Stiffness Prediction of Connections between CHS Tubes and Externally Welded I-Beams: FE Analyses and Analytical Study

Abstract

:1. Introduction

2. Experimental Activity

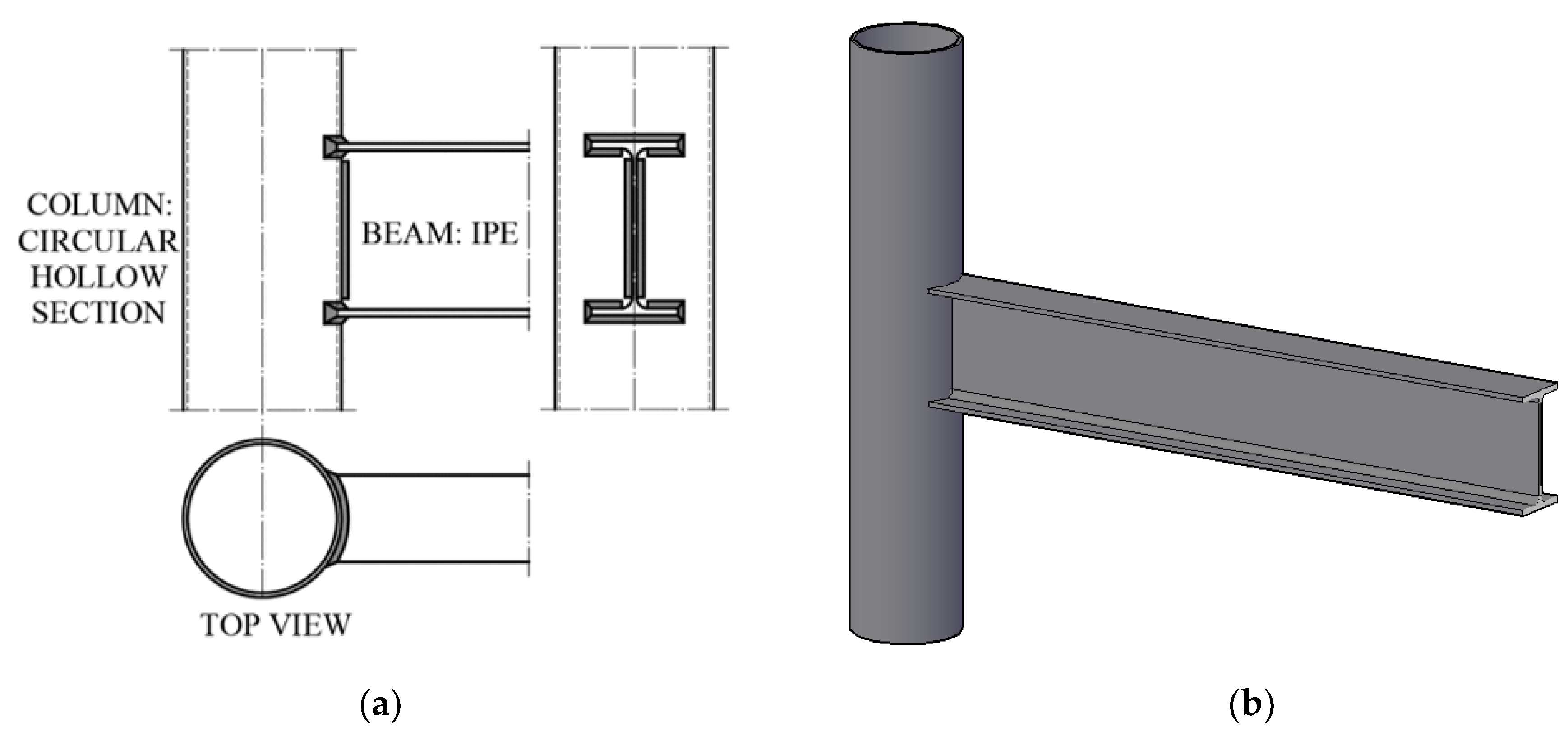

2.1. Tested Specimens and Experimental Set-Up

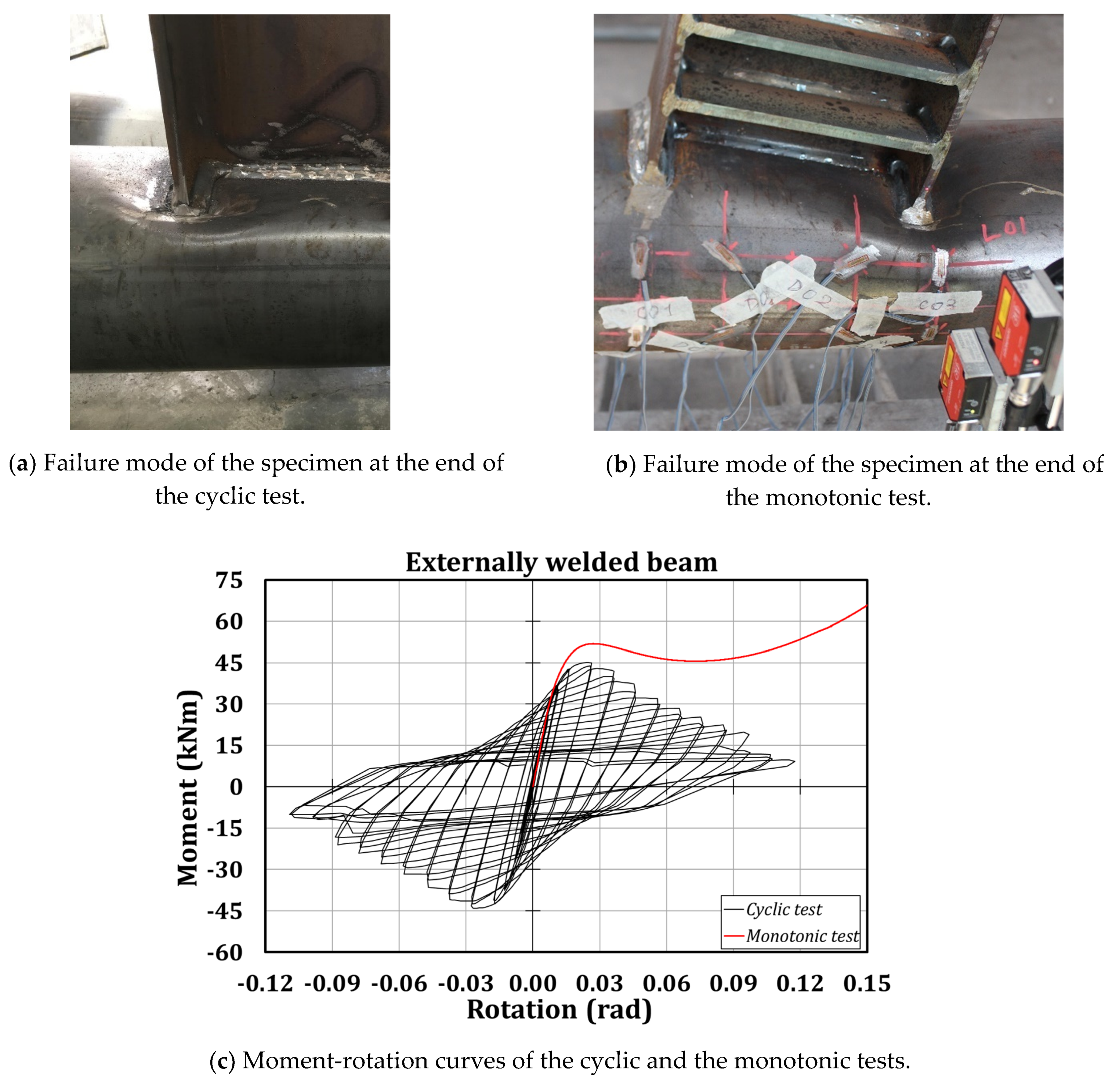

2.2. Experimental Results

3. Numerical Simulations

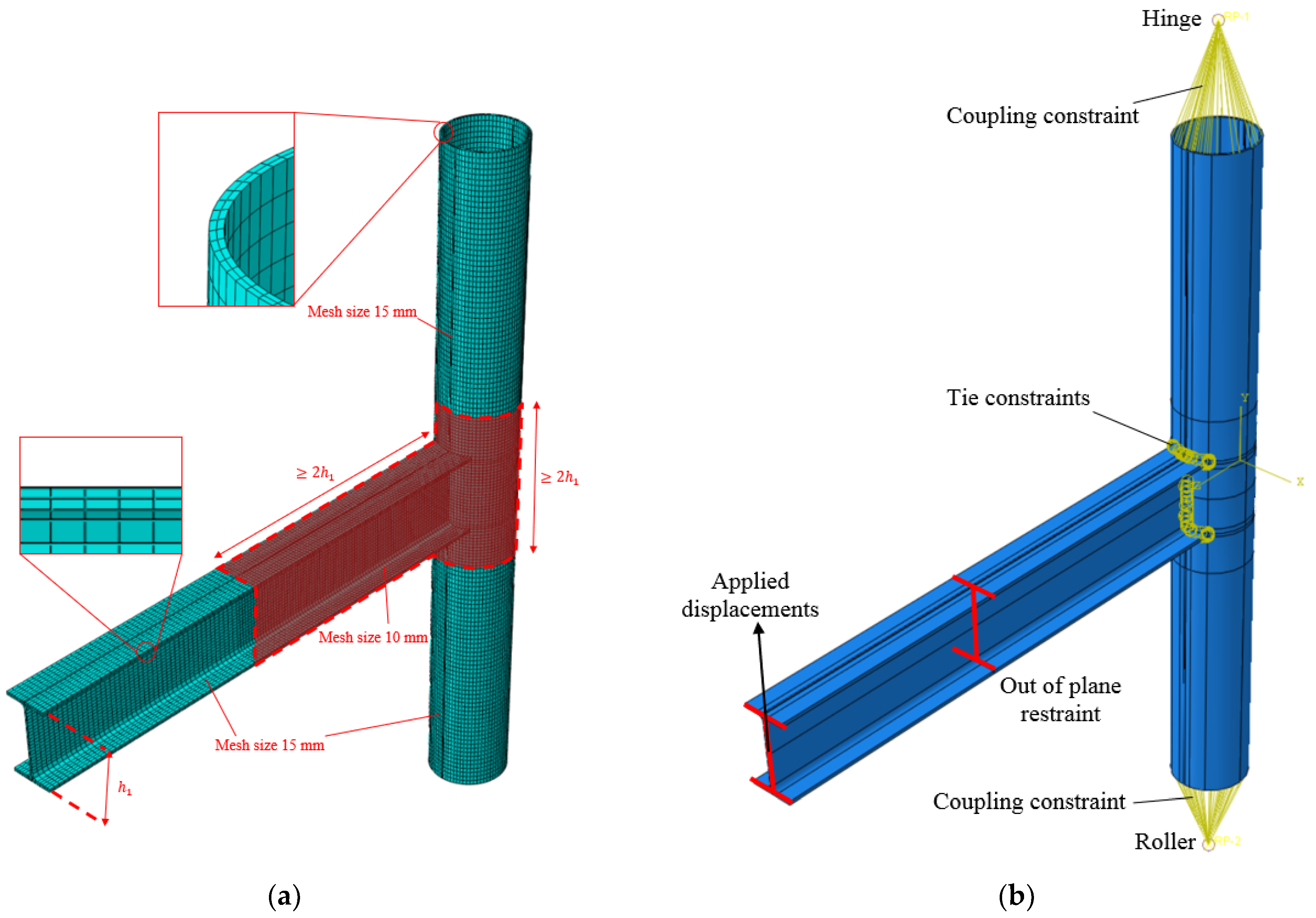

3.1. FE Modelling

3.2. Validation

3.3. Parametric Analysis

4. Proposal of a Design Equation

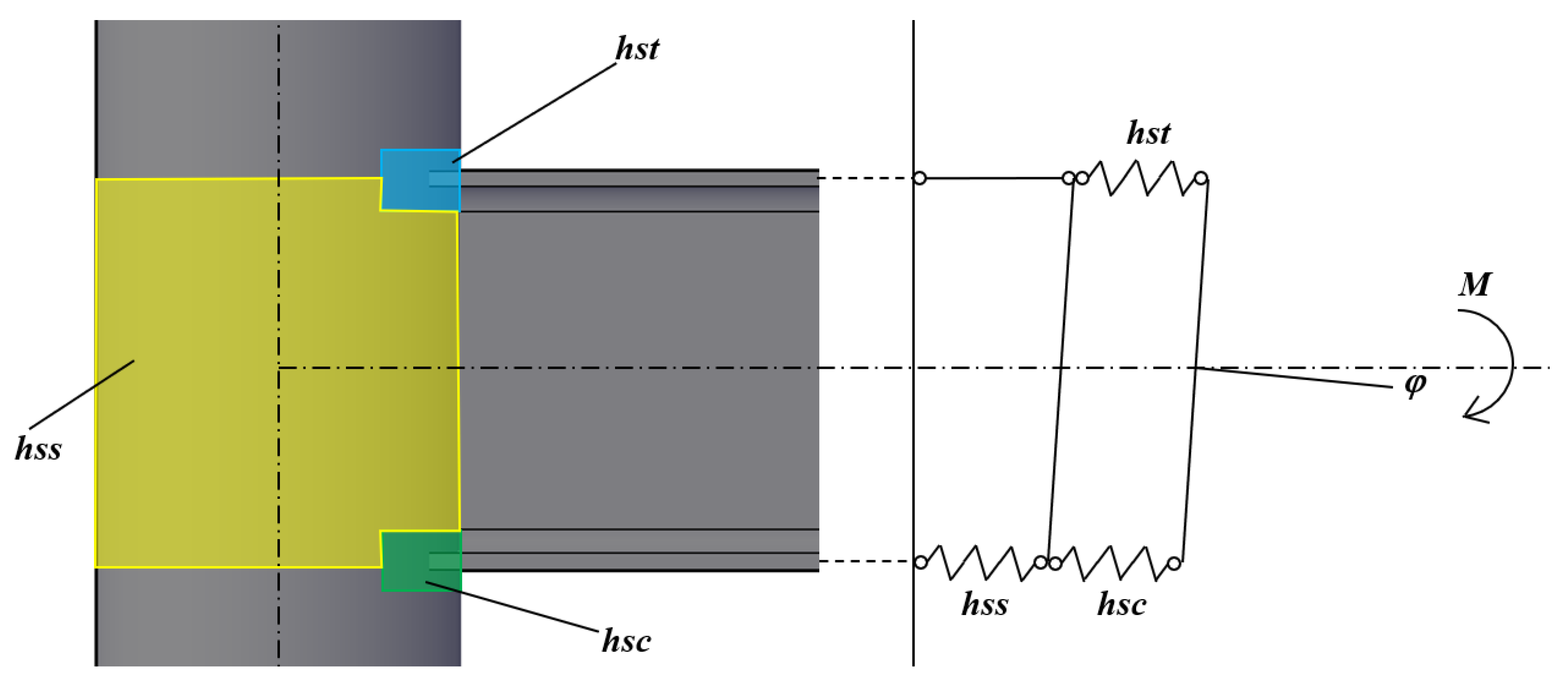

4.1. Theoretical Approach

- the hollow section in shear (hss);

- the hollow section in transverse compression (hsc);

- the hollow section in transverse tension (hst).

4.2. Regression Analysis and Assessment of the Accuracy of the Proposed Design Equation

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- SAC. Recommended Seismic Evaluation and Upgrade Criteria for Existing Welded Steel Moment-Frame Buildings; Report No. FEMA-351; SAC Joint Venture for the Federal Emergency Management Agency: Washington, DC, USA, 2000. [Google Scholar]

- Nogueiro, P.; Da Silva, L.S.; Bento, R.; Simões, R. Experimental behaviour of standardized European end-plate beam-to-column steel joints under arbitrary cyclic loading. In Proceedings of the International Colloquium on Stability and Ductility of Steel Structures, Prague, Czech Republic, 11–13 September 2019; pp. 951–960. [Google Scholar]

- Iannone, F.; Latour, M.; Piluso, V.; Rizzano, G. Experimental Analysis of Bolted Steel Beam-to-Column Connections: Component Identification. J. Earthq. Eng. 2011, 15, 214–244. [Google Scholar] [CrossRef]

