Recyclability of Asphalt Mixtures with Crumb Rubber Incorporated by Dry Process: A Laboratory Investigation

Abstract

1. Introduction

2. Materials and Methods

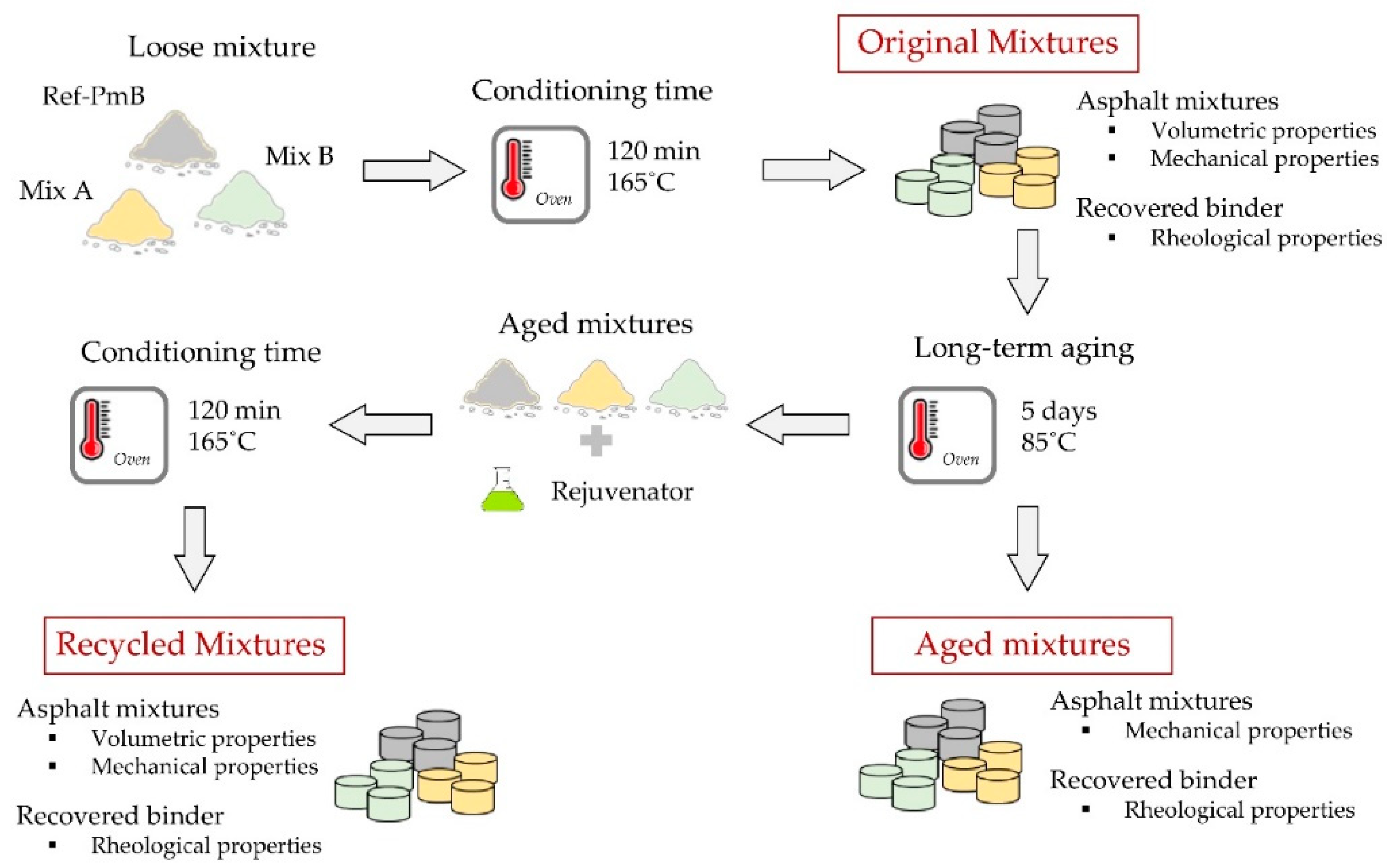

2.1. Asphalt Mixture Preparation and Aging Procedures

2.2. Characterization Tests

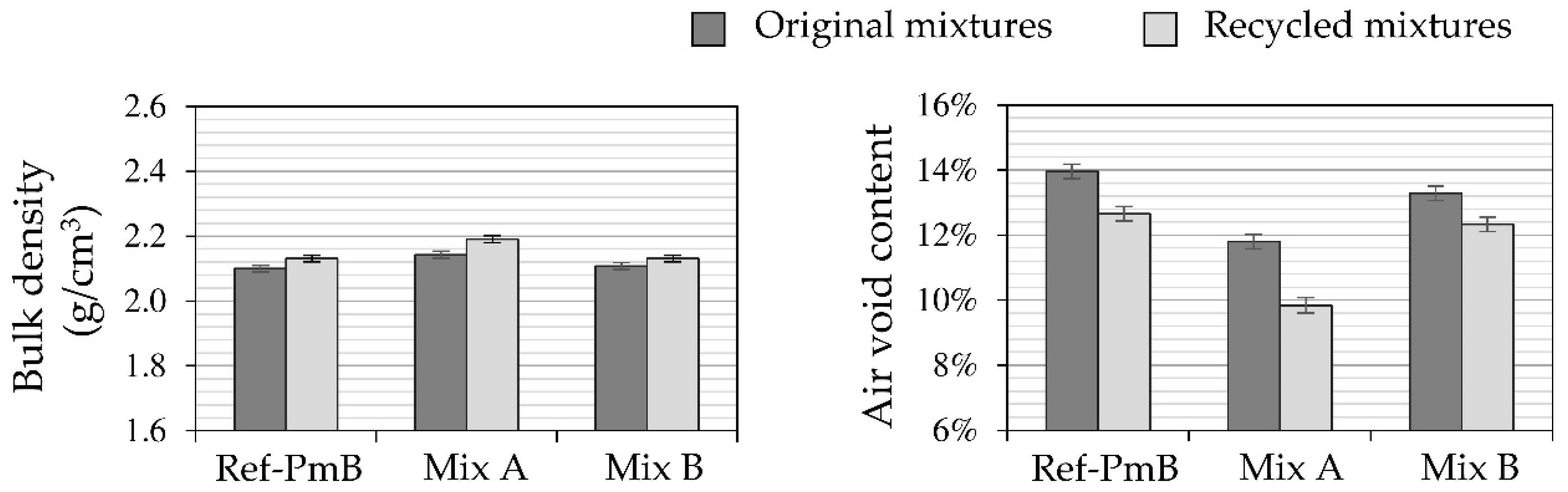

- Determination of the volumetric properties of asphalt mixtures: Bulk and maximum densities of several samples were experimentally obtained according to the standards EN 12697-6 (Saturated Surface Dry procedure) and EN 12697-5, respectively. As required, three specimens prepared by impact compactor (50 blows per face) were measured for the original and