Metal Matrix Composites Synthesized by Laser-Melting Deposition: A Review

Abstract

1. Introduction

- i.

- Initially, CAD software is used to build a 3D model, which is to be printed.

- ii.

- This CAD model is converted into stereolithography (STL) format (stereolithography, principally recognized AM practice, implemented as a standard in AM industry). This file is the wedge-shaped illustration of a 3D CAD model.

- iii.

- The file from the step (ii) is sliced into several thin cross-sectional layers using a slicing software. In this step, the building orientation is defined.

- iv.

- v.

- In the final step, post-processing steps such as surface treatments, sintering, or finishing, are usually required.

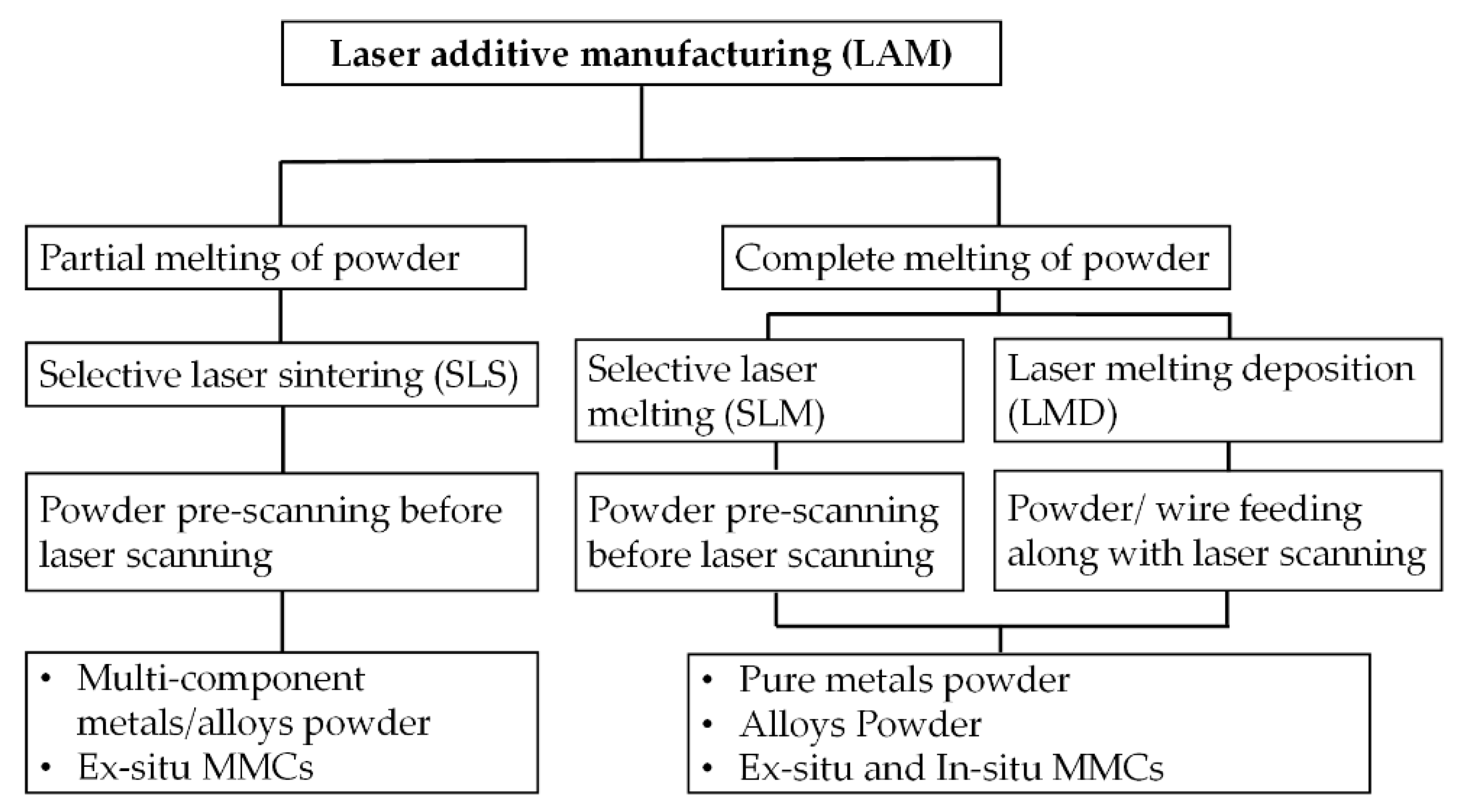

2. Laser Additive Manufacturing (LAM) Processes

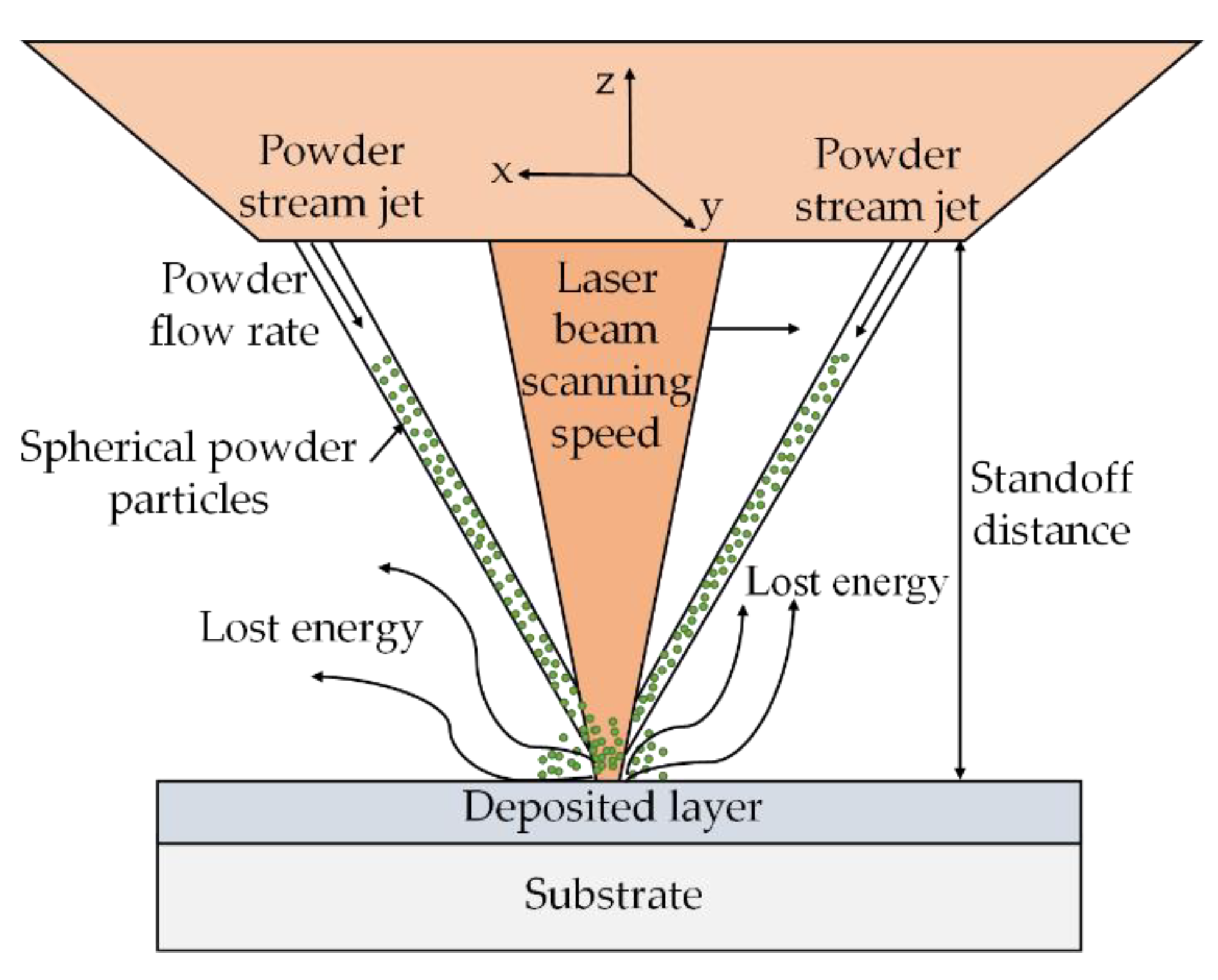

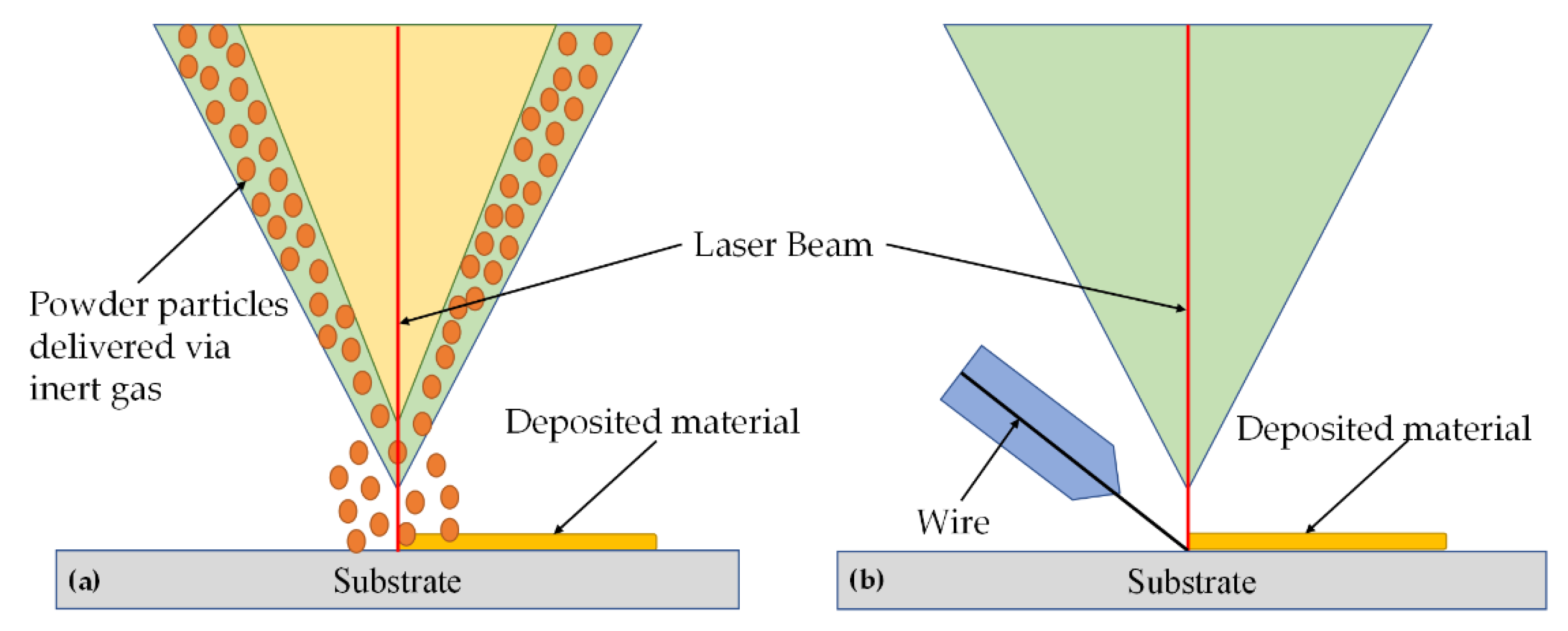

Laser-Melting Deposition (LMD) Process

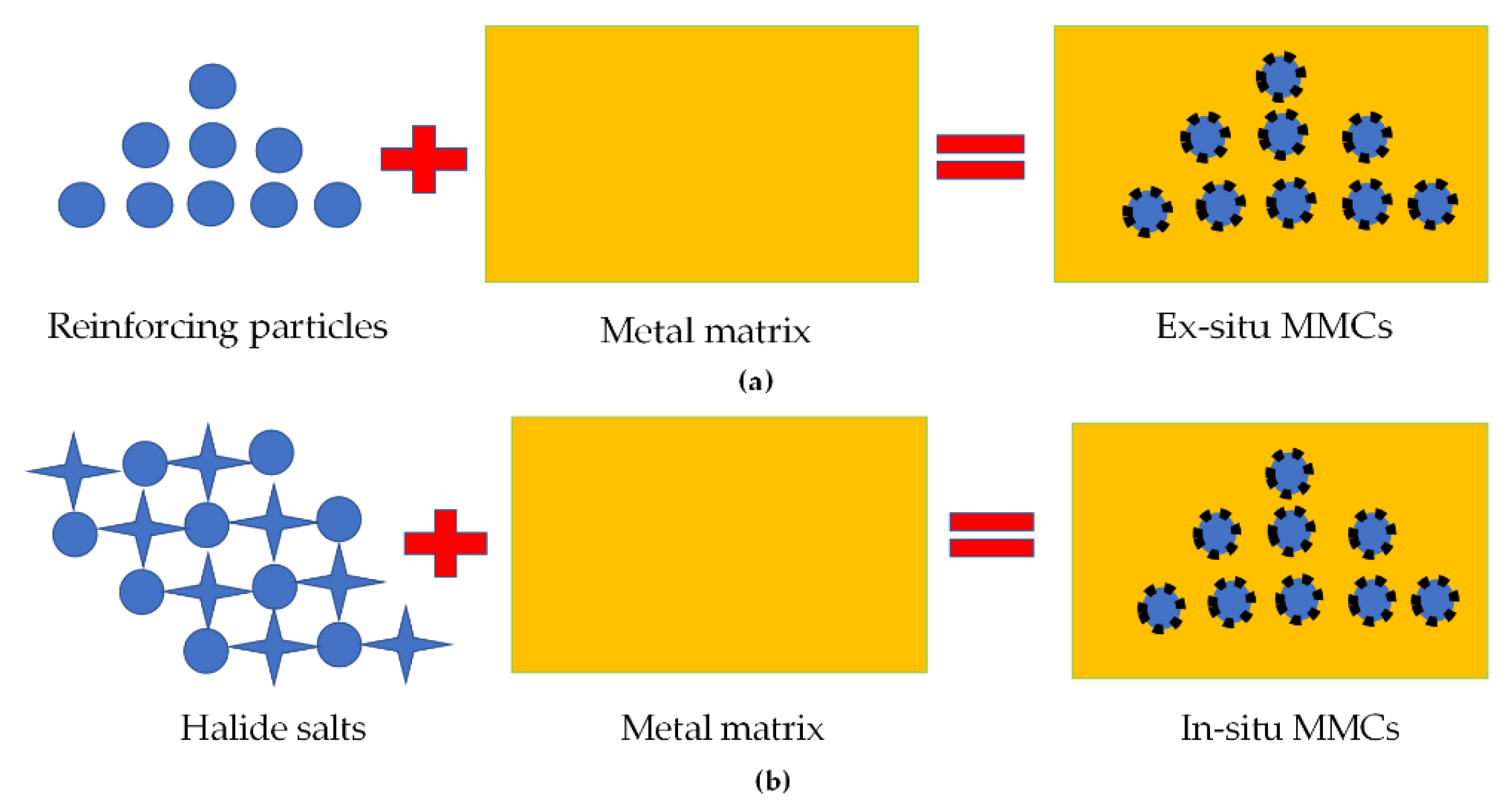

3. Metal Matrix Composites (MMCs)

3.1. MMCs Mixing Techniques

3.2. Metal Matrix Composites (MMCs) Deposited by Wire and Powder Particles Feedstock

3.3. Different Laser Sources for In-Situ MMCs Syntheses by LMD

3.4. Matrices for MMCS

3.4.1. Titanium-Based MMCs (TMCs)

3.4.2. Nickel-Based MMCs (NMCs)

3.4.3. Other Metal Matrix Composites

3.5. Properties of MMCs

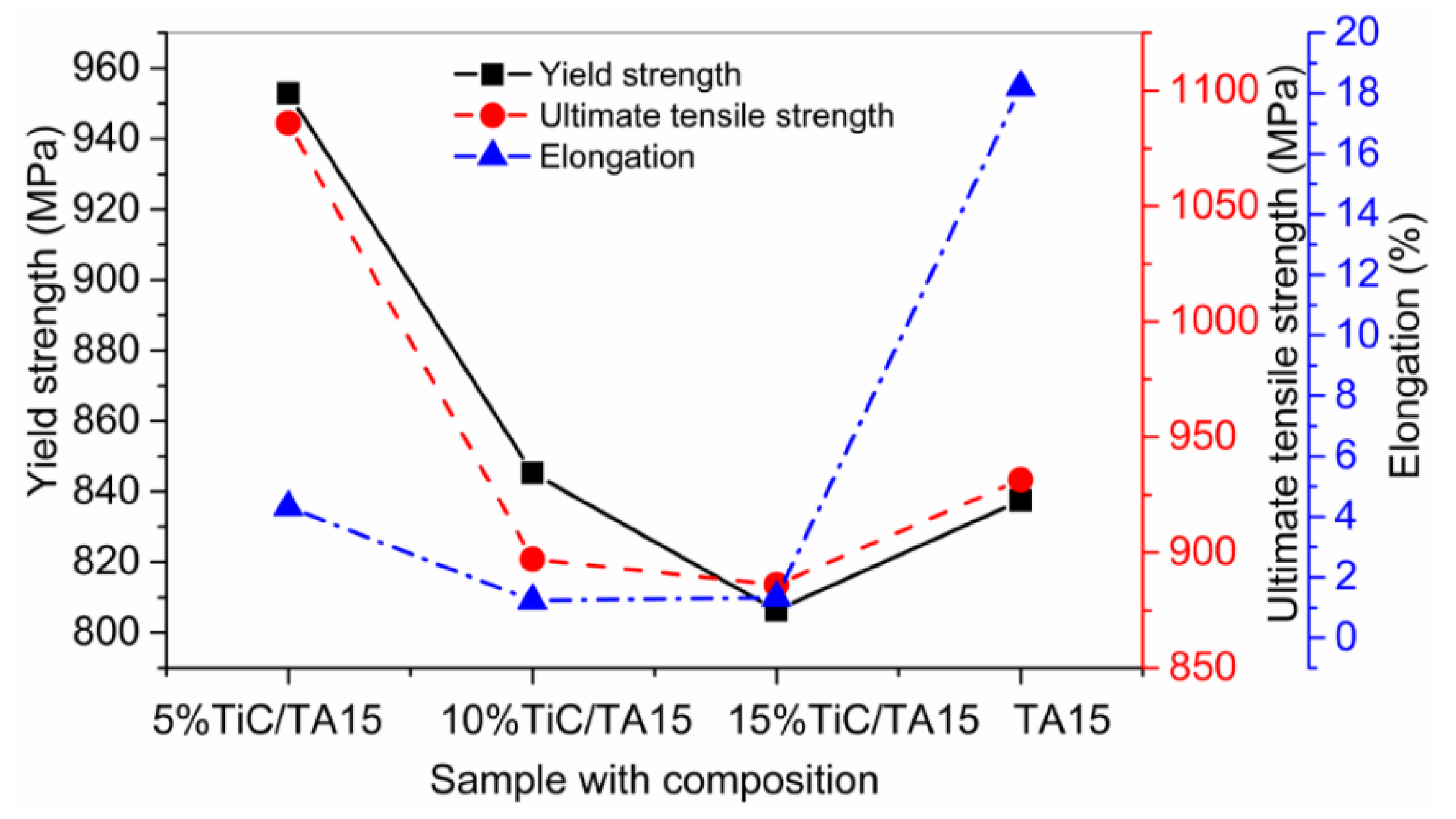

3.5.1. Mechanical Properties: Hardness, Ultimate Tensile Strength (UTS), Yield Strength (YS), Elongation, and Wear

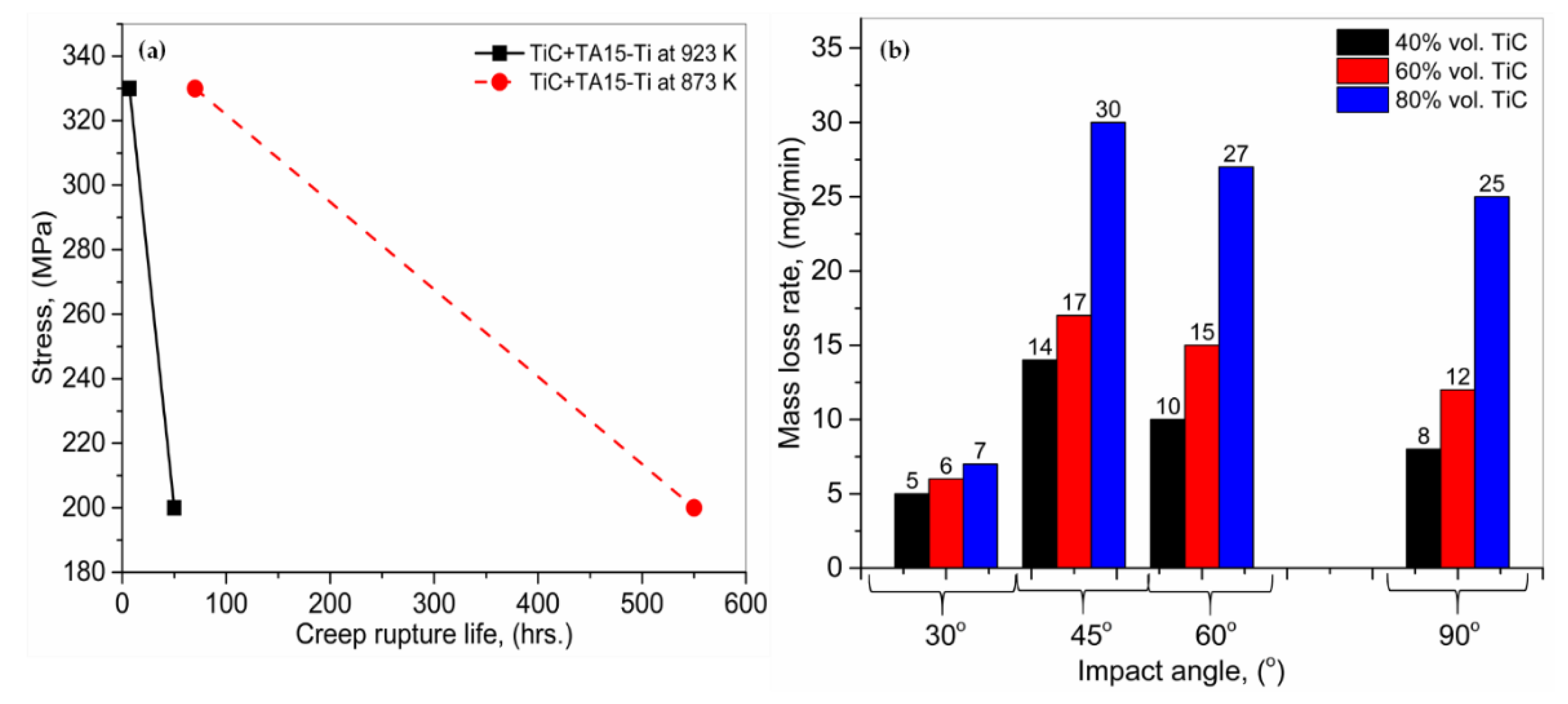

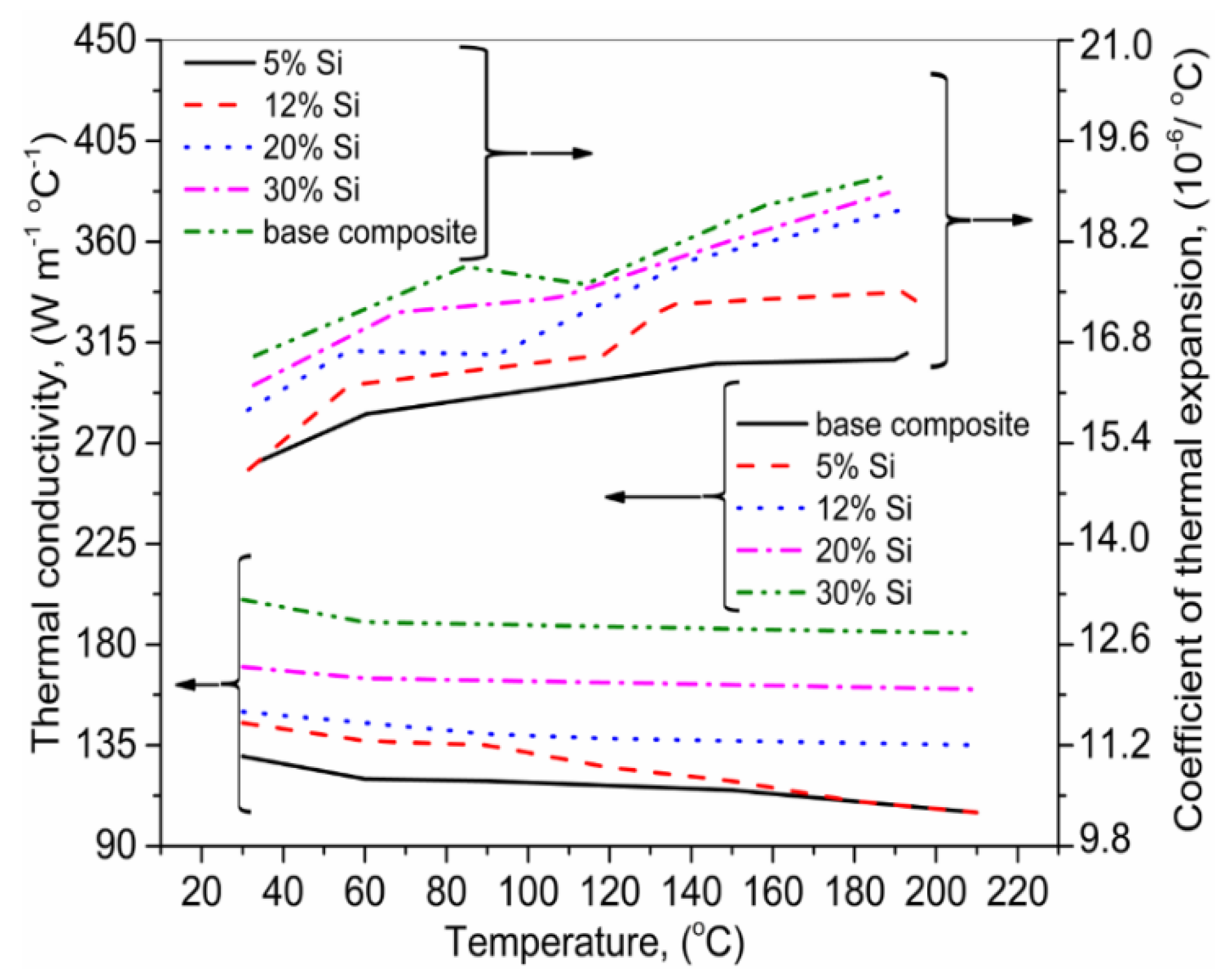

3.5.2. Creep Behavior, Erosion Resistance and Thermophysical

3.6. Applications of MMCs

3.6.1. Biomedical

3.6.2. Wear Resistance

3.6.3. Corrosion and Erosion Resistance

3.6.4. Industrial

3.7. MMCs by the LMD: Strengths, Challenges and Their Potential Solutions

3.8. Future Research Directions in MMCs

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- What is Additive Manufacturing? Wohlers Associates. Available online: https://wohlersassociates.com/additive-manufacturing.html (accessed on 13 October 2019).

- Hu, Y.; Cong, W. A review on laser deposition-additive manufacturing of ceramics and ceramic reinforced metal matrix composites. Ceram. Int. 2018, 44, 20599–20612. [Google Scholar] [CrossRef]

- Lee, H.; Lim, C.H.J.; Low, M.J.; Tham, N.; Murukeshan, V.M.; Kim, Y.J. Lasers in additive manufacturing: A review. Int. J. Precis. Eng. Manuf. Green Technol. 2017, 4, 307–322. [Google Scholar] [CrossRef]

