Wear Simulation of Ceramic-on-Crosslinked Polyethylene Hip Prostheses: A New Non-Oxide Silicon Nitride versus the Gold Standard Composite Oxide Ceramic Femoral Heads

Abstract

:1. Introduction

2. Materials and Methods

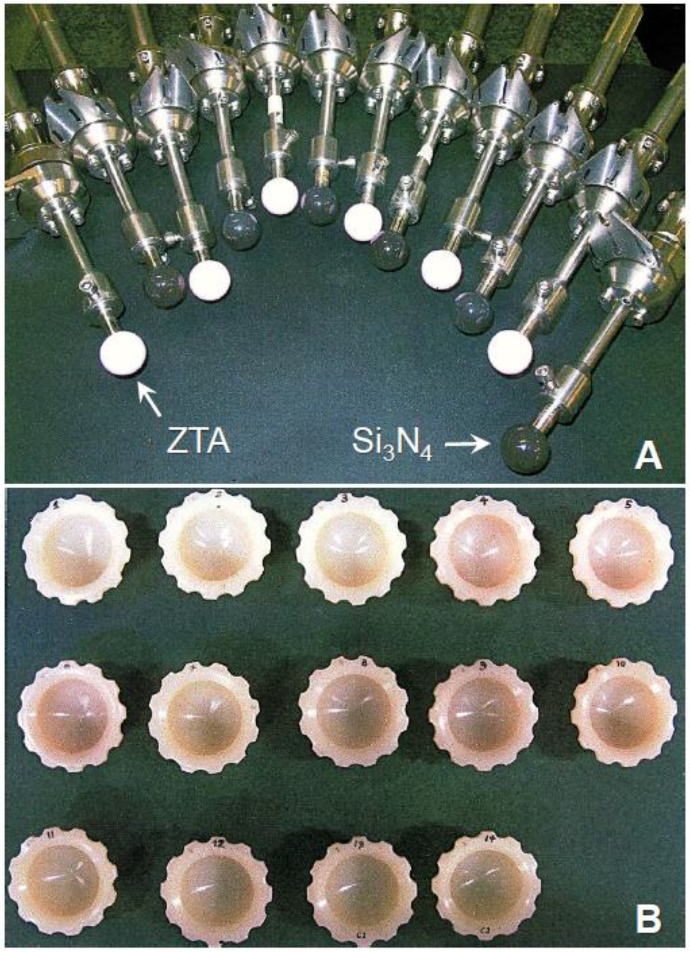

2.1. Specimens Tested

2.2. Experimental Wear Testing Details