recycled mixtures. Afterwards, the air void content was calculated for each specimen as the ratio between the bulk and maximum densities as specified in the standard EN 12697-8.

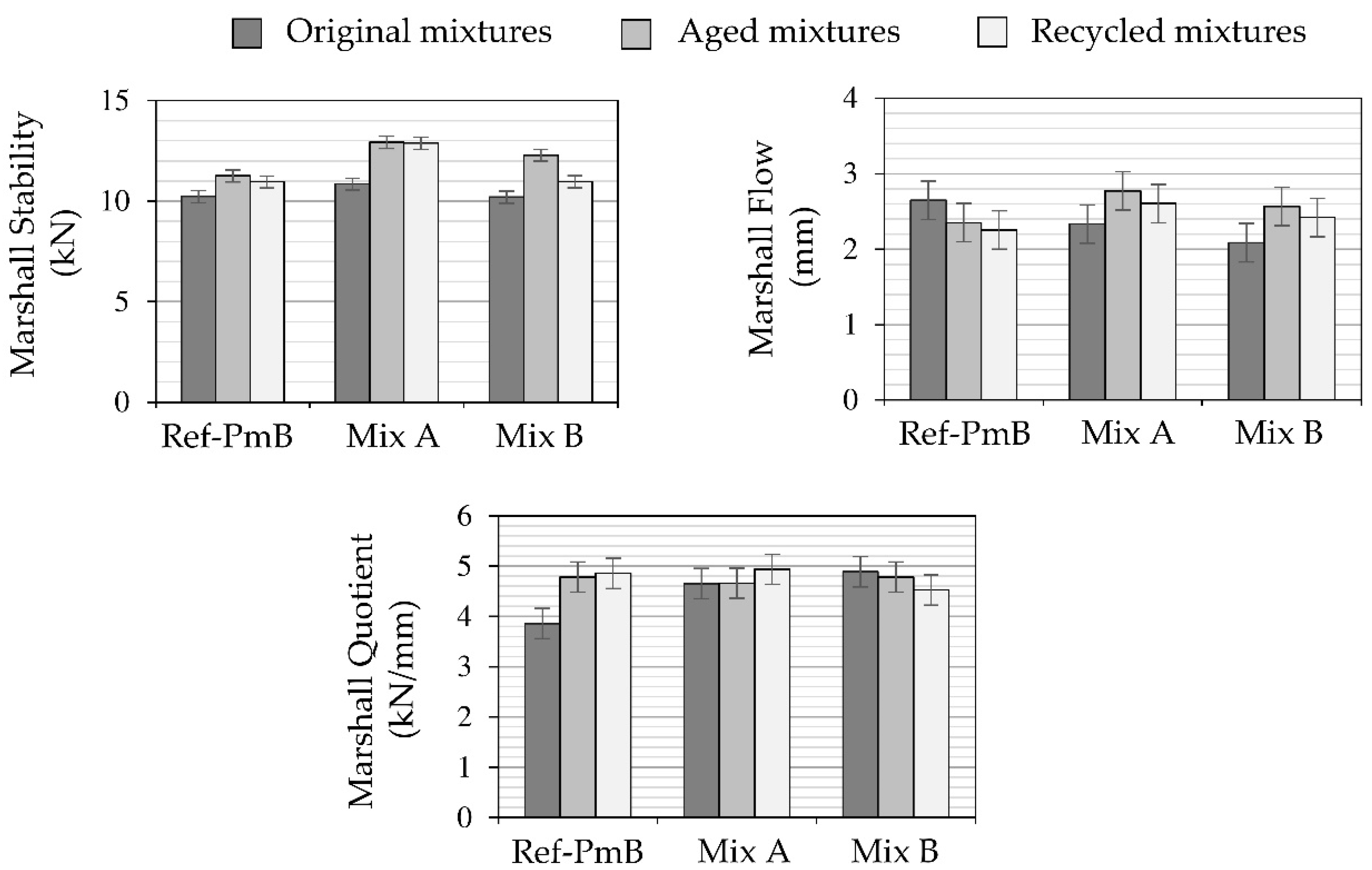

- Marshall test (EN 12697-34): From each mixture and aging state, three different specimens were prepared by impact compactor (50 blows per face). Before testing, the specimens were conditioned in water at 60 °C for 45 min. Thereafter, a load at a constant speed of 50 mm/min was applied to each specimen until failure, recording the deformation obtained throughout the test. This data allowed calculating the corresponding test parameters: stability, flow, and quotient.

