The Acoustic Emission Method Implementation Proposition to Confirm the Presence and Assessment of Reinforcement Quality and Strength of Fiber–Cement Composites

Abstract

:1. Introduction

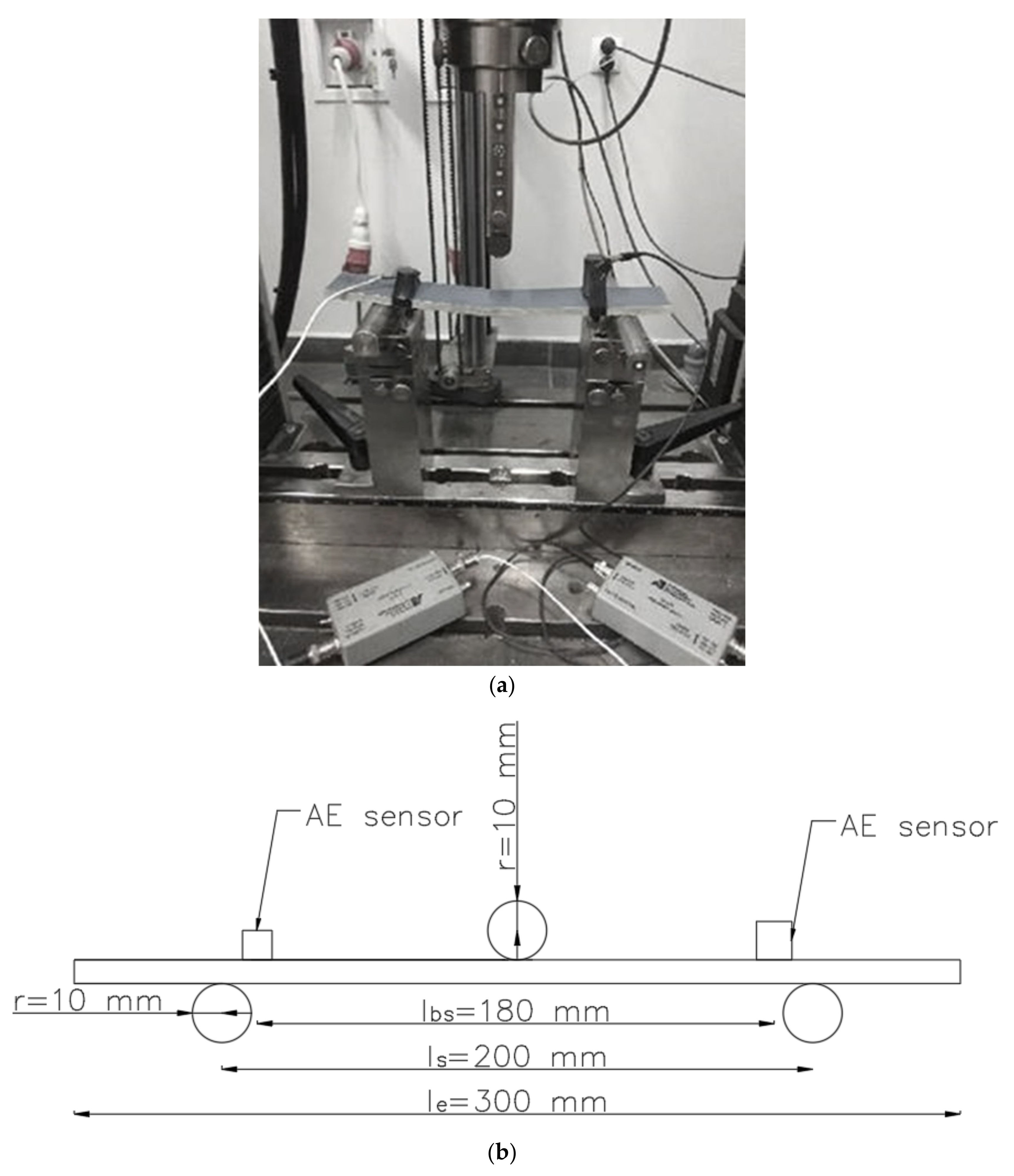

2. Materials and Methods

- The creation of microcracks;

- crack formation and propagation;

- cracks closing (friction at the concrete–concrete border);

- friction at the concrete–reinforcement border;

- corrosion, erosion;

- plasticisation and destroying of the reinforcement.

2.1. K-Means Algorithm in the AE Method

- Preliminary division of the set into k clusters;

- Calculation of an individual centroid for each cluster (centre of the group);

- Assigning of each element of the set to the nearest group (in this case, the distance from the group is the same as the distance from the centroid);

- Repetition of the previous two steps until the changes related to the object assignment to clusters ceases.

- generating signals in the laboratory while destroying specially designed samples in a certain way;

- comparison of signals received from samples with signals generated during the destruction of model beams subjected to various destruction processes;

- verification of reference signals on the basis of monitoring results of various types and lengths of composite panels loaded for destruction;

- final verification on the elements during their normal operation (this stage will be carried out in subsequent tests).

- AE signal duration (duration);

- AE rise time (rise time);

- Mean effective voltage (RMS);

- Number of counts;

- Number of counts to maximum signal amplitude (counts to peak);

- Amplitude AE signal (amplitude);

- Signal energy (energy);

- Average frequency AE (average frequency);

- Reverberation frequency;

- Initiation frequency;

- Absolute energy of the AE signal (absolute energy);

- Signal strength;

- Average signal level AE (ASL).

- expected number of destructive processes (based on literature and our own research);

- measures of distance between clusters—in this case, the Euclidean distance with time distribution;

- the number of iterations needed to find the optimal number of classes (minimum 1,000,000).

