Influence of Temperature on Mechanical Properties of Nanocrystalline 316L Stainless Steel Investigated via Molecular Dynamics Simulations

Abstract

1. Introduction

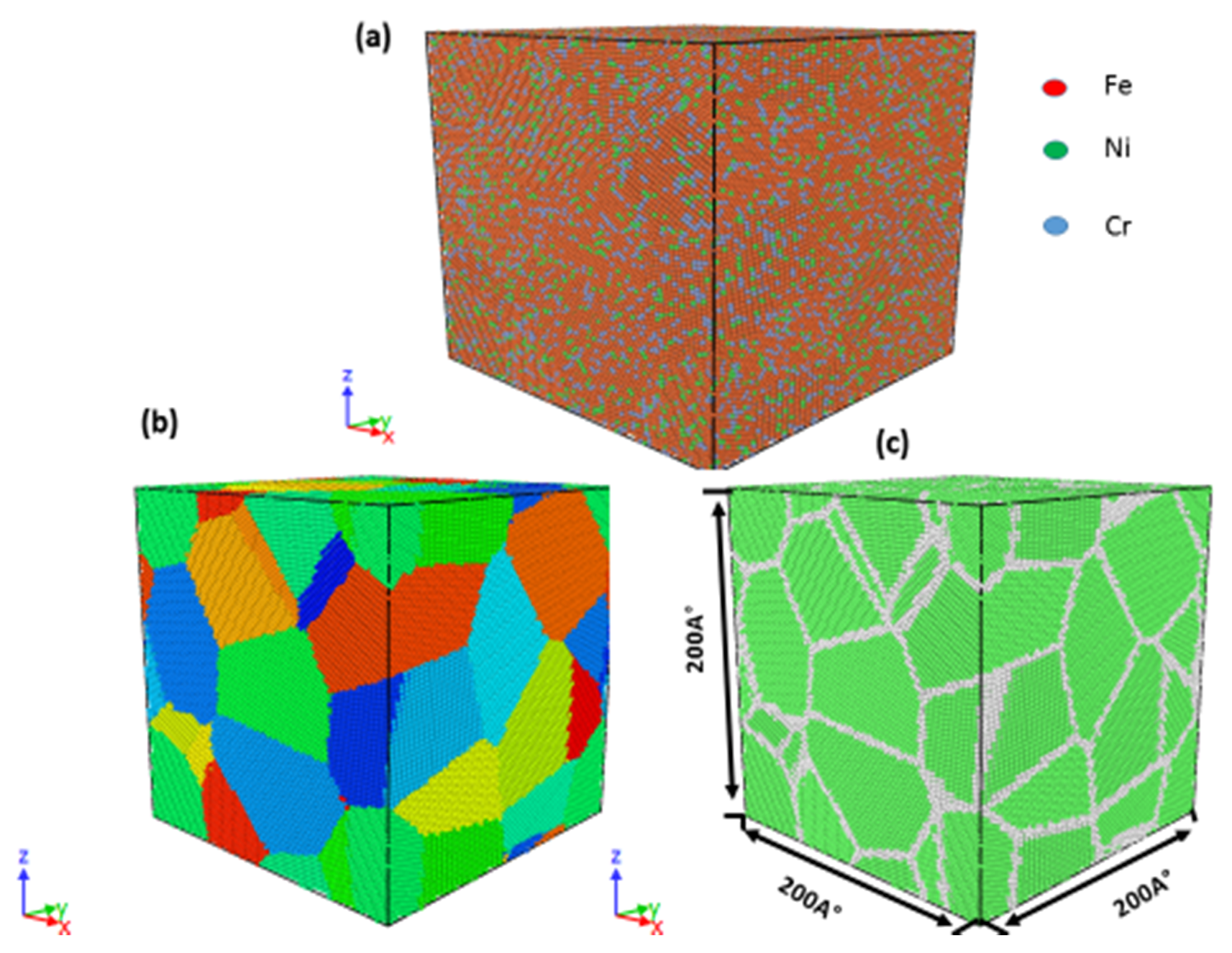

2. Simulation Methodology

