Research on Prediction Model for Durability of Straw Bale Walls in Warm (Humid) Continental Climate—A Case Study in Northeast China

Abstract

:1. Introduction

2. Background

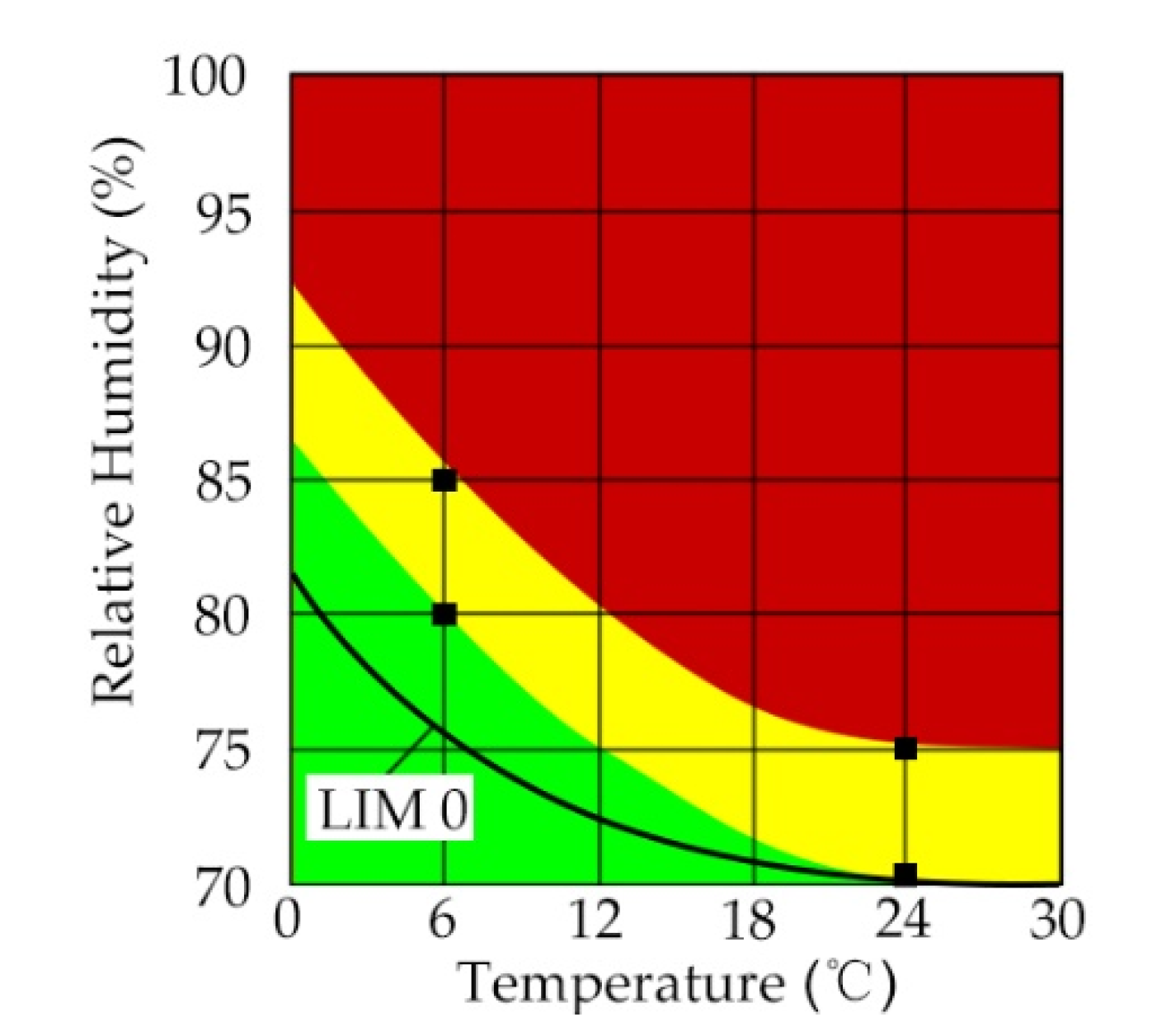

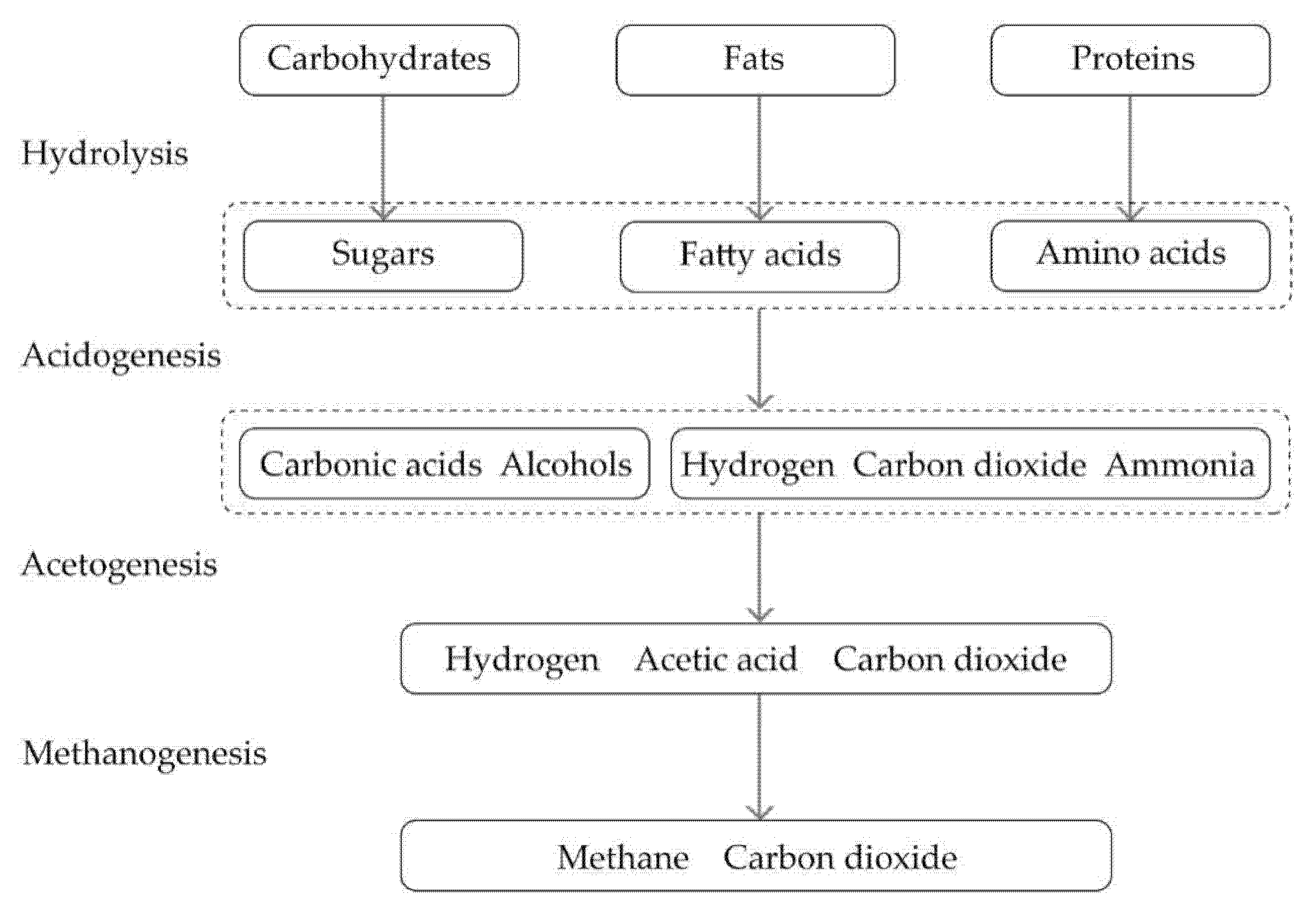

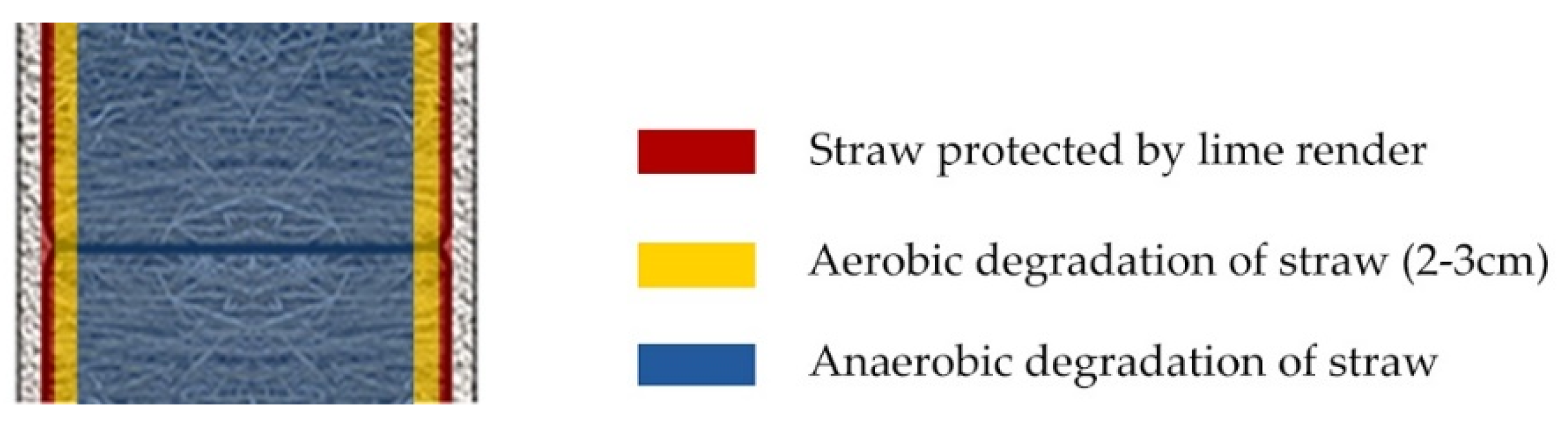

