Experimental Investigation on the In-Plane Creep Behavior of a Carbon-Fiber Sheet Molding Compound at Elevated Temperature at Different Stress States

Abstract

:1. Introduction

2. Literature Research

2.1. The Creep Mechanism

2.2. Anisotropic Material Behavior of Random-Oriented Fiber-Reinforced Composite Materials

2.3. Influence of Different Stress States on Composite Creep Behavior

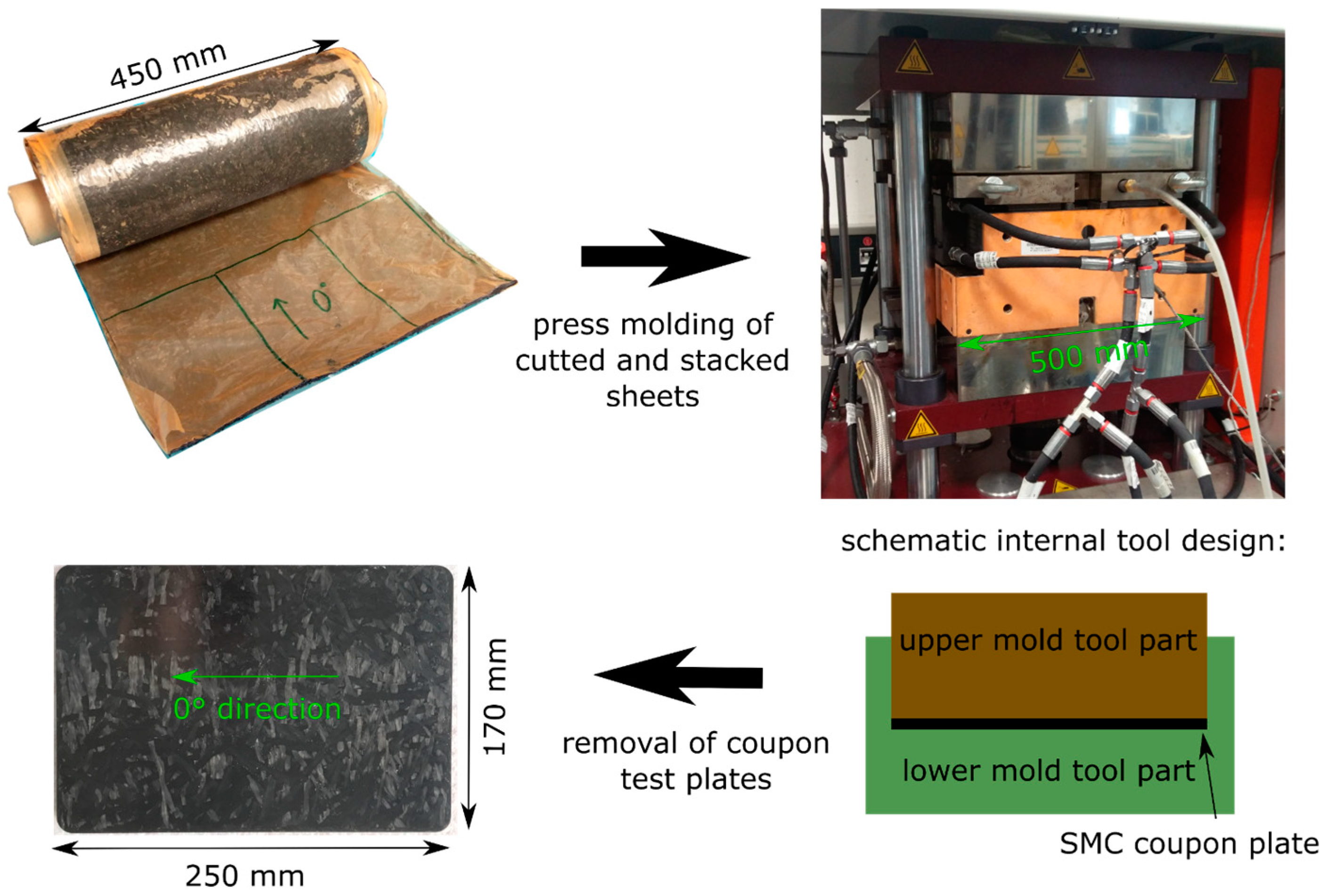

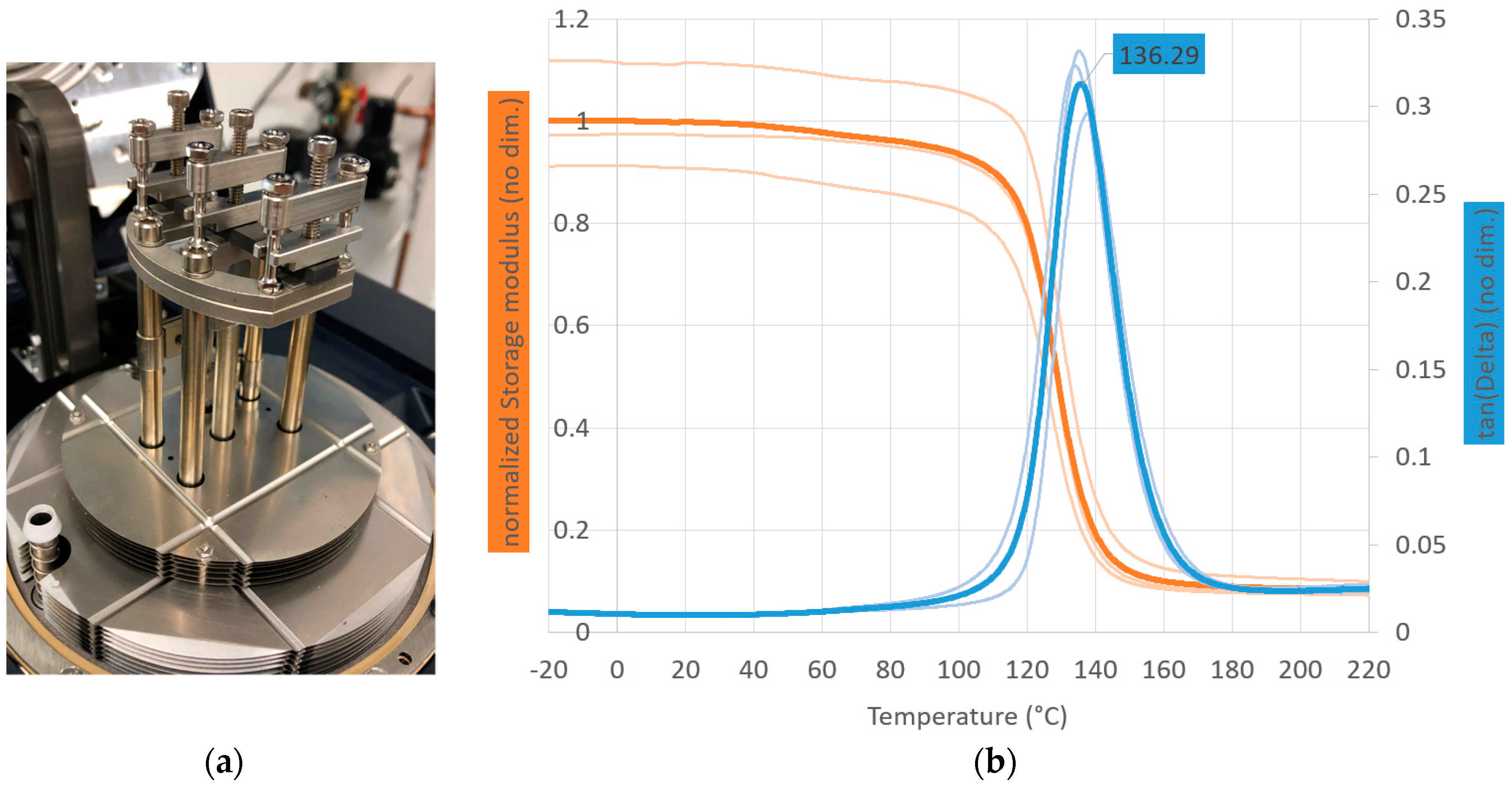

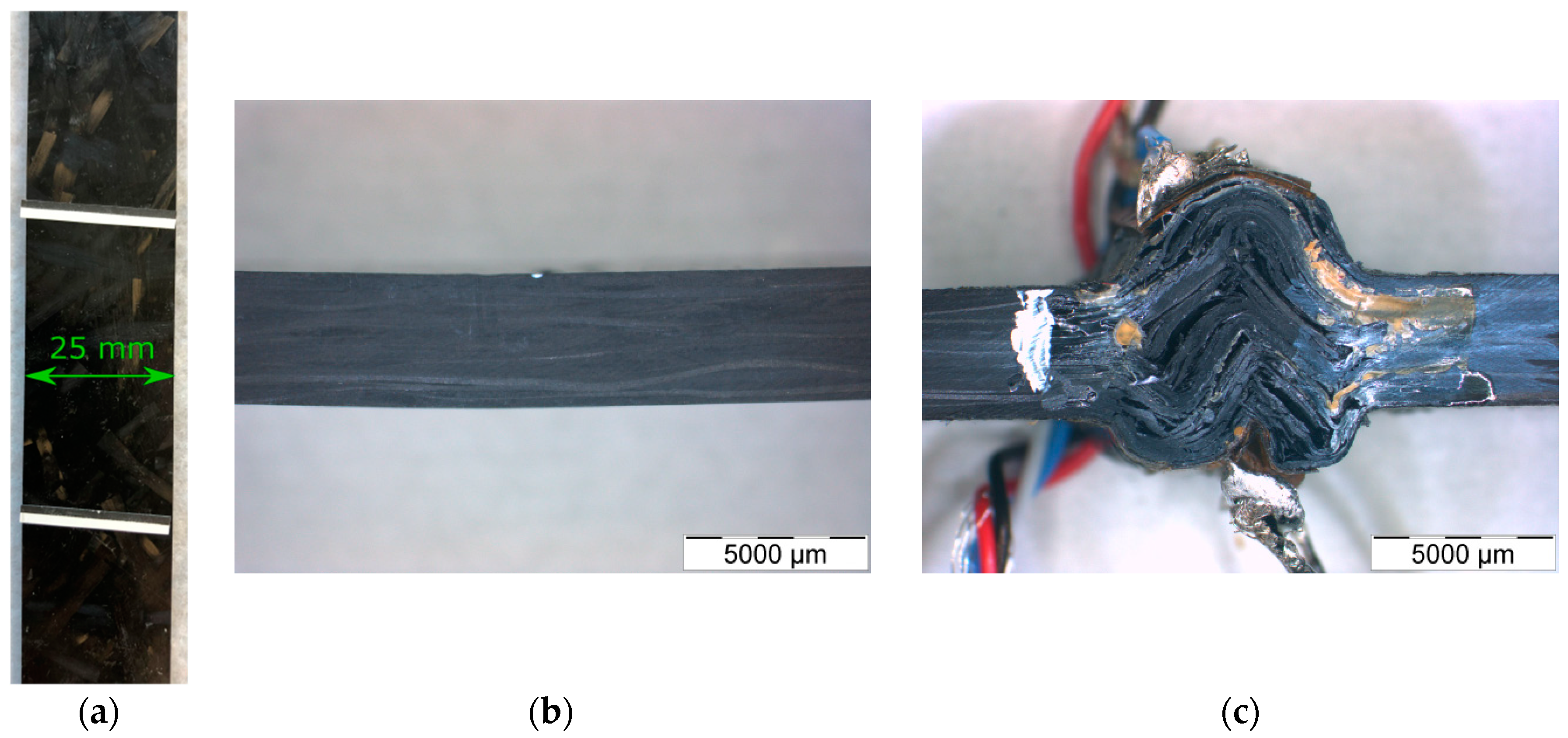

3. Material and Processing

4. Experimental Results

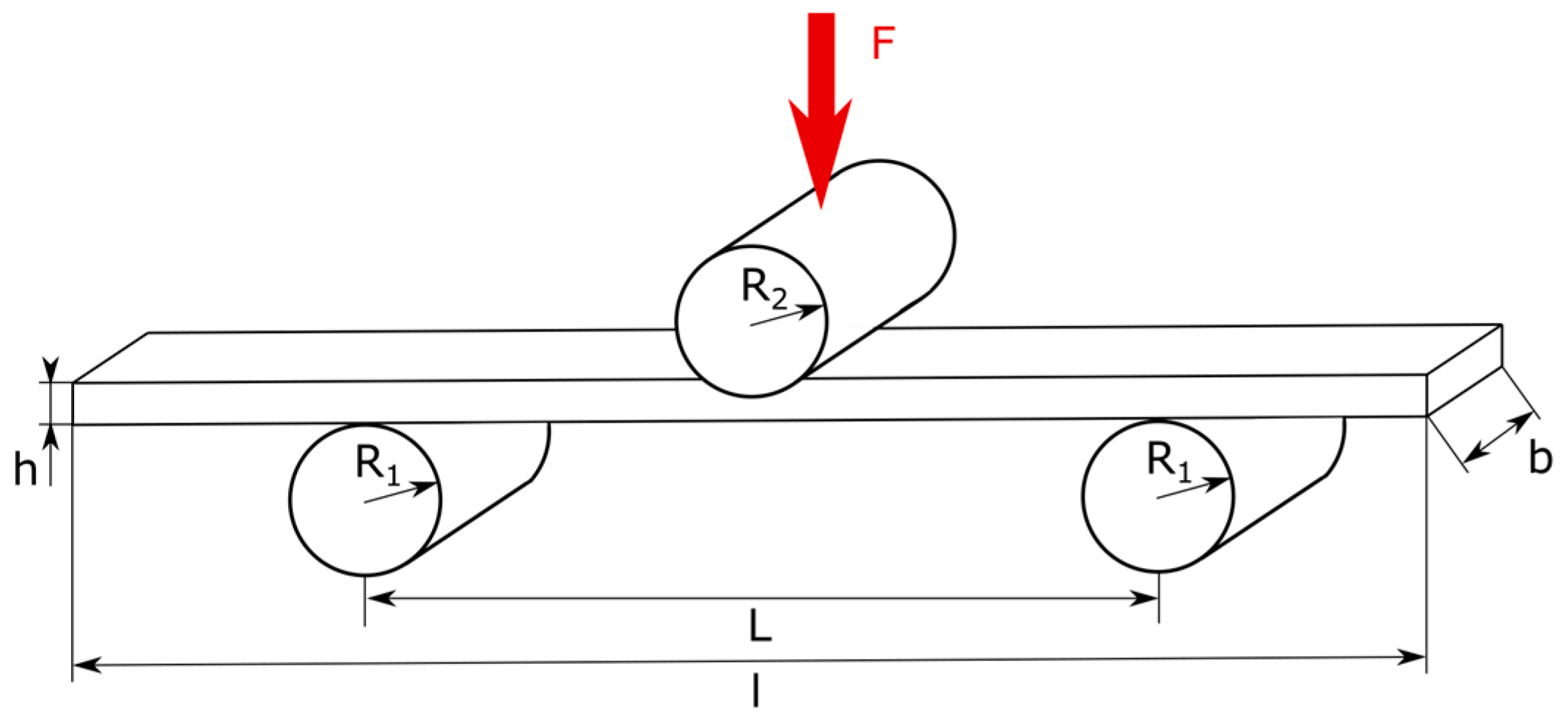

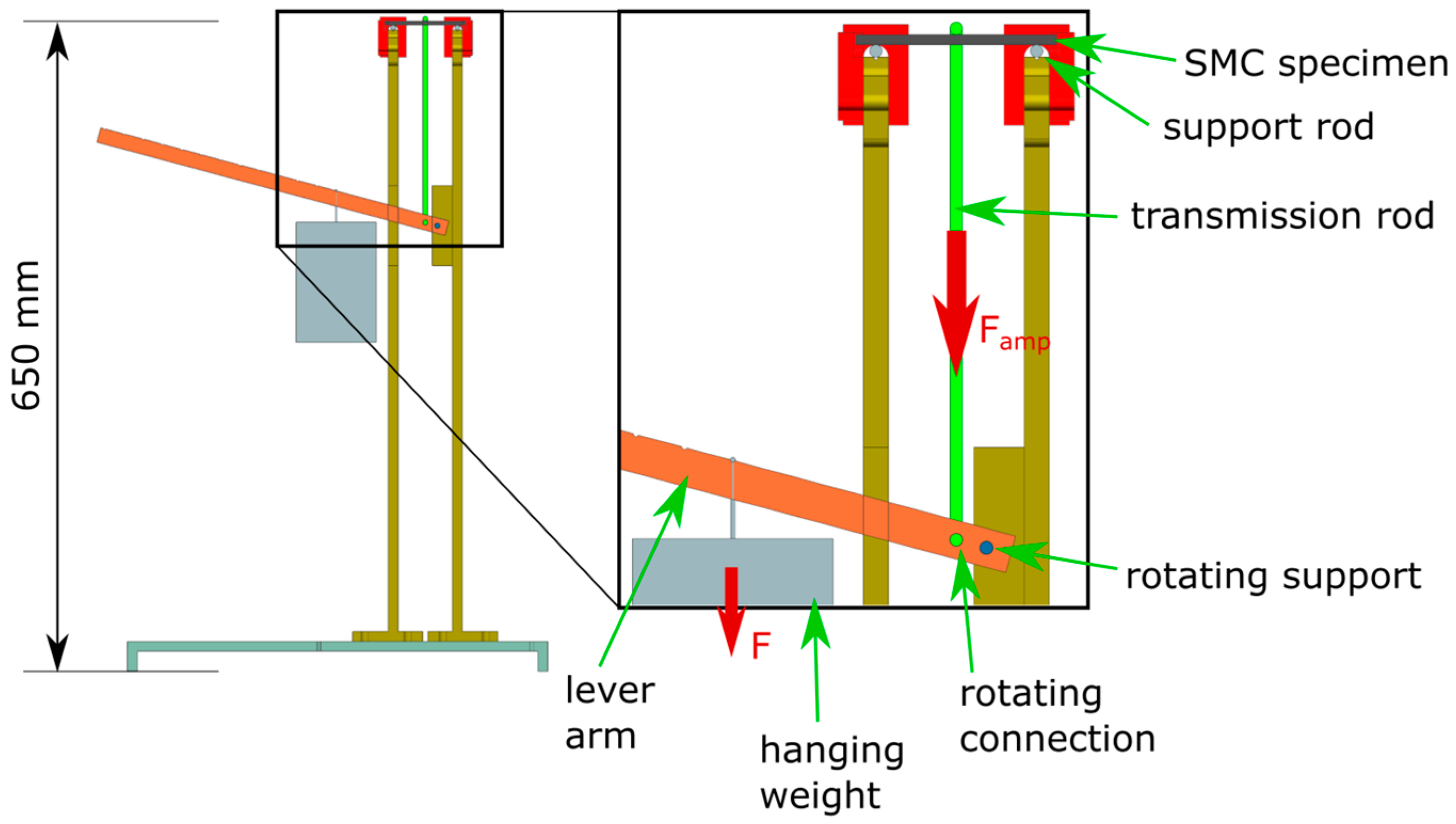