3. Results and Discussion

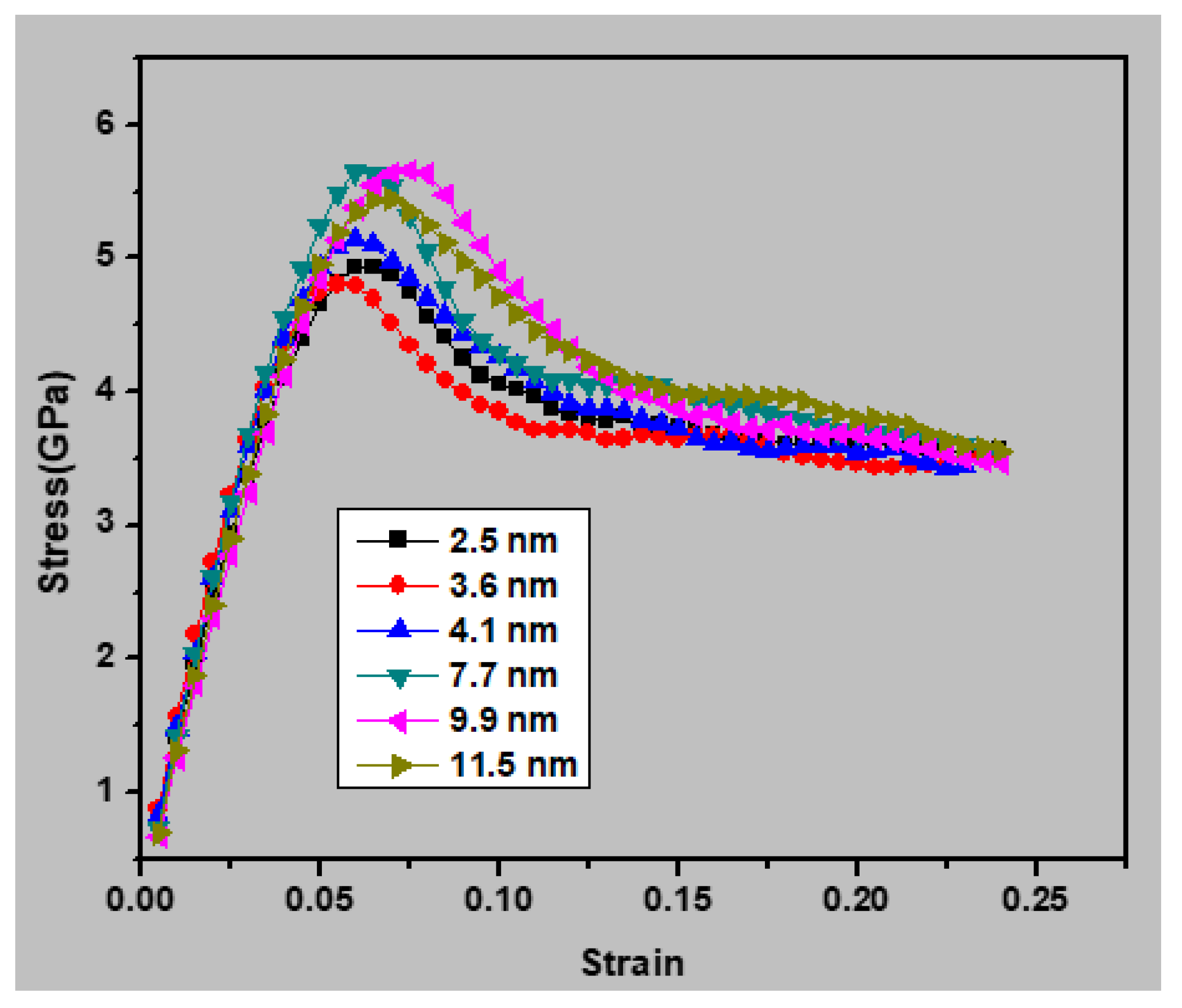

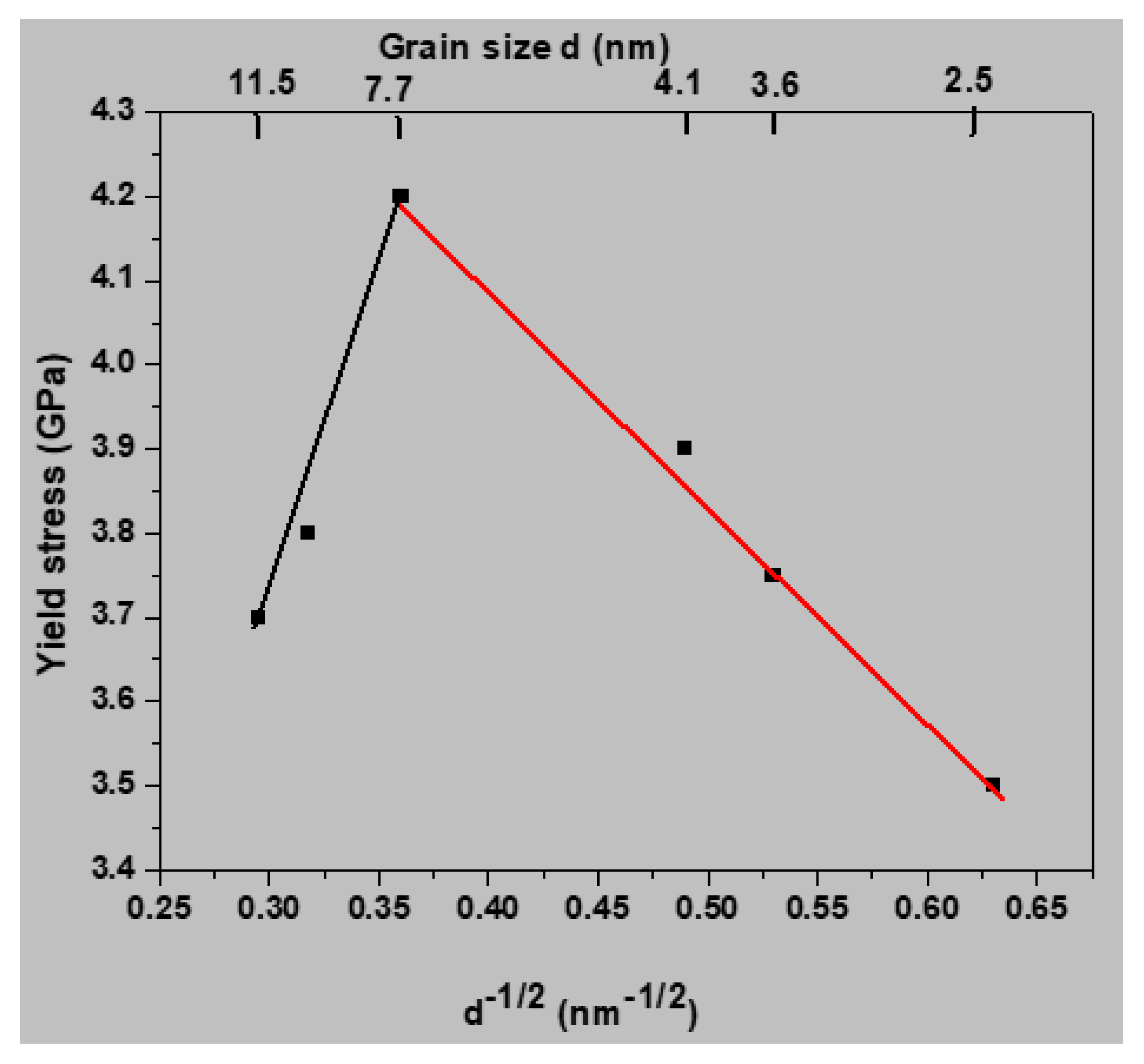

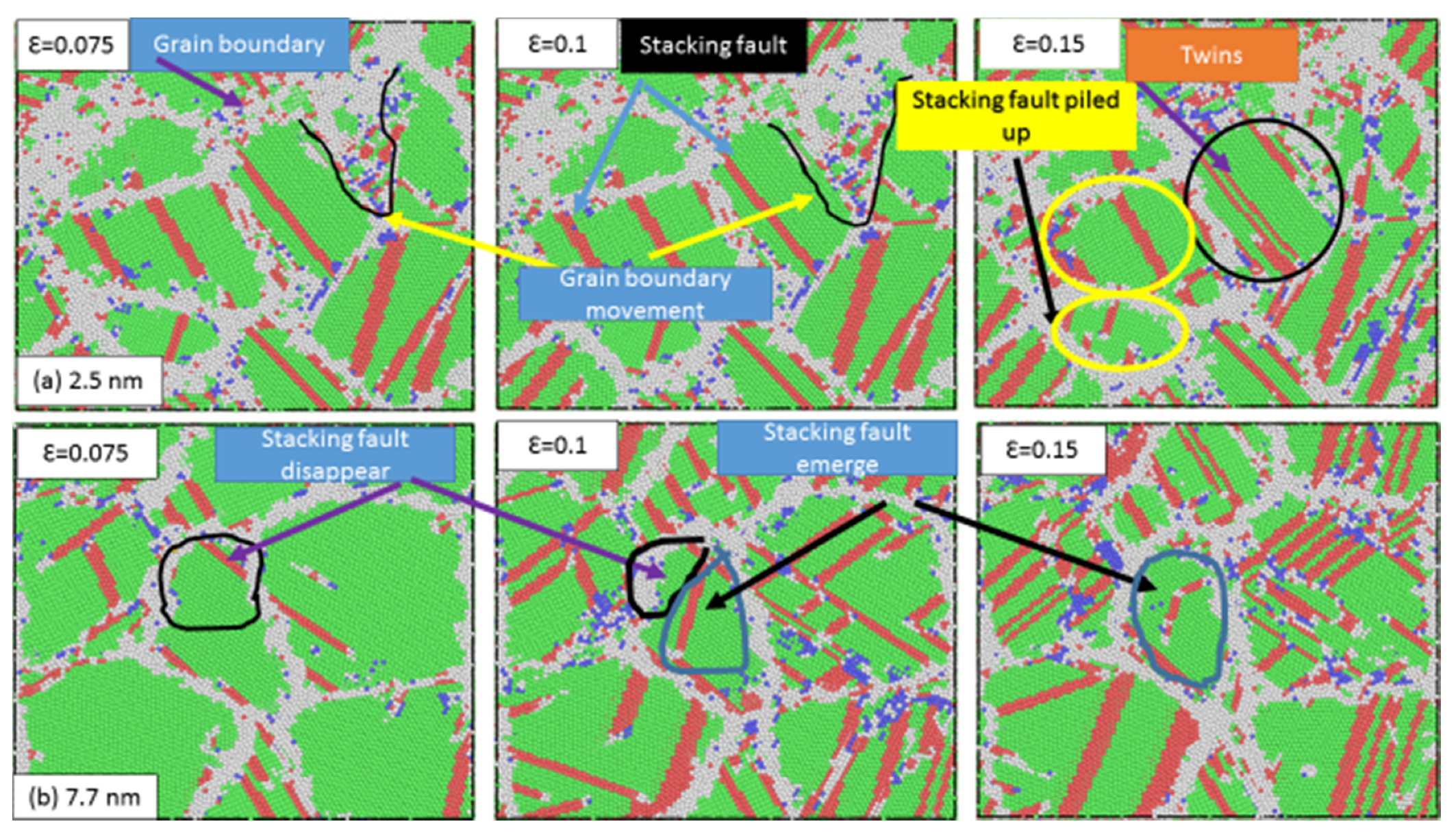

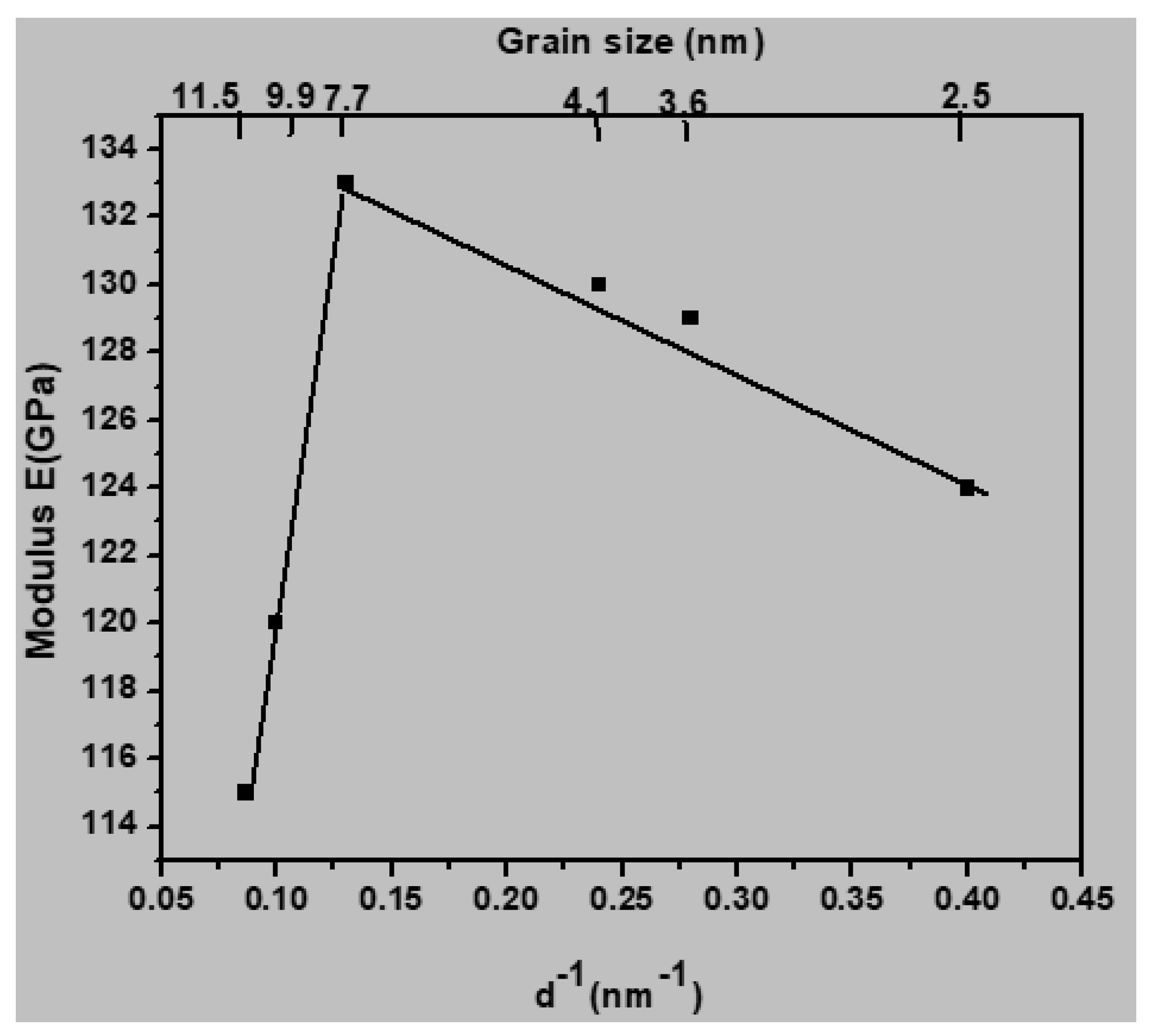

