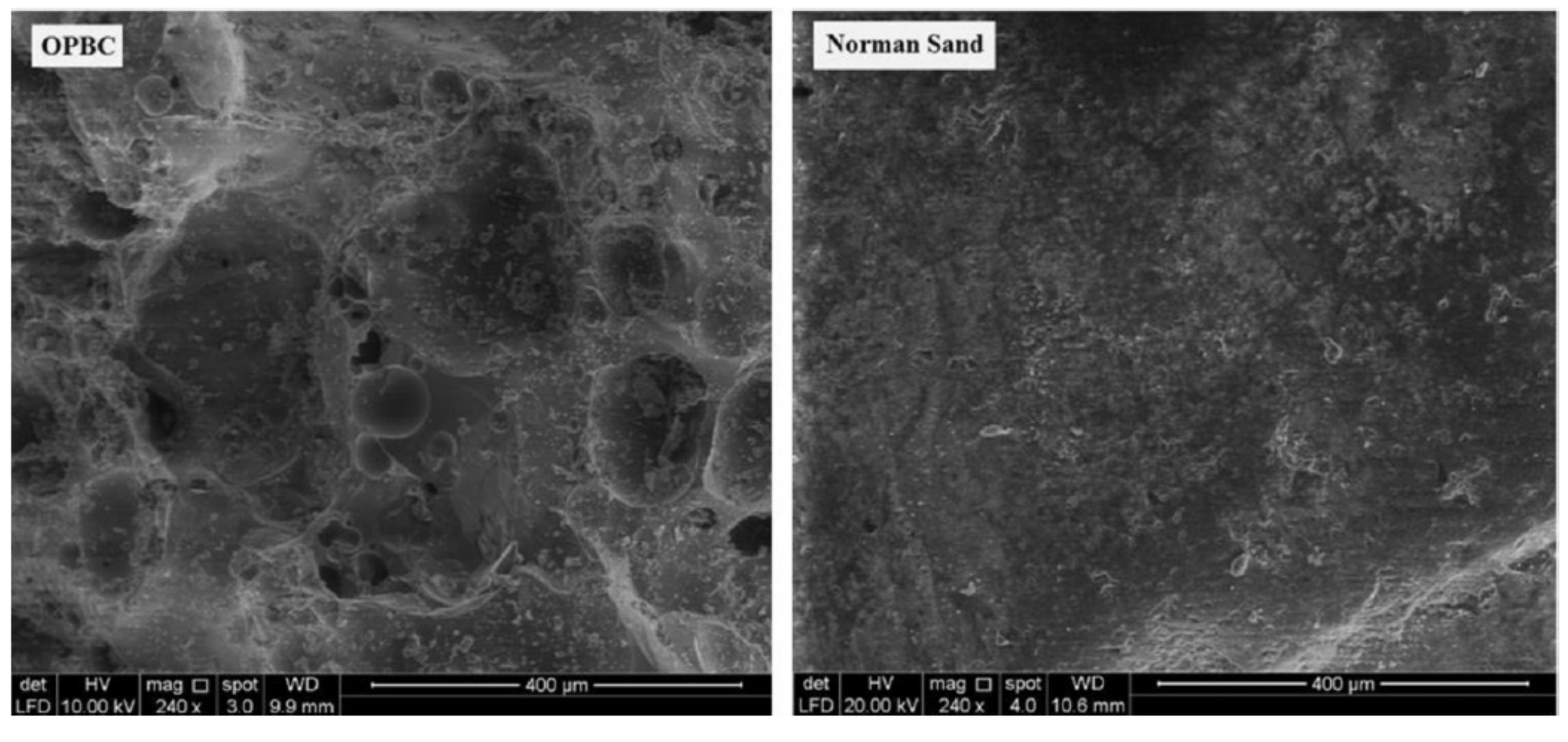

3.1. Agricultural Waste

3.2. Industrial Waste

3.3. Challenges

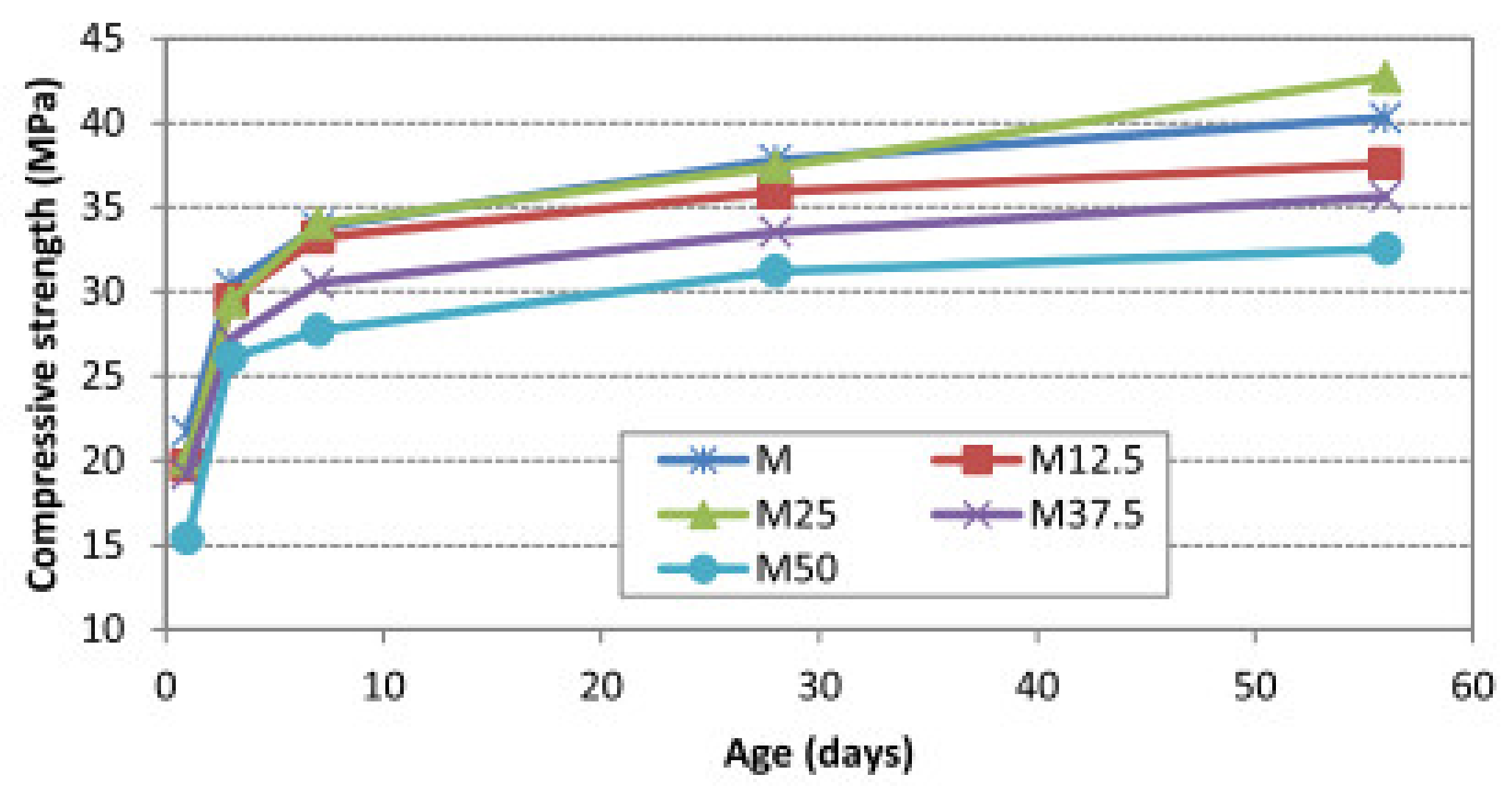

4. Mechanical Properties of Green LWAC

5. Shrinkage

5.1. Internal Curing

5.2. Shrinkage Reducing Admixture

6. Durability

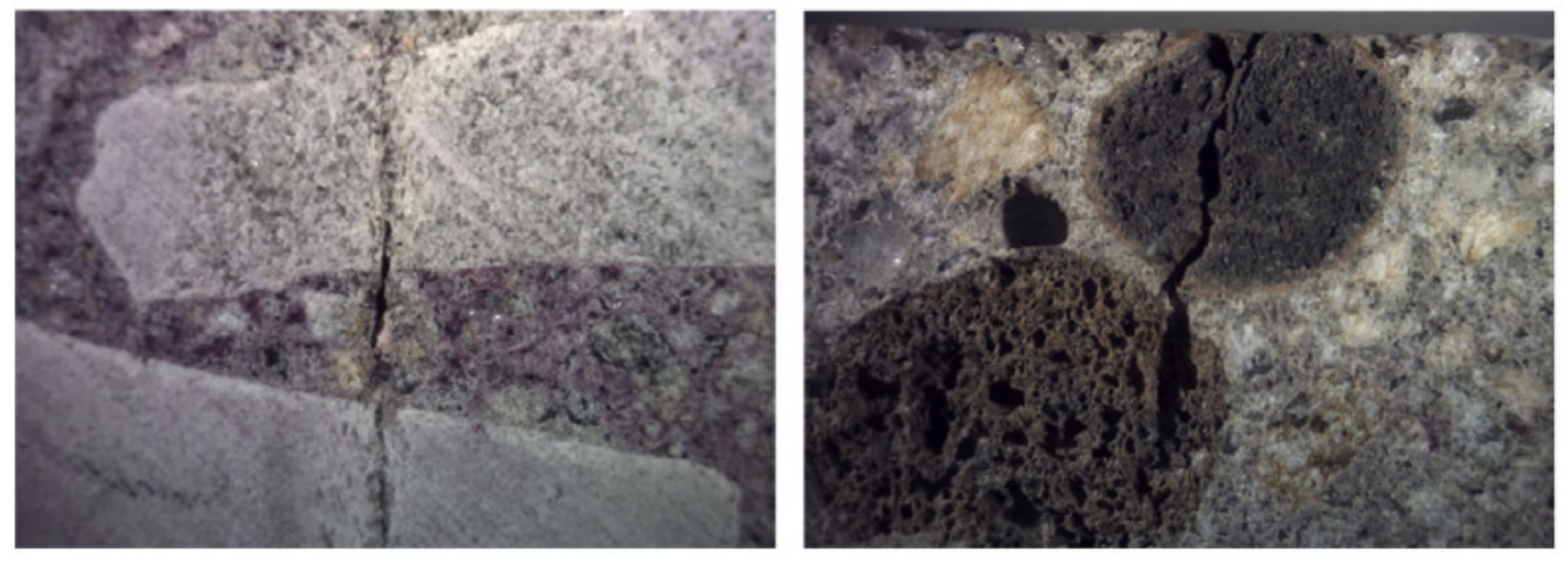

6.1. Carbonation-Induced Corrosion

6.2. Permeability

6.3. Freeze-Thaw Resistance

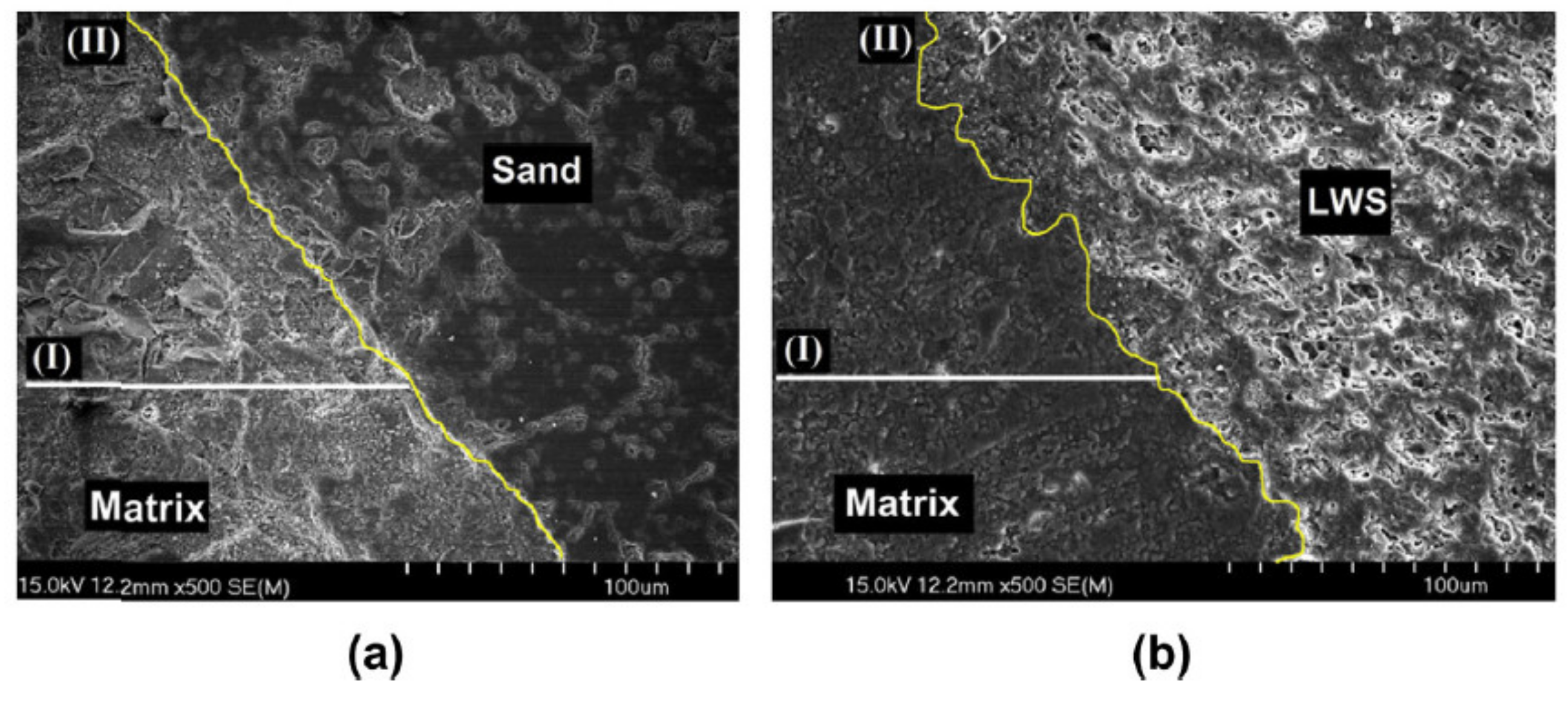

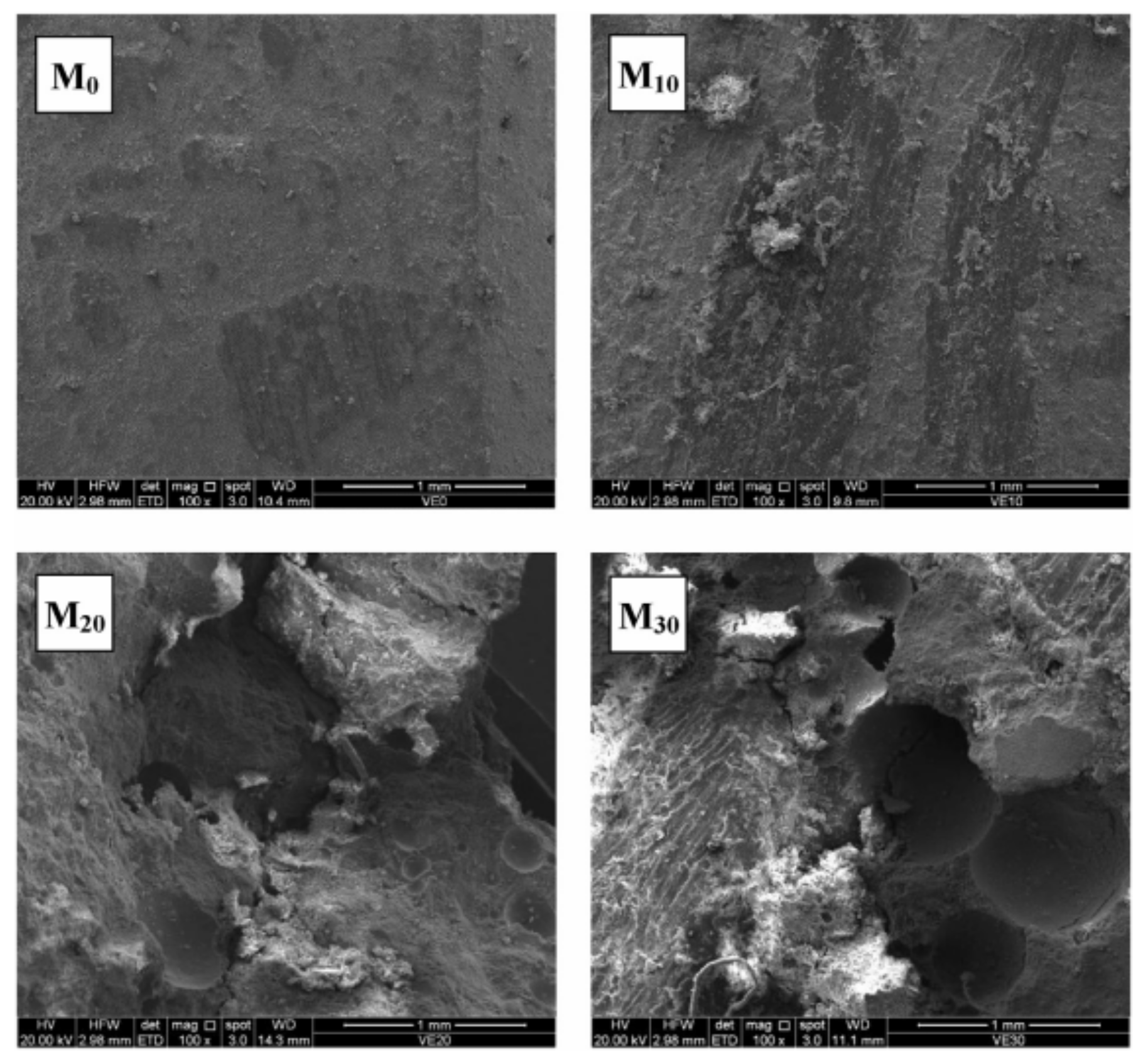

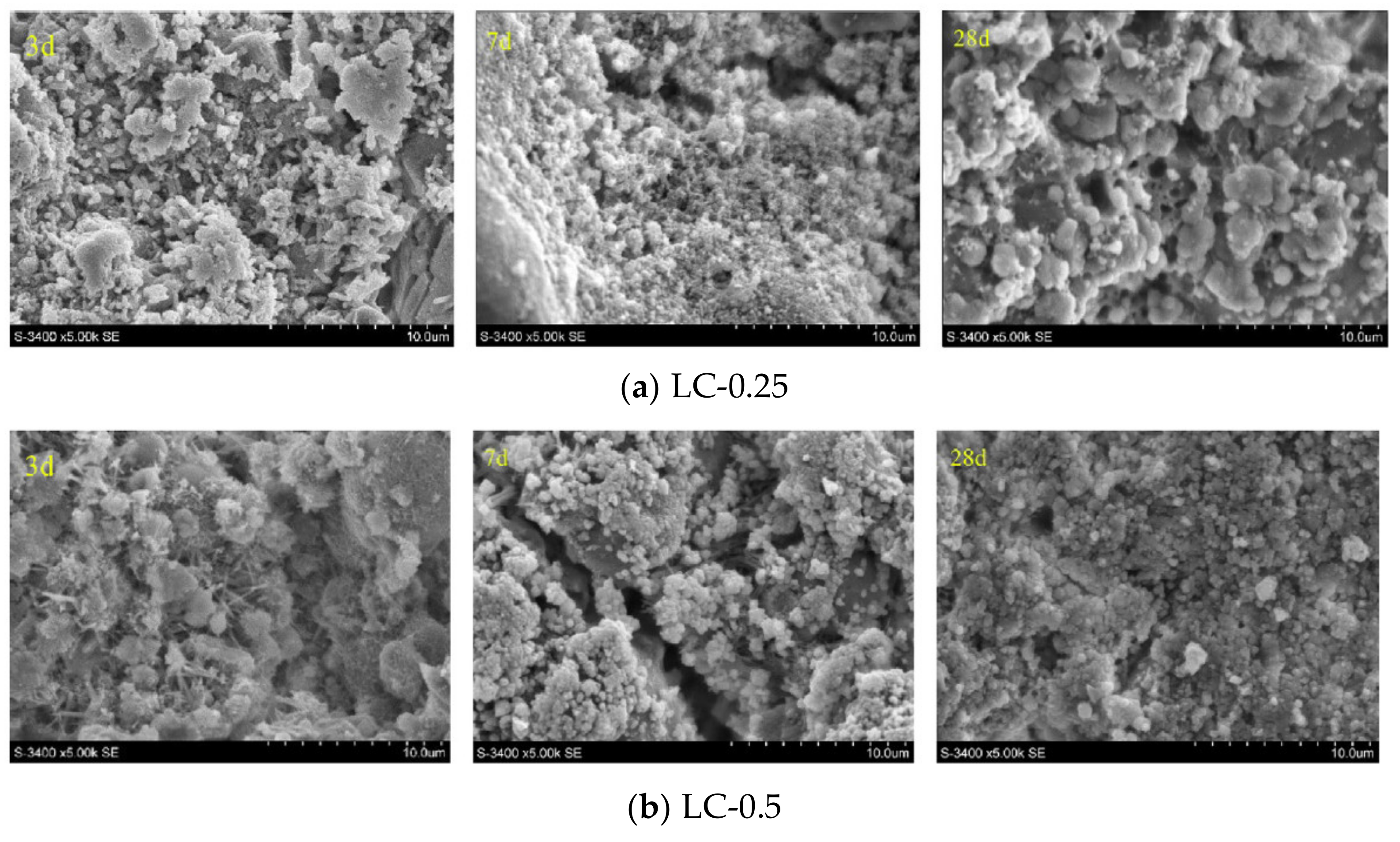

