1. Introduction

The conversion of vibrations into low-power electricity has been extensively explored since decades in view of the wide range of applications of the harvesters in distributed wireless sensors for structural health monitoring and for security systems, in embedded and implanted medical sensors and in recharging of batteries in various systems, see, e.g., the reviews [

1,

2]. To obtain an efficient energy harvester, one has to focus the mechanical energy produced by external vibrations in a given region of the system, where it can be then converted in electricity by means, e.g., of piezoelectric materials.

The use of structured materials for Energy Harvesters (EH) has more recently attracted the attention of the researchers and a number of possible configurations have been proposed [

3,

4,

5,

6,

7]. Localized defects in phononic crystals [

8] and in micro-structured plates [

9] have been exploited to focus vibration energy in a small region where a piezoelectric material converts the mechanical energy into the electric one. However, good performance is obtained only for frequencies close to the defect eigen-frequency which is related with the typical size of the unit cell of the lattice. Even though proper methods can be used to optimize the geometry of the cell [

10], for small devices, this frequency is very high when compared with the frequency of ambient vibrations in common applications. Localized defects in tensegrity materials have also been studied in [

11].

Locally resonant metastructures, which are structures that comprise Locally Resonant Material (LRM) components, enable band gap formation at wavelengths much longer than the lattice size (see, e.g., [

12,

13,

14,

15,

16]), therefore they can represent good candidates for efficient, small EH. In [

17] the localized deformation pattern achieved in the frequency neighborhood of the band gaps was employed in order to harvest a certain amount of the kinetic energy available in the oscillating members of the lattice. Recently [

18] proposed a prototype of locally resonant energy harvesting-metastructure composed of a primary beam with several small secondary cantilever beams with tip masses acting as mechanical resonators. The design of innovative metasurfaces, with graded resonators, that trap waves was proposed and developed in [

5] for enhanced piezoelectric energy harvesting.

In the present work we explore the possibility to couple the advantage of the LRM mechanism to create band gaps at low frequencies with the energy localization mechanism in local defects of regular lattices to design and optimize a Resonant Energy Harvester (REH). An initial attempt in this direction was presented in [

19], considering binary LRMs. The ternary LRM here considered, endowed with two-dimensional periodicity, is constituted by a stiff matrix with almost rigid cylindrical inclusions coated by a compliant material. The two-scale homogenization approach, proposed in [

20] for high-contrast binary composite materials in the long wavelength regime and developed by many authors ([

21,

22,

23]), provides a powerful tool to define equivalent material properties. The authors recently studied through homogenization the spectral properties and the band gaps of binary and ternary LRM in [

16,

24], respectively. The REH here proposed is constituted by two barriers made of the above LRM and a cavity, made of the matrix alone, which represents a line defect in the two dimensional regular lattice. The use of barriers made of LMR and of phononic crystals was also recently proposed to obtain an acoustic diode [

25]. To optimize the REH, the behavior of the LRM is here characterized by its homogenized properties and the dynamic response is analytically obtained. The conditions to obtain the maximal mechanical energy inside the cavity are explicitly given and the role of the different configurations of the unit cell of the metamaterial are highlighted.

Beside extending the analytic results obtained in [

19] for a REH with binary LRM to the case of a REH with three components LRM, the paper provides a new numerical validation, introduces the concept of indexes of concentration and develops maps of these indexes at varying frequency and geometry of the REH. The maps can be of practical use in the design of a real REH that, with a fixed geometry, should work in a wide range of frequencies.

The paper is organized as follows. The proposed configuration of the REH and the dynamic problem of shear wave propagation is set in

Section 2. In

Section 3 the energy in each part of the system is computed and the optimal width of the cavity to maximize the energy trapped in the cavity is obtained.

Section 4 provides a comparison of the analytic results with the numerical results obtained for a special choice of the LRM, thus validating the analytic results. These latter allows to perform a parametric study of the system. Some conclusions are given in

Section 5. The results of the asymptotic homogenization, obtained in [

24], which are used in the paper, are recalled in the

Appendix A.

