Feasibility of Reduced Ingot Hot-Top Height for the Cost-Effective Forging of Heavy Steel Ingots

Abstract

1. Introduction

2. Research Methodology

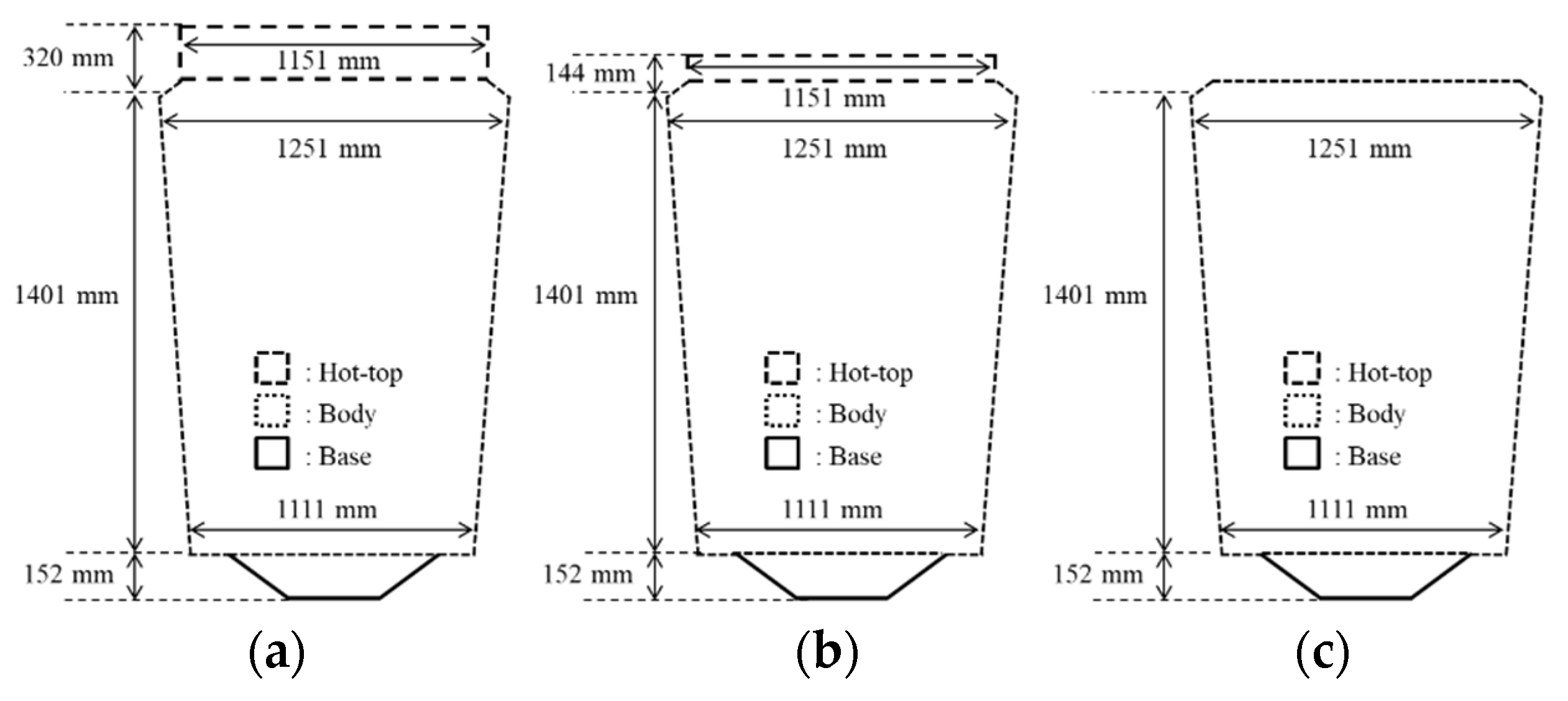

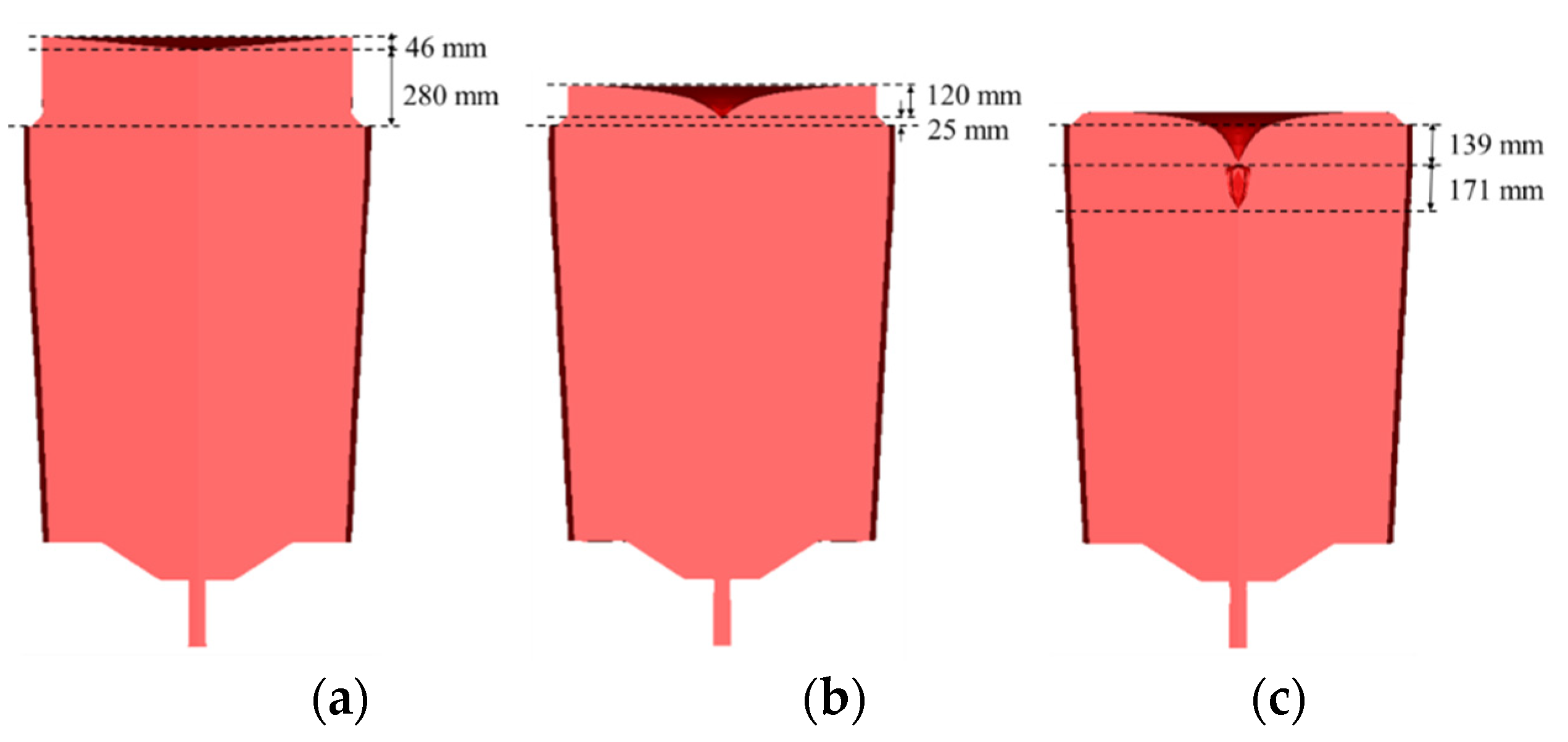

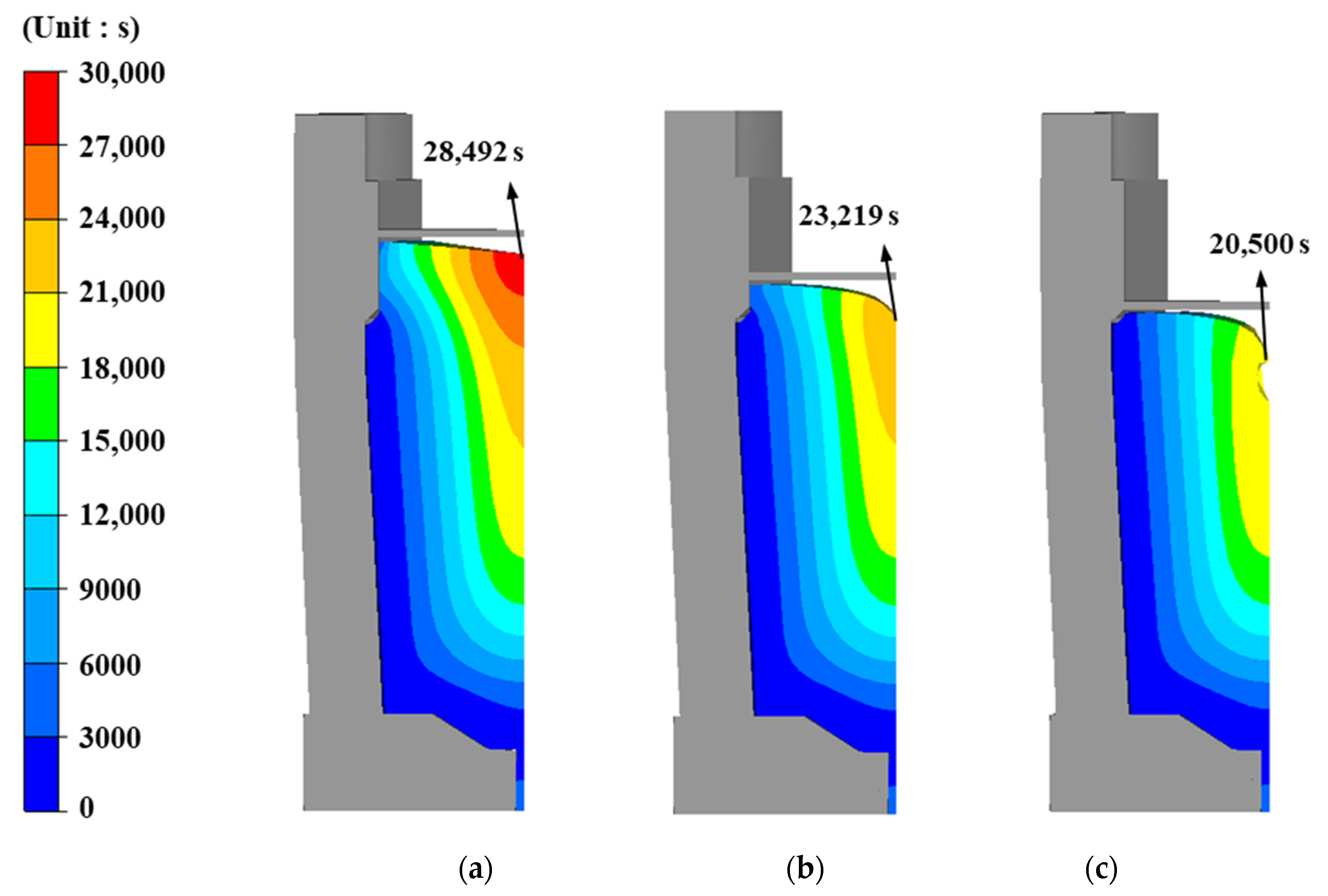

2.1. Finite Element Analysis of Ingot Casting

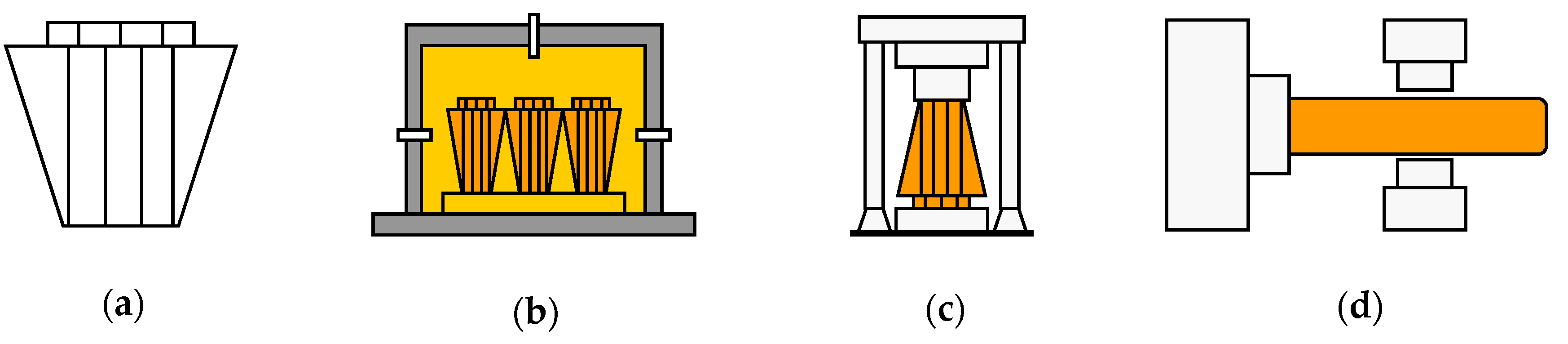

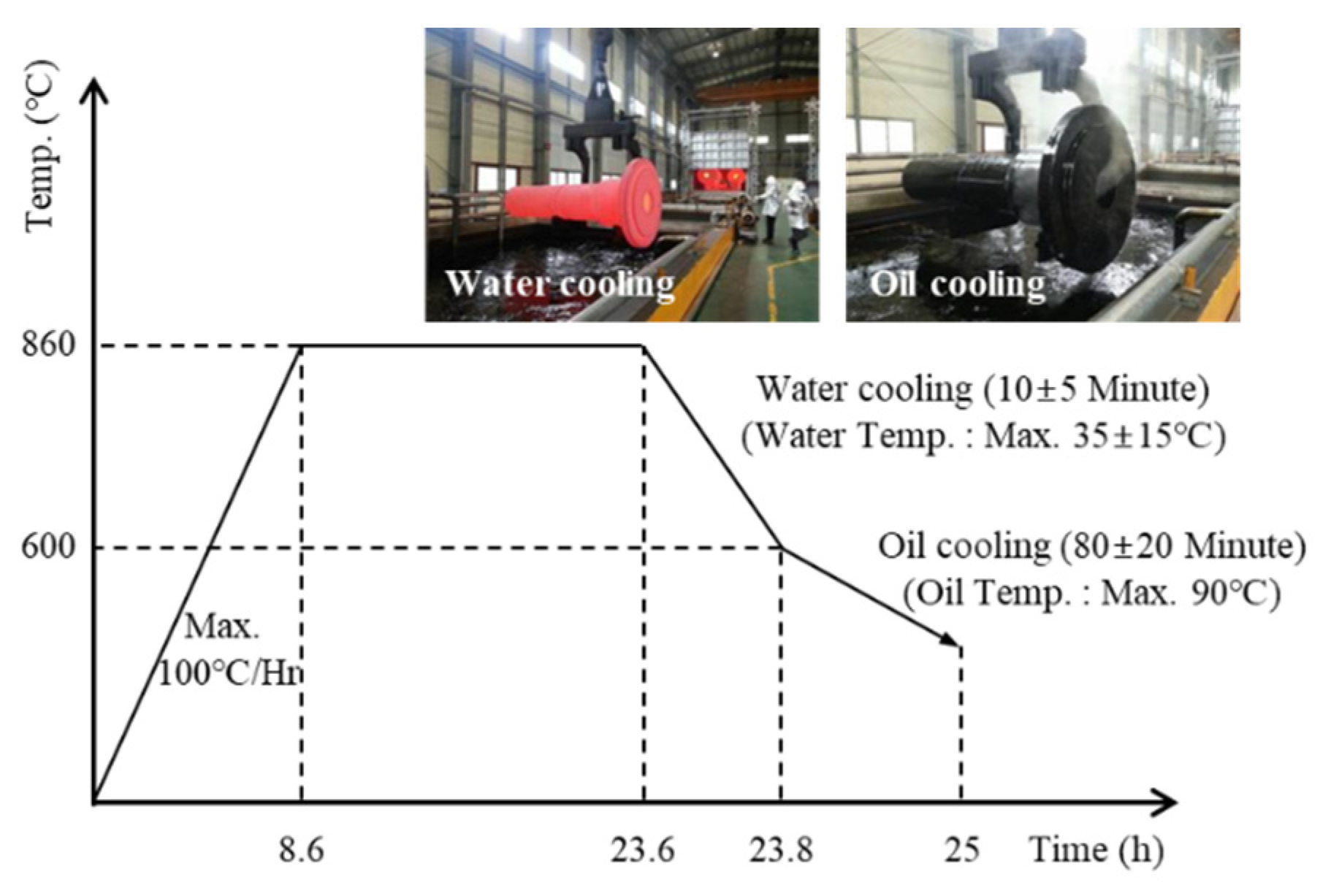

2.2. Materials and Forging Experiments

3. Results and Discussion

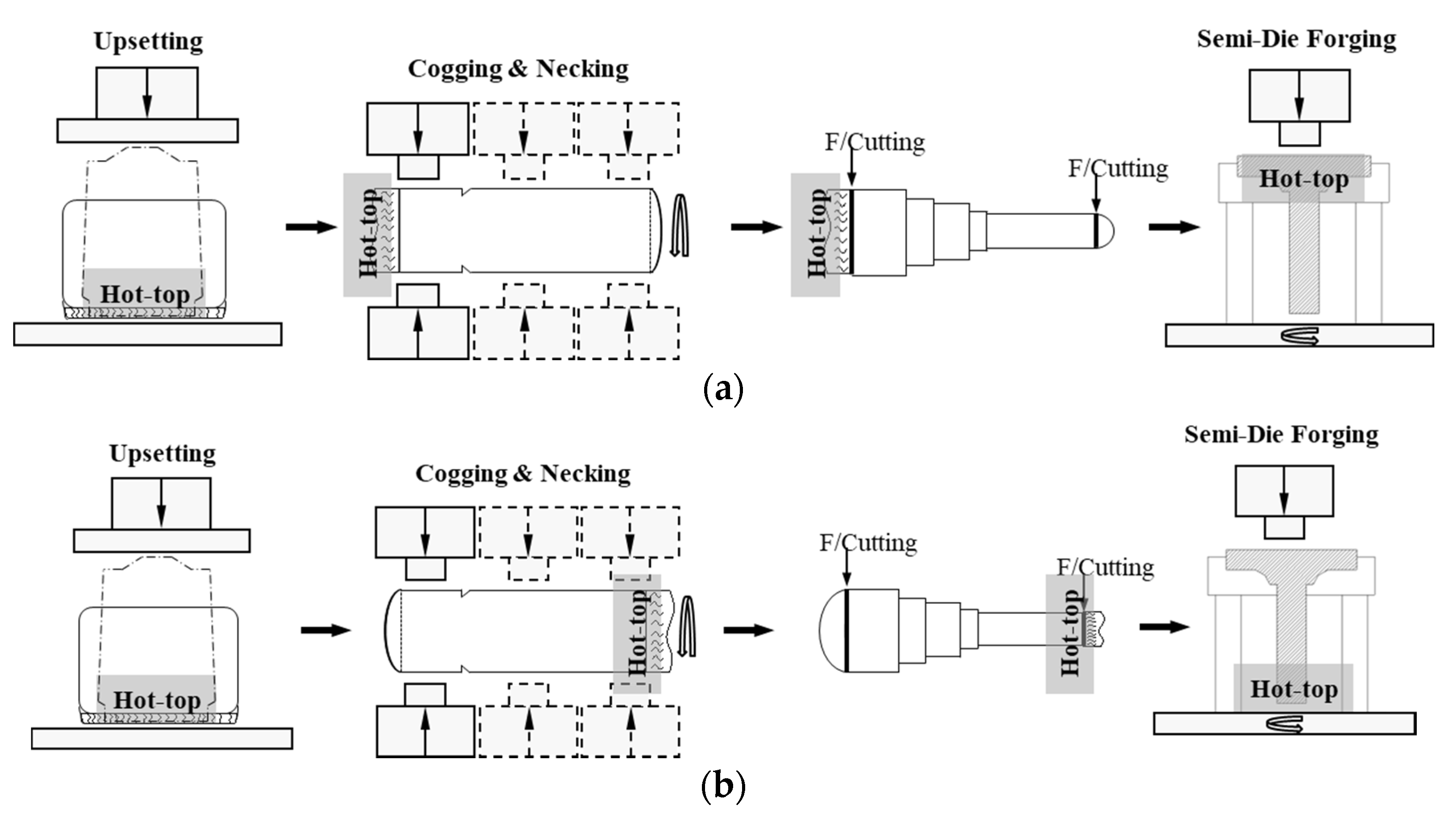

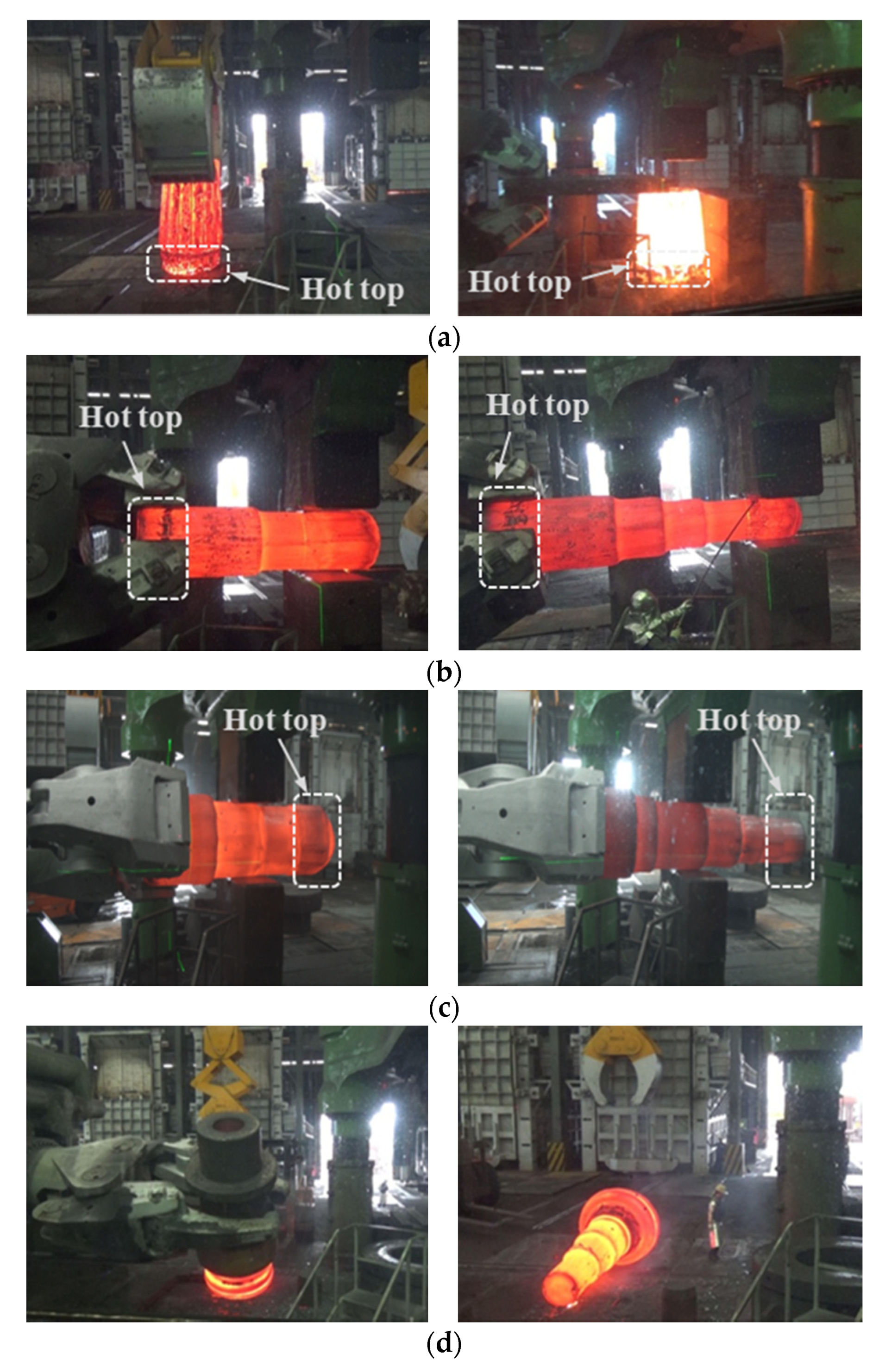

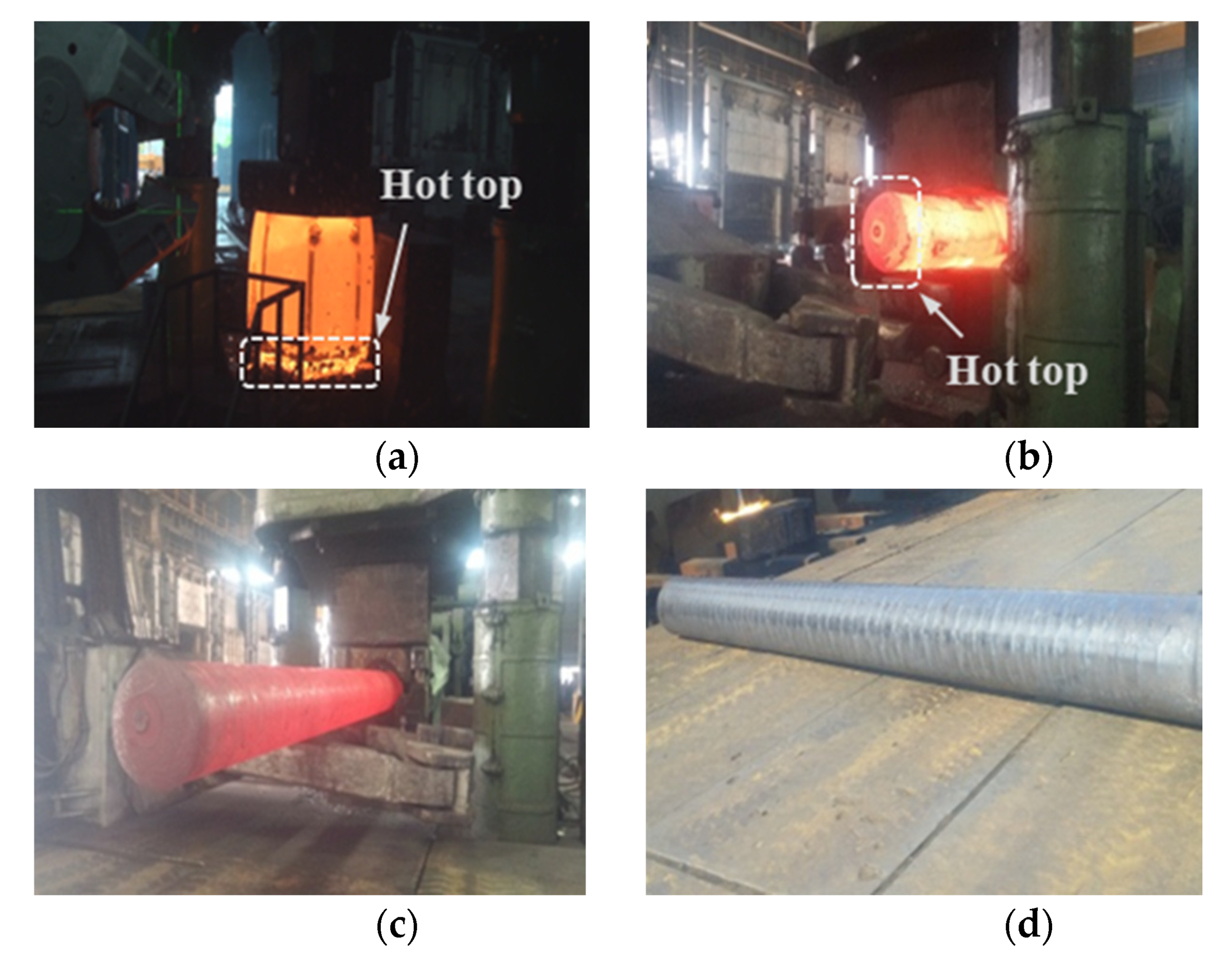

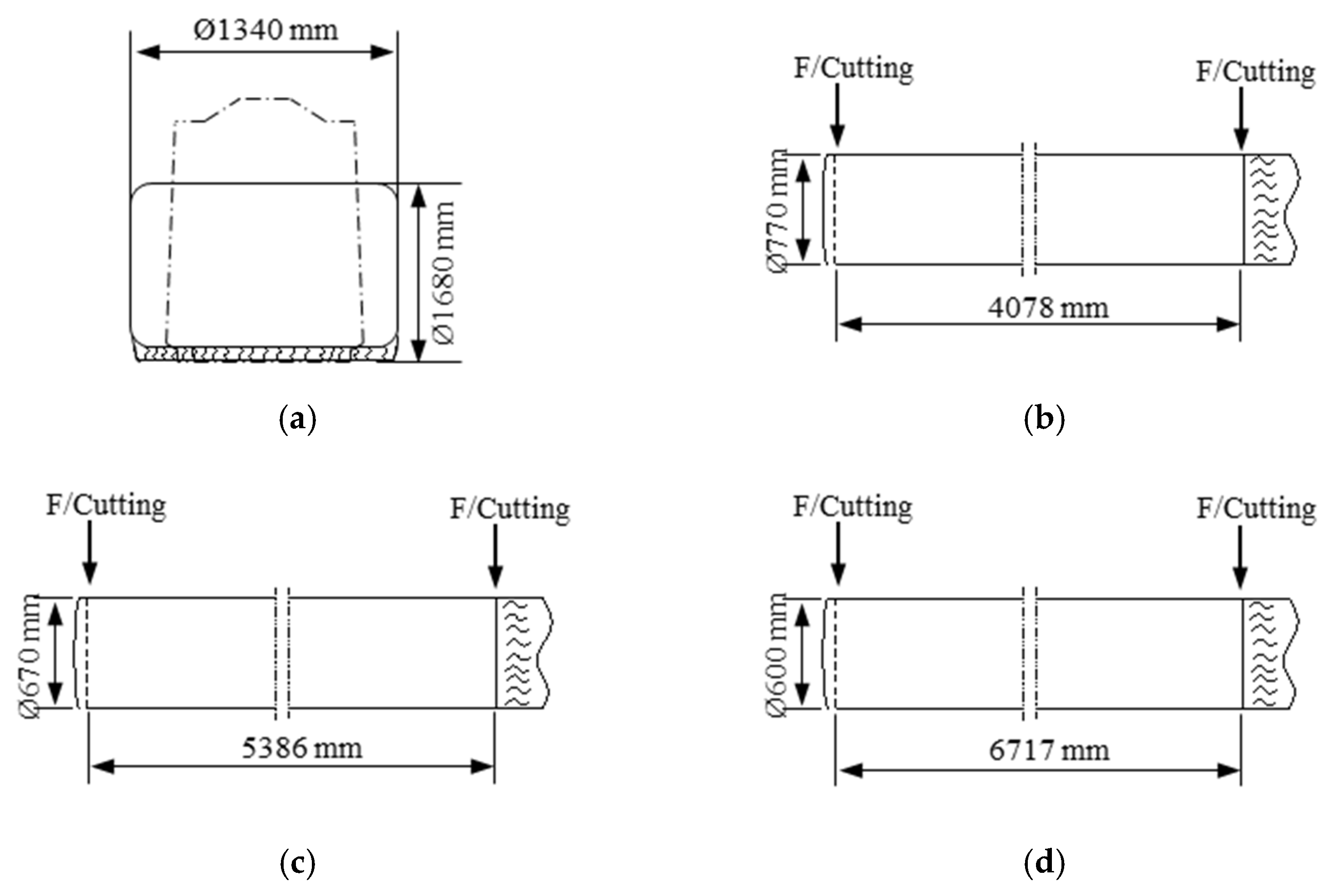

3.1. Main Shaft Forging

