Evaluation of Stone Mastic Asphalt Containing Ceramic Waste Aggregate for Cooling Asphalt Pavement

Abstract

1. Introduction

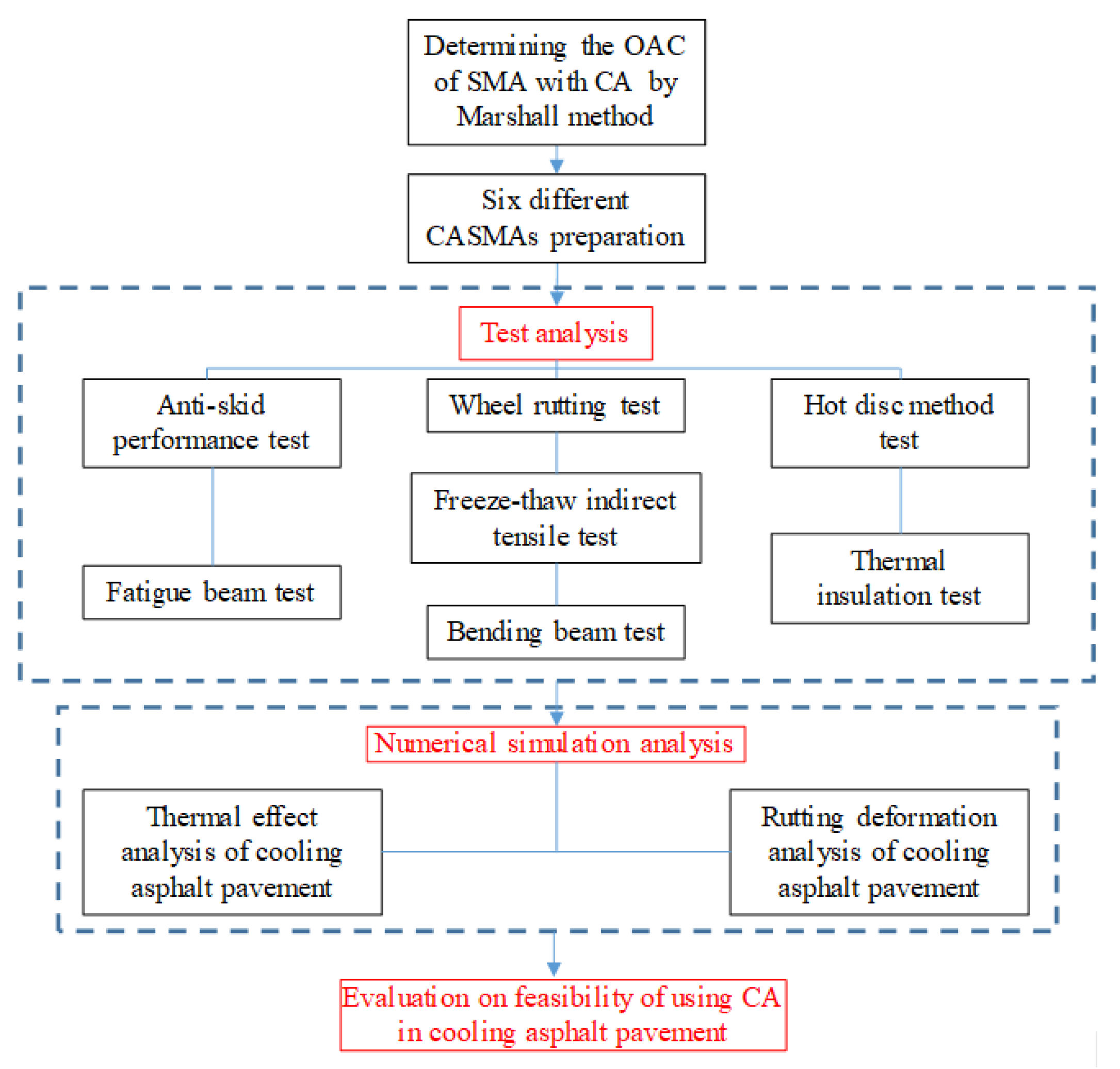

2. Research Objective and Approach

3. Materials and Methods

3.1. Materials and Specimen Preparation

3.1.1. Aggregate and Filler

3.1.2. Asphalt Binder

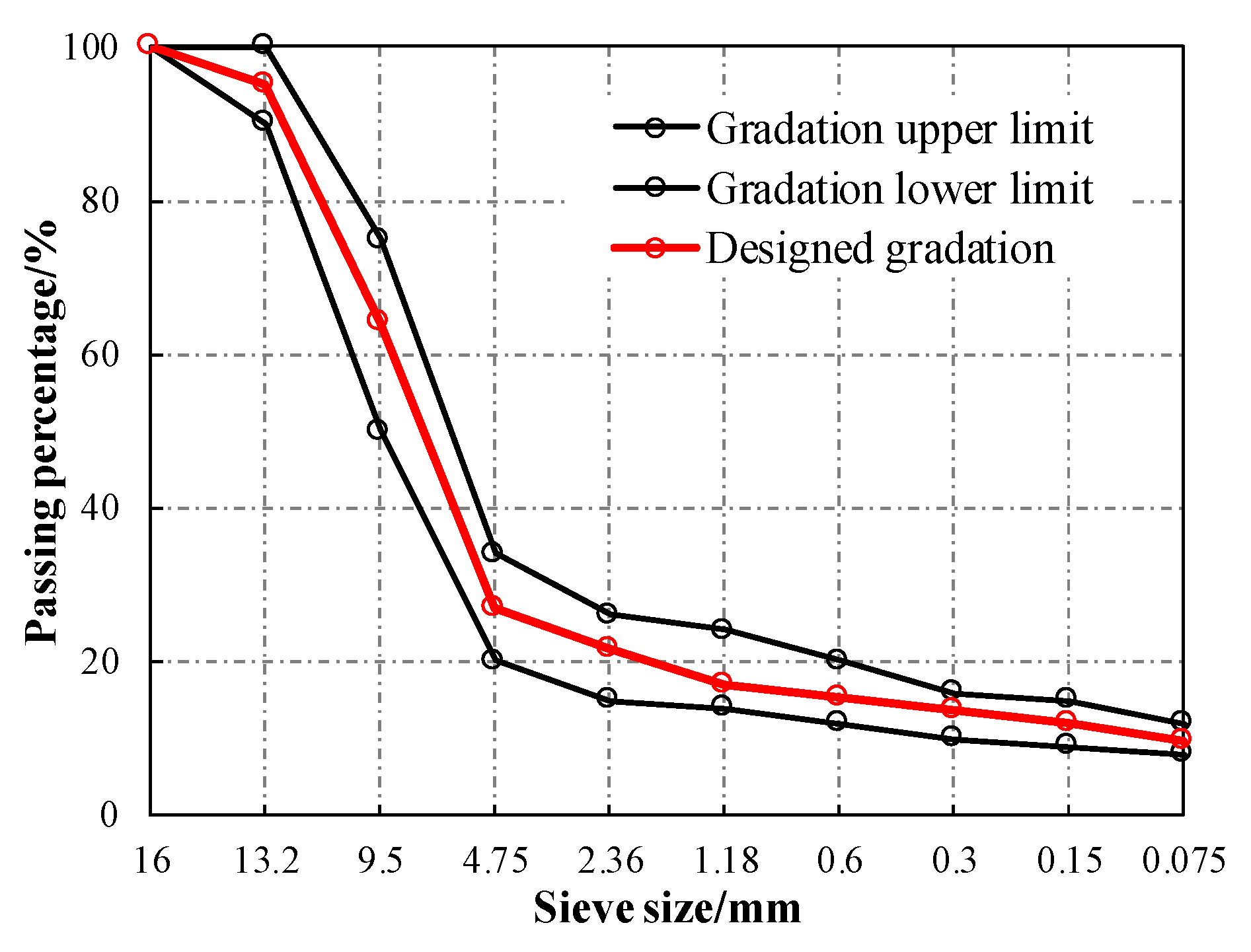

3.1.3. Mix Design

3.2. Experimental Methods

3.2.1. Wheel Rutting Test

3.2.2. Freeze-Thaw Indirect Tensile Test

3.2.3. Bending Beam Test

3.2.4. Hot Disc Method Test

3.2.5. Anti-Skid Performance Test

3.2.6. Fatigue Beam Test

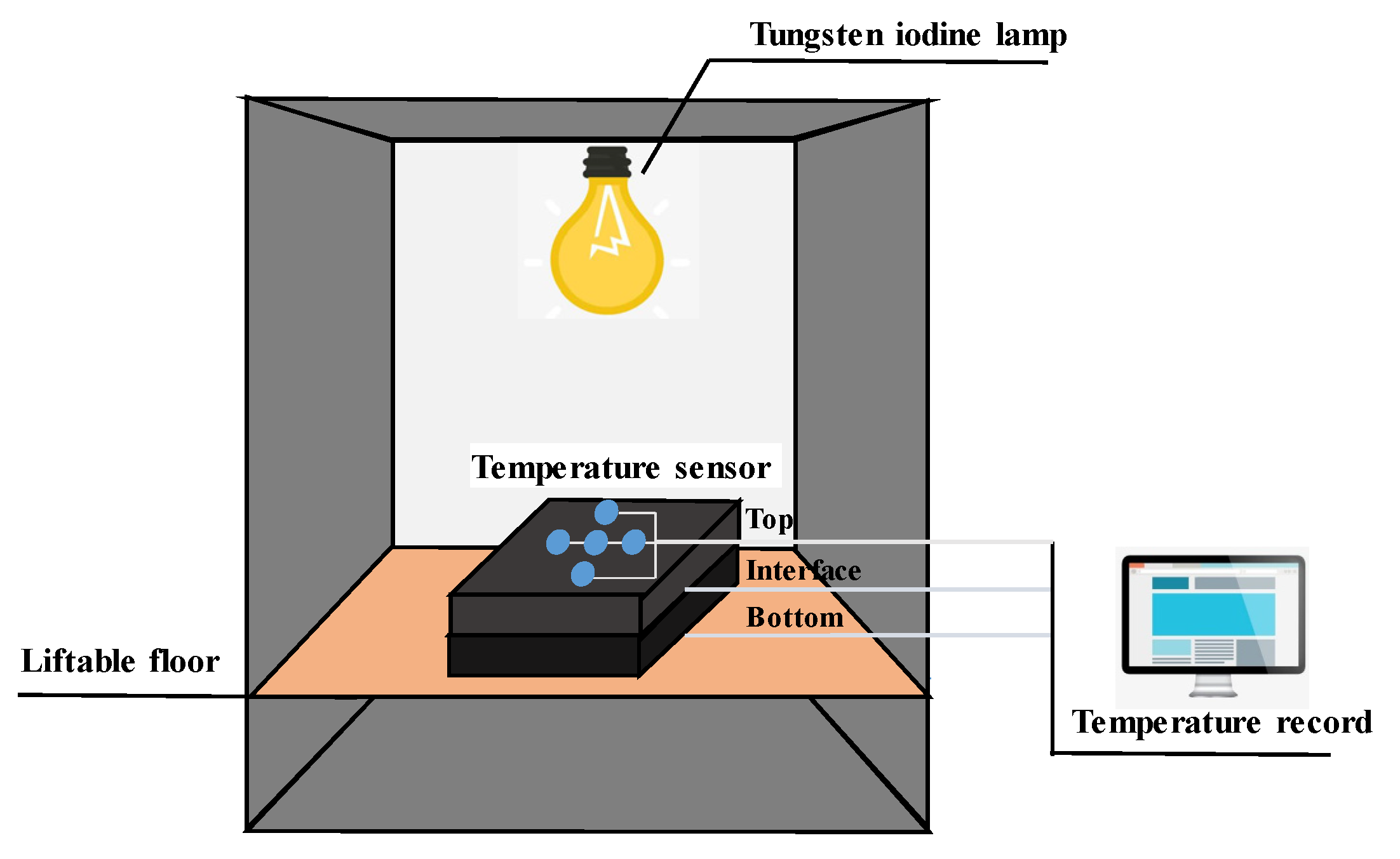

3.2.7. Thermal Insulation Test

3.3. Numerical Model

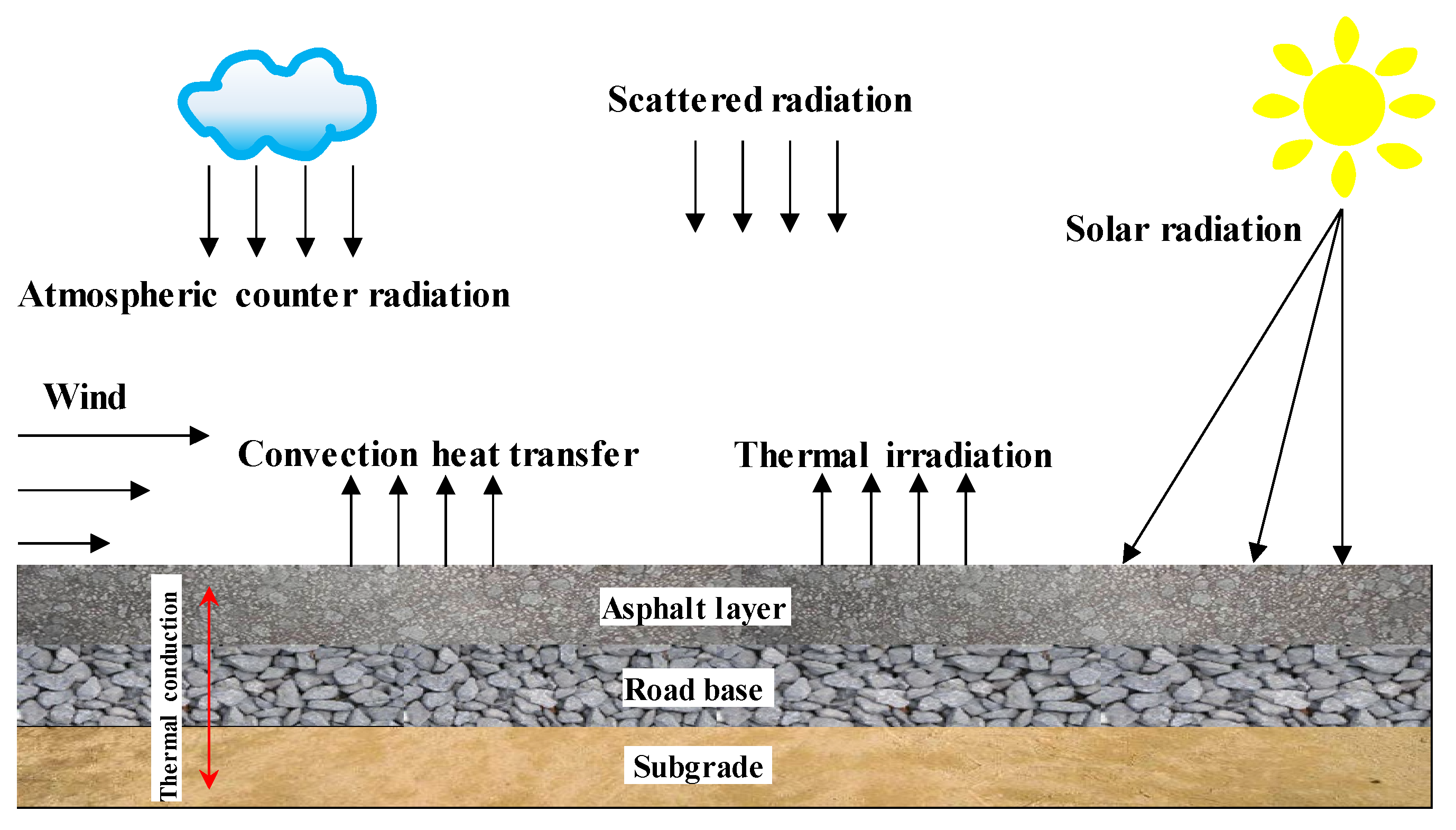

3.3.1. Theoretical Background

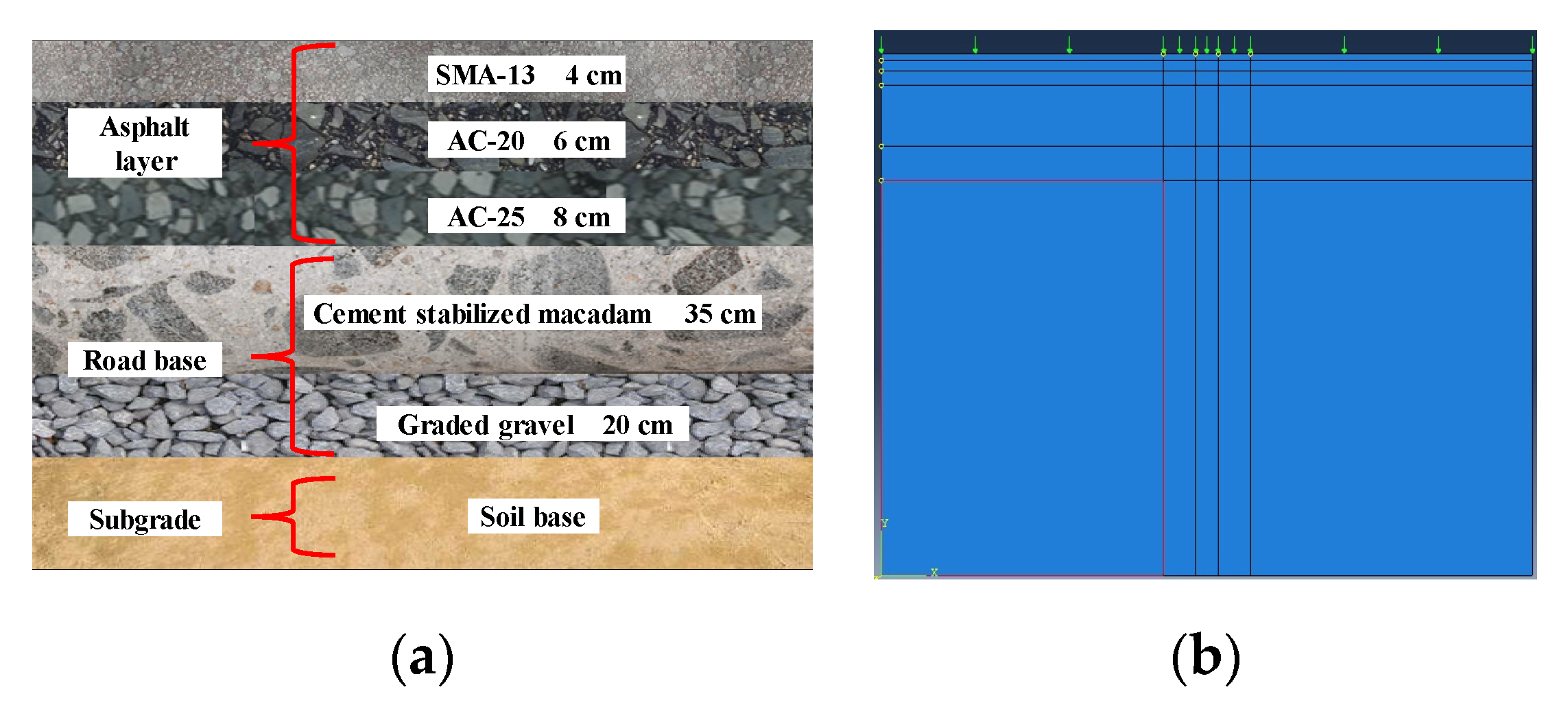

3.3.2. FE Model for Pavement Thermal Field and Mechanical Response Analysis

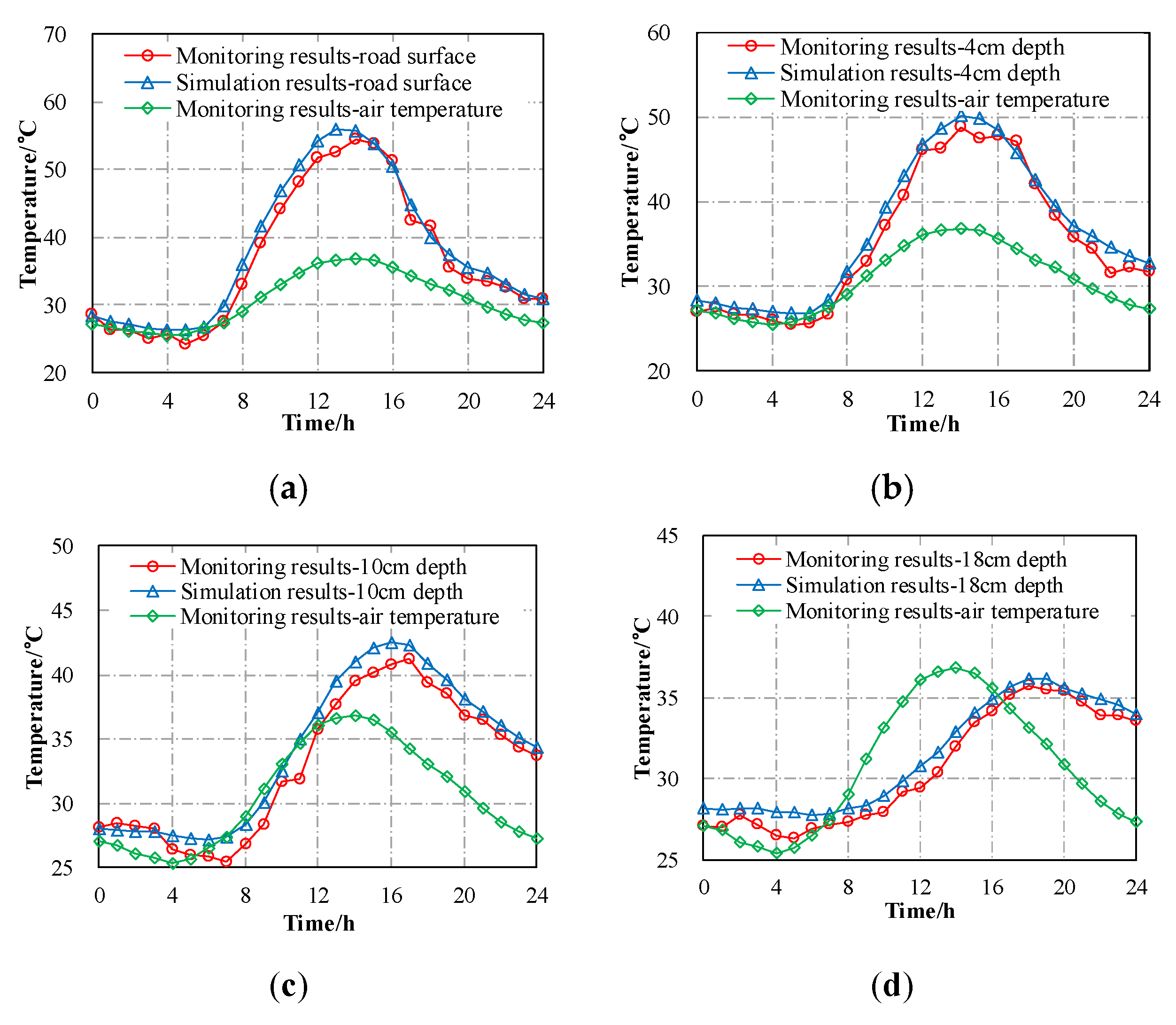

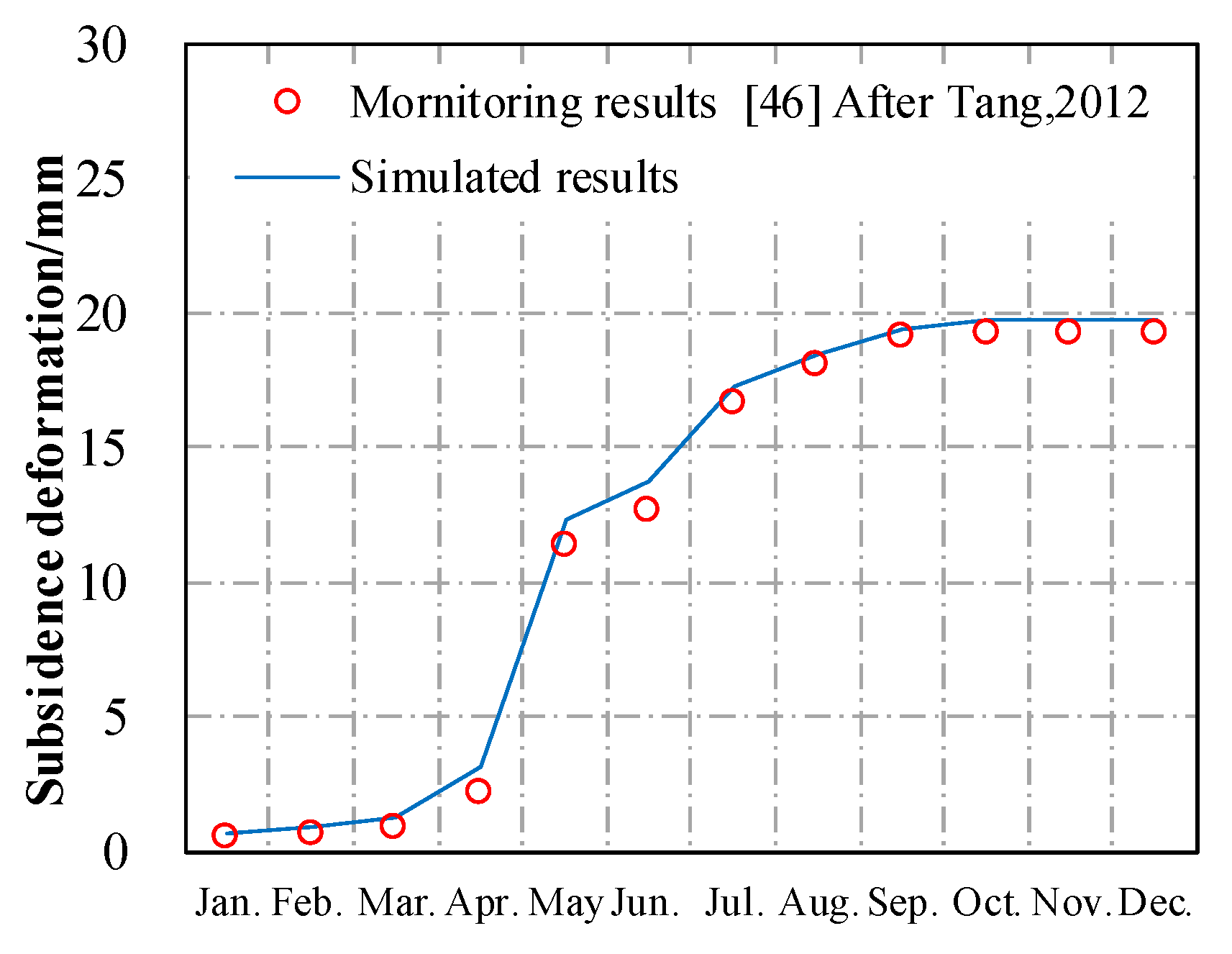

3.3.3. Model Verification

4. Results and Discussion

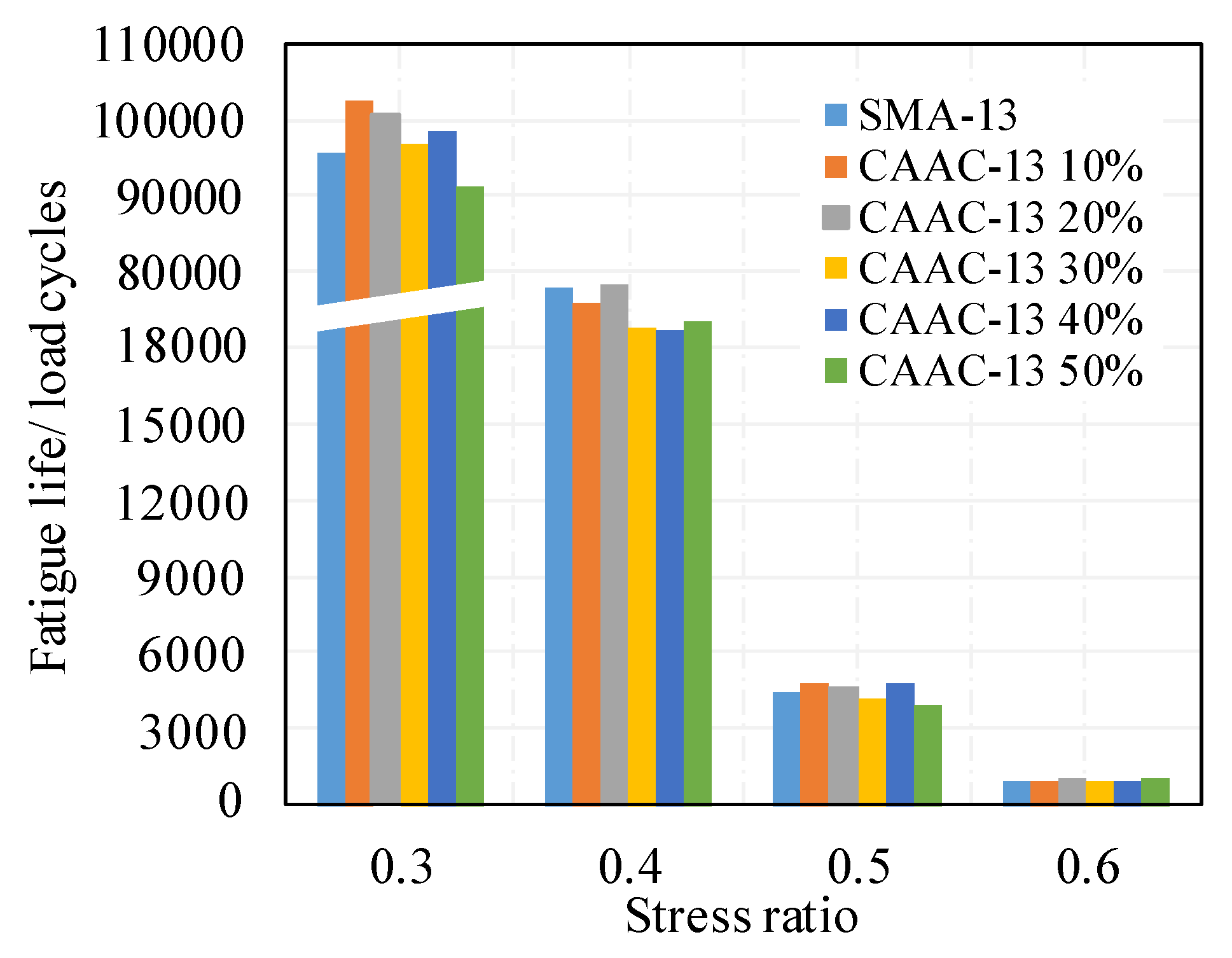

4.1. Experimental Results