2.1. Favourable Environment for Supporting Straw Degradation

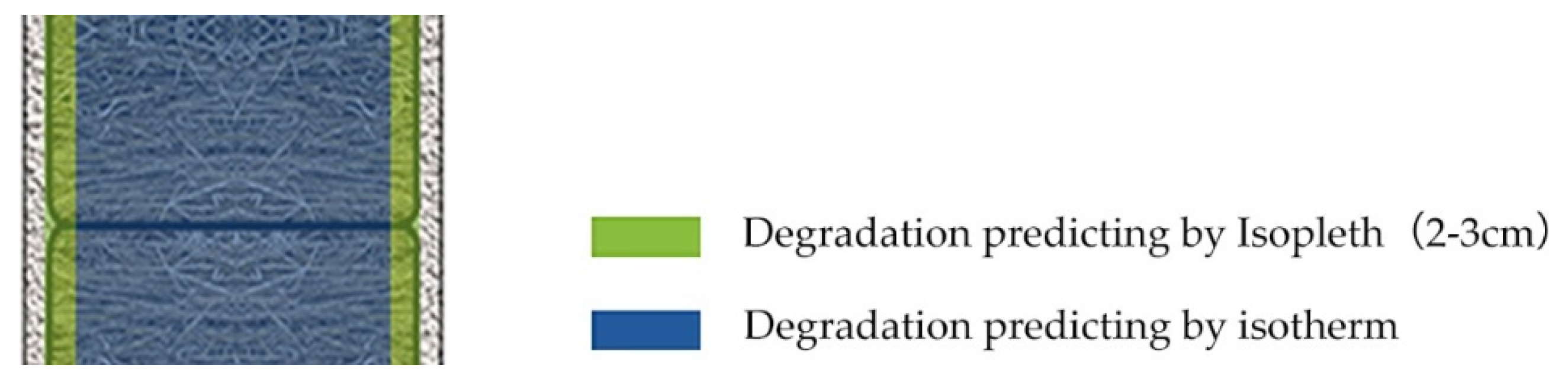

2.2. Predicting Models for Straw Degradation

3. Method

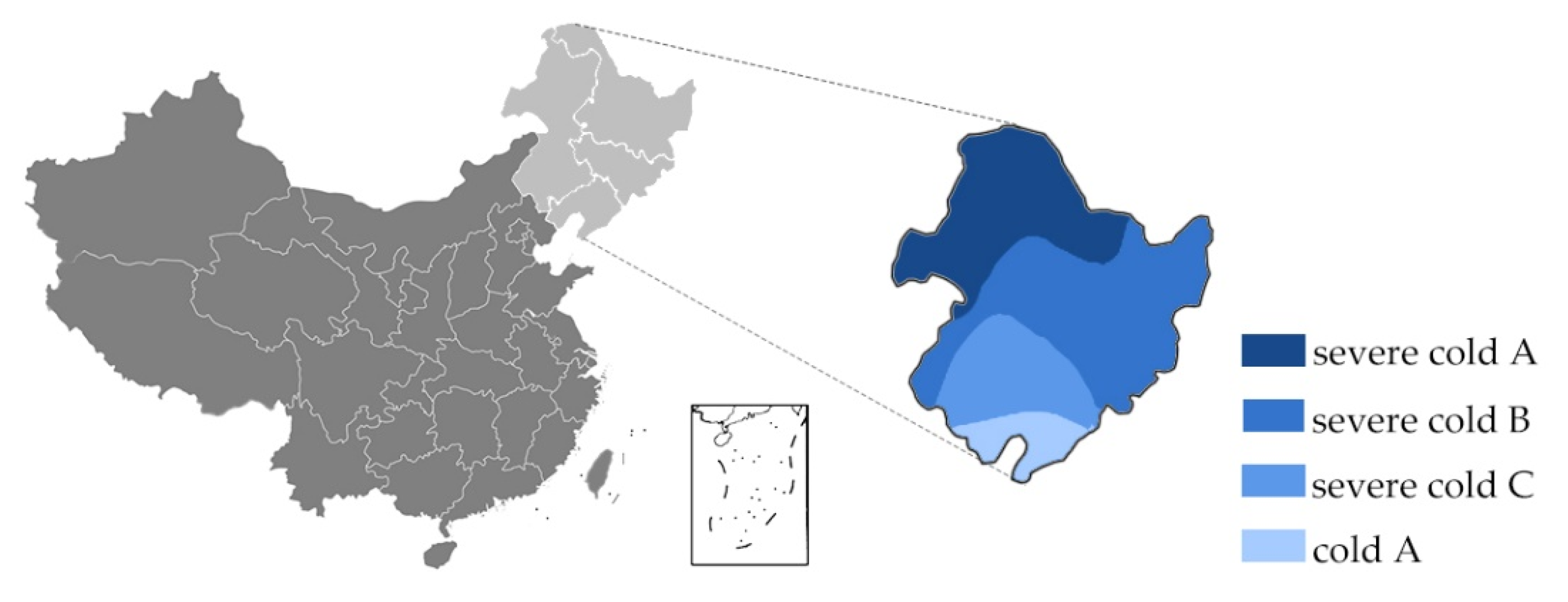

3.1. Climatic Condition of Examined Area

3.2. Conditions within Experimental Building