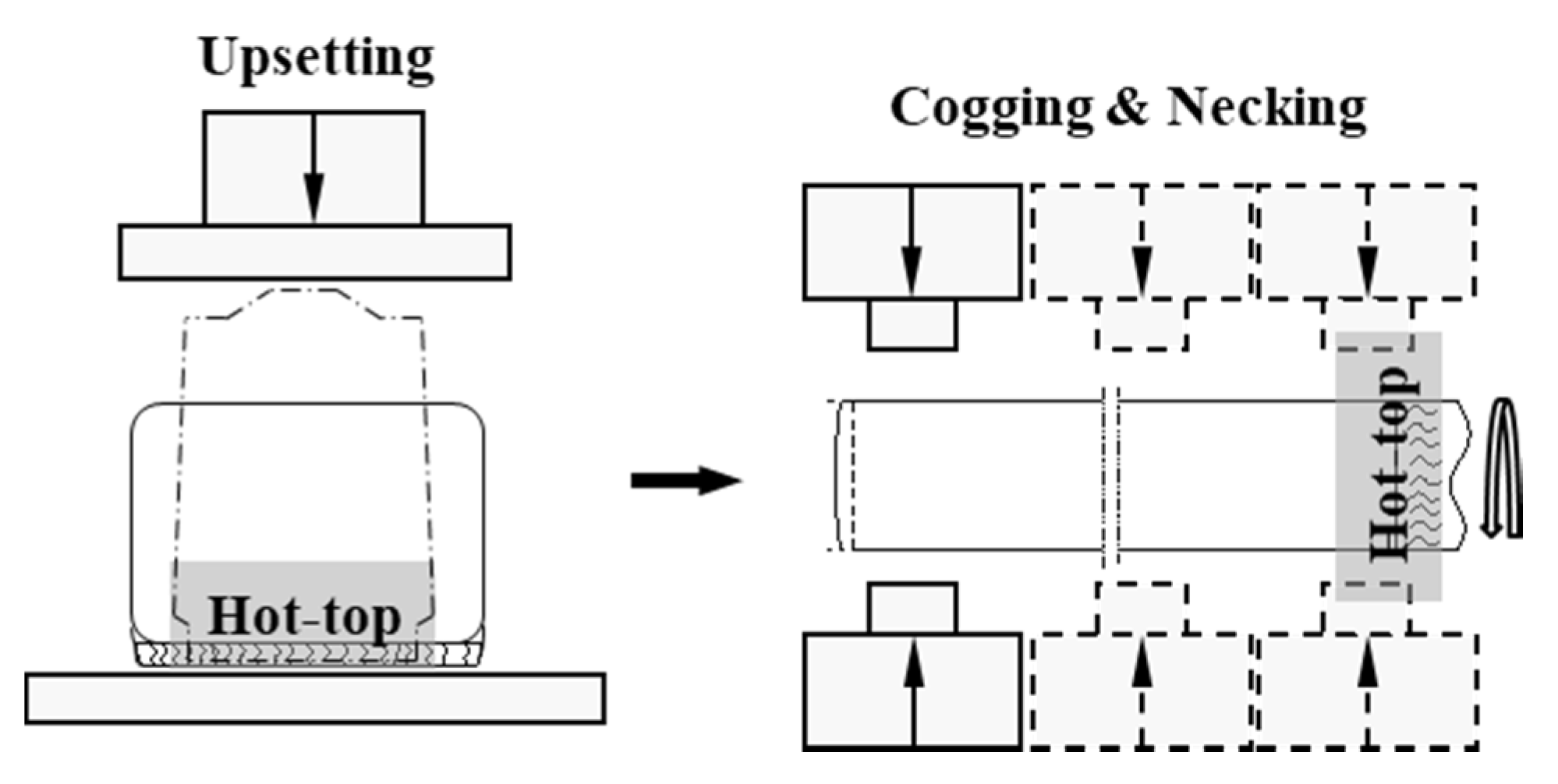

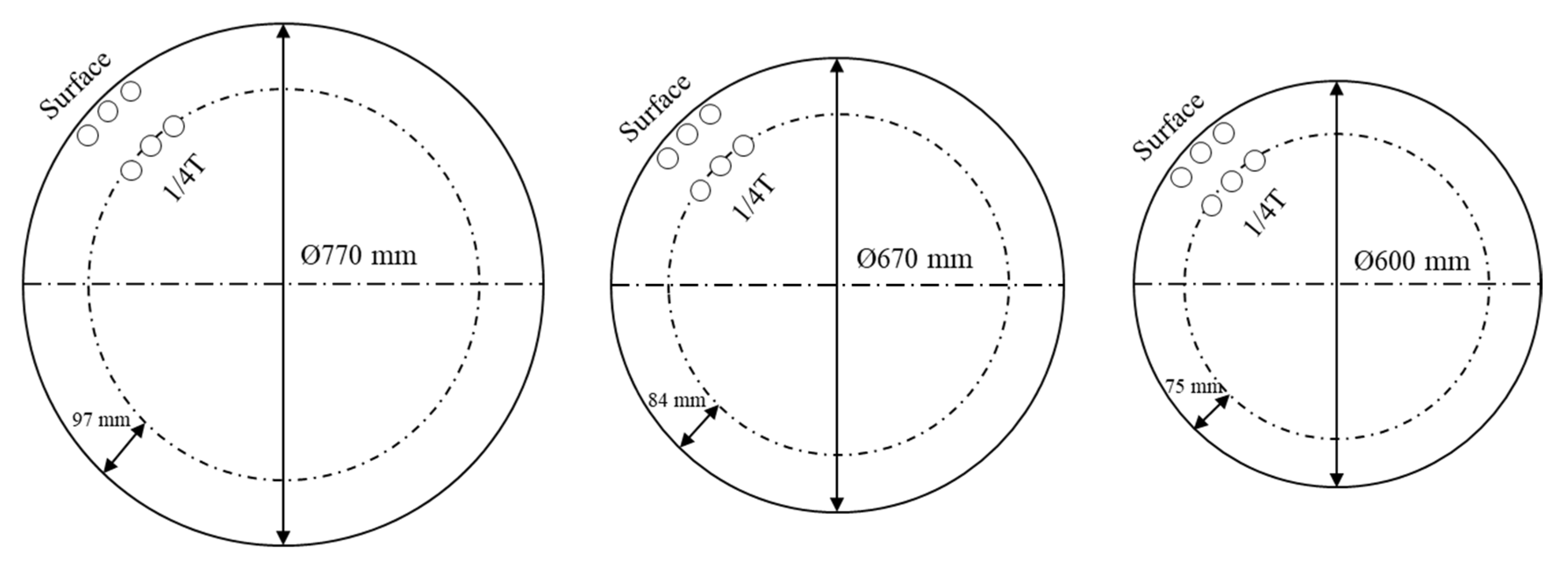

3.2. Round Bar Forging

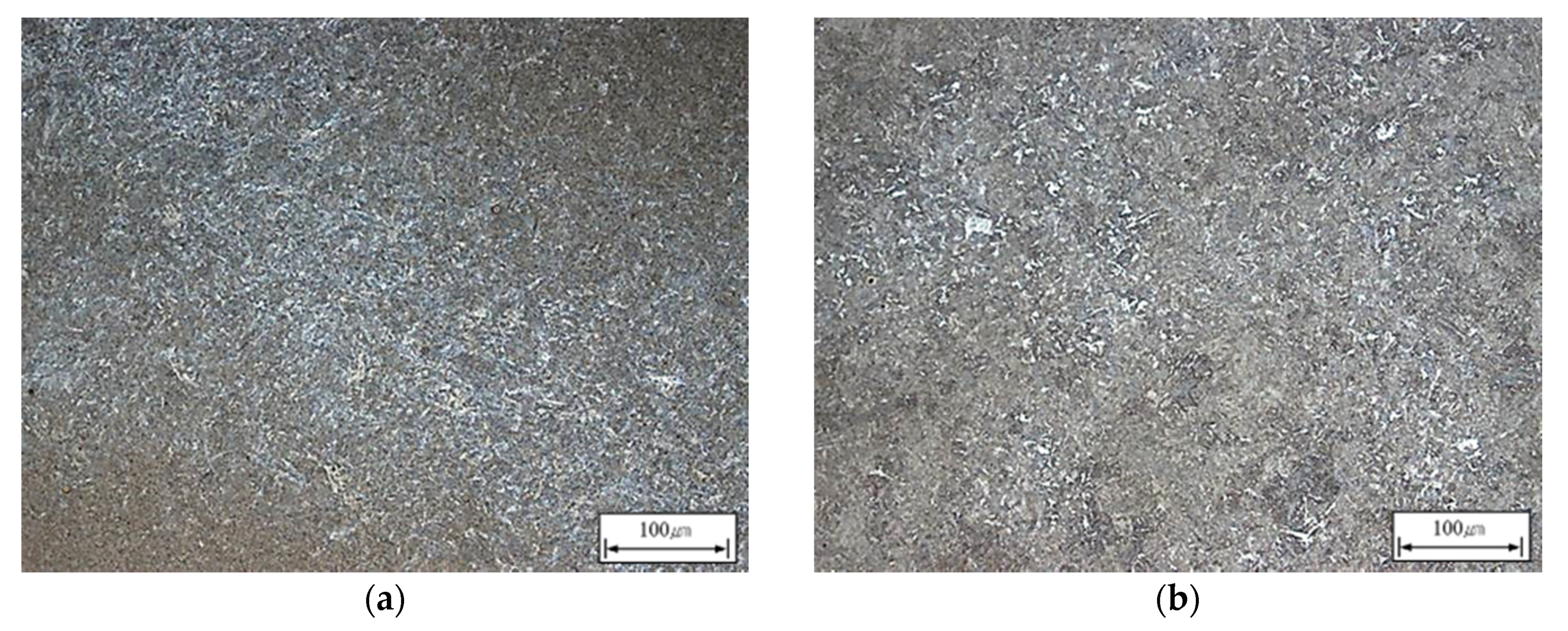

3.3. Mechanical Properties

4. Summary and Future Research

5. Conclusions

- (1)

- For cost-effective hot forging of heavy ingots, the size of the hot top should be decreased while increasing the forging reduction ratio.

- (2)

- As the quality of heavy ingots is commonly affected by internal voids, optimum hot-top heights and forging schedules must be determined to efficiently control the number and size of the internal voids.

- (3)

