Friction Stir Welding and Friction Spot Stir Welding Processes of Polymers—State of the Art

Abstract

1. Introduction

2. Common Joining Processes Used for Thermoplastics and Fiber Reinforced Thermoplastics

2.1. Adhesive Bonding

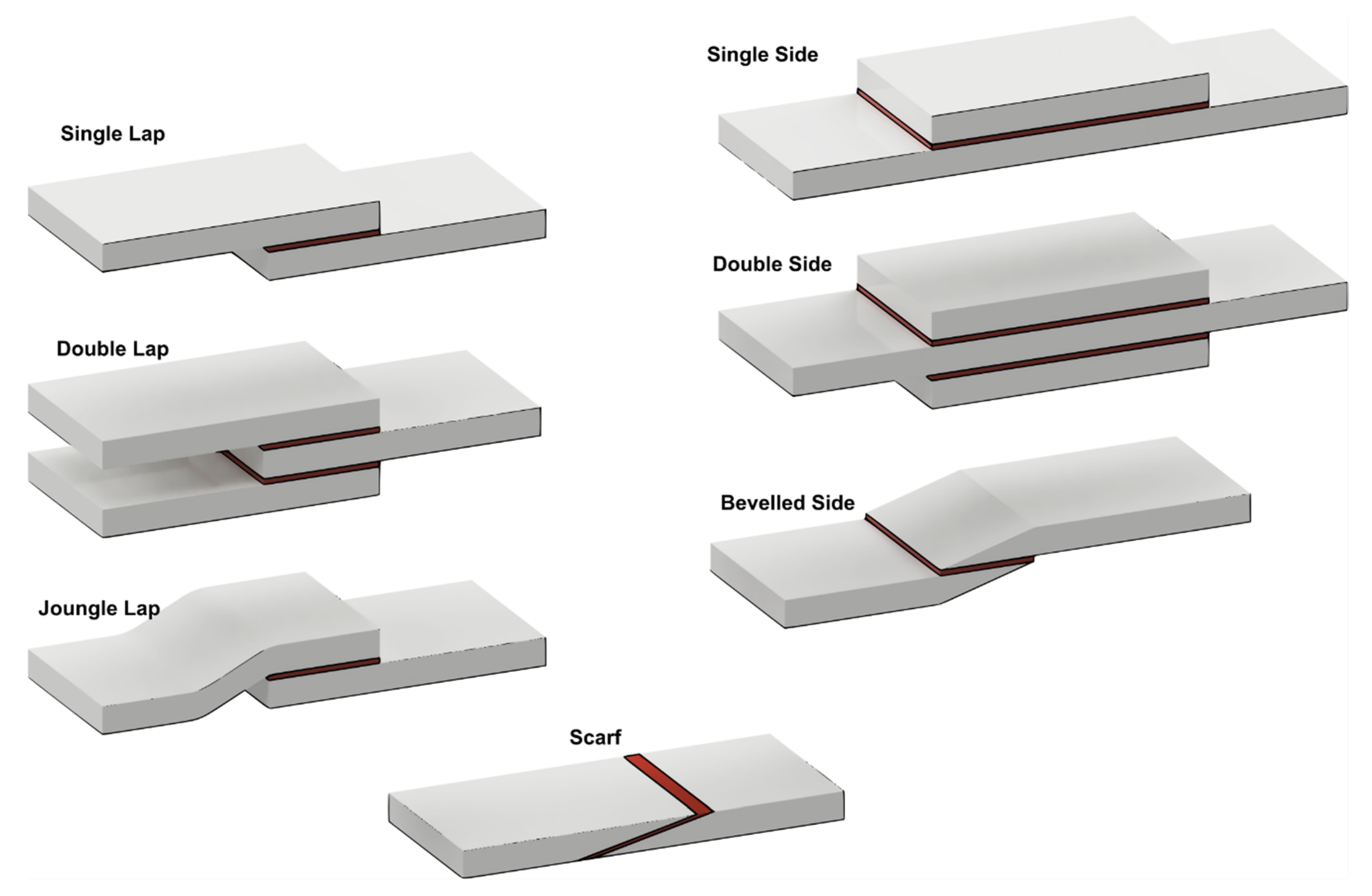

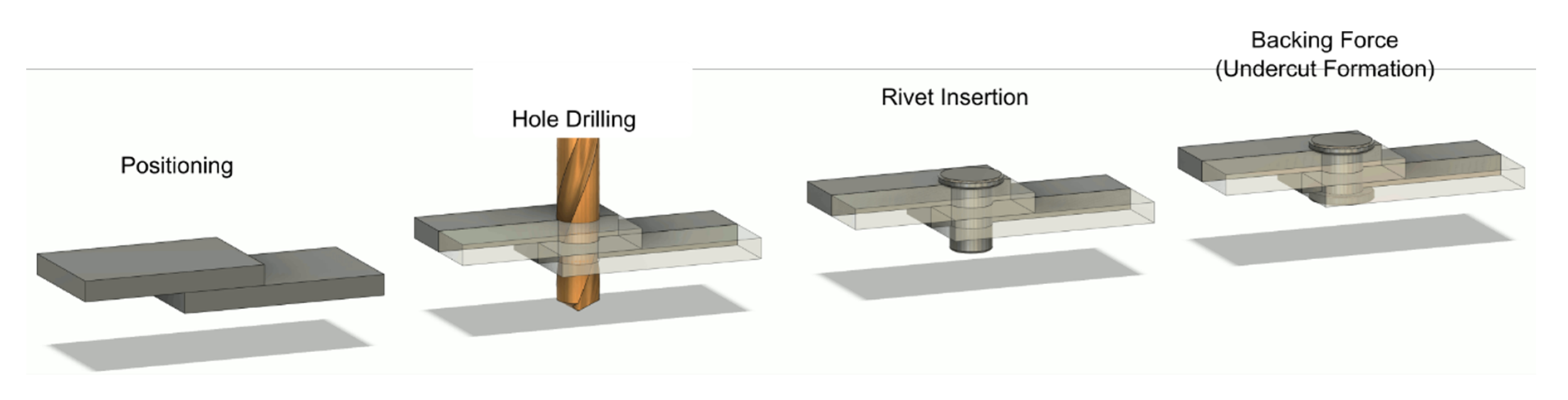

2.2. Mechanical Fastening

2.3. Plastics Welding

- Conduction heating: the heat is conducted from an external tool. Typical examples include heated tool welding, plate welding and resistive implant welding;

- Friction welding: the heat is generated by bringing into contact two workpieces under pressure, and a reciprocating motion (vibration) is applied along the interface. Here, the friction induces the increase in temperature of the material close to the components interface. Typical examples are vibration welding, ultrasonic welding;

- Wave induced welding: here, the materials are subjected to external waves (e.g., electromagnetic field). For example, radiofrequency welding involves high frequency (commonly 27.12 MHz) electromagnetic energy that is coupled with the material leading to a conversion of alternating electric energy to heat. Another example is represented by laser welding. Here, the optical coupling between a laser source and the polymeric materials is exploited instead of electric coupling. Examples include infrared welding, induction welding and microwave welding.

- Convective heating: the weld seam is heated by means of a convective source (typically a hot gas) e.g., hot gas welding;

- Heated filler: these processes involve an external (polymeric) filler that is previously heated and pressed against the two materials along the weld seam (e.g., extrusion welding).

3. Friction Stir Welding

- Lower material preheating (ahead the tools shoulder) owing to low thermal diffusivity of polymers;

- Longer cooling time due to lower heat diffusion towards the surrounding material once the tool has passed by a given position;

- In polymers, moisture content may give rise to bubble development, which affects the mechanical behavior of the welds;

- Severe reduction of the load bearing capacity (especially in semi-crystalline polymers) as the softening/melting temperature is approached. This may lead to unsteady material flow conditions;

- Polymeric chains have different lengths; thus, melting conditions may occur at some regions (where shorter chains are localized) leading to uneven material flow;

- Because of the poor thermal diffusivity of the polymers, the material under the tool shoulder is rapidly heated even above the softening/melting point (owing to the high tangential speed at the interface). This would cause the material ejection from the weld seam, with consequent reduction of the strength of the welds. Thus, FSW of polymer materials is preferably performed with a non-rotating tool shoulder;

- The poor thermal diffusivity of polymers also comes with steeper temperature gradients between the stirred and the surrounding regions. This may cause poor adhesion at the interface and differential shrinkage. In addition, the interface between these regions is also affected by the presence of porosities (often generated by the presence of moisture), that act as stress raiser. As a result, the interface between the stirred region and base material is even more critical in polymers than in welds performed in metals.

