Author Contributions

Conceptualization, P.A.E.-D., V.N., C.C., A.C; methodology, P.A.E.-D., V.N., C.C., A.C.; software P.A.E.-D.; validation, P.A.E.-D., V.N., C.C., A.C.; formal analysis, P.A.E.-D., V.N., C.C., A.C.; investigation, P.A.E.-D.; resources, P.A.E.-D., V.N., C.C, A.C.; data curation, P.A.E.-D.; writing—original draft preparation, P.A.E.-D.; writing—review and editing, P.A.E.-D., V.N., C.C, A.C., Y.C., J.G.; visualization, P.A.E.-D., V.N., C.C., A.C.; supervision, V.N., C.C., A.C.; project administration, P.A.E.-D., V.N., C.C., A.C.; funding acquisition, V.N., C.C. All authors have read and agreed to the published version of the manuscript.

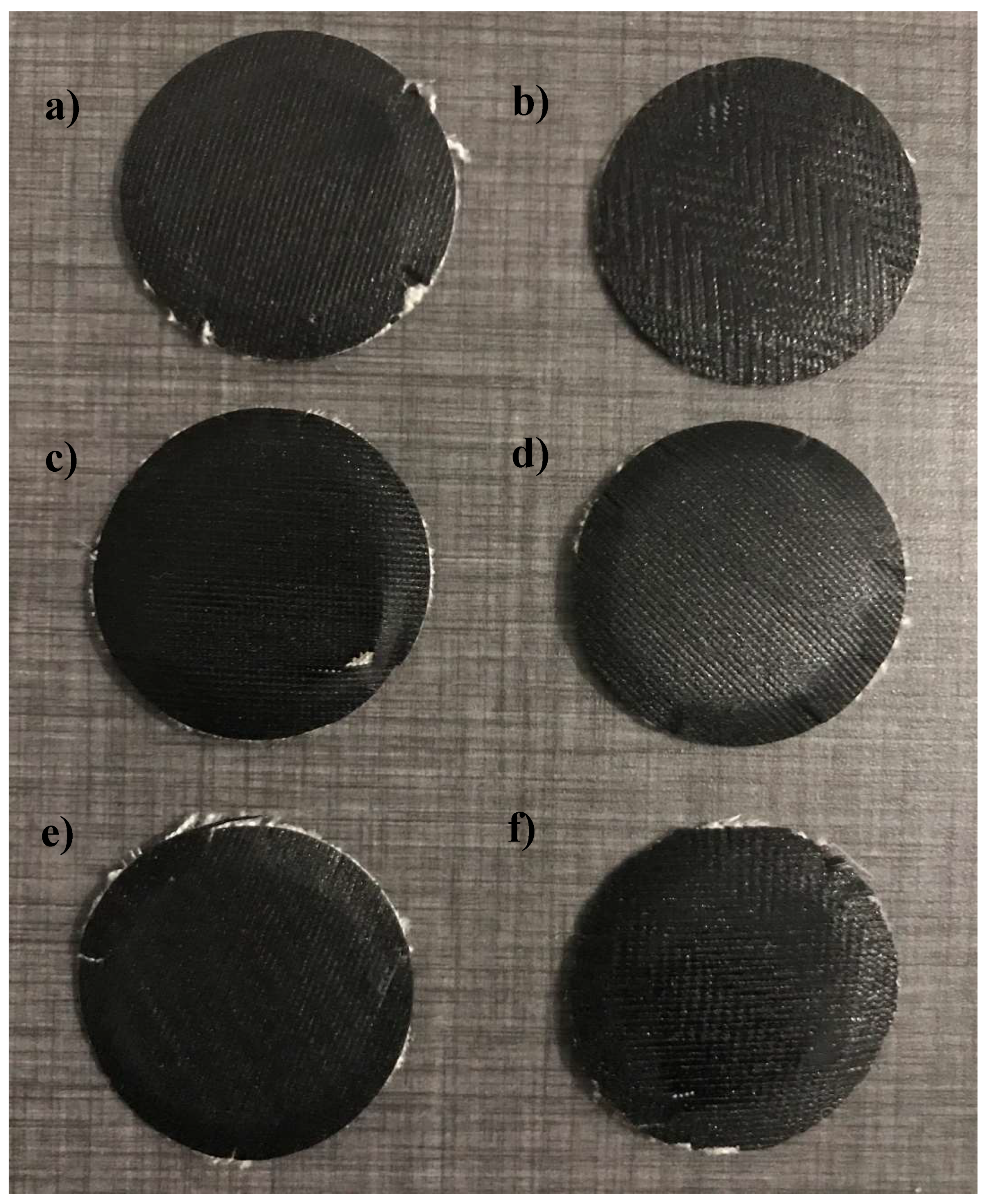

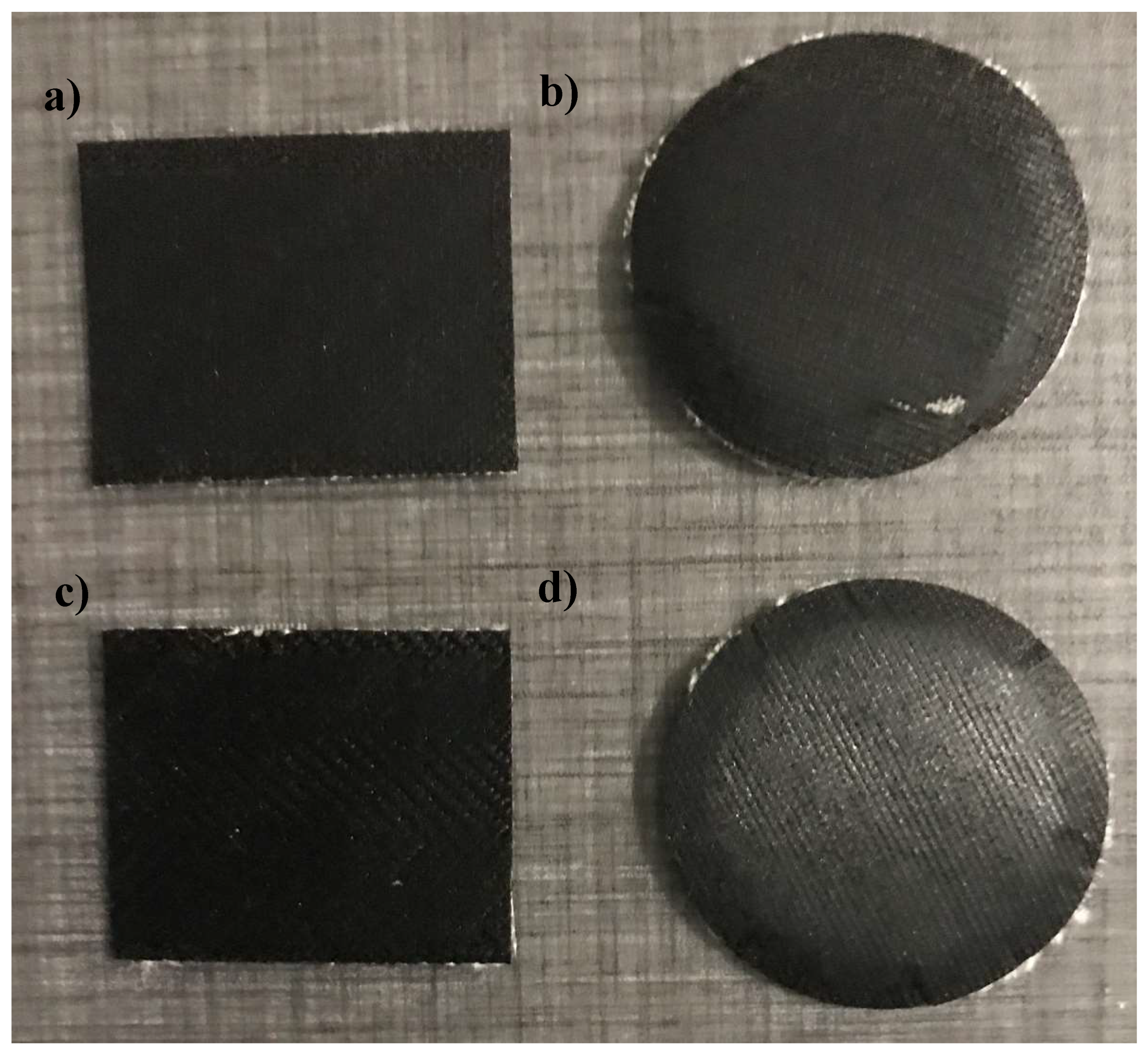