- Latour, M.; Piluso, V.; Rizzano, G. Cyclic Modeling of Bolted Beam-to-Column Connections: Component Approach. J. Earthq. Eng. 2011, 15, 537–563. [Google Scholar] [CrossRef]

- Aniello, M.D.; Tartaglia, R.; Costanzo, S.; Landolfo, R. Seismic design of extended stiffened end-plate joints in the framework of Eurocodes. J. Constr. Steel Res. 2017, 128, 512–527. [Google Scholar] [CrossRef]

- Francavilla, A.B.; Latour, M.; Piluso, V.; Rizzano, G. Design of full-strength full-ductility extended end-plate beam-to-column joints. J. Constr. Steel Res. 2018, 148, 77–96. [Google Scholar] [CrossRef]

- Swanson, J.A.; Leon, R.T. Bolted Steel Connections: Tests on T-Stub Components. J. Struct. Eng. 2000, 126, 50–56. [Google Scholar] [CrossRef]

- Latour, M.; Rizzano, G. Design of X-shaped double split tee joints accounting for moment–shear interaction. J. Constr. Steel Res. 2015, 104, 115–126. [Google Scholar] [CrossRef]

- Francavilla, A.B.; Latour, M.; Piluso, V.; Rizzano, G. Bolted T-stubs: A refined model for flange and bolt fracture modes. Steel Compos. Struct. 2016, 20, 267–293. [Google Scholar] [CrossRef]

- Engelhardt, M.D.; Winneburger, T.; Zekany, A.J.; Potyraj, T.J. The Dogbone Connection: Part II. Mod. Steel Construct. 1996, 36, 46–55. [Google Scholar]

- Moore, K.S.; Malley, J.O.; Engelhardt, M.D. Design of Reduced Beam Section (RBS) Moment Frame Connections. In Structural Steel Educational Council; AISC: Moraga, CA, USA, 1999. [Google Scholar]

- Gilton, C.; Chi, B.; Uang, C. Cyclic Response of RBS Moment Connections: Weak-Axis Configuration and Deep Column Effects; Report no. SSRP-2000/03; Structural Systems Research Project, Department of Structural Engineering, University of California: San Diego, CA, USA, 2000. [Google Scholar]

- Kulkarni, S.A.; Vesmawala, G. Study of steel moment connection with and without reduced beam section. Case Stud. Struct. Eng. 2014, 1, 26–31. [Google Scholar]

- Butterworth, J.W.; Clifton, G.C. Performance of Hierarchical Friction Dissipating Joints in Moment Resisting Steel Frames. In Proceedings of the 12th World Conference on Earthquake Engineering, Auckland, New Zealand, 30 January–4 February 2000. [Google Scholar]

- Khoo, H.-H.; Clifton, C.; Macrae, G.; Zhou, H.; Ramhormozian, S.; Clifton, G.C. Proposed design models for the asymmetric friction connection. Earthq. Eng. Struct. Dyn. 2014, 44, 1309–1324. [Google Scholar] [CrossRef]

- Latour, M.; Piluso, V.; Rizzano, G. Free from damage beam-to-column joints: Testing and design of DST connections with friction pads. Eng. Struct. 2015, 85, 219–233. [Google Scholar] [CrossRef]

- Tartaglia, R.; D’Aniello, M. Nonlinear Performance of Extended Stiffened End Plate Bolted Beam-to-column Joints Subjected to Column Removal. Open Civ. Eng. J. 2017, 11, 369–383. [Google Scholar] [CrossRef] [Green Version]

- Latour, M.; Aniello, M.D.; Zimbru, M.; Rizzano, G.; Piluso, V.; Landolfo, R. Removable friction dampers for low-damage steel beam-to-column joints. Soil Dyn. Earthq. Eng. 2018, 115, 66–81. [Google Scholar] [CrossRef]

- Tartaglia, R.; D’Aniello, M.; Rassati, G.A.; Swanson, J.A.; Landolfo, R. Full strength extended stiffened end-plate joints: AISC vs recent European design criteria. Eng. Struct. 2018, 159, 155–171. [Google Scholar] [CrossRef]

- Tartaglia, R.; D’Aniello, M.; Zimbru, M.; Landolfo, R. Finite element simulations on the ultimate response of extended stiffened end-plate joints, Steel and Composite Structures. Steel Compos. Struct. 2018, 27, 727–745. [Google Scholar] [CrossRef]

- Tartaglia, R.; Aniello, M.D.; Landolfo, R. The influence of rib stiffeners on the response of extended end-plate joints. J. Constr. Steel Res. 2018, 148, 669–690. [Google Scholar] [CrossRef]

- Tartaglia, R.; D’Aniello, M.; De Martino, A. Ultimate Performance of External End-plate Bolted Joints Under Column Loss Scenario Accounting for the Influence of the Transverse Beam. Open Constr. Build. Technol. J. 2018, 12, 132–139. [Google Scholar] [CrossRef]

- Tartaglia, R.; Aniello, M.D.; Rassati, G.A. Proposal of AISC-compliant seismic design criteria for ductile partially-restrained end-plate bolted joints. J. Constr. Steel Res. 2019, 159, 364–383. [Google Scholar] [CrossRef]

- Steenhuis, M.; Jaspart, J.P.; Gomes, F.; Leino, T. Application of the component method to steel joints. In Proceedings of the Control of the Semi-Rigid Behaviour of Civil Engineering Structural Connections Conference, Liège, Belgium, 17–19 September 1998. [Google Scholar]