3.1. Influence of Grain Size on Mechanical Properties

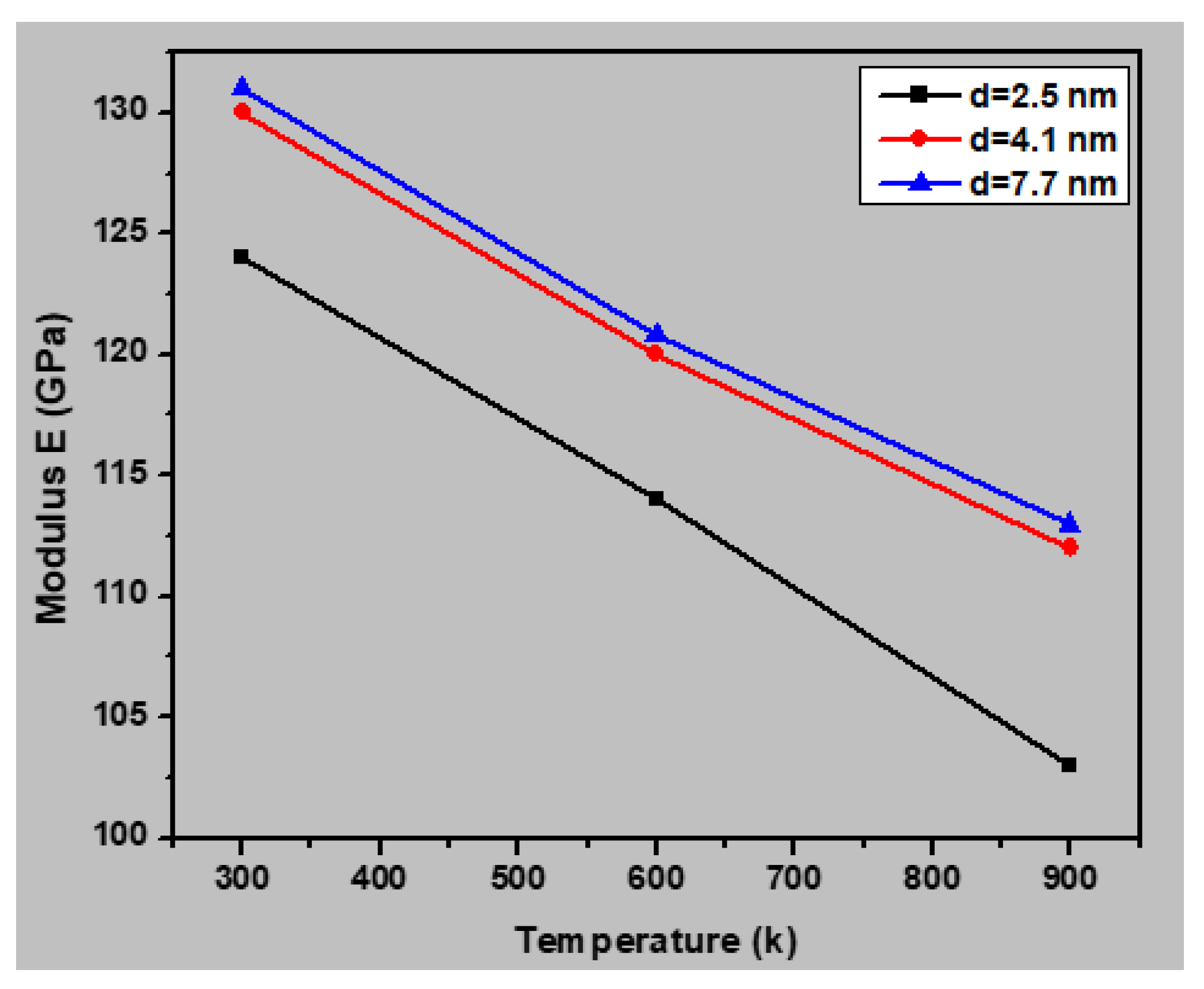

3.2. Young’s Modulus

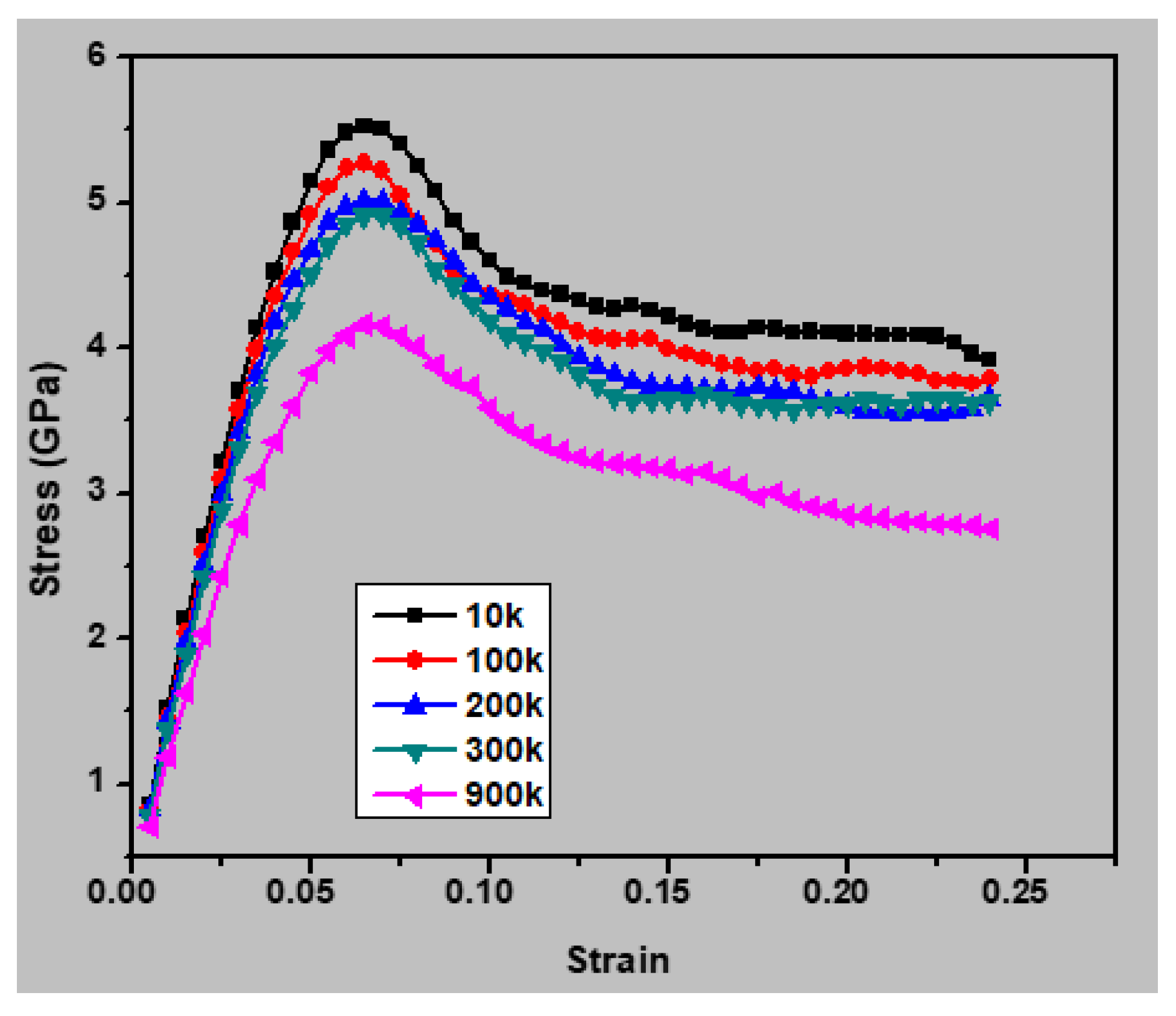

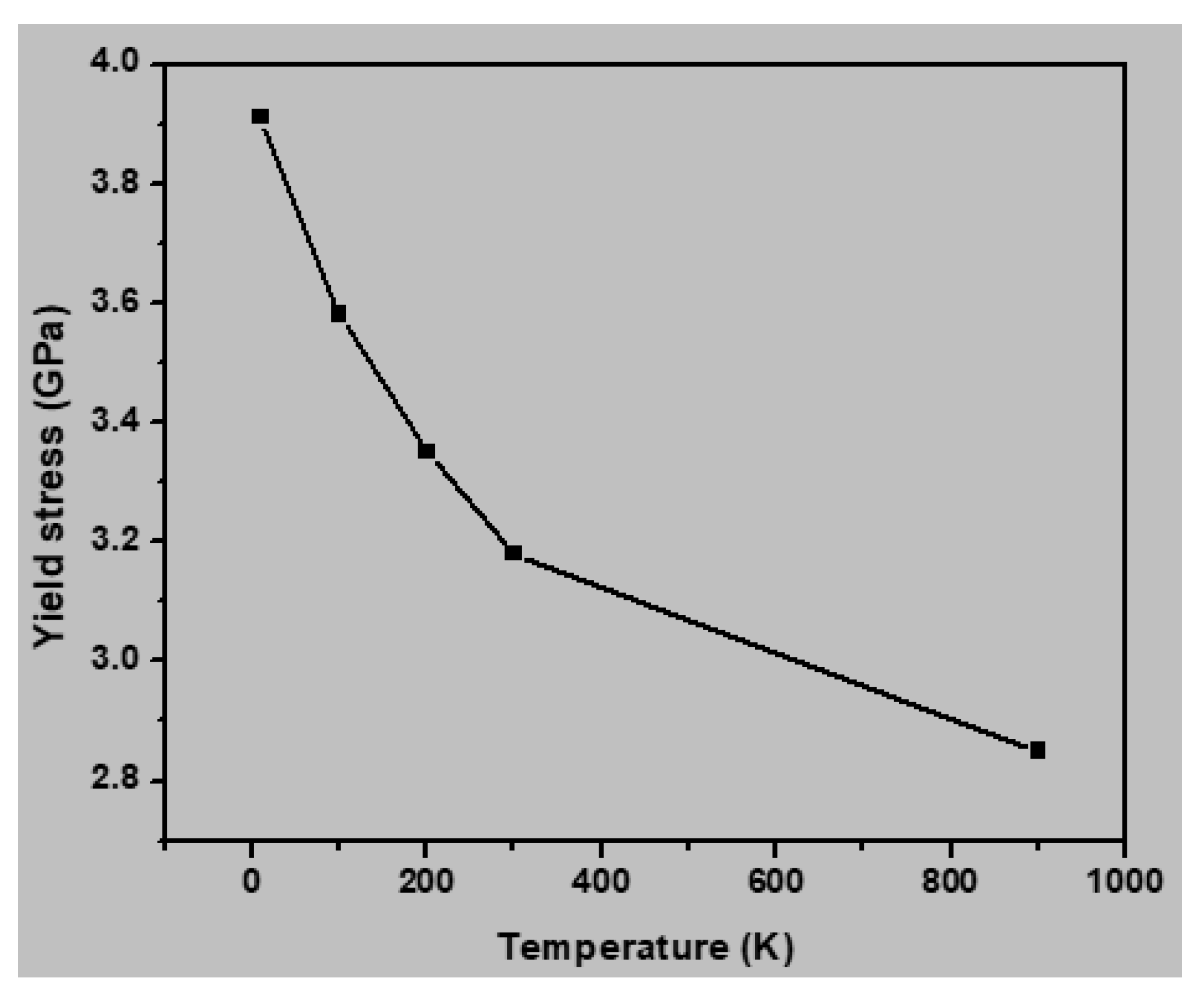

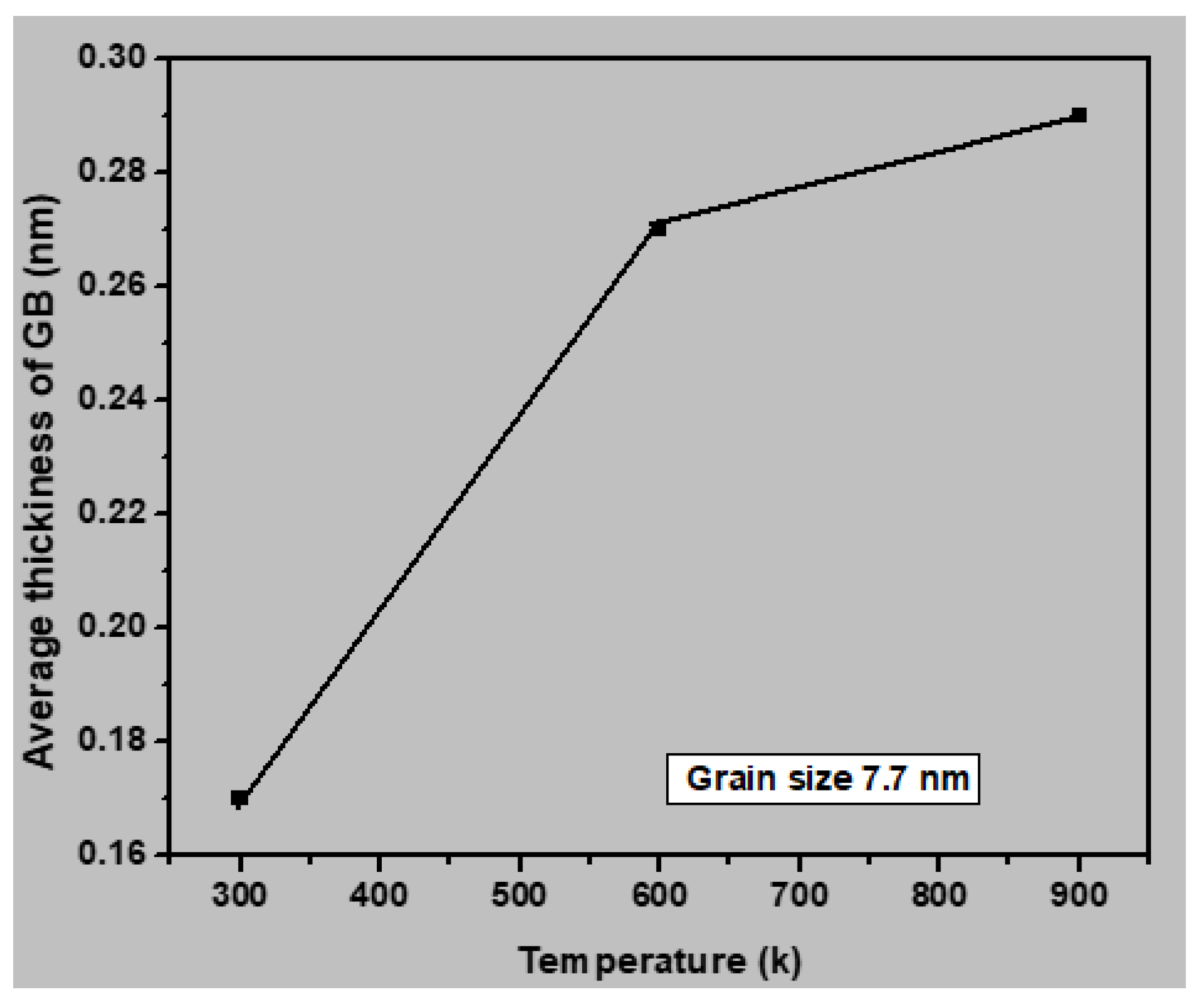