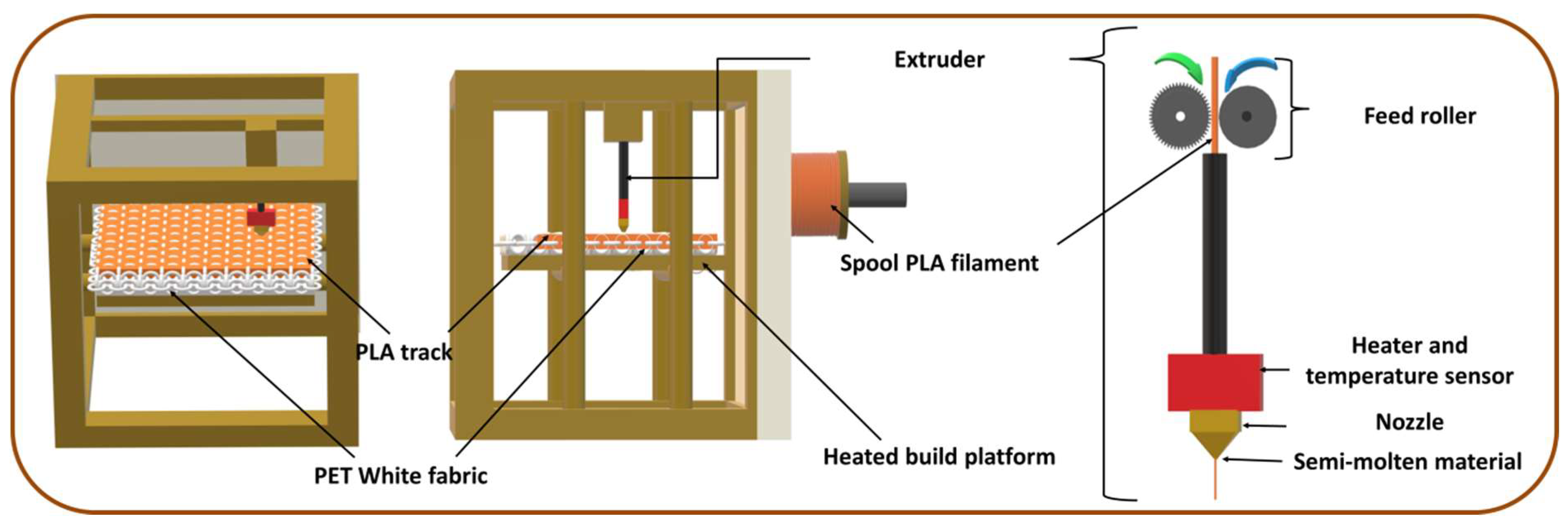

Figure 1.

Fused deposition modeling process onto textiles.

Figure 1.

Fused deposition modeling process onto textiles.

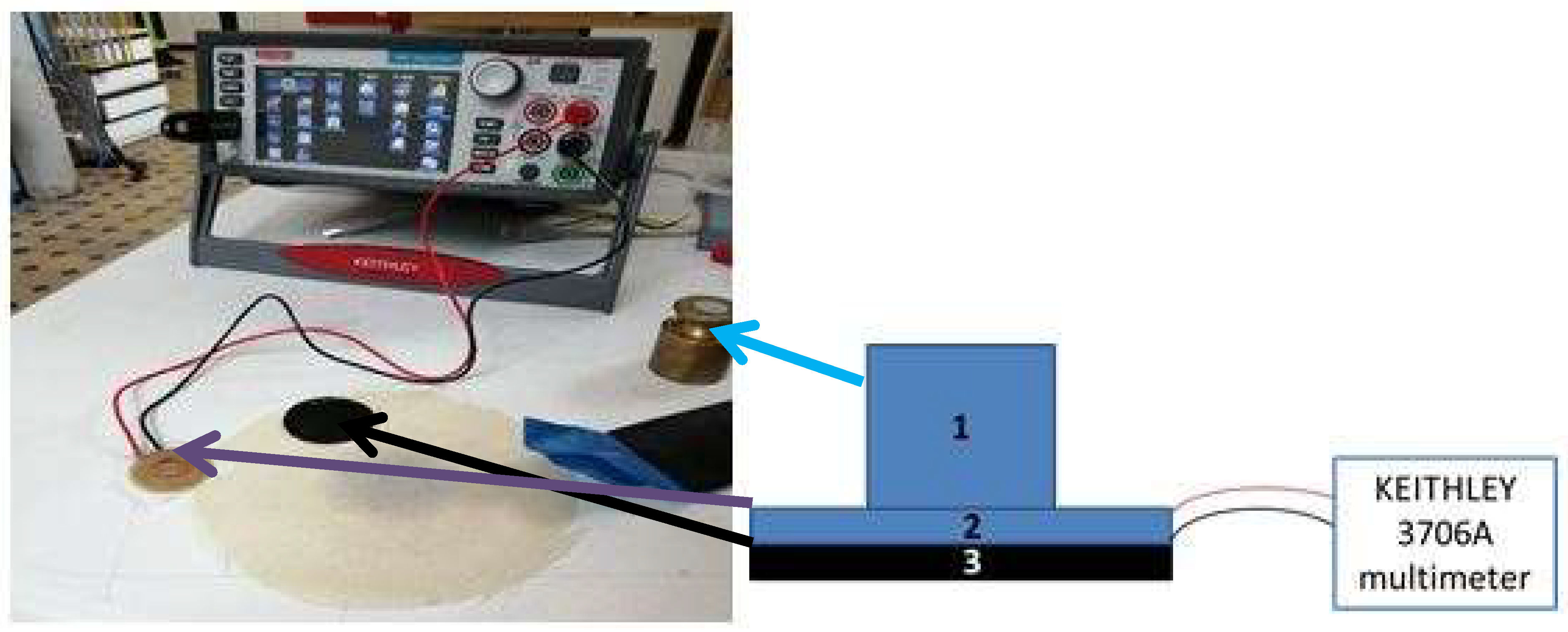

Figure 2.

Electrical conductivity measurement system used for 3D printed conductive polymers on textiles (3D-PPOT) materials before and after abrasion (“Martindale”). (1), (2) and (3) refer to the weight of 300 grams, the electrodes and the textile material, respectively.

Figure 2.

Electrical conductivity measurement system used for 3D printed conductive polymers on textiles (3D-PPOT) materials before and after abrasion (“Martindale”). (1), (2) and (3) refer to the weight of 300 grams, the electrodes and the textile material, respectively.