- Tschemmernegg, F.; Rubin, D.; Pavlov, A. Application of the component method to composite joints. In Proceedings of the Control of the Semi-Rigid Behaviour of Civil Engineering Structural Connections Conference, Liège, Belgium, 17–19 September 1998. [Google Scholar]

- Wald, F.; Gresnigt, A.M.; Weynand, K.; Jaspart, J.P. Application of the component method to column bases. In Proceedings of the Control of the Semi-Rigid Behaviour of Civil Engineering Structural Connections Conference, Liège, Belgium, 17–19 September 1998. [Google Scholar]

- Da Silva, L.S.; Santiago, A.; Real, P.V. Application of the Component Method to Steel Joints under Fire Loading. In The Paramount Role of Joints into the Reliable Response of Structures; Springer: Berlin/Heidelberg, Germany, 2000; pp. 425–434. [Google Scholar]

- Faella, C.; Piluso, V.; Rizzano, G. Structural Steel Semirigid Connections; CRC Press: Boca Raton, FL, USA, 2000. [Google Scholar]

- Augusto, H.; Da Silva, L.S.; Rebelo, C.; Castro, J.M. Cyclic behaviour characterization of web panel components in bolted end-plate steel joints. J. Constr. Steel Res. 2017, 133, 310–333. [Google Scholar] [CrossRef]

- Coelho, A.M.G.; Bijlaard, F.S.; Da Silva, L.S. Experimental assessment of the ductility of extended end plate connections. Eng. Struct. 2004, 26, 1185–1206. [Google Scholar] [CrossRef]

- Greene, T. Strength of steel tubing under combined column and transverse loading, including tests of columns and beams. In Technologic Papers of the Bureau of Standards; National Bureau of Standards: Washington, DC, USA, 1924. [Google Scholar]

- Bouwkamp, J. Buckling and Post-Buckling Strength of Circular Tubular Sections. In Proceedings of the Offshore Technology Conference, Houston, TX, USA, 5–8 May 1975; pp. 583–592. [Google Scholar]

- Marzullo, M.A.; Ostapenko, A. Tests on Two High-Strength Short Tubular Columns; Laboratory Report No. 406.10; Fritz Engineering Laboratory, Lehigh University: Bethlehem, PA, USA, 1977. [Google Scholar]

- Chen, W.F.; Ross, D.A. Test of fabricated tubular columns. J. Struct. Div. 1977, 103, 619–634. [Google Scholar]

- Elchalakani, M.; Zhao, X.-L.; Grzebieta, R. Tests on concrete filled double-skin (CHS outer and SHS inner) composite short columns under axial compression. Thin Walled Struct. 2002, 40, 415–441. [Google Scholar] [CrossRef]

- Ma, J.-L.; Chan, T.-M.; Young, B. Experimental Investigation on Stub-Column Behavior of Cold-Formed High-Strength Steel Tubular Sections. J. Struct. Eng. 2016, 142, 04015174. [Google Scholar] [CrossRef]

- Xiong, M.-X.; Xiong, D.-X.; Liew, J.R. Axial performance of short concrete filled steel tubes with high- and ultra-high- strength materials. Eng. Struct. 2017, 136, 494–510. [Google Scholar] [CrossRef]

- Meng, X.; Gardner, L. Cross-sectional behaviour of cold-formed high strength steel CHS under combined axial compression and bending. In Proceedings of the 8th International Conference on Thin-Walled Structures, Lisbon, Portugal, 24–27 July 2018. [Google Scholar]

- Meng, X.; Gardner, L.; Sadowski, A.J.; Rotter, J.M. Elasto-plastic behaviour and design of semi-compact circular hollow sections. Thin Walled Struct. 2020, 148, 106486. [Google Scholar] [CrossRef]

- Korol, R.M.; Hudoba, J. Plastic behavior of hollow structural sections. J. Struct. Div. 1972, 98, 1007–1023. [Google Scholar]

- Wilhoit, J.C., Jr.; Merwin, J.E. Critical Plastic Buckling Parameter for Tubing in Bending under Axial Tension. In Proceedings of the Offshore Technology Conference, Houston, TX, USA, 29 April–2 May 1973. [Google Scholar]

- Sherman, D.R. Test of circular steel tubes in bending. J. Struct. Div. 1976, 102, 2181–2195. [Google Scholar]

- Prion, H.G.L.; Birkemoe, P.C. Beam?Column Behavior of Fabricated Steel Tubular Members. J. Struct. Eng. 1992, 118, 1213–1232. [Google Scholar] [CrossRef]

- O’Shea, M.D.; Bridge, R.Q. Local buckling of thin-walled circular steel sections with or without internal restraint. J. Constr. Steel Res. 1997, 41, 137–157. [Google Scholar] [CrossRef]

- Pan, H.M. Research on Ultimate Bearing Capacity of Large-Sized Thin-Walled Steel Tubes. Ph.D. Thesis, Tongji University, Shanghai, China, 2004. [Google Scholar]

- Nseir, J. Development of a New Design Method for the Cross-Section Capacity of Steel Hollow Sections. Ph.D. Thesis, University of Liège, Liège, Belgium, 2015. [Google Scholar]

- Ma, J. Behaviour and Design of Cold-Formed High Strength Steel Tubular Members; The University of Hong Kong Libraries: Pok Fu Lam, Hong Kong, 2017. [Google Scholar]