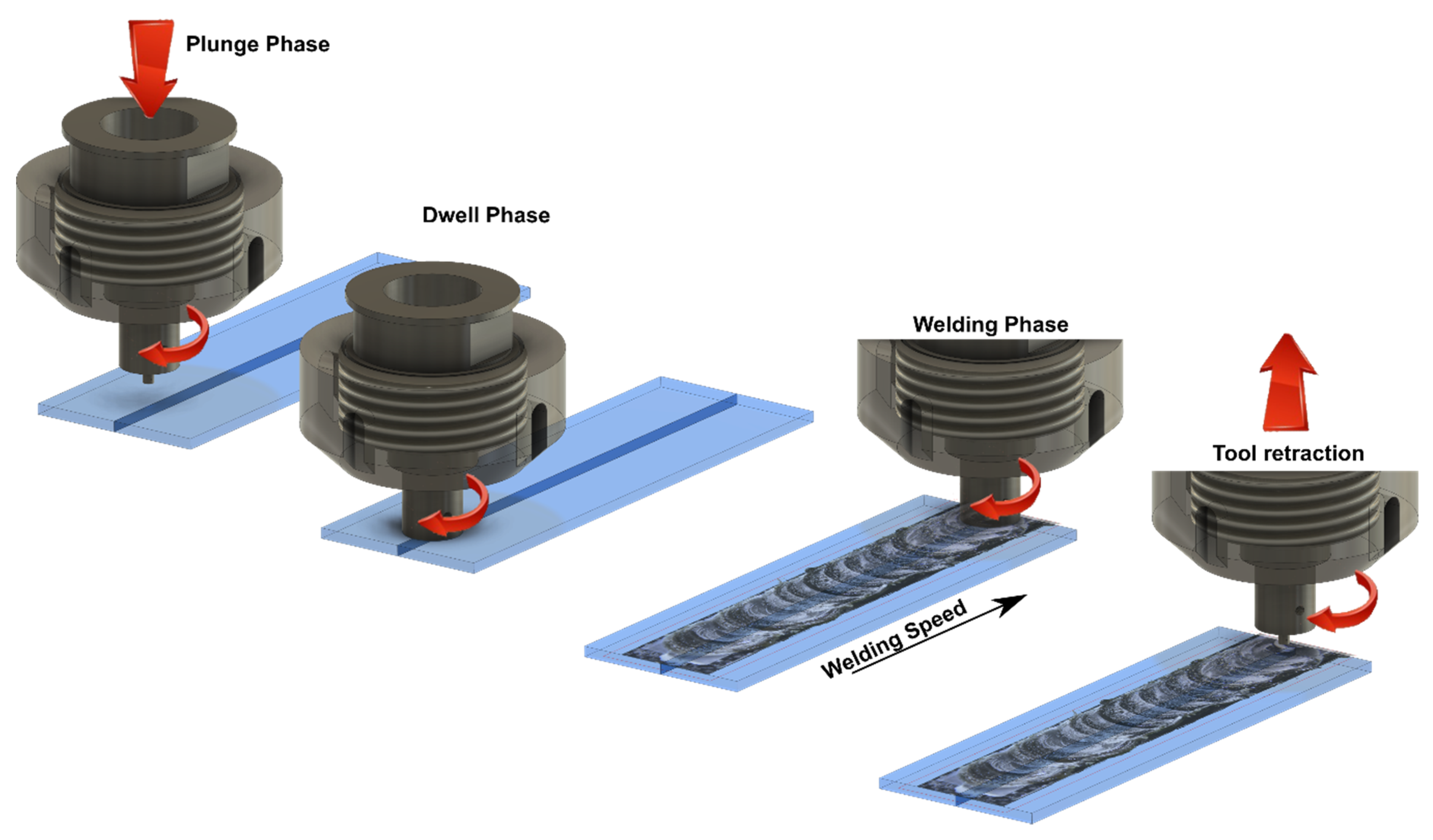

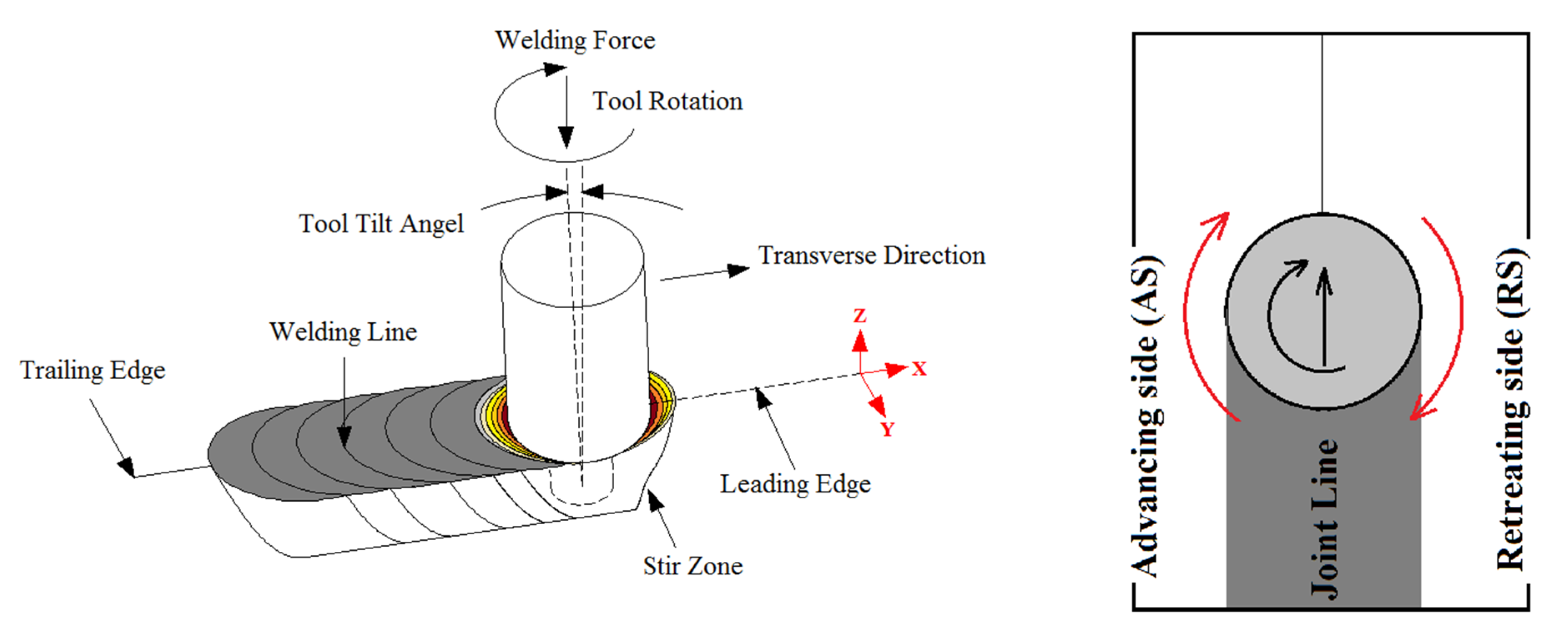

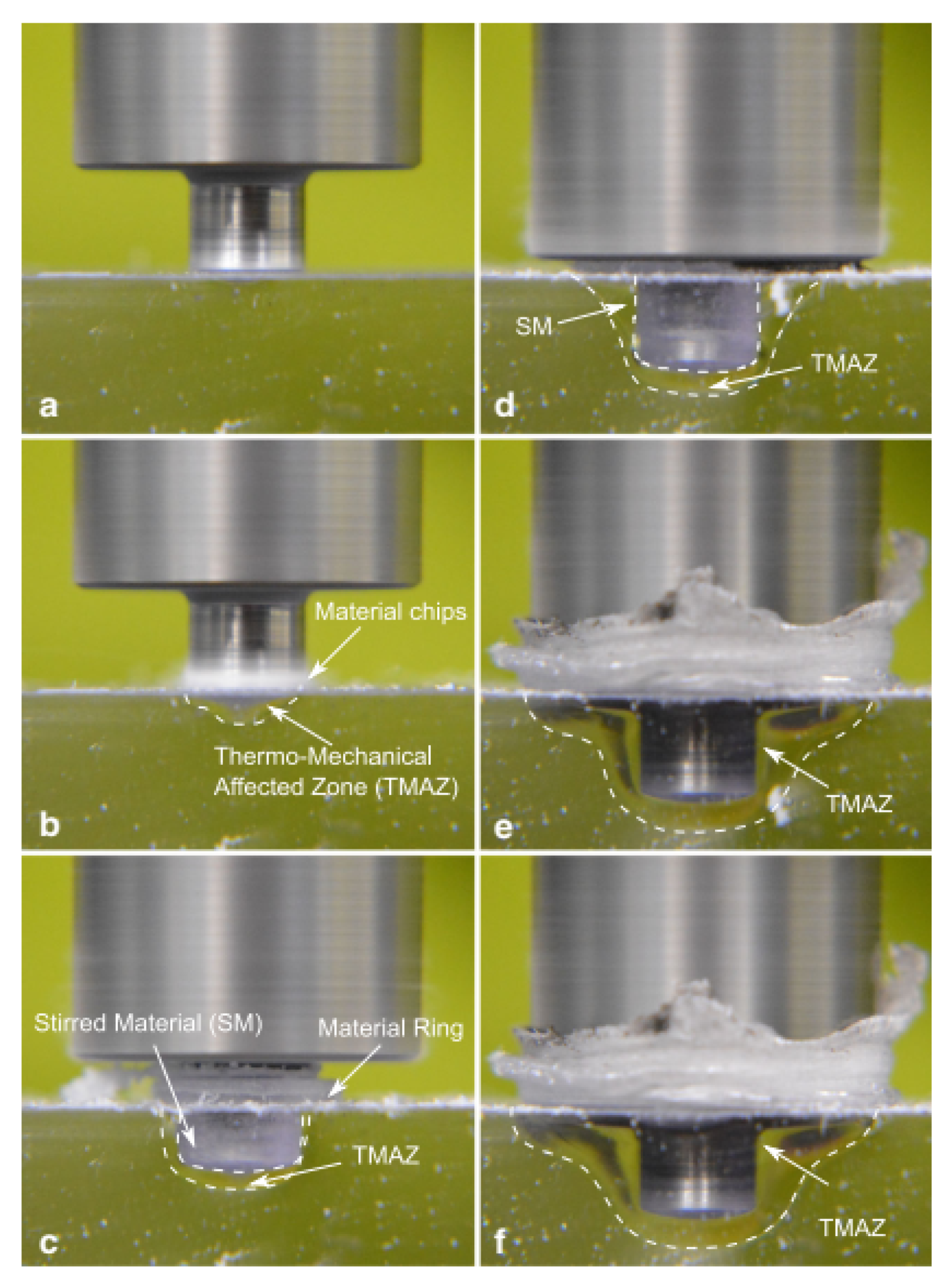

3.1. Description of the Main Phases

- Plunge phase: During this phase, the rotational tool moves in axial direction and plunged the cold materials. Downward motion of the tool is stopped as soon as the tool shoulder is in contact with the upper surface of the workpiece. In this phase, the axial force and the torque applied to the linear FSW (LFSW) tool reach a peak value and immediately reduce as the steep material heating. At the end of this phase, the LFSW tool pin was fully surrounded/embedded by the material to be stirred. The depth by which the tool shoulder penetrated the upper sheet surface is called plunge depth (TPD) [18].

- Dwell (stabilization) phase: At the end of the plunging phase, the tool is held at a prescribed position leading to material preheating;

- Advancing (welding) phase: The LFSW tool starts to move forward along weld seam. The tool velocity (V) in this phase represents the key aspect that determines the quality of the weld. Depending on the LFSW tool design, V and TPD, the LFSW tool may be tilted to improve the quality of the joint line.

- LFSW tool retract phase: As the tool reached the final position, the tool is rapidly removed from the weld seam [19].

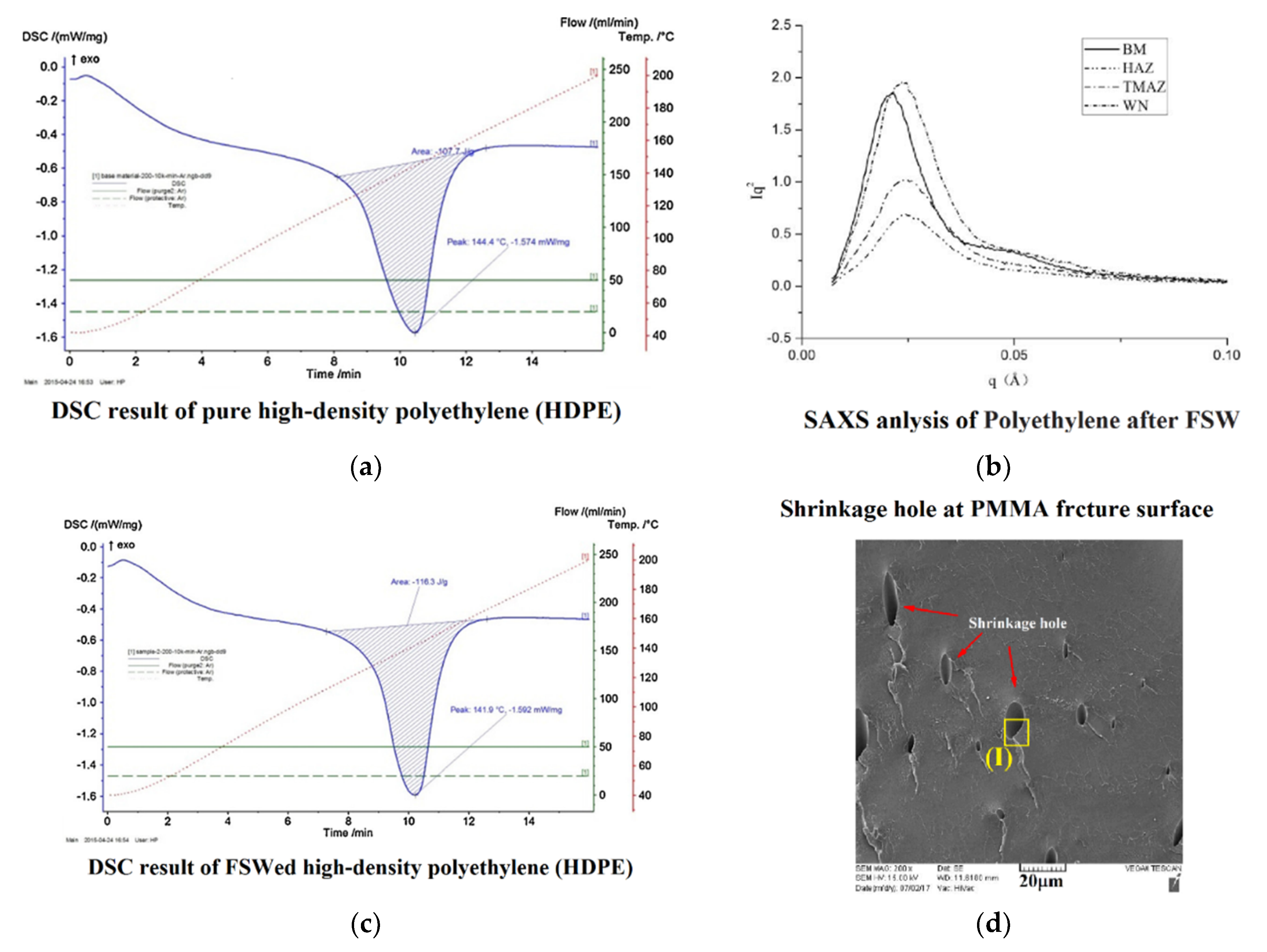

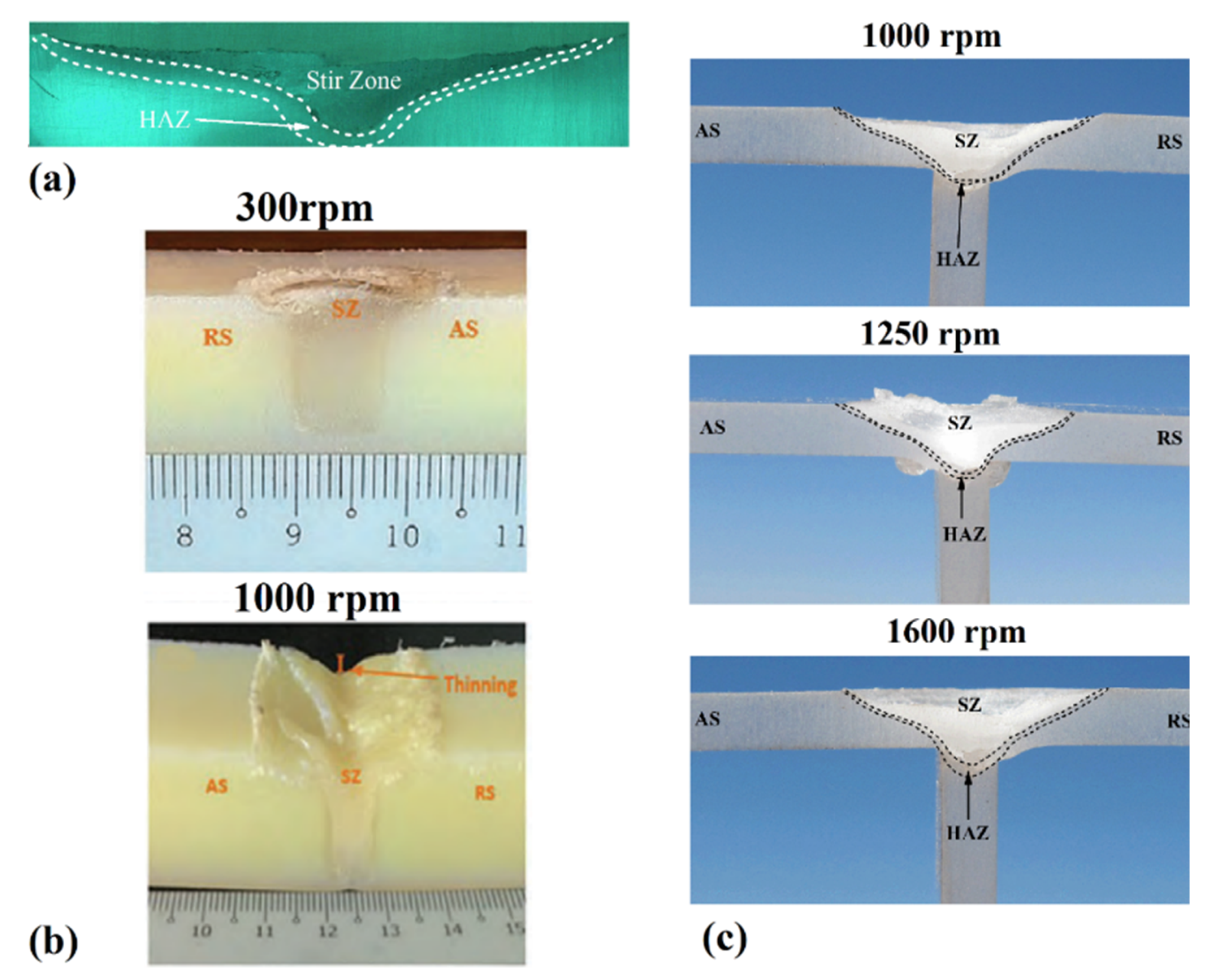

3.2. Material Flow

- Stir zone (SZ): The center of weld seam where the material undergoes to high rate of thermal and mechanical stirring cycles.

- Thermo-mechanical affected zone (TMAZ): A narrow area around SZ where the material experiences low rate of thermal and mechanical stirring cycles.

- Heat affected zone (HAZ): The region surrounding the TMAZ where the material undergoes thermal cycles diffused from SZ.

- Base material (BS): The neat area where the material is not involved into thermal and mechanical cycles.