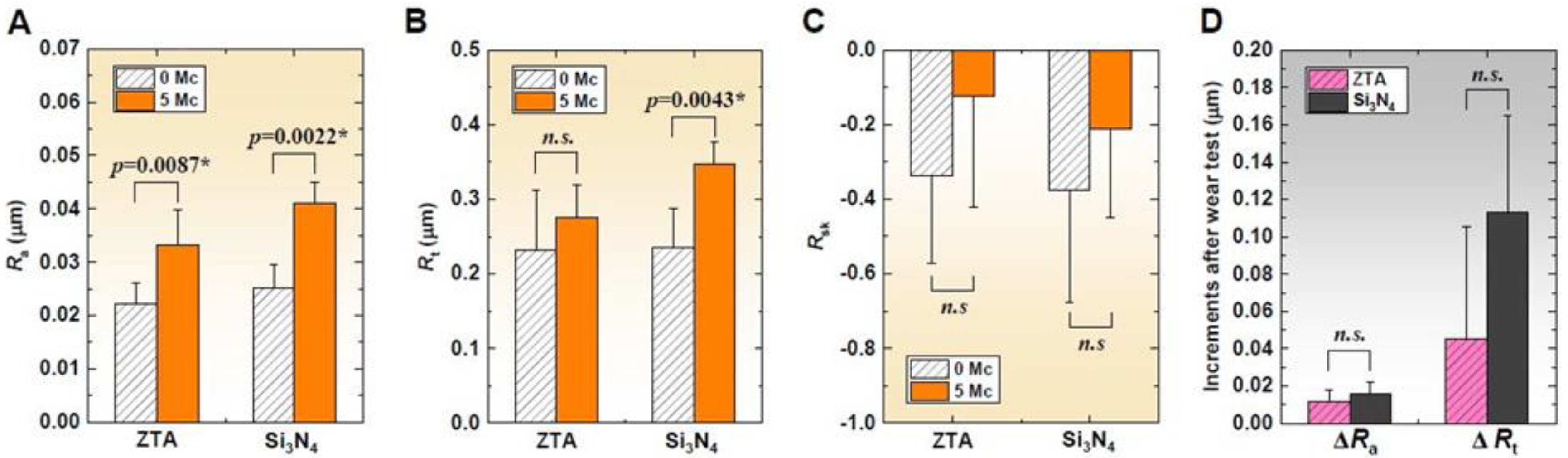

2.3. Surface Roughness Measurements

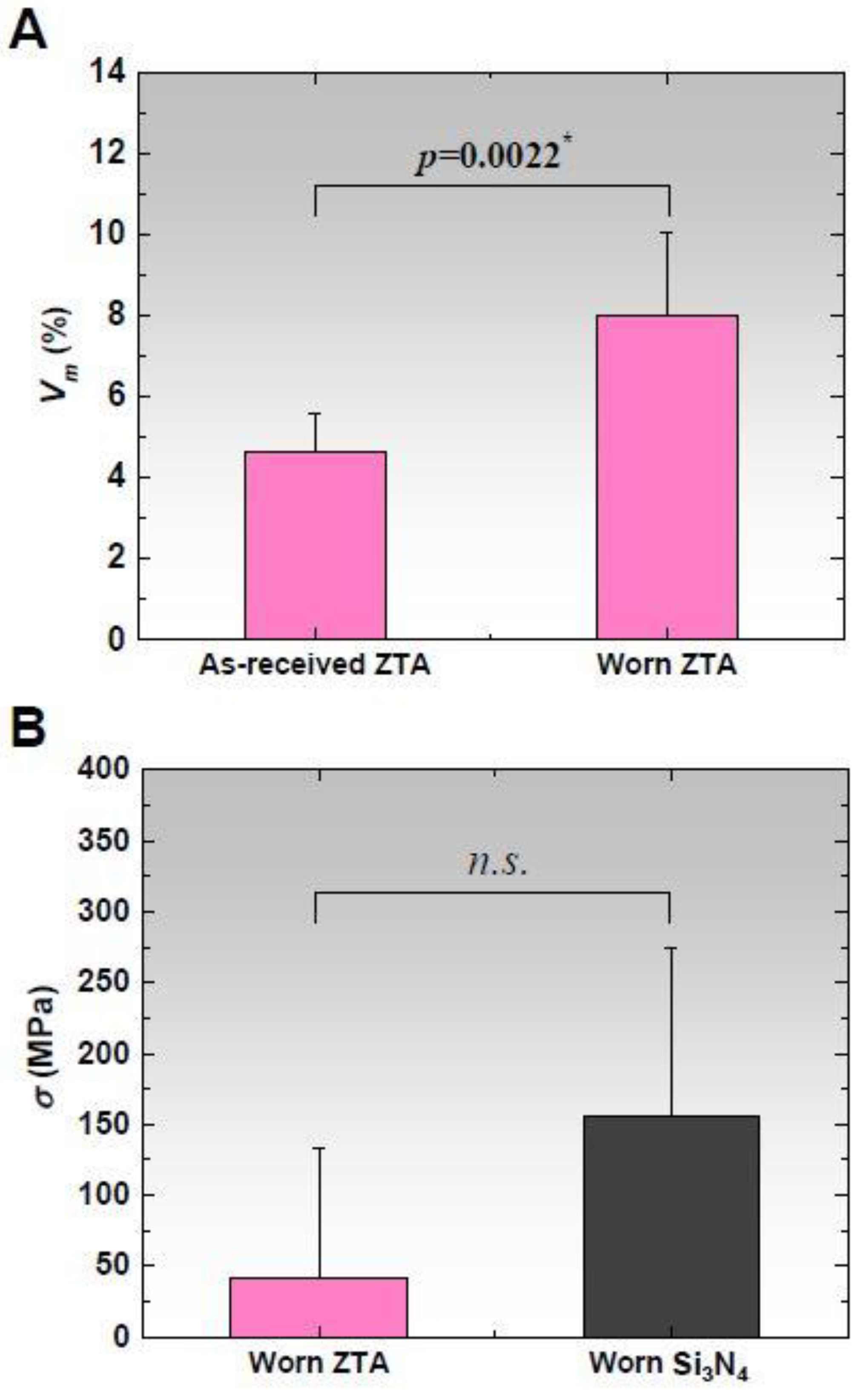

2.4. Surface Phase Contents and Stress Measurements