- Water sensitivity (EN 12697-12): The Indirect Tensile Strength Ratio (ITSR) is a parameter commonly used to quantify the moisture susceptibility of asphalt mixture. It is defined as the ratio of the Indirect Tensile Strength (ITS) of a water conditioned specimen (wet) and an unconditioned one (dry). In this study, for each asphalt mixture and aging state, a total of six specimens were prepared by impact compactor (35 blows per face) according the specification. The wet samples were conditioned at 40 °C for 72 h. Once conditioned, they were brought to the test temperature (22 °C) in a climate chamber and tested according to EN 12697-23 in order to obtain the corresponding values of ITS.

3. Results and Discussion

3.1. Volumetric Properties of the Asphalt Mixtures

3.2. Marshall test

3.3. Water Sensitivity Test

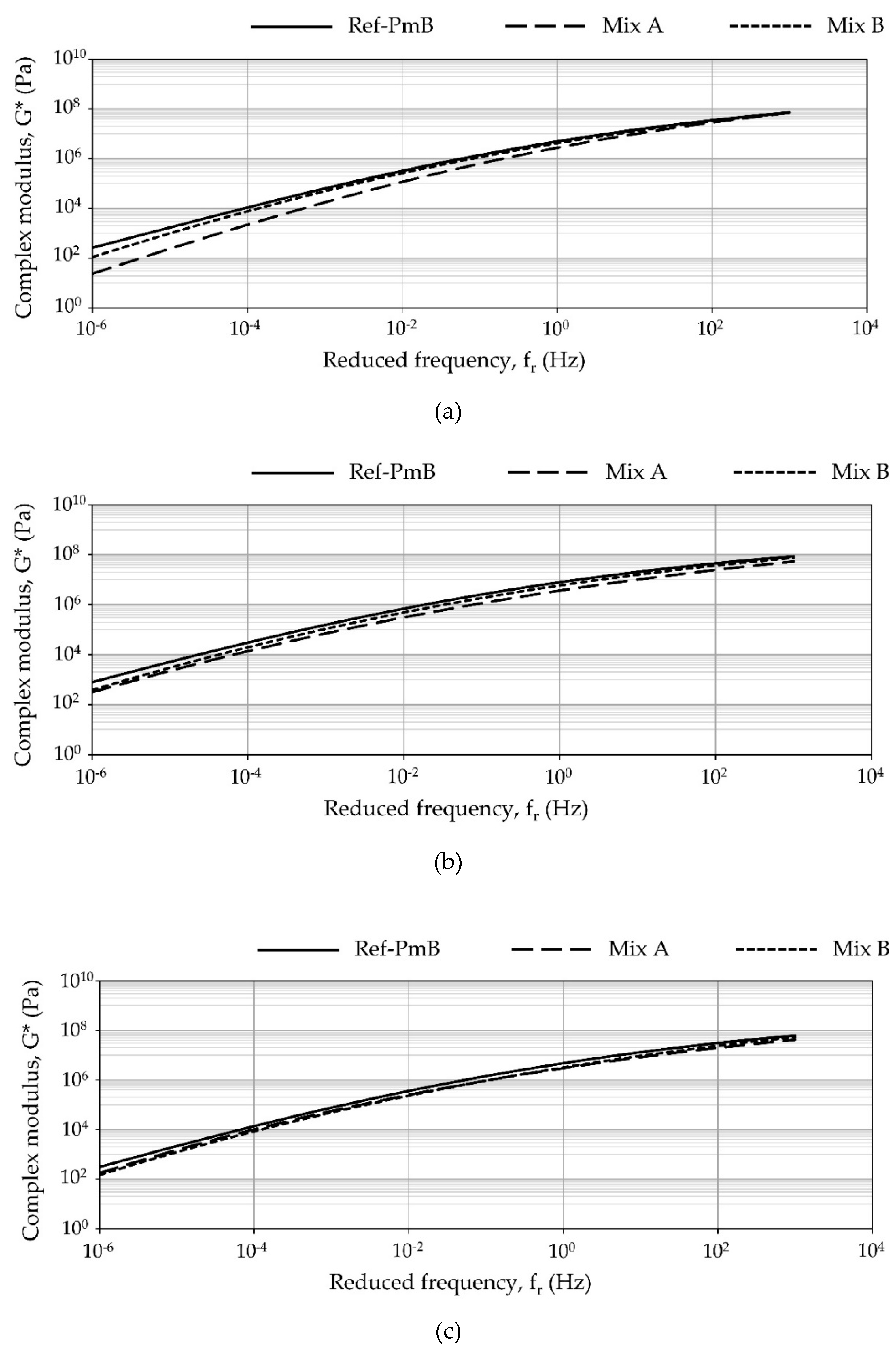

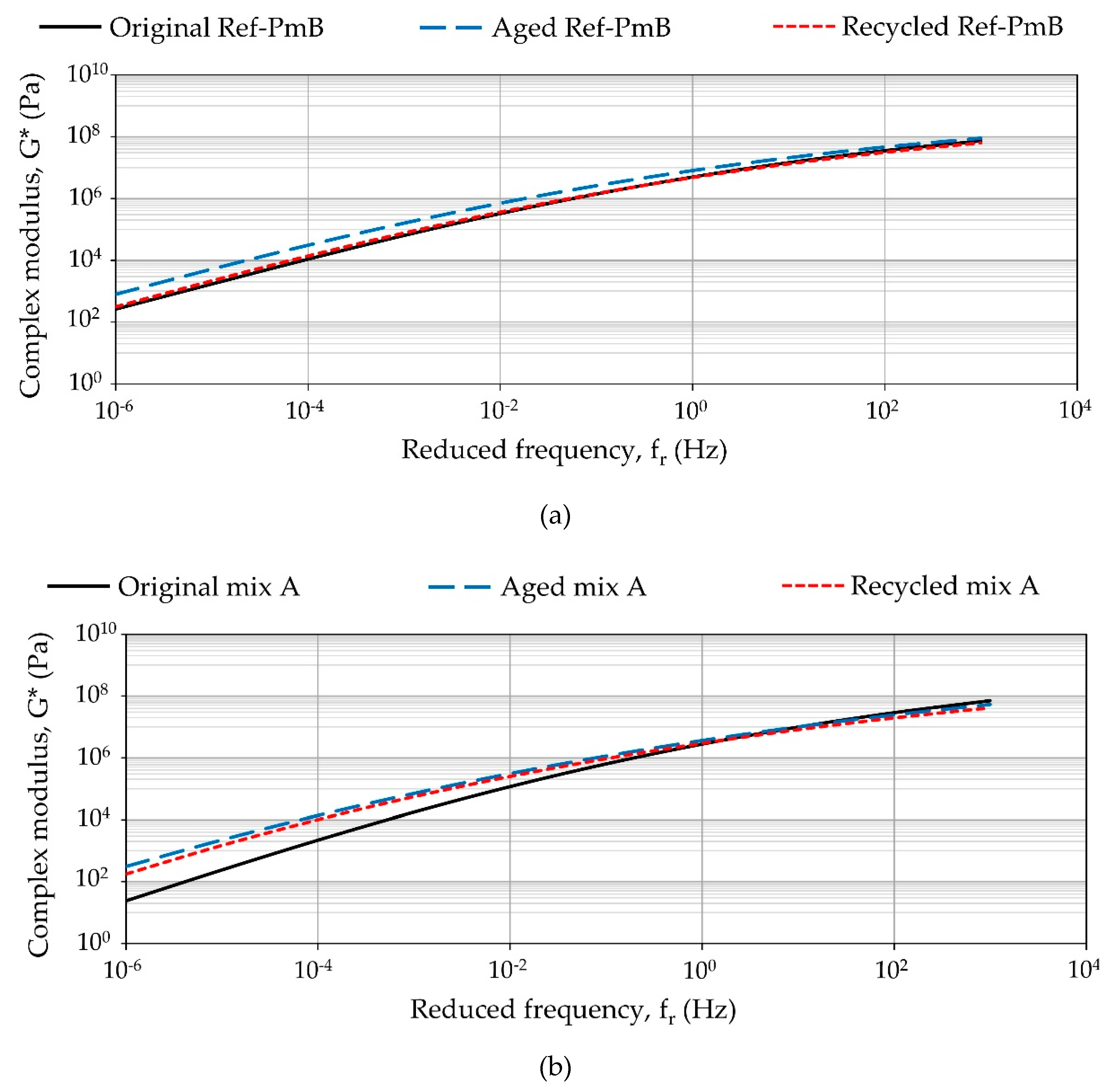

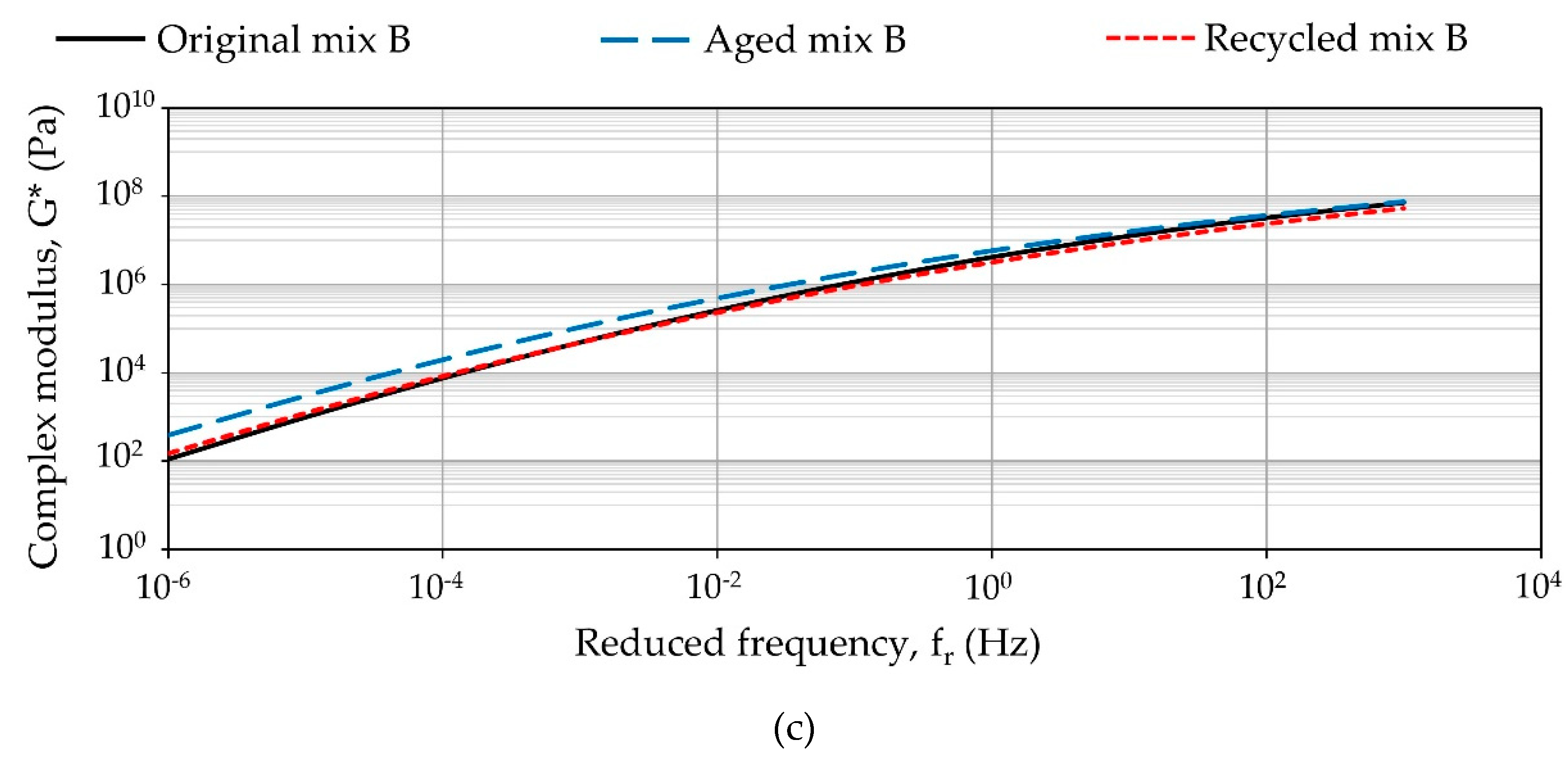

3.4. Rheological Behaviour of the Extracted Asphalt Binder Samples

4. Conclusions

- In general, the two CR experimental mixtures showed adequate behavior in comparison to the reference mixture with PmB. Nevertheless, further work is required to optimize their design in order to meet the requirements specified in the Swiss standard (ITSR > 70%).

- Regardless the type of CR, the experimental asphalt mixtures were found to be less susceptible to aging than the reference mixture (PmB).

- It was observed that the effect of the CR particles as elastic aggregate was more significant at high temperatures.

- The differences found in the volumetric properties (air void content reduction) and in the rheological response of the binder from recycled mixtures (rejuvenator capability) suggest that the polymer coating changes the resulting performance of the CR negatively.