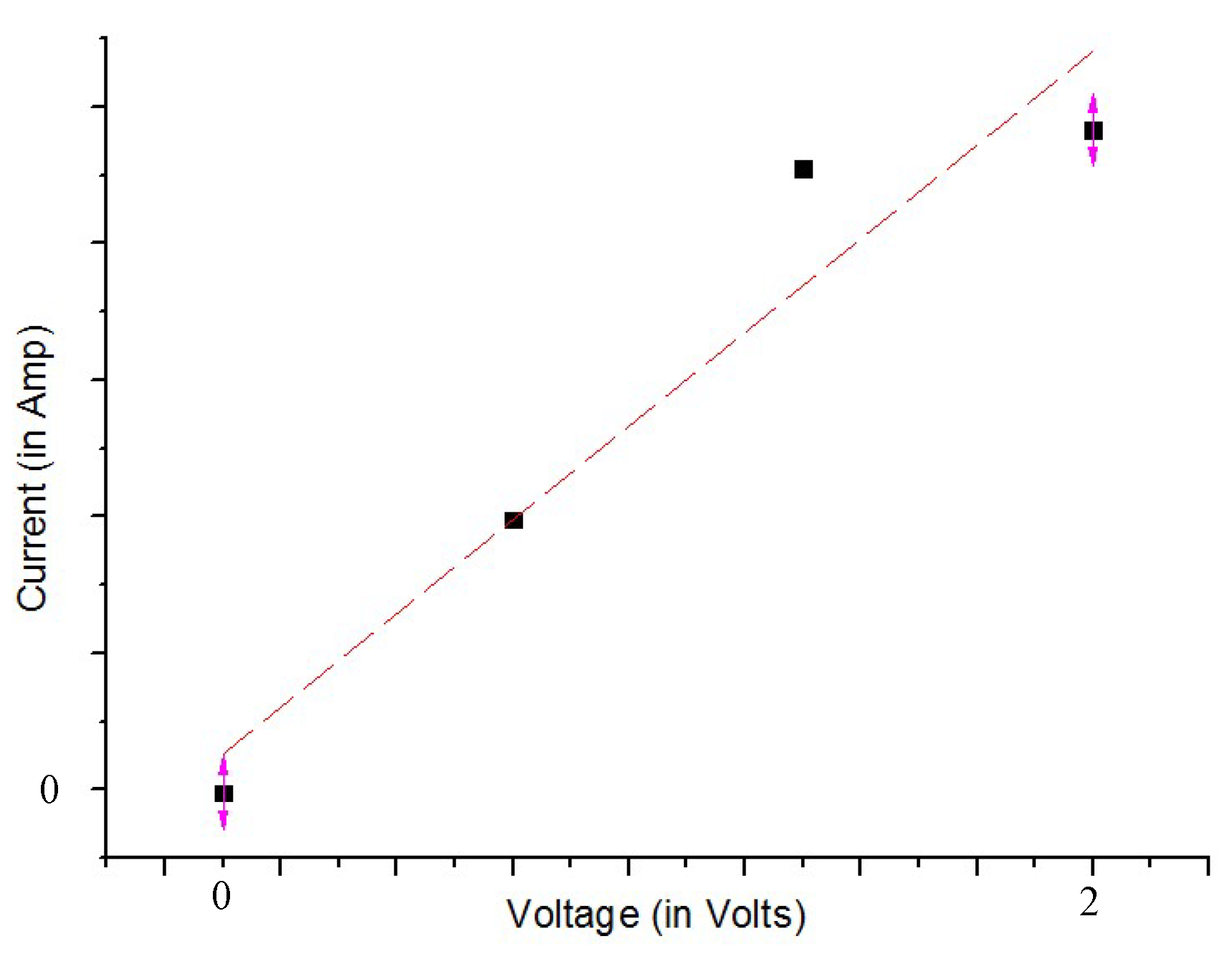

Figure 3.

Current–voltage characteristic and their linear fitting between 0 V and 2 V.

Figure 3.

Current–voltage characteristic and their linear fitting between 0 V and 2 V.

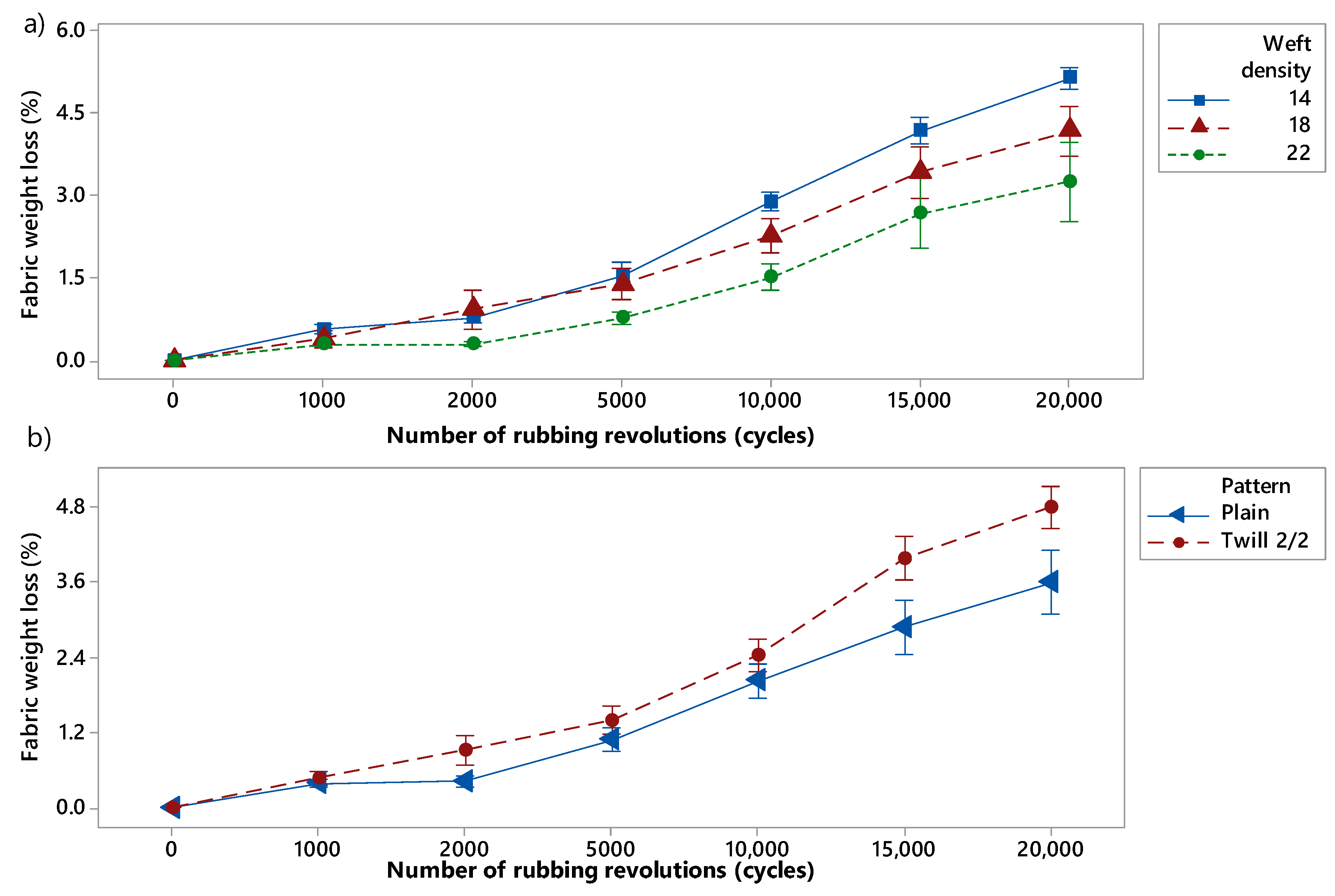

Figure 4.

Relationship between fabric weight loss (%) prior to Fused Deposition Modeling (FDM) process and number of rubbing cycles when varying (a) the weft density and (b) the pattern. The 14, 18, 22 picks/inch are in blue, red and green, respectively) and the plain and twill patterns are in blue and red, respectively.

Figure 4.

Relationship between fabric weight loss (%) prior to Fused Deposition Modeling (FDM) process and number of rubbing cycles when varying (a) the weft density and (b) the pattern. The 14, 18, 22 picks/inch are in blue, red and green, respectively) and the plain and twill patterns are in blue and red, respectively.