Notation, vectors and tensors are indicated by bold face letters. Complex numbers are denoted with sans serif letters, while italic is utilized for the Real numbers. The complex conjugate of a complex number is indicated by a superposed bar. The angular frequency is often called just frequency. The notation denotes the average over the period.

3. Energy Localization in the Cavity

3.1. Energy in the Homogeneous Parts

We are now interested in finding the mechanical energy density, averaged over a period, along the whole REH and the total energy in parts , and again averaged over a time period, .

The mechanical energy in regions

with

, 3 or 5 of homogeneous material, given by the sum of the potential energy

p and the kinetic energy

c, reads:

where the dependency over time is again accounted for, a superimposed dot denotes the time derivative and a prime denotes the space derivative; the displacement field

is given by

.

Averaging Equation (

10) over time gives:

Notice that

is independent from the position x. Finally, the total mechanical energy

inside part

reads:

While the energy inside the regions can be easily obtained, a particular treatment must be devoted to the calculation of the energy inside the two barriers.

3.2. Energy Inside the LRM: Homogenization Approach

Each cell is composed of a matrix, a coating layer and a fiber considered as rigid, hence the mechanical energy density of one cell reads:

The homogenization technique enables to find the displacement field and the stress over a cell composing the metamaterial. It should be noted that, while at the macro-scale the problem is one-dimensional, so that only the variable

must be retained, at the micro-scale (inside each cell) the problem remains 2D and the coordinates

or the polar coordinates

must be retained. Similarly, inside the cell the stress

is non-zero and a stress vector should be considered. At the leading order, one has:

and

with

and

defined in the

Appendix A.

Considering a frequency inside the band gap of the metamaterial, in regions

,

, one has

,

, with

given by Equation (

6). Denoting the real part of the displacement in the matrix by

the contributions to the energy density in Equation (

13) read

From Equations (

16) to (

20) after some manipulation, the energy

, with

or 4, can be written as:

where

is given by:

The averaged mechanical energy density for the barriers is thus dependent on the position

x along them. Integrating over their thickness

l, one can derive the averaged total mechanical energies

and

as:

3.3. Optimal Cavity Width

Our objective is now to exploit the attenuation capabilities of the employed LRMs for obtaining a concentration of mechanical energy inside the cavity. Let us focus our attention on frequencies inside a band gap for the analyzed LRM.

Fixing the materials used for the system, the width

l of the barriers and the frequency of the propagating wave, the modulus of the coefficient

given in Equation (

7) is maximized and becomes equal to 1 for a discrete set of optimal cavity widths

and, at the same time,

is null. The optimal cavity widths

can be found from the following relation (see [

19] for the details):

One should notice that Equation (

26) gives also the set of

d that minimize

.

Using the expression of the displacement

into Equation (

11), the total mechanical energy Equation (

12) inside part

reads:

From Equation (

27), as both

and

are independent from

d, the mechanical energy inside part

is maximized whenever

, i.e., when

is maximum.

When

, the total energy of the regions

,

and

reads:

3.4. Limit Case of the Well

By extending the barriers toward

and

the homogeneous parts

and

disappear and the above system tends to a well, as sketched in

Figure 4.

The difference with respect to the REH case, expressed by Equation (

3), is that now the two conditions at

and

are imposed to the metamaterial. Since no energy can be accumulated at

and

, the motion inside parts

and

of the well must respect the following statements:

By applying the above conditions to the general solution of Equation (

3), two of the six unknown integration constants can be given as functions of the remaining four. Furthermore, the continuity of displacements and stresses at each interface leads to a homogeneous system of four equations. This system admits a non-trivial solution only for a set of

values, which can be found from the following relation:

By fixing for instance the amplitude of the left-wards traveling wave inside the well, the remaining three amplitudes are found and the motion inside each part is finally defined.

The only solutions are now modes for which the frequency is a resonant frequency given by Equation (

30). Note that condition Equation (

30) can also be obtained directly from Equation (

26) by taking the limit for

. The total mechanical energy stored by each part can be expressed as a function of

and reads:

with

Fixing the amount of total energy of the system, one can find the coefficient and, thus, the motion inside each part.