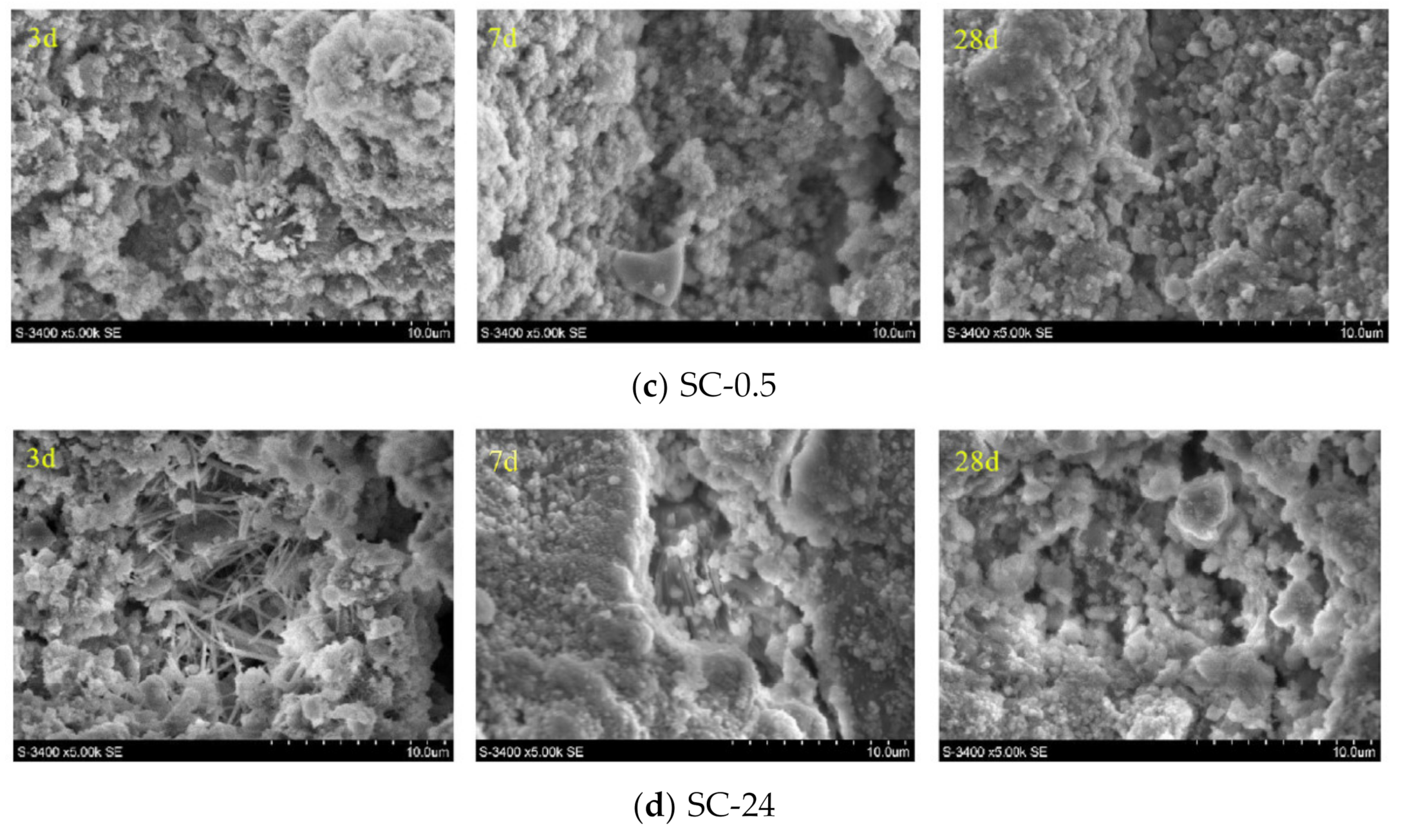

7. Advanced Characterization of LWAC

8. Concluding Remarks and Future Trends

- (1)

- The chemical reaction mechanisms between the recycled aggregates and cementitious binders should be investigated systematically. So far, the chemical bonding between the aggregates and the cementitious binders remains unclear. Further studies should focus on the chemical analysis of the aggregates, cementitious binder, and the interfacial area to elucidate and characterize the chemical reactions of the various recycled lightweight aggregates and the cementitious binders.

- (2)

- For the lightweight aggregate concrete in the construction, prewetting of the lightweight aggregate is an appropriate way to reduce water absorption and improve the workability. The interface wettability between the lightweight aggregate and the cementitious pastes needs to be investigated. The impact of the saturation degree of various recycled aggregates on the workability, mechanical properties, and even durability should be further investigated.