- Further recommendations include the validation of the experimental results through specific tests (resistance to fatigue and stiffness modulus at different temperatures). Likewise, it will be imperative to take into consideration other parameters at industrial scale (e.g., milling process, transportation, storage, or exhaust gas emissions).

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- EAPA. Asphalt in Every Day Life. Available online: https://eapa.org/asphalt-in-every-day-life/ (accessed on 6 May 2020).

- Bühlmann, E. Low-noise pavements as an effective noise abatement measure in urban areas—A “new” technology becomes a proven standard. In Proceedings of the 26th International Congress on Sound and Vibration, Montreal, QC, Canada, 7–11 July 2019. [Google Scholar]

- Tayfur, S.; Ozen, H.; Aksoy, A. Investigation of rutting performance of asphalt mixtures containing polymer modifiers. Constr. Build. Mater. 2007, 21, 328–337. [Google Scholar] [CrossRef]

- Von Quintus, H.L.; Mallela, J.; Buncher, M. Quantification of Effect of Polymer-Modified Asphalt on Flexible Pavement Performance. Transp. Res. Rec. J. Transp. Res. Board 2007, 2001, 141–154. [Google Scholar] [CrossRef]

- Zhu, J.; Birgisson, B.; Kringos, N. Polymer modification of bitumen: Advances and challenges. Eur. Polym. J. 2014, 54, 18–38. [Google Scholar] [CrossRef]

- Wang, T.; Xiao, F.; Zhu, X.; Huang, B.; Wang, J.; Amirkhanian, S. Energy consumption and environmental impact of rubberized asphalt pavement. J. Clean. Prod. 2018, 180, 139–158. [Google Scholar] [CrossRef]