4. Results

The results of the previous sections are valid provided several hypotheses on the materials composing the REH are fulfilled. For clarity, we summarize them here below:

Parts , and are constituted by the same material utilized for the matrix composing the LRM;

The coating layer of the fibers must be very compliant with respect to the matrix;

The fibers must be very stiff so that they can be treated as rigid in the homogenization procedure.

Since we are now interested in considering a real possible application, the material properties shall be fixed by respecting the three conditions just specified. We choose to use the following combination: an epoxy material is employed for the matrix, with lead inclusions coated by a layer of rubber. The material properties are specified in

Table 1.

We consider a lattice with square unit cells with side

mm, the radius of the coated circular inclusion is

, while the radius of the internal part is

. A scaling of the cell would simply scale the effective mass density when plotted with respect to the frequency, without changing the band gap structure; considering different filling fractions

or thicknesses of the coating, (

would instead modify the dynamic behavior and the band structure (see [

24] for other examples ).

4.1. Energy Localization: Analytic and Numerical Results

To check the validity of the analytic expressions derived in the previous sections, we have carried out some numerical analyses by using the commercial software COMSOL Multiphysics 5.4.

First of all, for the chosen material constants, from the homogenization technique we expect the presence of band gaps, as one can see from

Figure 5a, where we have plotted the

for a range of frequencies

from 0 to 25 kHz. The effective mass density becomes indeed negative between 2.4 and 5.7 kHz and between 22.5 and 24.1 kHz (within the range of frequencies shown by the plot). These intervals correspond to the band gaps obtained numerically by applying Bloch-Floquet’s periodic conditions at the unit cell boundaries of the LRM, as shown in

Figure 5b. For the dispersion analysis, the cell is meshed with 2D triangular quadratic Lagrange finite elements and the formal analogy with the acoustic problem is exploited. The real stiffness of lead, see

Table 1, is used, nonetheless the agreement with the analytic prediction, with the rigid inclusion assumption, is very good. One should remark that in the second band gap there are two flat modes which correspond to local resonances of the coated inclusion endowed with almost zero displacements in the matrix as already shown in [

16].

Fixing to 40 the number of cells employed for each of the two barriers (hence fixing the thickness

l) and optimizing the REH to work at a mid-band gap frequency

kHz, Equation (

26) gives a set of

, each of them giving a value of

23 times bigger than the energy

carried by an incoming wave of unit amplitude. The energy of the incoming wave is obtained from Equation (

11) and for a REH with the optimal cavity reads:

The dynamic behaviour of this REH and the energy densities in the different domains were also numerically computed. In the numerical analyses, the actual two-dimensional system sketched in

Figure 1 is considered. In the

direction, only one row of the metamaterial is discretized and symmetry boundary conditions are imposed to simulate the ideal case. In the

direction perfectly matched layers (PML) are added to consider the extension of the matrix towards infinity. 2D triangular quadratic elements are used to mesh the barriers, while 2D rectangular quadratic Lagrange finite elements are employed for the remaining homogeneous parts. Use is made again of the formal analogy with the acoustic problem, hence a background pressure field, analogous to the incoming out of plane wave, is imposed inside part

and the energy density is integrated in

and in time over a period to be compared with the analytic results.

The plot in

Figure 6 shows

(with

j from 1 to 5) along the whole system

for

mm. The orange lines represent the energy density computed by the analytic Equations (

11) and (

21), while the results of the numerical analysis are shown in blue. The oscillations of the numerical response are due to the intrinsic heterogeneity of the LRM composing the barriers, the analytic results, based on an homogenized material, give a mean value in good agreement.

In

Figure 7a, we report the transmission coefficient modulus

vs. frequency, from a transmission analysis of our REH. The results coming from the asymptotic technique agrees very well with those of the real case numerically studied. The expected peak of transmission at the frequency

inside the band gap is well captured both by the analytic and numerical results.

For showing how the presence of a cavity modifies this behavior, we have plotted in

Figure 7b the results coming from a transmission analysis in absence of the cavity, i.e., for a simple layer of LRM with a thickness equal to

(obtained by attaching together the two barriers and getting rid of the cavity in the middle). Comparing these results with those in

Figure 7a, it is clear how the peak inside the band gap disappears when no cavity is present.