- The design of appropriate forging sequences that increase the reduction ratio of hot tops can enhance the void closure in the hot-top zone. Therefore, it is favorable to consider the forging geometry when designing the reduced hot top of heavy ingots.

- (4)

- According to the operational results implemented in the present work, the forging reduction ratio in the hot-top zone must be maximized. To produce acceptable shaft and bar products using ingots with reduced hot-top heights, forging reduction ratios of at least 3S and 4S are required, respectively.

- (5)

- The mechanical properties of shop floor products created from ingots with reduced hot-top heights are not inferior and are similar to those of conventional ingots with larger hot tops.

Author Contributions

Funding

Conflicts of Interest

References

- Bitterlin, M.; Loucif, A.; Charbonnier, N.; Jahazi, M.; Lapierre-Boire, L.P.; Morin, J.B. Cracking mechanisms in large size ingots of high nickel content low alloyed steel. Eng. Fail. Anal. 2016, 68, 122–131. [Google Scholar] [CrossRef]

- Harris, N.; Shahriari, D.; Jahazi, M. Development of a fast converging material specific void closure model during ingot forging. J. Manuf. Process. 2017, 26, 131–141. [Google Scholar] [CrossRef]

- Christiansen, P.; Hattel, J.H.; Bay, N.; Martins, P.A.F. Physical modelling and numerical simulation of V-die forging ingot with central void. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2014, 228, 2347–2356. [Google Scholar] [CrossRef]

- Saby, M.; Bernacki, M.; Bouchard, P.O. Understanding and modeling of void closure mechanisms in hot metal forming processes: A multiscale approach. Procedia Eng. 2014, 81, 137–142. [Google Scholar] [CrossRef]

- Choi, S.K.; Chun, M.S.; Van Tyne, C.J.; Moon, Y.H. Optimization of open die forging of round shapes using FEM analysis. J. Mater. Process. Technol. 2006, 172, 88–95. [Google Scholar] [CrossRef]

- Kim, P.H.; Chun, M.S.; Yi, J.J.; Moon, Y.H. Pass schedule algorithms for hot open die forging. J. Mater. Process. Technol. 2002, 130, 516–523. [Google Scholar] [CrossRef]

- Vasconcellos da Costa e Silva, A.L. The effects of non-metallic inclusions on properties relevant to the performance of steel in structural and mechanical applications. J. Mater. Res. Technol. 2019, 8, 2408–2422. [Google Scholar] [CrossRef]

- Gordon, W.A.; Van Tyne, C.J.; Moon, Y.H. Axisymmetric extrusion through adaptable dies—Part 1: Flexible velocity fields and power terms. Int. J. Mech. Sci. 2007, 49, 86–95. [Google Scholar] [CrossRef]

- Gordon, W.A.; Van Tyne, C.J.; Moon, Y.H. Axisymmetric extrusion through adaptable dies—Part 3: Minimum pressure streamlined die shapes. Int. J. Mech. Sci. 2007, 49, 104–115. [Google Scholar] [CrossRef]