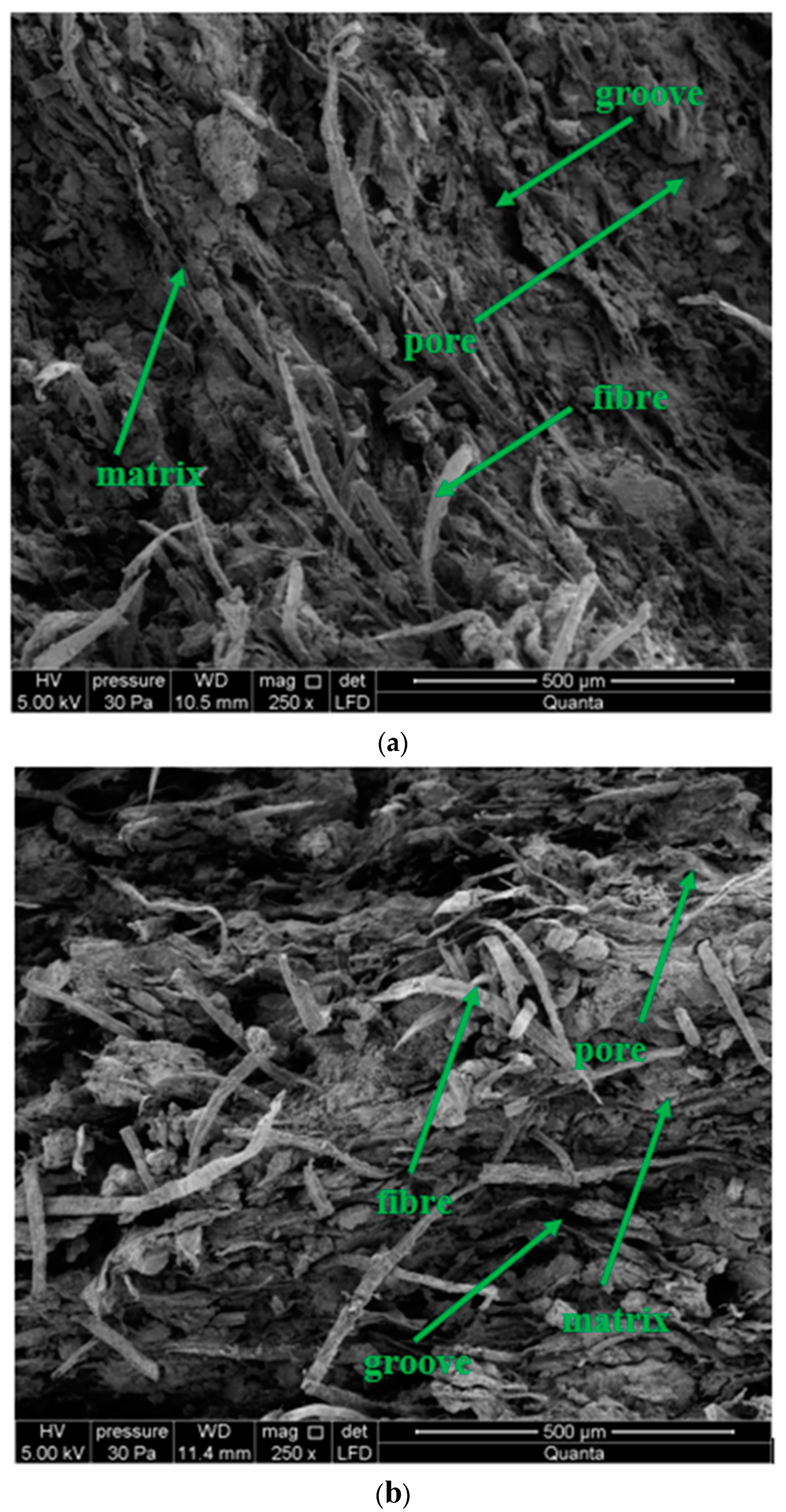

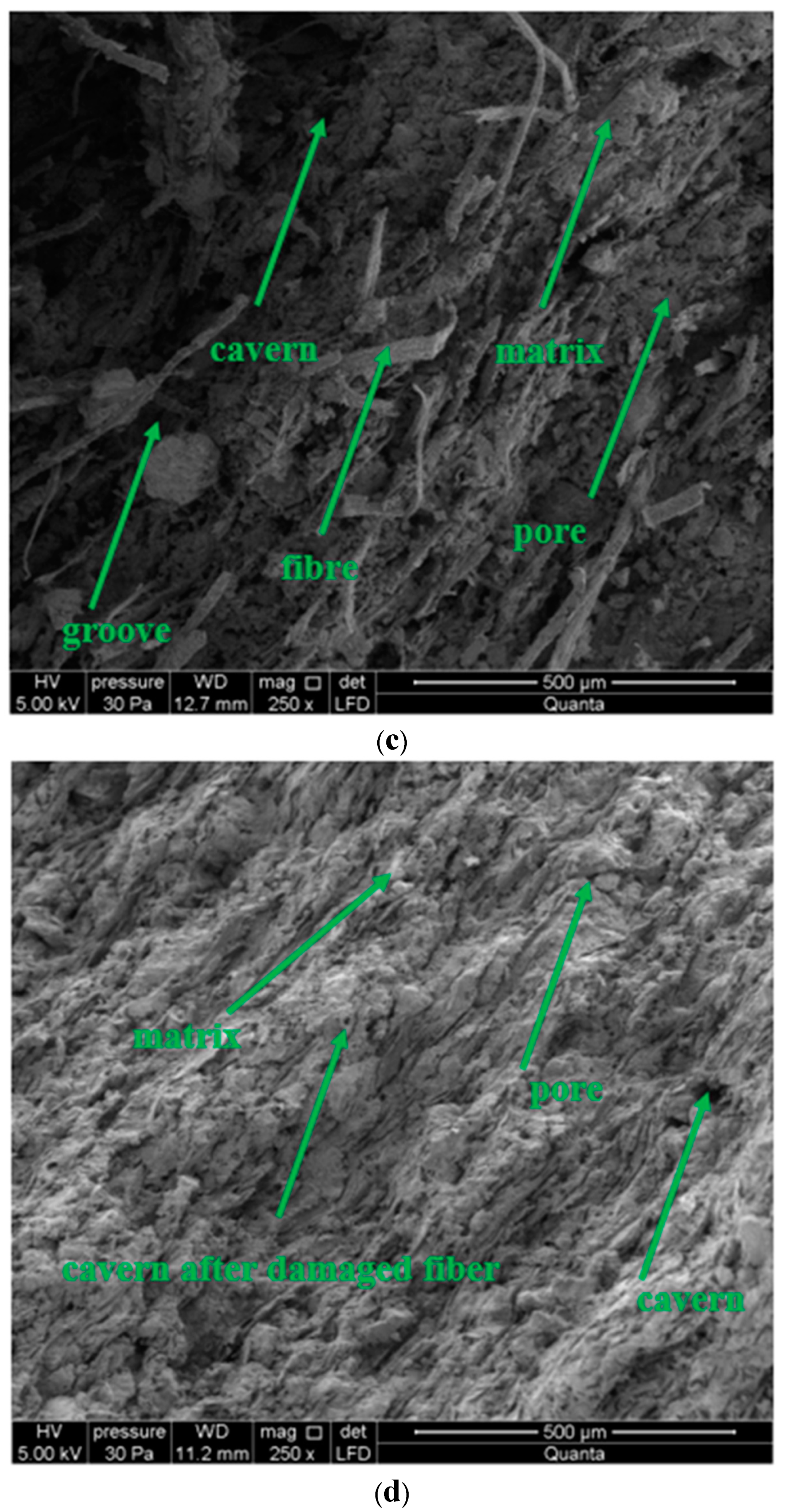

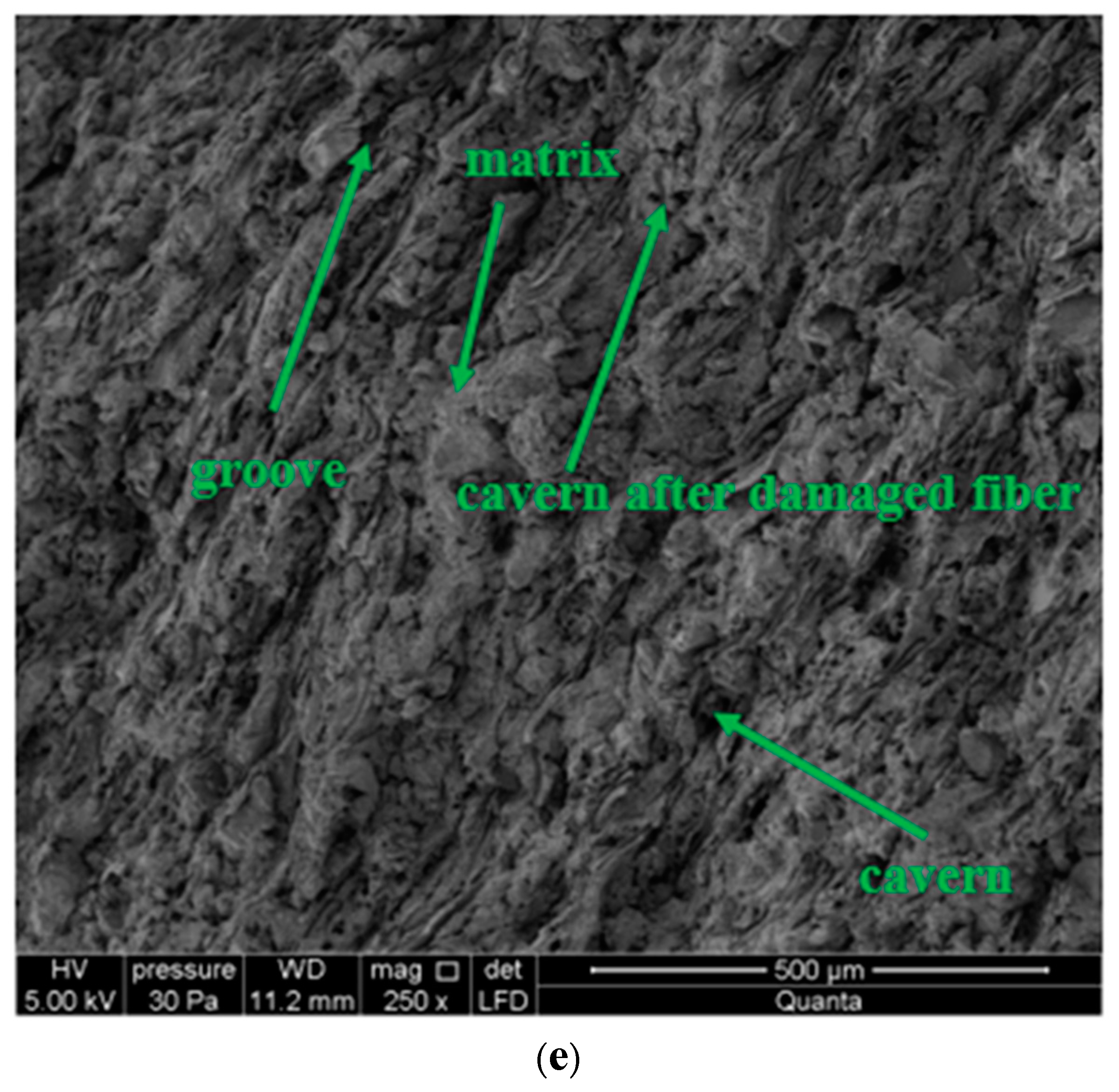

2.2. Scanning Electron Microscopy with Elemental Composition Analysis

3. Results

3.1. Results of AE Signal Analysis

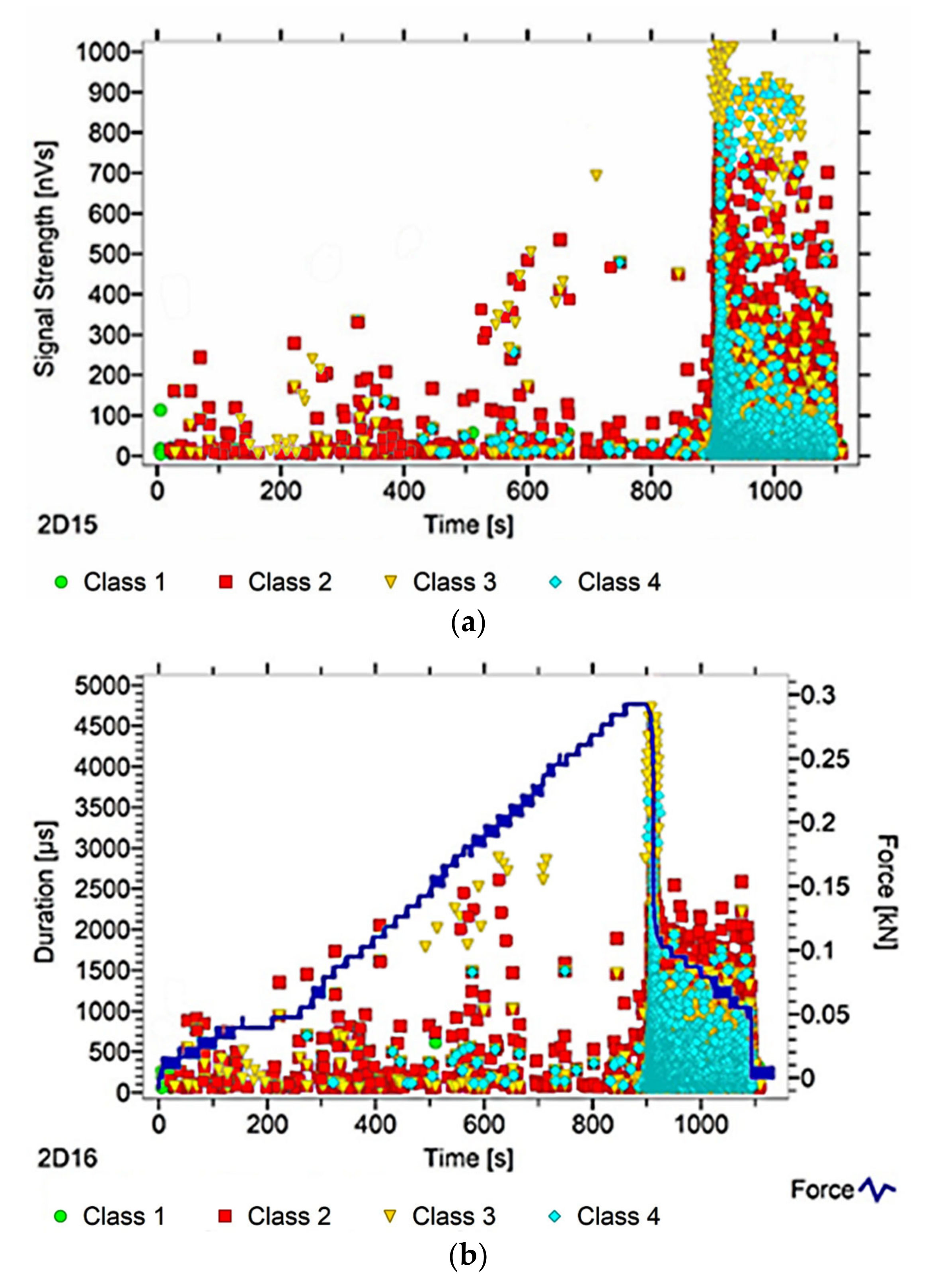