- (3)

- The porosity of the aggregates is another critical factor that determines the final properties of lightweight aggregate concrete. So far, the relationship between the porosity of the recycled lightweight aggregates and the final properties of the lightweight aggregate concrete is still lacking, especially when the chemical compositions of the lightweight aggregates were different.

- (4)

- At present, researches on lightweight aggregate concrete mainly focus on high strength, which is an inevitable trend of future development. However, the durability challenge and the segregation resistance in engineering applications are worthy of this concern.

Author Contributions

Funding

Conflicts of Interest

References

- Bui, N.K.; Satomi, T.; Takahashi, H. Influence of industrial by-products and waste paper sludge ash on properties of recycled aggregate concrete. J. Clean. Prod. 2019, 214, 403–418. [Google Scholar] [CrossRef]

- Tang, C.W.; Chen, H.J.; Wang, S.Y.; Spaulding, J. Production of synthetic lightweight aggregate using reservoir sediments for concrete and masonry. Cem. Concr. Compos. 2011, 33, 292–300. [Google Scholar] [CrossRef]

- Chandra, S.; Berntsson, L. 2—Production of Lightweight Aggregates and Its Properties; Chandra, S., Berntsson, L.B.T.-L.A.C., Eds.; William Andrew Publishing: Norwich, NY, USA, 2002; pp. 21–65. [Google Scholar] [CrossRef]

- Bremner, T.W. Environmental aspects of concrete: Problems and solutions. In Proceedings of the First Russian Conference on Concrete and Reinforced Concrete Problems, Moscow, Russia, 9–14 September 2001; pp. 232–246. [Google Scholar]

- Cheeseman, C.R.; Virdi, G.S. Properties and microstructure of lightweight aggregate produced from sintered sewage sludge ash. Resour. Conserv. Recycl. 2005, 45, 18–30. [Google Scholar] [CrossRef]

- Lo, Y.; Gao, X.F.; Jeary, A.P. Microstructure of pre-wetted aggregate on lightweight concrete. Build. Environ. 1999, 34, 759–764. [Google Scholar] [CrossRef]

- Hunag, L.J.; Wang, H.Y.; Wang, S.Y. A study of the durability of recycled green building materials in lightweight aggregate concrete. Constr. Build. Mater. 2015, 96, 353–359. [Google Scholar] [CrossRef]

- Ting, T.Z.H.; Rahman, M.E.; Lau, H.H.; Ting, M.Z.Y. Recent development and perspective of lightweight aggregates based self-compacting concrete. Constr. Build. Mater. 2019, 201, 763–777. [Google Scholar] [CrossRef]

- Mousa, A.; Mahgoub, M.; Hussein, M. Lightweight concrete in America: Presence and challenges. Sustain. Prod. Consum. 2018, 15, 131–144. [Google Scholar] [CrossRef]

- Moreno-Maroto, J.M.; Uceda-Rodríguez, M.; Cobo-Ceacero, C.J.; de Hoces, M.C.; MartínLara, M.Á.; Cotes-Palomino, T.; López García, A.B.; Martínez-García, C. Recycling of ‘alperujo’ (olive pomace) as a key component in the sintering of lightweight aggregates. J. Clean. Prod. 2019, 239, 118041. [Google Scholar] [CrossRef]

- Ganesh Babu, K.; Saradhi Babu, D. Performance of fly ash concretes containing lightweight EPS aggregates. Cem. Concr. Compos. 2004, 26, 605–611. [Google Scholar] [CrossRef]

- Juenger, M.C.G.; Winnefeld, F.; Provis, J.L.; Ideker, J.H. Advances in alternative cementitious binders. Cem. Concr. Res. 2011, 41, 1232–1243. [Google Scholar] [CrossRef]

- Damtoft, J.S.; Lukasik, J.; Herfort, D.; Sorrentino, D.; Gartner, E.M. Sustainable development and climate change initiatives. Cem. Concr. Res. 2008, 38, 115–127. [Google Scholar] [CrossRef]

- Farahani, J.N.; Shafigh, P.; Alsubari, B.; Shahnazar, S.; Mahmud, H. Engineering properties of lightweight aggregate concrete containing binary and ternary blended cement. J. Clean. Prod. 2017, 149, 976–988. [Google Scholar] [CrossRef]

- Shafigh, P.; Nomeli, M.A.; Alengaram, U.J.; Mahmud, H.; Bin Jumaat, M.Z. Engineering properties of lightweight aggregate concrete containing limestone powder and high volume fly ash. J. Clean. Prod. 2016, 135, 148–157. [Google Scholar] [CrossRef]

- Akçaözoğlu, S.; Akçaözoğlu, K.; Atiş, C.D. Thermal conductivity, compressive strength and ultrasonic wave velocity of cementitious composite containing waste PET lightweight aggregate (WPLA). Compos. Part B 2013, 45, 721–726. [Google Scholar] [CrossRef]

- Glasser, F.P.; Zhang, L. High-performance cement matrices based on calcium sulfoaluminate–belite compositions. Cem. Concr. Res. 2001, 31, 1881–1886. [Google Scholar] [CrossRef]

- Quillin, K. Performance of belite–sulfoaluminate cements. Cem. Concr. Res. 2001, 31, 1341–1349. [Google Scholar] [CrossRef]

- Mehdipour, I.; Khayat, K.H. Enhancing the performance of calcium sulfoaluminate blended cements with shrinkage reducing admixture or lightweight sand. Cem. Concr. Compos. 2018, 87, 29–43. [Google Scholar] [CrossRef]

- Arjunan, P.; Silsbee, M.R.; Della, M. Sulfoaluminate-belite cement from low-calcium fly ash and sulfur-rich and other industrial by-products. Cem. Concr. Res. 1999, 29, 1305–1311. [Google Scholar] [CrossRef]

- Bizzozero, J.; Gosselin, C.; Scrivener, K.L. Expansion mechanisms in calcium aluminate and sulfoaluminate systems with calcium sulfate. Cem. Concr. Res. 2014, 56, 190–202. [Google Scholar] [CrossRef]

- Chen, I.A.; Hargis, C.W.; Juenger, M.C.G. Understanding expansion in calcium sulfoaluminate–belite cements. Cem. Concr. Res. 2012, 42, 51–60. [Google Scholar] [CrossRef]

- Desbois, T.; Le Roy, R.; Pavoine, A.; Platret, G.; Feraille, A.; Alaoui, A. Effect of gypsum content on sulfoaluminate mortars stability. Eur. J. Environ. Civ. Eng. 2010, 14, 579–597. [Google Scholar] [CrossRef]

- Kasselouri, V.; Tsakiridis, P.; Malami, C.; Georgali, B.; Alexandridou, C. A study on the hydration products of a non-expansive sulfoaluminate cement. Cem. Concr. Res. 1995, 25, 1726–1736. [Google Scholar] [CrossRef]

- Zhang, M.-H.; Gjørv, O.E. Microstructure of the interfacial zone between lightweight aggregate and cement paste. Cem. Concr. Res. 1990, 20, 610–618. [Google Scholar] [CrossRef]

- Gruskovnjak, A.; Lothenbach, B.; Winnefeld, F.; Figi, R.; Ko, S.-C.; Adler, M.; Mäder, U. Hydration mechanisms of super sulphated slag cement. Cem. Concr. Res. 2008, 38, 983–992. [Google Scholar] [CrossRef] [Green Version]

- Masoudi, R.; Hooton, R.D. Examining the hydration mechanism of supersulfated cements made with high and low-alumina slags. Cem. Concr. Compos. 2019, 103, 193–203. [Google Scholar] [CrossRef]

- Grounds, T.; Nowell, D.V.; Wilburn, F.W. Resistance of supersulfated cement to strong sulfate solutions. J. Therm. Anal. Calorim. 2003, 72, 181–190. [Google Scholar] [CrossRef]

- Cerulli, T.; Pistolesi, C.; Maltese, C.; Salvioni, D. Durability of traditional plasters with respect to blast furnace slag-based plaster. Cem. Concr. Res. 2003, 33, 1375–1383. [Google Scholar] [CrossRef]

- Bogas, J.A.; Real, S.; Ferrer, B. Biphasic carbonation behaviour of structural lightweight aggregate concrete produced with different types of binder. Cem. Concr. Compos. 2016, 71, 110–121. [Google Scholar] [CrossRef]

- Shafigh, P.; Jumaat, M.Z.; Mahmud, H.; Bin Alengaram, U.J. Oil palm shell lightweight concrete containing high volume ground granulated blast furnace slag. Constr. Build. Mater. 2013, 40, 231–238. [Google Scholar] [CrossRef]