- Li, Y.; Hu, Y.; Cong, W.; Zhi, L.; Guo, Z. Additive manufacturing of alumina using laser engineered net shaping: Effects of deposition variables. Ceram. Int. 2017, 43, 7768–7775. [Google Scholar] [CrossRef]

- Hu, Y.; Ning, F.; Wang, H.; Cong, W.; Zhao, B. Laser engineered net shaping of quasi-continuous network microstructural TiB reinforced titanium matrix bulk composites: Microstructure and wear performance. Opt. Laser Technol. 2018, 99, 174–183. [Google Scholar] [CrossRef]

- Williams, J.M.; Adewunmi, A.; Schek, R.M.; Flanagan, C.L.; Krebsbach, P.H.; Feinberg, S.E.; Hollister, S.J.; Das, S. Bone tissue engineering using polycaprolactone scaffolds fabricated via selective laser sintering. Biomaterials 2005, 26, 4817–4827. [Google Scholar] [CrossRef]

- Kumar, S. Selective laser sintering: A qualitative and objective approach. JOM. 2003, 55, 43–47. [Google Scholar] [CrossRef]

- Yap, C.Y.; Chua, C.K.; Dong, Z.L.; Liu, Z.H.; Zhang, D.Q.; Loh, L.E.; Sing, S.L. Review of selective laser melting: Materials and applications. Appl. Phys. Rev. 2015, 2, 041101. [Google Scholar] [CrossRef]

- Yadroitsev, I.; Bertrand, P.; Smurov, I. Parametric analysis of the selective laser melting process. Appl. Surf. Sci. 2007, 253, 8064–8069. [Google Scholar] [CrossRef]

- Wang, T.; Zhu, Y.Y.; Zhang, S.Q.; Tang, H.B.; Wang, H.M. Grain morphology evolution behavior of titanium alloy components during laser melting deposition additive manufacturing. J. Alloys Compd. 2015, 632, 505–513. [Google Scholar] [CrossRef]

- Li, L.; Wang, J.; Lin, P.; Liu, H. Microstructure and mechanical properties of functionally graded TiCp/Ti6Al4V composite fabricated by laser melting deposition. Ceram. Int. 2017, 43, 16638–16651. [Google Scholar] [CrossRef]

- Anitha, R.; Arunachalam, S.; Radhakrishnan, P. Critical parameters influencing the quality of prototypes in fused deposition modelling. J. Mater. Process. Technol. 2001, 118, 385–388. [Google Scholar] [CrossRef]

- Sood, A.K.; Ohdar, R.K.; Mahapatra, S.S. Parametric appraisal of mechanical property of fused deposition modelling processed parts. Mater. Des. 2010, 31, 287–295. [Google Scholar] [CrossRef]

- Melchels, F.P.W.; Feijen, J.; Grijpma, D.W. A review on stereolithography and its applications in biomedical engineering. Biomaterials 2010, 31, 6121–6130. [Google Scholar] [CrossRef] [PubMed]

- Griffith, M.L.; Halloran, J.W. Freeform fabrication of ceramics via stereolithography. J. Am. Ceram. Soc. 2005, 79, 2601–2608. [Google Scholar] [CrossRef]

- Noguchi, Y.; Sekitani, T.; Yokota, T.; Someya, T. Direct inkjet printing of silver electrodes on organic semiconductors for thin-film transistors with top contact geometry. Appl. Phys. Lett. 2008, 93, 043303. [Google Scholar] [CrossRef]