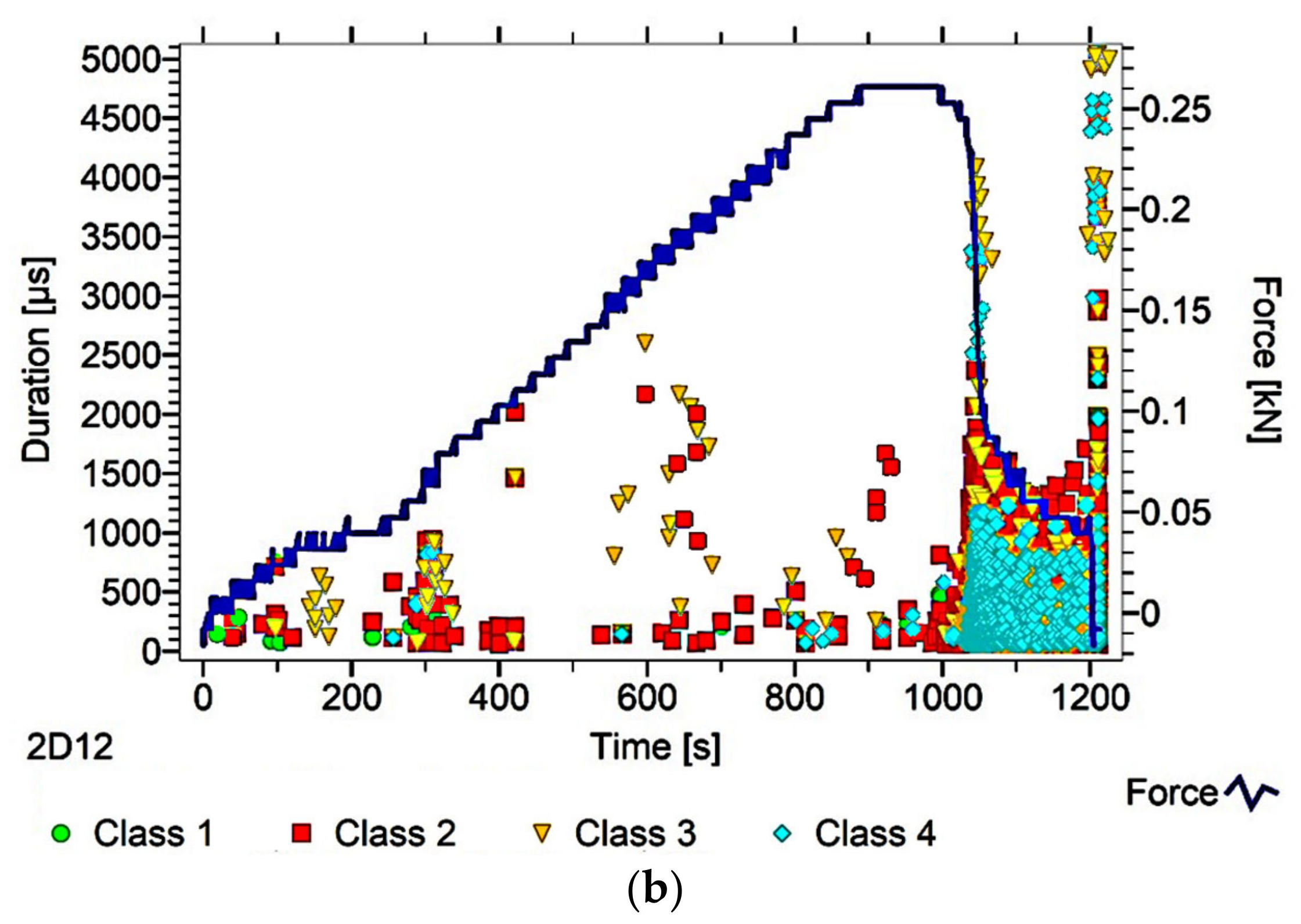

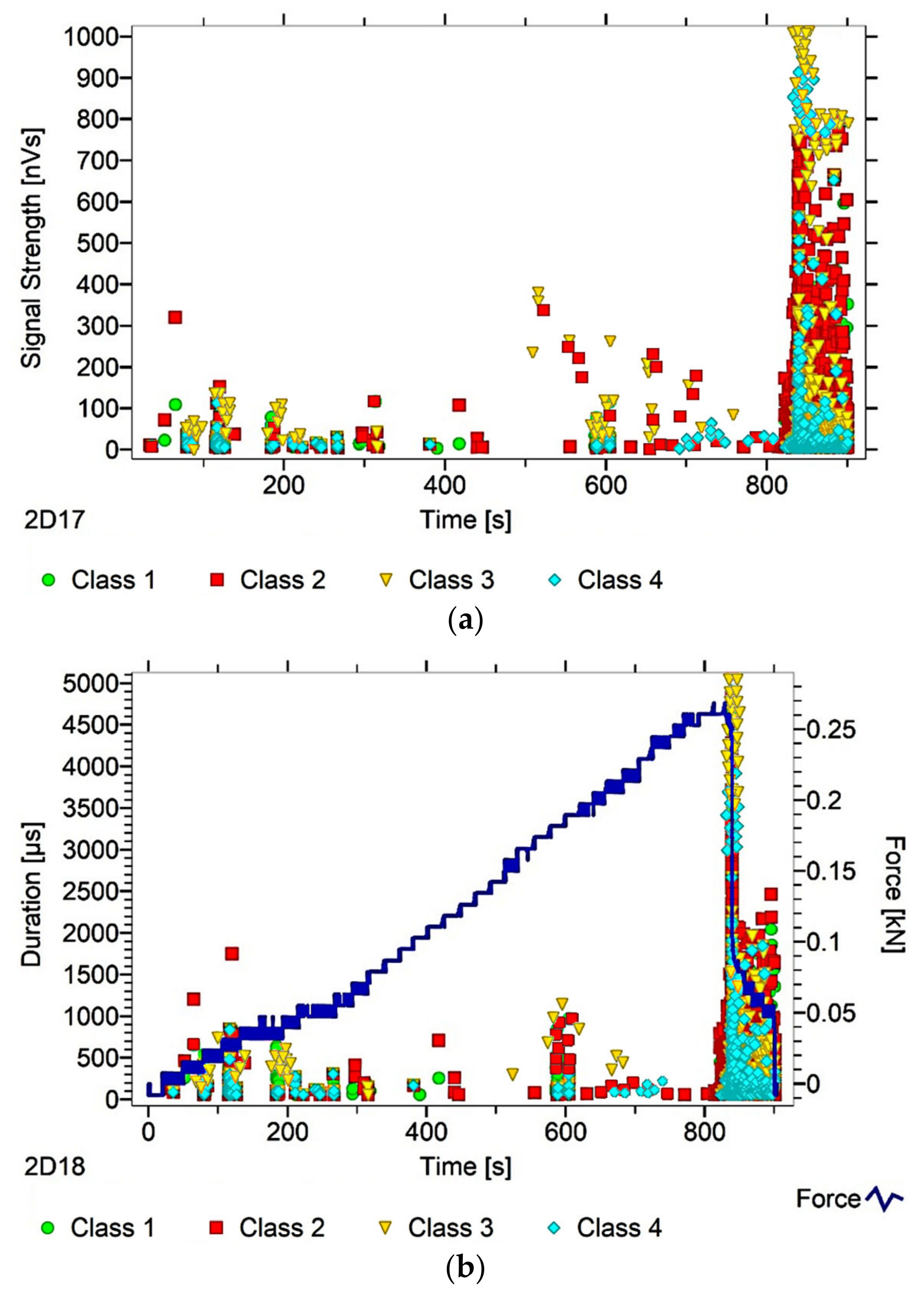

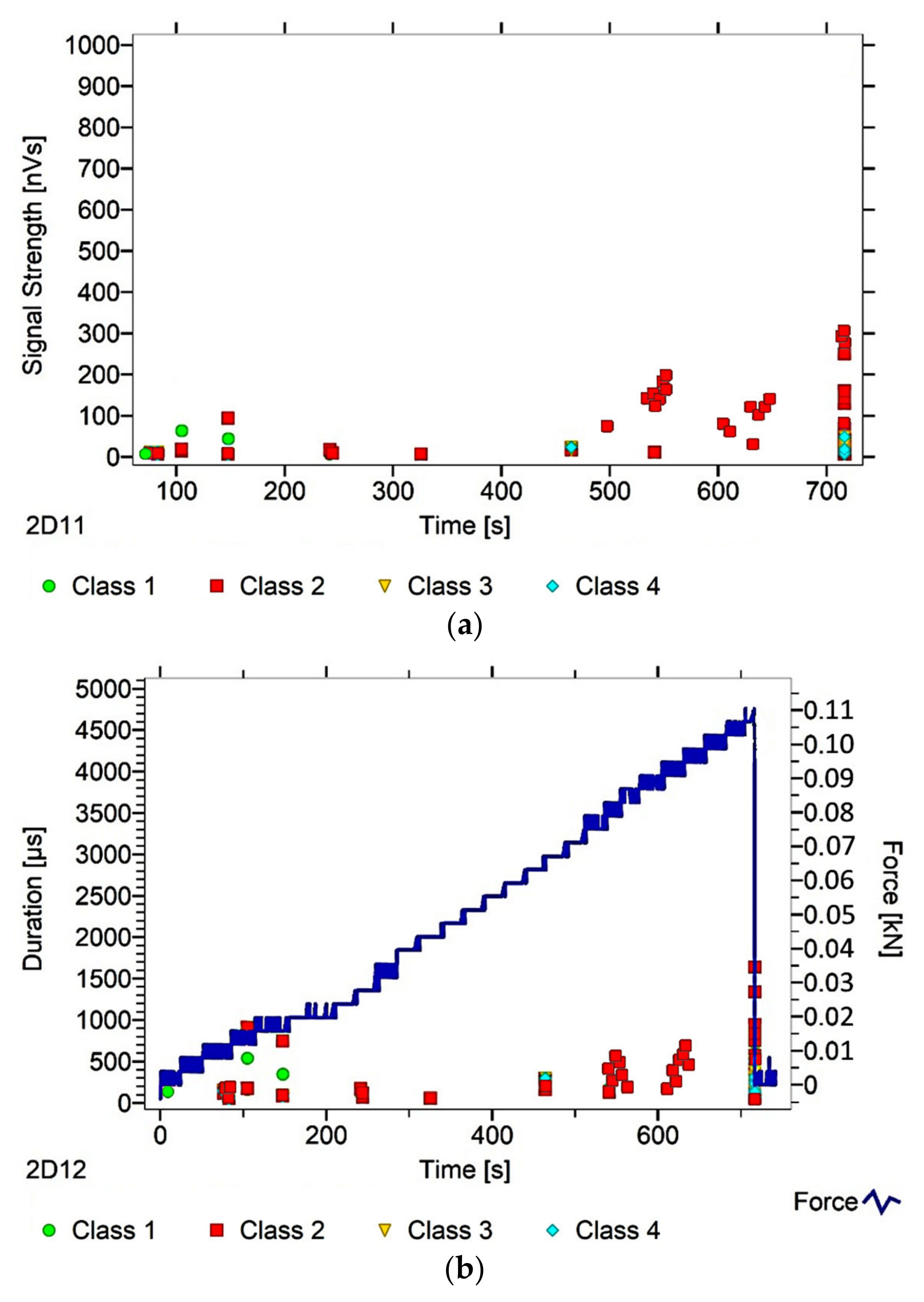

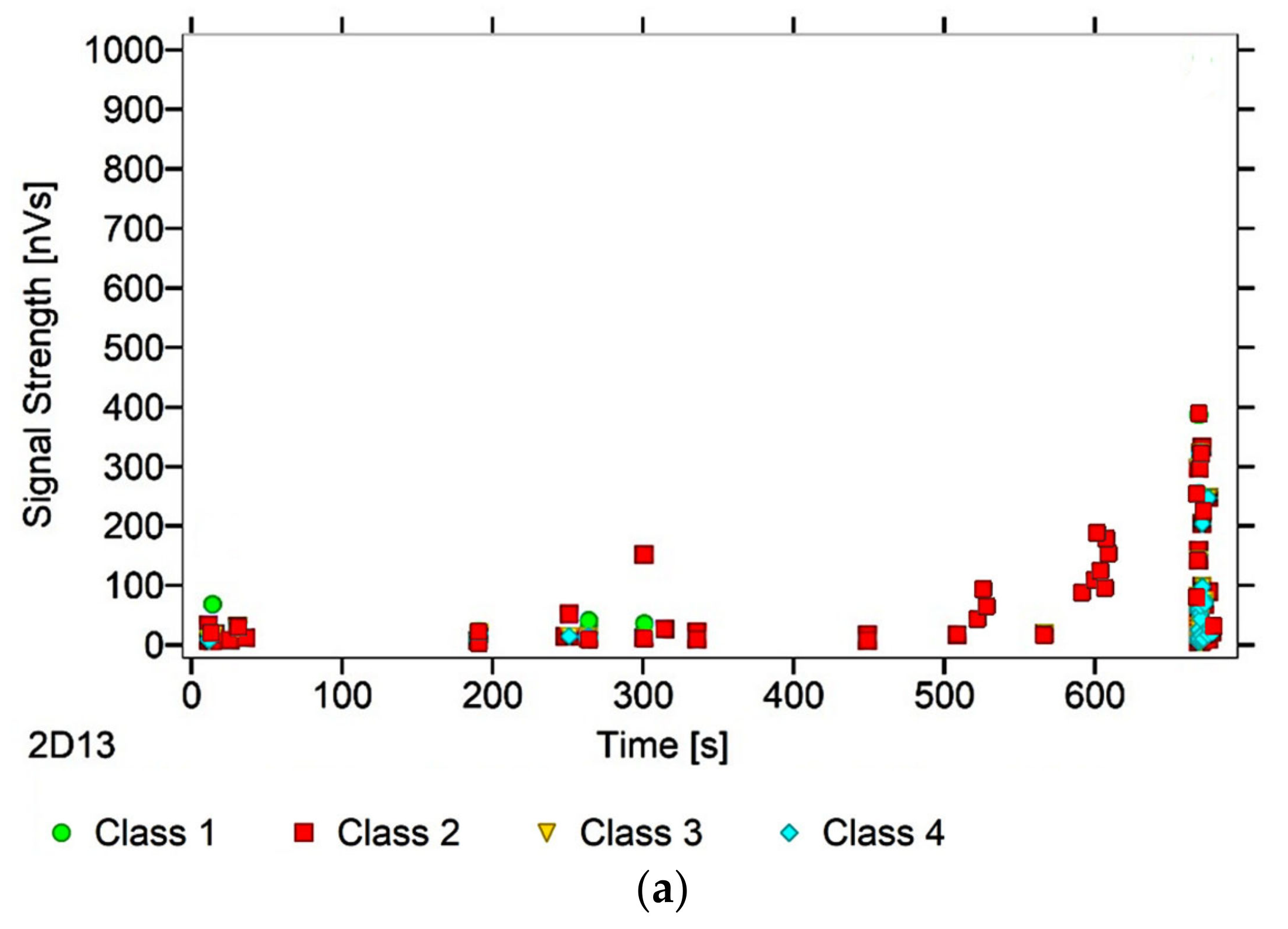

3.1.1. Individual AE Signal Class Distribution Analysis

- class 1 (green)—formation of microcracks;

- class 2 (red colour)—crack development;

- class 3 (yellow)—cracking of reinforcing fibers, delamination of the structure, detaching the fibers from the matrix;

- class 4 (colour blue)—breakdown of reinforcing fibers, sample destruction.