- Mo, K.H.; Alengaram, U.J.; Jumaat, M.Z. Utilization of ground granulated blast furnace slag as partial cement replacement in lightweight oil palm shell concrete. Mater. Struct. 2015, 48, 2545–2556. [Google Scholar] [CrossRef]

- Mo, K.H.; Johnson Alengaram, U.; Jumaat, M.Z.; Yap, S.P. Feasibility study of high volume slag as cement replacement for sustainable structural lightweight oil palm shell concrete. J. Clean. Prod. 2015, 91, 297–304. [Google Scholar] [CrossRef] [Green Version]

- Lynn, C.J.; Dhir, R.K.; Ghataora, G.S.; West, R.P. Sewage sludge ash characteristics and potential for use in concrete. Constr. Build. Mater. 2015, 98, 767–779. [Google Scholar] [CrossRef] [Green Version]

- Top, S.; Vapur, H. Effect of basaltic pumice aggregate addition on the material properties of fly ash based lightweight geopolymer concrete. J. Mol. Struct. 2018, 1163, 10–17. [Google Scholar] [CrossRef]

- AI-Sharif, M.M.; Attom, M.F. A geoenvironmental application of burned wastewater sludge ash in soil stabilization. Environ. Earth Sci. 2014, 71, 2453–2463. [Google Scholar] [CrossRef]

- Baeza-Brotons, F.; Garcés, P.; Payá, J.; Saval, J.M. Portland cement systems with addition of sewage sludge ash. Application in concretes for the manufacture of blocks. J. Clean. Prod. 2014, 82, 112–124. [Google Scholar] [CrossRef] [Green Version]

- Baeza, F.; Payá, J.; Galao, O.; Saval, J.M.; Garcés, P. Blending of industrial waste from different sources as partial substitution of Portland cement in pastes and mortars. Constr. Build. Mater. 2014, 66, 645–653. [Google Scholar] [CrossRef]

- De Lima, J.F.D.; Ingunza, M.D.P. Effects of sewage sludge ash addition in Portland cement concretes. In Proceedings of the Materials and Environmental Sciences, London, UK, 13–14 March 2015; Atlantis Press: Beijing, China; pp. 189–191. [Google Scholar]

- Merino, I.; Arévalo, L.F.; Romero, F. Preparation and characterization of ceramic products by thermal treatment of sewage sludge ashes mixed with different additives. Waste Manag. 2007, 27, 1829–1844. [Google Scholar] [CrossRef]

- Vogel, C.; Exner, R.M.; Adam, C. Heavy metal removal from sewage sludge ash by thermochemical treatment with polyvinylchloride. Environ. Sci. Technol. 2013, 47, 563–567. [Google Scholar] [CrossRef]

- Mefteh, H.; Kebaïli, O.; Oucief, H.; Berredjem, L.; Arabi, N. Influence of moisture conditioning of recycled aggregates on the properties of fresh and hardened concrete. J. Clean. Prod. 2013, 54, 282–288. [Google Scholar] [CrossRef]

- Shafigh, P.; Mahmud, H.; Jumaat, M.; Zargar, M. Agricultural wastes as aggregate in concrete mixtures–A review. Constr. Build. Mater. 2014, 53, 110–117. [Google Scholar] [CrossRef]

- Abdullah, A. Basic strength properties of lightweight concrete using agricultural wastes as aggregates. In Proceedings of the International Conference on Low-Cost Housing for Developing Countries, Roorkee, India, 14–17 November 1984. [Google Scholar]

- Alengaram, U.J.; Jumaat, M.Z.; Mahmud, H.; Fayyadh, M.M. Shear behaviour of reinforced palm kernel shell concrete beams. Constr. Build. Mater. 2011, 25, 2918–2927. [Google Scholar] [CrossRef]

- Alengaram, U.J.; Mahmud, H.; Jumaat, Z.M.; Shirazi, S.M. Effect of aggregate size and proportion on strength properties of palm kernel shell concrete. Int. J. Phys. Sci. 2010, 5, 1848–1856. [Google Scholar]

- Mannan, M.A.; Ganapathy, C. Concrete from an agricultural waste-oil palm shell (OPS). Build. Environ. 2004, 39, 441–448. [Google Scholar] [CrossRef]

- Mannan, M.A.; Ganapathy, C. Engineering properties of concrete with oil palm shell as coarse aggregate. Constr. Build. Mater. 2002, 16, 29–34. [Google Scholar] [CrossRef]

- Shafigh, P.; Jumaat, M.Z.; Mahmud, H.; Bin Alengaram, U.J. A new method of producing high strength oil palm shell lightweight concrete. Mater. Des. 2011, 32, 4839–4843. [Google Scholar] [CrossRef]

- Shafigh, P.; Mahmud, H.; Bin Jumaat, M.Z.; Bin Ahmmad, R.; Bahri, S. Structural lightweight aggregate concrete using two types of waste from the palm oil industry as aggregate. J. Clean. Prod. 2014, 80, 187–196. [Google Scholar] [CrossRef]

- Gunasekaran, K.P. An agricultural waste as aggregate in lightweight concrete. In Proceedings of the SEC-2008. Sixth Structural Engineering Convention, Chennai, India, 18–20 December 2008. [Google Scholar]

- Gunasekaran, K.K.P. Lightweight Concrete Mix Design Using Coconut Shell Aggregate. In Proceedings of the International Conference on Advances in Concrete and Construction, Hyderabad, India, 7–9 February 2008; pp. 450–459. [Google Scholar]

- Gunasekaran, K.; Annadurai, R.; Kumar, P.S. Long term study on compressive and bond strength of coconut shell aggregate concrete. Constr. Build. Mater. 2012, 28, 208–215. [Google Scholar] [CrossRef]

- Adesanya, D.A.; Raheem, A.A. A study of the permeability and acid attack of corn cob ash blended cements. Constr. Build. Mater. 2010, 24, 403–409. [Google Scholar] [CrossRef]

- Adesanya, D.A.; Raheem, A.A. A study of the workability and compressive strength characteristics of corn cob ash blended cement concrete. Constr. Build. Mater. 2009, 23, 311–317. [Google Scholar] [CrossRef]

- Pinto, J.; Vieira, B.; Pereira, H.; Jacinto, C.; Vilela, P.; Paiva, A.; Pereira, S.; Cunha, V.M.C.F.; Varum, H. Corn cob lightweight concrete for non-structural applications. Constr. Build. Mater. 2012, 34, 346–351. [Google Scholar] [CrossRef] [Green Version]

- Pacheco Menor, M.C.; Serna Ros, P.; Macías García, A.; Arévalo Caballero, M.J. Granulated cork with bark characterised as environment-friendly lightweight aggregate for cement based materials. J. Clean. Prod. 2019, 229, 358–373. [Google Scholar] [CrossRef]

- Ozturk, T.; Bayrakl, M. The possibilities of using tobacco wastes in producing lightweight concrete. Agric. Eng. Int. 2005, 7, BC05006. [Google Scholar]

- Salas, J.; Alvarez, M.; Veras, J. Lightweight insulating concretes with rice husk. Int. J. Cem. Compos. Light. Concr. 1986, 8, 171–180. [Google Scholar] [CrossRef]

- Bjørlykke, K. (Ed.) Introduction to Petroleum Geology; Petroleum Geoscience: Berlin Heidelberg, Germany, 2005. [Google Scholar]

- Ayati, B.; Molineux, C.; Newport, D.; Cheeseman, C. Manufacture and performance of lightweight aggregate from waste drill cuttings. J. Clean. Prod. 2019, 208, 252–260. [Google Scholar] [CrossRef] [Green Version]

- Colangelo, F.; Cioffi, R.; Liguori, B.; Iucolano, F. Recycled polyolefins waste as aggregates for lightweight concrete. Compos. Part B 2016, 106, 234–241. [Google Scholar] [CrossRef]

- El-Sayed, T.A. Flexural behavior of RC beams containing recycled industrial wastes as steel fibers. Constr. Build. Mater. 2019, 212, 27–38. [Google Scholar] [CrossRef]

- Lo, T.Y.; Cui, H.; Memon, S.A.; Noguchi, T. Manufacturing of sintered lightweight aggregate using high-carbon fly ash and its effect on the mechanical properties and microstructure of concrete. J. Clean. Prod. 2016, 112, 753–762. [Google Scholar] [CrossRef] [Green Version]

- Zhang, B.; Poon, C.S. Use of Furnace Bottom Ash for producing lightweight aggregate concrete with thermal insulation properties. J. Clean. Prod. 2015, 99, 94–100. [Google Scholar] [CrossRef]

- Patel, J.; kumar Patil, H.; Patil, Y.; Vesmawala, G. Production and performance of alkali-activated cold-bonded lightweight aggregate in concrete. J. Build. Eng. 2018, 20, 616–623. [Google Scholar] [CrossRef]

- Pierce, C.E.; Blackwell, M.C. Potential of scrap tire rubber as lightweight aggregate in flowable fill. Waste Manag. 2003, 23, 197–208. [Google Scholar] [CrossRef]