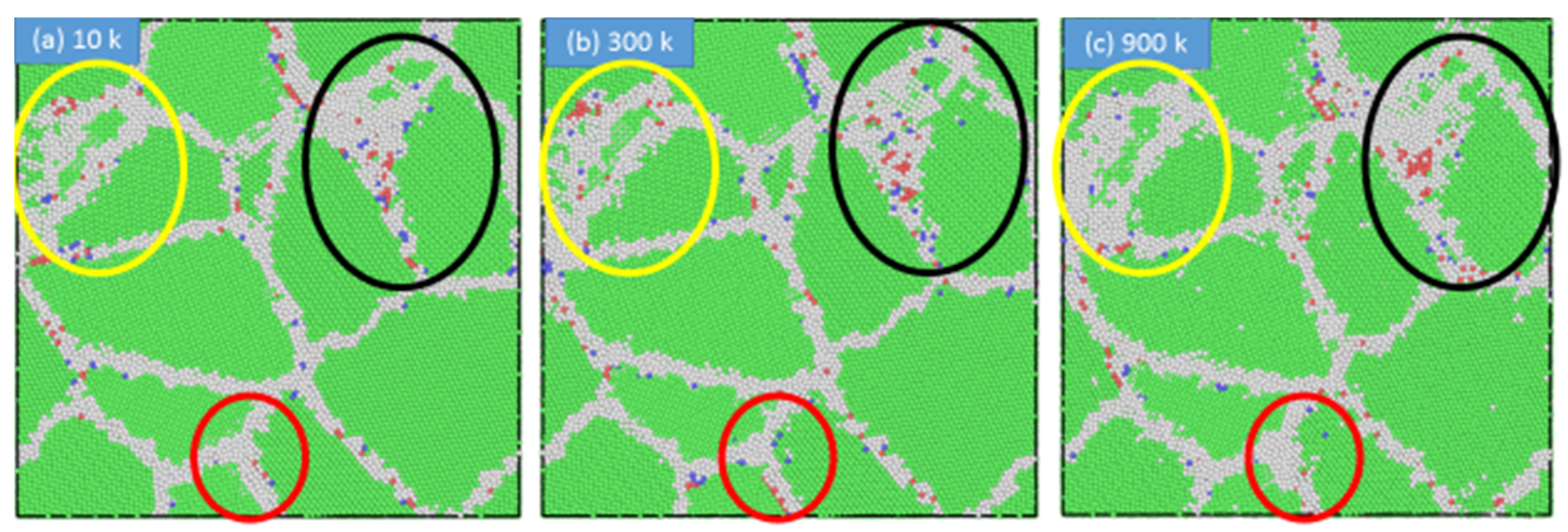

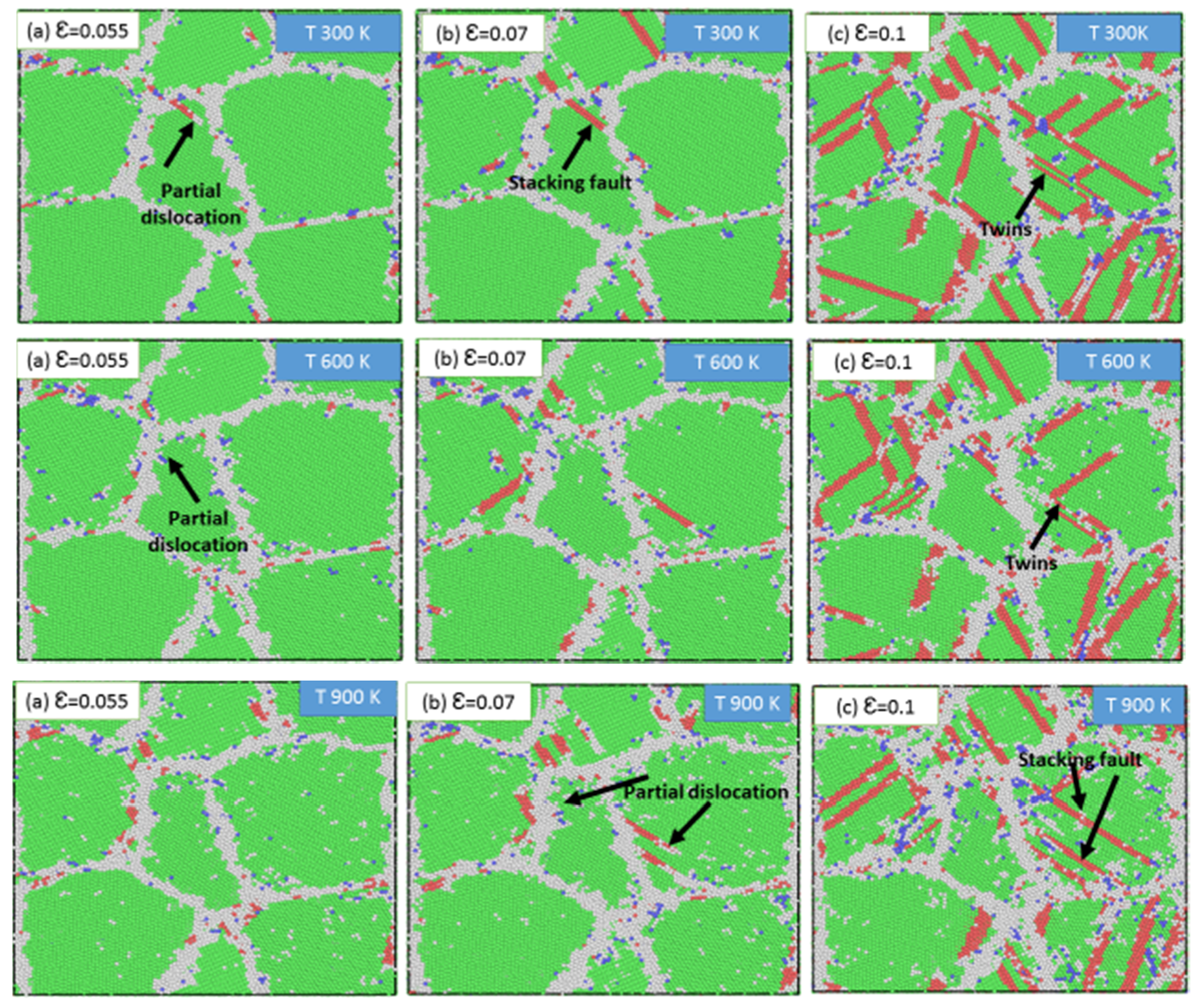

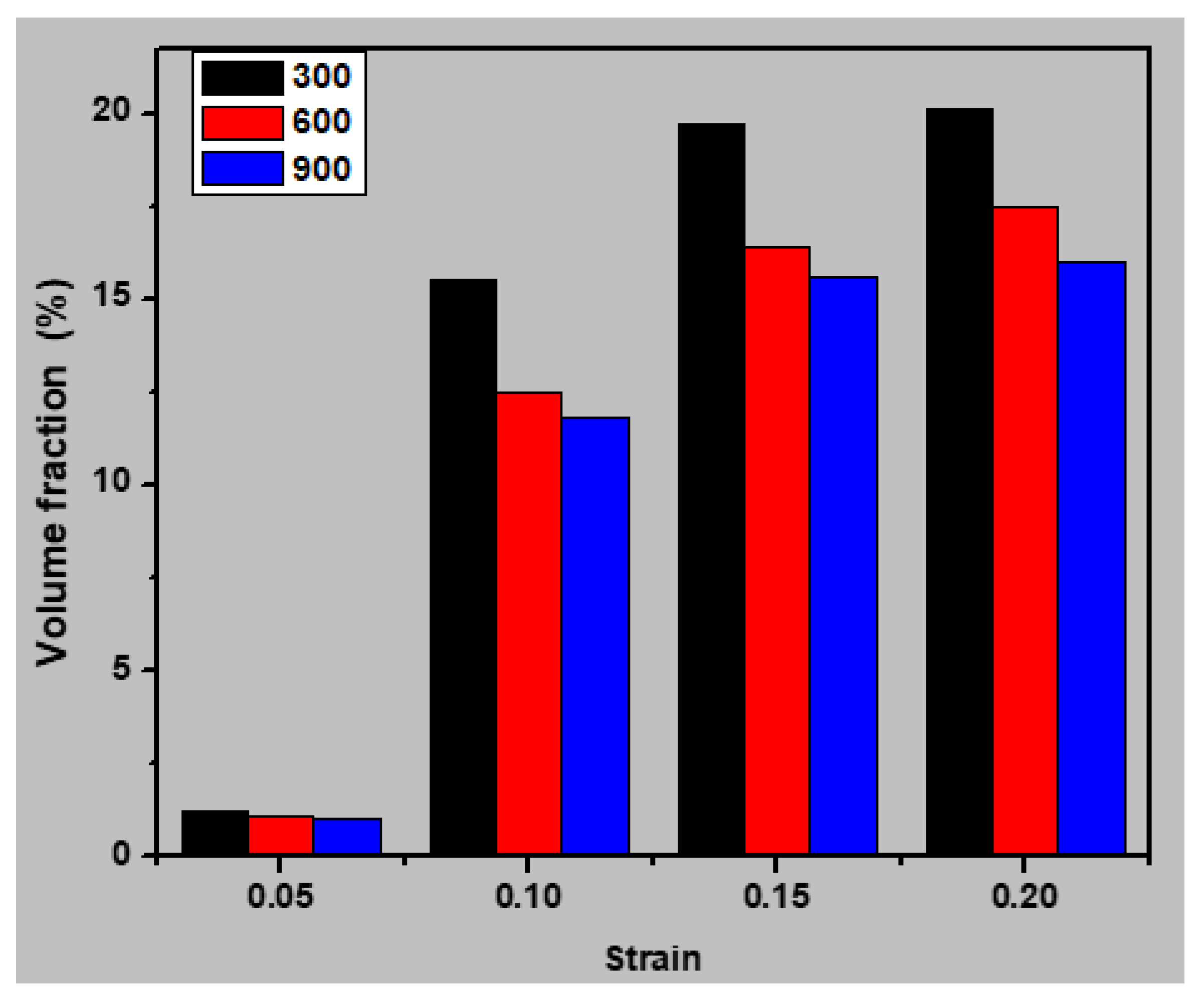

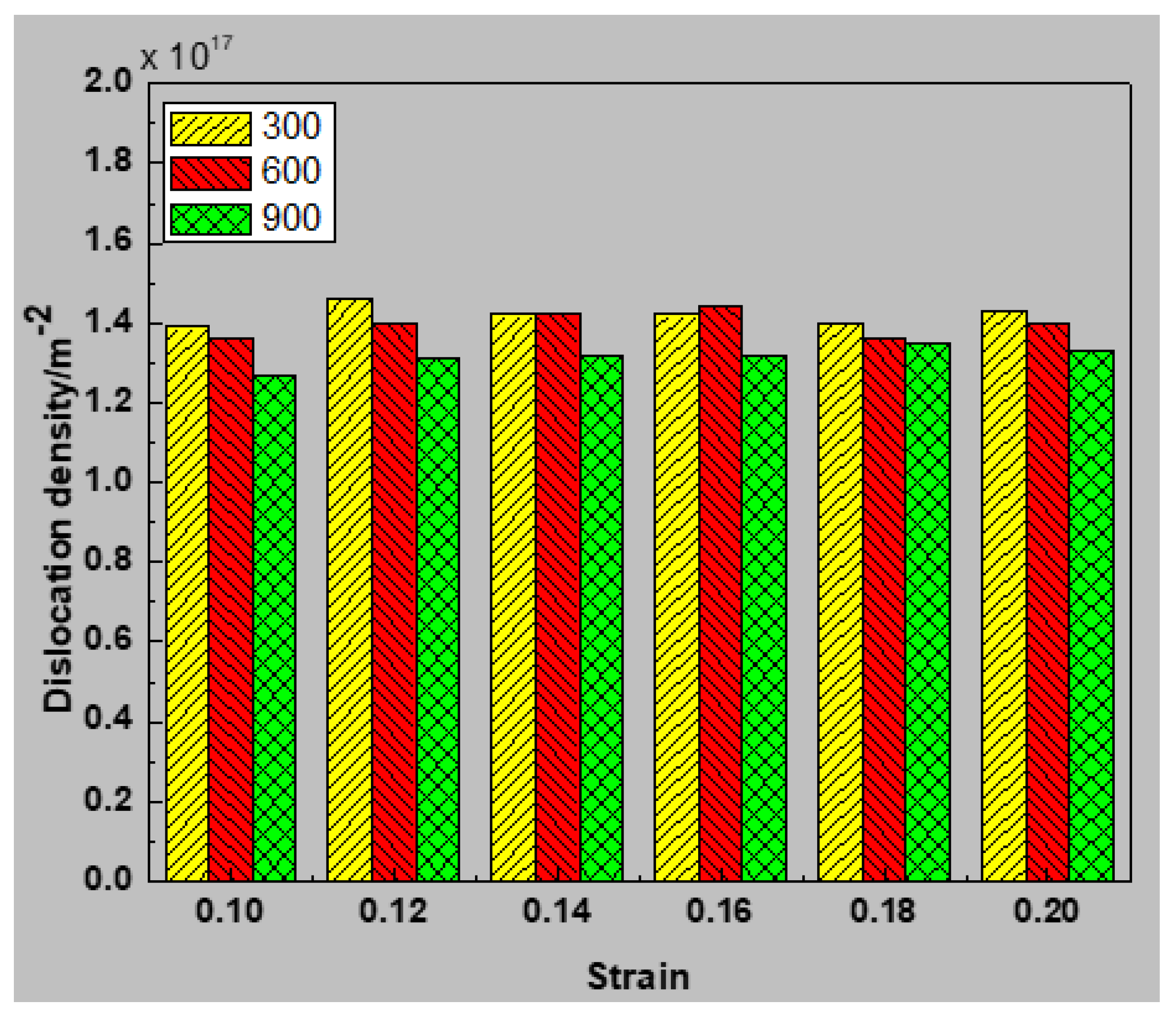

3.3. Influence of Temperature on The Mechanical Properties

4. Conclusions

- (1)

- The results indicate a reflection of the conventional Hall–Petch relationship down to critical grain size of 7.7 nm with a critical average grain size of 7.7 nm and a temperature of 300 K.

- (2)