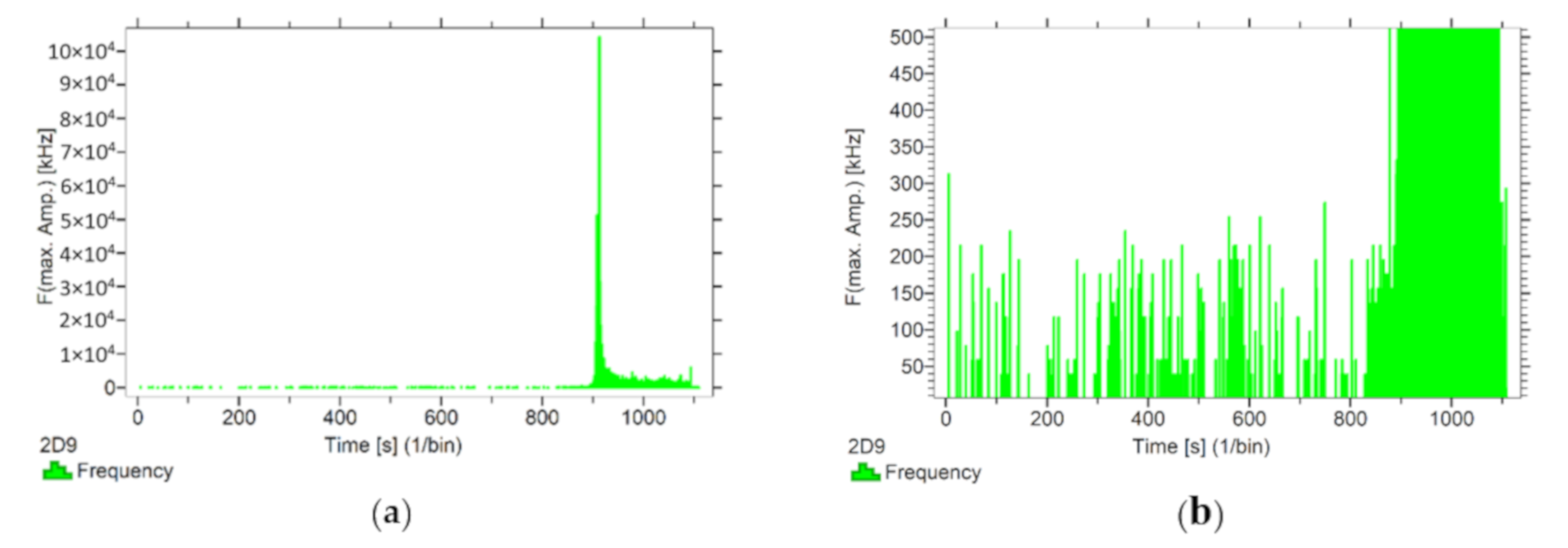

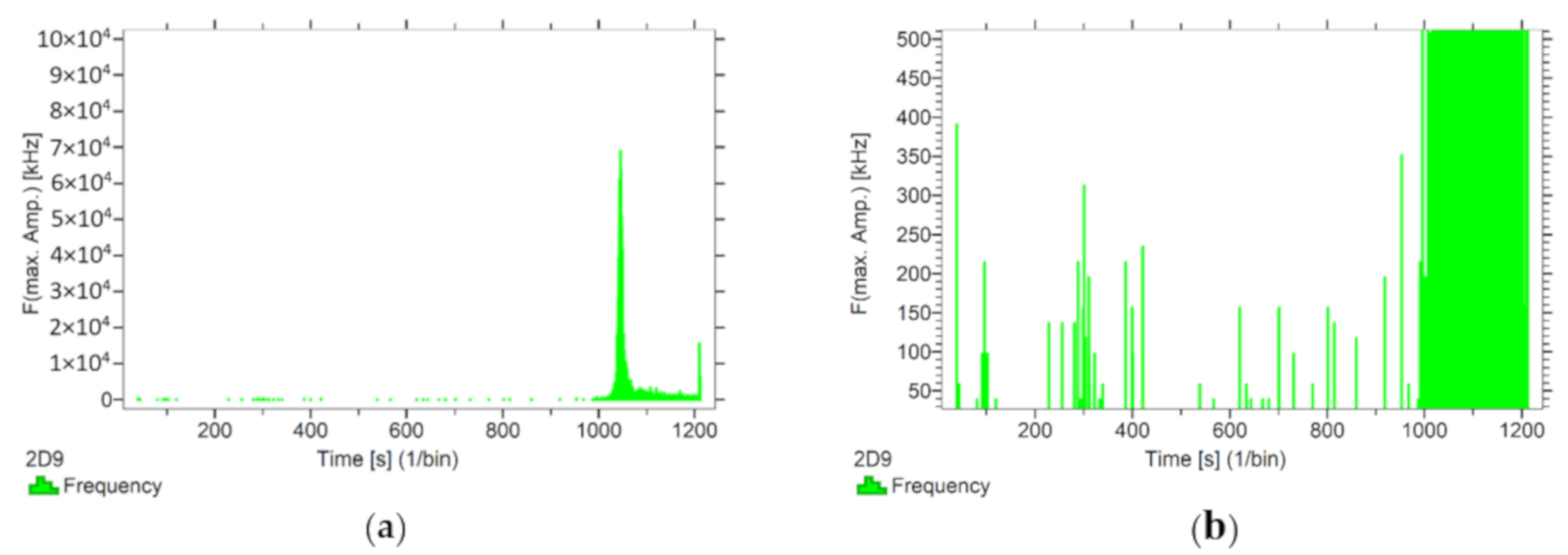

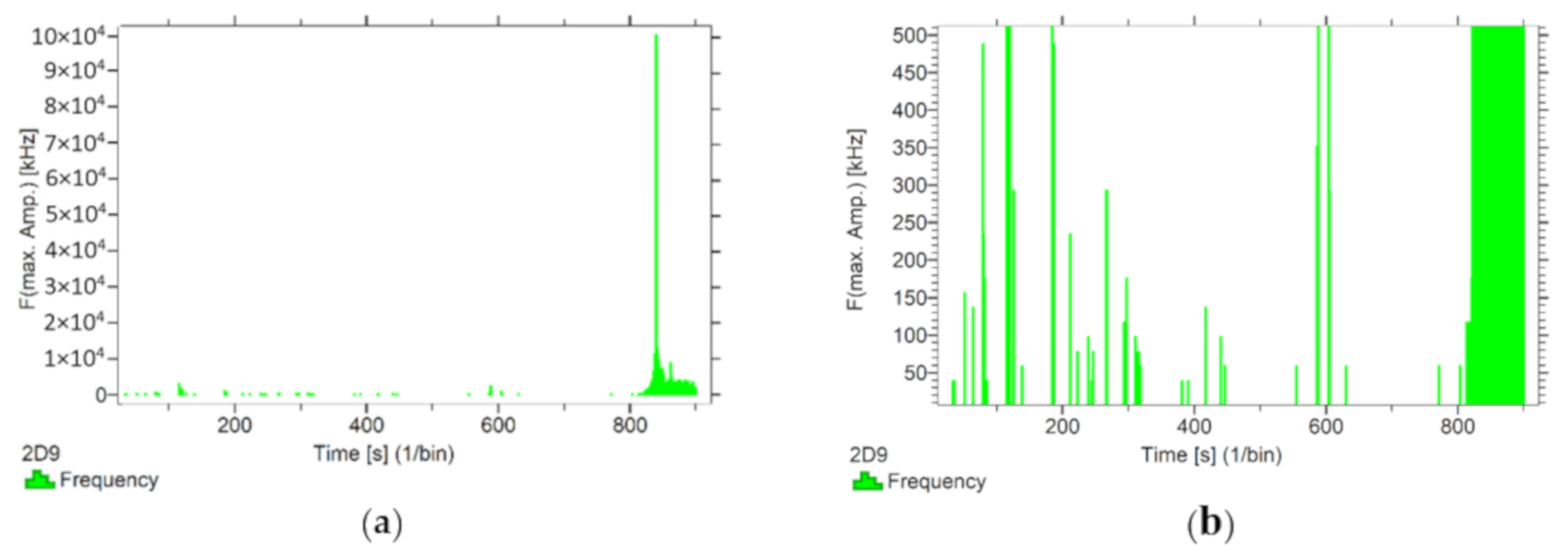

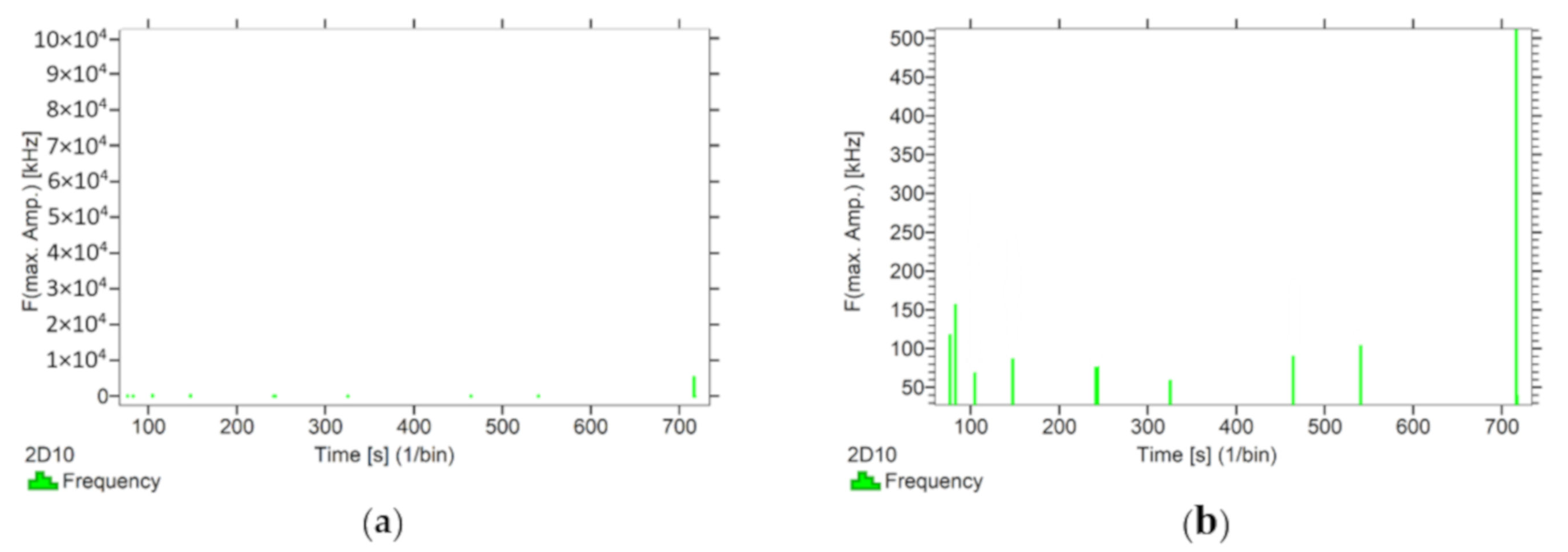

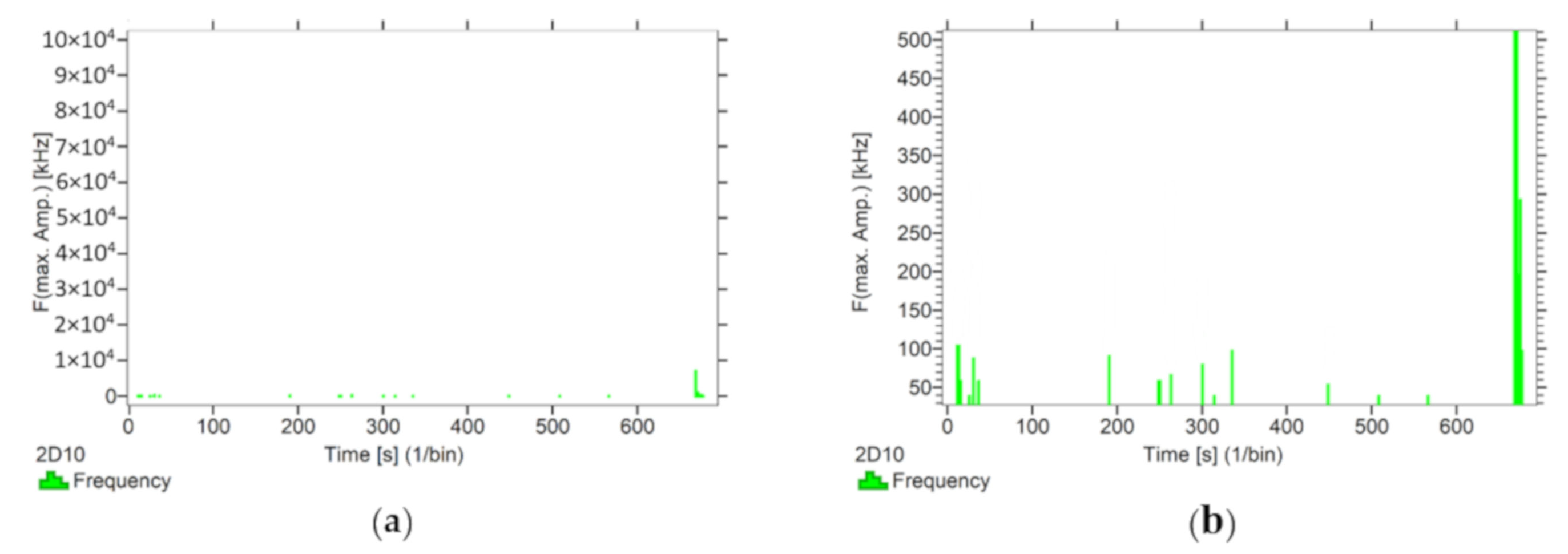

3.1.2. Analysis of Frequencies Accompanying Changes in Mechanical Parameters

3.2. Results of Microscopic Analyses

4. Discussion

5. Conclusions

- The implementation of the k-means grouping method based on the analysis of the AE signal parameters gives positive results in the classification of destructive processes taking place in the structure of fiber–cement boards.

- The application of the k-means grouping method allows the distinguishing of the processes taking place in the structure of fiber–cement boards subjected to an external load.

- Tracking events assigned to specific signal classes allows for evaluating the changes in the mechanical parameters of the material.

- The presence of reinforcing fibers significantly affects the distribution and the number of AE signals of individual classes, and the strength of the boards.

- The frequencies emitted by changes in the fiber–cement structure are closely linked to the presence of fiber reinforcement.

- It was found that the application of the AE method enables the effective detection and monitoring of the initiation of changes in the structure, as well as the separation and identification of AE signals corresponding to different types of processes affecting the change of the mechanical parameters of fiber–cement boards.

- The developed reference signal base provides a theoretical basis for the application of the AE technology, based on the standard for the detection and monitoring of cracks and delamination propagation in full-size fiber–cement components.

Author Contributions

Funding

Conflicts of Interest

References

- Biagiotti, J.; Puglia, D.; Kenny, J.M. A review on natural fibre-based composites-part I. J. Nat. Fibers 2004, 1, 37–41. [Google Scholar] [CrossRef]

- John, M.; Thomas, S. Biofibres and biocomposites. Carbohydr. Polym. 2008, 71, 343–364. [Google Scholar] [CrossRef]

- Akhavan, A.; Catchmark, J.; Rajabipour, F. Ductility enhancement of autoclaved cellulose fibre reinforced cement boards manufactured using a laboratory method simulating the Hatschek process. Constr. Build. Mater. 2017, 135, 251–259. [Google Scholar] [CrossRef]

- Ardanuy, M.; Claramunt, J.; Toledo Filho, R.D. Cellulosic fibre reinforced cement-based composites: A review of recent research. Constr. Build. Mater. 2015, 79, 115–128. [Google Scholar] [CrossRef] [Green Version]

- Ranachowski, Z.; Jóźwiak-Niedźwiedzka, D.; Brandt, A.M.; Debowski, T. Application of acoustic emission method to determine critical stress in fibre reinforced mortar beams. Arch. Acoust. 2012, 37, 261–268. [Google Scholar] [CrossRef] [Green Version]

- Fernández-Carrasco, L.; Claramunt, J.; Ardanuy, M. Autoclaved cellulose fibre reinforced cement: Effects of silica fume. Constr. Build. Mater. 2014, 66, 138–145. [Google Scholar] [CrossRef]

- Soroushian, P.; Elzafraney, M.; Nossoni, A.; Chowdhury, H. Evaluation of normal-weight and light-weight fillers in extruded cellulose fibre cement products. Cem. Concr. Compos. 2006, 28, 69–76. [Google Scholar] [CrossRef]

- Savastano, H.; Warden, P.G.; Coutts, R.S.P. Microstructure and mechanical properties of waste fibre–cement composites. Cem. Concr. Compos. 2005, 27, 583–592. [Google Scholar] [CrossRef]