- Farahani, J.N.; Shafigh, P.; Mahmud, H. Production of A Green Lightweight Aggregate Concrete by Incorporating High Volume Locally Available Waste Materials. Procedia Eng. 2017, 184, 778–783. [Google Scholar] [CrossRef]

- Sarabèr, A.; Overhof, R.; Green, T.; Pels, J. Artificial lightweight aggregates as utilization for future ashes–A case study. Waste Manag. 2012, 32, 144–152. [Google Scholar] [CrossRef] [PubMed]

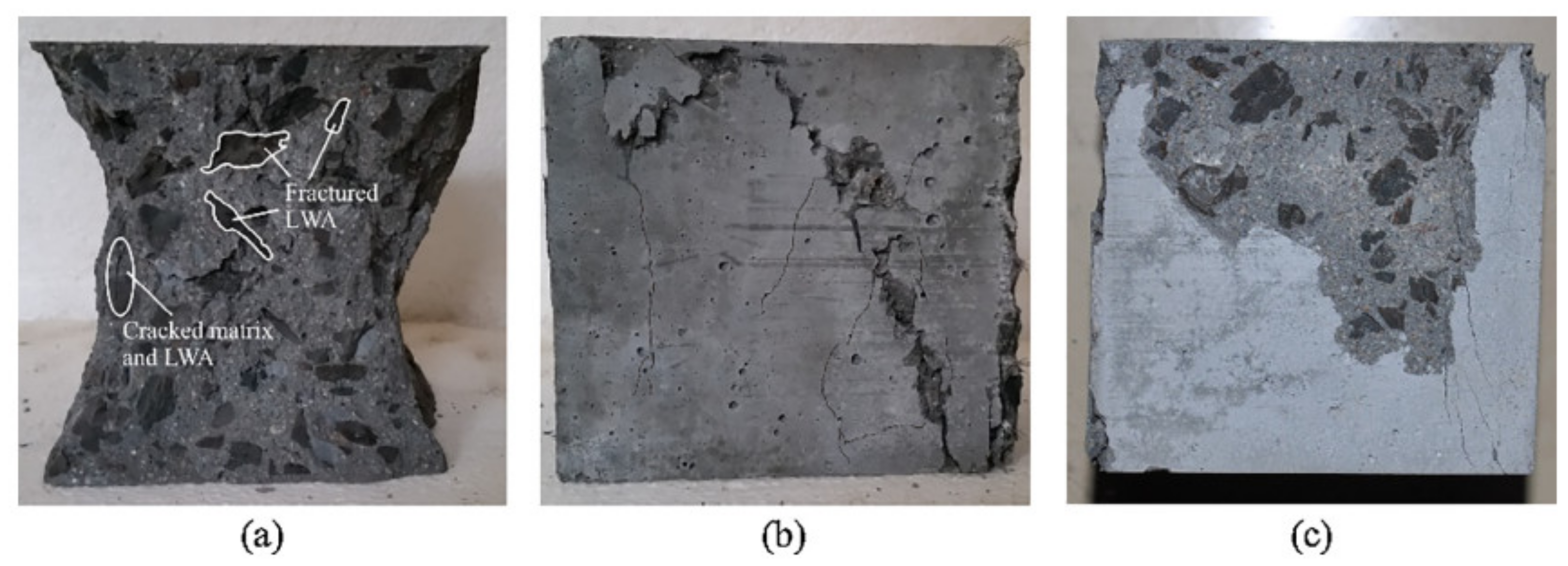

- Øverli, J.A. Towards a better understanding of the ultimate behaviour of LWAC in compression and bending. Eng. Struct. 2017, 151, 821–838. [Google Scholar] [CrossRef]

- Yap, S.P.; Khaw, K.R.; Alengaram, U.J.; Jumaat, M.Z. Effect of fibre aspect ratio on the torsional behaviour of steel fibre-reinforced normal weight concrete and lightweight concrete. Eng. Struct. 2015, 101, 24–33. [Google Scholar] [CrossRef]

- Teo, D.C.L.; Mannan, M.A.; Kurian, V.J.; Ganapathy, C. Lightweight concrete made from oil palm shell (OPS): Structural bond and durability properties. Build. Environ. 2007, 42, 2614–2621. [Google Scholar] [CrossRef]

- Ahmmad, R.; Jumaat, M.Z.; Alengaram, U.J.; Bahri, S.; Rehman, M.A.; Hashim, H. Performance evaluation of palm oil clinker as coarse aggregate in high strength lightweight concrete. J. Clean. Prod. 2016, 112, 566–574. [Google Scholar] [CrossRef]

- Bogas, J.A.; Gomes, A. Non-steady-state accelerated chloride penetration resistance of structural lightweight aggregate concrete. Cem. Concr. Compos. 2015, 60, 111–122. [Google Scholar] [CrossRef]

- Zhao, Y.; Gao, J.; Chen, F.; Liu, C.; Chen, X. Utilization of waste clay bricks as coarse and fine aggregates for the preparation of lightweight aggregate concrete. J. Clean. Prod. 2018, 201, 706–715. [Google Scholar] [CrossRef]

- Xie, J.; Liu, J.; Liu, F.; Wang, J.; Huang, P. Investigation of a new lightweight green concrete containing sludge ceramsite and recycled fine aggregates. J. Clean. Prod. 2019, 235, 1240–1254. [Google Scholar] [CrossRef]

- Yi, Q.; Chen, H.; Zeng, Z.; Wang, Q.; Huang, X. Experiment on the Mechanical Performance of Ceramsite Foam Concrete. Constr. Tech. 2018, 14, 114–117. [Google Scholar]

- Costa, H.; Júlio, E.; Lourenço, J. New approach for shrinkage prediction of high-strength lightweight aggregate concrete. Constr. Build. Mater. 2012, 35, 84–91. [Google Scholar] [CrossRef]

- Øverli, J.A.; Jensen, T.M. Increasing ductility in heavily reinforced LWAC structures. Eng. Struct. 2014, 62, 11–22. [Google Scholar] [CrossRef] [Green Version]

- Shafigh, P.; Hassanpour, M.M.; Vahid Razavi, S.; Kobraei, M. An investigation of the flexural behaviour of reinforced lightweight concrete beams. Int. J. Phys. Sci. 2011, 6, 2414–2421. [Google Scholar]

- Sin, L.H.; Islam, M.R.; Huan, W.T.; Mansur, M.A. Reinforced Lightweight Concrete Beams in Flexure. ACI Struct. J. 2011, 108, 3–12. [Google Scholar] [CrossRef]

- Wu, T.; Yang, X.; Wei, H.; Liu, X. Mechanical properties and microstructure of lightweight aggregate concrete with and without fibers. Constr. Build. Mater. 2019, 199, 526–539. [Google Scholar] [CrossRef]

- Gao, X.F.; Lo, Y.T.; Tam, C.M. Investigation of micro-cracks and microstructure of high performance lightweight aggregate concrete. Build. Environ. 2002, 37, 485–489. [Google Scholar] [CrossRef]

- Rashiddadash, P.; Ramezanianpour, A.A.; Mahdikhani, M. Experimental investigation on flexural toughness of hybrid fiber reinforced concrete (HFRC) containing metakaolin and pumice. Constr. Build. Mater. 2014, 51, 313–320. [Google Scholar] [CrossRef]

- Li, J.; Niu, J.; Wan, C.; Liu, X.; Jin, Z. Comparison of flexural property between high performance polypropylene fiber reinforced lightweight aggregate concrete and steel fiber reinforced lightweight aggregate concrete. Constr. Build. Mater. 2017, 157, 729–736. [Google Scholar] [CrossRef]

- Mehta, P.K. Mechanism of expansion associated with ettringite formation. Cem. Concr. Res. 1973, 3, 1–6. [Google Scholar] [CrossRef]

- Nagataki, S.; Gomi, H. Expansive admixtures (mainly ettringite). Cem. Concr. Compos. 1998, 20, 163–170. [Google Scholar] [CrossRef]

- Bentur, A.; Igarashi, S.; Kovler, K. Prevention of autogenous shrinkage in high-strength concrete by internal curing using wet lightweight aggregates. Cem. Concr. Res. 2001, 31, 1587–1591. [Google Scholar] [CrossRef]

- Bentz, D.P.; Snyder, K.A. Protected paste volume in concrete: Extension to internal curing using saturated lightweight fine aggregate. Cem. Concr. Res. 1999, 29, 1863–1867. [Google Scholar] [CrossRef]

- Bentz, D.P.; Geiker, M.R.; Hansen, K.K. Shrinkage-reducing admixtures and early-age desiccation in cement pastes and mortars. Cem. Concr. Res. 2001, 31, 1075–1085. [Google Scholar] [CrossRef]

- Folliard, K.J.; Berke, N.S. Properties of high-performance concrete containing shrinkage-reducing admixture. Cem. Concr. Res. 1997, 27, 1357–1364. [Google Scholar] [CrossRef]