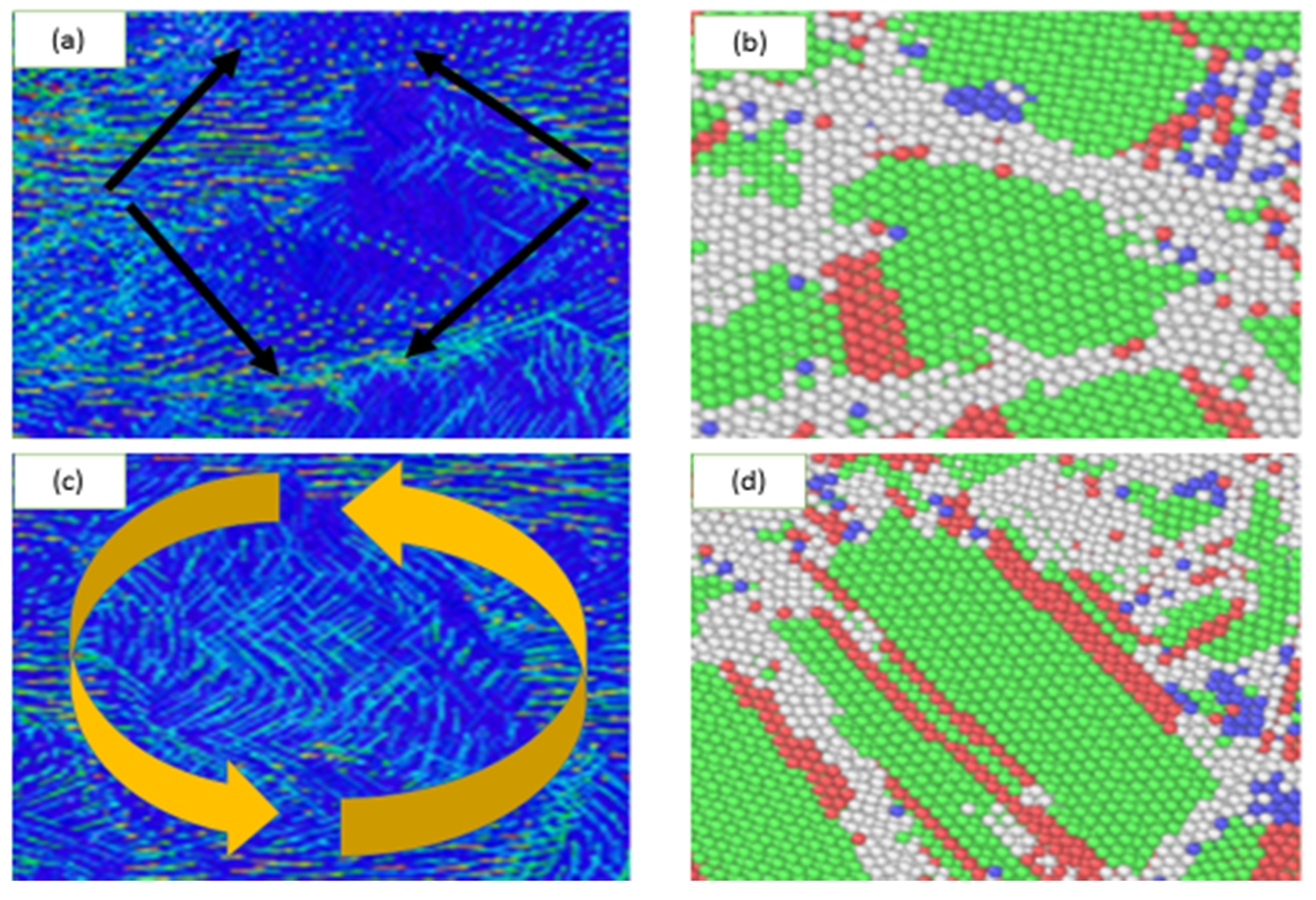

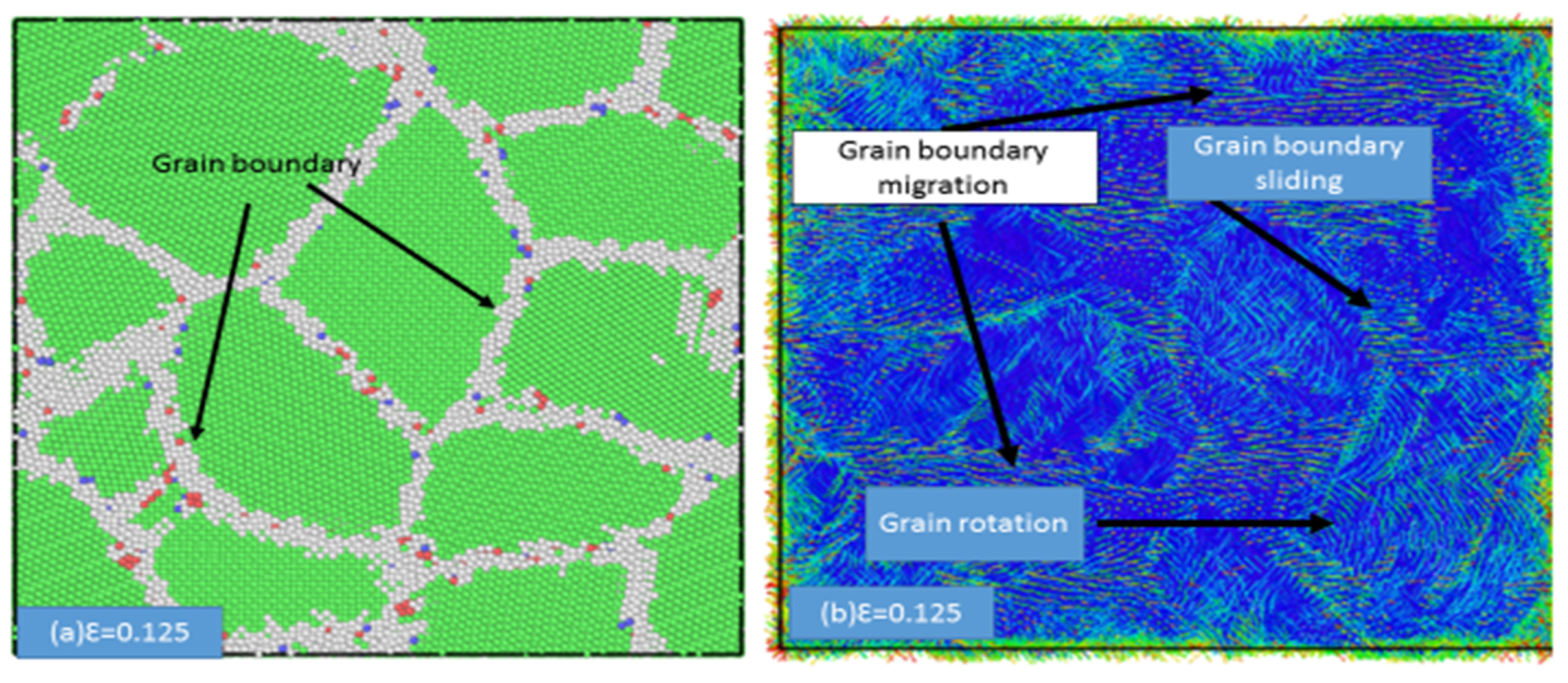

- For grain sizes below 7.7 nm, the yield stress gradually decreased with decreasing grain size. The dominant plastic deformation mechanisms were grain boundary sliding and grain rotation.

- (3)