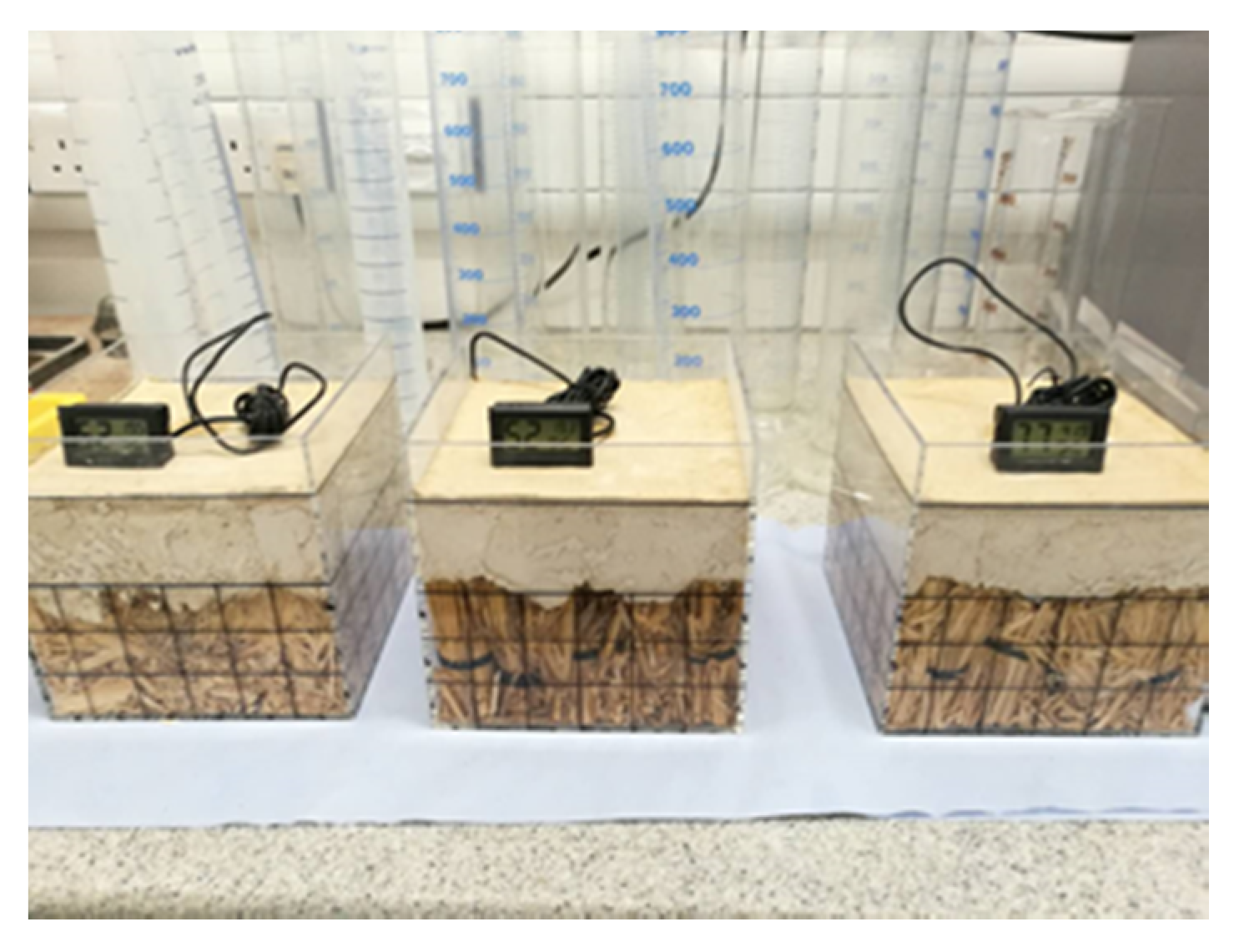

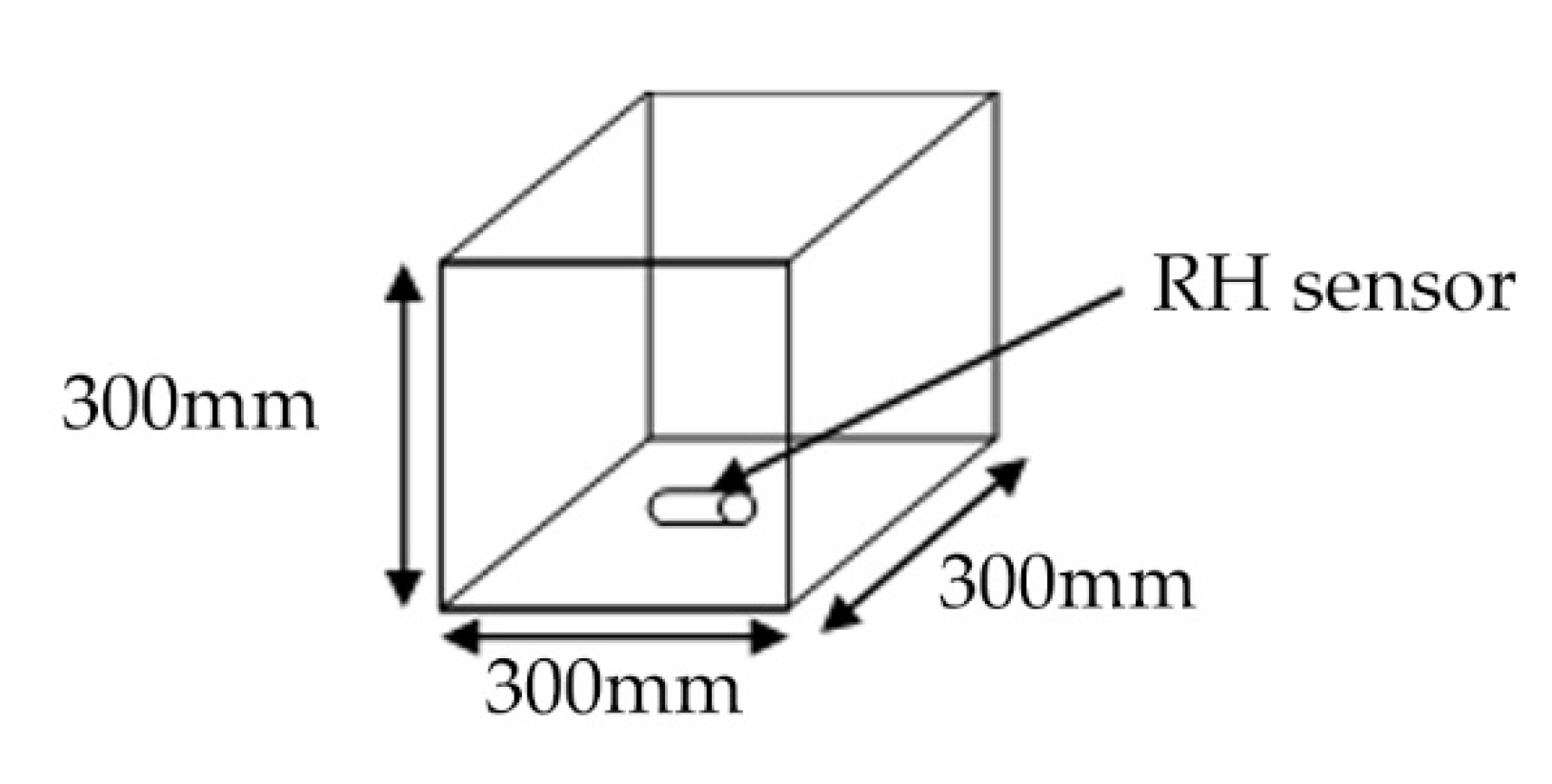

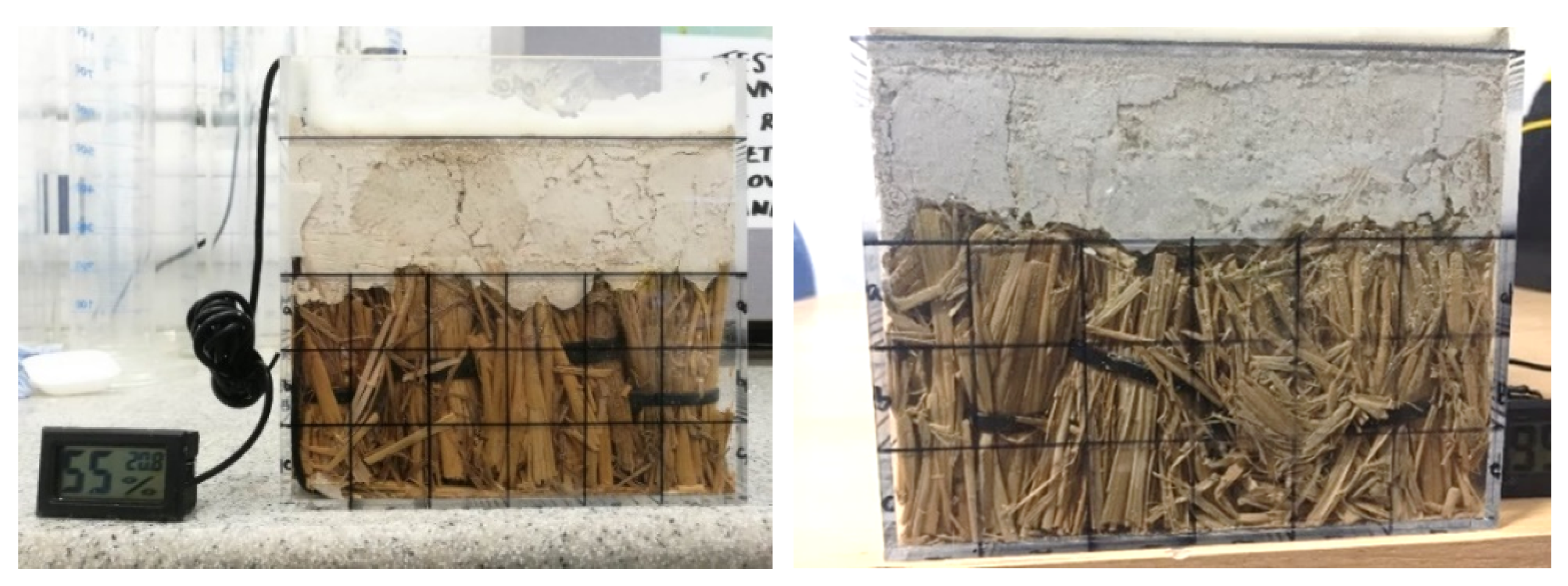

3.3. Small Scale Controlled Conditions

4. Results

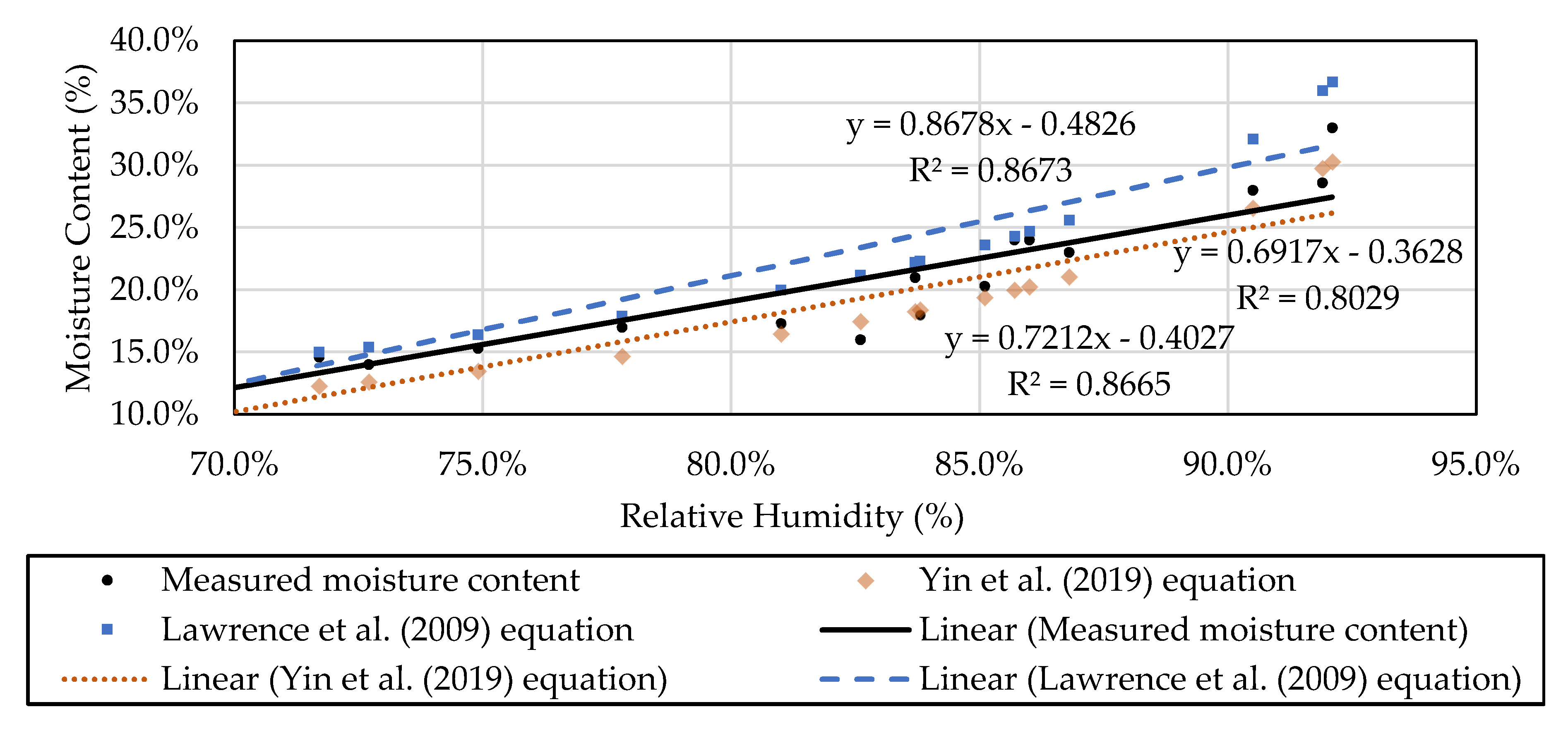

4.1. Small Scale Controlled Conditions

4.2. Results of the Experimental Building

5. Assessment of Straw Degradation of the Experimental Building

6. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- King, B. Design of Straw Bale Buildings: The State of the Art, 2nd ed.; Green Building: San Rafael, CA, USA, 2006. [Google Scholar]

- Steen, A.S.; Steen, B.; Bainbridge, D. The Straw Bale House; Chelsea Green Publishing: Hartford, VT, USA, 1994. [Google Scholar]

- Lacinski, P.; Bergeron, M. Serious Straw Bale, a home Construction Guide for All Climates; Chelsea Green Publishing Company: Hartford, VT, USA, 2000. [Google Scholar]

- Steen, A.S.; Steen, B. The Beauty of Straw Bale Homes; Chelsea Green Publishing Company: Hartford, VT, USA, 2000. [Google Scholar]

- Ministry of Housing and Rural Urban Development. Standard of Climatic Regionalization for Architecture GB50178-93; Ministry of Housing and Rural Urban Development: Beijing, China, 1994.