4.2. Numerical Results

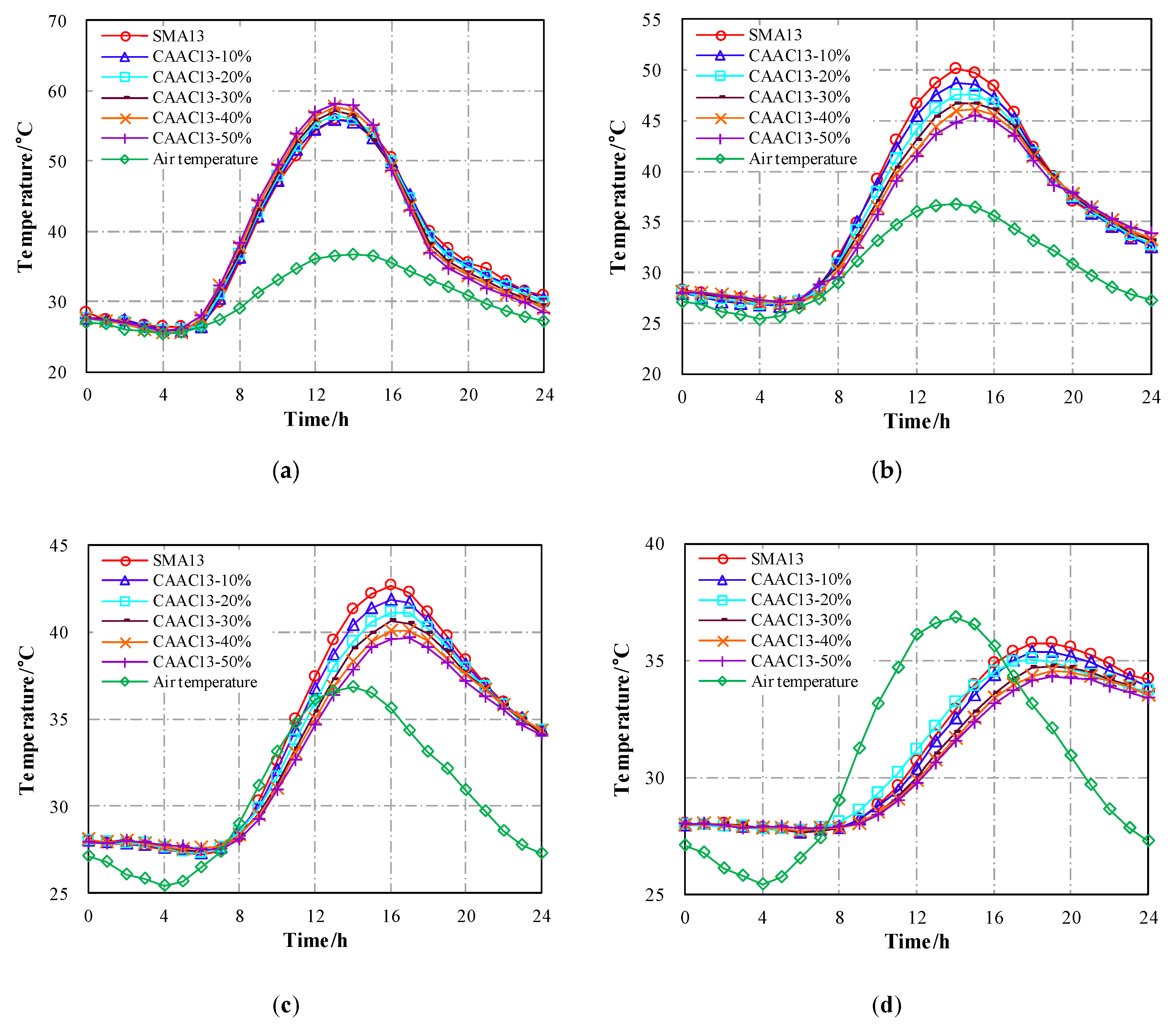

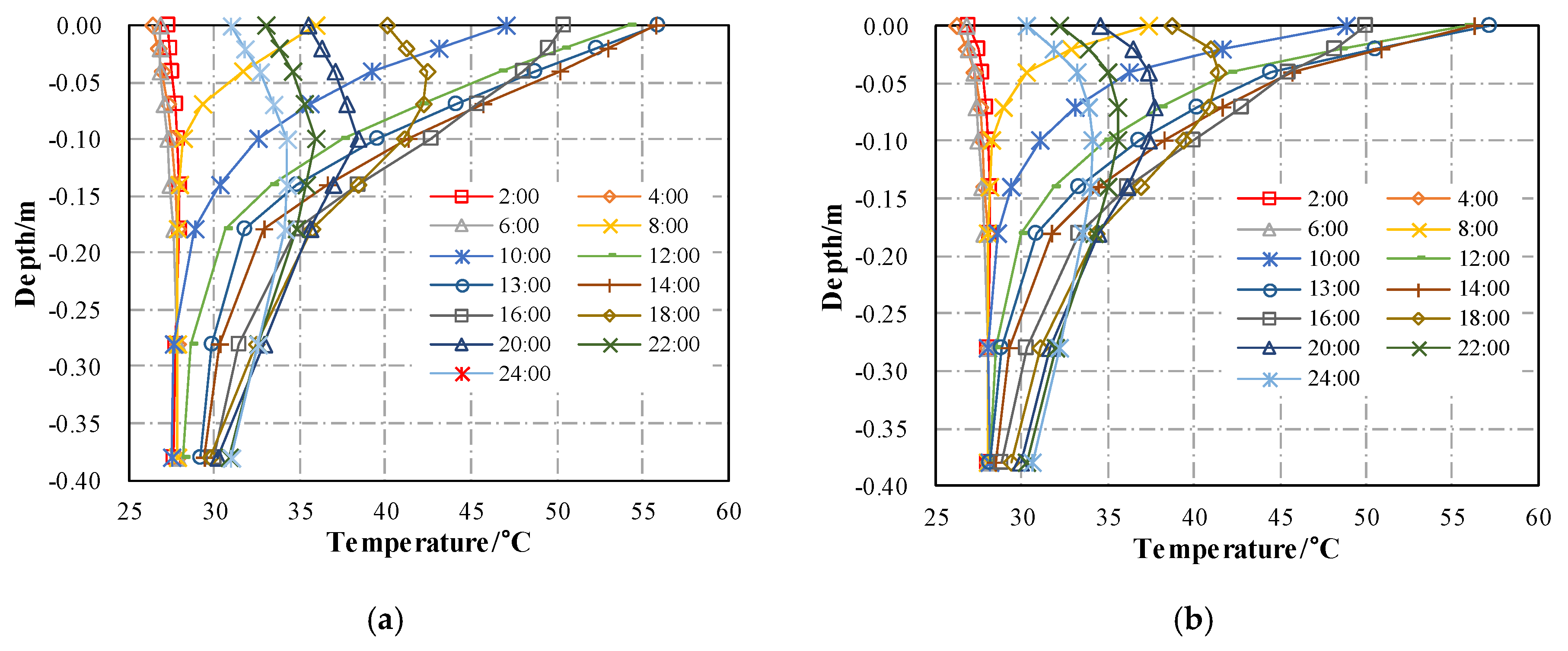

4.2.1. Thermal Effect Analysis of Cooling Asphalt Pavement

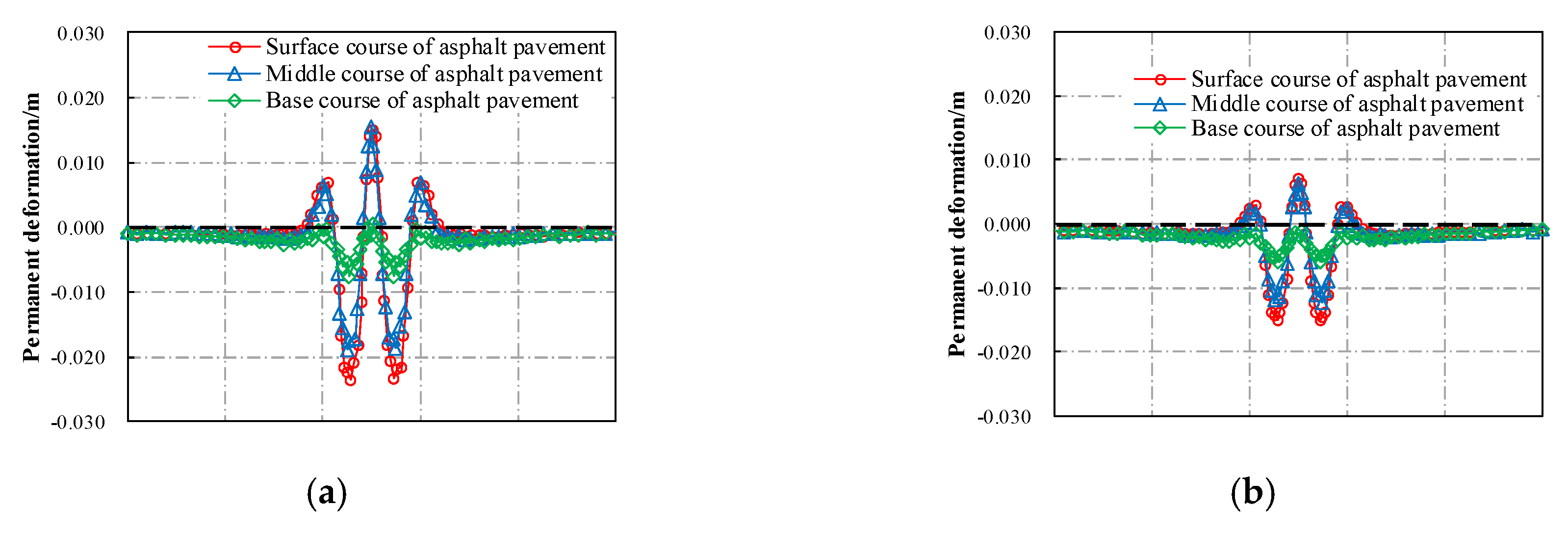

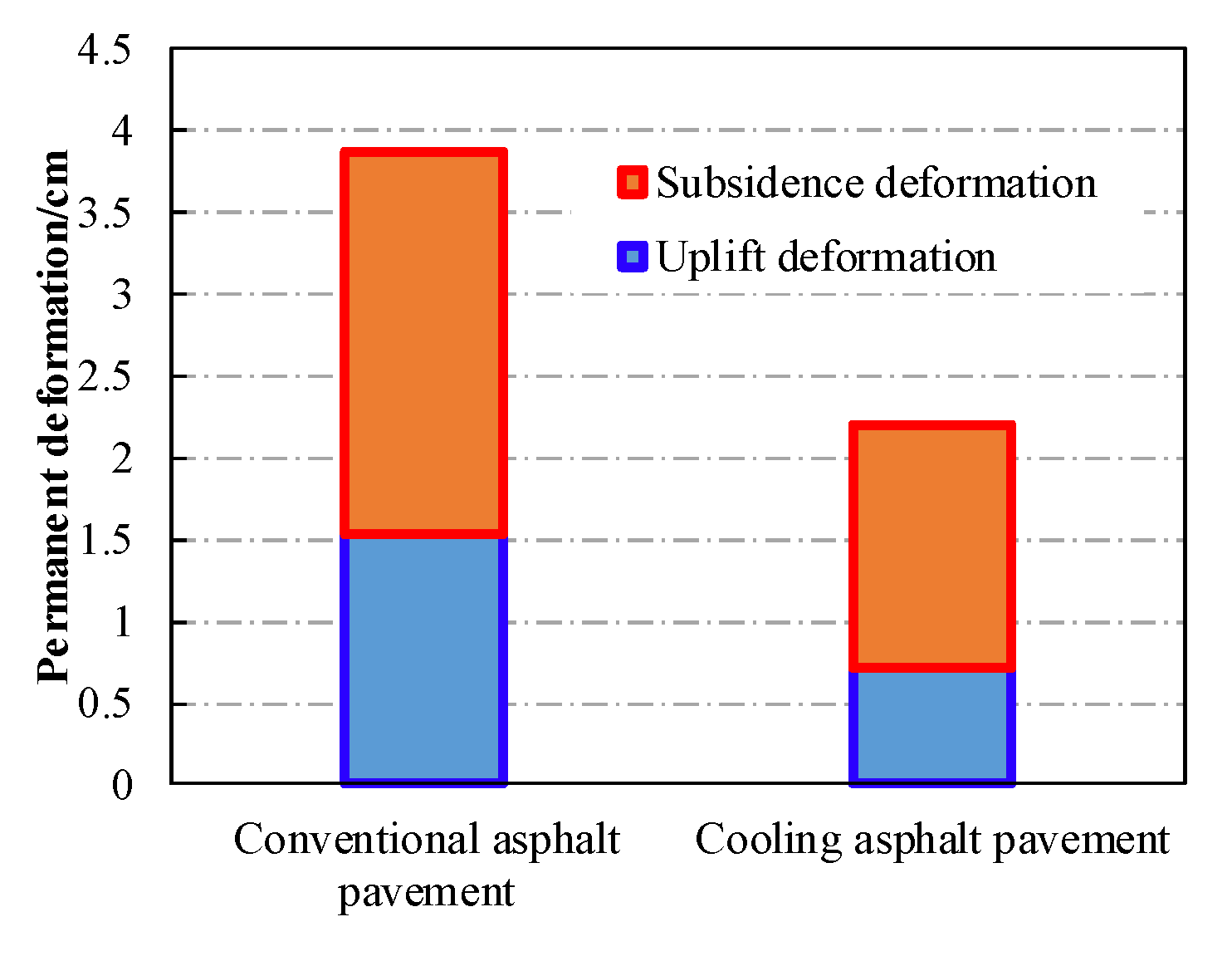

4.2.2. Rutting Deformation Analysis of Cooling Asphalt Pavement

5. Conclusions

- (1)

- As the incorporation of ceramic waste aggregate increased, the stone mastic asphalt’s optimum asphalt content and flow value gradually increased, while the stone mastic asphalt’s Marshall stability and density gradually decreased.

- (2)

- The CASMAs designed in this paper experienced degradation of some road performances as the content of ceramic waste aggregate increased. The smallest dynamic stability of CASMAs was about 62% lower than that of conventional SMA. The smallest TSR value and failure bending strain of CASMAs were about 15% smaller than those of SMA. In contrast, SMA and CASMAs have no significant difference in fatigue life, and both can provide friction as a surface course of cooling asphalt pavement.

- (3)