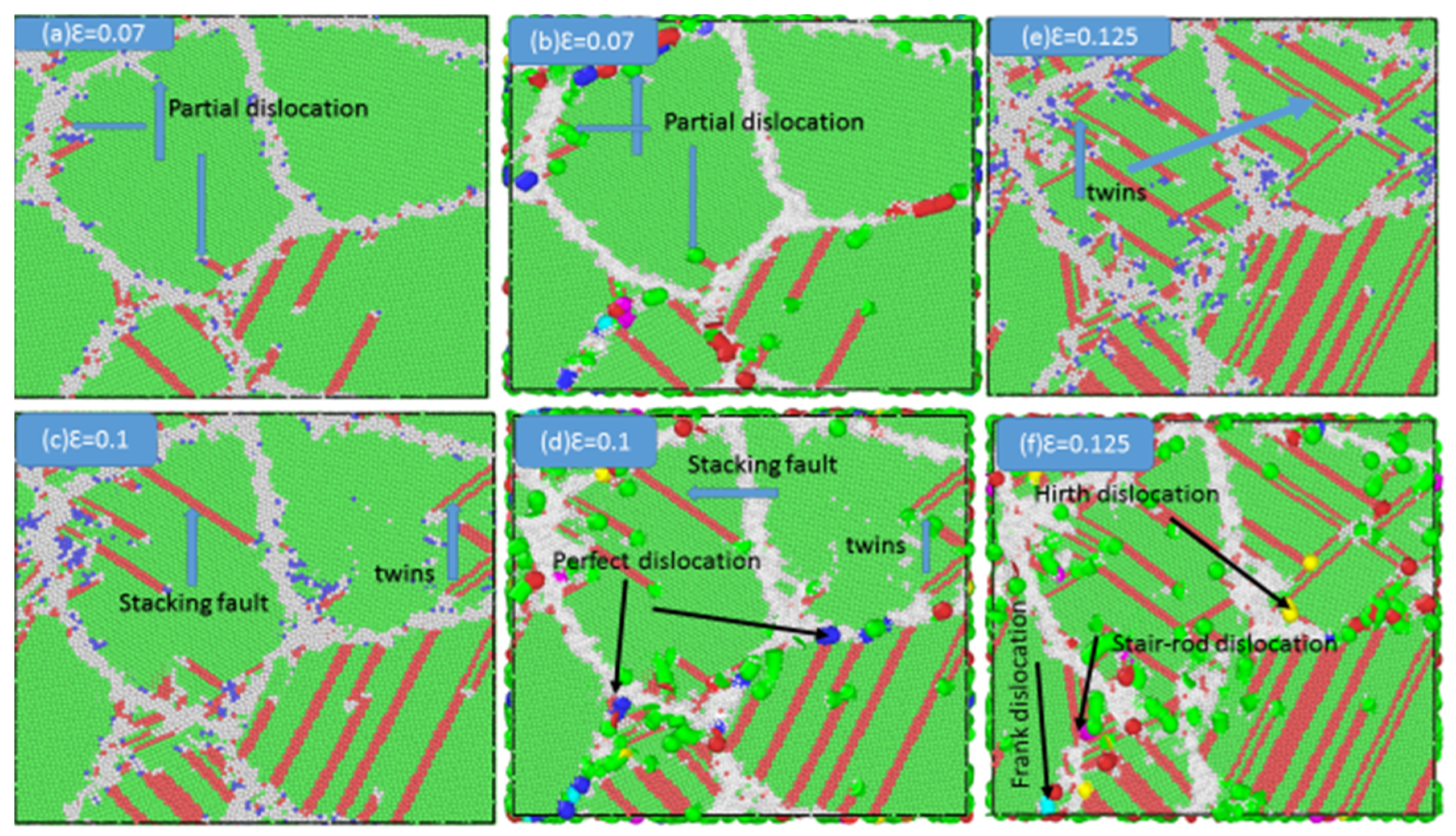

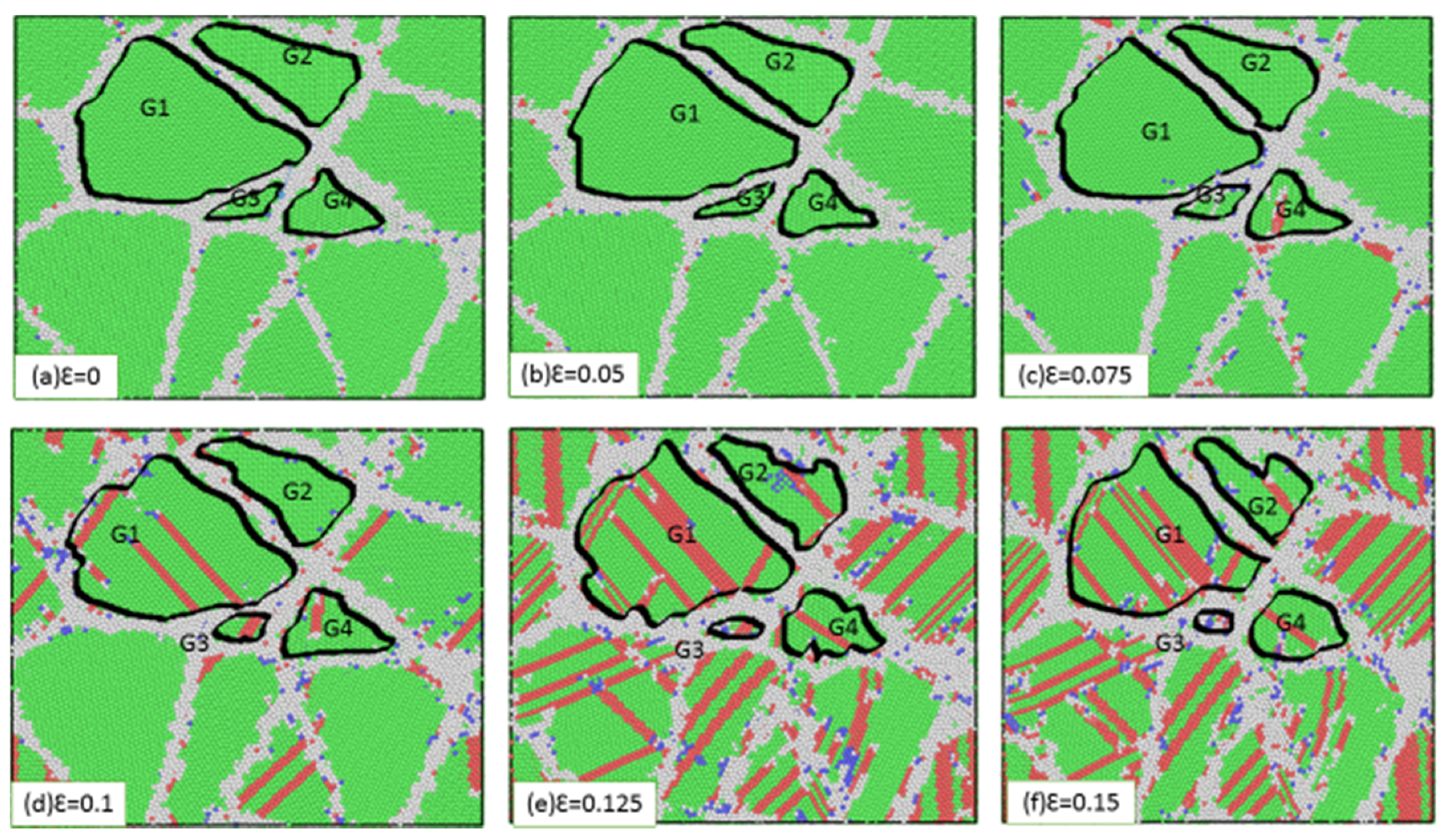

- For grain sizes larger than 7.7 nm, the yield stress gradually increased with decreasing grain size. The dominant plastic deformation mechanisms were dislocation formation and deformation twinning.