- Ozturk, H.I.; Kamran, F. Laboratory evaluation of dry process crumb rubber modified mixtures containing Warm Mix Asphalt Additives. Constr. Build. Mater. 2019, 229, 116940. [Google Scholar] [CrossRef]

- Lo Presti, D. Recycled Tyre Rubber Modified Bitumens for road asphalt mixtures: A literature review. Constr. Build. Mater. 2013, 49, 863–881. [Google Scholar] [CrossRef]

- Paje, S.E.; Bueno, M.; Terán, F.; Miró, R.; Pérez-Jiménez, F.; Martínez, A. Acoustic field evaluation of asphalt mixtures with crumb rubber. Appl. Acoust. 2010, 71, 578–582. [Google Scholar] [CrossRef]

- Loderer, C.; Partl, M.N.; Poulikakos, L.D. Effect of crumb rubber production technology on performance of modified bitumen. Constr. Build. Mater. 2018, 191, 1159–1171. [Google Scholar] [CrossRef]

- Rahman, M.M.; Airey, G.D.; Collop, A.C. Moisture Susceptibility of High and Low Compaction Dry Process Crumb Rubber–Modified Asphalt Mixtures. Transp. Res. Rec. J. Transp. Res. Board 2010, 2180, 121–129. [Google Scholar] [CrossRef]

- Shook, J. Experimental Construction of Rubber-Modified Asphalt Pavements in New York State; Engineering Consultants Report; ARE Inc.: New York, NY, USA, May 1990. [Google Scholar]

- Lawrence, C.; Killackey, B.; Lynch, D. Experimental hot mix pavement with scrap tire rubber at Thamesville, Ontario, Report #1 in Canadian Technical Asphalt Association Proceedings. In Proceedings of the 36th Annual Conference, West Kelowna, BC, Canada, 15–18 November 1991. [Google Scholar]

- Buncher, M. Evaluating the Effects of the Wet and Dry Processes for Including Crumb Rubber Modifier in Hot Mix Asphalt. Ph.D. Thesis, Auburn University, Auburn, AL, USA, August 1995. Available online: https://apps.dtic.mil/dtic/tr/fulltext/u2/a303241.pdf (accessed on 16 June 2020).