4.2. Towards the Optimization of the Harvester: Parametric Study

The results of the previous subsection refer to a particular case, with all the parameters involved in the problem fixed. In this subsection we consider the effect of different possible configurations of the system and, to compare them, we introduce two indexes as a “measure” of the harvesting capabilities of the REH.

By keeping for the unit cell the same geometric dimensions employed in the previous subsection, there are three parameters which can be left free to vary, namely the barrier width

l, the optimal cavity width

and the frequency

. To compare different configurations we introduce the following two indexes:

where IC stands for “index of concentration” and AIC for “averaged index of concentration”. The former represents a measure of the concentration level of energy reached by the system, whereas the latter gives a ratio between values of energy averaged over the dimensions of the corresponding REH components.

As stated previously, Equation (

26) gives a set of optimal cavity widths

, that maximize the focused energy for a given frequency inside the band gap. In the contours of

Figure 8, we show the variation of the two smallest elements of this set

and

with respect to the frequency

inside the band gap and the width

l of the barriers. One can observe that the optimal cavity width is almost independent from the width of the barriers

l while it strongly depends on the frequency. This dependence is slightly attenuated when considering thin barriers. This is important for the real design of an harvester, with a fixed cavity width, which should work in a wide range of frequencies.

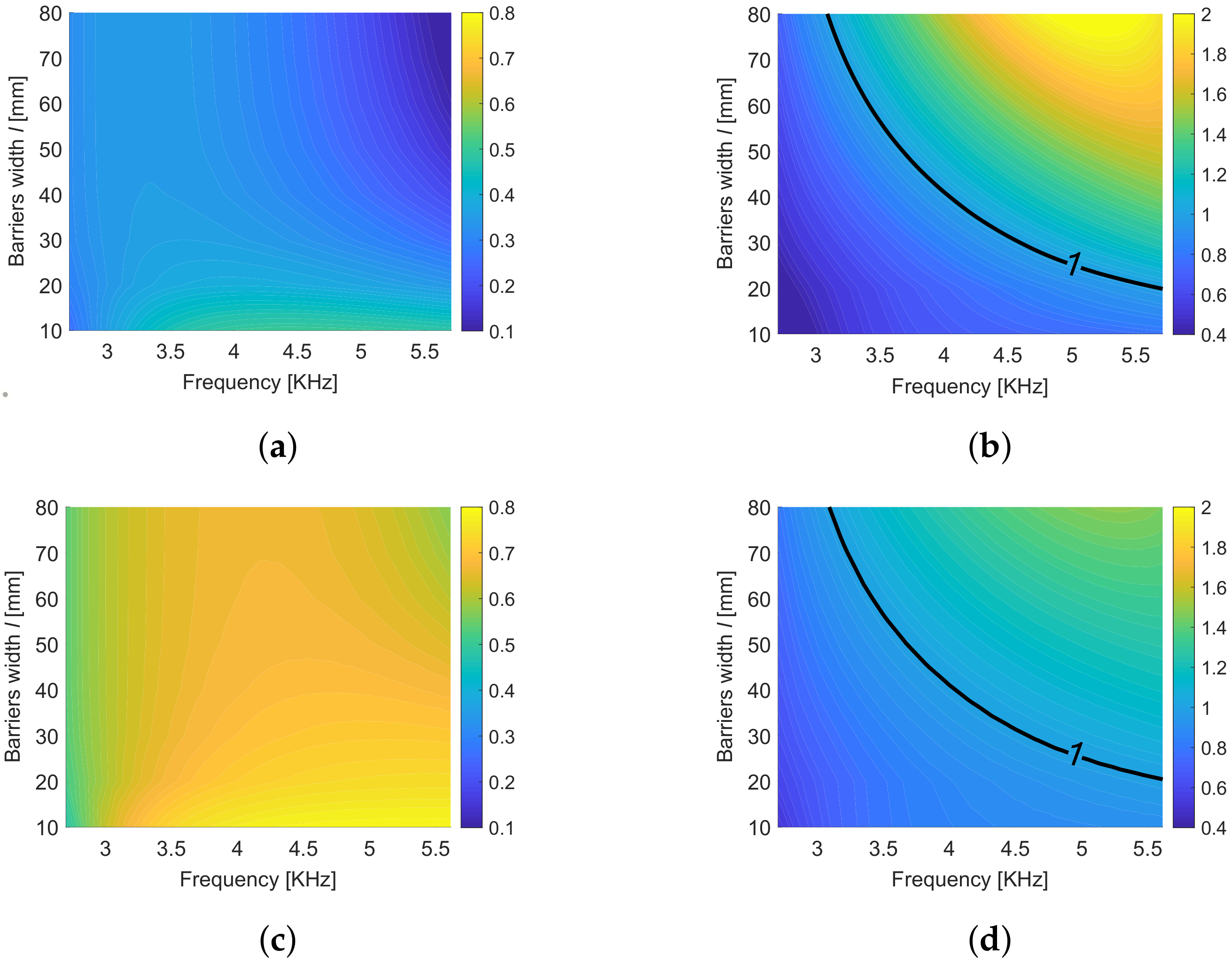

Keeping the frequency inside the band gap and the barrier width as variables, the two indexes IC and AIC are plotted in

Figure 9 using the first two optimal cavity widths

and

. The index IC (panels

Figure 9a,c) which measures the quantity of energy localized in the cavity with respect to the global energy in the metamaterial with the cavity is higher when considering the larger cavity (

). The dependence on the width of the barriers

l is very limited when considering a frequency close to the band gap opening, while IC decreases with

l when considering a higher frequency, close to the band gap closing. A different pattern is exhibited by the index AIC (

Figure 9b,d) which measures the density of energy localized in the cavity with respect to mean energy density in the metamaterial with the cavity. Values of AIC greater than one correspond to systems effectively concentrating energy in the cavity. High concentration is obtained, for both cavity dimensions, considering high frequency and large barriers; the smaller cavity gives a higher concentration (see

Figure 9b,d).