- Beck, H.E.; Zimmermann, N.E.; McVicar, T.R.; Vergopolan, N.; Berg, A.; Wood, E.F. Present and future Köppen-Geiger climate classification maps at 1-km resolution. Sci. Data 2018, 5, 180214. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Rubel, F.; Kottek, M. Comments on: “The thermal zones of the Earth” by Wladimir Köppen (1884). Meteorol. Z. 2011, 2, 361–365. [Google Scholar] [CrossRef]

- Wu, X.L.; Wang, Q.P.; Liu, X.C.; Shang, T. The rural ecological and energy-saving residential construction technology in the severe cold region. Renew. Energy Resour. 2013, 31, 115–118. (In Chinese) [Google Scholar]

- Li, N.; Yang, L.; Luo, Z.; Wang, Q. Study of Adaptability for Straw-Bale Houses in Northern Rural Area. Ind. Constr. 2014, 150, 64–67. (In Chinese) [Google Scholar]

- Yin, X.; Lawrence, M.; Maskell, D. Straw bale construction in northern China—Analysis of existing practices and recommendations for future development. J. Build. Eng. 2018, 18, 408–417. [Google Scholar] [CrossRef]

- Summers, M.D.; Blunk, S.L.; Jenkins, B.M. How straw decomposes: Implications for straw bale construction. Ecol. Build. Netw. 2003, 1–6. [Google Scholar]

- Cascone, S.; Rapisarda, R.; Cascone, D. Physical Properties of Straw Bales as a Construction Material: A Review. Sustainability 2019, 11, 3388. [Google Scholar] [CrossRef] [Green Version]

- Zhu, N. Effect of low initial C/N ratio on aerobic composting of swine manure with rice straw. Bioresour. Technol. 2007, 98, 9–13. [Google Scholar] [CrossRef]

- Thomson, A.; Walker, P. Durability characteristics of straw bales in building envelopes. Constr. Build. Mater. 2014, 68, 135–141. [Google Scholar] [CrossRef] [Green Version]

- Jones, B. Building with Straw Bales: A Practical Guide for the UK and Ireland; Green Books: Cambridge, UK, 2009. [Google Scholar]

- Wihan, J. Humidity in Straw Bale Walls and Its Effect on the Decomposition of Straw. Master Thesis, University of East London, London, UK, 2007. [Google Scholar]

- Thomson, A.; Dick, K.; Walker, P. Steady-state and dynamic hygrothermal performance of rendered straw bale walls. Proc. Inst. Civ. Eng. Constr. Mater. 2019, 1–11. [Google Scholar] [CrossRef]

- Hopkins, W.G. Introduction to Plant Physiology; John Wiley and Sons: New York, NY, USA, 1999. [Google Scholar]

- Dresbøll, D.B.; Magid, J. Structural changes of plant residues during decomposition in a compost environment. Bioresour. Technol. 2006, 97, 973–981. [Google Scholar] [CrossRef] [PubMed]

- Jusoh, M.L.C.; Manaf, L.A.; Latiff, P.A. Composting of rice straw with effective microorganisms (EM) and its influence on compost quality. Iran. J. Environ. Health Sci. Eng. 2013, 10, 17. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Magan, N.; Lacey, J. Effects of gas composition and water activity on growth of field and storage fungi and their interactions. Trans. Br. Mycol. Soc. 1984, 82, 305–314. [Google Scholar] [CrossRef]

- Sedlbauer, K.; Hofbauer, W.; Krueger, N.; Mayer, F.; Breuer, K. Material specific isopleth-systems as valuable tools for the assessment of the durability of building materials against mould infestation—The ‘‘isopleth-traffic light’’. In Proceedings of the International Conference on Building Materials and Components, Porto, Portugal, 12–15 April 2011. [Google Scholar]

- Hens, H.S. Building Physics-Heat, Air and Moisture: Fundamentals and Engineering Methods with Examples and Exercises; John Wiley & Sons: Leuven, Belgium, 2012. [Google Scholar]

- Hedlin, C.P. Sorption isotherms of five types of grain straw at 70 degrees F. Can. Agric. Eng. 1967, 9, 37–39. [Google Scholar]

- Strømdahl, K. Water Sorption in Wood and Plant Fibres. Ph.D. Thesis, Technical University of Denmark, Kongens Lyngby, Denmark, 2000. [Google Scholar]

- Duggal, A.; Muir, W. Adsorption equilibrium moisture content of wheat straw. J. Agric. Eng. Res. 1981, 26, 315–320. [Google Scholar] [CrossRef]

- Lawrence, M.; Heath, A.; Walker, P. Determining moisture levels in straw bale construction. Constr. Build. Mater. 2009, 23, 2763–2768. [Google Scholar] [CrossRef] [Green Version]

- Yin, X.; Lawrence, M.; Maskell, D.; Ansell, M. Comparative micro-structure and sorption isotherms of rice straw and wheat straw. Energy Build. 2018, 173, 11–18. [Google Scholar] [CrossRef]

- Zhang, H.; Yoshino, H. Analysis of indoor humidity environment in Chinese residential buildings. Build. Environ. 2010, 45, 2132–2140. [Google Scholar] [CrossRef]

- Makhlouf, N.N.; Maskell, D.; Marsh, A.; Natarajan, S.; Dabaieh, M.; Afify, M.M. Hygrothermal performance of vernacular stone in a desert climate. Constr. Build. Mater. 2019, 216, 687–696. [Google Scholar] [CrossRef]