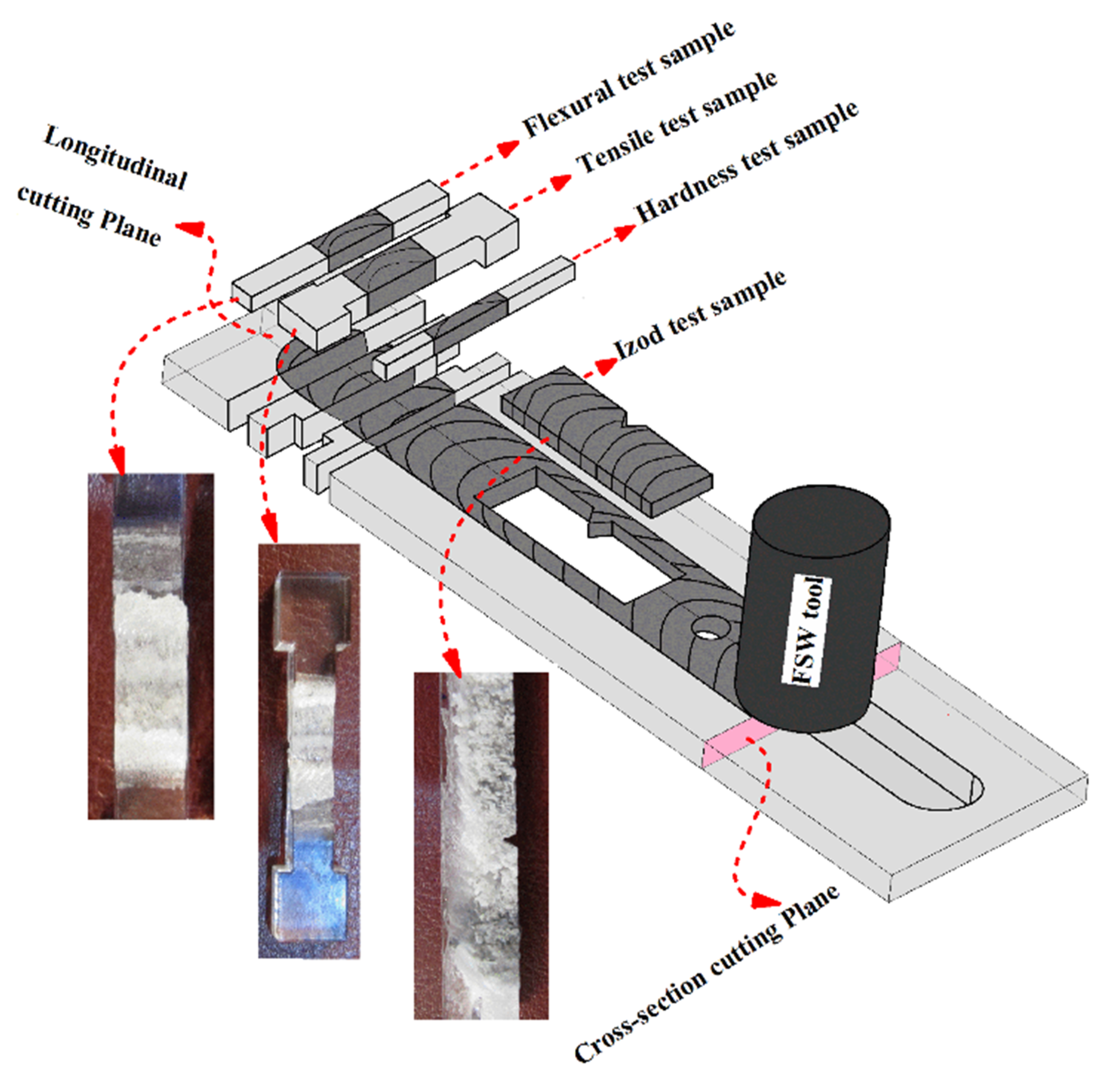

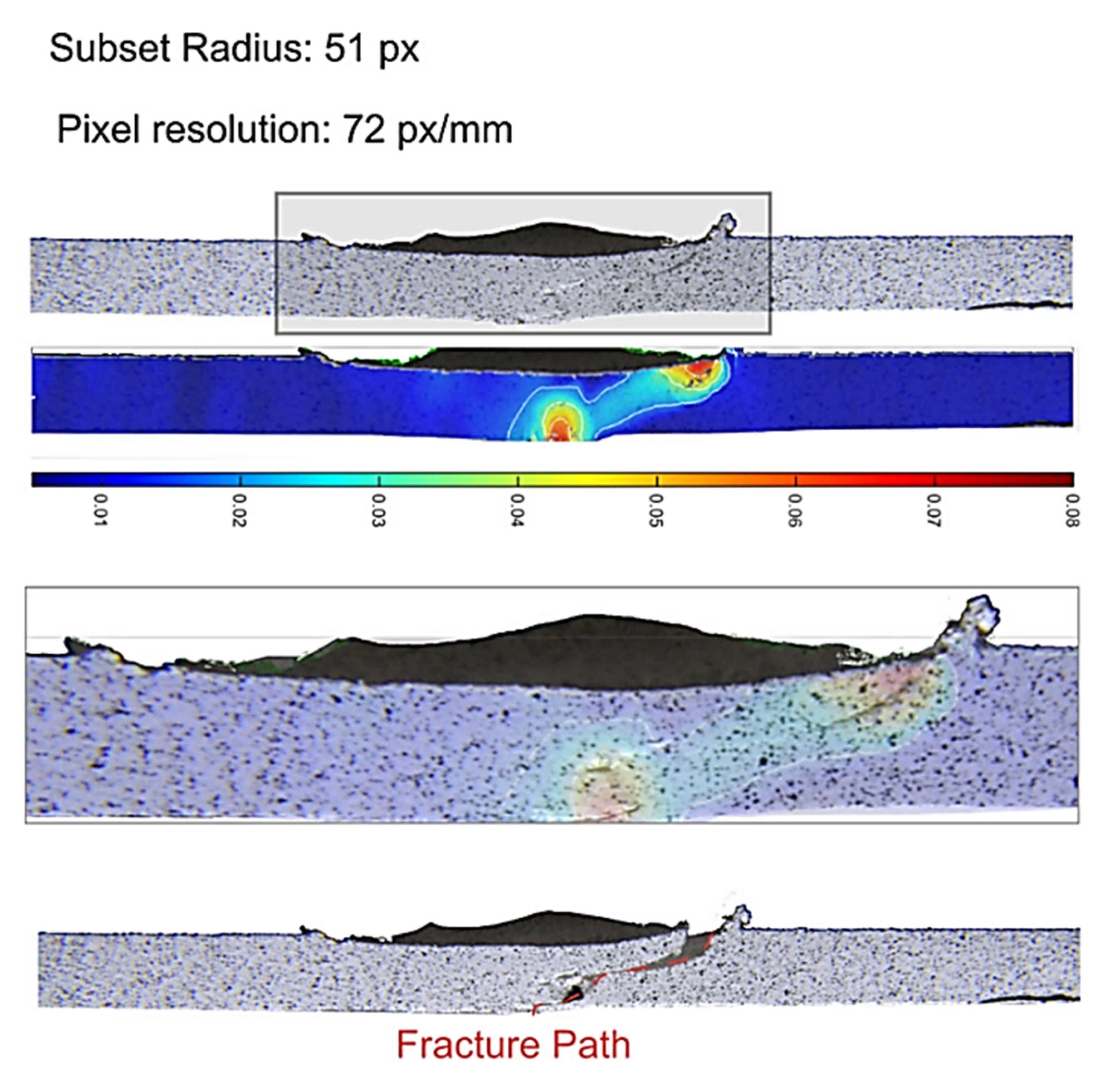

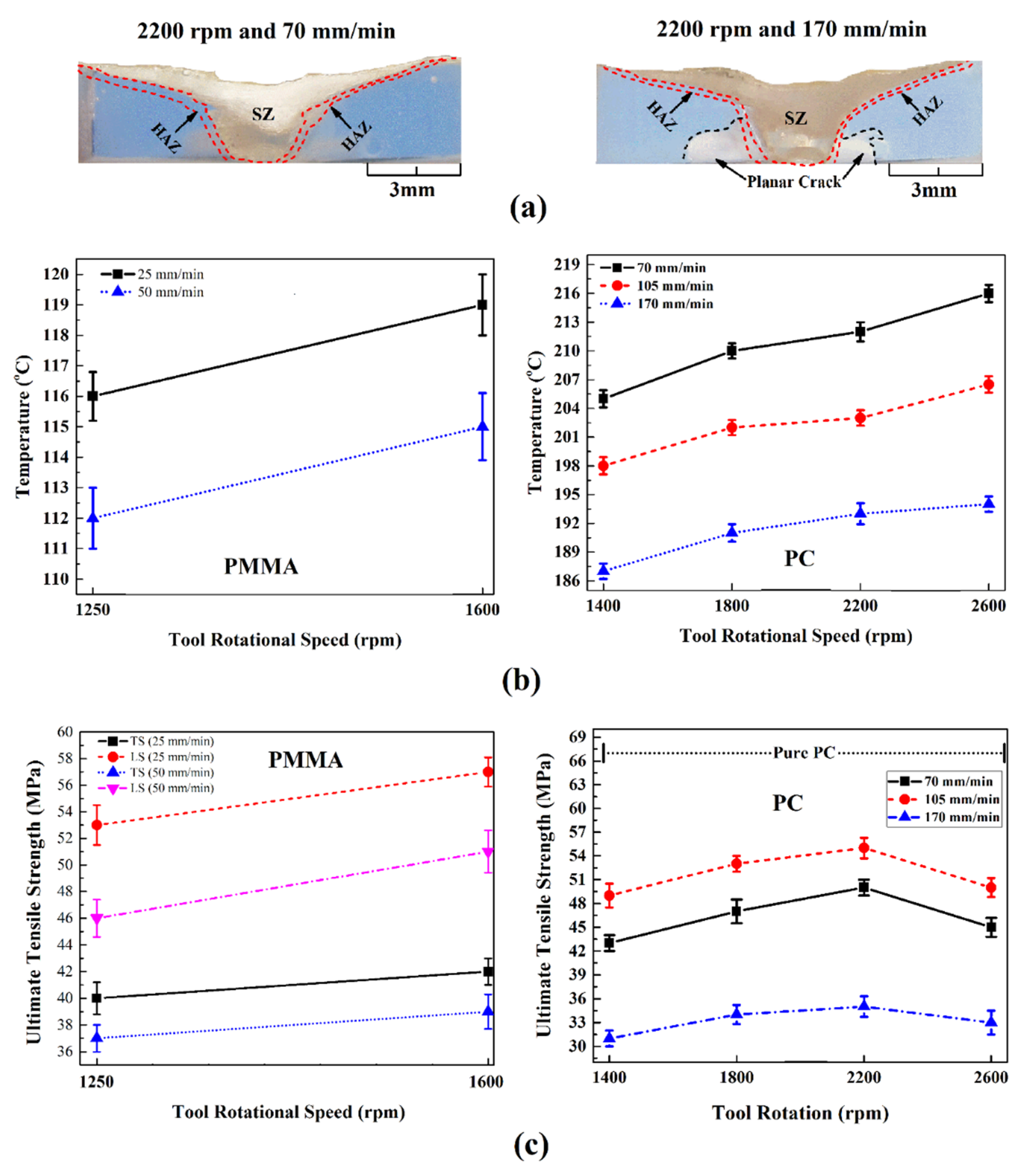

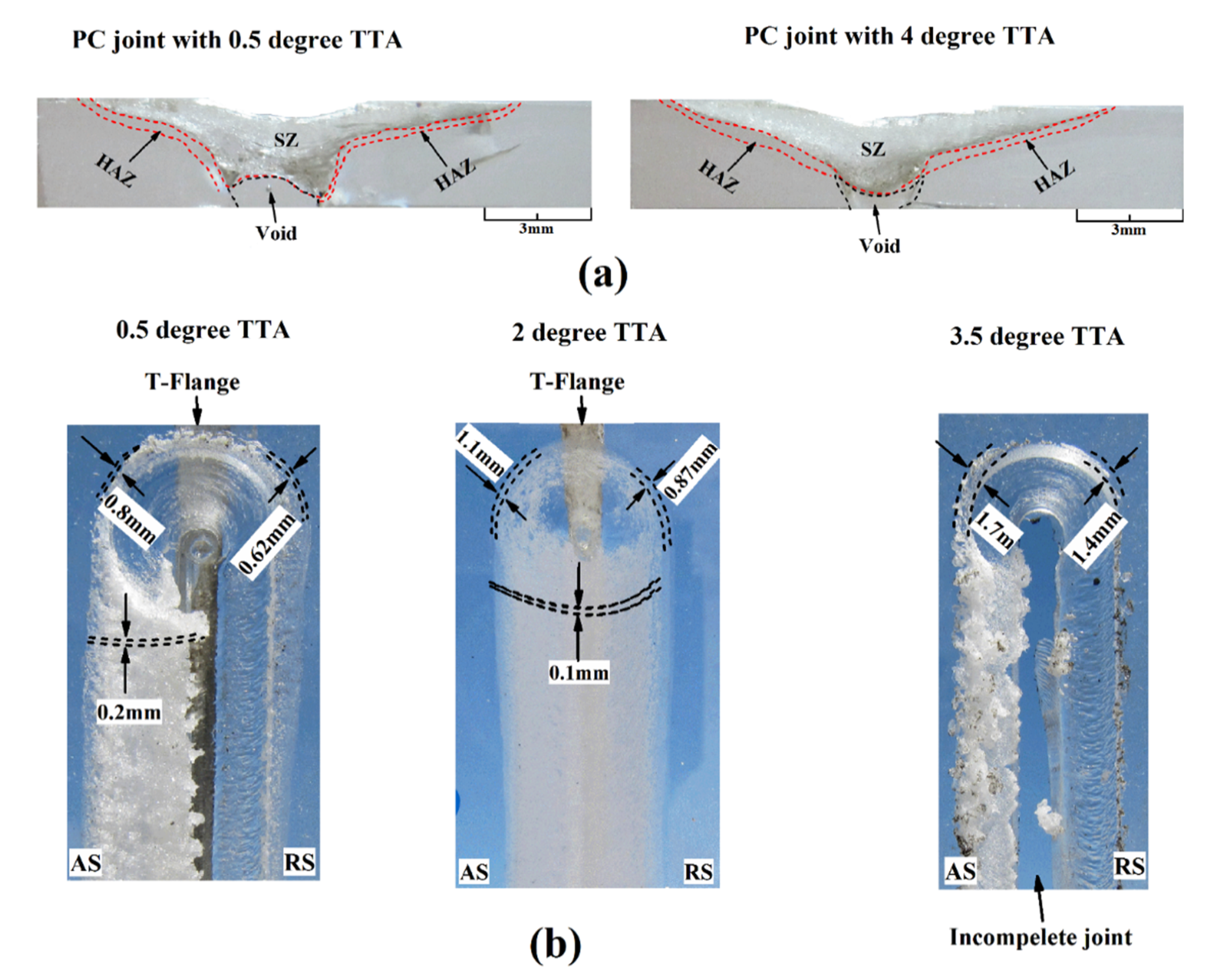

3.3. Morphology of the Welds and Quality Assessment

- Adhesive failure: detachment of the stirred region from the side walls. This failure mode mainly developed due to low temperature and hydrostatic stress developed during the process;

- Cohesive failure: failure developing from the weld seam due to the presence of defects such as tunneling and/or porosities;

- Stress concentration: due to the material removal from the upper weld surface due to adhesion of the material to the bottom surface of the tool shoulder, which exerted a milling action.