- Ebert, J.; Özkol, E.; Zeichner, A.; Uibel, K.; Weiss, Ö.; Koops, U.; Telle, R.; Fischer, H. Direct inkjet printing of dental prostheses made of zirconia. J. Dent. Res. 2009, 88, 673–676. [Google Scholar] [CrossRef]

- Tian, X.; Li, D.; Heinrich, J.G. Rapid prototyping of porcelain products by layer-wise slurry deposition (LSD) and direct laser sintering. Rapid Prototyp. J. 2012, 18, 362–373. [Google Scholar] [CrossRef]

- Gahler, A.; Heinrich, J.G.; Günster, J. Direct laser sintering of Al2O3-SiO2 dental ceramic components by layer-wise slurry deposition. J. Am. Ceram. Soc. 2006, 89, 3076–3080. [Google Scholar] [CrossRef]

- Klosterman, D.; Chartoff, R.; Graves, G.; Osborne, N.; Priore, B. Interfacial characteristics of composites fabricated by laminated object manufacturing. Compos. Part A Appl. Sci. Manuf. 1998, 29, 1165–1174. [Google Scholar] [CrossRef]

- Mueller, B.; Kochan, D. Laminated object manufacturing for rapid tooling and patternmaking in foundry industry. Comput. Ind. 1999, 39, 47–53. [Google Scholar] [CrossRef]

- Gu, D. Laser Additive Manufacturing of High-Performance Materials; Springer: Berlin, Germany, 2015; ISBN 978-3-662-46089-4. [Google Scholar]

- Fan, W.; Ji, J.; Wu, P.; Wu, D.; Chen, H. Modeling and simulation of trajectory smoothing and feedrate scheduling for vibration-damping CNC machining. Simul. Model. Pract. Theory 2020, 99, 102028. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhao, M.; Ye, P.; Zhang, H. A G4 continuous B-spline transition algorithm for CNC machining with jerk-smooth feedrate scheduling along linear segments. CAD Comput. Aided Des. 2019, 115, 231–243. [Google Scholar] [CrossRef]

- Li, J.; Wang, H.M. Microstructure and mechanical properties of rapid directionally solidified Ni-base superalloy Rene’41 by laser melting deposition manufacturing. Mater. Sci. Eng. A. 2010, 527, 4823–4829. [Google Scholar] [CrossRef]

- Zhang, Y.; Guo, Y.; Chen, Y.; Kang, L.; Cao, Y.; Qi, H.; Yang, S. Ultrasonic -assisted laser metal deposition of the Al 4047 alloy. Met. 2019, 9, 1111. [Google Scholar]

- Niu, F.; Wu, D.; Ma, G.; Wang, J.; Guo, M.; Zhang, B. Nanosized microstructure of Al2O3-ZrO2 (Y2O3) eutectics fabricated by laser engineered net shaping. Scr. Mater. 2015, 95, 39–41. [Google Scholar] [CrossRef]

- Hu, Y.; Cong, W.; Wang, X.; Li, Y.; Ning, F.; Wang, H. Laser deposition-additive manufacturing of TiB-Ti composites with novel three-dimensional quasi-continuous network microstructure: Effects on strengthening and toughening. Compos. Part B Eng. 2018, 133, 91–100. [Google Scholar] [CrossRef]