- The thermal conductivity of conventional SMA was 1.25–2.28 times that of CASMAs, and CASMAs could be an attractive material for the thermal insulation layer of cooling asphalt pavement. The indoor thermal insulation analysis confirmed that CASMAs had better thermal insulation performance than SMA. The best cooling effect was an 8.8 °C reduction in temperature at the interface, and an 11.5 °C reduction in temperature at the bottom, respectively.

- (4)

- When CASMAs were implemented as a surface course in the thermal field simulation model, the pavement surface temperature increased, while the temperature within the pavement decreased. Combining the test results of road performance and thermal simulation results, the optimal content of ceramic waste aggregate in stone mastic asphalt was recommended as 40%.

- (5)

- When subjected to repeated traffic load outdoors, the permanent rutting deformation of cooling asphalt pavement was 45.36% smaller than that of conventional asphalt pavement, indicating that the cooling asphalt pavement with CASMA thermal insulation layer had a better anti-rutting performance.

Author Contributions

Funding

Conflicts of Interest

References

- Majidifard, H.; Adu-Gyamfi, Y.; Buttlar, W.G. Deep machine learning approach to develop a new asphalt pavement condition index. Constr. Build. Mater. 2020, 247. [Google Scholar] [CrossRef]

- Akbari, H.; Matthews, H.D. Global cooling updates: Reflective roofs and pavements. Energy Build. 2012, 55, 2–6. [Google Scholar] [CrossRef]

- Mohajerani, A.; Bakaric, J.; Jeffrey-Bailey, T. The urban heat island effect, its causes, and mitigation, with reference to the thermal properties of asphalt concrete. J. Environ. Manag. 2017, 197, 522–538. [Google Scholar] [CrossRef] [PubMed]

- Xiao, F.; Ma, D.; Wang, J.; Cai, D.; Lou, L.; Yuan, J. Impacts of high modulus agent and anti-rutting agent on performances of airfield asphalt pavement. Constr. Build. Mater. 2019, 204. [Google Scholar] [CrossRef]

- Garcia, V.M.; Barros, L.; Garibay, J.; Abdallah, I.; Nazarian, S. Effect of aggregate gradation on performance of asphalt concrete mixtures. J. Mater. Civ. Eng. 2020, 32. [Google Scholar] [CrossRef]