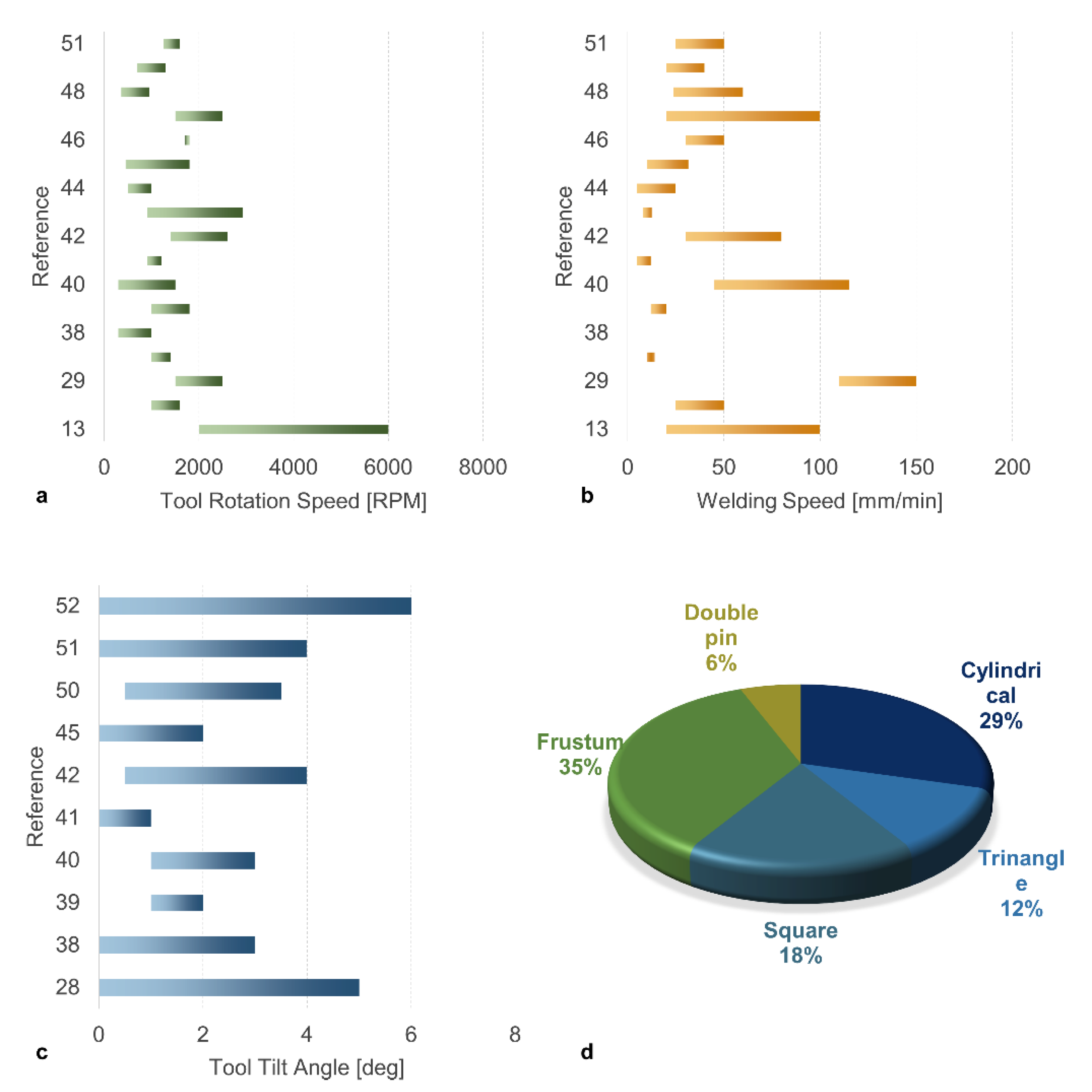

3.4. Effects of Processing Parameters on the Quality of Polymer Joints

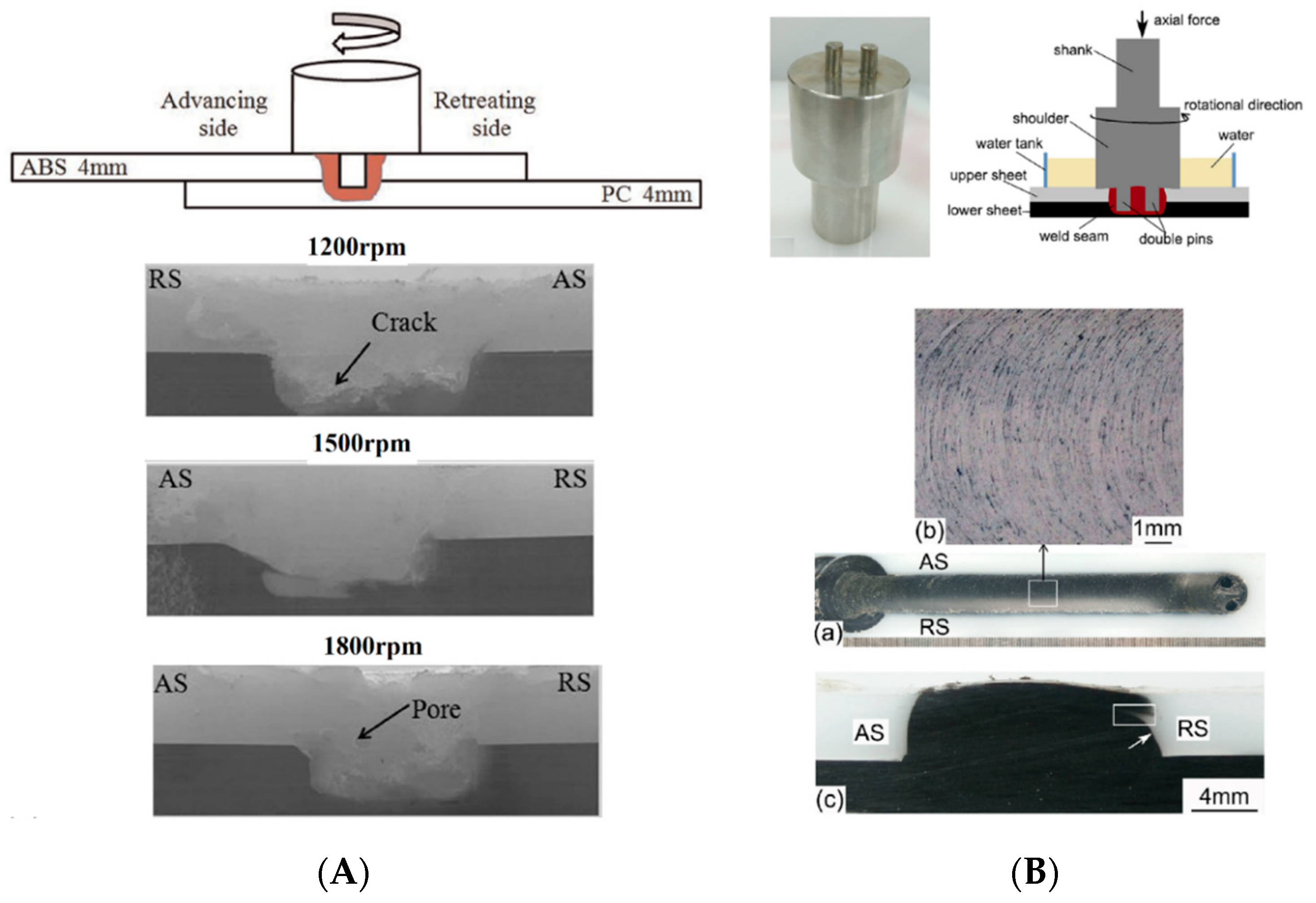

3.5. Rotation Speed

3.6. Welding Speed

3.7. Tool Tilt Angle (TTA)

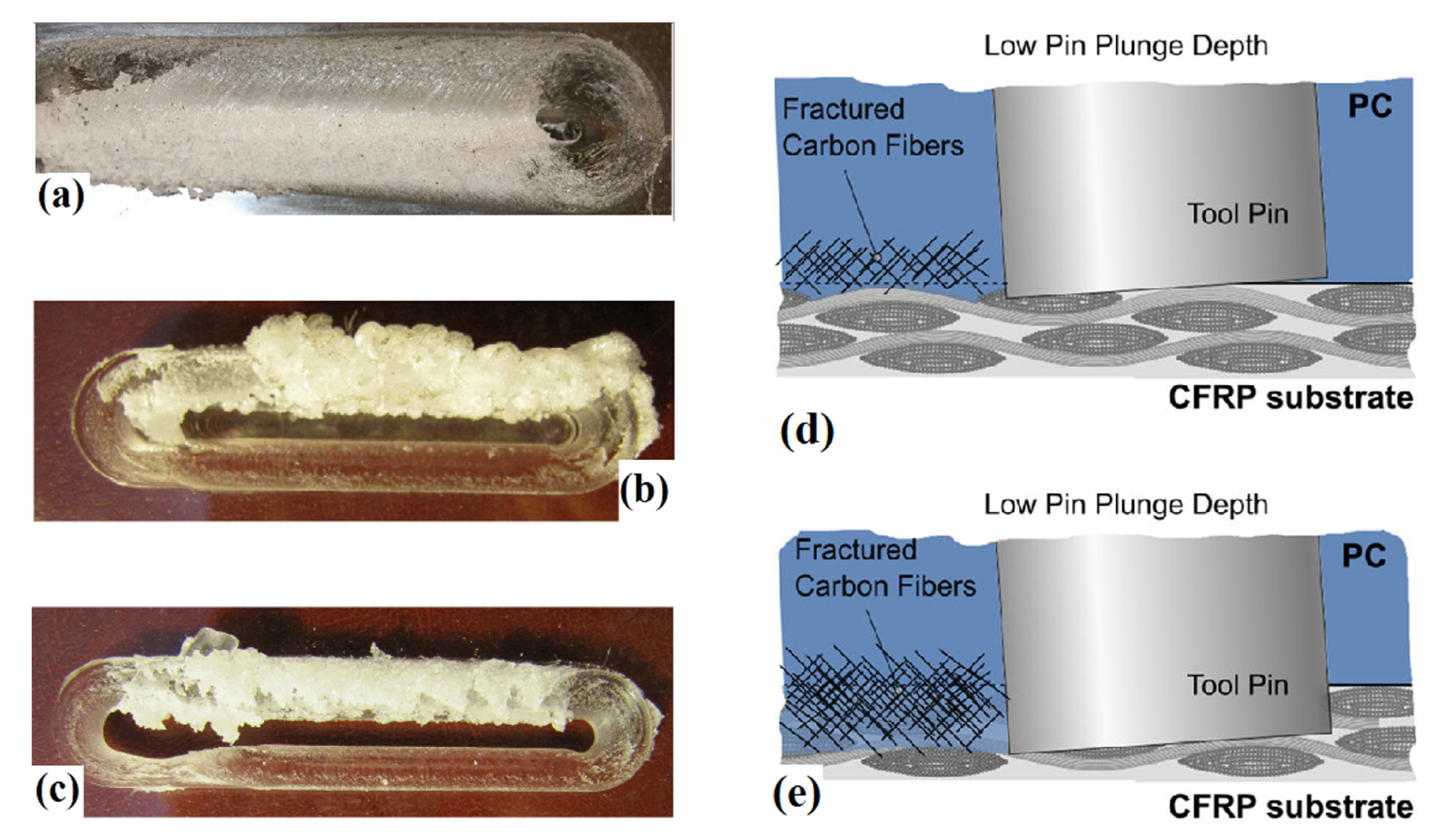

3.8. Tool Plunge Depth (TPD)

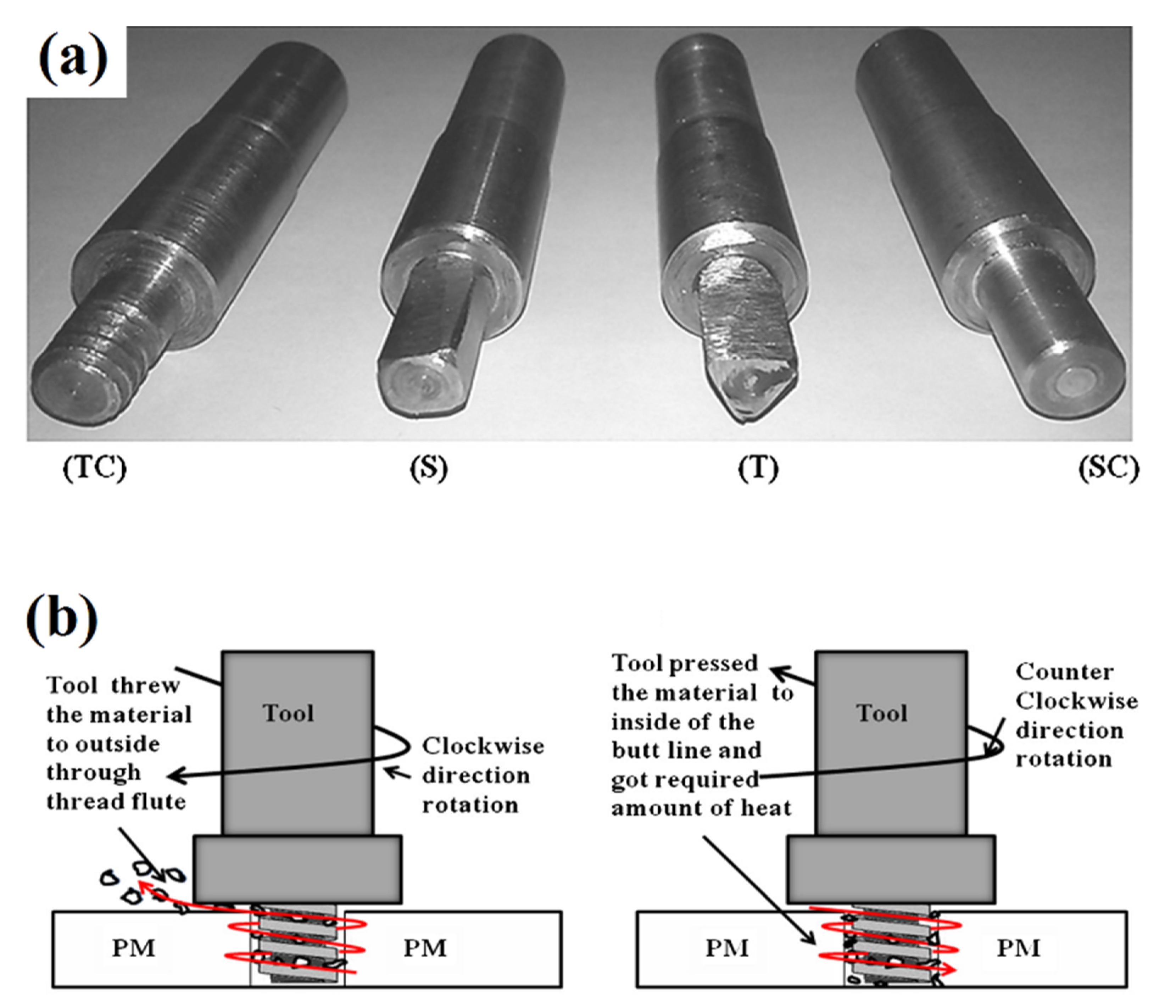

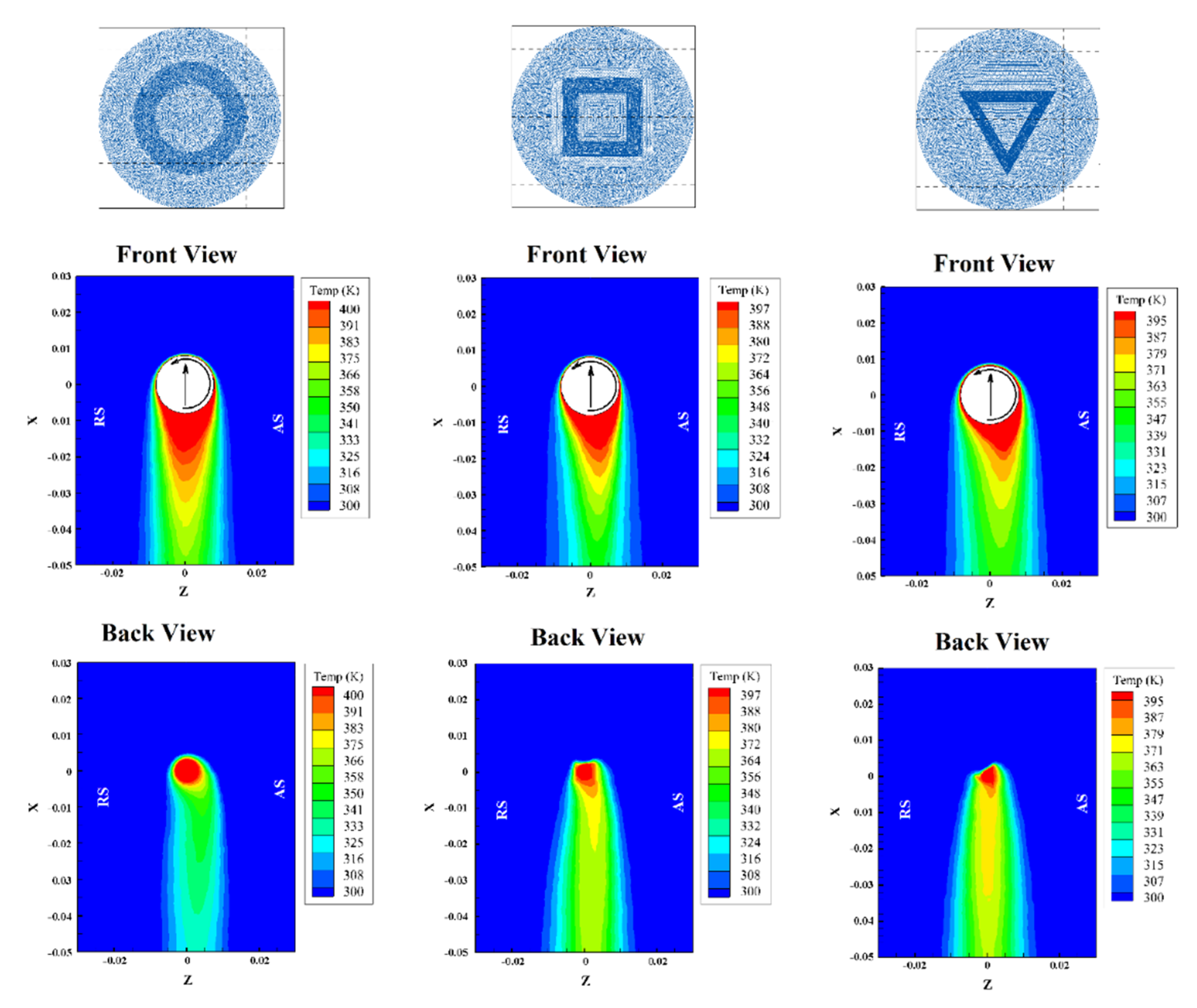

3.9. Probe Shape