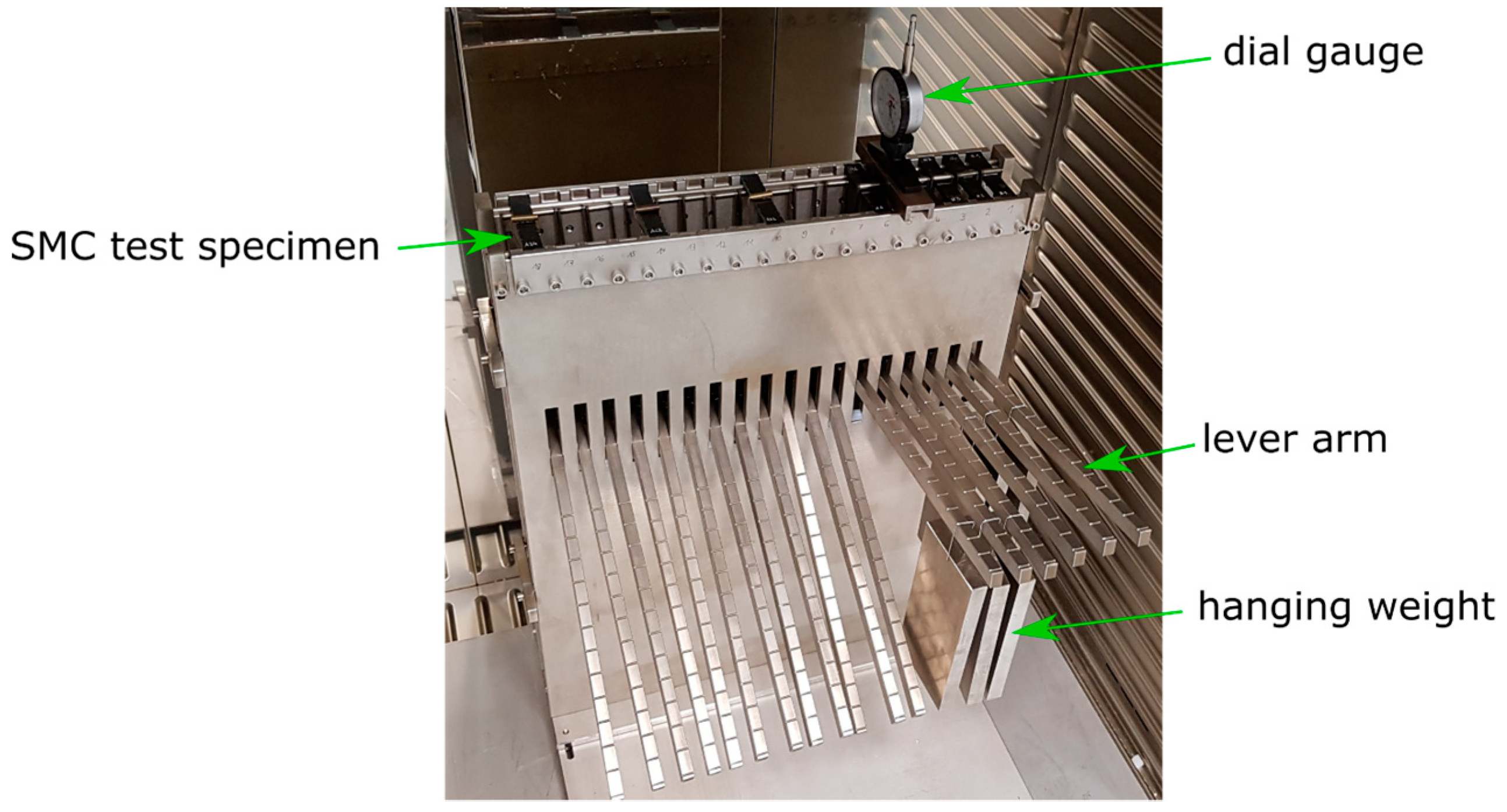

4.1. Creep under Flexural Load

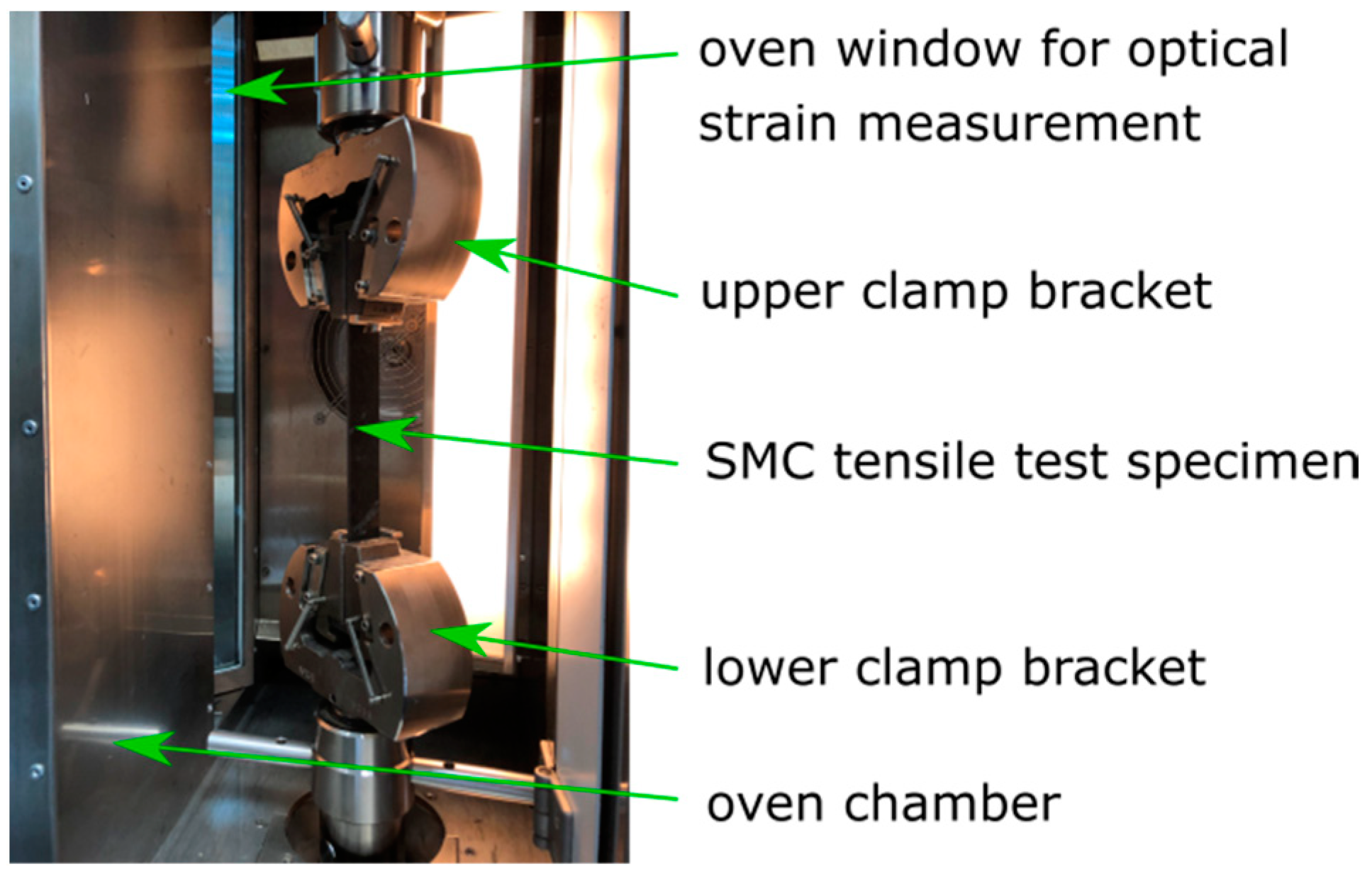

4.2. Creep under Tensile Load

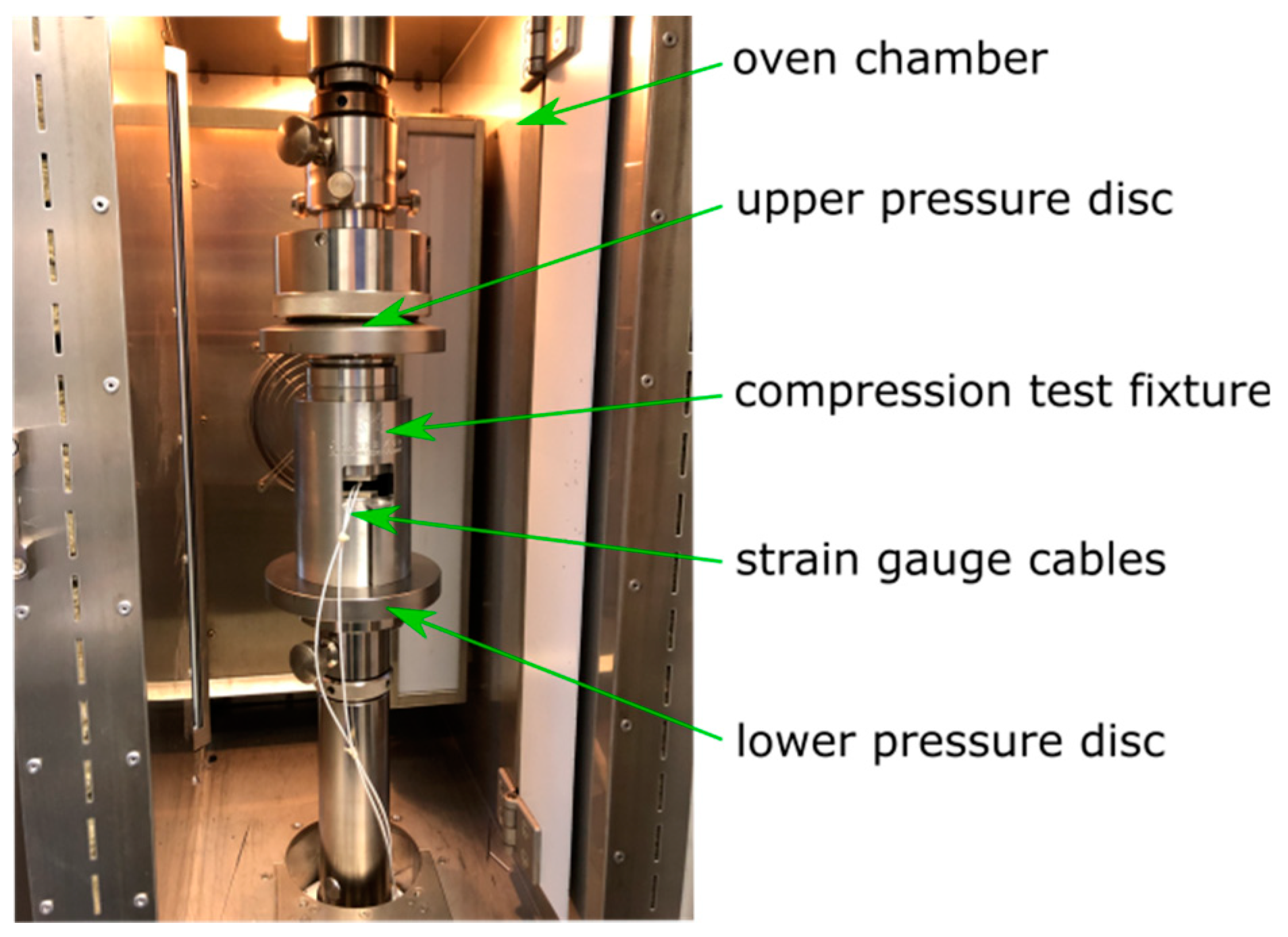

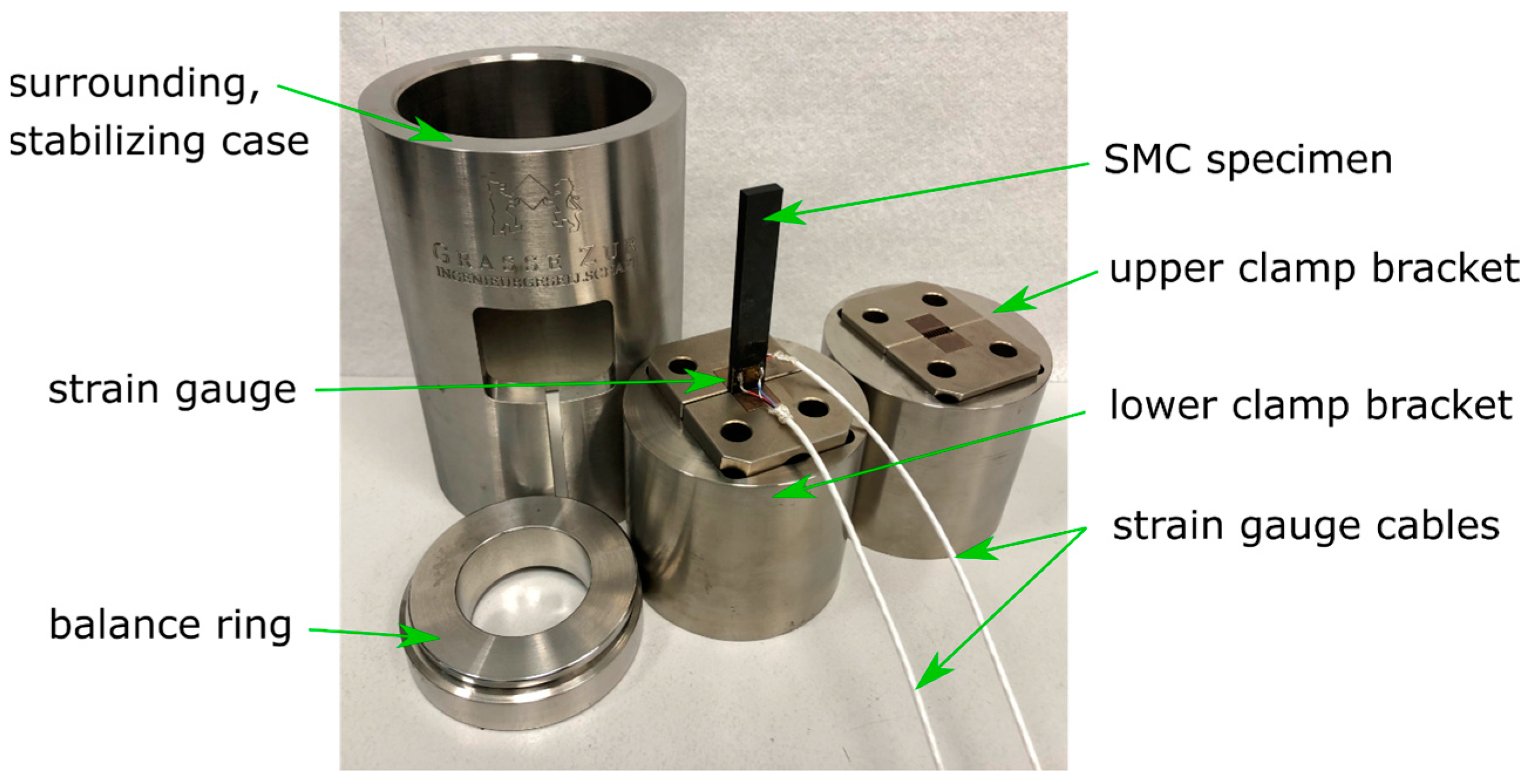

4.3. Creep under Compression Load

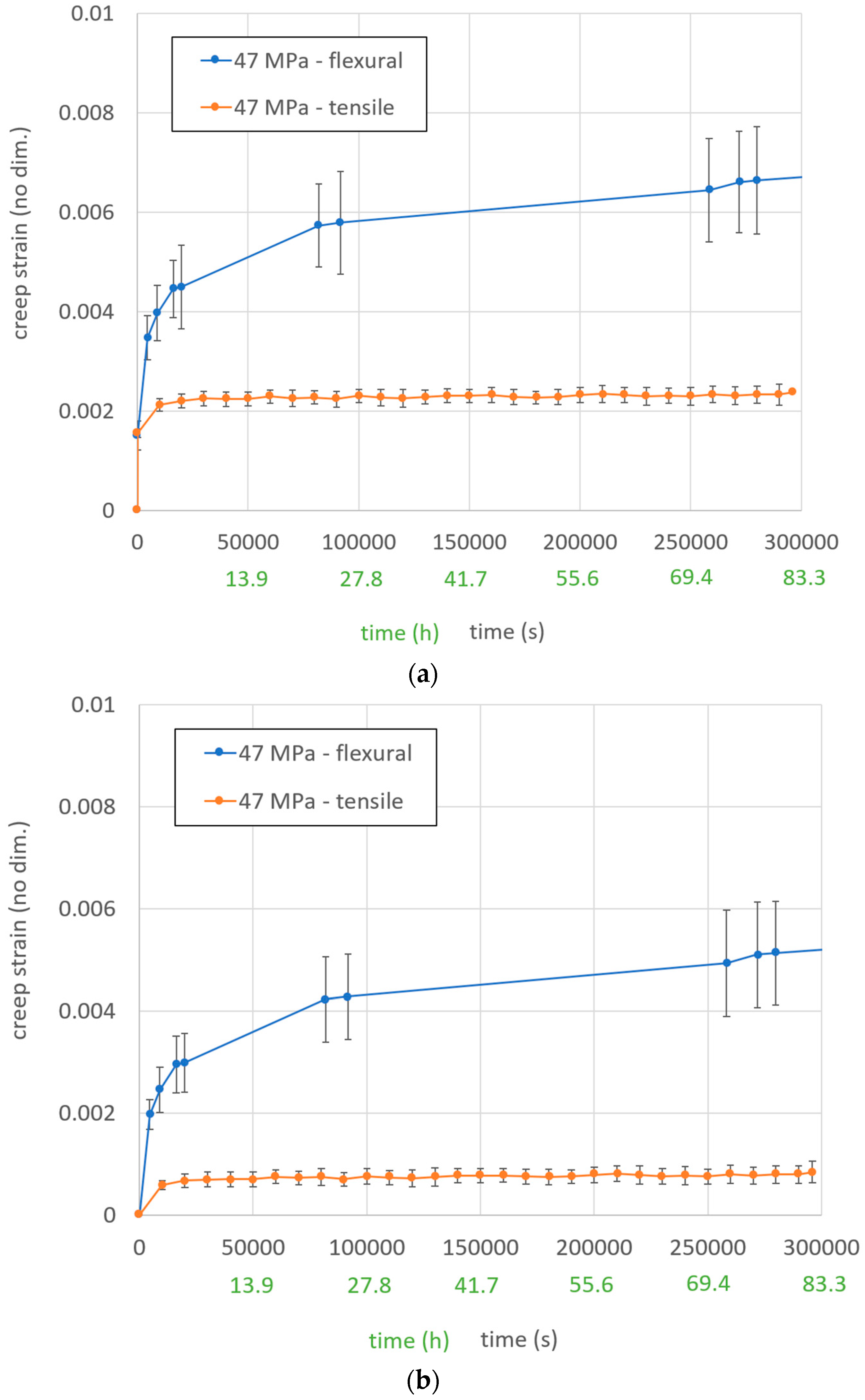

5. Comparison of Creep Strain over Time at Different Stress States

6. Conclusions and Outlook

- Different stress states result in significantly different creep strain rates for the investigated SMC on the same stress value. Since the matrix experiences different load carrying shares at the individual load cases, the various strain rates had been expected.