- Banthia, N.; Nandakumar, N. Crack growth resistance of hybrid fiber reinforced cement composites. Cem. Concr. Compos. 2003, 25, 3–9. [Google Scholar] [CrossRef]

- Grzybowski, M.; Shah, S.P. Shrinkage Cracking of Fiber Reinforced Concrete. ACI Mater. J. 1990, 87, 138–148. [Google Scholar] [CrossRef]

- Wang, X.F.; Fang, C.; Kuang, W.Q.; Li, D.W.; Han, N.X.; Xing, F. Experimental study on early cracking sensitivity of lightweight aggregate concrete. Constr. Build. Mater. 2017, 136, 173–183. [Google Scholar] [CrossRef]

- Zhutovsky, S.; Kovler, K.; Bentur, A. Effect of hybrid curing on cracking potential of high-performance concrete. Cem. Concr. Res. 2013, 54, 36–42. [Google Scholar] [CrossRef]

- Kohno, K.; Okamoto, T.; Isikawa, Y.; Sibata, T.; Mori, H. Effects of artificial lightweight aggregate on autogenous shrinkage of concrete. Cem. Concr. Res. 1999, 29, 611–614. [Google Scholar] [CrossRef]

- Cusson, D.; Hoogeveen, T. Internal curing of high-performance concrete with pre-soaked fine lightweight aggregate for prevention of autogenous shrinkage cracking. Cem. Concr. Res. 2008, 38, 757–765. [Google Scholar] [CrossRef] [Green Version]

- Zhutovsky, S.; Kovler, K.; Bentur, A. Efficiency of lightweight aggregates for internal curing of high strength concrete to eliminate autogenous shrinkage. Mater. Struct. 2002, 35, 97–101. [Google Scholar] [CrossRef]

- Zou, D.; Li, K.; Li, W.; Li, H.; Cao, T. Effects of pore structure and water absorption on internal curing efficiency of porous aggregates. Constr. Build. Mater. 2018, 163, 949–959. [Google Scholar] [CrossRef]

- Meddah, M.S.; Suzuki, M.; Sato, R. Influence of a combination of expansive and shrinkage-reducing admixture on autogenous deformation and self-stress of silica fume high-performance concrete. Constr. Build. Mater. 2011, 25, 239–250. [Google Scholar] [CrossRef]

- Güneyisi, E.; Gesoğlu, M.; Mohamadameen, A.; Alzeebaree, R.; Algın, Z.; Mermerdaş, K. Enhancement of shrinkage behavior of lightweight aggregate concretes by shrinkage reducing admixture and fiber reinforcement. Constr. Build. Mater. 2014, 54, 91–98. [Google Scholar] [CrossRef]

- Ling, Y.; Wang, K.; Fu, C. Shrinkage behavior of fly ash based geopolymer pastes with and without shrinkage reducing admixture. Cem. Concr. Compos. 2019, 98, 74–82. [Google Scholar] [CrossRef]

- Rongbing, B.; Jian, S. Synthesis and evaluation of shrinkage-reducing admixture for cementitious materials. Cem. Concr. Res. 2005, 35, 445–448. [Google Scholar] [CrossRef]

- Tazawa, E.; Miyazawa, S. Influence of cement and admixture on autogenous shrinkage of cement paste. Cem. Concr. Res. 1995, 25, 281–287. [Google Scholar] [CrossRef]

- Sant, G.; Lothenbach, B.; Juilland, P.; Le Saout, G.; Weiss, J.; Scrivener, K. The origin of early age expansions induced in cementitious materials containing shrinkage reducing admixtures. Cem. Concr. Res. 2011, 41, 218–229. [Google Scholar] [CrossRef]

- Lo, T.Y.; Tang, W.C.; Cui, H.Z. The effects of aggregate properties on lightweight concrete. Build. Environ. 2007, 42, 3025–3029. [Google Scholar] [CrossRef]

- Malami, C.; Kaloidas, V.; Batis, G.; Kouloumbi, N. Carbonation and porosity of mortar specimens with pozzolanic and hydraulic cement admixtures. Cem. Concr. Res. 1994, 24, 1444–1454. [Google Scholar] [CrossRef]

- Newman, J.B. Structural Lightweight Aggregate Concrete: Chapter 2. In Properties of Structural Lightweight Aggregate Concrete; Clarke, J.L., Ed.; CRC Pressing: London, UK, 1993. [Google Scholar]

- Bogas, J.A. Characterization of Structural Lightweight Expanded Clay Aggregate Concrete; Technical University of Lisbon: Lisboa, Portugal, 2011. [Google Scholar]

- Bogas, J.A.; Carriço, A.; Pontes, J. Influence of cracking on the capillary absorption and carbonation of structural lightweight aggregate concrete. Cem. Concr. Compos. 2019, 104, 103382. [Google Scholar] [CrossRef]

- Gao, Y.; Cheng, L.; Gao, Z.; Guo, S. Effects of different mineral admixtures on carbonation resistance of lightweight aggregate concrete. Constr. Build. Mater. 2013, 43, 506–510. [Google Scholar] [CrossRef]

- Oh, B.H.; Cha, S.W.; Jang, B.S.; Jang, S.Y. Development of high-performance concrete having high resistance to chloride penetration. Nucl. Eng. Des. 2002, 212, 221–231. [Google Scholar] [CrossRef] [Green Version]

- Ahmad, M.R.; Chen, B. Experimental research on the performance of lightweight concrete containing foam and expanded clay aggregate. Compos. Part B 2019, 171, 46–60. [Google Scholar] [CrossRef]

- Tang, P.; Brouwers, H.J.H. The durability and environmental properties of self-compacting concrete incorporating cold bonded lightweight aggregates produced from combined industrial solid wastes. Constr. Build. Mater. 2018, 167, 271–285. [Google Scholar] [CrossRef]

- Güneyisi, E.; Gesoğlu, M.; Altan, İ.; Öz, H.Ö. Utilization of cold bonded fly ash lightweight fine aggregates as a partial substitution of natural fine aggregate in self-compacting mortars. Constr. Build. Mater. 2015, 74, 9–16. [Google Scholar] [CrossRef]

- Güneyisi, E.; Gesoğlu, M.; Pürsünlü, Ö.; Mermerdaş, K. Durability aspect of concretes composed of cold bonded and sintered fly ash lightweight aggregates. Compos. Part B 2013, 53, 258–266. [Google Scholar] [CrossRef]

- Real, S.; Bogas, J.A. Chloride ingress into structural lightweight aggregate concrete in real marine environment. Mar. Struct. 2018, 61, 170–187. [Google Scholar] [CrossRef]

- Zhu, C.; Niu, J.; Li, J.; Wan, C.; Peng, J. Effect of aggregate saturation degree on the freeze–thaw resistance of high performance polypropylene fiber lightweight aggregate concrete. Constr. Build. Mater. 2017, 145, 367–375. [Google Scholar] [CrossRef]

- Van der Heijden, G.H.A.; Pel, L.; Adan, O.C.G. Fire spalling of concrete, as studied by NMR. Cem. Concr. Res. 2012, 42, 265–271. [Google Scholar] [CrossRef]

- Ozawa, M.; Uchida, S.; Kamada, T.; Morimoto, H. Study of mechanisms of explosive spalling in high-strength concrete at high temperatures using acoustic emission. Constr. Build. Mater. 2012, 37, 621–628. [Google Scholar] [CrossRef]

- Gutenberg, B.; Richter, C.F. Frequency of earthquakes in california. Bull. Seismol. Soc. Am. 1944, 34, 185–188. [Google Scholar]

- Sedighi-Gilani, M.; Griffa, M.; Mannes, D.; Lehmann, E.; Carmeliet, J.; Derome, D. Visualization and quantification of liquid water transport in softwood by means of neutron radiography. Int. J. Heat Mass Transf. 2012, 55, 6211–6221. [Google Scholar] [CrossRef]

- Joos, A.; Schmitz, G.; Mühlbauer, M.J.; Schillinger, B. Investigation of moisture phase change in porous media using neutron radiography and gravimetric analysis. Int. J. Heat Mass Transf. 2010, 53, 5283–5288. [Google Scholar] [CrossRef]