- Koczak, M.J.; Premkumar, M.K. Emerging technologies for the in-situ production of MMCs. JOM. 1993, 45, 44–48. [Google Scholar] [CrossRef]

- Emamian, A.; Alimardani, M.; Khajepour, A. Effect of cooling rate and laser process parameters on additive manufactured Fe-Ti-C metal matrix composites microstructure and carbide morphology. J. Manuf. Process. 2014, 16, 511–517. [Google Scholar] [CrossRef]

- Nevelos, J.E.; Ingham, E.; Doyle, C.; Nevelos, A.B.; Fisher, J. The influence of acetabular cup angle on the wear of “BIOLOX Forte” alumina ceramic bearing couples in a hip joint simulator. J. Mater. Sci. Mater. Med. 2001, 12, 141–144. [Google Scholar] [CrossRef]

- Höland, W.; Schweiger, M.; Watzke, R.; Peschke, A.; Kappert, H. Ceramics as biomaterials for dental restoration. Expert Rev. Med. Devices. 2008, 5, 729–745. [Google Scholar] [CrossRef]

- Miracle, D.B. Metal matrix composites - From science to technological significance. Compos. Sci. Technol. 2005, 65, 2526–2540. [Google Scholar] [CrossRef]

- Mandal, N.; Doloi, B.; Mondal, B. Predictive modeling of surface roughness in high speed machining of AISI 4340 steel using yttria stabilized zirconia toughened alumina turning insert. Int. J. Refract. Met. Hard Mater. 2013, 38, 40–46. [Google Scholar] [CrossRef]

- He, X.; Zhang, Y.Z.; Mansell, J.P.; Su, B. Zirconia toughened alumina ceramic foams for potential bone graft applications: Fabrication, bioactivation, and cellular responses. J. Mater. Sci. Mater. Med. 2008, 19, 2743–2749. [Google Scholar] [CrossRef] [PubMed]

- Zeng, W.M.; Li, Z.C.; Pei, Z.J.; Treadwell, C. Experimental observation of tool wear in rotary ultrasonic machining of advanced ceramics. Int. J. Mach. Tools Manuf. 2005, 45, 1468–1473. [Google Scholar] [CrossRef]

- Rosso, M. Ceramic and metal matrix composites: Routes and properties. J. Mater. Process. Technol. 2006, 175, 364–375. [Google Scholar] [CrossRef]

- Zhang, B.; Zheng, X.L.; Tokura, H.; Yoshikawa, M. Grinding induced damage in ceramics. J. Mater. Process. Technol. 2003, 132, 353–364. [Google Scholar] [CrossRef]

- Singh, R.; Davim, J.P. Additive Manufacturing: Applications and Innovations; CRC Press: Boca Raton, FL, USA, 2018; ISBN 1351686666. [Google Scholar]

- Levy, G.N. The role and future of the laser technology in the additive manufacturing environment. Phys. Procedia 2010, 5, 65–80. [Google Scholar] [CrossRef]

- 3D Printed Metals—LENS Metal Additive Manufacturing Technology. Available online: https://www.optomec.com/3d-printed-metals/lens-technology/ (accessed on 4 October 2019).

- Borkar, T.; Gopagoni, S.; Nag, S.; Hwang, J.Y.; Collins, P.C.; Banerjee, R. In situ nitridation of titanium-molybdenum alloys during laser deposition. J. Mater. Sci. 2012, 47, 7157–7166. [Google Scholar] [CrossRef]

- Chandrasekar, P.; Balusamy, V.; Chandran, K.S.R.; Kumar, H. Laser surface hardening of titanium-titanium boride (Ti-TiB) metal matrix composite. Scr. Mater. 2007, 56, 641–644. [Google Scholar] [CrossRef]

- Lu, W.J.; Xiao, L.; Geng, K.; Qin, J.N.; Zhang, D. Growth mechanism of in situ synthesized TiBw in titanium matrix composites prepared by common casting technique. Mater. Charact. 2008, 59, 912–919. [Google Scholar] [CrossRef]

- Mahamood, R.M.; Akinlabi, E.T.; Shukla, M.; Pityana, S. Scanning velocity influence on microstructure, microhardness and wear resistance performance of laser deposited Ti6Al4V/TiC composite. Mater. Des. 2013, 50, 656–666. [Google Scholar] [CrossRef]

- Shishkovsky, I.; Missemer, F.; Smurov, I. Metal matrix composites with ternary intermetallic inclusions fabricated by laser direct energy deposition. Compos. Struct. 2018, 183, 663–670. [Google Scholar] [CrossRef]

- Tamirisakandaia, S.; Miracle, D.B.; Srinivasan, R.; Gunasekera, J.S. Titanium alloyed with boron. Adv. Mater. Process. 2006, 164, 41–43. [Google Scholar]

- Liu, D.; Zhang, S.Q.; Li, A.; Wang, H.M. Microstructure and tensile properties of laser melting deposited TiC/TA15 titanium matrix composites. J. Alloys Compd. 2009, 485, 156–162. [Google Scholar] [CrossRef]

- Wu, C.L.; Zhang, S.; Zhang, C.H.; Zhang, J.B.; Liu, Y.; Chen, J. Effects of SiC content on phase evolution and corrosion behavior of SiC-reinforced 316L stainless steel matrix composites by laser melting deposition. Opt. Laser Technol. 2019, 115, 134–139. [Google Scholar] [CrossRef]

- Deoker, B.F.; Kasper, J.S. The crystal structure of TiB. Acta Cryst. 1954, 7, 77–80. [Google Scholar] [CrossRef]

- Donadello, S.; Motta, M.; Demir, A.G.; Previtali, B. Monitoring of laser metal deposition height by means of coaxial laser triangulation. Opt. Lasers Eng. 2019, 112, 136–144. [Google Scholar] [CrossRef]

- Hu, Y.; Ning, F.; Wang, X.; Wang, H.; Zhao, B.; Cong, W.; Li, Y. Laser deposition-additive manufacturing of in situ TiB reinforced titanium matrix composites: TiB growth and part performance. Int. J. Adv. Manuf. Technol. 2017, 93, 3409–3418. [Google Scholar] [CrossRef]

- Jiang, B.; Zhenglong, L.; Xi, C.; Peng, L.; Nannan, L.; Yanbin, C. Microstructure and mechanical properties of TiB2-reinforced 7075 aluminum matrix composites fabricated by laser melting deposition. Ceram. Int. 2019, 45, 5680–5692. [Google Scholar] [CrossRef]

- Li, N.; Liu, W.; Xiong, H.; Qin, R.; Huang, S.; Zhang, G.; Gao, C. In-situ reaction of Ti-Si-C composite powder and formation mechanism of laser deposited Ti6Al4V/(TiC+Ti3SiC2) system functionally graded material. Mater. Des. 2019, 183, 108155. [Google Scholar] [CrossRef]

- Li, X.; Zhang, C.H.; Zhang, S.; Wu, C.L.; Zhang, J.B.; Chen, H.T.; Abdullah, A.O. Design, preparation, microstructure and properties of novel wear-resistant stainless steel-base composites using laser melting deposition. Vacuum 2019, 165, 139–147. [Google Scholar] [CrossRef]

- Wang, J.; Li, L.; Tan, C.; Liu, H.; Lin, P. Microstructure and tensile properties of TiCp/Ti6Al4V titanium matrix composites manufactured by laser melting deposition. J. Mater. Process. Technol. 2018, 252, 524–536. [Google Scholar] [CrossRef]

- Chioibasu, D.; Achim, A.; Popescu, C.; Stan, G.; Pasuk, I.; Enculescu, M.; Iosub, S.; Duta, L.; Popescu, A. Prototype orthopedic bone plates 3D printed by laser melting deposition. Materials 2019, 12, 906. [Google Scholar] [CrossRef] [PubMed]

- Additive Manufacturing by Direct Metal Deposition. Available online: https://www.researchgate.net/publication/279617679_Additive_Manufacturing_by_Direct_Metal_Deposition (accessed on 12 October 2019).

- Mazumder, J.; Dutta, D.; Kikuchi, N.; Ghosh, A. Closed loop direct metal deposition: Art to Part. Opt. Lasers Eng. 2000, 34, 397–414. [Google Scholar] [CrossRef]

- Griffith, M.L.; Keicher, D.M.; Atwood, C.L.; Romero, J.A.; Smugeresky, E.; Harwell, L.D.; Greene, D.L. Free Form Fabrication of Metallic Components Using Laser Engineered Net Shaping (Lenstm); Sandia National Labs: Albuquerque, NM, USA, 1996. [Google Scholar]

- Milewski, J.O.; Lewis, G.K.; Thoma, D.J.; Keel, G.I.; Nemec, R.B.; Reinert, R.A. Directed light fabrication of a solid metal hemisphere using 5-axis powder deposition. J. Mater. Process. Technol. 1998, 75, 165–172. [Google Scholar] [CrossRef]

- Nagel, J.K.S.; Liou, F.W. Hybrid manufacturing system modeling and development. Proc. ASME Des. Eng. Tech. Conf. 2012, 3, 189–198. [Google Scholar]

- Nam, S.; Cho, H.; Kim, C.; Kim, Y.M. Effect of process parameters on deposition properties of functionally graded STS 316/Fe manufactured by laser direct metal deposition. Metals 2018, 8, 607. [Google Scholar] [CrossRef]

- Pityana, S.; Mahamood, R.M.; Akinlabi, E.T.; Shukla, M. Gas flow rate and powder flow rate effect on properties of laser metal deposited Ti6Al4V. Lect. Notes Eng. Comput. Sci. 2013, 2203, 848–851. [Google Scholar]

- Ruiz, J.E.; Cortina, M.; Arrizubieta, J.I.; Lamikiz, A. Study of the influence of shielding gases on Laser Metal Deposition of Inconel 718 superalloy. Materials 2018, 11, 1388. [Google Scholar] [CrossRef]

- España, F.A.; Balla, V.K.; Bose, S.; Bandyopadhyay, A. Design and fabrication of CoCrMo alloy based novel structures for load bearing implants using laser engineered net shaping. Mater. Sci. Eng. C 2010, 30, 50–57. [Google Scholar] [CrossRef]

- Cordova, L.; Campos, M.; Tinga, T.; Li, H.; Ramezani, M.; Li, M.; Ma, C.; Wang, J. Powder characterization and optimization for additive manufacturing. Tribol. Int. 2017, 128, 926872. [Google Scholar]

- Erinosho, M.F.; Akinlabi, E.T. Influence of laser power on the surfacing microstructures and microhardness properties of Ti-6Al-4V-cualloys using the ytterbium fiber laser. Mater. Today Proc. 2017, 4, 596–602. [Google Scholar] [CrossRef]

- Kong, C.Y.; Carroll, P.A.; Brown, P.; Scudamore, R.J. The Effect of Average Powder Particle Size on Deposition Efficiency, Deposit Height and Surface Roughness in the Direct Metal Laser Deposition Process. In Proceedings of the 14th International Conference on Joining of Materials, Helsingør, Denmark, 29 April–2 May 2007. [Google Scholar]

- Dr. Kumar Sundaram—Ex-situ and in-situ Metal Matrix Composites. Available online: https://sites.google.com/site/kumarspage/Home/research/ex-situ-and-in-situ-composites (accessed on 21 October 2019).