- The creep strains in flexural loading were significantly higher than in tensile loading.

- It was observed that the creep strength for the mentioned material was significantly lower under compression than under tensile or bending. Therefore, it was assumed that the higher creep strains under flexural loading, which was a mixed stress loading, were caused by the compression loading shares.

- Literature research on expectable creep behavior of endless fiber composites was already indicating that the creep strains under flexural loading would be higher than under tensile loading [14]. As creep strains under tensile and compression loading could not be compared here, no comparison could be made with a study by NASA [13].

- It was also shown that the presented thermosetting press molding material, with a relatively high glass transition temperature of 136 °C reinforced with chopped fibers, could suffer from creep at a temperature of 120 °C. As this temperature is still in range for different applications, such as the automotive application, the creep behavior of these materials has to be considered for the development of structural loaded components [2].

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Papanicolaou, G.C.; Zaoutsos, S.P. Chapter 1—Viscoelastic constitutive modeling of creep and stress relaxation in polymers and polymer matrix composites. In Creep and Fatigue in Polymer Matrix Composites; Woodhead Publishing Limited: New Delhi, India, 2011. [Google Scholar]

- Schuermann, H. Konstruieren mit Faser-Kunststoff-Verbunden, 2. In Auflage [Designing with Fiber-Polymer-Composites, 2nd ed.]; Springer: Berlin/Heidelberg, Germany, 2007. [Google Scholar]

- Verein Deutscher Ingenieure. VDI 2014—Entwicklung von Bauteilen aus Faser-Kunststoff-Verbund—Blatt 1 [VDI 2014—Development of FRP components—Part 1]; Verein Deutscher Ingenieure: Duesseldorf, Germany, 1989. [Google Scholar]