- Neithalath, N.; Weiss, J.; Olek, J. Acoustic performance and damping behaviour of cellulose-cement composites. Cem. Concr. Compos. 2004, 26, 359–370. [Google Scholar] [CrossRef]

- Horikoshi, T.; Ogawa, A.; Saito, T.; Hoshiro, H.; Fischer, G.; Li, V. Properties of polyvinyl alcohol fiber as reinforcing materials for cementitious composites. In Proceedings of the International RILEM Workshop on High Performance Fiber Reinforced Cementitious Composites in Structural Applications, Aachen, Germany, 5–7 September 2006; pp. 145–153. [Google Scholar]

- Liu, J.; Li, C.; Liu, J.; Cui, G.; Yang, Z. Study on 3D spatial distribution of steel fibres in fibre reinforced cementitious composites through micro-CT technique. Constr. Build. Mater. 2013, 48, 656–661. [Google Scholar] [CrossRef]

- Roma, L.C.; Martello, L.S.; Savastano, H., Jr. Evaluation of mechanical, physical and thermal performance of cement-based tiles reinforced with vegetable fibers. Constr. Build. Mater. 2008, 22, 668–674. [Google Scholar] [CrossRef]

- Ardanuy, M.; Claramunt, J.; García-Hortal, J.A.; Barra, M. Fiber-matrix interactions in cement mortar composites reinforced with cellulosic fibers. Cellulose 2011, 18, 281–289. [Google Scholar] [CrossRef]

- Savastano, H.; Warden, P.G.; Coutts, R.S.P. Brazilian waste fibres as reinforcement for cement-based composites. Cem. Concr. Compos. 2000, 22, 379–384. [Google Scholar] [CrossRef]

- Jawaid, M.; Khalil, H.A. Cellulosic/synthetic fibre reinforced polymer hybrid composites: A review. Carbohydr. Polym. 2011, 86, 1–18. [Google Scholar] [CrossRef]

- Tonoli, G.H.D.; Fuente, E.; Monte, C.; Savastano, H. Effect of fibre morphology on flocculation of fibre–cement suspensions. Cem. Concr. Res. 2009, 39, 1017–1022. [Google Scholar] [CrossRef]

- Claramunt, J.; Ventura, H.; Parés, F.; Ardanuy, M. Natural fibre nonwovens as reinforcement for cement mortar composites. In Proceedings of the B. Abstr. 1st Int. Conf. Nat. Fibers Sustain. Mater. Adv. Appl., Guimarães, Portugal, 9–11 June 2013; Fangueiro, R., Ed.; Universidade do Minho: Braga, Portugal, 2013; pp. 191–192. [Google Scholar]

- Fidelis, M.E.A.; Silva, F.D.; Filho, R.D. The influence of fiber treatment on the mechanical behavior of jute textile reinforced concrete. Key Eng. Mater. 2014, 600, 469–474. [Google Scholar] [CrossRef]

- Agopyan, V.; Savastano, H.; John, V.M.; Cincotto, M. Developments on vegetable fibre–cement based materials in São Paulo, Brazil: An overview. Cem. Concr. Compos. 2005, 27, 527–536. [Google Scholar] [CrossRef]

- Ramakrishna, G.; Sundararajan, T. Studies on the durability of natural fibres and the effect of corroded fibres on the strength of mortar. Cem. Concr. Compos. 2005, 27, 575–582. [Google Scholar] [CrossRef]

- Claramunt, J.; Ardanuy, M.; García-Hortal, J.A. Effect of drying and rewetting cycles on the structure and physicochemical characteristics of softwood fibres for reinforcement of cementitious composites. Carbohydr. Polym. 2010, 79, 200–205. [Google Scholar] [CrossRef]

- Pizzol, V.D.; Mendes, L.M.; Savastano, H.; Frías, M.; Davila, F.J.; Cincotto, M.A.; John, V.M.; Tonoli, G.H.D. Mineralogical and microstructural changes promoted by accelerated carbonation and ageing cycles of hybrid fibre–cement composites. Constr. Build. Mater. 2014, 68, 750–756. [Google Scholar] [CrossRef]