As stated before, a change of the geometry of the unit cell, in terms of both filling fraction and coating thickness, would change the expression of the effective mass density (hence the frequencies of the band gap). Moreover, a change in the filling fraction (or equivalently in the ratio between the radius

and the cell size

L) would also modify the value of the effective stiffness of the barriers. To explore the effect of these variations on the energy localization of the system, we study, in particular, the four cases specified in

Table 2.

Figure 10 shows the effect of the geometric modifications of the cell on the indexes IC and AIC; the cavity width is fixed to

in all cases. Note that the change of the cell also affects the band gap frequencies. In

Figure 10 the represented frequency range always corresponds to the first band gap of the LRM. By comparing

Figure 10a,b with

Figure 10c,d, one can observe that the concentration of energy is improved by increasing the filling fraction of the LRM. At equal filling fraction, a smaller thickness of the coating (

Figure 10a,c) also leads to a higher concentration with respect to the case with a large thickness of the coating (

Figure 10b,d, respectively).

5. Conclusions

This paper investigates the possibility to localize the vibration mechanical energy in a cavity between two barriers constituted by ternary LRMs. The concentration of energy is possible for waves having frequency inside the bandgap of the LRM. The proposed system can be reduced to a one-dimensional problem of wave propagation, thus allowing for a complete analytic solution. We consider the long-wave length regime, and we apply the asymptotic homogenization to obtain the dynamic effective properties of the LRM. The optimal dimension of the cavity for energy localization is given in close form. Results are applied to a specific LRM and validated by comparison with numerical results. The analytic solution allows to highlight the influence of the different material and geometric parameters of the metamaterial on the energy concentration. In particular it is shown that, high filling fraction and small coating thickness of the LRM, besides resulting in a larger band gap at low frequency as shown in [

24], improve the energy concentration.

The results obtained in this paper could represent a first step to design a REH with optimal performance in terms of localization of the mechanical energy carried by waves within a specific frequency interval.

The analysis was here restricted to the out-of-plane wave propagation, the case of in-plane propagation, even though leading to more complex expressions, could be treated in a similar way.

The treatment of a real REH, with finite out-of-plane dimension, deserves further studies, as the decoupling between the two cases does not hold anymore. The experimental validation should then be carried out.