- Moreno, F.; Rubio, M.C.; Martinez-Echevarria, M.J. Analysis of digestion time and the crumb rubber percentage in dry-process crumb rubber modified hot bituminous mixes. Constr. Build. Mater. 2011, 25, 2323–2334. [Google Scholar] [CrossRef]

- Nguyen, H.T.; Tran, N. Effects of crumb rubber content and curing time on the properties of asphalt concrete and stone mastic asphalt using dry process. Int. J. Pavement Res. Technol. 2018, 11, 236–244. [Google Scholar] [CrossRef]

- Hassan, N.A.; Airey, G.; Jaya, R.P.; Mashros, N.; Aziz, M.A. A Review of Crumb Rubber Modification in Dry Mixed Rubberised Asphalt Mixtures. J. Teknol. 2014, 70. [Google Scholar] [CrossRef]

- Da Silva, L.; Benta, A.; Picado-Santos, L. Asphalt rubber concrete fabricated by the dry process: Laboratory assessment of resistance against reflection cracking. Constr. Build. Mater. 2018, 160, 539–550. [Google Scholar] [CrossRef]

- Feiteira Dias, J.L.; Picado-Santos, L.G.; Capitão, S.D. Mechanical performance of dry process fine crumb rubber asphalt mixtures placed on the Portuguese road network. Constr. Build. Mater. 2014, 73, 247–254. [Google Scholar] [CrossRef]

- Cao, W. Study on properties of recycled tire rubber modified asphalt mixtures using dry process. Constr. Build. Mater. 2007, 21, 1011–1015. [Google Scholar] [CrossRef]

- Moreno, F.; Rubio, M.C.; Martinez-Echevarria, M.J. The mechanical performance of dry-process crumb rubber modified hot bituminous mixes: The influence of digestion time and crumb rubber percentage. Constr. Build. Mater. 2012, 26, 466–474. [Google Scholar] [CrossRef]

- Hernández-Olivares, F.; Witoszek-Schultz, B.; Alonso-Fernández, M.; Benito-Moro, C. Rubber-modified hot-mix asphalt pavement by dry process. Int. J. Pavement Eng. 2009, 10, 277–288. [Google Scholar] [CrossRef]

- Xie, Z.; Shen, J. Long-Term Performance of SMA Mixtures Added with Crumb Rubbers in Dry Process. In Proceedings of the Airfield and Highway Pavement conference, Los Angeles, CA, USA, 9–12 June 2013; pp. 1145–1155. [Google Scholar] [CrossRef]

- Farouk, A.I.B.; Hassan, N.A.; Mahmud, M.Z.H.; Mirza, J.; Jaya, R.P.; Hainin, M.R.; Yaacob, H.; Yusoff, N.I.M. Effects of mixture design variables on rubber–bitumen interaction: Properties of dry mixed rubberized asphalt mixture. Mater. Struct. 2017, 50, 12. [Google Scholar] [CrossRef]

- Liang, R.; Lee, S. Short-Term and Long-Term Aging Behavior of Rubber Modified Asphalt Paving Mixture. Transp. Res. Rec. J. Transp. Res. Board 1996, 1530, 11–17. [Google Scholar] [CrossRef]

- Shen, J.; Amirkhanian, S.; Lee, S.J. The effects of rejuvenating agents on recycled aged CRM binders. Int. J. Pavement Eng. 2005, 6, 273–279. [Google Scholar] [CrossRef]

- Mitchell, M.R.; Link, R.E.; Xiao, F.; Amirkhanian, S.N.; Shen, J. Effects of Various Long-Term Aging Procedures on the Rheological Properties of Laboratory Prepared Rubberized Asphalt Binders. J. Test. Eval. 2009, 37, 101706. [Google Scholar] [CrossRef]

- Saboundjian, S.; Knopke, T.; Raad, L. Field aging effects of asphalt rubber mixes and conventional mixes for runway surface applications. In Proceedings of the FAA Worldwide Airport Technology Transfer Conference, Atlantic City, NJ, USA, 18–21 April 2004. [Google Scholar]

- Shen, J.; Amirkhanian, S.; Lee, S.J.; Putman, B. Recycling of Laboratory-Prepared Reclaimed Asphalt Pavement Mixtures Containing Crumb Rubber-Modified Binders in Hot-Mix Asphalt. Transp. Res. Rec. J. Transp. Res. Board 2006, 1962, 71–78. [Google Scholar] [CrossRef]

- Shen, J.; Li, B.; Xie, Z. Interaction between crumb rubber modifier (CRM) and asphalt binder in dry process. Constr. Build. Mater. 2017, 149, 202–206. [Google Scholar] [CrossRef]

- Rahman, M.; Airey, G.D.; Collop, A. The mechanical properties of the dry process CRM asphalt mixtures following short-term and long-term ageing. In Proceedings of the Seventh International Conference on the Bearing Capacity of Roads, Railways and Airfields, Trondheim, Norway, 25–27 June 2005. [Google Scholar]

- Mikhailenko, P.; Kadhim, H.; Baaj, H.; Tighe, S. Observation of asphalt binder microstructure with ESEM. J. Microsc. 2017, 267, 347–355. [Google Scholar] [CrossRef] [PubMed]