- Azarhoosh, A.; Koohmishi, M. Investigation of the rutting potential of asphalt binder and mixture modified by styrene-ethylene/propylene-styrene nanocomposite. Constr. Build. Mater. 2020, 255. [Google Scholar] [CrossRef]

- Cheng, X.; Liu, Y.; Ren, W.; Huang, K. Performance evaluation of asphalt rubber mixture with additives. Materials 2019, 12, 1200. [Google Scholar] [CrossRef]

- Anting, N.; Din, M.F.M.; Iwao, K.; Ponraj, M.; Jungan, K.; Yong, L.Y.; Siang, A.J.L.M. Experimental evaluation of thermal performance of cool pavement material using waste tiles in tropical climate. Energy Build. 2017, 142, 211–219. [Google Scholar] [CrossRef]

- Synnefa, A.; Karlessi, T.; Gaitani, N.; Santamouris, M.; Assimakopoulos, D.N.; Papakatsikas, C. Experimental testing of cool colored thin layer asphalt and estimation of its potential to improve the urban microclimate. Build. Environ. 2011, 46, 38–44. [Google Scholar] [CrossRef]

- Jiang, Y.; Deng, C.; Chen, Z.; Tian, Y. Evaluation of the cooling effect and anti-rutting performance of thermally resistant and heat-reflective pavement. Int. J. Pavement. Eng. 2020, 21, 447–456. [Google Scholar] [CrossRef]

- Wang, C.; Fu, Y.; Liu, L.; Li, T. Surface treatment optimization of thermal-resistant aggregate for pavement. J. Mater. Civ. Eng. 2020, 32. [Google Scholar] [CrossRef]

- Ghaffar, S.H.; Burman, M.; Braimah, N. Pathways to circular construction: An integrated management of construction and demolition waste for resource recovery. J. Clean. Prod. 2020, 244. [Google Scholar] [CrossRef]

- Mercante, I.T.; Bovea, M.D.; Ibanez-Fores, V.; Arena, A.P. Life cycle assessment of construction and demolition waste management systems: A spanish case study. Int. J. Life Cycle. Ass. 2012, 17, 232–241. [Google Scholar] [CrossRef]

- Kisku, N.; Joshi, H.; Ansari, M.; Panda, S.K.; Nayak, S.; Dutta, S.C. A critical review and assessment for usage of recycled aggregate as sustainable construction material. Constr. Build. Mater. 2017, 131, 721–740. [Google Scholar] [CrossRef]

- Soutsos, M.N.; Tang, K.; Millard, S.G. Concrete building blocks made with recycled demolition aggregate. Constr. Build. Mater. 2011, 25, 726–735. [Google Scholar] [CrossRef]