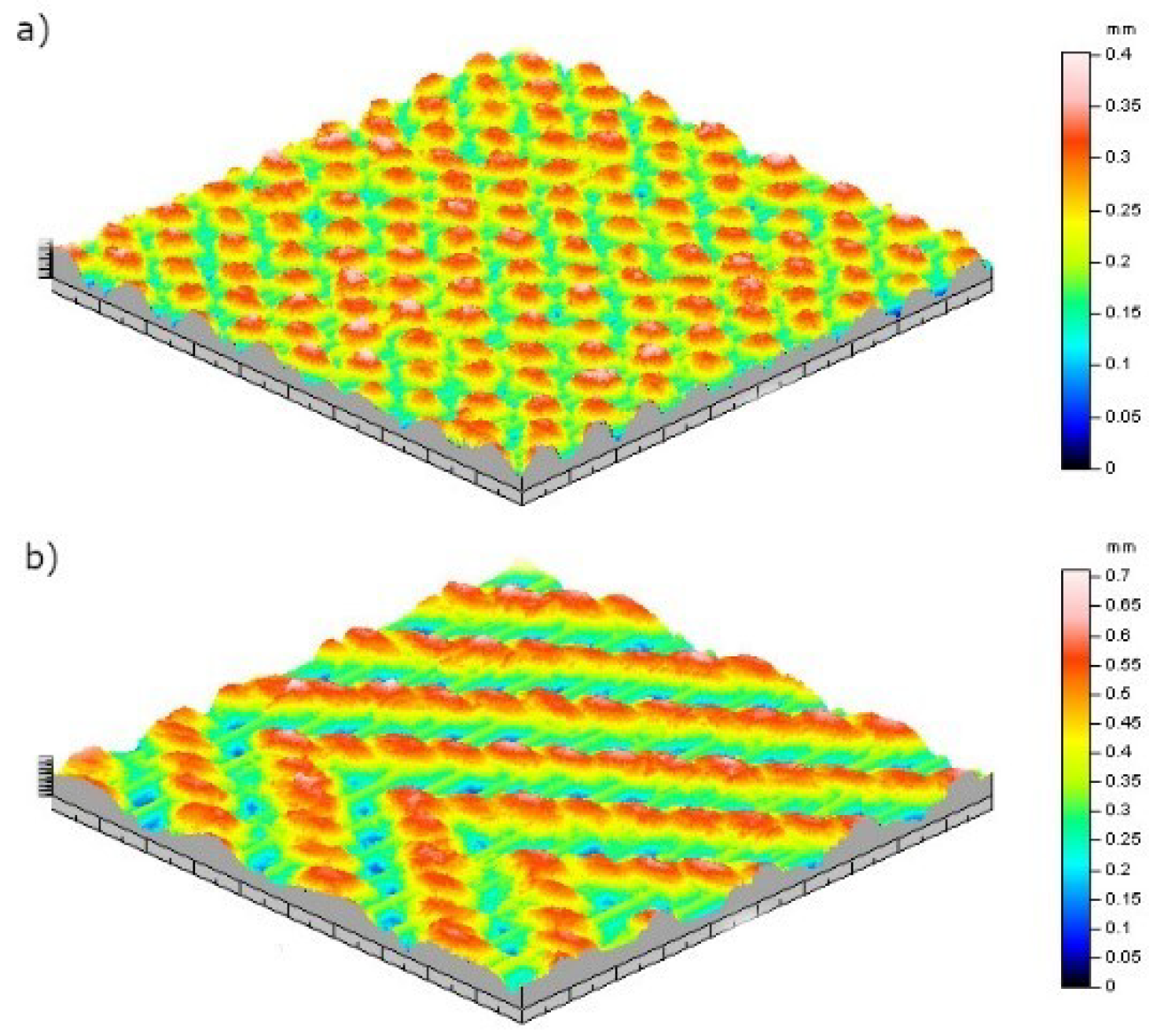

Figure 5.

(

a) Plain and (

b) twill 2/2 structures visualization through profilometry method [

5].

Figure 5.

(

a) Plain and (

b) twill 2/2 structures visualization through profilometry method [

5].

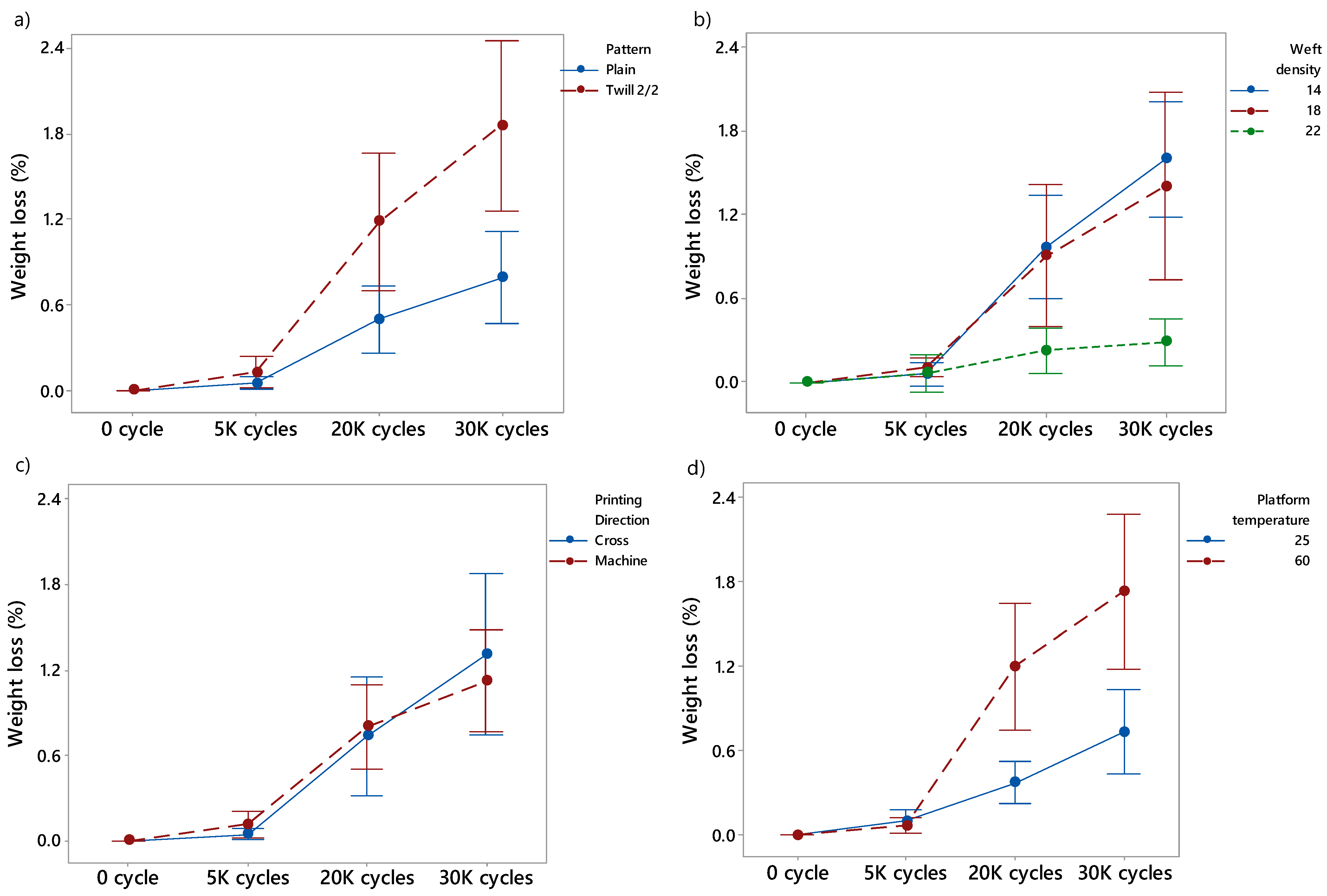

Figure 6.

Weight loss (%) of the 3D-PPOT conductive materials after 0 cycles, 5000 (5 K), 20,000 (20 K) and 30,000 (30 K) rubbing cycles using two different patterns (a) plain in blue and twill 2/2 in red, three different weft densities (b) 14, 18 and 22 in blue, red and green, respectively, two different printing directions (c) cross in blue and machine in red and two different platform temperatures (d) 25, 60 °C in blue and red, respectively.

Figure 6.

Weight loss (%) of the 3D-PPOT conductive materials after 0 cycles, 5000 (5 K), 20,000 (20 K) and 30,000 (30 K) rubbing cycles using two different patterns (a) plain in blue and twill 2/2 in red, three different weft densities (b) 14, 18 and 22 in blue, red and green, respectively, two different printing directions (c) cross in blue and machine in red and two different platform temperatures (d) 25, 60 °C in blue and red, respectively.