- Wu, C. Long Term Performance of Polymers; University of Minnesota—College of Science & Engineering: Minneapolis, MN, USA, 2004. [Google Scholar]

- Hornbogen, E.; Eggeler, G.; Ewald, W. Werkstoffe: Aufbau und Eigenschaften von Keramik-, Metall-, Polymer- und Verbundwerkstoffen 8. Auflage [Materials: Structure and Properties of Ceramic-, Metal-, Polymer- and Composite-Materials 8. Edition]; Springer: Berlin/Heidelberg, Germany, 2012. [Google Scholar]

- Finck, D.; Seidel, C.; Hausmann, J.; Rief, T. Creep-Induced Screw Preload Loss of Carbon-Fiber Sheet Molding Compound at Elevated Temperature. Materials 2019, 12, 3598. Available online: https://www.mdpi.com/1996-1944/12/21/3598 (accessed on 29 May 2020). [CrossRef] [PubMed] [Green Version]

- Mesarovic, S.D. Dislocation Creep: Climb and Glide in the Lattice Continuum. Crystals 2017, 7, 243. [Google Scholar] [CrossRef]

- Friedrich, C.; Hubbertz, H. Friction behavior and preload relaxation of fastening systems with composite structures. Compos. Struct. 2014, 110, 335–341. [Google Scholar] [CrossRef]

- Szymanski, N.K. Self Healing of Deformation-Induced Damage in Fe-W Alloys; Delft University of Technology: Delft, The Netherlands, 2017. [Google Scholar]