- Hussein, A.A.; Jaya, R.P.; Yaacob, H.; Hassan, N.A.; Aletba, S.R.O.; Huseien, G.F.; Shaffie, E.; Hasan, M.R.M. Physical, chemical and morphology characterisation of nano ceramic powder as bitumen modification. Int. J. Pavement. Eng. 2019. [Google Scholar] [CrossRef]

- Ratnasamy, M.; Elzarroug, A.E.; Bin, H.H.; Bt, Y.R. An initial investigation of the use of local industrial wastes and by-products as mineral fillers in stone mastic asphalt pavements. J. Eng. Appl. Sci. 2009, 4, 54–63. [Google Scholar]

- Van de Ven, M.F.; Molenaar, A.A.; Poot, M.R. Asphalt mixtures with waste materials: Possibilities and constraints. In Proceedings of the Conference on Asphalt Pavements for Southern Africa, KwaZulu-Natal, South Africa, 1 September 2010–31 August 2011. [Google Scholar]

- Silvestre, R.; Medel, E.; Garcia, A.; Navas, J. Using ceramic wastes from tile industry as a partial substitute of natural aggregates in hot mix asphalt binder courses. Constr. Build. Mater. 2013, 45, 115–122. [Google Scholar] [CrossRef]

- BS 812-110. Methods for Determination of Aggregate Crushing Value (acv); British Standard: London, UK, 1990. [Google Scholar]

- ASTM C131. Standard Test Method for Resistance to Degradation of Small-Size Coarse Aggregate by Abrasion and Impact in the Los Angeles Machine; American Standard for Testing and Materials: West Conshohocken, PA, USA, 2014. [Google Scholar]

- ASTM D4791. Standard Test Method for Flat Particles, Elongated Particles, or Flat and Elongated Particles in Coarse Aggregate; American Standard for Testing and Materials: West Conshohocken, PA, USA, 2010. [Google Scholar]

- ASTM C127. Standard Test Method for Relative Density (Specific Gravity) and Absorption of Coarse Aggregate; American Standard for Testing and Materials: West Conshohocken, PA, USA, 2015. [Google Scholar]

- ASTM C128. Standard Test Method for Relative Density (Specific Gravity) and Absorption of Fine Aggregate; American Standard for Testing and Materials: West Conshohocken, PA, USA, 2015. [Google Scholar]

- ASTM D4318. Standard Test Methods for Liquid Limit, Plastic Limit, and Plasticity Index of Soils; American Standard for Testing and Materials: West Conshohocken, PA, USA, 2017. [Google Scholar]

- ASTM D5. Standard Test Method for Penetration of Bituminous Materials; American Standard for Testing and Materials: West Conshohocken, PA, USA, 2013. [Google Scholar]

- ASTM D36. Standard Test Method for Softening Point of Bitumen; American Standard for Testing and Materials: West Conshohocken, PA, USA, 2014. [Google Scholar]

- ASTM D113. Standard Test Method for Ductility of Bituminous Materials; American Standard for Testing and Materials: West Conshohocken, PA, USA, 2007. [Google Scholar]

- ASTM D2042. Standard Test Method for Solubility of Asphalt Materials in Trichloroethylene; American Standard for Testing and Materials: West Conshohocken, PA, USA, 2015. [Google Scholar]

- ASTM D92. Standard Test Method for Flash and Fire Points by Cleveland Open Cup Tester; American Standard for Testing and Materials: West Conshohocken, PA, USA, 2016. [Google Scholar]

- ASTM D2170. Standard Test Methods for Kinematic Viscosity of Asphalts (Bitumens); American Standard for Testing and Materials: West Conshohocken, PA, USA, 2010. [Google Scholar]

- ASTM D1754. Standard Test Method for Effects of Heat and Air on Asphaltic Materials; American Standard for Testing and Materials: West Conshohocken, PA, USA, 2014. [Google Scholar]

- JTG F40-2004. Technical Specification for Construction of Highway Asphalt Pavements; China Communications Press: Beijing, China, 2004. [Google Scholar]

- JTG E20-2011. Standard Test Methods of Bitumen and Bituminous Mixtures for Highway Engineering; China Communications Press: Beijing, China, 2011. [Google Scholar]

- ASTM WK49591. New Test Method for Determining Thermal Conductivity and Thermal Diffusivity Using the Transient Plane Source or Hot Disc Method; American Standard for Testing and Materials: West Conshohocken, PA, USA, 2015. [Google Scholar]

- ASTM E303. Standard Test Method for Measuring Surface Frictional Properties Using the British Pendulum Tester; American Standard for Testing and Materials: West Conshohocken, PA, USA, 2013. [Google Scholar]

- ASTM E965. Standard Test Method for Measuring Pavement Macrotexture Depth Using a Volumetric Technique; American Standard for Testing and Materials: West Conshohocken, PA, USA, 2006. [Google Scholar]

- CEN-EN 12697-24. Bituminous Mixtures-Test Methods—Part 24: Resistance to Fatigue; European Committee for Standardization (CEN): Brussels, Belgium, 2018. [Google Scholar]

- Al-Ajlan, S.A. Measurements of thermal properties of insulation materials by using transient plane source technique. Appl. Therm. Eng. 2006, 26, 2184–2191. [Google Scholar] [CrossRef]

- Yang, Y.; Qian, Z.; Song, X. A pothole patching material for epoxy asphalt pavement on steel bridges: Fatigue test and numerical analysis. Constr. Build. Mater. 2015, 94, 299–305. [Google Scholar] [CrossRef]

- Zhu, X.; Yu, Y.; Chen, L.; Zhang, D. Solar heat reflective coating for sidewalks considering cooling effect, anti-skid performance, and human comfort. J. Test. Eval. 2020, 48, 2028–2039. [Google Scholar] [CrossRef]

- Ozbolt, J.; Bosnjak, J.; Periskic, G.; Sharma, A. 3D numerical analysis of reinforced concrete beams exposed to elevated temperature. Eng. Struct. 2014, 58, 166–174. [Google Scholar] [CrossRef]

- Alonso-Estebanez, A.; Pascual-Munoz, P.; Luis Sampedro-Garcia, J.; Castro-Fresno, D. 3D numerical modelling and experimental validation of an asphalt solar collector. Appl. Therm. Eng. 2017, 126, 678–688. [Google Scholar] [CrossRef]

- Sreedhar, S.; Biligiri, K.P. Development of pavement temperature predictive models using thermophysical properties to assess urban climates in the built environment. Sustain. Cities Soc. 2016, 22, 78–85. [Google Scholar] [CrossRef]

- Kassem, H.; Chehab, G.; Saad, G. An fem-predictive tool for simulating the cooling characteristics of freshly paved asphalt concrete layers. Int. J. Pavement. Eng. 2015, 16, 157–167. [Google Scholar] [CrossRef]

- Tang, J. Study on Climatic Regionalization and Temperature-Field Induced Rutting of Asphalt Pavement in Hainan Province; Central South University: Hunan, China, 2012. [Google Scholar]

- Hu, J.; Qian, Z.; Yang, Y. High temperature properties of composite structure of gussasphalt + epoxy asphalt at bridge deck pavement. J. Central South Univ. 2015, 46, 1946–1952. [Google Scholar] [CrossRef]

| Technical Indices | Aggregate/Filler | Measure Value | Test Method | Criteria |

|---|---|---|---|---|

| Crushing value/% | CA | 22.7 | BS 812-110 [20] | Maximum of 35 |

| Basalt aggregate | 10.6 | |||

| Los Angeles abrasion/% | CA | 20.5 | ASTM C131 [21] | Maximum of 40 |

| Basalt aggregate | 11.4 | |||

| Flat and elongated particle content/% | CA | 13.8 | ASTM D4791 [22] | Maximum of 10 |

| Basalt aggregate | 2.6 | |||

| Water absorption rate/% | CA | 0.86 | ASTM C127 [23] | None |

| Basalt aggregate | 0.32 | |||

| Density/g·cm−3 | CA | 2.348 | ASTM C127 [23] | None |

| Basalt aggregate | 2.941 | |||

| Limestone filler | 2.723 | ASTM C128 [24] | ||

| Plasticity index | Limestone filler | Non-plastic | ASTM D4318 [25] | Non-plastic |