2.5. Statistical Analysis

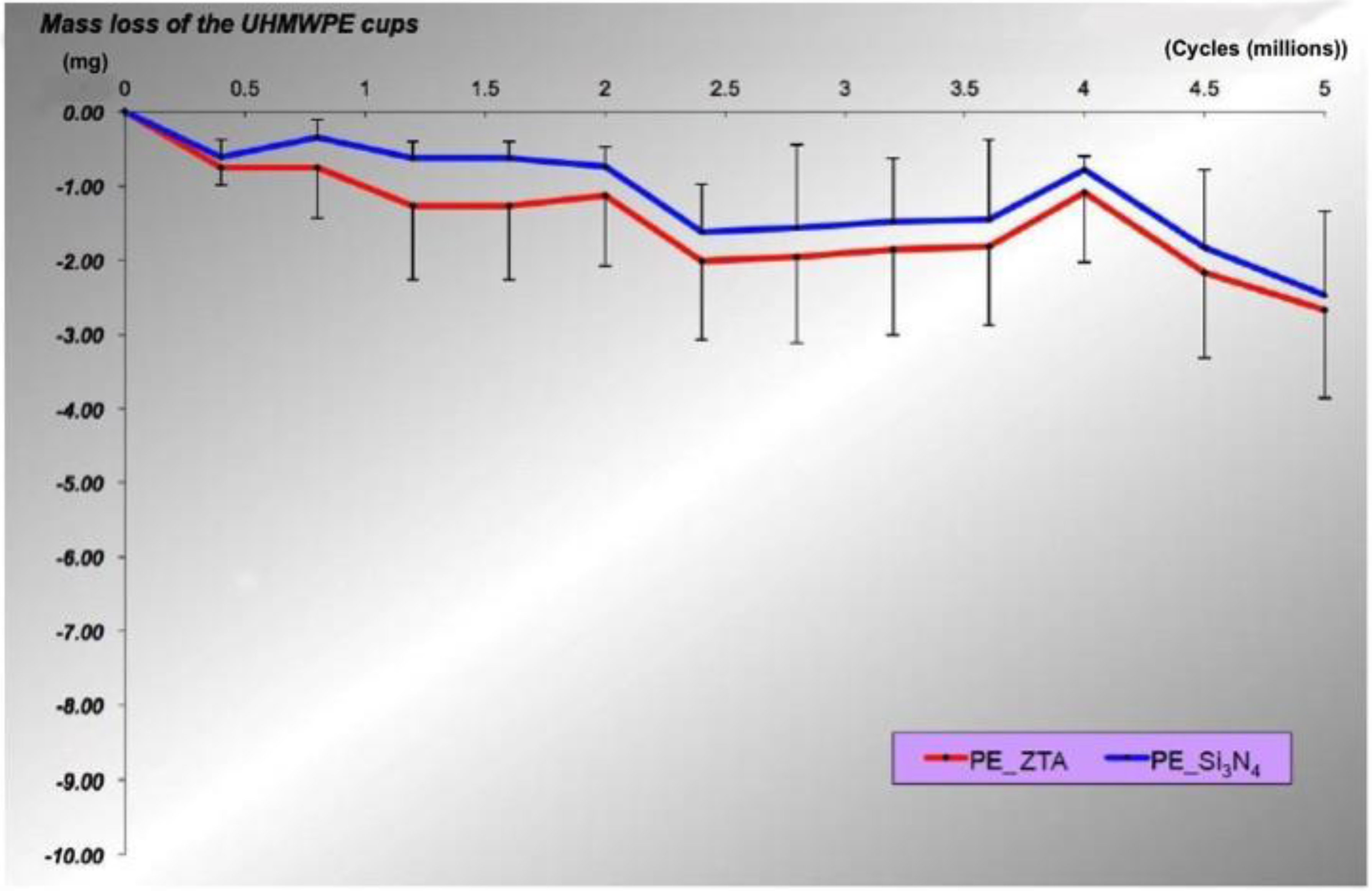

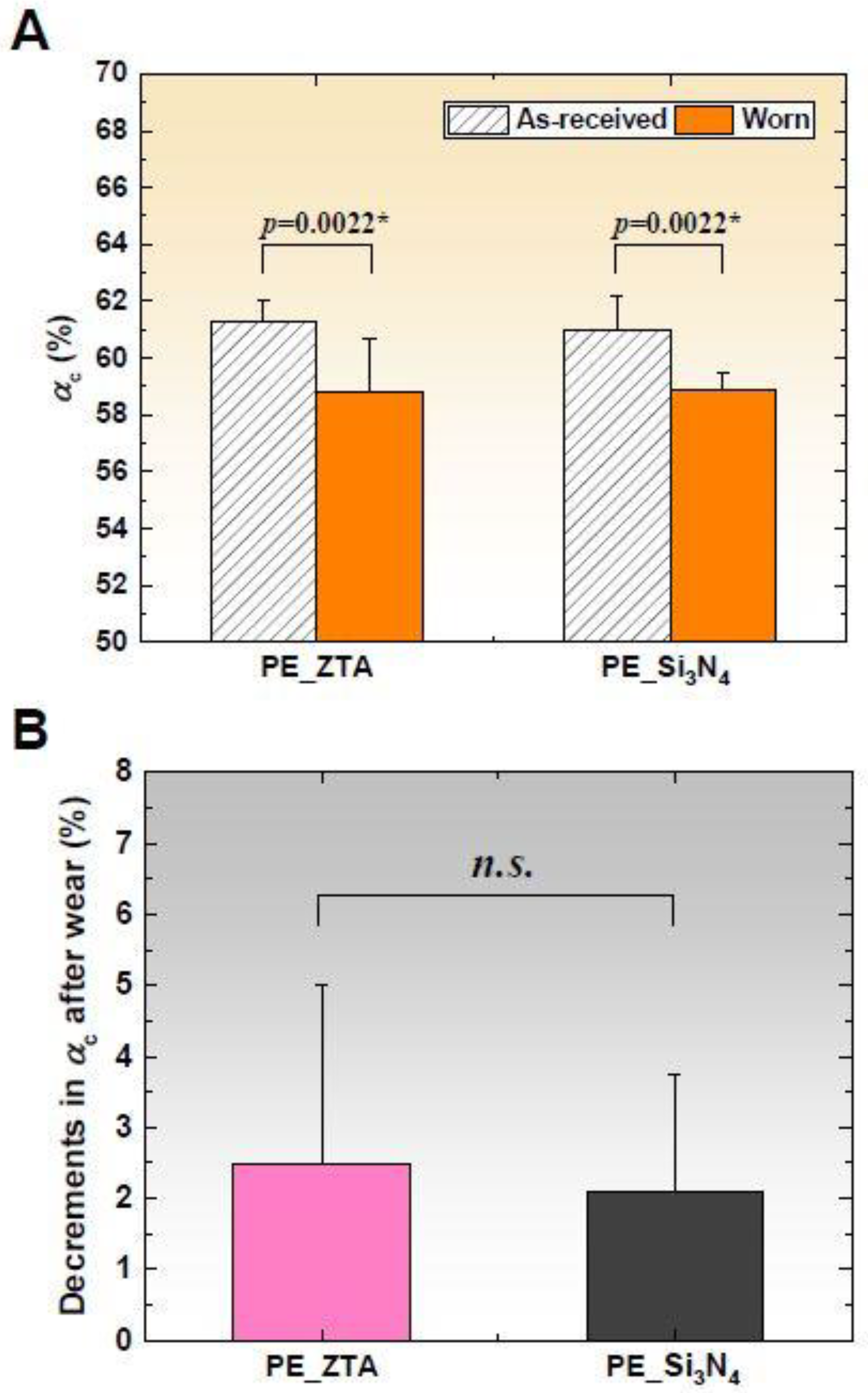

3. Results

4. Discussion

5. Conclusions

- (i)