- Pournara, A.E.; Karamanos, S.A.; Mecozzi, E.; Lucci, A. Structural resistance of high-strength steel CHS members. J. Constr. Steel Res. 2017, 128, 152–165. [Google Scholar] [CrossRef] [Green Version]

- Zhou, F.; Young, B. Concrete-filled aluminum circular hollow section column tests. Thin Walled Struct. 2009, 47, 1272–1280. [Google Scholar] [CrossRef]

- Di Benedetto, S.; Latour, M.; Rizzano, G. Chord failure resistance of 3D cut welded connections with CHS columns and through I-BEAMS. Thin Walled Struct. 2020, 154, 106821. [Google Scholar] [CrossRef]

- Di Benedetto, S.; Latour, M.; Rizzano, G. Assessment of the stiffness of 3D cut welded connections with CHS columns and through I-BEAMS. Structures 2020, 27, 247–258. [Google Scholar] [CrossRef]

- Makino, Y.; Kurobane, Y.; Paul, J.C.; Orita, Y.; Hiraishi, K. Ultimate capacity of gusset plate-to-tube joints under axial and in plane bending loads. In Proceedings of the 4th International Symposium on Tubular Structures, Delft, The Netherlands, 26–28 June 1991; pp. 424–434. [Google Scholar]

- Makino, Y.; Kurobane, Y.; Ochi, K.; Vegte, G.; Wilmshurst, S.R. Database of Test and Numerical Analysis Results for Unstiffened Tubular Joints; Kumamoto University: Kumamoto, Japan, 1996. [Google Scholar]

- de Winkel, G.D. The Static Strength of I-beam to Circular Hollow Section. Ph.D. Thesis, Delft University of Technology, Delft, The Netherlands, 1998. [Google Scholar]

- CEN. EN 1993-1-8 Eurocode 3: Design of Steel Structures. Part 1–8: Design of Joints; CEN: Brussels, Belgium, 2005. [Google Scholar]

- AIJ. Recommendations for the Design and Fabrication of Tubular Truss Structures in Steel; Architectural Institute of Japan: Tokyo, Japan, 2002. [Google Scholar]

- Sawada, Y.; Idogaki, S.; Sekita, K. Static and Fatigue Tests on T-Joints Stiffened by an Internal Ring. In Proceedings of the Offshore Technology Conference, Houston, TX, USA, 30 April–3 May 1979. [Google Scholar]

- Khador, M.; Chan, T.-M. Cyclic behaviour of external diaphragm joint to CHS column with built-in replaceable links. Steel Constr. 2016, 9, 331–338. [Google Scholar] [CrossRef]

- Li, L.; Wang, W.; Chen, Y.; Lu, Y. Experimental investigation of beam-to-tubular column moment connections under column removal scenario. J. Constr. Steel Res. 2013, 88, 244–255. [Google Scholar] [CrossRef]

- Wang, W.; Chen, Y.; Li, W.; Leon, R.T. Bidirectional seismic performance of steel beam to circular tubular column connections with outer diaphragm. Earthq. Eng. Struct. Dyn. 2010, 40, 1063–1081. [Google Scholar] [CrossRef]

- Zhao, X.; Packer, J. Tests and design of concrete-filled elliptical hollow section stub columns. Thin Walled Struct. 2009, 47, 617–628. [Google Scholar] [CrossRef]

- Alostaz, Y.; Schneider, S.P. Analytical behavior of connections to concrete-filled steel tubes. J. Constr. Steel Res. 1996, 40, 95–127. [Google Scholar] [CrossRef]

- Quan, C.; Wang, W.; Zhou, J. Cyclic behavior of stiffened joints between concrete-filled steel tubular column and steel beam with narrow outer diaphragm and partial joint penetration welds. Front. Struct. Civ. Eng. 2016, 10, 333–344. [Google Scholar] [CrossRef]

- Li, X.; Xiao, Y.; Wu, Y. Seismic behavior of exterior connections with steel beams bolted to CFT columns. J. Constr. Steel Res. 2009, 65, 1438–1446. [Google Scholar] [CrossRef]

- Voth, A.; Packer, J.A. Branch Plate-to-Circular Hollow Structural Section Connections. I: Experimental Investigation and Finite-Element Modeling. J. Struct. Eng. 2012, 138, 995–1006. [Google Scholar] [CrossRef] [Green Version]

- Togo, T. Experimental Study on Mechanical Behavior of Tubular Joints. Ph.D. Thesis, Osaka University, Osaka, Japan, 1967. [Google Scholar]

- Wardenier, J. Hollow Section Joints; Delft University Press: Delft, The Netherlands, 1982. [Google Scholar]

- de Winkel, G.D.; Wardenier, J. Parametric Study on the Static Strength of Axially Loaded Multiplanar Plate to Circular Column Connections. In Proceedings of the ISOPE Fifth International Offshore and Polar Engineering Conference, The Hague, The Netherlands, 11–16 June 1995; Volume 4. [Google Scholar]

- De Winkel, G.; Wardenier, J. The static strength and behaviour of multiplanar i-beam to tubular column connections loaded with in-plane bending moments. In Connections in Steel Structures III; Elsevier BV: Amsterdam, The Netherlands, 1996; pp. 137–147. [Google Scholar]

- de Winkel, G.D.; Wardenier, J. Parametric Study on the Static behavior of Uniplanar I-beam-to-tubular Column Connections Loaded with In-plane Bending Moments Combined with Pre-stressed Columns. In Proceedings of the Seventh Int. Symposium on Tubular Structures VII, Miskolc, Hungary, 28–30 August 1996. [Google Scholar]