- Drelich, R.; Gorzelańczyk, T.; Pakuła, M.; Schabowicz, K. Automated control of cellulose fibre cement boards with a non-contact ultrasound scanner. Autom. Constr. 2015, 57, 55–63. [Google Scholar] [CrossRef]

- Schabowicz, K.; Gorzelańczyk, T. A non-destructive methodology for the testing of fibre cement boards by means of a non-contact ultrasound scanner. Constr. Build. Mater. 2016, 102, 200–207. [Google Scholar] [CrossRef]

- Chady, T.; Schabowicz, K.; Szymków, M. Automated multisource electromagnetic inspection of fibre-cement boards. Autom. Constr. 2018, 94, 383–394. [Google Scholar] [CrossRef]

- Chady, T.; Schabowicz, K. Non-destructive testing of fibre-cement boards, using terahertz spectroscopy in time domain. Badania Nieniszczące i Diagnostyka 2016, 1, 62–66. (In Polish) [Google Scholar]

- Schabowicz, K.; Ranachowski, Z.; Józwiak-Niedźwiedzka, D.; Radzik, Ł.; Kudela, S.; Dvorak, T. Application of X-ray microtomography to quality assessment of fibre cement boards. Constr. Build. Mater. 2016, 110, 182–188. [Google Scholar] [CrossRef]

- Gorzelańczyk, T.; Schabowicz, K.; Szymków, M. Non-destructive testing of fibre-cement boards, using acoustic emission. Przegląd Spawalnictwa 2016, 88, 35–38. (In Polish) [Google Scholar]

- Pazdera, L.; Topolar, L. Application acoustic emission method during concrete frost resistance. Russ. J. Nondestruct. Test. 2014, 50, 127–131. [Google Scholar] [CrossRef]

- Shields, Y.; Garboczi, E.; Weiss, J.; Farnam, Y. Freeze-thaw crack determination in cementitious materials using 3D X-ray computed tomography and acoustic emission. Cem. Concr. Compos. 2018, 89, 120–129. [Google Scholar] [CrossRef]

- Topolar, L.; Kucharczykowa, B.; Kocab, D.; Pazdera, L. The Acoustic Emission Parameters Obtained during Three-point Bending Test on Thermal-stressed Concrete Specimens. Procedia Eng. 2017, 190, 111–117. [Google Scholar] [CrossRef]

- Mpalaskas, A.; Matikas, T.; Aggelis, D. Acoustic emission of fire damaged fiber reinforced concrete. In Smart Materials and Nondestructive Evaluation for Energy Systems 2016, Proceedings of the International Society for Optics and Photonics, Las Vegas, NV, USA, 1 April 2016; SPIE: Las Vegas, NV, USA, 2016; Volume 9806, p. 980618. [Google Scholar]

- Marzec, A.; Lewicki, P.; Ranachowski, Z.; Debowski, T. The influence of moisture content on spectral characteristic of acoustic signals emitted by flat bread samples. In Proceedings of the AMAS Course on Nondestructive Testing of Materials and Structures, Centre of Excellence for Advanced Materials and Structures, Warszawa, Poland, 20–22 May 2002; pp. 127–135. [Google Scholar]

- Lucchi, E. Non-invasive method for investigating energy and environmental performances in existing buildings. In Proceedings of the PLEA Conference on Passive and Low Energy Architecture, Louvain-la-Neuve, Belgium, 13–15 July 2011; pp. 571–576. [Google Scholar]

- Dębowski, T.; Lewandowski, M.; Mackiewicz, S.; Ranachowski, Z.; Schabowicz, K. Ultrasonic tests of fibre-cement boards. Przegląd Spawalnictwa 2016, 10, 69–71. (In Polish) [Google Scholar]

- Schabowicz, K.; Józwiak-Niedźwiedzka, D.; Ranachowski, Z.; Kudela, S.; Dvorak, T. Microstructural characterization of cellulose fibres in reinforced cement boards. Arch. Civ. Mech. Eng. 2018, 4, 1068–1078. [Google Scholar] [CrossRef]

- Adamczak-Bugno, A.; Gorzelańczyk, T.; Krampikowska, A.; Szymków, M. Non-destructive testing of the structure of fibre-cement materials by means of a scanning electron microscope. Badania Nieniszczące i Diagnostyka 2017, 3, 20–23. (In Polish) [Google Scholar]

- Adamczak-Bugno, A.; Krampikowska, A. The basics of a system for evaluation of fiber-cement materials based on acoustic emission and time-frequency analysis. Math. Biosci. Eng. 2020, 17, 2218–2235. [Google Scholar] [CrossRef] [PubMed]

- Adamczak-Bugno, A.; Świt, G.; Krampikowska, A. Assessment of destruction processes in fiber-cement composites using the acoustic emission method and wavelet analysis. IOP Conf. Ser. Mater. Sci. Eng. 2018, 214, 1–9. [Google Scholar]

- Tinkey, B.V.; Fowler, T.J.; Klingner, R.E. Nondestructive Testing of Prestressed Bridge Girders with Distributed Damage, Research Raport 1857-2; Center for Transportation Research University of Texas: Austin, TX, USA, 2002. [Google Scholar]

- Ono, K.; Ohtsu, M. Crack classification in concrete based on acoustic emission. Constr. Build. Mater. 2010, 24, 2339–2346. [Google Scholar] [CrossRef]

- Golaski, L.; Gębski, P.; Ono, K. Diagnostics of reinforced concrete bridges by acoustic emission. J. Acoust. Emiss. 2002, 20, 83–98. [Google Scholar]

- Suzuki, H.; Kinjo, T.; Hayashi, Y.; Takemoto, M.; Ono, K. Wavelet Transform of Acoustic Emission Signals. J. Acoust. Emiss. 1996, 14, 69–84. [Google Scholar]

- Goszczyńska, B.; Swit, G.; Trąmpczyński, W. Application of the IADP acoustic emission method to automatic control of traffic on reinforced concrete bridges to ensure their safe operation. Arch. Civ. Mech. Eng. 2016, 16, 867–875. [Google Scholar] [CrossRef]

- Goszczyńska, B.; Swit, G.; Trąmpczyński, W. Analysis of the microcracking process with the Acoustic Emission method with respect to the service life of reinforced concrete structures with the example of the RC beams. Bull. Pol. Acad. Sci. Tech. Sci. 2015, 63, 55–65. [Google Scholar] [CrossRef] [Green Version]

- Krampikowska, A.; Pała, R.; Dzioba, I.; Swit, G. The Use of the Acoustic Emission Method to Identify Crack Growth in 40CrMo Steel. Materials 2019, 12, 2140. [Google Scholar] [CrossRef] [Green Version]

- Krampikowska, A.; Adamczak-Bugno, A. Assessment of the technical condition of prefabricated elements using the acoustic emission method. Sci. Rev. Eng. Environ. Sci. 2019, 28, 356–365. [Google Scholar] [CrossRef] [Green Version]

- Goszczyńska, B. Analysis of the process of crack initiation and evolution in concrete with acoustic emission testing. Arch. Civ. Mech. Eng. 2014, 14, 134–143. [Google Scholar] [CrossRef]

- Goszczyńska, B.; Świt, G.; Trąmpczyński, W.; Krampikowska, A. Application of the acoustic emission (AE) method to bridge testing and diagnostics comparison of procedures. In Proceedings of the IEEE Prognostics and System Health Management Conference, Beijing, China, 23–25 May 2012; pp. 1–10. [Google Scholar]

- Swit, G. Diagnostics of prestressed concrete structures by means of acoustic emission. In Proceedings of the 2009 8th International Conference on Reliability, Maintainability and Safety, Chengdu, China, 20 July 2009; Volume 2, pp. 958–962. [Google Scholar]

- Proverbio, E.; Venturi, V. Reliability of Nondestructive Tests for on Site Concrete Strength Assessment. In Proceedings of the 10DBMC, Lyon, France, 17–20 April 2005. [Google Scholar]

- Olaszek, P.; Casas, J.R.; Swit, G. On-site assessment of bridges supported by acoustic emission. In Proceedings of the Institution of Civil Engineers-Bridge Engineering, London, UK, 2 June 2016; 2016; Volume 169, pp. 81–92. [Google Scholar]

- Adamczak-Bugno, A.; Świt, G.; Krampikowska, A. Scanning electron microscopy in the tests of fibre-cement boards. In Proceedings of the MATEC Web of Conferences, 2018, 3RD SCIENTIFIC CONFERENCE ENVIRONMENTAL CHALLENGES IN CIVIL ENGINEERING (ECCE), Opole, Poland, 23–25 April 2018; Volume 174, p. 02015. [Google Scholar]

- Coutts, R.S.P.; Kightly, P. Microstructure of autoclaved refined wood-fibre cement mortars. J. Mater. Sci. 1982, 17, 1801–1806. [Google Scholar] [CrossRef]

- Mohr, B.J.; Biernacki, J.J.; Kurtis, K.E. Microstructural and chemical effects of wet/dry cycling on pulp fiber–cement composites. Cem. Concr. Res. 2006, 36, 1240–1251. [Google Scholar] [CrossRef]

- Tonoli, G.H.D.; Santos, S.F.; Savastano, H.; Delvasto, S.; De Gutiérrez, R.M.; de Murphy, M.D.M.L. Effects of natural weathering on microstructure and mineral composition of cementitious roofing tiles reinforced with fique fibre. Cem. Concr. Compos. 2011, 33, 225–232. [Google Scholar] [CrossRef]

- Szymków, M.; Schabowicz, K.; Gorzelańczyk, T. Non-destructive assessment of the effect of high temperature on the destruction of the structure of the fiber-cement board. Non-Destr. Test. Diagn. 2018, 4, 44–45. (In Polish) [Google Scholar]