- Zhou, W.; Xu, Z.M. Casting of SiC reinforced metal matrix composites. J. Mater. Process. Technol. 1997, 63, 358–363. [Google Scholar] [CrossRef]

- Gupta, M.; Lai, M.O.; Lim, C.Y.H. Development of a novel hybrid aluminum-based composite with enhanced properties. J. Mater. Process. Technol. 2006, 176, 191–199. [Google Scholar] [CrossRef]

- Ourdjini, A.; Chew, K.C.; Khoo, B.T. Settling of silicon carbide particles in cast metal matrix composites. J. Mater. Process. Technol. 2001, 116, 72–76. [Google Scholar] [CrossRef]

- Srivatsan, T.S.; Sudarshan, T.S.; Lavernia, E.J. Processing of discontinuously-reinforced metal matrix composites by rapid solidification. Prog. Mater. Sci. 1995, 39, 317–409. [Google Scholar] [CrossRef]

- Manna, A.; Mahapatra, P.B.; Bains, H.S. Experimental study on fabrication of Al-Al2O3/Grp metal matrix composites. J. Compos. Mater. 2010, 44, 3069–3079. [Google Scholar] [CrossRef]

- Naher, S.; Brabazon, D.; Looney, L. Development and assessment of a new quick quench stir caster design for the production of metal matrix composites. J. Mater. Process. Technol. 2005, 166, 430–439. [Google Scholar] [CrossRef]

- Flemings, M.C. Behavior of metal alloys in the semisolid state. Metall. Trans. A 1991, 22, 957–981. [Google Scholar] [CrossRef]

- Narasimha, B.G.; Krishna, V.M.; Xavior, A.M. A review on processing of particulate metal matrix composites and its properties. Int. J. Appl. Eng. Res. 2013, 8, 647–666. [Google Scholar]

- Williams, G.; Fisher, K.M. Squeeze forming of aluminium-alloy components. Met. Technol. 1981, 8, 263–267. [Google Scholar] [CrossRef]

- Ghomashchi, M.R.; Vikhrov, A. Squeeze casting: An overview. J. Mater. Process. Technol. 2000, 101, 1–9. [Google Scholar] [CrossRef]

- Schwam, D.; Wallace, J.F.; Chang, Q.; Zhu, Y.; Schwam, D.; Wallace, J.F.; Chang, Q.; Zhu, Y. Optimization of the squeeze casting process for aluminum alloy parts. STIN 2002, 3, 01652. [Google Scholar]

- Das, S.; Behera, R.; Datta, A.; Majumdar, G.; Oraon, B.; Sutradhar, G. Experimental investigation on the effect of reinforcement particles on the forgeability and the mechanical properties of aluminum metal matrix composites. Mater. Sci. Appl. 2010, 1, 310–316. [Google Scholar] [CrossRef][Green Version]

- Manjunathal, H.; Dinesh, P. Fabrication and properties of dispersed carbon nanotube-Al6061 composites. Int. J. Innov. Res. Sci. Eng. Technol. 2013, 2, 500–507. [Google Scholar]

- Barekar, N.S.; Patel, J.B.; Barekar, N.; Tzamtzis, S.; Dhindaw, B.K.; Patel, J.; Babu, N.H.; Fan, Z. Processing of aluminum-graphite particulate metal matrix composites by advanced shear technology. J. Mater. Eng. Perform. 2009, 18, 1230–1240. [Google Scholar] [CrossRef]

- Barekar, N.S.; Tzamtzis, S.; Hari Babu, N.; Fan, Z.; Dhindaw, B.K. Processing of ultrafine-size particulate metal matrix composites by advanced shear technology. Metall. Mater. Trans. A Phys. Metall. Mater. Sci. 2009, 40, 691–701. [Google Scholar] [CrossRef]

- Donthamsetty, S. Investigation on mechanical properties of a356 nanocomposites fabricated by ultrasonic assisted cavitation. J. Mech. Eng. 2011, 41, 121–129. [Google Scholar] [CrossRef]

- Sato, Y.S.; Nelson, T.W.; Sterling, C.J. Recrystallization in type 304L stainless steel during friction stirring. Acta Mater. 2005, 53, 637–645. [Google Scholar] [CrossRef]

- Chen, C.L.; Tatlock, G.J.; Jones, A.R. Microstructural evolution in friction stir welding of nanostructured ODS alloys. J. Alloys Compd. 2010, 504, S460–S466. [Google Scholar] [CrossRef]

- Lanfant, B.; Bär, F.; Mohanta, A.; Leparoux, M. Fabrication of metal matrix composite by laser metal deposition—A new process approach by direct dry injection of nanopowders. Materials 2019, 12, 3584. [Google Scholar] [CrossRef] [PubMed]

- Liu, D.; Zhang, S.Q.; Li, A.; Wang, H.M. High temperature mechanical properties of a laser melting deposited TiC/TA15 titanium matrix composite. J. Alloys Compd. 2010, 496, 189–195. [Google Scholar] [CrossRef]

- Cooper, D.E.; Blundell, N.; Maggs, S.; Gibbons, G.J. Additive layer manufacture of Inconel 625 metal matrix composites, reinforcement material evaluation. J. Mater. Process. Technol. 2013, 213, 2191–2200. [Google Scholar] [CrossRef]

- Klocke, F.; Arntz, K.; Teli, M.; Winands, K.; Wegener, M.; Oliari, S. State-of-the-art laser additive manufacturing for hot-work tool steels. Procedia CIRP 2017, 63, 58–63. [Google Scholar] [CrossRef]

- Li, F.; Gao, Z.; Zhang, Y.; Chen, Y. Alloying effect of titanium on WCp/Al composite fabricated by coincident wire-powder laser deposition. Mater. Des. 2016, 93, 370–378. [Google Scholar] [CrossRef]

- Kaierle, S.; Barroi, A.; Noelke, C.; Hermsdorf, J.; Overmeyer, L.; Haferkamp, H. Review on laser deposition welding: From micro to macro. Phys. Procedia 2012, 39, 336–345. [Google Scholar] [CrossRef]

- Shishkovsky, I.; Missemer, F.; Smurov, I. Direct metal deposition of functional graded structures in Ti-Al System. Phys. Procedia 2012, 39, 382–391. [Google Scholar] [CrossRef]

- Oliari, S.H.; D’Oliveira, A.S.C.M.; Schulz, M.; Oliari, S.H.; D’Oliveira, A.S.C.M.; Schulz, M. Additive manufacturing of H11 with wire-based laser metal deposition. Soldag. Inspeção 2017, 22, 466–479. [Google Scholar] [CrossRef]

- Keicher, D.M.; Smugeresky, J.E. The laser forming of metallic components using particulate materials. JOM. 1997, 49, 51–54. [Google Scholar] [CrossRef]

- Farayibi, P.K.; Folkes, J.A.; Clare, A.T. Laser deposition of Ti-6Al-4V wire with WC powder for functionally graded components. Mater. Manuf. Process. 2013, 28, 514–518. [Google Scholar] [CrossRef]

- Farayibi, P.K.; Abioye, T.E.; Kennedy, A.; Clare, A.T. Development of metal matrix composites by direct energy deposition of ‘satellited’ powders. J. Manuf. Process. 2019, 45, 429–437. [Google Scholar] [CrossRef]

- Ramakrishnan, A.; Dinda, G.P. Microstructural control of an Al–W aluminum matrix composite during direct laser metal deposition. J. Alloys Compd. 2020, 813, 152208. [Google Scholar] [CrossRef]

- Lei, Z.; Bi, J.; Chen, Y.; Chen, X.; Tian, Z.; Qin, X. Effect of TiB2 content on microstructural features and hardness of TiB2/AA7075 composites manufactured by LMD. J. Manuf. Process. 2020, 53, 283–292. [Google Scholar] [CrossRef]

- Peters, M.; Kumpfert, J.; Ward, C.H.; Leyens, C. Titanium alloys for aerospace applications. Adv. Eng. Mater. 2003, 5, 419–427. [Google Scholar] [CrossRef]

- Ravi Chandran, K.S.; Panda, K.B.; Sahay, S.S. TiBw-reinforced Ti composites: Processing, properties, application prospects, and research needs. JOM. 2004, 56, 42–48. [Google Scholar] [CrossRef]

- Hayat, M.D.; Singh, H.; He, Z.; Cao, P. Titanium metal matrix composites: An overview. Compos. Part A Appl. Sci. Manuf. 2019, 121, 418–438. [Google Scholar] [CrossRef]

- Sciolti, M.S.; Frigione, M.; Aiello, M.A. Wet Lay-up manufactured FRPs for concrete and masonry repair: Influence of water on the properties of composites and on their epoxy components. J. Compos. Constr. 2010, 14, 823–833. [Google Scholar] [CrossRef]

- Pank, D.R.; Jackson, J.J. Metal- matrix composite processing technologies for aircraft engine applications. J. Mater. Eng. Perform. 1993, 2, 341–346. [Google Scholar] [CrossRef]

- Lobley, C.M.; Guo, Z.X. Viable routes to large-scale commercialisation of silicon carbide fibre titanium matrix composites. Mater. Technol. 1999, 14, 133–138. [Google Scholar] [CrossRef]

- Lobley, C.M.; Quo, Z.X. Processing of Ti-SiC metal matrix composites by tape casting. Mater. Sci. Technol. 1998, 14, 1024–1028. [Google Scholar] [CrossRef]

- Kondoh, K. Titanium Powder Metallurgy: Science, Technology and Applications; Elsevier Inc.: Amsterdam, The Netherlands, 2015; pp. 277–297. ISBN 9780128009109. [Google Scholar]

- Huang, L.; Geng, L. Discontinuously reinforced titanium matrix composites; Springer: Berlin, Germany, 2017; ISBN 978-981-10-4449-6. [Google Scholar]

- Vert, R.; Pontone, R.; Dolbec, R.; Dionne, L.; Boulos, M.I. Induction plasma technology applied to powder manufacturing: Example of titanium-based materials. Key Eng. Mater. 2016, 704, 282–286. [Google Scholar] [CrossRef]

- Fan, Z.; Miodownik, A.P.; Chandrasekaran, L.; Ward-Close, M. The Young’s moduli of in situ Ti/TiB composites obtained by rapid solidification processing. J. Mater. Sci. 1994, 29, 1127–1134. [Google Scholar] [CrossRef]

- Gofrey, T.M.T.; Goodwin, P.S.; Ward-Close, C.M. Titanium particulate metal matrix composites - reinforcement, production methods, and mechanical properties. Adv. Eng. Mater. 2000, 2, 85–91. [Google Scholar] [CrossRef]

- Sivakumar, G.; Ananthi, V.; Ramanathan, S. Production and mechanical properties of nano SiC particle reinforced Ti–6Al–4V matrix composite. Trans. Nonferrous Met. Soc. China Eng. Ed. 2017, 27, 82–90. [Google Scholar] [CrossRef]

- Morsi, K.; Patel, V.V. Processing and properties of titanium-titanium boride (TiBw) matrix composites—A review. J. Mater. Sci. 2007, 42, 2037–2047. [Google Scholar] [CrossRef]

- Geng, L.; Ni, D.R.; Zhang, J.; Zheng, Z.Z. Hybrid effect of TiBw and TiCp on tensile properties of in situ titanium matrix composites. J. Alloys Compd. 2008, 463, 488–492. [Google Scholar] [CrossRef]

- Shivakumar, N.; Vasu, V.; Narasaiah, N. Synthesis and characterization of nano-sized Al2O3 particle reinforced ZA-27 metal matrix composites. Procedia Mater. Sci. 2015, 10, 159–167. [Google Scholar] [CrossRef]

- Dougherty, T.; Xu, Y.; Hanizan, A. Mechanical properties and microstructure of PM Ti-Si3N4 discontinuous fibre composite. In Proceedings of the TMS Annual Meeting; Wiley: Hoboken, NJ, USA, 2016; pp. 721–728. [Google Scholar]

- Saito, T. The automotive application of discontinuously reinforced TiB-Ti composites. JOM 2004, 56, 33–36. [Google Scholar] [CrossRef]

- Munir, K.S.; Kingshott, P.; Wen, C. Carbon nanotube reinforced titanium metal matrix composites prepared by powder metallurgy - A review. Crit. Rev. Solid State Mater. Sci. 2015, 40, 38–55. [Google Scholar] [CrossRef]

- Metcalfe, A.G. Interaction and fracture of titanium-boron composites. J. Compos. Mater. 1967, 1, 356–365. [Google Scholar] [CrossRef]

- Smith, P.R.; Froes, F.H. Developments in titanium metal matrix composites. JOM J. Miner. Met. Mater. Soc. 1984, 36, 19–26. [Google Scholar] [CrossRef]

- NASA Technical Reports Server (NTRS) - Control of interface reactions in SIC/TI composites. Available online: https://ntrs.nasa.gov/search.jsp?R=19820009392 (accessed on 3 November 2019).