| Technical Indices | Measure Value | Test Method | Criteria |

|---|---|---|---|

| Penetration at 25 °C/0.1 mm | 63.4 | ASTM D5 [26] | 50–70 |

| Softening point/°C | 72.0 | ASTM D36 [27] | ≥60 |

| Ductility at 5 °C/cm | 78.5 | ASTM D113 [28] | ≥30 |

| Solubility in trichloroethylene/% | 99.4 | ASTM D2042 [29] | ≥99 |

| Flash point/°C | 260 | ASTM D92 [30] | ≥230 |

| Viscosity at 135 °C/Pa·s | 2.16 | ASTM D2170 [31] | ≥3 |

| Elastic recovery/% | 94 | ASTM D113 [28] | ≥99 |

| After the Rolling Thin Film Oven Test (RTFOT) | |||

| Loss in weight/% | 0.12 | ASTM D1754 [32] | ≥1.0 |

| Retained penetration/% | 64 | ASTM D5 [26] | ≥70 |

| Ductility at 5 °C/cm | 28 | ASTM D113 [28] | ≥20 |

| Index | SMA-13 | CASMA-13 | Criteria | ||||

|---|---|---|---|---|---|---|---|

| 10% | 20% | 30% | 40% | 50% | |||

| Optimum asphalt content/% | 5.7 | 5.8 | 5.8 | 5.9 | 6.0 | 6.2 | - |

| Density/g·cm−3 | 2.520 | 2.493 | 2.479 | 2.438 | 2.418 | 2.362 | - |

| Air void/% | 4.0 | 3.9 | 3.8 | 3.9 | 4.0 | 3.9 | 3.0–4.0 |

| VFA/% | 78.1 | 78.6 | 80.2 | 78.40 | 79.21 | 81.22 | 75–85 |

| VMA/% | 17.3 | 17.3 | 17.1 | 16.9 | 17.4 | 17.0 | ≥17 |

| Stability/kN | 8.65 | 7.39 | 7.36 | 7.28 | 7.13 | 6.57 | ≥6.0 |

| Flow value/0.1 mm | 20.8 | 21.0 | 23.5 | 22.8 | 25.61 | 28.37 | 20–50 |

| Leakage loss/% | 0.05 | 0.06 | 0.06 | 0.07 | 0.09 | 0.12 | ≥0.1 |

| Scattering loss/% | 3.5 | 5.5 | 5.8 | 7.3 | 11.5 | 13.2 | ≥15 |

| Test | Property | Material | Index | Test Method |

|---|---|---|---|---|

| Wheel rutting test | Deformation resistance | SMA-13 (0%), CASMA-13 (10%), CASMA-13 (20%), CASMA-13 (30%), CASMA-13 (40%), CASMA-13 (50%). | Dynamic stability | JTG E20-2011 T0719 [34] |

| Freeze-thaw indirect tensile test | Moisture susceptibility | Tensile strength ratio (TSR) | AASHTO T283 [29] | |

| Bending beam test | Cracking resistance | Bending strength | JTG E20-2011 T0715 [34] | |

| Thermophysical parameter test (hot disc method test) | Thermophysical performance | Conductivity | ASTM WK49591 [35] | |

| Diffusivity | ||||

| Specific heat | ||||

| Anti-skid performance test | Anti-skid performance | British pendulum number (BPN) | ASTM E303 [36] | |

| Mean texture depth (MTD) | ASTM E965 [37] | |||

| Fatigue beam test | Fatigue performance | Failure cycles | CEN-EN 12697-24 [38] | |

| Thermal insulation test | Thermal insulation performance | Temperature difference | Designed in this study |

| Item | SMA-13 | AC-20C | AC-25C | CSM | Graded Gravel | Soil Base |

|---|---|---|---|---|---|---|

| Thermal conductivity/W m−1·K−1 | 1.302 | 1.070 | 1.000 | 1.560 | 1.200 | 1.560 |

| Density/kg m−3 | 2520 | 2412 | 2333 | 2200 | 2000 | 1800 |

| Specific heat/J kg−1 K−1 | 812.6 | 852.1 | 801.4 | 911.7 | 900.0 | 1040.0 |

| Solar radiation absorption rate | 0.90 | |||||

| Emissivity coefficient | 0.81 | |||||

| Time Hardening Creep Model | Asphalt Mixture Type | Temperature/°C | A | n | m | R2 |

|---|---|---|---|---|---|---|

| SMA-13-0% | 20 | 6.536 × 10−11 | 0.937 | −0.592 | 0.9326 | |

| 30 | 3.325 × 10−9 | 0.862 | −0.587 | 0.9459 | ||

| 40 | 1.446 × 10−8 | 0.792 | −0.577 | 0.9420 | ||

| 50 | 1.390 × 10−6 | 0.414 | −0.525 | 0.9244 | ||

| 60 | 1.464 × 10−5 | 0.336 | −0.502 | 0.9049 | ||

| CASMA-13-40% | 20 | 5.029 × 10−11 | 0.909 | −0.784 | 0.9855 | |

| 30 | 2.368 × 10−9 | 0.852 | −0.778 | 0.9860 | ||

| 40 | 3.267 × 10−8 | 0.767 | −0.668 | 0.9693 | ||

| 50 | 1.598 × 10−6 | 0.396 | −0.637 | 0.9470 | ||

| 60 | 1.698 × 10−5 | 0.341 | −0.611 | 0.9523 |

| Index | Temperature/°C | SMA−13 | CASMA-13 | Criterion | ||||

|---|---|---|---|---|---|---|---|---|

| 10% | 20% | 30% | 40% | 50% | ||||

| Dynamic stability/pass·mm−1 | 60 | 5364 | 4652 | 4531 | 4181 | 3524 | 2036 | ≥3000 |

| TSR/% | 15 | 90.6 | 85.7 | 83.5 | 83.2 | 80.2 | 74.8 | ≥75 |

| Failure bending strain/με | −10 | 3024 | 2751 | 2730 | 2698 | 2703 | 2583 | ≥2500 |

| Thermal conductivity/W·m−1·K−1 | 20 | 1.302 | 1.035 | 0.831 | 0.716 | 0.611 | 0.570 | - |

| Thermal diffusivity/10−7 m2·s−1 | 6.358 | 4.864 | 3.642 | 3.010 | 2.569 | 2.341 | ||

| Specific heat/J·kg−1·K−1 | 812 | 982 | 1093 | 1168 | 1269 | 1324 | ||

| BPN | 25 | 73 | 70 | 72 | 70 | 71 | 72 | ≥45 |

| Mean texture depth/mm | 25 | 1.04 | 0.88 | 0.98 | 0.95 | 0.94 | 1.0 5 | ≥0.8 |

| Object | Factor | DF | F-Value | p-Value | Significance |

|---|---|---|---|---|---|

| Fatigue life | Stress ratio | 3 | 2568.85 | <0.001 | *** |

| CA content | 5 | 1.800 | 0.173 | — |

| Index | SMA-13 | CASMA-13 | ||||

|---|---|---|---|---|---|---|

| 10% | 20% | 30% | 40% | 50% | ||

| Temperature of compound specimen surface/°C | 68.5 | 68.9 | 69.1 | 69.6 | 70.7 | 70.9 |

| Temperature of compound specimen interface/°C | 66.1 | 63.1 | 61.4 | 60.5 | 60.3 | 59.7 |

| Temperature of compound specimen bottom/°C | 51.6 | 46.9 | 45.3 | 43.7 | 43.2 | 42.5 |

| Temperature difference between surface and interface/°C | 2.4 | 5.8 | 7.7 | 9.1 | 10.4 | 11.2 |

| Temperature difference between surface and bottom/°C | 16.9 | 22.0 | 23.8 | 25.9 | 27.5 | 28.4 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Huang, Q.; Qian, Z.; Hu, J.; Zheng, D. Evaluation of Stone Mastic Asphalt Containing Ceramic Waste Aggregate for Cooling Asphalt Pavement. Materials 2020, 13, 2964. https://doi.org/10.3390/ma13132964

Huang Q, Qian Z, Hu J, Zheng D. Evaluation of Stone Mastic Asphalt Containing Ceramic Waste Aggregate for Cooling Asphalt Pavement. Materials. 2020; 13(13):2964. https://doi.org/10.3390/ma13132964

Chicago/Turabian StyleHuang, Qibo, Zhendong Qian, Jing Hu, and Dong Zheng. 2020. "Evaluation of Stone Mastic Asphalt Containing Ceramic Waste Aggregate for Cooling Asphalt Pavement" Materials 13, no. 13: 2964. https://doi.org/10.3390/ma13132964

APA StyleHuang, Q., Qian, Z., Hu, J., & Zheng, D. (2020). Evaluation of Stone Mastic Asphalt Containing Ceramic Waste Aggregate for Cooling Asphalt Pavement. Materials, 13(13), 2964. https://doi.org/10.3390/ma13132964