- Carfrae, J. The Moisture Performance of Straw Bale Construction in a Temperate Maritime Climate. Ph.D. Thisis, University of Plymouth, Plymouth, UK, 2011. [Google Scholar]

- Clynes, J. Decay Characteristics of Different Types of Straw Used in Straw Bale Building. Master Thesis, University of East London, London, UK, 2009. [Google Scholar]

- Liu, X.B. 中国传统灰浆的化学组成特征及粘结机理研究. Ph.D. Thesis, Zhejiang University, Hangzhou, China, 2015. (In Chinese). [Google Scholar]

- Mussoline, W.; Esposito, G.; Giordano, A.; Lens, P. The Anaerobic Digestion of Rice Straw: A Review. Crit. Rev. Environ. Sci. Technol. 2013, 43, 895–915. [Google Scholar] [CrossRef]

- Athienitis, A.K.; Liu, C.; Hawes, D.; Banu, D.; Feldman, D. Investigation of the thermal performance of a passive solar test-room with wall latent heat storage. Build. Environ. 1997, 32, 405–410. [Google Scholar] [CrossRef]

- Rijal, H.B.; Tuohy, P.; Nicol, F.; Humphreys, M.A.; Samuel, A.; Clarke, J. Development of an adaptive window-opening algorithm to predict the thermal comfort, energy use and overheating in buildings. J. Build. Perform. Simul. 2008, 1, 17–30. [Google Scholar] [CrossRef] [Green Version]

| Monitoring Location | Inner Monitored Moisture Content | Outer Monitored Moisture Content | Render Thickness |

|---|---|---|---|

| High position of west gable wall | 20.3% | 28% | 75 mm |

| Low position of west gable wall | 15.3% | 24% | 65 mm |

| High position of laid on-edge bale wall | 12.8% | 14.6% | 50 mm |

| Low position of laid on-edge bale wall | 17.3% | 21.0% | 70 mm |

| High position of east gable wall | 18.0% | 23.0% | 105 mm |

| Low position of east gable wall | 28.6% | 33.0% | 40 mm |

| High position of laid flat bale wall | 17.0% | 14.0% | 50 mm |

| Low position of laid flat bale wall | 24.0% | 16.0% | 100 mm |

| Monitoring Location | Measured Moisture Content | Monitored RH | Yin et al. Equation [25] | Lawrence et al. Equation [24] | |

|---|---|---|---|---|---|

| High position of west gable wall | Inner | 20.3% | 85.1% | 19.4% | 23.6% |

| Outer | 28% | 90.5% | 26.6% | 32.1% | |

| Low position of west gable wall | Inner | 15.3% | 74.9% | 13.5% | 16.4% |

| Outer | 24% | 85.7% | 20.0% | 24.3% | |

| High position of laid on-edge bale wall | Inner | 12.8% | 65.5% | 10.5% | 12.8% |

| Outer | 14.6% | 71.7% | 12.3% | 15.0% | |

| Low position of laid on-edge bale wall | Inner | 17.3% | 81.0% | 16.5% | 20.0% |

| Outer | 21.0% | 83.7% | 18.3% | 22.2% | |

| High position of east gable wall | Inner | 18.0% | 83.8% | 18.4% | 22.3% |

| Outer | 23% | 86.8% | 21.1% | 25.6% | |

| Low position of east gable wall | Inner | 28.6% | 91.9% | 29.8% | 36.0% |

| Outer | 33.0% | 92.1% | 30.3% | 36.7% | |

| High position of laid flat bale wall | Inner | 17.0% | 77.8% | 14.7% | 17.9% |

| Outer | 14% | 72.7% | 12.6% | 15.4% | |

| Low position of laid flat bale wall | Inner | 24.0% | 86.0% | 20.3% | 24.7% |

| Outer | 16% | 82.6% | 17.5% | 21.2% | |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yin, X.; Dong, Q.; Lawrence, M.; Maskell, D.; Yu, J.; Sun, C. Research on Prediction Model for Durability of Straw Bale Walls in Warm (Humid) Continental Climate—A Case Study in Northeast China. Materials 2020, 13, 3007. https://doi.org/10.3390/ma13133007

Yin X, Dong Q, Lawrence M, Maskell D, Yu J, Sun C. Research on Prediction Model for Durability of Straw Bale Walls in Warm (Humid) Continental Climate—A Case Study in Northeast China. Materials. 2020; 13(13):3007. https://doi.org/10.3390/ma13133007

Chicago/Turabian StyleYin, Xunzhi, Qi Dong, Mike Lawrence, Daniel Maskell, Jiaqi Yu, and Cheng Sun. 2020. "Research on Prediction Model for Durability of Straw Bale Walls in Warm (Humid) Continental Climate—A Case Study in Northeast China" Materials 13, no. 13: 3007. https://doi.org/10.3390/ma13133007

APA StyleYin, X., Dong, Q., Lawrence, M., Maskell, D., Yu, J., & Sun, C. (2020). Research on Prediction Model for Durability of Straw Bale Walls in Warm (Humid) Continental Climate—A Case Study in Northeast China. Materials, 13(13), 3007. https://doi.org/10.3390/ma13133007