- Guo, S. Fiber size effects on mechanical behaviours of SiC fibres-reinforced Ti3AlC2 matrix composites. J. Eur. Ceram. Soc. 2017, 37, 5099–5104. [Google Scholar] [CrossRef]

- Thurston, J.R. Elevated temperature tensile and creep behavior of a SiC fiber-reinforced titanium metal matrix composite; Final Report; Ohio Aerospace Institute: Cleveland, OH, USA, 4 January 1995. [Google Scholar]

- MacKay, R.A.; Brindley, P.K.; Froes, F.H. Continuous fiber-reinforced titanium aluminide composites. JOM 1991, 43, 23–29. [Google Scholar] [CrossRef]

- Pellous, R.M. Composites Research in Support of the Nasp Institute for Composites (NIC); Final Report; Massachusetts Institute of Technology: Cambridge, MA, USA, 1994. [Google Scholar]

- Kingston, W.R. Carbon-Titanium Composites. U.S. Patent 5,733,390, 31 March 1998. [Google Scholar]

- Wu, T.; Qiao, J.; Jiang, D. Preparation and properties of carbon fiber/titanium alloy composite for automobile. In Proceedings of SAE-China Congress 2015: Selected Papers; Springer: Singapore, 2016; Volume 364, pp. 289–295. [Google Scholar]

- Smith, P.R.; Gambone, M.L.; Williams, D.S.; Garner, D.I. Heat treatment effects on SiC fiber. J. Mater. Sci. 1998, 33, 5855–5872. [Google Scholar] [CrossRef]

- Baker, A.M.; Grant, P.S.; Jenkins, M.L. The response of SiC fibres to vacuum plasma spraying and vacuum hot pressing during the fabrication of titanium matrix composites. J. Microsc. 1999, 196, 162–174. [Google Scholar] [CrossRef]

- Hong, C.; Gu, D.; Dai, D.; Alkhayat, M.; Urban, W.; Yuan, P.; Cao, S.; Gasser, A.; Weisheit, A.; Kelbassa, I.; et al. Laser additive manufacturing of ultrafine TiC particle reinforced Inconel 625 based composite parts: Tailored microstructures and enhanced performance. Mater. Sci. Eng. A 2015, 635, 118–128. [Google Scholar] [CrossRef]

- Li, Y.; Bai, P.; Wang, Y.; Hu, J.; Guo, Z. Effect of TiC content on Ni/TiC composites by direct laser fabrication. Mater. Des. 2009, 30, 1409–1412. [Google Scholar] [CrossRef]

- Li, X.C.; Stampfl, J.; Prinz, F.B. Mechanical and thermal expansion behavior of laser deposited metal matrix composites of invar and TiC. Mater. Sci. Eng. A 2000, 282, 86–90. [Google Scholar] [CrossRef]

- Xiong, Y.; Smugeresky, J.E.; Schoenung, J.M. The influence of working distance on laser deposited WC-Co. J. Mater. Process. Technol. 2009, 209, 4935–4941. [Google Scholar] [CrossRef]

- Xiong, Y.; Smugeresky, J.E.; Ajdelsztajn, L.; Schoenung, J.M. Fabrication of WC-Co cermets by laser engineered net shaping. Mater. Sci. Eng. A 2008, 493, 261–266. [Google Scholar] [CrossRef]

- Picas, J.A.; Xiong, Y.; Punset, M.; Ajdelsztajn, L.; Forn, A.; Schoenung, J.M. Microstructure and wear resistance of WC-Co by three consolidation processing techniques. Int. J. Refract. Met. Hard Mater. 2009, 27, 344–349. [Google Scholar] [CrossRef]

- Choi, J.; Mazumder, J. Non-equilibrium synthesis of Fe-Cr-C-W alloy by laser cladding. J. Mater. Sci. 1994, 29, 4460–4476. [Google Scholar] [CrossRef]

- Zhong, M.; Xu, X.; Liu, W.; Sun, H. Laser synthesizing NiAl intermetallic and TiC reinforced NiAl intermetallic matrix composite. Cit. J. Laser Appl. 2004, 16, 160. [Google Scholar] [CrossRef][Green Version]

- Composite Materials Processing and applications of MMCs. Available online: http://metalurji.mu.edu.tr/Icerik/metalurji.mu.edu.tr/Sayfa/CompositeMaterials6(1).pdf (accessed on 26 February 2020).

- Li, F.; Gao, Z.; Li, L.; Chen, Y. Microstructural study of MMC layers produced by combining wire and coaxial WC powder feeding in laser direct metal deposition. Opt. Laser Technol. 2016, 77, 134–143. [Google Scholar] [CrossRef]

- Bi, G.; Sun, C.N.; Nai, M.L.; Wei, J. Micro-structure and mechanical properties of nano-TiC reinforced Inconel 625 deposited using LAAM. In Proceedings of the Physics. Procedia; Elsevier B.V.: Amsterdam, The Netherlands, 2013; Volume 41, pp. 828–834. [Google Scholar]

- Gopagoni, S.; Hwang, J.Y.; Singh, A.R.P.; Mensah, B.A.; Bunce, N.; Tiley, J.; Scharf, T.W.; Banerjee, R. Microstructural evolution in laser deposited nickel-titanium-carbon in situ metal matrix composites. J. Alloys Compd. 2011, 509, 1255–1260. [Google Scholar] [CrossRef]

- Hong, C.; Gu, D.; Dai, D.; Gasser, A.; Weisheit, A.; Kelbassa, I.; Zhong, M.; Poprawe, R. Laser metal deposition of TiC/Inconel 718 composites with tailored interfacial microstructures. Opt. Laser Technol. 2013, 54, 98–109. [Google Scholar] [CrossRef]

- Sateesh, N.H.; Mohan Kumar, G.C.; Krishna, P. Influence of Ni-P coated SiC and laser scan speed on the microstructure and mechanical properties of IN625 metal matrix composites. Lasers Manuf. Mater. Process. 2015, 2, 187–198. [Google Scholar] [CrossRef][Green Version]

- Zhang, Y.; Wei, Z.; Shi, L.; Xi, M. Characterization of laser powder deposited Ti-TiC composites and functional gradient materials. J. Mater. Process. Technol. 2008, 206, 438–444. [Google Scholar] [CrossRef]

- Liu, D.; Zhang, S.Q.; Li, A.; Wang, H.M. Creep rupture behaviors of a laser melting deposited TiC/TA15 in situ titanium matrix composite. Mater. Des. 2010, 31, 3127–3133. [Google Scholar] [CrossRef]

- Jiang, W.H.; Kovacevic, R. Laser deposited TiC/H13 tool steel composite coatings and their erosion resistance. J. Mater. Process. Technol. 2007, 186, 331–338. [Google Scholar] [CrossRef]

- Lei, Z.; Tian, Z.; Li, P.; Chen, Y.; Zhang, H.; Gu, J.; Su, X. Effect of Si content on microstructure and thermo-physical properties of the joint of Sip/6063Al composite by laser melting deposition. Opt. Laser Technol. 2017, 97, 116–123. [Google Scholar] [CrossRef]

- Das, M.; Balla, V.K.; Kumar, T.S.S.; Manna, I. Fabrication of biomedical implants using laser engineered net shaping (LENSTM). Trans. Indian Ceram. Soc. 2013, 72, 169–174. [Google Scholar] [CrossRef]

- Balla, V.K.; Bhat, A.; Bose, S.; Bandyopadhyay, A. Laser processed TiN reinforced Ti6Al4V composite coatings. J. Mech. Behav. Biomed. Mater. 2012, 6, 9–20. [Google Scholar] [CrossRef] [PubMed]

- Das, M.; Balla, V.K.; Kumar, T.S.S.; Bandyopadhyay, A.; Manna, I. Tribological, electrochemical and in vitro biocompatibility properties of SiC reinforced composite coatings. Mater. Des. 2016, 95, 510–517. [Google Scholar] [CrossRef]

- Florian, P.E.; Duta, L.; Grumezescu, V.; Popescu-Pelin, G.; Popescu, A.C.; Oktar, F.N.; Evans, R.W.; Roseanu Constantinescu, A. Lithium-doped biological-derived hydroxyapatite coatings sustain in vitro differentiation of human primary mesenchymal stem cells to osteoblasts. Coatings 2019, 9, 781. [Google Scholar] [CrossRef]

- Chioibasu, D.; Duta, L.; Popescu-Pelin, G.; Popa, N.; Milodin, N.; Iosub, S.; Balescu, L.M.; Catalin Galca, A.; Claudiu Popa, A.; Oktar, F.N.; et al. Animal origin bioactive hydroxyapatite thin films synthesized by RF-magnetron sputtering on 3D printed cranial implants. Metals 2019, 9, 1332. [Google Scholar] [CrossRef]

- Weng, F.; Chen, C.; Yu, H. Research status of laser cladding on titanium and its alloys: A review. Mater. Des. 2014, 58, 412–425. [Google Scholar] [CrossRef]

- Man, H.C.; Zhang, S.; Cheng, F.T.; Guo, X. In situ formation of a TiN/Ti metal matrix composite gradient coating on NiTi by laser cladding and nitriding. Surf. Coatings Technol. 2006, 200, 4961–4966. [Google Scholar] [CrossRef]

- Das, M.; Balla, V.K.; Basu, D.; Manna, I.; Sampath Kumar, T.S.; Bandyopadhyay, A. Laser processing of in situ synthesized TiB-TiN-reinforced Ti6Al4V alloy coatings. Scr. Mater. 2012, 66, 578–581. [Google Scholar] [CrossRef]

- Van Acker, K.; Vanhoyweghen, D.; Persoons, R.; Vangrunderbeek, J. Influence of tungsten carbide particle size and distribution on the wear resistance of laser clad WC/Ni coatings. In Proceedings of the Wear; Elsevier: Amsterdam, The Netherlands, 2005; Volume 258, pp. 194–202. [Google Scholar]

- Smurov, I. Laser cladding and laser assisted direct manufacturing. Surf. Coatings Technol. 2008, 202, 4496–4502. [Google Scholar] [CrossRef]

- Wang, H.M.; Wang, C.M.; Cai, L.X. Wear and corrosion resistance of laser clad Ni2Si/NiSi composite coatings. Surf. Coatings Technol. 2003, 168, 202–208. [Google Scholar] [CrossRef]

- Tucker, T.R.; Clauer, A.H.; Wright, I.G.; Stropki, J.T. Laser-processed composite metal cladding for slurry erosion resistance. Thin Solid Films 1984, 118, 73–84. [Google Scholar] [CrossRef]

- Gasser, A.; Backes, G.; Kelbassa, I.; Weisheit, A.; Wissenbach, K. Laser additive manufacturing. Laser Tech. J. 2010, 7, 58–63. [Google Scholar] [CrossRef]