3.10. Environment

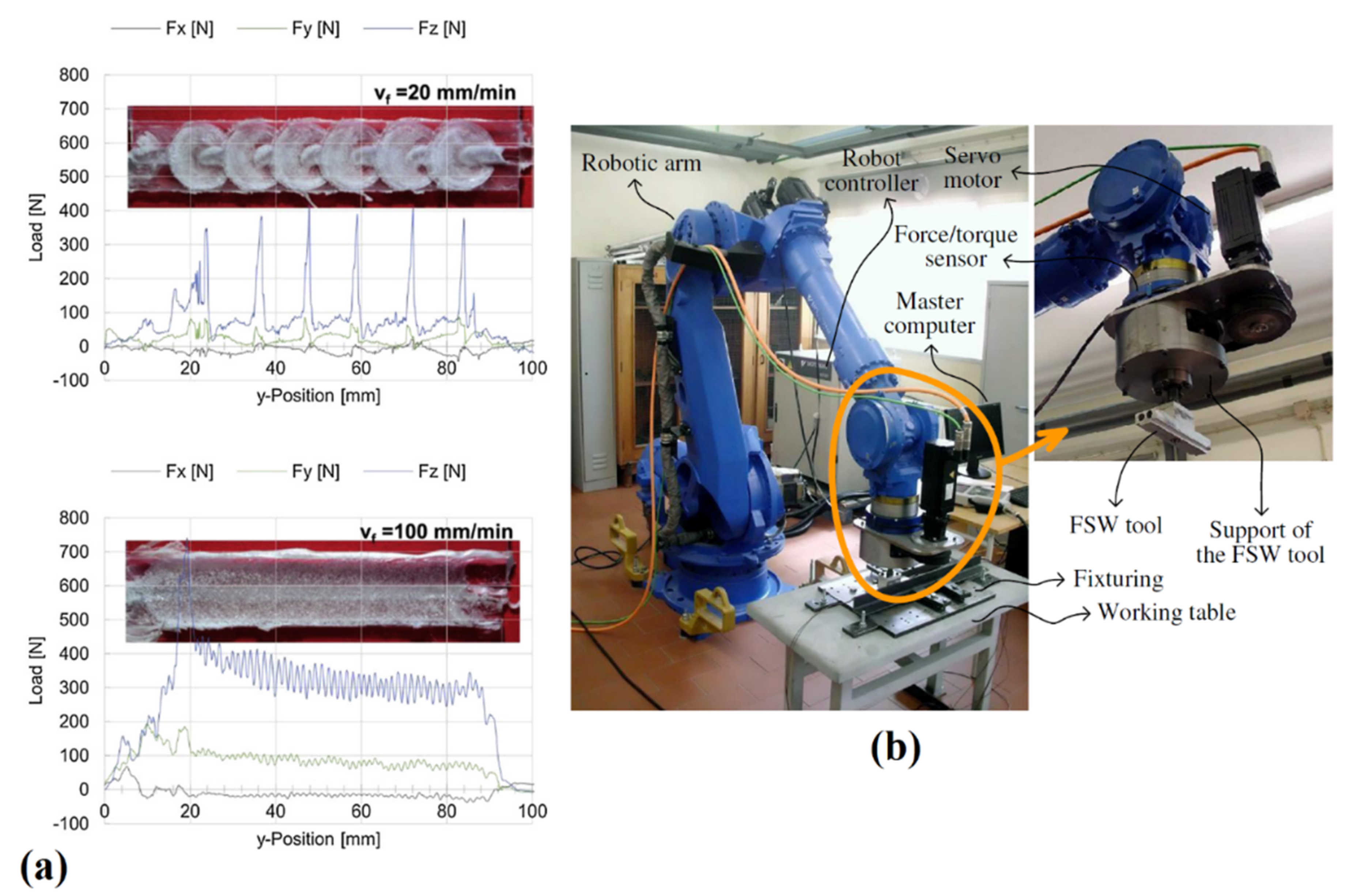

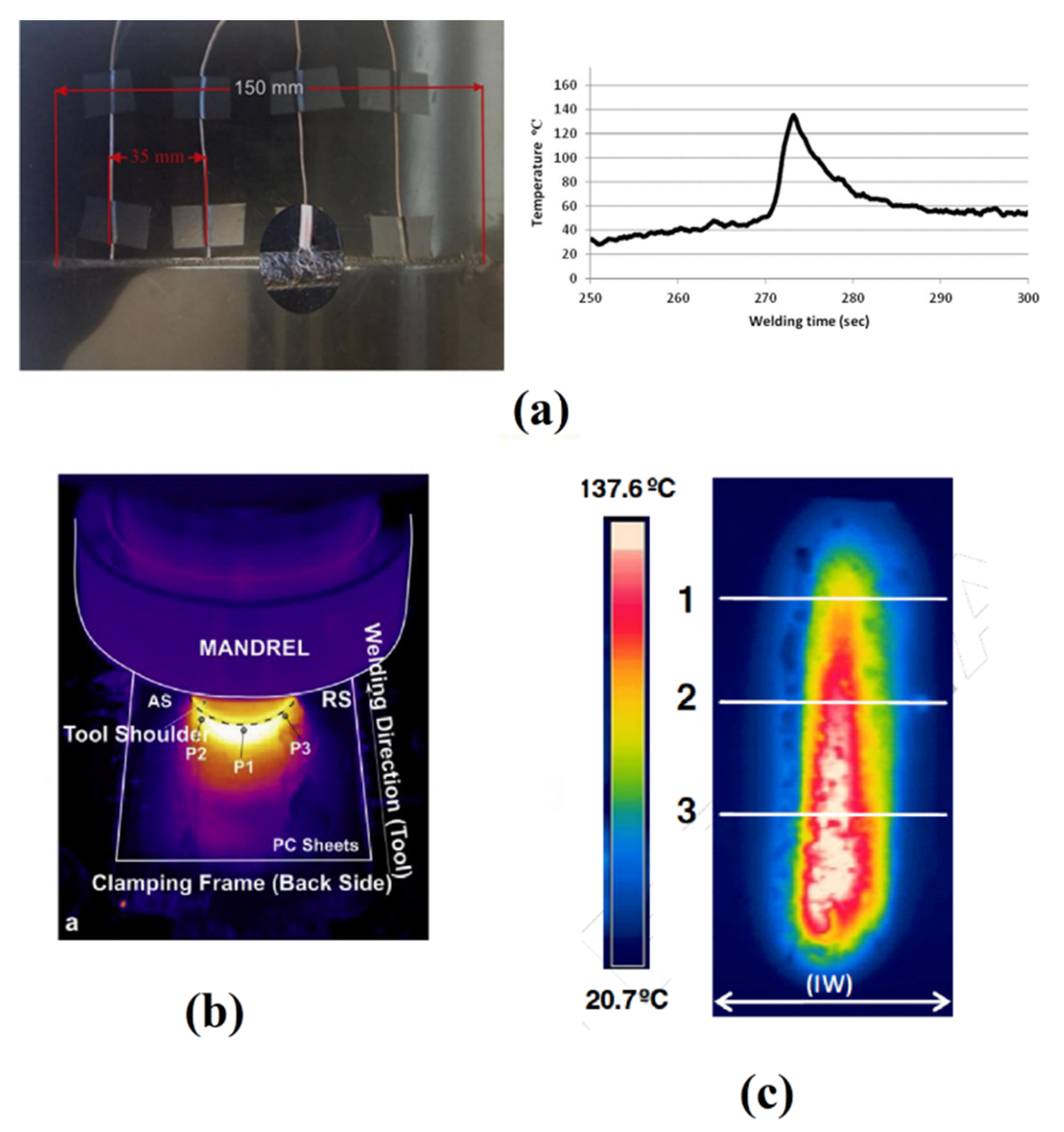

3.11. Process Monitoring

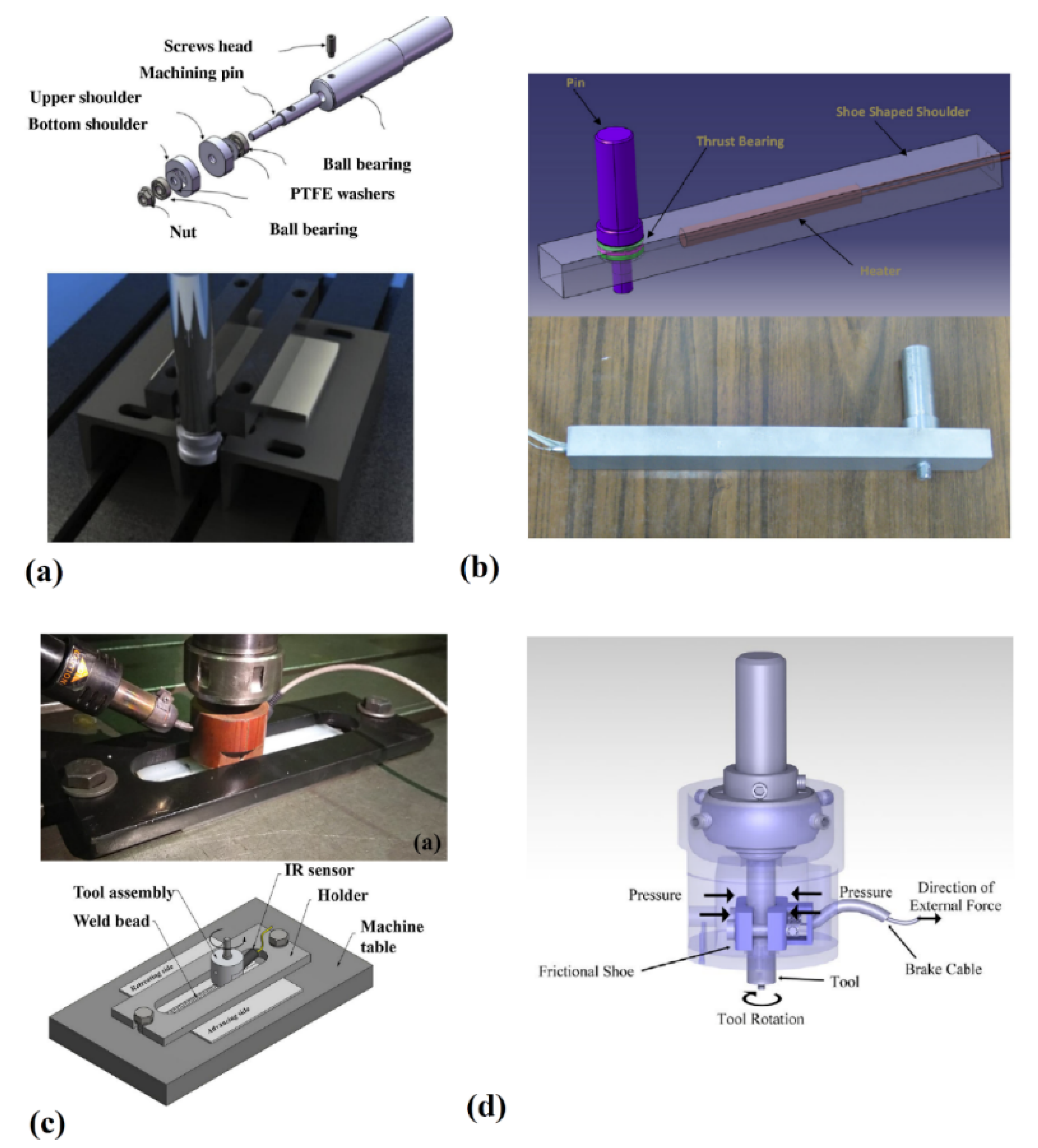

3.12. Special Tooling

3.13. Simulation Modeling

- Base material supposed non-Newtonian fluid with visco-plastic flow behavior;

- Eulerian solution and adaptive meshing;

- Crystal structure changing during LFSW process was ignored.