- Schabowicz, K.; Gorzelańczyk, T.; Szymków, M. Identification of the Degree of Degradation of Fibre-Cement Boards Exposed to Fire by Means of the Acoustic Emission Method and Artificial Neural Networks. Materials 2019, 4, 656. [Google Scholar] [CrossRef] [Green Version]

| Sample Determination | Type of Conditioning | Sample Length [mm] | Sample Width [mm] | Sample Thickness [mm] | Number of Samples in the Group |

|---|---|---|---|---|---|

| BS | Air-dry state | 300 | 50 | 8 | 5 |

| BW | Soaking in water | 300 | 50 | 8 | 5 |

| BM | 50 freezing–defrosting cycles | 300 | 50 | 8 | 5 |

| BP | A direct flame of a gas burner for 10 min | 300 | 50 | 8 | 5 |

| BC | Firing in a laboratory oven at 230 °C for 3 h | 300 | 50 | 8 | 5 |

| Manufacturer Information about Composition of Boards | Result of Observation and EDS Analysis |

|---|---|

| Portland cement | Presence confirmed |

| Mineral binders | Silicate binder |

| Natural organic reinforcing fibers | Cellulose fibers |

| Synthetic organic reinforcing fibers | PVA (Polyvinyl Alcohol) fibers |

| Parameter | Conditions | Value | Unit |

|---|---|---|---|

| Density | Dry condition | >1.65 | g/cm3 |

| Flexural strength | Perpendicular Parallel | >23 >18.5 | N/mm2 N/mm2 |

| Modulus of elasticity | 12,000 | N/mm2 | |

| Stretching at humidity | 30–95% | 1.0 | mm/m |

| Porosity | 0–100% | >18 | % |

| Sample | Number of Class 1 Signals | Number of Class 2 Signals | Number of Class 3 Signals | Number of Class 4 Signals | Max. Signal Energy [eu] | Max. Force [kN] | MOR [MPa] | Max. Frequency before Destruction [kHz] |

|---|---|---|---|---|---|---|---|---|

| BS1 | 1747 | 8644 | 2040 | 2648 | 5049 | 0.29 | 27.19 | 316 |

| BS2 | 2042 | 7256 | 2165 | 2543 | 5126 | 0.30 | 28.13 | 403 |

| BS3 | 1635 | 7269 | 1847 | 2714 | 5098 | 0.29 | 27.19 | 359 |

| BS4 | 1798 | 9842 | 2264 | 2796 | 4863 | 0.30 | 28.13 | 426 |

| BS5 | 2249 | 11365 | 2073 | 2379 | 5194 | 0.30 | 28.13 | 511 |

| Arithmetic average | 1894.2 | 8875.2 | 2077.8 | 2616 | 5066 | 0.296 | 27.75 | 403 |

| Standard deviation | 221.74 | 1574.10 | 139.28 | 144.59 | 111.81 | 0.005 | 0.46 | 65.88 |

| Sample | Number of Class 1 Signals | Number of Class 2 Signals | Number of Class 3 Signals | Number of Class 4 Signals | Max. Signal Energy [eu] | Max. Force [kN] | MOR [MPa] | Max. Frequency before Destruction [kHz] |

|---|---|---|---|---|---|---|---|---|

| BW1 | 2365 | 7424 | 2084 | 2215 | 5055 | 0.26 | 24.38 | 398 |

| BW2 | 1823 | 7982 | 2152 | 2196 | 5139 | 0.28 | 26.25 | 452 |

| BW3 | 1964 | 8214 | 1836 | 2364 | 5024 | 0.29 | 27.19 | 374 |

| BW4 | 2159 | 6920 | 2174 | 1974 | 5097 | 0.28 | 26.25 | 512 |

| BW5 | 2144 | 7563 | 2296 | 2259 | 4936 | 0.28 | 26.25 | 367 |

| Arithmetic average | 2091 | 7620.6 | 2108.4 | 2201.6 | 5050.2 | 0.278 | 26.06 | 420.6 |

| Standard deviation | 184.64 | 450.68 | 152.44 | 127.81 | 69.03 | 0.01 | 0.92 | 54.58 |

| Sample | Number of Class 1 Signals | Number of Class 2 Signals | Number of Class 3 Signals | Number of Class 4 Signals | Max. Signal Energy [eu] | Max. Force [kN] | MOR [MPa] | Max. Frequency before Destruction [kHz] |

|---|---|---|---|---|---|---|---|---|

| BM1 | 1736 | 6422 | 1759 | 2168 | 5023 | 0.26 | 24.38 | 1023 |

| BM2 | 2054 | 6948 | 2052 | 2232 | 5102 | 0.27 | 25.31 | 415 |

| BM3 | 2148 | 6536 | 1866 | 2085 | 5074 | 0.26 | 24.38 | 504 |

| BM4 | 1947 | 7049 | 2173 | 2266 | 5130 | 0.28 | 26.25 | 362 |

| BM5 | 2072 | 7197 | 1945 | 1987 | 5069 | 0.26 | 24.38 | 388 |

| Arithmetic average | 1991.4 | 6830.4 | 1959 | 2147.6 | 5079.6 | 0.266 | 24.94 | 538.4 |

| Standard deviation | 142.93 | 299.82 | 143.73 | 101.26 | 35.75 | 0.008 | 0.75 | 246.98 |

| Sample | Number of Class 1 Signals | Number of Class 2 Signals | Number of Class 3 Signals | Number of Class 4 Signals | Max. Signal Energy [eu] | Max. Force [kN] | MOR [MPa] | Max. Frequency before Destruction [kHz] |

|---|---|---|---|---|---|---|---|---|

| BP1 | 17 | 67 | 4 | 4 | 1823 | 0.11 | 10.31 | 113 |

| BP2 | 25 | 84 | 3 | 8 | 1526 | 0.09 | 8.44 | 109 |

| BP3 | 12 | 66 | 4 | 10 | 1465 | 0.10 | 9.38 | 126 |

| BP4 | 10 | 72 | 7 | 9 | 1506 | 0.11 | 10.31 | 94 |

| BP5 | 20 | 79 | 3 | 12 | 1764 | 0.9 | 8.44 | 116 |

| Arithmetic average | 16.8 | 73.6 | 4.2 | 8.6 | 1616.8 | 0.10 | 9.38 | 111.6 |

| Standard deviation | 5.42 | 6.95 | 1.47 | 2.65 | 146.80 | 0.009 | 0.84 | 10.44 |

| Sample | Number of Class 1 Signals | Number of Class 2 Signals | Number of Class 3 Signals | Number of Class 4 Signals | Max. Signal Energy [eu] | Max. Force [kN] | MOR [MPa] | Max. Frequency before Destruction [kHz] |

|---|---|---|---|---|---|---|---|---|

| BC1 | 20 | 70 | 4 | 4 | 1885 | 0.15 | 14.06 | 113 |

| BC2 | 14 | 84 | 2 | 10 | 1624 | 0.10 | 9.38 | 135 |

| BC3 | 10 | 112 | 1 | 11 | 1894 | 0.09 | 8.44 | 92 |

| BC4 | 23 | 62 | 4 | 6 | 1733 | 0.11 | 10.31 | 84 |

| BC5 | 11 | 97 | 2 | 8 | 2014 | 0.11 | 10.31 | 141 |

| Arithmetic average | 15.6 | 85 | 1.44 | 6.56 | 1830 | 0.11 | 10.5 | 113 |

| Standard deviation | 5.08 | 18.04 | 1.2 | 2.56 | 136.25 | 0.02 | 1.91 | 22.58 |

| Sample | Average Number of Class 1 Signals | Average Number of Class 2 Signals | Average Number of Class 3 Signals | Average Number of Class 4 Signals | Average Max. Signal Energy [eu] | Average Max. Force [kN] | Average MOR [MPa] | Average Max. Frequency before Destruction [kHz] |

|---|---|---|---|---|---|---|---|---|

| BS | 1894.2 | 8875.2 | 2077.8 | 2616 | 5066 | 0.296 | 27.75 | 403 |

| BW | 2091 | 7620.6 | 2108.4 | 2201.6 | 5050.2 | 0.278 | 26.06 | 420.6 |

| BM | 1991.4 | 6830.4 | 1959 | 2147.6 | 5079.6 | 0.266 | 24.94 | 538.4 |

| BP | 16.8 | 73.6 | 4.2 | 8.6 | 1616.8 | 0.10 | 9.38 | 111.6 |

| BC | 15.6 | 85 | 1.44 | 6.56 | 1830 | 0.11 | 10.5 | 113 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Adamczak-Bugno, A.; Krampikowska, A. The Acoustic Emission Method Implementation Proposition to Confirm the Presence and Assessment of Reinforcement Quality and Strength of Fiber–Cement Composites. Materials 2020, 13, 2966. https://doi.org/10.3390/ma13132966

Adamczak-Bugno A, Krampikowska A. The Acoustic Emission Method Implementation Proposition to Confirm the Presence and Assessment of Reinforcement Quality and Strength of Fiber–Cement Composites. Materials. 2020; 13(13):2966. https://doi.org/10.3390/ma13132966

Chicago/Turabian StyleAdamczak-Bugno, Anna, and Aleksandra Krampikowska. 2020. "The Acoustic Emission Method Implementation Proposition to Confirm the Presence and Assessment of Reinforcement Quality and Strength of Fiber–Cement Composites" Materials 13, no. 13: 2966. https://doi.org/10.3390/ma13132966

APA StyleAdamczak-Bugno, A., & Krampikowska, A. (2020). The Acoustic Emission Method Implementation Proposition to Confirm the Presence and Assessment of Reinforcement Quality and Strength of Fiber–Cement Composites. Materials, 13(13), 2966. https://doi.org/10.3390/ma13132966