- Jang, J.H.; Mun, S.M.; Sung, M.Y.; Moon, Y.H. Application of direct laser melting to restore damaged steel dies. Met. Mater. Int. 2011, 17, 167–174. [Google Scholar] [CrossRef]

- Wang, H.M.; Zhang, L.Y.; Li, A.; Tang, H.B.; Zhang, S.Q.; Fang, Y.L.; Li, P. Progress on laser melting deposition processing and manufacturing of advanced aeronautical metallic structural materials and coatings. Heat Treat. Met. 2008, 33, 82–85. [Google Scholar]

- Qi, H.; Azer, M.; Singh, P. Adaptive toolpath deposition method for laser net shape manufacturing and repair of turbine compressor airfoils. Int. J. Adv. Manuf. Technol. 2010, 48, 121–131. [Google Scholar] [CrossRef]

- Kelbassa, I.; Albus, P.; Dietrich, J.; Wilkes, J. Manufacture and Repair of Aero Engine Components Using Laser Technology. In Proceedings of the 3rd Pacific International Conference on Application of Lasers and Optics, Beijing, China, 16–18 April 2008. [Google Scholar]

- Pratt, V.D.; Scheidt, W.D.; Whitney, E.J. Fabrication of Components by Layered Deposition. U.S. Patent 5,038,014, 6 August 1991. [Google Scholar]

- Mazumder, J. Fabrication of Customized Die Inserts Using Closed-Loop Direct Metal Deposition (DMD). U.S. Patent 10/629,062, 5 February 2004. [Google Scholar]

- Guo, W. Laser Powder Fusion Repair of Z-Notches with Nickel Based Superalloy Powder. U.S. Patent 7,009,137, 7 March 2006. [Google Scholar]

- Kawasaki, M.; Takase, K.; Kato, S.; Nakagawa, M.; Mori, K.; Nemoto, M.; Takagi, S.; Sugimoto, H. Development of engine valve seats directly deposited onto aluminum cylinder head by laser cladding process. J. Engines 1992, 101, 1000–1014. [Google Scholar]

- Withey, P.; Schlienger, M. Forming Structures by Laser Deposition. U.S. Patent 11/224,138, 16 March 2006. [Google Scholar]

- Zheng, B.; Smugeresky, J.E.; Zhou, Y.; Baker, D.; Lavernia, E.J. Microstructure and properties of laser-deposited Ti6Al4V metal matrix composites using Ni-Coated powder. Metall. Mater. Trans. A Phys. Metall. Mater. Sci. 2008, 39 A, 1196–1205. [Google Scholar] [CrossRef]

- Zheng, B.; Topping, T.; Smugeresky, J.E.; Zhou, Y.; Biswas, A.; Baker, D.; Lavernia, E.J. The influence of Ni-coated TiC on laser-deposited IN625 metal matrix composites. Metall. Mater. Trans. A Phys. Metall. Mater. Sci. 2010, 41, 568–573. [Google Scholar] [CrossRef]

- Sayyad Amin, J.; Nikooee, E.; Ayatollahi, S.; Alamdari, A. Investigating wettability alteration due to asphaltene precipitation: Imprints in surface multifractal characteristics. Appl. Surf. Sci. 2010, 256, 6466–6472. [Google Scholar] [CrossRef]

- Hu, Y.; Ning, F.; Cong, W.; Li, Y.; Wang, X.; Wang, H. Ultrasonic vibration-assisted laser engineering net shaping of ZrO2-Al2O3 bulk parts: Effects on crack suppression, microstructure, and mechanical properties. Ceram. Int. 2018, 44, 2752–2760. [Google Scholar] [CrossRef]

- Attar, H.; Bönisch, M.; Calin, M.; Zhang, L.C.; Scudino, S.; Eckert, J. Selective laser melting of in situ titanium-titanium boride composites: Processing, microstructure and mechanical properties. Acta Mater. 2014, 76, 13–22. [Google Scholar] [CrossRef]

- Hu, Y.; Zhao, B.; Ning, F.; Wang, H.; Cong, W. In-situ ultrafine three-dimensional quasi-continuous network microstructural TiB reinforced titanium matrix composites fabrication using laser engineered net shaping. Mater. Lett. 2017, 195, 116–119. [Google Scholar] [CrossRef]

- Wu, Q.; Li, W.; Zhong, N.; Gang, W.; Haishan, W. Microstructure and wear behavior of laser cladding VC-Cr7C3 ceramic coating on steel substrate. Mater. Des. 2013, 49, 10–18. [Google Scholar] [CrossRef]

- Triantafyllidis, D.; Li, L.; Stott, F.H. Crack-free densification of ceramics by laser surface treatment. Surf. Coatings Technol. 2006, 201, 3163–3173. [Google Scholar] [CrossRef]

- Yang, Y.; Lan, J.; Li, X. Study on bulk aluminum matrix nano-composite fabricated by ultrasonic dispersion of nano-sized SiC particles in molten aluminum alloy. Mater. Sci. Eng. A 2004, 380, 378–383. [Google Scholar] [CrossRef]

- Ning, F.; Hu, Y.; Liu, Z.; Wang, X.; Li, Y.; Cong, W. Ultrasonic vibration-assisted laser engineered net shaping of inconel 718 parts: Microstructural and mechanical characterization. J. Manuf. Sci. Eng. Trans. ASME 2018, 140, 061012–061023. [Google Scholar] [CrossRef]

- Zhou, S.; Huang, Y.; Zeng, X.; Hu, Q. Microstructure characteristics of Ni-based WC composite coatings by laser induction hybrid rapid cladding. Mater. Sci. Eng. A 2008, 480, 564–572. [Google Scholar] [CrossRef]

- Liu, W.; DuPont, J.N. Fabrication of carbide-particle-reinforced titanium aluminide-matrix composites by laser-engineered net shaping. Metall. Mater. Trans. A Phys. Metall. Mater. Sci. 2004, 35, 1133–1140. [Google Scholar] [CrossRef]

- Wu, C.; Ma, M.; Liu, W.; Zhong, M.; Zhang, H.; Zhang, W. Laser cladding in-situ carbide particle reinforced Fe-based composite coatings with rare earth oxide addition. J. Rare Earths 2009, 27, 997–1002. [Google Scholar] [CrossRef]

- Niu, F.; Wu, D.; Ma, G.; Zhou, S.; Zhang, B. Effect of second-phase doping on laser deposited Al2O3 ceramics. Rapid Prototyp. J. 2015, 21, 201–206. [Google Scholar] [CrossRef]

- Huang, L.J.; Geng, L.; Peng, H.X. Microstructurally inhomogeneous composites: Is a homogeneous reinforcement distribution optimal? Prog. Mater. Sci. 2015, 71, 93–168. [Google Scholar] [CrossRef]

- Zhang, S.; Sun, D.; Fu, Y.; Du, H. Toughening of hard nanostructural thin films: A critical review. Surf. Coatings Technol. 2005, 198, 2–8. [Google Scholar] [CrossRef]

| AM Processes | Processes | Layer Forming Principle | Forming Material | MMCs Application | References |

|---|---|---|---|---|---|

| Direct-AM Process |

| Partially melting by laser | Powder | Yes | [6,7] |

| Complete melting by laser | Powder | Yes | [8,9] | |

| Complete melting by laser | Powder/Wire | Yes | [10,11] | |

| Indirect-AM Process |

| Extrusion | Filament | Yes | [12,13] |

| Photo curing via laser scanning | Resin and powder | No | [14,15] | |

| Inkjet printing | Powder suspension | No | [16,17] | |

| Slurry deposition | Slurry | Yes | [18,19] | |

| Sheet binding and laser cutting | Sheet | Yes | [20,21] |

| Method | Feedback Loop | Deposition Technique | Layer Height (µm) | Deposition Rate (cm3/min) | Dimensional Precision (mm) | Surface Roughness (µm) | References |

|---|---|---|---|---|---|---|---|

| DMD | Available | Cladding via laser beam | 250–254 | 0.99–4.00 | N/A | 38–40 | [59] |

| LENS | Not available | 129–381 | N/A | XY-aixs = ±5, Z-axis = ± 0.40 | 59–93 | [60] | |

| DLF | Not available | 195–200 | 1.0 | ±0.13 | 18–20 | [61] |

| Technique Name and Description | Essential Features | References | |

|---|---|---|---|

|

| [71,72,73,74,75] | |

In this process, the reinforcing particulates are mixed into the matrix, usually a metal. The given matrix is in between the solidus and liquidus temperature. The reinforcing particles are entrapped within the matrix, mechanically. |

| [76,77] | |

In this technique, the pressure is applied and maintained until the molten metal solidifies. The applied pressure assists in grain refinement that ultimately enhances the mechanical properties of the final product. |

| [78,79,80,81] | |

In this technique, a blending of fine powder particles, compacting into an anticipated form. Mostly, material heating is also involved. |

| [82,83] | |

This process uses the melting-condition advanced shear technology technique. A sufficient quantity of shear stresses is applied to the particles, within the liquidus metal, to get over the cohesive force and the malleable strength of the given mixture. It consists of the following mixing steps: |

| [84,85] | |

| Step I: Distributive mixing | Step II: Dispersive mixing | ||

| It employs the conventional mechanical stirring to pre-mix the metal matrix with the reinforcing particles. The equipment is the same as stir casting. | In this step, adequate shear stress is applied to overcome the average tensile strength of the agglomerated structures. | ||

It is a well-known process to produce lightweight nano-metal matrix composites (NMMCs) with excellent reinforcement distribution. However, NMMCs present severe problems regarding the uniform dispersion in liquid metal that induces clustering. This drawback can be solved by integrating the ultrasonic system with the casting process. |

| [78,86] | |

It is a technique that can change the microstructure and mechanical properties through plastic deformation. |

| [87,88] | |

| Powder-Based LMD | Wire-Based LMD | References | ||

|---|---|---|---|---|

| Pros | Cons | Pros | Cons | |

|

|

|

| [93,94,95,96,97] |

| Powder + Wire-Based LMDs | References | |

|---|---|---|

| Pros | Cons | |

|

| [92] |

| Continuous Reinforced TMCs Formation Techniques | |||

|---|---|---|---|

| Technique and illustration | Pros | Cons | References |

|

|

| [105] |

|

|

| [106] |

|

|

| [107] |

|

|

| [108] |

| Discontinuous Reinforced TMCs Formation Techniques | |||

|

|

| [109,110] |

|

|

| [111,112,113] |

| Study by | MMCs by LMD | Hardness (HV) | Ultimate Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) | Wear Loss (µm2) | References |

|---|---|---|---|---|---|---|---|

| Li et al. | WC + Ti-wire | 500 | - | - | - | - | [141] |

| Bi et al. | Inconel 625 + TiC particulates (0.25/99.75; 0.50/99.50; 1.0/99.0) | 285; 310; 312; 320 | 840; 930; 980; 990 | 530; 650; 642; 690 | 16; 19; 28; 21 | - | [142] |

| Gopagoni et al. | Nickel (80 wt.%) + Titanium (10 wt.%) + Carbon (10 wt.%) | 370 | - | - | - | - | [143] |

| Wang et al. | TiC particulates (0; 5; 10; 15; 20; 30 vol.%) + Ti6Al4V | 375; 425; 427; 432; 475; 477 | 1100; 1200; 1100; 1000; 900; 700 | - | 5; 1; 0.8; 0.7; 0.5; 0.1 | - | [56] |