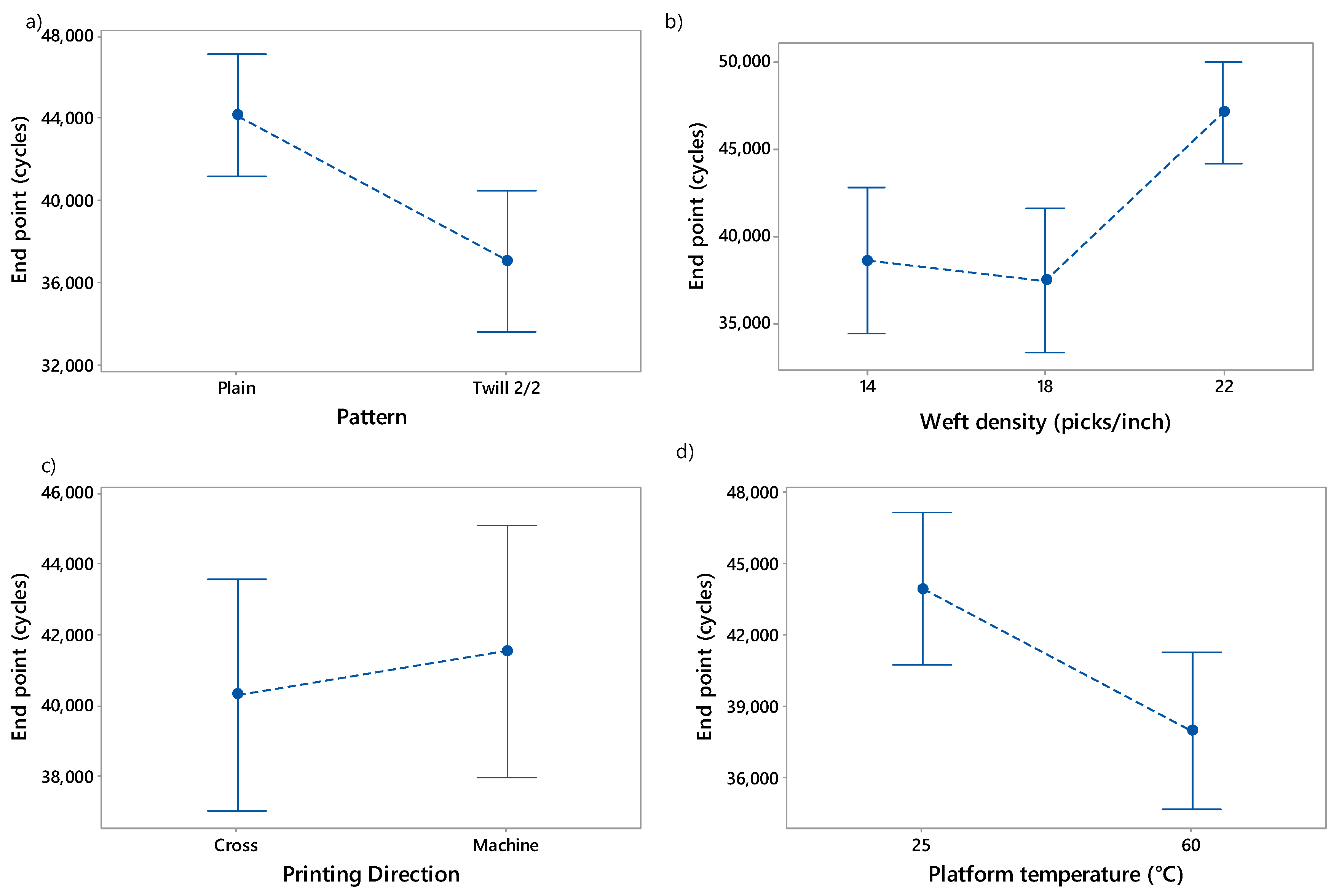

Figure 7.

Influence of (a) fabric pattern, (b) weft density, (c) printing direction and (d) platform temperature on the end point which is the maximum number of cycles (cycles) of 3D-PPOT conductive materials.

Figure 7.

Influence of (a) fabric pattern, (b) weft density, (c) printing direction and (d) platform temperature on the end point which is the maximum number of cycles (cycles) of 3D-PPOT conductive materials.

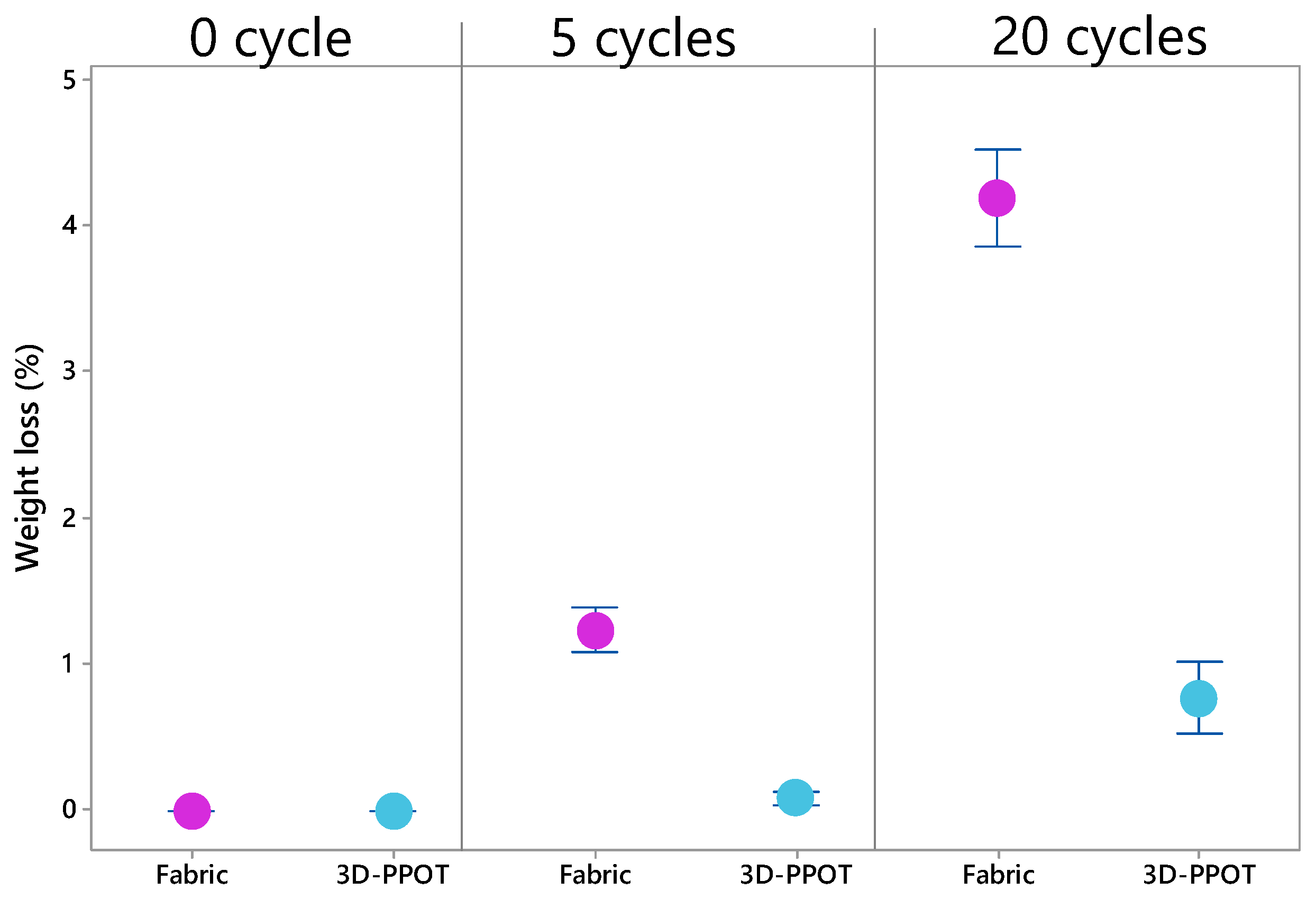

Figure 8.

Weight loss (%) of woven fabric and 3D-PPOT material after 0, 5 and 20 cycles.

Figure 8.

Weight loss (%) of woven fabric and 3D-PPOT material after 0, 5 and 20 cycles.