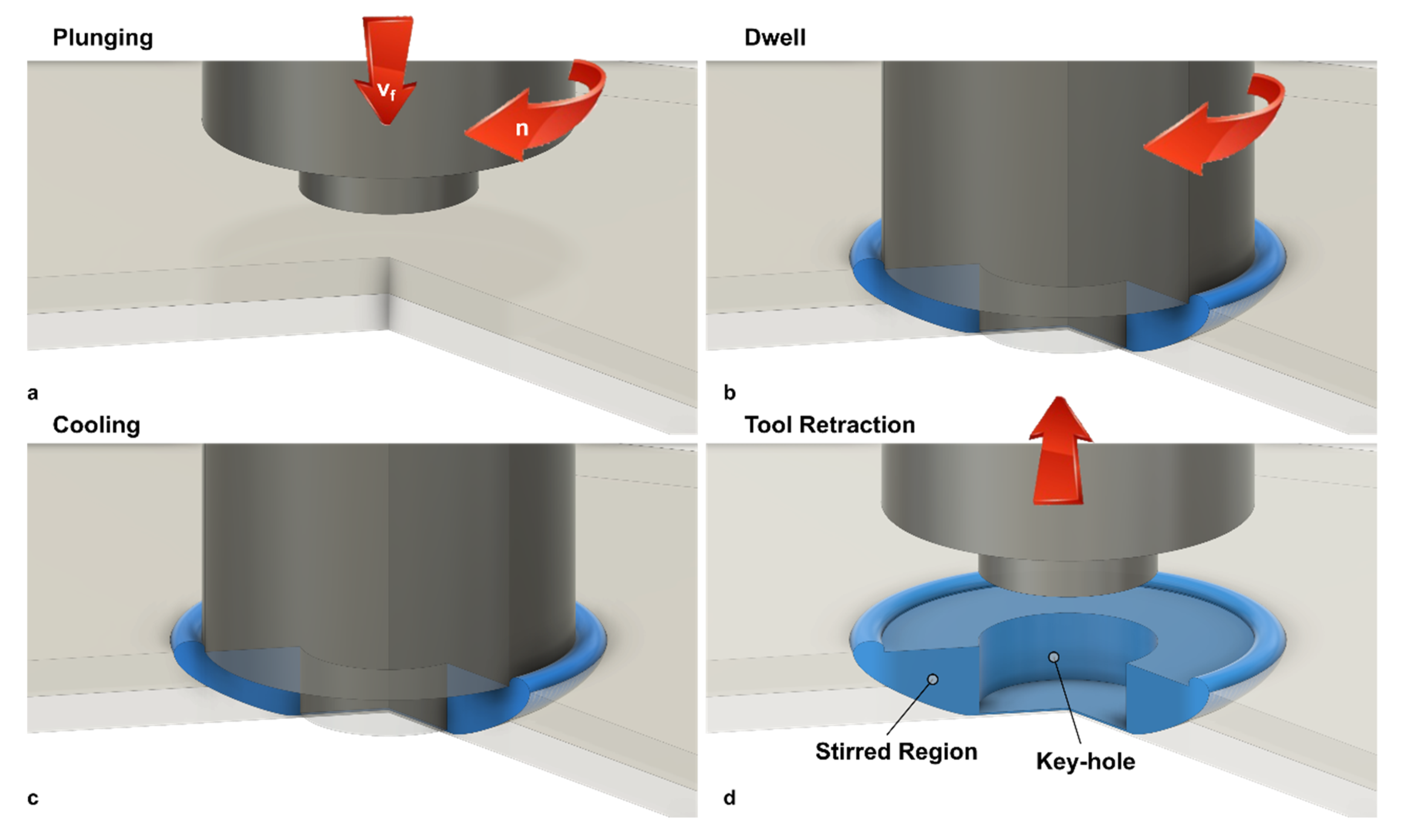

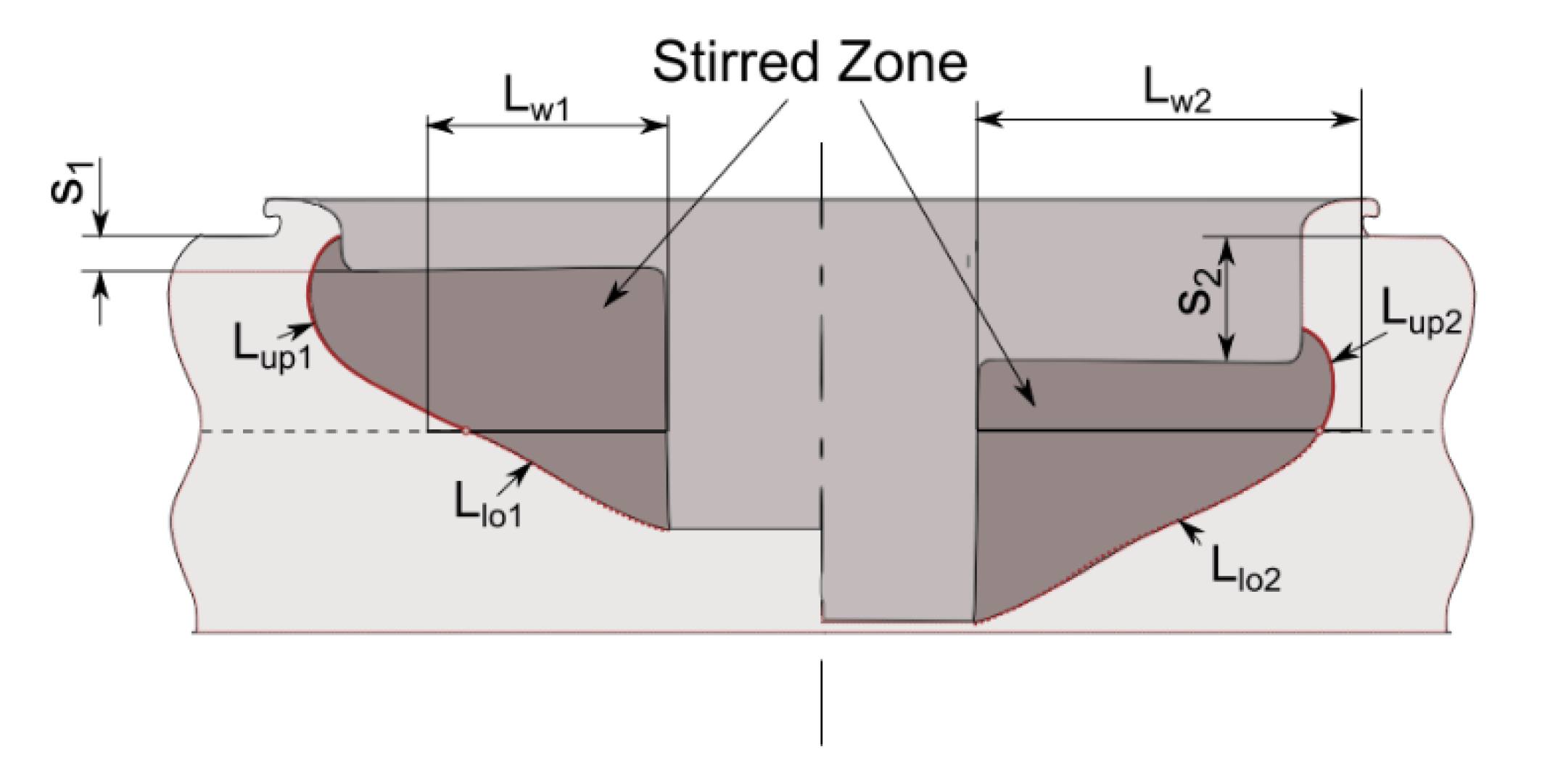

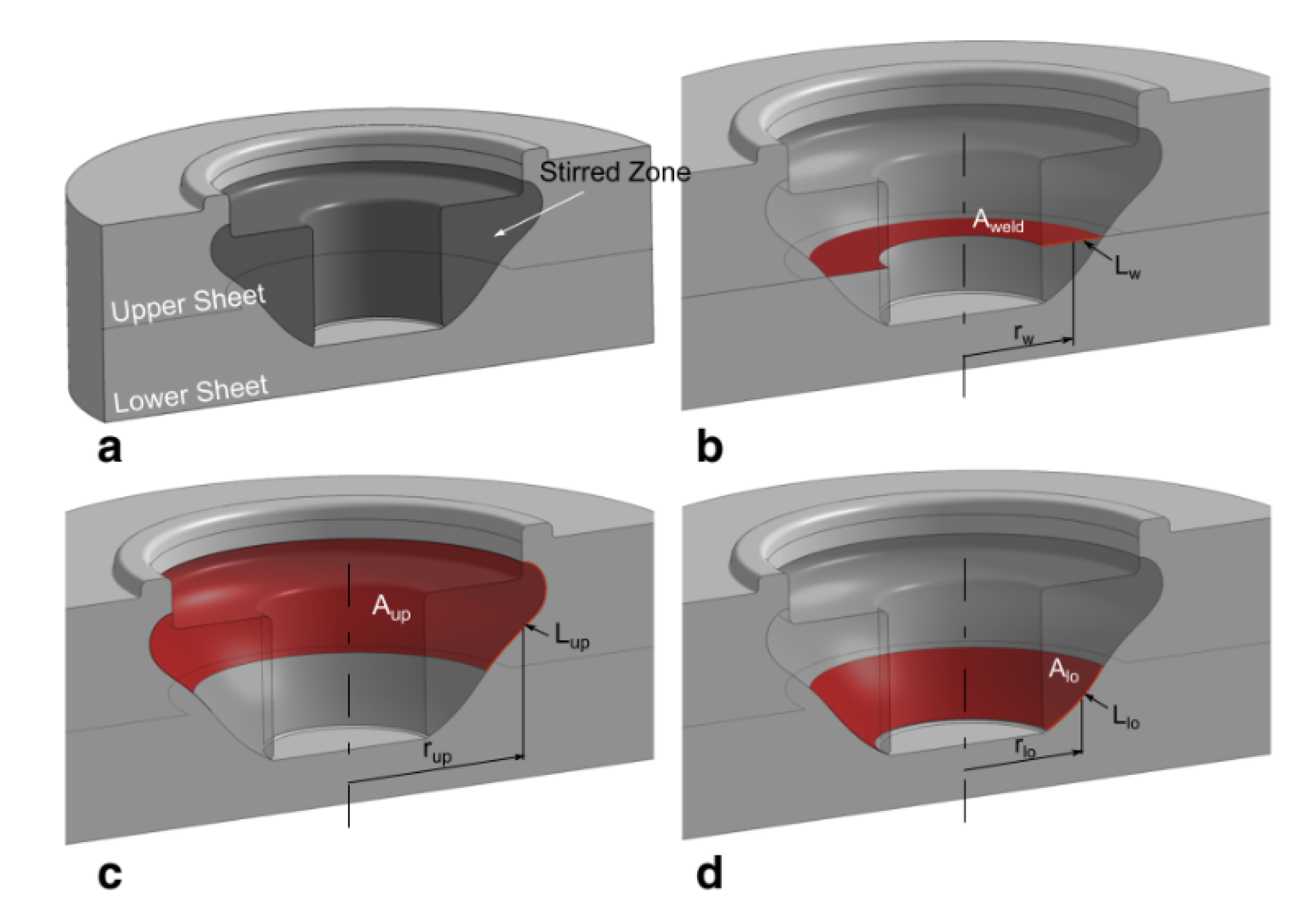

4. Friction Spot Stir Welding

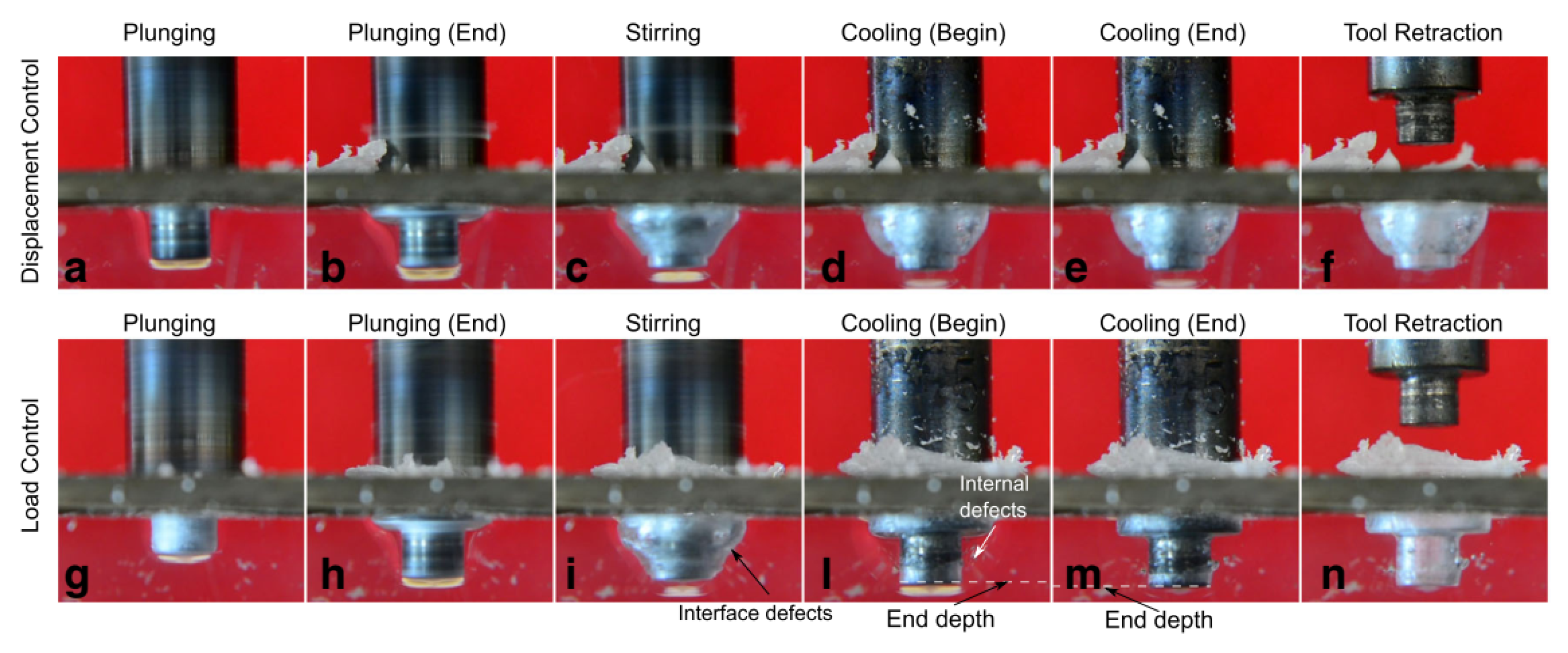

4.1. Description of the Main Phases

4.2. Material Flow

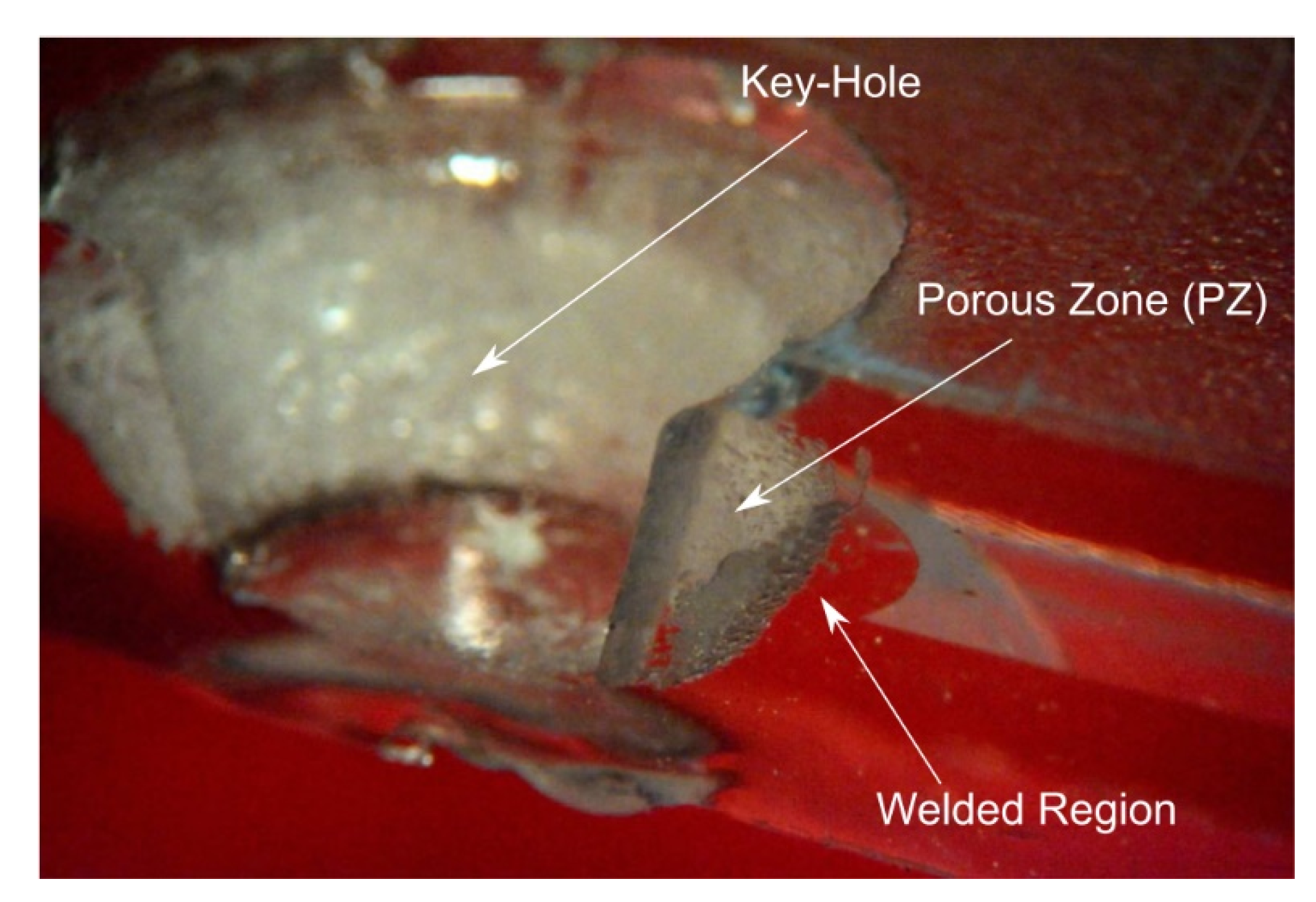

4.3. Morphology of the Welds and Quality Assessment

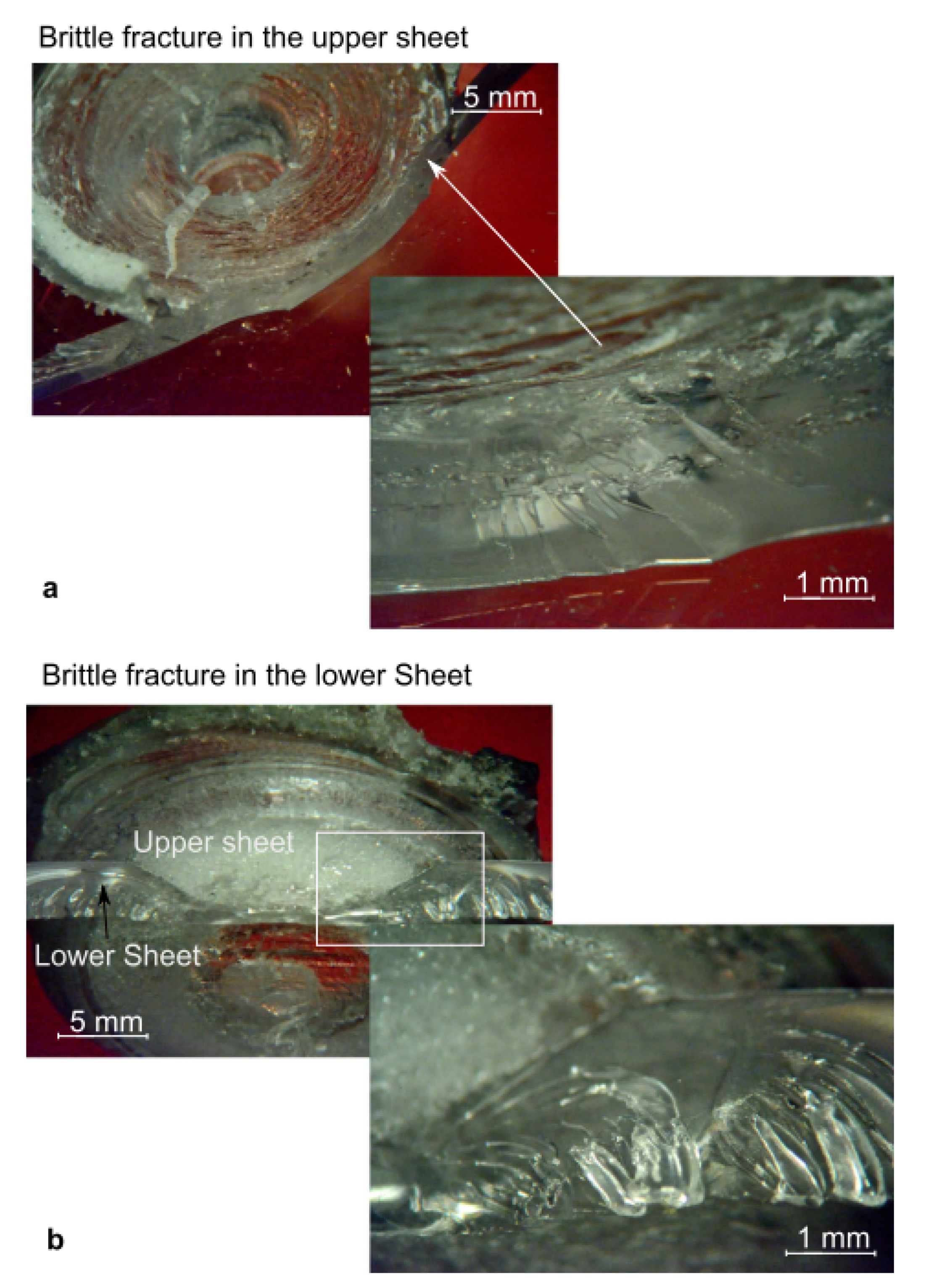

- Brittle fracture in the upper sheet (M1);