- Batchelor, A.W.; Loh, N.L.; Chandrasekaran, M. Materials Degradation and Its Control by Surface Engineering; Imperial College Press: London, UK, 2011. [Google Scholar]

- Cai, H.; Ye, J.; Wang, Y.; Saafi, M.; Huang, B.; Yang, D.; Ye, J. An Effective Microscale Approach for Determining the Anisotropy of Polymer Composites Reinforced with Randomly Distributed Short Fibers. Compos. Struct. 2020, 240, 112087. [Google Scholar] [CrossRef]

- Hao, X.; Zhou, H.; Mu, B.; Chen, L.; Guo, Q.; Yi, X.; Sun, L.; Wang, Q.; Ou, R. Effects of Fiber Geometry and Orientation Distribution on the Anisotropy of Mechanical Properties, Creep Behavior, and Thermal Expansion of Natural Fiber/HDPE Composites. Compos. Part B Eng. 2020, 185, 107778. [Google Scholar] [CrossRef]

- Gates, T.S.; Veazie, D.R.; Brinson, L.C. A Comparison of Tension and Compression Creep in a Polymeric Composite and the Effects of Physical Aging on Creep; NASA—National Aeronautics and Space Administration: Hampton, VI, USA, 1996.

- Goertzen, W.K.; Kessler, M.R. Creep Behavior of Carbon Fiber/Epoxy Matrix Composites; Elsevier: Amsterdam, The Netherlands, 2006. [Google Scholar]

- Page, C.L.; Page, M.M. Durability of Concrete and Cement Composites; Woodhead Publishing Limited: New Delhi, India, 2007. [Google Scholar]

- Polynt Composites Germany GmbH. Datasheet—SMCarbon 80 CF60-3K/2; Polynt Composites Germany GmbH: Miehlen, Germany, 2017. [Google Scholar]

- Menard, K.P. Dynamic Mechanical Analysis: A Practical Introduction, 2nd ed.; CRC Press: Boca Raton, FL, USA, 2008. [Google Scholar]

- Kastner, J. Prozesscharakterisierung und Thermomechanische Eigenschaften von GF/CF-SMC Hybridmaterialien [Process Characterization and Thermomechanical Properties of GF/CF-SMC Hybrid-Materials]; Technische Hochschule Nürnberg Georg Simon Ohm: Nürnberg, Germany, 2019. [Google Scholar]

- International Standards Organization. DIN EN ISO 14125: Faserverstärkte Kunststoffe—Bestimmung der Biegeeigenschaften [DIN EN ISO 14125: FRP—Determination of Flexural Properties]; International Standards Organization: Geneva, Switzerland, 2011. [Google Scholar]

- International Standards Organization. ISO 527-4: Determination of Tensile Properties—Part 4: Test Conditions for Isotropic and Orthotropic Fibre-Reinforced Plastic Composites; International Standards Organization: Geneva, Switzerland, 1997. [Google Scholar]

- Zwick/Roell AG, Zwick/Roell Videoxtens Extensometer, (n.d.). Available online: https://www.zwickroell.com/en/extensometers/videoxtens (accessed on 3 April 2020).

- International Standards Organization. DIN EN ISO 14126: Bestimmung der Druckeigenschaften in der Laminatebene [DIN EN ISO 14126: Determination of Laminate Properties]; International Standards Organization: Geneva, Switzerland, 2000. [Google Scholar]

- HBM (Hottinger Baldwin Messtechnik) GmbH. QuantumX: The Universal and Distributable Data Acquisition System, (n.d.). Available online: https://www.hbm.com/en/2128/quantumx-compact-universal-data-acquisition-system/ (accessed on 3 April 2020).

- Feraboli, P.; Gasco, F.; Wade, B.; Maier, S.; Kwan, R.; Masini, A.; DeOto, L.; Reggiani, M. Lamborghini “Forged Composite®” Technology for the Suspension Arms of the Sesto Elemento; Advanced Composite Structures Laboratory: Seattle, WA, USA, 2011; Available online: http://www.lambolab.org/wp-content/uploads/03research/pub/05chop/2011-ASC-montreal-forged-suspens-ICE.pdf (accessed on 29 May 2020).

- MITSUBISHI CHEMICAL, Mitsubishi Chemical’s SMC Adopted for New Lexus LC500 and LC500h Luxury Coupes. 2017. Available online: https://www.m-chemical.co.jp/en/news/2017/__icsFiles/afieldfile/2017/05/18/20170517e.pdf (accessed on 11 May 2020).

- Plastics Today, SMC Adopted for Rear Door Frame of Toyota’s New Prius PHV. 2017. Available online: https://www.plasticstoday.com/automotive-and-mobility/smc-adopted-rear-door-frame-toyota-s-new-prius-phv/163725208056557 (accessed on 29 May 2020).

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Finck, D.; Seidel, C.; Ostermeier, A.; Hausmann, J.; Rief, T. Experimental Investigation on the In-Plane Creep Behavior of a Carbon-Fiber Sheet Molding Compound at Elevated Temperature at Different Stress States. Materials 2020, 13, 2545. https://doi.org/10.3390/ma13112545

Finck D, Seidel C, Ostermeier A, Hausmann J, Rief T. Experimental Investigation on the In-Plane Creep Behavior of a Carbon-Fiber Sheet Molding Compound at Elevated Temperature at Different Stress States. Materials. 2020; 13(11):2545. https://doi.org/10.3390/ma13112545

Chicago/Turabian StyleFinck, David, Christian Seidel, Anika Ostermeier, Joachim Hausmann, and Thomas Rief. 2020. "Experimental Investigation on the In-Plane Creep Behavior of a Carbon-Fiber Sheet Molding Compound at Elevated Temperature at Different Stress States" Materials 13, no. 11: 2545. https://doi.org/10.3390/ma13112545

APA StyleFinck, D., Seidel, C., Ostermeier, A., Hausmann, J., & Rief, T. (2020). Experimental Investigation on the In-Plane Creep Behavior of a Carbon-Fiber Sheet Molding Compound at Elevated Temperature at Different Stress States. Materials, 13(11), 2545. https://doi.org/10.3390/ma13112545