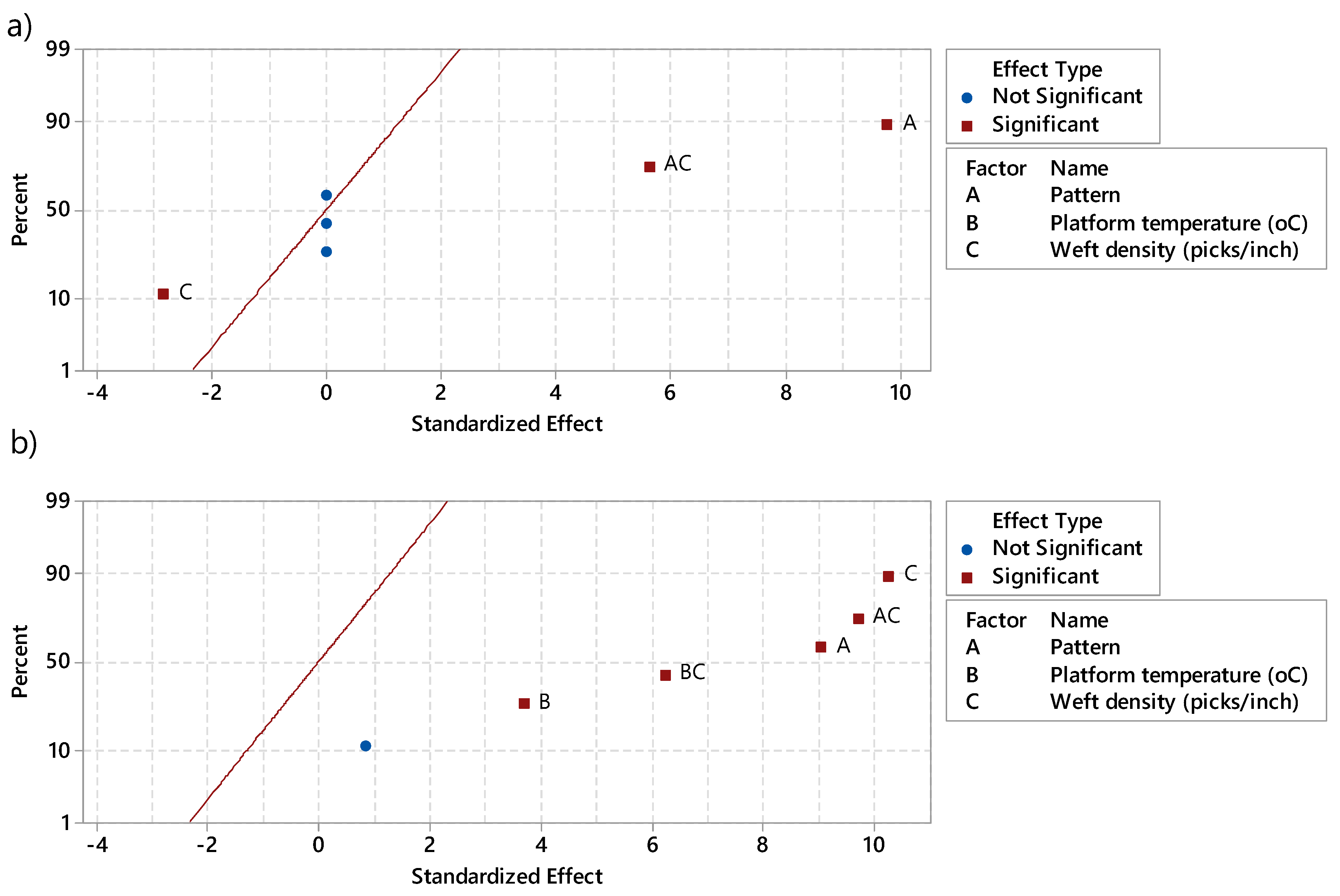

Figure 9.

Effect of (A) pattern, (B) platform temperature in °C, and (C) weft density in picks/inch on (a) pore size of the fabric prior to 3D printing process and (b) 3D-PPOT materials after 3D printing process, obtained through pareto analysis of Minitab 17. AC and BC represent the interaction between the factors A and C and, B and C, respectively.

Figure 9.

Effect of (A) pattern, (B) platform temperature in °C, and (C) weft density in picks/inch on (a) pore size of the fabric prior to 3D printing process and (b) 3D-PPOT materials after 3D printing process, obtained through pareto analysis of Minitab 17. AC and BC represent the interaction between the factors A and C and, B and C, respectively.

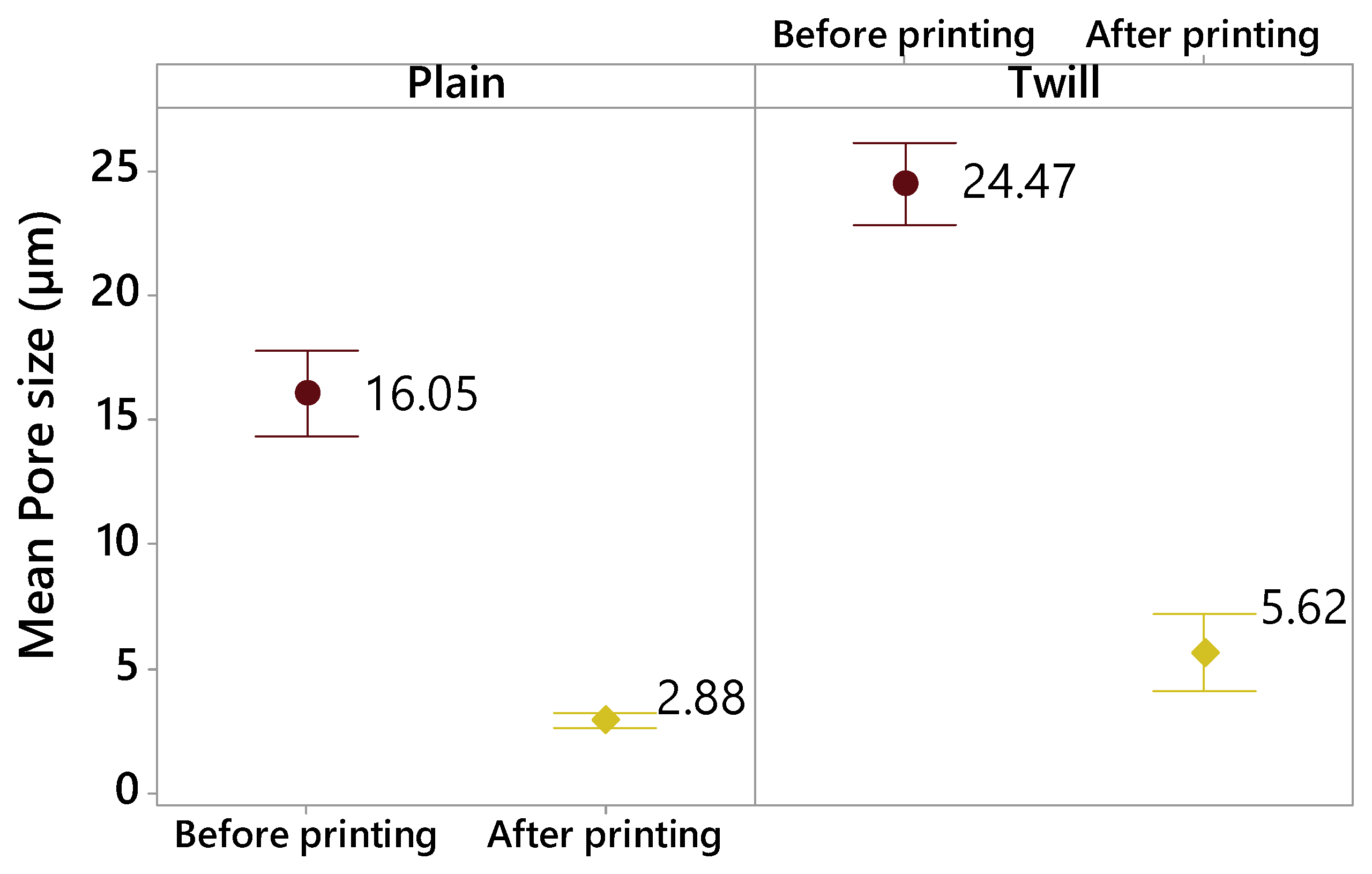

Figure 10.

Mean pore size (µm) of the pores localized at the surface of the textile fabrics before 3D printing (in purple) and the 3D-PPOT materials after 3D printing (in yellow) depending on the fabric pattern (plain and twill).

Figure 10.

Mean pore size (µm) of the pores localized at the surface of the textile fabrics before 3D printing (in purple) and the 3D-PPOT materials after 3D printing (in yellow) depending on the fabric pattern (plain and twill).