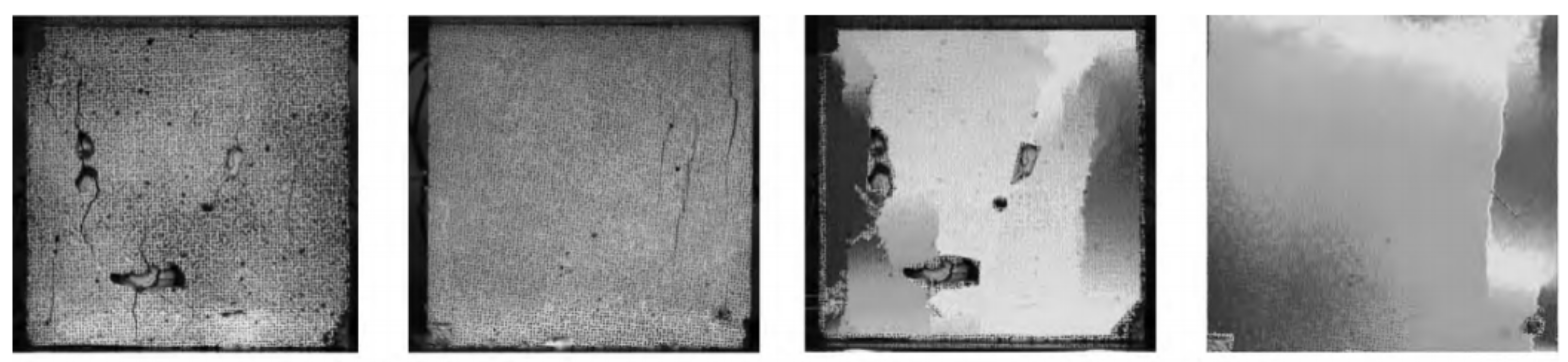

- Trtik, P.; Münch, B.; Weiss, W.J.; Kaestner, A.; Jerjen, I.; Josic, L.; Lehmann, E.; Lura, P. Release of internal curing water from lightweight aggregates in cement paste investigated by neutron and X-ray tomography. Nucl. Instrum. Methods Phys. Res. Sect. A 2011, 651, 244–249. [Google Scholar] [CrossRef]

- Yang, F.; Prade, F.; Griffa, M. Dark-field X-ray imaging of unsaturated water transport in porous materials. Appl. Phys. Lett. 2014, 105, 154105. [Google Scholar] [CrossRef] [Green Version]

- Wyrzykowski, M.; Trtik, P.; Münch, B.; Weiss, J.; Vontobel, P.; Lura, P. Plastic shrinkage of mortars with shrinkage reducing admixture and lightweight aggregates studied by neutron tomography. Cem. Concr. Res. 2015, 73, 238–245. [Google Scholar] [CrossRef]

- Breysse, D. Nondestructive evaluation of concrete strength: An historical review and a new perspective by combining NDT methods. Constr. Build. Mater. 2012, 33, 139–163. [Google Scholar] [CrossRef]

- McGinnis, M.J.; Pessiki, S. Experimental study of the core-drilling method for evaluating in situ stresses in concrete structures. J. Mater. Civ. Eng. 2015. [Google Scholar] [CrossRef]

- Tan, Y.; Yu, H.; Mi, R.; Zhang, Y. Compressive strength evaluation of coral aggregate seawater concrete (CAC) by non-destructive techniques. Eng. Struct. 2018, 176, 293–302. [Google Scholar] [CrossRef]

| Mix No. | Density (kg/m3) | Saturated at 28 Days | Oven Dry |

|---|---|---|---|

| Demolded | |||

| M | 1908 | 1996 | 1900 |

| M12.5 | 1976 | 1989 | 1880 |

| M25 | 1966 | 1993 | 1868 |

| M37.5 | 1917 | 1948 | 1771 |

| M50 | 1881 | 1914 | 1743 |

| Mix | Cement (kg/m3) | Coarse Aggregate | Mining Sand (kg/m3) | Water (kg/m3) | Silica Fume (kg/m3) | Superplasticizer (kg/m3) | Steel Fiber (v.%.) | Aspect Ratio of Steel Fiber | |

|---|---|---|---|---|---|---|---|---|---|

| Granite Aggregate (kg/m3) | OPS (kg/m3) | ||||||||

| NWC series | |||||||||

| NWC | 320 | 810 | 0 | 1030 | 200 | 0 | 0 | 0 | - |

| NWFRC-55 | 320 | 810 | 0 | 1030 | 200 | 0 | 0 | 0.50 | 55 |

| NWFRC-65 | 320 | 810 | 0 | 1030 | 200 | 0 | 0 | 0.50 | 65 |

| NWFRC-80 | 320 | 810 | 0 | 1030 | 200 | 0 | 0 | 0.50 | 80 |

| OPSC series | |||||||||

| OPSC-0 | 530 | 0 | 320 | 970 | 170 | 53 | 0.35 | 0 | - |

| OPSFRC-55 | 530 | 0 | 320 | 970 | 170 | 53 | 0.35 | 0.50 | 55 |

| OPSFRC-65 | 530 | 0 | 320 | 970 | 170 | 53 | 0.35 | 0.50 | 65 |

| OPSFRC-80 | 530 | 0 | 320 | 970 | 170 | 53 | 0.35 | 0.50 | 80 |

| Mix | Density (kg/m3) | Compressive Strength (MPa) | Splitting Tensile Strength (MPa) | Flexural Strength (MPa) | Brittleness | Modulus of Elasticity (GPa) |

|---|---|---|---|---|---|---|

| NWC series | ||||||

| NWC | 2369 | 31.7 | 3.89 | 4.37 | 7.25 | 17.23 |

| NWFRC-55 | 2492 | 35.1 | 3.98 | 5.42 | 6.48 | 19.59 |

| NWFRC-65 | 2467 | 36.5 | 3.95 | 5.14 | 7.10 | 21.43 |

| NWFRC-80 | 2488 | 36.8 | 4.11 | 5.57 | 6.61 | 20.71 |

| OPSC series | ||||||

| OPSC | 1970 | 32.8 | 2.83 | 3.81 | 8.61 | 13.25 |

| OPSFRC-55 | 2068 | 34.4 | 3.63 | 5.74 | 5.99 | 16.24 |

| OPSFRC-65 | 2041 | 35.6 | 3.85 | 5.79 | 6.15 | 14.72 |

| OPSFRC-80 | 2070 | 37.0 | 3.91 | 6.04 | 6.13 | 15.48 |

| Type of Concrete | w/c | wc (mm) | Accelerated Carbonation | |||||

|---|---|---|---|---|---|---|---|---|

| xc/xc,UR (mm) | xc,C (mm) | LC (mm) | Kc/Kc,UR | R2 | Kc,C | |||

| 28 d | 28 d | 28 d | mm/y0.5 | mm/y0.5 | ||||

| NWC | 0.55 | 0 | 5.4 | - | - | 16.5 | 0.97 | - |

| 0.1 | 5.2 | 11.7 | 9.8 | 16.3 | 0.97 | 60.8 | ||

| 0.2 | 5.5 | 13.5 | 10.9 | 16.8 | 0.97 | 87.0 | ||

| 0.3 | 5.2 | 15.3 | 12.6 | 16.3 | 0.98 | 113.3 | ||

| LWAC with Stalite | 0.55 | 0 | 5.9 | - | - | 18.6 | 0.97 | - |

| 0.1 | 5.3 | 12.0 | 9.9 | 18.2 | 0.98 | 64.2 | ||

| 0.2 | 6.2 | 15.5 | 13.0 | 19.2 | 0.96 | 92.0 | ||

| 0.3 | 6.1 | 18.3 | 16.1 | 18.8 | 0.96 | 115.7 | ||

| LWAC with Leca | 0.55 | 0 | 7.9 | - | - | 25.9 | 0.98 | - |

| 0.1 | 6.8 | 12.9 | 11.0 | 24.9 | 0.97 | 56.6 | ||

| 0.2 | 8.3 | 16.5 | 14.0 | 24.8 | 0.95 | 78.6 | ||

| 0.3 | 8.2 | 17.1 | 13.0 | 25.9 | 0.97 | 108.0 | ||

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, J.; Zheng, K.; Cui, N.; Cheng, X.; Ren, K.; Hou, P.; Feng, L.; Zhou, Z.; Xie, N. Green and Durable Lightweight Aggregate Concrete: The Role of Waste and Recycled Materials. Materials 2020, 13, 3041. https://doi.org/10.3390/ma13133041

Wang J, Zheng K, Cui N, Cheng X, Ren K, Hou P, Feng L, Zhou Z, Xie N. Green and Durable Lightweight Aggregate Concrete: The Role of Waste and Recycled Materials. Materials. 2020; 13(13):3041. https://doi.org/10.3390/ma13133041

Chicago/Turabian StyleWang, Jiyu, Kai Zheng, Na Cui, Xin Cheng, Kai Ren, Pengkun Hou, Lichao Feng, Zonghui Zhou, and Ning Xie. 2020. "Green and Durable Lightweight Aggregate Concrete: The Role of Waste and Recycled Materials" Materials 13, no. 13: 3041. https://doi.org/10.3390/ma13133041

APA StyleWang, J., Zheng, K., Cui, N., Cheng, X., Ren, K., Hou, P., Feng, L., Zhou, Z., & Xie, N. (2020). Green and Durable Lightweight Aggregate Concrete: The Role of Waste and Recycled Materials. Materials, 13(13), 3041. https://doi.org/10.3390/ma13133041