- The wear data from hip simulation tests suggest that Si3N4 can be considered as a candidate material for femoral head components in innovative Ceramic-on-Polyethylene (CoP) hip joint articulations.

- (ii)

- The wear performance of Si3N4 femoral heads was at least equivalent to that of the gold standard BIOLOX®delta after a 5 Mc test with negligible wear induced by both bioceramics against Vit-E XLPE counterparts.

- (iii)

- Considering that the fracture toughness of Si3N4 components is superior to any other bioceramic so far tested [12], the present wear data represent positive news for the future development of long-lasting hip components.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Harris, W.H. The problem is osteolysis. Clin. Orthop. Relat. Res. 1995, 311, 46–53. [Google Scholar]

- Affatato, S.; Freccero, N.; Taddei, P. The biomaterials challenge: A comparison of polyethylene wear using a hip joint simulator. J. Mech. Behav. Biomed. Mater. 2016, 53, 40–48. [Google Scholar] [CrossRef]

- Yamamoto, K.; Tateiwa, T.; Takahashi, Y. Vitamin E-stabilized highly crosslinked polyethylenes: The role and effectiveness in total hip arthroplasty. J. Orthop. Sci. 2017, 22, 384–390. [Google Scholar] [CrossRef]

- Oral, E.; Godleski Beckos, C.; Malhi, A.S.; Muratoglu, O.K. The effects of high dose irradiation on the cross-linking of vitamin E-blended ultrahigh molecular weight polyethylene. Biomaterials 2008, 29, 3557–3560. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Oral, E.; Muratoglu, O.K. Vitamin E diffused, highly crosslinked UHMWPE: A review. Int. Orthop. 2011, 35, 215–223. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Affatato, S.; Ruggiero, A.; De Mattia, J.S.; Taddei, P. Does metal transfer affect the tribological behaviour of femoral heads? Roughness and phase transformation analyses on retrieved zirconia and Biolox® Delta composites. Compos. Part B Eng. 2016, 92, 290–298. [Google Scholar] [CrossRef]

- Affatato, S.; Ruggiero, A.; Merola, M. Advanced biomaterials in hip joint arthroplasty. A review on polymer and ceramics composites as alternative bearings. Compos. Part B Eng. 2015, 83, 276–283. [Google Scholar] [CrossRef]

- Affatato, S.; Modena, E.; Toni, A.; Taddei, P. Retrieval analysis of three generations of Biolox® femoral heads: Spectroscopic and SEM characterization. J. Mech. Behav. Biomed. Mater. 2012, 13, 118–128. [Google Scholar] [CrossRef]

- Kurtz, S.M.; Kocagöz, S.; Arnholt, C.; Huet, R.; Ueno, M.; Walter, W.L. Advances in zirconia toughened alumina biomaterials for total joint replacement. J. Mech. Behav. Biomed. Mater. 2014, 31, 107–116. [Google Scholar] [CrossRef] [Green Version]

- Pezzotti, G.; Yamada, K.; Sakakura, S.; Pitto, R.P. Raman spectroscopic analysis of advanced ceramic composite for hip prosthesis. J. Am. Ceram. Soc. 2008, 91, 1199–1206. [Google Scholar] [CrossRef]

- Pezzotti, G.; Affatato, S.; Rondinella, A.; Yorifuji, M.; Marin, E.; Zhu, W.; McEntire, B.; Bal, S.B.; Yamamoto, K. In vitro versus in vivo phase instability of zirconia-toughened alumina femoral heads: A critical comparative assessment. Materials 2017, 10, 466. [Google Scholar] [CrossRef] [Green Version]