- (4)

- As the temperature was increased, the mechanical properties (Young’s modulus, ultimate strength, yield stress, and flow stress) deteriorated.

Author Contributions

Funding

Conflicts of Interest

References

- Zhang, B.M. Handbook of Foundry: Cast Steels; China Machine Press: Beijing, China, 2010. [Google Scholar]

- Pakiela, Z.; Sus-Ryszkowska, M.; Druzycka-Wiencek, A.; Kurzydlowski, K.J. 2004 Nanotechnology Events & Conferences. In Proceedings of the 7th International Conference on Nanostructured Materials, Wiesbaden, Germany, 20–24 June 2004. [Google Scholar]

- Chen, X.H.; Lu, J.; Lu, L.; Lu, K. Tensile properties of a nanocrystalline 316L austenitic stainless steel. Scr. Mater. 2005, 52, 1039–1044. [Google Scholar] [CrossRef]

- Valiev, R.Z.; Islamgaliev, R.K.; Alexandrov, I.V. Bulk nanostructured materials from severe plastic deformation. Prog. Mater. Sci. 2000, 45, 103–189. [Google Scholar] [CrossRef]

- La, P.; Wei, F.; Lu, X.; Chu, C.; Wei, Y.; Wang, H. Effect of annealing temperature on microstructure and mechanical properties of bulk 316L stainless steel with nano- and micro-crystalline dual phases. Metall. Mater. Trans. A 2014, 45, 5236–5244. [Google Scholar] [CrossRef]

- Li, Z.N.; Wei, F.A.; La, P.Q.; Ma, F.L. Enhanced mechanical properties of 316L stainless steel prepared by aluminothermic reaction subjected to multiple warm rolling. Met. Mater. Int. 2018, 24, 633–643. [Google Scholar] [CrossRef]

- Guo, X.; La, P.; Li, H.; Wei, Y.; Lu, X. Microstructure evolution and mechanical properties of 316L austenitic stainless steel with aluminum addition by warm rolling. J. Iron Steel Res. Int. 2018, 25, 1068–1077. [Google Scholar] [CrossRef]

- Sheng, J.; Li, J.; La, P.; Wei, F.; Song, Y.; Wang, K. Investigation of tensile properties of 316L stainless steel with micro-nano-structure in SEM by in situ tension. Integr. Ferroelectr. 2017, 181, 33–41. [Google Scholar]

- Van Swygenhoven, H.; Derlet, P.M. Grain-boundary sliding in nanocrystalline fcc metals. Phys. Rev. B 2001, 64, 224105. [Google Scholar] [CrossRef]

- Van Swygenhoven, H.; Derlet, P.M.; Hasnaoui, A. Grain boundaries and dislocations. Phys. Rev. B 2002, 66, 024101. [Google Scholar] [CrossRef]

- Zheng, Y.G.; Zhang, H.W.; Chen, Z.; Lu, C.; Mai, Y.-W. Roles of grain boundary and dislocations at different deformation stages of nanocrystalline copper under tension. Phys. Lett. A 2009, 373, 570–574. [Google Scholar] [CrossRef]

- Schiøtz, J. Atomic-scale modeling of plastic deformation of nanocrystalline copper. Scr. Mater. 2004, 51, 837–841. [Google Scholar] [CrossRef]

- Li, X.; Wei, Y.; Yang, W.; Gao, H. Competing grain-boundary- and dislocation-mediated mechanisms in plastic strain recovery in nanocrystalline aluminum. Proc. Natl. Acad. Sci. USA 2009, 106, 16108–16113. [Google Scholar] [CrossRef]

- Ding, J.; Tian, Y.; Wang, L.; Huang, X. Micro-mechanism of the effect of grain size and temperature on the mechanical properties of polycrystalline TiAl. Comput. Mater. Sci. 2019, 158, 76–87. [Google Scholar] [CrossRef]

- Li, J.; Lu, B.; Zhou, H.; Tian, C.; Xian, Y.; Hu, G.; Xia, R. Molecular dynamics simulation of mechanical properties of nanocrystalline platinum: Grain-size and temperature effects. Phys. Lett. A 2019, 383, 1922–1928. [Google Scholar] [CrossRef]

- Yamakov, V.; Wolf, D.; Phillpot, S.R.; Mukherjee, A.K.; Gleiter, H. Deformation mechanism map for nanocrystalline metals by molecular dynamics simulation. Nat. Mater. 2004, 3, 43–47. [Google Scholar] [CrossRef]

- Vo, N.Q.; Averback, R.S.; Bellon, P.; Odunuga, S.; Caro, A. Quantitative description of plastic deformation in nanocrystalline Cu: Dislocation glide versus grain boundary sliding. Phys. Rev. B 2008, 77, 134108. [Google Scholar] [CrossRef]

- Plimpton, S. Fast parallel algorithms for short-range molecular dynamics. J. Comput. Phys. 1995, 117, 1–19. [Google Scholar] [CrossRef]

- Hirel, P. Atomsk: A tool for manipulating and converting atomic data files. Comput. Phys. Commun. 2015, 197, 212–219. [Google Scholar] [CrossRef]

- Finney, J.L. A procedure for the construction of Voronoi polyhedral. J. Comput. Phys. 1979, 32, 137–143. [Google Scholar] [CrossRef]

- Zhou, X.W.; Foster, M.E.; Sills, R.B. An Fe-Ni-Cr embedded atom method potential for austenitic and ferritic systems. Comput. Chem. 2018, 39, 2420–2431. [Google Scholar] [CrossRef]

- Evans, D.J.; Holian, B.L. The Nose–Hoover thermostat. J. Chem. Phys. 1985, 83, 4069–4074. [Google Scholar] [CrossRef]

- Stukowski, A. Visualization and analysis of atomistic simulation data with OVITO–The Open Visualization Tool. Model. Simul. Mater. Sci. Eng. 2010, 18, 1–7. [Google Scholar] [CrossRef]

- Ray, J.R.; Rahman, A. Statistical ensembles and molecular dynamics studies of anisotropic solids. J. Chem. Phys. 1984, 80, 4423. [Google Scholar] [CrossRef]

- Nan, C.W.; Liao, X.; Cai, K.; Tong, J. Grain size-dependent elastic moduli of nanocrystals. J. Mater. Sci. Lett. 1998, 17, 1917–1919. [Google Scholar] [CrossRef]

- Zhou, K.; Liu, B.; Yao, Y.; Zhong, K. Effects of grain size and shape on mechanical properties of nanocrystalline copper investigated by molecular dynamics. Mater. Sci. Eng. A 2014, 615, 92–97. [Google Scholar] [CrossRef]

- Rida, A.; Rouhaud, E.; Makke, A.; Micoulaut, M.; Mantisi, B. Study of the effects of grain size on the mechanical properties of nanocrystalline copper using molecular dynamics simulation with initial realistic samples. Philos. Mag. 2017, 97, 2387–2405. [Google Scholar] [CrossRef]

- Sanders, P.G.; Eastman, J.A.; Weertman, J.R. Elastic and tensile behavior of nanocrystalline copper and palladium. Acta Mater. 1997, 45, 4019–4025. [Google Scholar] [CrossRef]

| Grain Size (nm) | Tensile Strength (GPa) | Yield Strength (GPa) | Young’s Modulus (GPa) |

|---|---|---|---|

| 11.5 | 5.44 | 3.7 | 120 |

| 9.9 | 5.6 | 3.8 | 115 |

| 7.7 | 5.65 | 4.2 | 131 |

| 4.1 | 5.1 | 3.9 | 130 |

| 3.6 | 4.8 | 3.75 | 129 |

| 2.5 | 4.9 | 3.5 | 124 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Husain, A.; La, P.; Hongzheng, Y.; Jie, S. Influence of Temperature on Mechanical Properties of Nanocrystalline 316L Stainless Steel Investigated via Molecular Dynamics Simulations. Materials 2020, 13, 2803. https://doi.org/10.3390/ma13122803

Husain A, La P, Hongzheng Y, Jie S. Influence of Temperature on Mechanical Properties of Nanocrystalline 316L Stainless Steel Investigated via Molecular Dynamics Simulations. Materials. 2020; 13(12):2803. https://doi.org/10.3390/ma13122803

Chicago/Turabian StyleHusain, Abdelrahim, Peiqing La, Yue Hongzheng, and Sheng Jie. 2020. "Influence of Temperature on Mechanical Properties of Nanocrystalline 316L Stainless Steel Investigated via Molecular Dynamics Simulations" Materials 13, no. 12: 2803. https://doi.org/10.3390/ma13122803

APA StyleHusain, A., La, P., Hongzheng, Y., & Jie, S. (2020). Influence of Temperature on Mechanical Properties of Nanocrystalline 316L Stainless Steel Investigated via Molecular Dynamics Simulations. Materials, 13(12), 2803. https://doi.org/10.3390/ma13122803