- Wardenier, J. A uniform effective width approach for the design of CHS overlap joints. In Proceedings of the 5th International Conference on Advances in Steel Structures (ICASS), Singapore, 5–7 December 2007; Volume 2, pp. 155–165. [Google Scholar]

- Wardenier, J.; Packer, J.A.; Zhao, X.L.; van der Vegte, G.J. Hollow Section in Structural Applications, 2nd ed.; CIDECT and Bowen met Staal: Rotterdam, The Netherlands, 2010. [Google Scholar]

- Kanyilmaz, A.; Castiglioni, C.A.; Brambilla, G.; Gjoka, K.; Galazzi, A.; Raso, S.; Valli, A.; Brugnolli, M.; Hojda, R. 03.33: Experimental assessment of tolerances for the fabrication of laser-cut steel joints. ce/papers 2017, 1, 776–785. [Google Scholar] [CrossRef]

- Kanyilmaz, A. The problematic nature of steel hollow section joint fabrication, and a remedy using laser cutting technology: A review of research, applications, opportunities. Eng. Struct. 2019, 183, 1027–1048. [Google Scholar] [CrossRef]

- Voth, A. Branch Plate-to-Circular Hollow Structural Section Connections. Ph.D. Thesis, University of Toronto, Toronto, ON, Canada, 2010. [Google Scholar]

- Abaqus. Analysis User’s Manual, version 6.17; Abaqus Inc.: Palo Alto, CA, USA, 2017. [Google Scholar]

- CEN. EN 1993-1-4 Eurocode 3: Design of Steel Structures. Part 1–4: General Rules–Supplementary Rules for Stainless Steel; CEN, European Committee for Standardization: Brussels, Belgium, 2006. [Google Scholar]

- ANSI/AISC 341-16, Seismic Provisions for Structural Steel Buildings; American Institute for Steel Construction: Chicago, IL, USA, 2016.

- CEN. EN 1998-1 Eurocode 8: Design of Structures for Earthquake Resistance. Part 1: General Rules, Seismic Actions and Rules for Buildings; CEN, European Committee for Standardization: Brussels, Belgium, 2005. [Google Scholar]

- Faralli, A.C. Large Deformation of T-Stub Connection in Bolted Steel Joints. Ph.D. Thesis, University College of London, London, UK, 2019. [Google Scholar]

- Pavlovic, M.; Marković, Z.; Veljkovic, M.; Buđevac, D. Bolted shear connectors vs. headed studs behaviour in push-out tests. J. Constr. Steel Res. 2013, 88, 134–149. [Google Scholar] [CrossRef]

- CEN. EN 1993-1-5 Eurocode 3: Design of Steel Structures. Part 1–5: Piling; CEN, European Committee for Standardization: Brussels, Belgium, 2006. [Google Scholar]

- EN 10034, Structural Steel I and H Sections—Tolerances on Shape and Dimensions; British Standards Institution: London, UK, 1995.

- Steinboeck, A.; Kugi, A.; Mang, H. Energy-consistent shear coefficients for beams with circular cross sections and radially inhomogeneous materials. Int. J. Solids Struct. 2013, 50, 1859–1868. [Google Scholar] [CrossRef] [Green Version]