- Bal, B.S.; Rahaman, M.N. Orthopedic applications of silicon nitride ceramics. Acta Biomater. 2012, 8, 2889–2898. [Google Scholar] [CrossRef]

- Bal, B.S.; Khandkar, A.; Lakshminarayanan, R.; Clarke, I.; Hoffman, A.A.; Rahaman, M.N. Fabrication and testing of silicon nitride bearings in total hip arthroplasty: Winner of the 2007 “HAP” PAUL. Award. J Arthroplast. 2009, 24, 110–116. [Google Scholar] [CrossRef] [PubMed]

- Ma, L.; Rainforth, W.M. A study of Biolox delta subject to water lubricated reciprocating wear. Tribol. Int. 2010, 43, 1872–1881. [Google Scholar] [CrossRef]

- Nečas, D.; Vrbka, M.; Urban, F.; Gallo, J.; Křupka, I.; Hartl, M. In situ observation of lubricant film formation in THR considering real conformity: The effect of diameter clearance and material. J. Mech. Behav. Biomed. Mater. 2017, 69, 66–74. [Google Scholar] [CrossRef]

- Nečas, D.; Vrbka, M.; Křupka, I.; Hartl, M.; Galandakova, A. Lubrication within hip replacements—Implication for ceramic-on-hard bearing couples. J. Mech. Behav. Biomed. Mater. 2016, 61, 371–383. [Google Scholar] [CrossRef]

- Parkes, M.; Sayer, K.; Goldhofer, M.; Cann, P.; Walter, W.L.; Jeffers, J. Zirconia phase transformation in retrieved, wear simulated, and artificially aged ceramic femoral heads. J. Orthop. Res. 2017, 35, 2781–2789. [Google Scholar] [CrossRef] [Green Version]

- Clarke, I.C.; Green, D.D.; Williams, P.A.; Kubo, K.; Kubo, K.; Pezzotti, G.; Lombardi, A.; Turnbull, A.; Donaldson, T.K. Hip-simulator wear studies of an alumina-matrix composite (AMC) ceramic compared to retrieval studies of AMC balls with 1–7 years follow-up. Wear 2009, 267, 702–709. [Google Scholar] [CrossRef]

- Al-Hajjar, M.; Fisher, J.; Tipper, J.T.; Williams, S.; Jennings, L.M. Wear of 36-mm BIOLOX® Delta ceramic-on-ceramic bearing in total hip replacements under edge loading conditions. Proc. Inst. Mech. Eng. H 2013, 227, 535–542. [Google Scholar] [CrossRef]

- Affatato, S.; Spinelli, M.; Zavalloni, M.; Traina, F.; Carmignato, S.; Toni, A. Mixing and matching in ceramic-on-metal hip arthroplasty: An in-vitro hip simulator study. J. Biomech. 2009, 42, 2439–2446. [Google Scholar] [CrossRef]

- Affatato, S.; Torrecillas, R.; Taddei, P.; Rocchi, M.; Fagnano, C.; Ciapetti, G.; Toni, A. Advanced nanocomposite materials for orthopaedic applications. I. A long-term in vitro wear study of zirconia-toughened alumina. J. Biomed. Mater. Res. Part. B Appl. Biomater. 2006, 78B, 76–82. [Google Scholar] [CrossRef] [PubMed]

- Affatato, S.; Goldoni, M.; Testoni, M.; Toni, A. Mixed oxides prosthetic ceramic ball heads. Part 3: Effect of the ZrO2 fraction on the wear of ceramic on ceramic hip joint prostheses. A long-term in vitro wear study. Biomaterials 2001, 22, 717–723. [Google Scholar] [CrossRef]

- Affatato, S.; Bersaglia, G.; Junqiang, Y.; Traina, F.; Toni, A.; Viceconti, M. The predictive power of surface profile parameters on the amount of wear measured in vitro on metal-on-polyethylene artificial hip joints. Proc. Inst. Mech. Eng. H 2006, 220, 457–464. [Google Scholar] [CrossRef]

- Takahashi, Y.; Puppulin, L.; Zhu, W.; Pezzotti, G. Raman tensor analysis of ultra-high molecular weight polyethylene and its application to study retrieved hip joint components. Acta Biomater. 2010, 6, 3583–3594. [Google Scholar] [CrossRef]