- Brittle fracture in the lower sheet (M2);

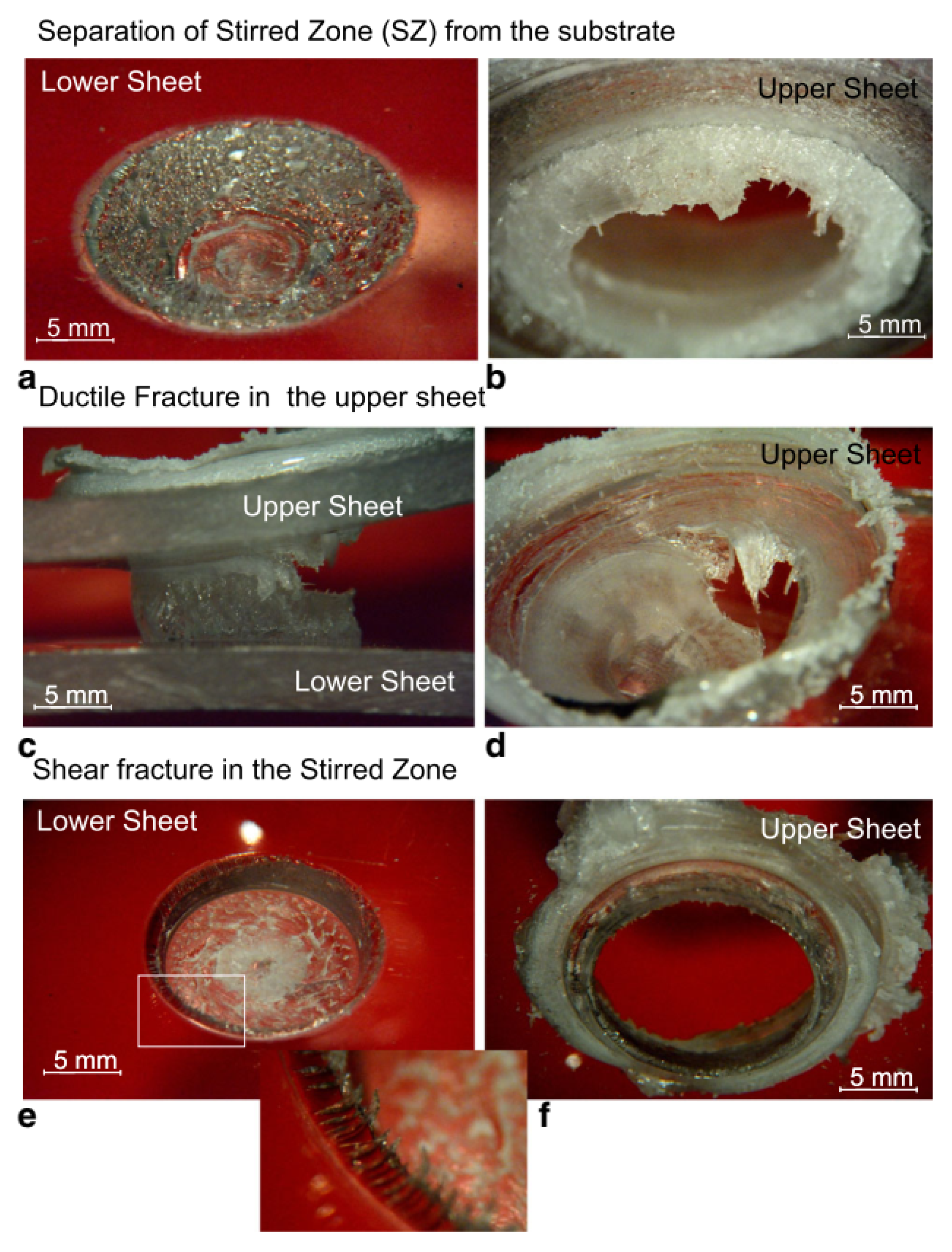

- Separation of the SZ from the lower sheet (M3);

- Separation of the SZ from the upper sheet (M4);

- Shear fracture in the SZ (M5).

- Geometrical: incorrect choice of the plunging depth and/or tool dimension, shape of the tool probe;

- Morphological: formation of porosities, cavities. These depends on the selection of process parameters such as process speed, length of the dwell time, waiting time, load/displacement control, etc.

- Residual stress: thermal shrinkage leading to residual stress and formation of voids and cavities.

4.4. Effect of Process Parameters

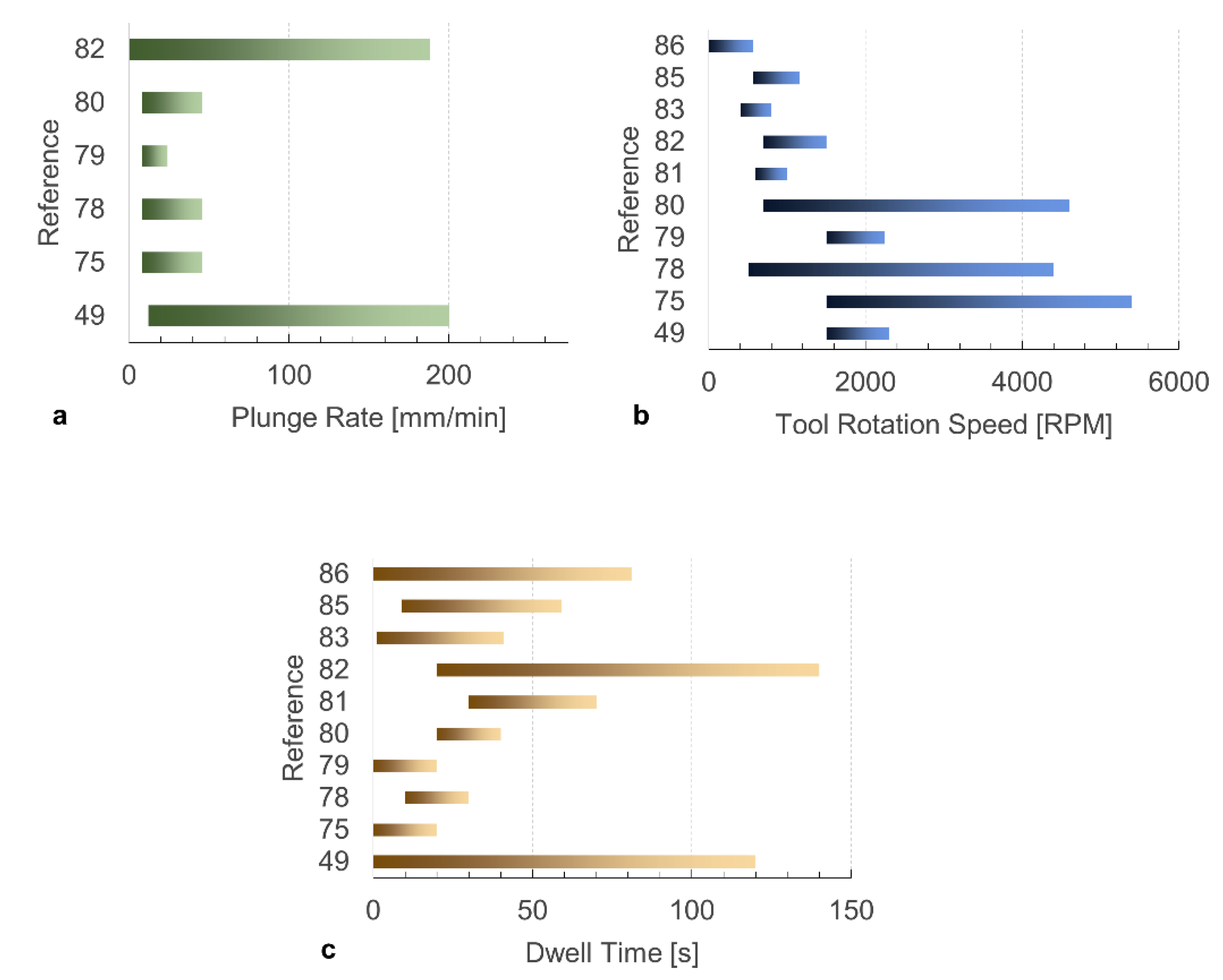

4.5. Plunge Rate

4.6. Rotation Speed

- The adoption of different ranges;

- The adoption of different tool dimensions;

- The investigation of different materials, which are characterized by different Tg and softening/melting points;

- The temperature reached during the process.

4.7. Pre-Heating Time

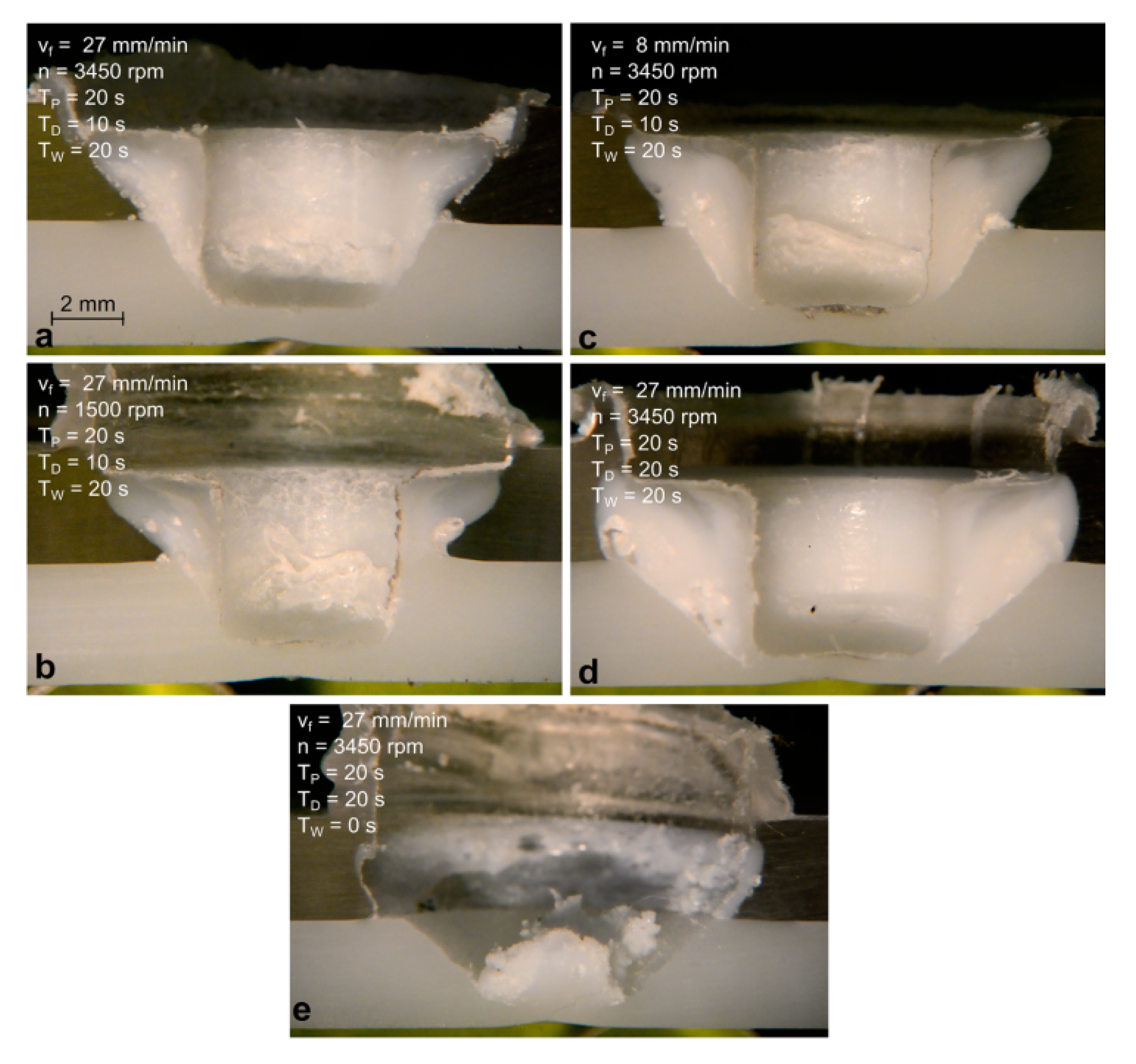

4.8. Dwell Time

4.9. Cooling Time

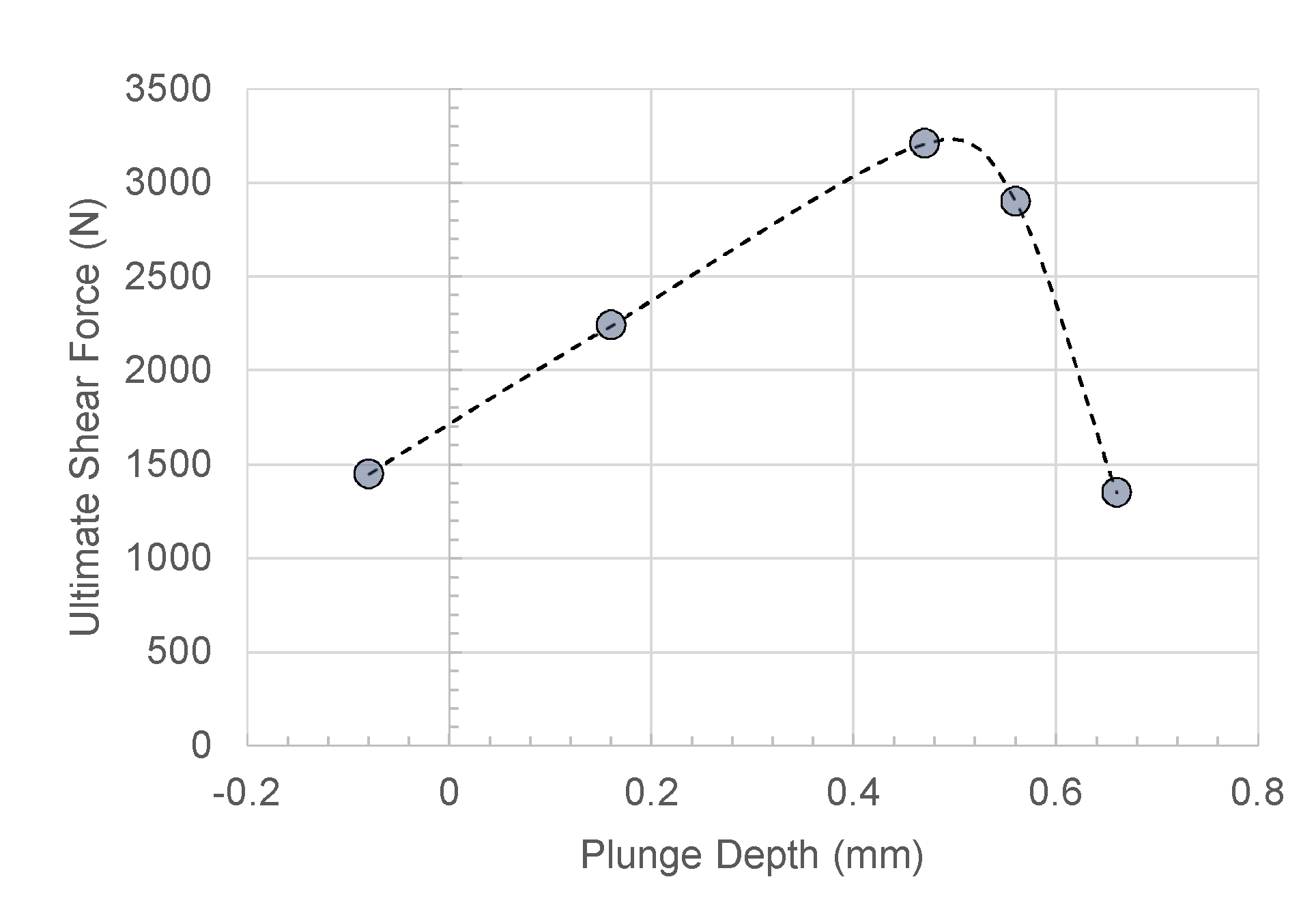

4.10. Plunge Depth

4.11. Tool Shoulder and Probe Diameter

4.12. Geometry of the Tool Probe

4.13. Effect of Plunging Force

5. Conclusions and Future Perspectives

6. Industry 4.0

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Lambiase, F.; Ko, D.-C. Feasibility of mechanical clinching for joining aluminum AA6082-T6 and Carbon Fiber Reinforced Polymer sheets. Mater. Des. 2016, 107, 341–352. [Google Scholar] [CrossRef]