| Stiffness (kNm/rad) | Resistance (kNm) | |||||

|---|---|---|---|---|---|---|

| Exp. | FEM | FEM/Exp. | Exp. | FEM | FEM/Exp. | |

| Monotonic test | 4151 | 4072 | 0.98 | 52 | 52 | 1.00 |

| Cyclic test | 3849 | 3786 | 0.98 | 45 | 49 | 1.08 |

| Test | Column (Diameter/Thickness) | Beam | β | γ | η | Stiffness (kNm/mrad) |

|---|---|---|---|---|---|---|

| 1 | 193.7/6 | IPE240 | 0.62 | 16.14 | 1.24 | 9.84 |

| 2 | 219.1/4 | IPE300 | 0.68 | 27.39 | 1.37 | 9.20 |

| 3 | 219.1/6 | IPE240 | 0.55 | 18.26 | 1.10 | 8.29 |

| 4 | 219.1/6 | IPE270 | 0.62 | 18.26 | 1.23 | 10.89 |

| 5 | 219.1/6 | IPE300 | 0.68 | 18.26 | 1.37 | 15.30 |

| 6 | 219.1/6 | IPE330 | 0.73 | 18.26 | 1.51 | 20.45 |

| 7 | 244.5/8 | IPE330 | 0.65 | 15.28 | 1.35 | 23.80 |

| 8 | 244.5/8 | IPE360 | 0.70 | 15.28 | 1.47 | 30.89 |

| 9 | 273/5 | IPE300 | 0.55 | 27.30 | 1.10 | 8.67 |

| 10 | 273/5 | IPE330 | 0.59 | 27.30 | 1.21 | 10.86 |

| 11 | 273/5 | IPE360 | 0.62 | 27.30 | 1.32 | 13.06 |

| 12 | 273/8 | IPE400 | 0.66 | 17.06 | 1.47 | 32.41 |

| 13 | 323.9/5 | IPE330 | 0.49 | 32.39 | 1.02 | 8.76 |

| 14 | 323.9/5 | IPE360 | 0.52 | 32.39 | 1.11 | 10.55 |

| 15 | 323.9/5 | IPE400 | 0.56 | 32.39 | 1.23 | 14.57 |

| 16 | 323.9/6.3 | IPE360 | 0.52 | 25.71 | 1.11 | 14.07 |

| 17 | 323.9/6.3 | IPE400 | 0.56 | 25.71 | 1.23 | 18.74 |

| 18 | 323.9/6.3 | IPE450 | 0.59 | 25.71 | 1.39 | 23.57 |

| 19 | 355.6/6 | IPE400 | 0.51 | 29.63 | 1.12 | 15.33 |

| 20 | 355.6/6 | IPE450 | 0.53 | 29.63 | 1.27 | 18.92 |

| 21 | 355.6/6 | IPE500 | 0.56 | 29.63 | 1.41 | 24.62 |

| 22 | 355.6/6 | IPE550 | 0.59 | 29.63 | 1.55 | 31.33 |

| 23 | 355.6/6 | IPE600 | 0.62 | 29.63 | 1.69 | 39.76 |

| 24 | 406.4/6 | IPE450 | 0.47 | 33.87 | 1.11 | 16.45 |

| 25 | 406.4/6 | IPE500 | 0.49 | 33.87 | 1.23 | 21.49 |

| 26 | 406.4/6 | IPE550 | 0.52 | 33.87 | 1.35 | 26.11 |

| 27 | 406.4/6 | IPE600 | 0.54 | 33.87 | 1.48 | 33.18 |

| 28 | 406.4/10 | IPE500 | 0.49 | 20.32 | 1.23 | 42.58 |

| 29 | 406.4/10 | IPE550 | 0.52 | 20.32 | 1.35 | 52.54 |

| 30 | 406.4/10 | IPE600 | 0.54 | 20.32 | 1.48 | 65.79 |

| Test | Column (d0/t0) | Beam | kϕ, FEM (kNm/mrad) | kϕ, Proposal (kNm/mrad) | Proposal/FEM |

|---|---|---|---|---|---|

| 1 | 193.7/6 | IPE240 | 9.84 | 7.18 | 0.73 |

| 2 | 219.1/4 | IPE300 | 9.20 | 7.24 | 0.79 |

| 3 | 219.1/6 | IPE240 | 8.29 | 6.64 | 0.80 |

| 4 | 219.1/6 | IPE270 | 10.89 | 8.58 | 0.79 |

| 5 | 219.1/6 | IPE300 | 15.30 | 10.86 | 0.71 |

| 6 | 219.1/6 | IPE330 | 20.45 | 13.67 | 0.67 |

| 7 | 244.5/8 | IPE330 | 23.80 | 17.12 | 0.72 |

| 8 | 244.5/8 | IPE360 | 30.89 | 21.68 | 0.70 |

| 9 | 273/5 | IPE300 | 8.67 | 7.84 | 0.90 |

| 10 | 273/5 | IPE330 | 10.86 | 9.97 | 0.92 |

| 11 | 273/5 | IPE360 | 13.06 | 12.70 | 0.97 |

| 12 | 273/8 | IPE400 | 32.41 | 25.96 | 0.80 |

| 13 | 323.9/5 | IPE330 | 8.76 | 8.83 | 1.01 |

| 14 | 323.9/5 | IPE360 | 10.55 | 11.33 | 1.07 |

| 15 | 323.9/5 | IPE400 | 14.57 | 14.58 | 1.00 |

| 16 | 323.9/6.3 | IPE360 | 14.07 | 14.27 | 1.01 |

| 17 | 323.9/6.3 | IPE400 | 18.74 | 18.37 | 0.98 |

| 18 | 323.9/6.3 | IPE450 | 23.57 | 24.46 | 1.04 |

| 19 | 355.6/6 | IPE400 | 15.33 | 16.39 | 1.07 |

| 20 | 355.6/6 | IPE450 | 18.92 | 21.91 | 1.16 |

| 21 | 355.6/6 | IPE500 | 24.62 | 28.80 | 1.17 |

| 22 | 355.6/6 | IPE550 | 31.33 | 36.46 | 1.16 |

| 23 | 355.6/6 | IPE600 | 39.76 | 46.20 | 1.16 |

| 24 | 406.4/6 | IPE450 | 16.45 | 19.92 | 1.21 |

| 25 | 406.4/6 | IPE500 | 21.49 | 26.34 | 1.23 |

| 26 | 406.4/6 | IPE550 | 26.11 | 33.54 | 1.28 |

| 27 | 406.4/6 | IPE600 | 33.18 | 42.79 | 1.29 |

| 28 | 406.4/10 | IPE500 | 42.58 | 43.90 | 1.03 |

| 29 | 406.4/10 | IPE550 | 52.54 | 55.90 | 1.06 |

| 30 | 406.4/10 | IPE600 | 65.79 | 71.31 | 1.08 |

| Mean= | 0.98 | ||||

| Standard deviation= | 0.18 | ||||

| Coefficient of variation= | 0.19 | ||||

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Di Benedetto, S.; Latour, M.; Rizzano, G. Stiffness Prediction of Connections between CHS Tubes and Externally Welded I-Beams: FE Analyses and Analytical Study. Materials 2020, 13, 3030. https://doi.org/10.3390/ma13133030

Di Benedetto S, Latour M, Rizzano G. Stiffness Prediction of Connections between CHS Tubes and Externally Welded I-Beams: FE Analyses and Analytical Study. Materials. 2020; 13(13):3030. https://doi.org/10.3390/ma13133030

Chicago/Turabian StyleDi Benedetto, Sabatino, Massimo Latour, and Gianvittorio Rizzano. 2020. "Stiffness Prediction of Connections between CHS Tubes and Externally Welded I-Beams: FE Analyses and Analytical Study" Materials 13, no. 13: 3030. https://doi.org/10.3390/ma13133030