- Pezzotti, G. Raman spectroscopy of biomedical polyethylenes. Acta Biomater. 2017, 55, 28–99. [Google Scholar] [CrossRef]

- Katagiri, G.; Ishida, H.; Ishitani, A.; Masaki, T. Direct determination by a Raman microprobe of transformation zone size in Y2O3-containing tetragonal ZrO2 polycrystals. In Science and Technology of Zirconia III; Advances in Ceramics; Somiya, S., Yamamoto, N., Yanagida, H., Eds.; American Ceramic Society: Columbus, OH, USA, 1988; Volume 24, pp. 537–544. [Google Scholar]

- Pezzotti, G. Stress microscopy and confocal Raman imaging of load-bearing surfaces in artificial hip joints. Expert. Rev. Med. Devices 2007, 4, 165–189. [Google Scholar] [CrossRef] [PubMed]

- Takahashi, Y.; Yamamoto, K.; Shishido, T.; Masaoka, T.; Tateiwa, T.; Puppulin, L.; Pezzotti, G. Strain-induced microstructural rearrangement in ultra-high molecular weight polyethylene for hip joints: A comparison between conventional and vitamin E-infused highly-crosslinked liners. J. Mech. Behav. Biomed. Mater. 2014, 31, 31–44. [Google Scholar] [CrossRef]

- Oral, E.; Christensen, S.D.; Malhi, A.S.; Wannomae, K.K.; Muratoglu, O.K. Wear resistance and mechanical properties of highly cross-linked, ultrahigh-molecular weight polyethylene doped with vitamin E. J. Arthroplast. 2006, 21, 580–591. [Google Scholar] [CrossRef] [Green Version]

- Pezzotti, G.; Saito, T.; Takahashi, Y.; Fukatsu, K. Surface topology of advanced alumina/zirconia composite femoral head as compared with commercial femoral heads made of monolithic zirconia. J. Am. Ceram. Soc. 2011, 94, 945–950. [Google Scholar] [CrossRef]

- Browsher, J.G.; Clarke, I.C. Thermal conductivity of femoral ball strongly influenced UHMWPE wear in a hip simulator study. In Proceedings of the 53rd Orthopaedic Research Society, San Diego, CA, USA, 11–14 February 2007; p. 278. [Google Scholar]

- Lu, Z.; McKellop, H.; Liao, P.; Benya, P. Potential thermal artifacts in hip joint wear simulators. J. Biomed. Mater. Res. 1999, 48, 458–464. [Google Scholar] [CrossRef]

- Liao, Y.S.; McKellop, H.; Lu, Z.; Campbell, P.; Benya, P. The effect of frictional heating and forced cooling on the serum lubricant and wear of UHMW polyethylene cups against cobalt-chromium and zirconia balls. Biomaterials 2003, 24, 3047–3059. [Google Scholar] [CrossRef]

- Zhou, Y.S.; Ohashi, M.; Tomita, N.; Ikeuchi, K.; Takashima, K. Study on the possibility of silicon nitride-silicon nitride as a material for hip prostheses. Mater. Sci. Eng. C 1997, 5, 125–129. [Google Scholar] [CrossRef]

- Xu, J.; Kato, K. Formation of tribochemical layer of ceramics sliding in water and its role for low friction. Wear 2000, 245, 61–75. [Google Scholar] [CrossRef]

- Abdel-Jaber, S.; Belvedere, C.; Leardini, A.; Affatato, S. Wear simulation of total knee prostheses using load and kinematics waveforms from stair climbing. J. Biomech. 2015, 48, 3830–3836. [Google Scholar] [CrossRef]

- Abdel-Jaber, S.; Belvedere, C.; De Mattia, J.S.; Leardini, A.; Affatato, S. A new protocol for wear testing of total knee prostheses from real joint kinematic data: Towards a scenario of realistic simulations of daily living activities. J. Biomech. 2016, 49, 2925–2931. [Google Scholar] [CrossRef]