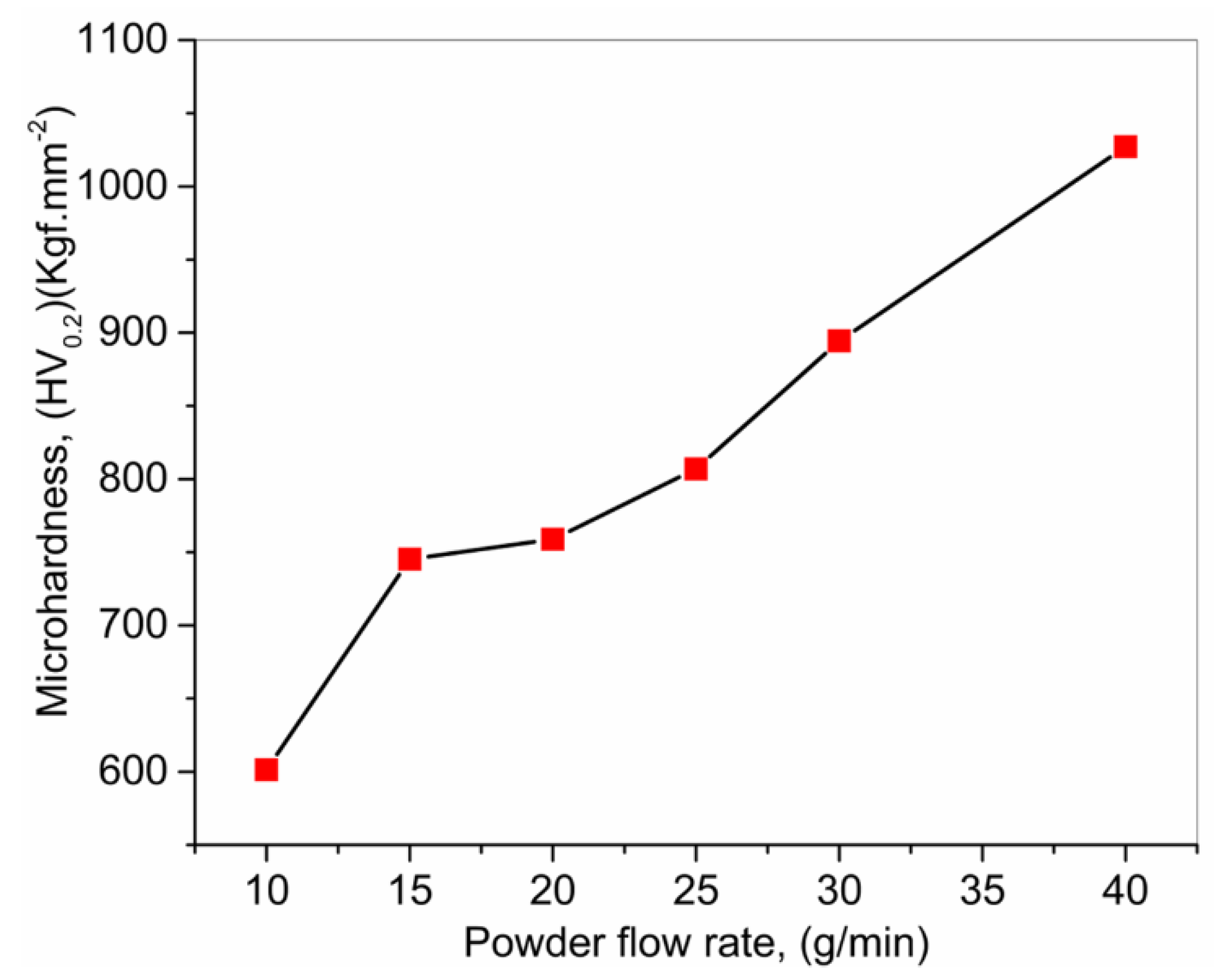

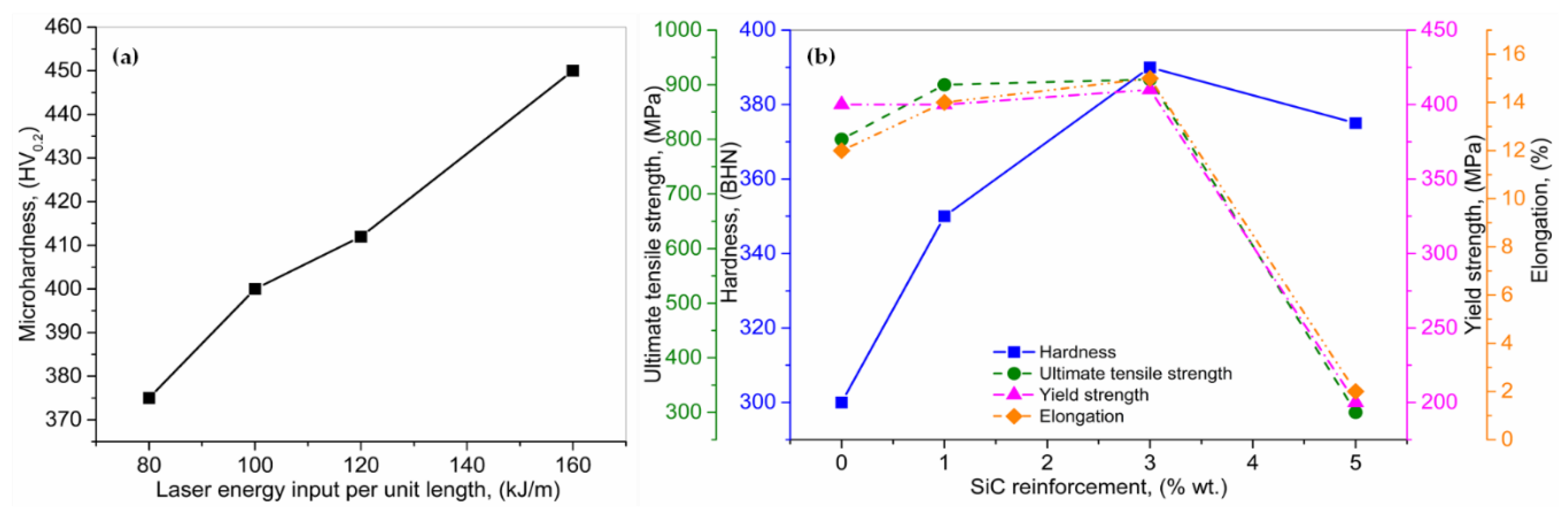

| Hong et al. | Inconel 718 + TiC (Laser energy = 80; 100; 120; 160 kJ/m) | 375; 400; 410; 450 | - | - | - | - | [144] |

| Sateesh et al. | Ni-P + SiC (0; 1; 3; 5 wt.%) | 300; 350; 390; 375 | 800; 900; 910; 300 | 400; 400; 410; 200 | 12; 14; 15; 2 | - | [145] |

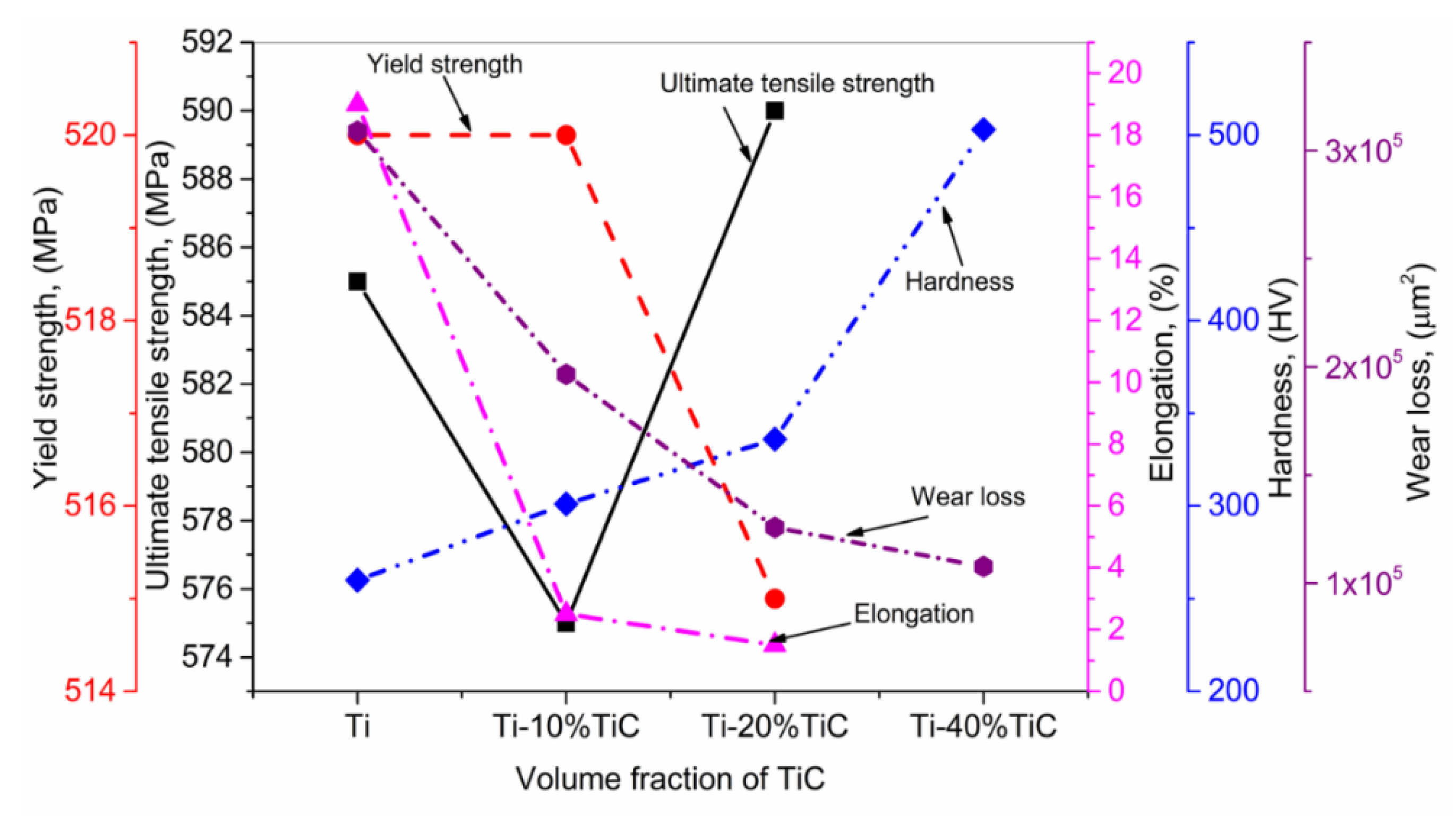

| Zhang et al. | Ti+TiC (10; 20; 40 vol.%) | 260; 301; 336; 503 | 585; 575; 590; - | 520; 520; 515; - | 19; 2.5; 1.5; - | 309,022.1; 196,579.5; 125,786.7; 107,735.6 | [146] |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mahmood, M.A.; Popescu, A.C.; Mihailescu, I.N. Metal Matrix Composites Synthesized by Laser-Melting Deposition: A Review. Materials 2020, 13, 2593. https://doi.org/10.3390/ma13112593

Mahmood MA, Popescu AC, Mihailescu IN. Metal Matrix Composites Synthesized by Laser-Melting Deposition: A Review. Materials. 2020; 13(11):2593. https://doi.org/10.3390/ma13112593

Chicago/Turabian StyleMahmood, Muhammad Arif, Andrei C. Popescu, and Ion N. Mihailescu. 2020. "Metal Matrix Composites Synthesized by Laser-Melting Deposition: A Review" Materials 13, no. 11: 2593. https://doi.org/10.3390/ma13112593

APA StyleMahmood, M. A., Popescu, A. C., & Mihailescu, I. N. (2020). Metal Matrix Composites Synthesized by Laser-Melting Deposition: A Review. Materials, 13(11), 2593. https://doi.org/10.3390/ma13112593