- Lee, Y.S.; Lee, S.U.; Van Tyne, C.J.; Joo, B.D.; Moon, Y.H. Internal void closure during the forging of large cast ingots using a simulation approach. J. Mater. Process. Technol. 2011, 211, 1136–1145. [Google Scholar] [CrossRef]

- Moon, Y.H.; Kim, D.W.; Van Tyne, C.J. Analytical model for prediction of sidewall curl during stretch-bend sheet metal forming. Int. J. Mech. Sci. 2008, 50, 666–675. [Google Scholar] [CrossRef]

- Yi, H.K.; Kim, D.W.; Van Tyne, C.J.; Moon, Y.H. Analytical prediction of springback based on residual differential strain during sheet metal bending. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2008, 222, 117–129. [Google Scholar] [CrossRef]

- Flemings, M.C. Principles of control of soundness and homogeneity of large ingots. Scand. J. Metall. 1976, 5, 1–15. [Google Scholar]

- Tashiro, K.; Watanabe, S.; Kitagawa, I.; Tamura, I. Influence of mould design on the solidification and soundness of heavy forging ingots. Trans. Iron. Steel Inst. Jpn. 1983, 23, 312–321. [Google Scholar] [CrossRef]

- Scepi, M.; Andreoli, B.; Basevi, S.; Giorgetti, A.L. Thermal and metallurgical control of the efficiency of ingot moulds for forging ingots. Boll. Tec. Finsider 1981, 391, 77–82. [Google Scholar]

- Kermanpur, A.; Eskandari, M.; Purmohamad, H.; Soltani, M.A.; Shateri, R. Influence of mould design on the solidification of heavy forging ingots of low alloy steels by numerical simulation. Mater. Des. 2010, 31, 1096–1104. [Google Scholar] [CrossRef]

- Dang, W.D.; Wu, X.C.; Min, Y.A.; Wang, H.B. Numerical simulation research on the influence of riser height on inner quality of large forging ingot. Foundry Technol. 2010, 31, 753–758. [Google Scholar]

- Ma, W.; Zhao, J.H.; Song, G. Numerical simulation on influence of riser heat preservation conditions on solidification process of steel ingot. Hot Work. Technol. 2011, 21, 41–43. [Google Scholar]

- Zhbankov, I.G.; Perig, A.V. Forging of ingots without hot tops. Mater. Manuf. Process. 2013, 28, 229–235. [Google Scholar] [CrossRef]

- Xuan, F.Z.; Huang, X.; Tu, S.T. Comparisons of 30Cr2Ni4MoV rotor steel with different treatments on corrosion resistance in high temperature water. Mater. Des. 2008, 29, 1533–1539. [Google Scholar] [CrossRef]

- Shuster, R.E.; Cockcroft, S.L.; Maijer, D.M.; Yao, L.; Tripp, D.W.; Fiore, D. A three-dimensional transient thermal-fluid flow-compositional study of ingot casting during electron beam remelting of Ti–6Al–4V. Appl. Math. Modell. 2016, 40, 9095–9117. [Google Scholar] [CrossRef]

- Sengupa, J.; Cockcroft, S.L.; Maijer, D.M.; Larouche, A. Quantification of temperature, stress, and strain fields during the start-up phase of direct chill casting process by using a 3D fully coupled thermal and stress model for AA5182 ingots. Mater. Sci. Eng. A 2005, 397, 157–177. [Google Scholar] [CrossRef]

- Kim, S.Y.; Joo, B.D.; Shin, S.; Van Tyne, C.J.; Moon, Y.H. Discrete layer hydroforming of three-layered tubes. Int. J. Mach. Tools Manuf. 2013, 68, 56–62. [Google Scholar] [CrossRef]

- Park, K.S.; VanTyne, C.J.; Moon, Y.H. Process analysis of multistage forging by using finite element method. J. Mater. Process. Technol. 2007, 187, 586–590. [Google Scholar] [CrossRef]

- Li, Y.; Zhai, W.; Wang, Z.; Li, X.; Sun, L.; Li, J.; Zhao, G. Investigation on the material flow and deformation behavior during ultrasonic-assisted incremental forming of straight grooves. J. Mater. Res. Technol. 2020, 9, 433–454. [Google Scholar] [CrossRef]

- Lee, E.S.; Park, J.W.; Moon, Y.H. A study on electrochemical micromachining for fabrication of microgrooves in an air-lubricated hydrodynamic bearing. Int. J. Adv. Manuf. Technol. 2002, 20, 720–726. [Google Scholar] [CrossRef]

- Jeon, C.H.; Han, S.W.; Joo, B.D.; Van Tyne, C.J.; Moon, Y.H. Deformation analysis for cold rolling of Al-Cu double layered sheet by physical modeling and finite element method. Met. Mater. Int. 2013, 19, 1069–1076. [Google Scholar] [CrossRef]

- Lebon, G.S.B.; Li, H.T.; Patel, J.B.; Assadi, H.; Fan, Z. Numerical modelling of melt-conditioned direct-chill casting. Appl. Math. Modell. 2020, 77, 1310–1330. [Google Scholar] [CrossRef]

- Kil, T.D.; Lee, J.M.; Moon, Y.H. Quantitative formability estimation of ring rolling process by using deformation processing map. J. Mater. Process. Technol. 2015, 220, 224–230. [Google Scholar] [CrossRef]

- Koshikawa, T.; Bellet, M.; Gandin, C.A.; Yamamura, H.; Bobadilla, M. Experimental study and two-phase numerical modeling of macrosegregation induced by solid deformation during punch pressing of solidifying steel ingots. Acta Mater. 2017, 124, 513–527. [Google Scholar] [CrossRef]

- Wang, J.; Fu, P.; Liu, H.; Li, D.; Li, Y. Shrinkage porosity criteria and optimized design of a 100-ton 30Cr2Ni4MoV forging ingot. Mater. Des. 2012, 35, 446–456. [Google Scholar] [CrossRef]

- Maduriya, B.; Yadav, N.P. Prediction of Solidification Behaviour of Alloy Steel Ingot Casting. Mater. Today Proc. 2018, 5, 20380–20390. [Google Scholar] [CrossRef]

- Chen, Q.; Shen, H. A finite element formulation for macrosegregation during alloy solidification using a fractional step method and equal-order elements. Comput. Mater. Sci. 2018, 154, 335–345. [Google Scholar] [CrossRef]

- Pardeshi, R. Computational model for multi alloy casting of aluminum rolling ingots. J. Manuf. Process. 2016, 21, 23–29. [Google Scholar] [CrossRef]

- Niyama, E.; Uchida, T.; Morikawa, M. Predicting shrinkage in large steel castings from temperature gradient calculations. Int. Cast Met. J. 1981, 6, 16–22. [Google Scholar]

- Monroe, C.; Beckermann, C. Prediction of hot tearing using a dimensionless Niyama criterion. JOM 2014, 66, 1439–1445. [Google Scholar] [CrossRef]

- Khaled, I. Prediction of shrinkage porosity in Ti-46Al-8Nb tilt-casting using the Niyama criterion function. Int. J. Metalcast. 2013, 7, 35–42. [Google Scholar] [CrossRef]

- Bayani, H.; Mirbagheri, S.M.H.; Barzegari, M.; Firoozi, S. Simulation of unconstrained solidification of A356 aluminum alloy on distribution of micro/macro shrinkage. J. Mater. Res. Technol. 2014, 3, 55–70. [Google Scholar] [CrossRef]