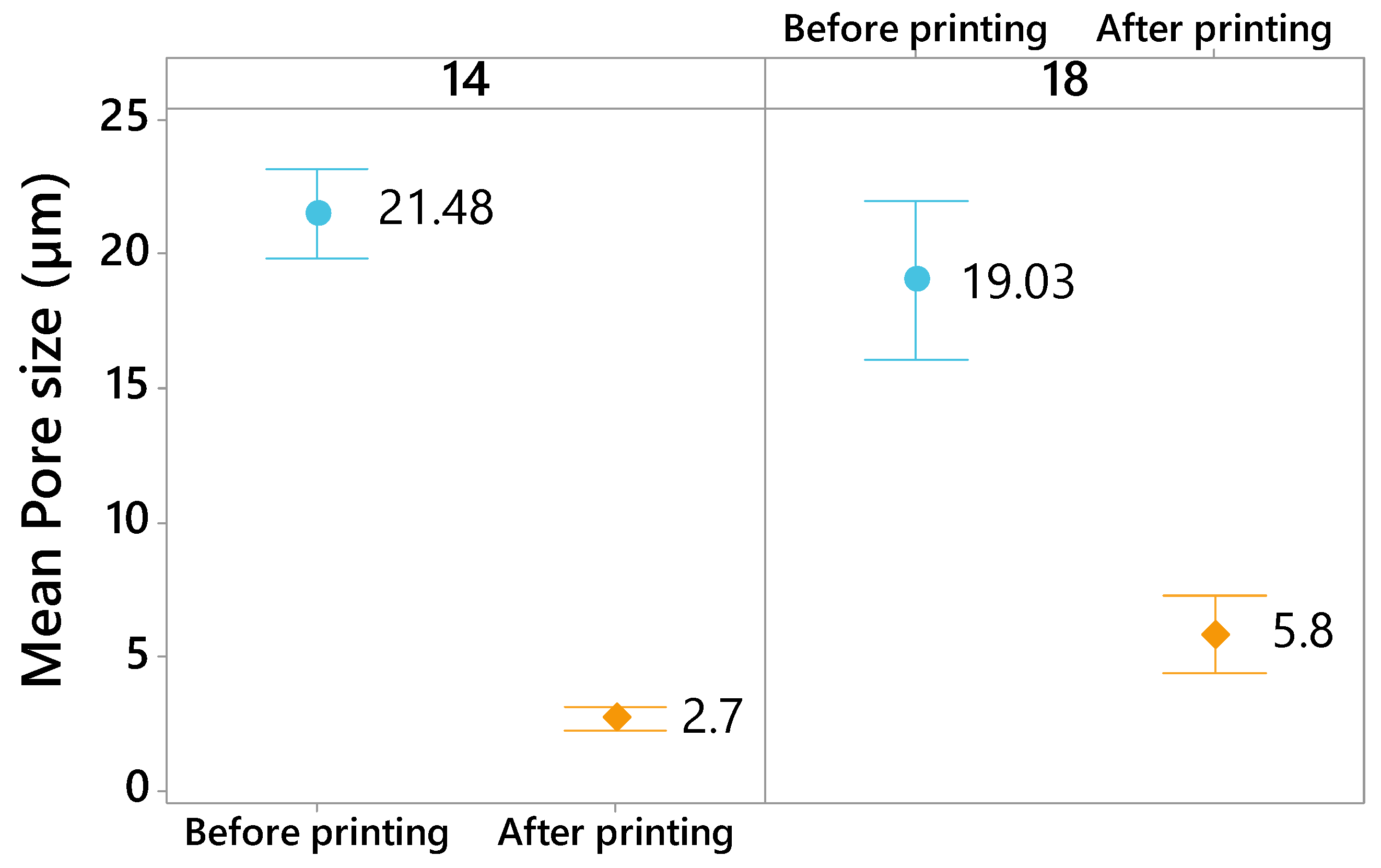

Figure 11.

Mean pore size (µm) of the pores localized at the surface of the textile fabrics before 3D printing (in blue) and the 3D-PPOT materials after 3D printing (in orange) depending on the weft density of the fabric (14 and 18 pick/inch).

Figure 11.

Mean pore size (µm) of the pores localized at the surface of the textile fabrics before 3D printing (in blue) and the 3D-PPOT materials after 3D printing (in orange) depending on the weft density of the fabric (14 and 18 pick/inch).

Figure 12.

Mean thickness (µm) of the textile fabrics before 3D printing (PREF and TREF) and the 3D-PPOT materials after 3D printing (P14, P22, T14 and T22). PREF and TREF stands for plain fabric reference and twill fabric reference, respectively. P14, P22, T14 and T22 are designed as the following 3D-PPOT materials: plain—14 picks/inch, plain—22 picks/inch, twill—14 picks/inch, twill—22 picks/inch.

Figure 12.

Mean thickness (µm) of the textile fabrics before 3D printing (PREF and TREF) and the 3D-PPOT materials after 3D printing (P14, P22, T14 and T22). PREF and TREF stands for plain fabric reference and twill fabric reference, respectively. P14, P22, T14 and T22 are designed as the following 3D-PPOT materials: plain—14 picks/inch, plain—22 picks/inch, twill—14 picks/inch, twill—22 picks/inch.

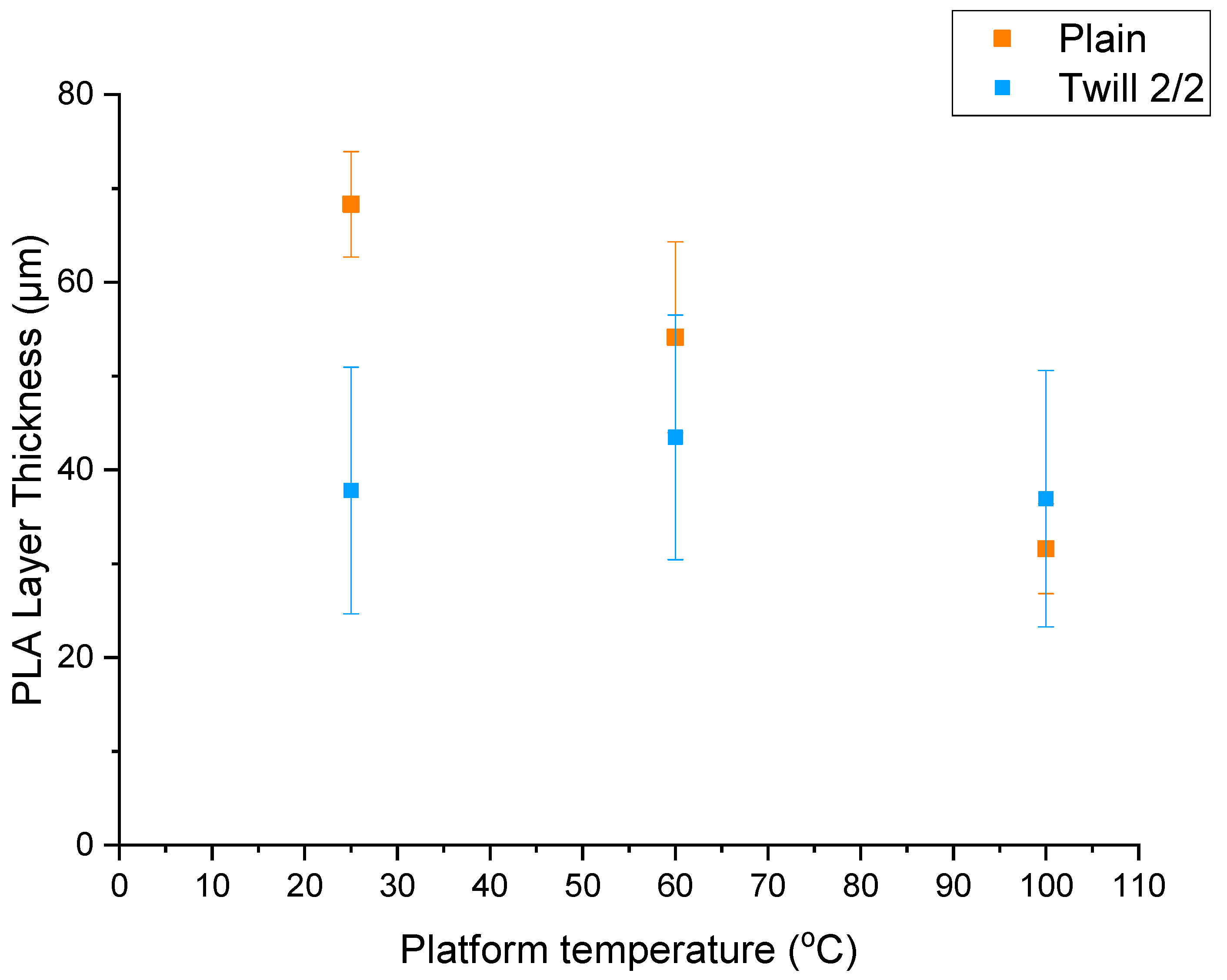

Figure 13.