- Liu, F.; Fisher, J.; Jin, Z. Tribology International Effect of motion inputs on the wear prediction of artificial hip joints. Tribiol. Int. 2013, 63, 105–114. [Google Scholar] [CrossRef] [Green Version]

- Maskiewicz, V.K.; Williams, P.A.; Prates, S.J.; Bowsher, J.G.; Clarke, I.C. Characterization of protein degradation in serum-based lubricants during simulation wear testing of metal-on-metal hip prostheses. J. Biomed. Mater. Res. B Appl. Biomater. 2010, 94, 429–440. [Google Scholar] [CrossRef]

| Test Cycles (Mc) | Mass Loss Average ± Standard Deviation (mg) | p-Value | |

|---|---|---|---|

| PE_ZTA | PE_Si3N4 | ||

| 0.4 | 0.767 ± 0.2658 | 0.617 ± 0.2563 | 0.180 |

| 0.8 | 0.733 ± 0.6919 | 0.333 ± 0.2582 | 0.394 |

| 1.2 | 1.267 ± 0.9933 | 0.633 ± 0.2160 | 0.310 |

| 1.6 | 1.267 ± 0.9933 | 0.633 ± 0.2160 | 0.310 |

| 2.0 | 1.133 ± 0.9223 | 0.733 ± 0.2503 | 0.310 |

| 2.4 | 2.017 ± 1.0647 | 1.617 ± 0.6274 | 0.589 |

| 2.8 | 1.967 ± 1.1466 | 1.583 ± 1.1179 | 0.699 |

| 3.2 | 1.867 ± 1.1639 | 1.483 ± 0.8424 | 0.589 |

| 3.6 | 1.817 ± 1.0666 | 1.433 ± 1.0708 | 0.589 |

| 4.0 | 1.083 ± 0.9411 | 0.767 ± 0.1966 | 0.699 |

| 4.5 | 2.150 ± 1.1640 | 1.800 ± 1.0488 | 0.699 |

| 5.0 | 2.650 ± 1.2046 | 2.467 ± 1.1325 | 0.818 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yorifuji, M.; Affatato, S.; Tateiwa, T.; Takahashi, Y.; Shishido, T.; Marin, E.; Zanocco, M.; Zhu, W.; Pezzotti, G.; Yamamoto, K. Wear Simulation of Ceramic-on-Crosslinked Polyethylene Hip Prostheses: A New Non-Oxide Silicon Nitride versus the Gold Standard Composite Oxide Ceramic Femoral Heads. Materials 2020, 13, 2917. https://doi.org/10.3390/ma13132917

Yorifuji M, Affatato S, Tateiwa T, Takahashi Y, Shishido T, Marin E, Zanocco M, Zhu W, Pezzotti G, Yamamoto K. Wear Simulation of Ceramic-on-Crosslinked Polyethylene Hip Prostheses: A New Non-Oxide Silicon Nitride versus the Gold Standard Composite Oxide Ceramic Femoral Heads. Materials. 2020; 13(13):2917. https://doi.org/10.3390/ma13132917

Chicago/Turabian StyleYorifuji, Makiko, Saverio Affatato, Toshiyuki Tateiwa, Yasuhito Takahashi, Takaaki Shishido, Elia Marin, Matteo Zanocco, Wenliang Zhu, Giuseppe Pezzotti, and Kengo Yamamoto. 2020. "Wear Simulation of Ceramic-on-Crosslinked Polyethylene Hip Prostheses: A New Non-Oxide Silicon Nitride versus the Gold Standard Composite Oxide Ceramic Femoral Heads" Materials 13, no. 13: 2917. https://doi.org/10.3390/ma13132917

APA StyleYorifuji, M., Affatato, S., Tateiwa, T., Takahashi, Y., Shishido, T., Marin, E., Zanocco, M., Zhu, W., Pezzotti, G., & Yamamoto, K. (2020). Wear Simulation of Ceramic-on-Crosslinked Polyethylene Hip Prostheses: A New Non-Oxide Silicon Nitride versus the Gold Standard Composite Oxide Ceramic Femoral Heads. Materials, 13(13), 2917. https://doi.org/10.3390/ma13132917