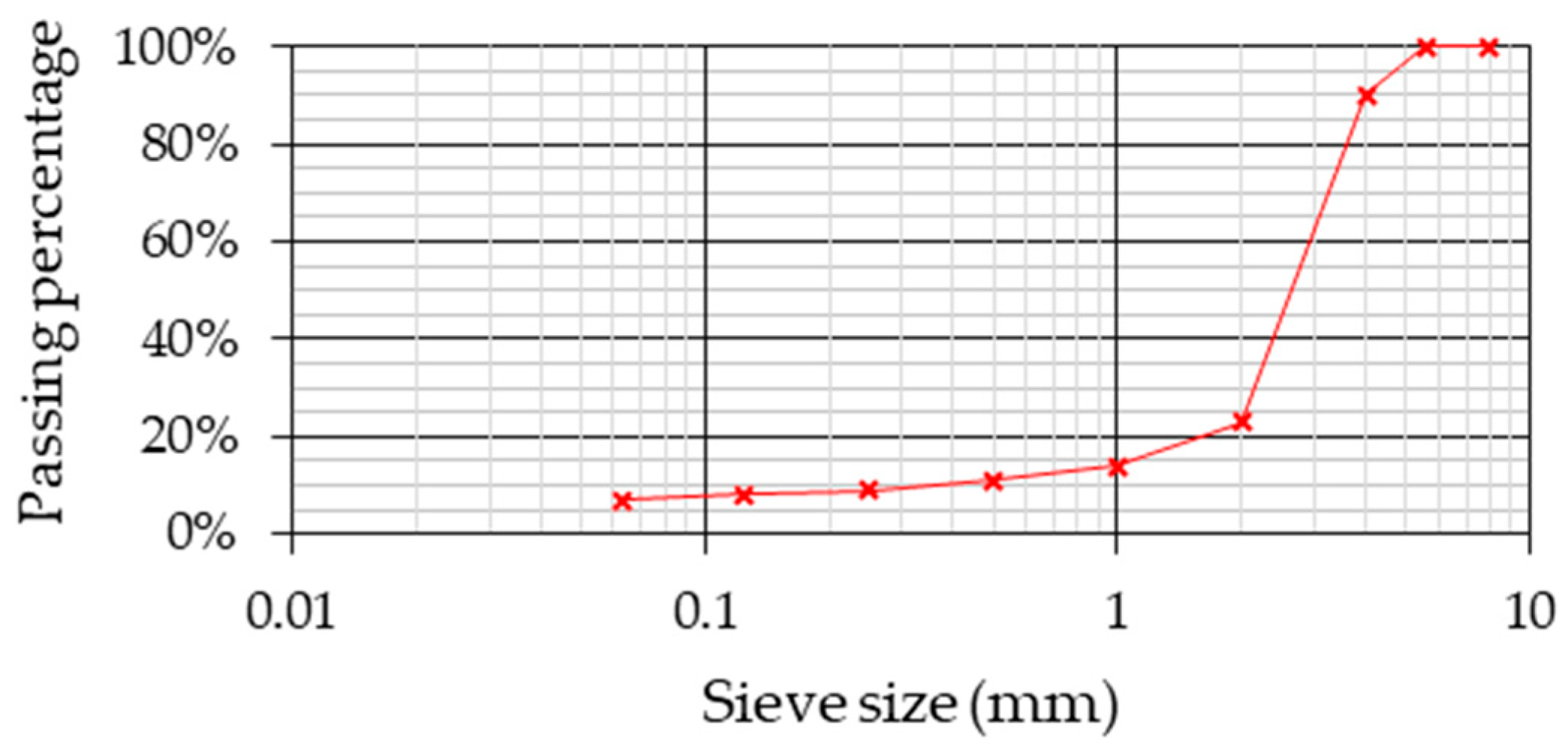

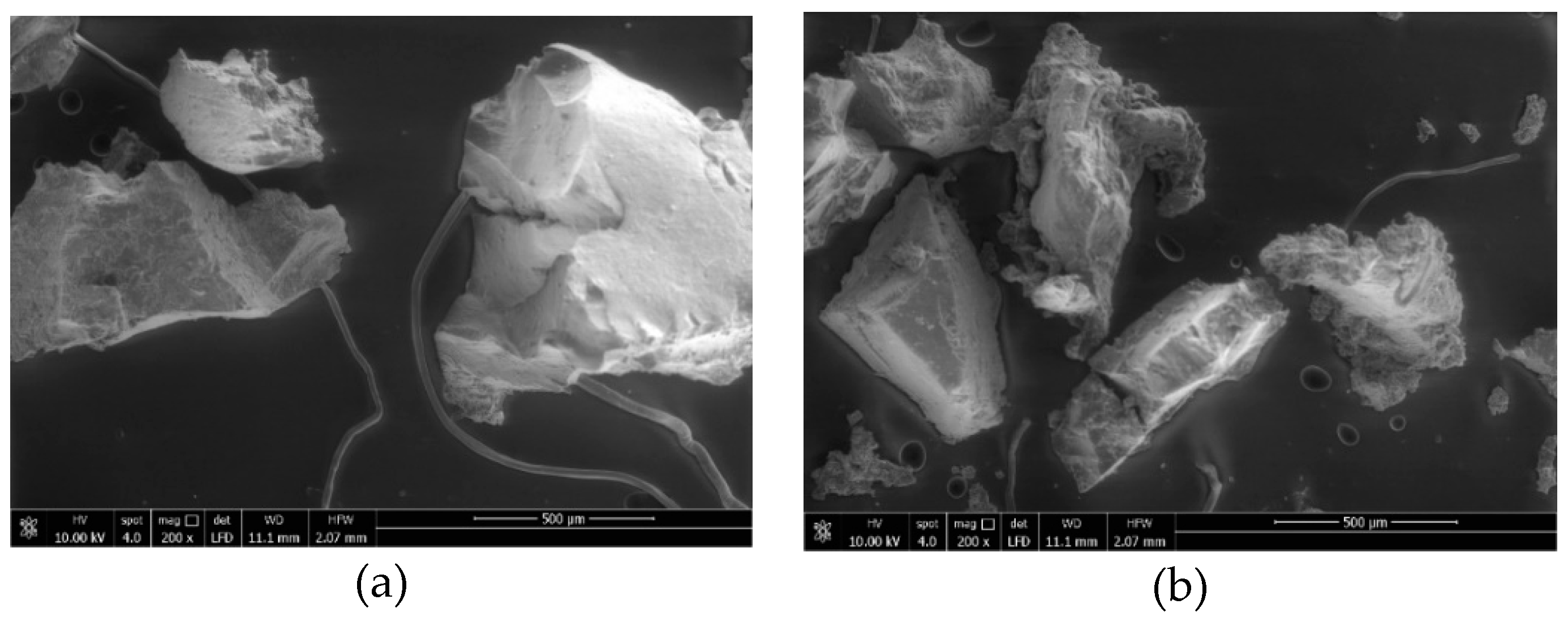

- Rodríguez-Fernández, I.; Baheri, F.T.; Cavalli, M.C.; Poulikakos, L.D.; Bueno, M. Microstructure analysis and mechanical performance of crumb rubber modified asphalt concrete using the dry process. Constr. Build. Mater. 2020, 259, 119662. [Google Scholar] [CrossRef]

- Airey, G.D. State of the Art Report on Ageing Test Methods for Bituminous Pavement Materials. Int. J. Pavement Eng. 2003, 4, 165–176. [Google Scholar] [CrossRef]

- Cavalli, M.C.; Zaumanis, M.; Mazza, E.; Partl, M.N.; Poulikakos, L.D. Aging effect on rheology and cracking behaviour of reclaimed binder with bio-based rejuvenators. J. Clean. Prod. 2018, 189, 88–97. [Google Scholar] [CrossRef]

- Muniandy, R.; Ismail, D.H.; Hassim, S. Performance of recycled ceramic waste as aggregates in hot mix asphalt (HMA). J. Mater. Cycles Waste Manag. 2018, 20, 844–849. [Google Scholar] [CrossRef]

- Ghavibazoo, A.; Abdelrahman, M.; Ragab, M. Evaluation of Oxidization of Crumb Rubber–Modified Asphalt during Short-Term Aging. Transp. Res. Rec. J. Transp. Res. Board 2015, 1, 84–91. [Google Scholar] [CrossRef]

- Harvey, J.T.; Tsai, B.-W. Effects of Asphalt Content and Air Void Content on Mix Fatigue and Stiffness. Transp. Res. Rec. J. Transp. Res. Board 1996, 1543, 38–45. [Google Scholar] [CrossRef]

- Pérez-Jiménez, F.; Martínez, A.H.; Miró, R.; Hernández-Barrera, D.; Araya-Zamorano, L. Effect of compaction temperature and procedure on the design of asphalt mixtures using Marshall and gyratory compactors. Constr. Build. Mater. 2014, 65, 264–269. [Google Scholar] [CrossRef]

- Srinivasan, G. Evaluation of Indirect Tensile Strength to Identify Asphalt Concrete Rutting Potential. Master’s Theses, West Virginia University, Morgantown, WV, USA, 2004. [Google Scholar] [CrossRef]