Poly lactic acid (PLA) track thickness (µm) depending on the platform temperature of the 3D printer (25, 60 and 100 °C) for plain fabrics (in orange) and twill fabric (in blue).

Figure 13.

Poly lactic acid (PLA) track thickness (µm) depending on the platform temperature of the 3D printer (25, 60 and 100 °C) for plain fabrics (in orange) and twill fabric (in blue).

Figure 14.

Electrical conductivity (S) before and after abrasion (20 K cycles) for the 3D-PPOT materials samples P2260, P2225, T1425, T1825 and T2225. P2260, P2225, T1425, T1825 and T2225. P2260 is designed as the following: plainof 22 picks/inch weft density and printed at a platform temperature of 60 °C.

Figure 14.

Electrical conductivity (S) before and after abrasion (20 K cycles) for the 3D-PPOT materials samples P2260, P2225, T1425, T1825 and T2225. P2260, P2225, T1425, T1825 and T2225. P2260 is designed as the following: plainof 22 picks/inch weft density and printed at a platform temperature of 60 °C.

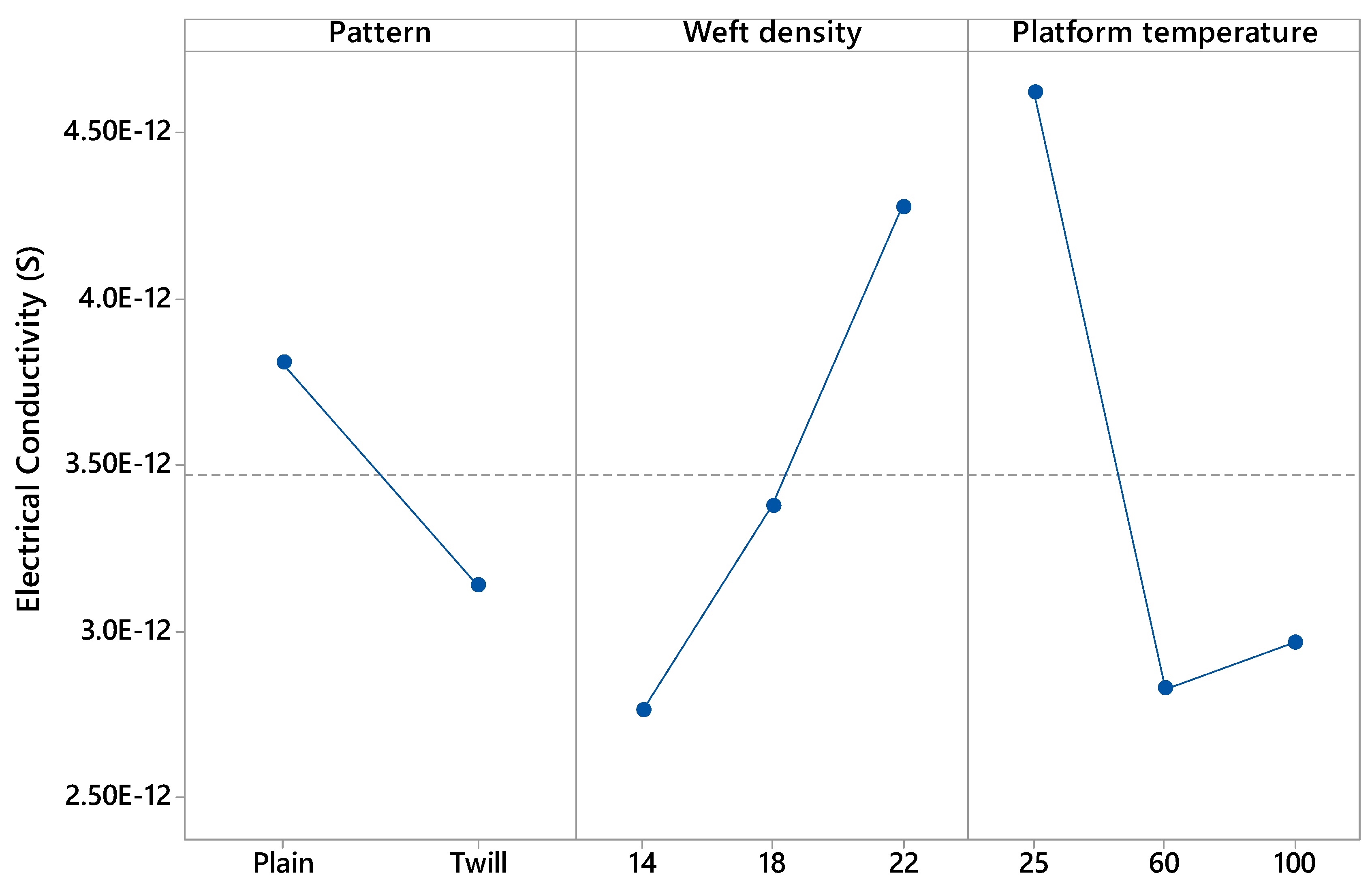

Figure 15.

Influence of pattern (plain and twill), weft density (14,18 and 22 picks/inch) and platform temperature (25, 60 and 100 °C) on the electrical conductivity (S) of the samples after abrasion (20 K cycles). In y-axis the following scientific notation 2.50E-12 means 2.50 × 10−12.

Figure 15.

Influence of pattern (plain and twill), weft density (14,18 and 22 picks/inch) and platform temperature (25, 60 and 100 °C) on the electrical conductivity (S) of the samples after abrasion (20 K cycles). In y-axis the following scientific notation 2.50E-12 means 2.50 × 10−12.

Table 1.

Printing process parameters.

Table 1.

Printing process parameters.

| Parameters | Values (unit) |

|---|

| Infill percentage | 20 (%) |

| Z offset (distance between the head) | 0 (mm) |

| Printing speed | 3600 (mm·min−1) |

| Extruder (or printing) diameter | 0.4 (mm) |

| Extruder temperature | 250 (°C) |

Table 2.

Factors of the statistical design of experiments and their levels for abrasion measurements.

Table 2.

Factors of the statistical design of experiments and their levels for abrasion measurements.

| Factors | Name | Level |

|---|

| −1 | 0 | 1 |

|---|

| A | Pattern | Plain | - | Twill |

| B | Weft density (picks/inch) | 14 | 18 | 22 |

| C | Fabric orientation | Cross | - | Machine |

| D | Printing bed temperature (°C) | 25 | - | 60 |

Table 3.

Factors of the statistical design of experiments and their levels for mean pore size measurement.

Table 3.

Factors of the statistical design of experiments and their levels for mean pore size measurement.

| Factors | Name | Level |

|---|

| −1 | 1 |

|---|

| A | Pattern | Plain | Twill |

| B | Weft density (picks/inch) | 14 | 18 |

Table 4.

Factors of the statistical design of experiments and their levels for thickness measurements.

Table 4.

Factors of the statistical design of experiments and their levels for thickness measurements.

| Factors | Name | Level |

|---|

| −1 | 0 | 1 |

|---|

| A | Pattern | Plain | - | Twill |

| B | Weft density (picks/inch) | 14 | - | 22 |

| C | Printing bed temperature (°C) | 25 | 60 | 100 |

Table 5.

Factors of the statistical design of experiments and their levels for electrical conductivity measurements.

Table 5.

Factors of the statistical design of experiments and their levels for electrical conductivity measurements.

| Factors | Name | Level |

|---|

| −1 | 0 | 1 |

|---|

| A | Pattern | Plain | - | Twill |

| B | Weft density (picks/inch) | 14 | 18 | 22 |

| C | Fabric orientation | Cross | - | Machine |

| D | Printing bed temperature (°C) | 25 | 60 | 100 |