- Jang, J.H.; Lee, J.H.; Joo, B.D.; Moon, Y.H. Flow characteristics of aluminum coated boron steel in hot press forming. Trans. Nonferrous Met. Soc. China 2009, 19, 913–916. [Google Scholar] [CrossRef]

- Kim, E.S.; Lee, K.H.; Moon, Y.H. A feasibility study of the partial squeeze and vacuum die casting process. J. Mater. Process. Technol. 2000, 105, 42–48. [Google Scholar] [CrossRef]

- Vizman, D.; Friedrich, J.; Mueller, G. 3D time-dependent numerical study of the influence of the melt flow on the interface shape in a silicon ingot casting process. J. Cryst. Growth 2007, 303, 231–235. [Google Scholar] [CrossRef]

- Jung, H.K.; Kang, C.G.; Moon, Y.H. Induction heating of semisolid billet and control of globular microstructure to prevent coarsening phenomena. J. Mater. Eng. Perform. 2000, 9, 12–23. [Google Scholar] [CrossRef]

- Brotzu, A.; Felli, F.; Mondal, A.; Pilone, D. Production issues in the manufacturing of TiAl turbine blades by investment casting. Procedia Struct. Integrity 2020, 25, 79–87. [Google Scholar] [CrossRef]

- Hwang, T.W.; Woo, Y.Y.; Han, S.W.; Moon, Y.H. Functionally graded properties in directed-energy-deposition titanium parts. Opt. Laser Technol. 2018, 105, 80–88. [Google Scholar] [CrossRef]

- Kim, D.K.; Woo, Y.Y.; Park, K.S.; Sim, W.J.; Moon, Y.H. Advanced induction heating system for hot stamping. Int. J. Adv. Manuf. Technol. 2018, 99, 583–593. [Google Scholar] [CrossRef]

- Tamura, I.; Watanabe, S.; Watanabe, K.; Nakajima, K. Development of new processes for control of internal deformation and internal stress in hot free forging of heavy ingots. Trans. Iron. Steel Inst. Jpn. 1984, 24, 101–106. [Google Scholar] [CrossRef][Green Version]

- ASTM A370. Standard Test Methods and Definitions for Mechanical Testing of Steel Products; Annual Book of ASTM Standards: West Conshohocken, PA, USA, 2018. [Google Scholar]

| Ingot Type | Weight (kg) | |||

|---|---|---|---|---|

| Total | Body | Hot Top | Base | |

| 16% hot top | 16,100 | 13,324 | 2576 | 200 |

| 8% hot top | 14,683 | 13,324 | 1159 | 200 |

| Free hot top | 13,524 | 13,324 | 0 | 200 |

| Condition | Value (Unit) |

|---|---|

| Ingot material | 34CrNiMo6 |

| Mold material | FC200 (3.8C-1.0Si-0.4Mn) |

| Computation mode | Thermomechanical mode |

| Analysis model | 1/8 model |

| Ingot body weight | 13,324 [kg] |

| Superheat | 30 (°C) |

| Element type | Tetrahedron |

| Element number | 34,526 |

| Fe | C | Si | Mn | P | S | Cu | Ni | Cr | Mo | Al | V |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Bal | 0.33 | 0.31 | 0.60 | 0.015 | 0.003 | 0.07 | 1.59 | 1.70 | 0.18 | 0.026 | 0.047 |

| Test No. | Forging Process | Hot-Top Type | Forging Ratio |

|---|---|---|---|

| Case 1 | Method 1 | 16% hot top | 2.2S–4.5S |

| Case 2 | Method 1 | 8% hot top | 2.2S–4.5S |

| Case 3 | Method 2 | 8% hot top | 2.2S–4.5S |

| No. | 2.2S | 3.1S | 3.8S | 4.5S |

|---|---|---|---|---|

| Case 1 | No Indication | No Indication | No Indication | No Indication |

| Case 2 | Defects in flange zone | No Indication | No Indication | No Indication |

| Case 3 | No Indication | No Indication | No Indication | No Indication |

| Forging Ratio | Internal Defects | Forging Hit Number |

|---|---|---|

| 3S | Defects | 1080 |

| 4S | No Indication | 1260 |

| 5S | No Indication | 1440 |

| Hot-Top Type | Test Number | Position | Tensile Properties | |||

|---|---|---|---|---|---|---|

| Yield Strength (MPa) | Tensile Strength (MPa) | Elongation | Reduction of Area | |||

| 16% Hot-top Ingot (Case 1, method 1) | 1 | Surface | 808.8 | 918.1 | 21.0 | 64.2 |

| 1/4T | 772.5 | 892.2 | 21.4 | 65.4 | ||

| 2 | Surface | 806.7 | 915.0 | 21.3 | 64.1 | |

| 1/4T | 770.5 | 889.0 | 21.5 | 65.6 | ||

| 3 | Surface | 812.2 | 922.6 | 21.1 | 64.1 | |

| 1/4T | 780.3 | 897.4 | 21.9 | 65.6 | ||

| Average | Surface | 809.2 | 918.6 | 21.1 | 64.1 | |

| 1/4T | 774.4 | 892.9 | 21.6 | 65.5 | ||

| 8% Hot-top Ingot (Case 3, method 2) | 1 | Surface | 809.0 | 915.4 | 21.0 | 63.9 |

| 1/4T | 780.9 | 899.1 | 21.4 | 65.0 | ||

| 2 | Surface | 810.9 | 920.2 | 20.8 | 63.7 | |

| 1/4T | 777.5 | 888.8 | 21.5 | 65.7 | ||

| 3 | Surface | 803.7 | 912.4 | 21.4 | 64.2 | |

| 1/4T | 780.5 | 903.4 | 21.7 | 64.7 | ||

| Average | Surface | 807.9 | 916.0 | 21.1 | 63.9 | |

| 1/4T | 779.6 | 897.1 | 21.5 | 65.1 | ||

| Forging Ratio | Position | Tensile Properties | |||

|---|---|---|---|---|---|

| Yield Strength (MPa) | Tensile Strength (MPa) | Elongation | Reduction of Area | ||

| 3S | Surface | 591 | 722 | 18 | 60 |

| 1/4T | 582 | 711 | 17 | 60 | |

| 4S | Surface | 608 | 739 | 19 | 61 |

| 1/4T | 601 | 733 | 19 | 60 | |

| 5S | Surface | 621 | 760 | 20 | 65 |

| 1/4T | 617 | 754 | 20 | 64 | |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, N.Y.; Ko, D.-C.; Kim, Y.; Han, S.W.; Oh, I.Y.; Moon, Y.H. Feasibility of Reduced Ingot Hot-Top Height for the Cost-Effective Forging of Heavy Steel Ingots. Materials 2020, 13, 2916. https://doi.org/10.3390/ma13132916

Kim NY, Ko D-C, Kim Y, Han SW, Oh IY, Moon YH. Feasibility of Reduced Ingot Hot-Top Height for the Cost-Effective Forging of Heavy Steel Ingots. Materials. 2020; 13(13):2916. https://doi.org/10.3390/ma13132916

Chicago/Turabian StyleKim, Nam Yong, Dae-Cheol Ko, Yangjin Kim, Sang Wook Han, Il Yeong Oh, and Young Hoon Moon. 2020. "Feasibility of Reduced Ingot Hot-Top Height for the Cost-Effective Forging of Heavy Steel Ingots" Materials 13, no. 13: 2916. https://doi.org/10.3390/ma13132916

APA StyleKim, N. Y., Ko, D.-C., Kim, Y., Han, S. W., Oh, I. Y., & Moon, Y. H. (2020). Feasibility of Reduced Ingot Hot-Top Height for the Cost-Effective Forging of Heavy Steel Ingots. Materials, 13(13), 2916. https://doi.org/10.3390/ma13132916