- Hassan, N.A.; Airey, G.; Yusoff, N.I.M.; Hainin, M.R.; Putrajaya, R.; Abdullah, M.E.; Aziz, M.A. Microstructural characterisation of dry mixed rubberised asphalt mixtures. Constr. Build. Mater. 2015, 82, 173–183. [Google Scholar] [CrossRef]

- Eskandarsefat, S.; Sangiorgi, C.; Dondi, G.; Lamperti, R. Recycling asphalt pavement and tire rubber: A full laboratory and field scale study. Constr. Build. Mater. 2018, 176, 283–294. [Google Scholar] [CrossRef]

| Mixture | Type of Binder | Binder Content | Type of CR | CR Content |

|---|---|---|---|---|

| Mix A | 50/70 | 6.2% | CR-A | 1% by weight of aggregate |

| Mix B | 50/70 | 6.2% | CR-B | 1% by weight of aggregate |

| Reference | PmB 45/80–65 | 6.2% | - | - |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rodríguez-Fernández, I.; Cavalli, M.C.; Poulikakos, L.; Bueno, M. Recyclability of Asphalt Mixtures with Crumb Rubber Incorporated by Dry Process: A Laboratory Investigation. Materials 2020, 13, 2870. https://doi.org/10.3390/ma13122870

Rodríguez-Fernández I, Cavalli MC, Poulikakos L, Bueno M. Recyclability of Asphalt Mixtures with Crumb Rubber Incorporated by Dry Process: A Laboratory Investigation. Materials. 2020; 13(12):2870. https://doi.org/10.3390/ma13122870

Chicago/Turabian StyleRodríguez-Fernández, Israel, Maria Chiara Cavalli, Lily Poulikakos, and Moises Bueno. 2020. "Recyclability of Asphalt Mixtures with Crumb Rubber Incorporated by Dry Process: A Laboratory Investigation" Materials 13, no. 12: 2870. https://doi.org/10.3390/ma13122870

APA StyleRodríguez-Fernández, I., Cavalli, M. C., Poulikakos, L., & Bueno, M. (2020). Recyclability of Asphalt Mixtures with Crumb Rubber Incorporated by Dry Process: A Laboratory Investigation. Materials, 13(12), 2870. https://doi.org/10.3390/ma13122870