- Katayama, S. Handbook of Laser Welding Technologies; Woodhead Publishing: Cambridge, UK, 2013. [Google Scholar]

- Troughton, M. Handbook of Plastics Joining: A Practical Guide; William Andrew: Norwich, NY, USA, 2008; p. 600. [Google Scholar]

- Camanho, P.P.; Tong, L. Composite Joints and Connections. Principles, Modelling and Testing; Woodhead Publishing: Cambridge, UK, 2011; p. 544. [Google Scholar]

- Kiss, Z.; Czigány, T. Applicability of friction stir welding in polymeric materials. Period. Polytech. Mech. Eng. 2007, 51, 15. [Google Scholar] [CrossRef]

- Eslami, S.; Tavares, P.J.; Moreira, P.M.G.P. Friction stir welding tooling for polymers: Review and prospects. Int. J. Adv. Manuf. Technol. 2016, 89, 1677–1690. [Google Scholar] [CrossRef]

- Kumar, R.; Singh, R.; Ahuja, I.P.S.; Penna, R.; Feo, L. Weldability of thermoplastic materials for friction stir welding—A state of art review and future applications. Compos. Part B Eng. 2018, 137, 1–15. [Google Scholar] [CrossRef]

- Lambiase, F.; Ko, D.C. Two-steps clinching of aluminum and Carbon Fiber Reinforced Polymer sheets. Compos. Struct. 2017, 164, 180–188. [Google Scholar] [CrossRef]

- Lambiase, F.; Paoletti, A.; Di Ilio, A. Advances in Mechanical Clinching: Employment of a Rotating Tool. Procedia Eng. 2017, 183, 200–205. [Google Scholar] [CrossRef]

- Lambiase, F.; Paoletti, A. Friction-assisted clinching of Aluminum and CFRP sheets. J. Manuf. Process. 2018, 31, 812–822. [Google Scholar] [CrossRef]

- Lee, C.-J.; Shen, G.; Kim, B.-M.; Lambiase, F.; Ko, D.-C. Analysis of Failure-Mode Dependent Joint Strength in Hole Clinching from the Aspects of Geometrical Interlocking Parameters. Metals 2018, 8, 1020. [Google Scholar] [CrossRef]

- Derazkola, H.A.; Elyasi, M. The influence of process parameters in friction stir welding of Al-Mg alloy and polycarbonate. J. Manuf. Process. 2018, 35, 88–98. [Google Scholar] [CrossRef]

- Derazkola, H.A.; Khodabakhshi, F.; Simchi, A. Friction-stir lap-joining of aluminium-magnesium/poly-methyl-methacrylate hybrid structures: Thermo-mechanical modelling and experimental feasibility study. Sci. Technol. Weld. Join. 2018, 23, 35–49. [Google Scholar] [CrossRef]

- Lambiase, F.; Paoletti, A.; Di Ilio, A. Forces and temperature variation during friction stir welding of aluminum alloy AA6082-T6. Int. J. Adv. Manuf. Technol. 2018, 99, 337–346. [Google Scholar] [CrossRef]

- Lambiase, F.; Paoletti, A.; Grossi, V.; Di Ilio, A. Analysis of loads, temperatures and welds morphology in FSW of polycarbonate. J. Mater. Process. Technol. 2019, 266, 639–650. [Google Scholar] [CrossRef]

- Derazkola, H.A.; Simchi, A. An investigation on the dissimilar friction stir welding of T-joints between AA5754 aluminum alloy and poly(methyl methacrylate). Thin-Walled Struct. 2019, 135, 376–384. [Google Scholar] [CrossRef]

- Nandan, R.; DebRoy, T.; Bhadeshia, H.K.D.H. Recent advances in friction-stir welding–Process, weldment structure and properties. Prog. Mater. Sci. 2008, 53, 980–1023. [Google Scholar] [CrossRef]

- Simar, A.; Bréchet, Y.; de Meester, B.; Denquin, A.; Gallais, C.; Pardoen, T. Integrated modeling of friction stir welding of 6xxx series Al alloys: Process, microstructure and properties. Prog. Mater. Sci. 2012, 57, 95–183. [Google Scholar] [CrossRef]

- He, X.; Gu, F.; Ball, A. A review of numerical analysis of friction stir welding. Prog. Mater. Sci. 2014, 65, 1–66. [Google Scholar] [CrossRef]

- Derazkola, H.A.; Khodabakhshi, F. A novel fed friction-stir (FFS) technology for nanocomposite joining. Sci. Technol. Weld. Join. 2020, 25, 89–100. [Google Scholar] [CrossRef]

- Elyasi, M.; Aghajani Derazkola, H.; Hosseinzadeh, M. Investigations of tool tilt angle on properties friction stir welding of A441 AISI to AA1100 aluminium. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2016, 230, 1234–1241. [Google Scholar] [CrossRef]

- Derazkola, H.A.; Aval, H.J.; Elyasi, M. Analysis of process parameters effects on dissimilar friction stir welding of AA1100 and A441 AISI steel. Sci. Technol. Weld. Join. 2015, 20, 553–562. [Google Scholar] [CrossRef]

- Derazkola, H.A.; Fard, R.K.; Khodabakhshi, F. Effects of processing parameters on the characteristics of dissimilar friction-stir-welded joints between AA5058 aluminum alloy and PMMA polymer. Weld. World 2018, 62, 117–130. [Google Scholar] [CrossRef]

- Huang, Y.; Meng, X.; Xie, Y.; Wan, L.; Lv, Z.; Cao, J.; Feng, J. Friction stir welding/processing of polymers and polymer matrix composites. Compos. Part A Appl. Sci. Manuf. 2018, 105, 235–257. [Google Scholar] [CrossRef]

- Elyasi, M.; Derazkola, H.A. Experimental and thermomechanical study on FSW of PMMA polymer T-joint. Int. J. Adv. Manuf. Technol. 2018, 97, 1445–1456. [Google Scholar] [CrossRef]

- Moreno-Moreno, M.; Macea Romero, Y.; Rodríguez Zambrano, H.; Restrepo-Zapata, N.C.; Afonso, C.R.M.; Unfried-Silgado, J. Mechanical and thermal properties of friction-stir welded joints of high density polyethylene using a non-rotational shoulder tool. Int. J. Adv. Manuf. Technol. 2018, 97, 2489–2499. [Google Scholar] [CrossRef]

- Kumar, S.; Roy, B.S. Novel study of joining of acrylonitrile butadiene styrene and polycarbonate plate by using friction stir welding with double-step shoulder. J. Manuf. Process. 2019, 45, 322–330. [Google Scholar] [CrossRef]

- Arici, A.; Sinmazçelýk, T. Effects of double passes of the tool on friction stir welding of polyethylene. J. Mater. Sci. 2005, 40, 3313–3316. [Google Scholar] [CrossRef]

- Mosavvar, A.; Azdast, T.; Moradian, M.; Hasanzadeh, R. Tensile properties of friction stir welding of thermoplastic pipes based on a novel designed mechanism. Weld. World 2019, 63, 691–699. [Google Scholar] [CrossRef]

- ASTM D 638. Standard Test Method for Tensile Properties of Plastics; ASTM: West Conshohocken, PA, USA, 2000.

- Derazkola, H.A.; Simchi, A. Effects of alumina nanoparticles on the microstructure, strength and wear resistance of poly(methyl methacrylate)-based nanocomposites prepared by friction stir processing. J. Mech. Behav. Biomed. Mater. 2018, 79, 246–253. [Google Scholar] [CrossRef]

- Gao, J.; Cui, X.; Liu, C.; Shen, Y. Application and exploration of friction stir welding/processing in plastics industry. Mater. Sci. Technol. 2017, 33, 1145–1158. [Google Scholar] [CrossRef]

- ASTM D2240-Standard Test Method for Rubber Property—Durometer Hardness; ASTM: West Conshohocken, PA, USA, 2000.

- Lambiase, F.; Grossi, V.; Paoletti, A. Advanced mechanical characterization of friction stir welds made on polycarbonate. Int. J. Adv. Manuf. Technol. 2019, 104, 2089–2102. [Google Scholar] [CrossRef]

- Vijendra, B.; Sharma, A. Induction heated tool assisted friction-stir welding (i-FSW): A novel hybrid process for joining of thermoplastics. J. Manuf. Process. 2015, 20, 234–244. [Google Scholar] [CrossRef]

- Nandhini, R.; Moorthy, M.K.; Muthukumaran, S. Effect of Welding Parameters on Microstructure and Tensile Strength of Friction Stir Welded PA 6,6 Joints. Int. Polym. Process. 2017, 32, 416–424. [Google Scholar] [CrossRef]

- Gao, J.; Shen, Y.; Zhang, J.; Xu, H. Submerged friction stir weld of polyethylene sheets. J. Appl. Polym. Sci. 2014, 131. [Google Scholar] [CrossRef]

- Zafar, A.; Awang, M.; Khan, S.R.; Emamian, S. Investigating Friction Stir Welding on Thick Nylon 6 Plates. Weld. Res. 2016, 95, 201–218. [Google Scholar]

- Saeedy, S.; Givi, M.K.B. Investigation of the effects of critical process parameters of friction stir welding of polyethylene. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2011, 225, 1305–1310. [Google Scholar] [CrossRef]

- Bozkurt, Y. The optimization of friction stir welding process parameters to achieve maximum tensile strength in polyethylene sheets. Mater. Des. 2012, 35, 440–445. [Google Scholar] [CrossRef]

- Jaiganesh, V.; Maruthu, B.; Gopinath, E. Optimization of Process Parameters on Friction Stir Welding of High Density Polypropylene Plate. Procedia Eng. 2014, 97, 1957–1965. [Google Scholar] [CrossRef]

- Derazkola, H.A.; Simchi, A.; Lambiase, F. Friction stir welding of polycarbonate lap joints: Relationship between processing parameters and mechanical properties. Polym. Test. 2019, 79, 105999. [Google Scholar] [CrossRef]

- Rezaee Hajideh, M.; Farahani, M.; Alavi, S.A.D.; Molla Ramezani, N. Investigation on the effects of tool geometry on the microstructure and the mechanical properties of dissimilar friction stir welded polyethylene and polypropylene sheets. J. Manuf. Process. 2017, 26, 269–279. [Google Scholar] [CrossRef]

- Sahu, S.K.; Mishra, D.; Mahto, R.P.; Sharma, V.M.; Pal, S.K.; Pal, K.; Banerjee, S.; Dash, P. Friction stir welding of polypropylene sheet. Eng. Sci. Technol. Int. J. 2018, 21, 245–254. [Google Scholar] [CrossRef]

- Hoseinlaghab, S.; Mirjavadi, S.S.; Sadeghian, N.; Jalili, I.; Azarbarmas, M.; Besharati Givi, M.K. Influences of welding parameters on the quality and creep properties of friction stir welded polyethylene plates. Mater. Des. 2015, 67, 369–378. [Google Scholar] [CrossRef]

- Eslami, S.; Mourão, L.; Viriato, N.; Tavares, P.J.; Moreira, P.M.G.P. Multi-axis force measurements of polymer friction stir welding. J. Mater. Process. Technol. 2018, 256, 51–56. [Google Scholar] [CrossRef]

- Bagheri, A.; Azdast, T.; Doniavi, A. An experimental study on mechanical properties of friction stir welded ABS sheets. Mater. Des. 2013, 43, 402–409. [Google Scholar] [CrossRef]

- Eslami, S.; Ramos, T.; Tavares, P.J.; Moreira, P.M.G.P. Shoulder design developments for FSW lap joints of dissimilar polymers. J. Manuf. Process. 2015, 20, 15–23. [Google Scholar] [CrossRef]

- Yan, Y.; Shen, Y.; Zhang, W.; Guan, W. Effects of friction stir spot welding parameters on morphology and mechanical property of modified cast nylon 6 joints produced by double-pin tool. Int. J. Adv. Manuf. Technol. 2017, 92, 2511–2523. [Google Scholar] [CrossRef]

- Lambiase, F.; Grossi, V.; Paoletti, A. Effect of tilt angle in FSW of polycarbonate sheets in butt configuration. Int. J. Adv. Manuf. Technol. 2020, 107, 489–501. [Google Scholar] [CrossRef]

- Aghajani Derazkola, H.; Simchi, A. Experimental and thermomechanical analysis of friction stir welding of poly(methyl methacrylate) sheets. Sci. Technol. Weld. Join. 2018, 23, 209–218. [Google Scholar] [CrossRef]

- Eyvazian, A.; Hamouda, A.M.; Aghajani Derazkola, H.; Elyasi, M. Study on the effects of tool tile angle, offset and plunge depth on friction stir welding of poly(methyl methacrylate) T-joint. Proc. Inst. Mech. Eng. Part B: J. Eng. Manuf. 2019, 0954405419889180. [Google Scholar] [CrossRef]

- Kiss, Z.; Czigány, T. Effect of welding parameters on the heat affected zone and the mechanical properties of friction stir welded poly(ethylene-terephthalate-glycol). J. Appl. Polym. Sci. 2012, 125, 2231–2238. [Google Scholar] [CrossRef]

- Ülker, A.; Sayer, S.; Ceyhun, V. Welding parameters and joint strength optimization during friction stir welding of high density polyethylene (HDPE) using the Taguchi method. Mater. Test. 2016, 58, 423–432. [Google Scholar] [CrossRef]

- Arici, A.; Selale, S. Effects of tool tilt angle on tensile strength and fracture locations of friction stir welding of polyethylene. Sci. Technol. Weld. Join. 2007, 12, 536–539. [Google Scholar] [CrossRef]

- Lambiase, F.; Grossi, V.; Di Ilio, A.; Paoletti, A. Feasibility of friction stir joining of polycarbonate to CFRP with thermosetting matrix. Int. J. Adv. Manuf. Technol. 2020, 106, 2451–2462. [Google Scholar] [CrossRef]

- Sadeghian, N.; Besharati Givi, M.K. Experimental optimization of the mechanical properties of friction stir welded Acrylonitrile Butadiene Styrene sheets. Mater. Des. 2015, 67, 145–153. [Google Scholar] [CrossRef]

- Panneerselvam, K.; Lenin, K. Joining of Nylon 6 plate by friction stir welding process using threaded pin profile. Mater. Des. 2014, 53, 302–307. [Google Scholar] [CrossRef]

- Gao, J.; Shen, Y.; Xu, H. Investigations for the mechanical, macro-, and microstructural analyses of dissimilar submerged friction stir welding of acrylonitrile butadiene styrene and polycarbonate sheets. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2015, 230, 1213–1220. [Google Scholar] [CrossRef]

- Yan, Y.; Shen, Y.; Lan, B.; Gao, J. Influences of friction stir welding parameters on morphology and tensile strength of high density polyethylene lap joints produced by double-pin tool. J. Manuf. Process. 2017, 28, 33–40. [Google Scholar] [CrossRef]

- Trimble, D.; Monaghan, J.; O’Donnell, G.E. Force generation during friction stir welding of AA2024-T3. Cirp Ann. Manuf. Technol. 2012, 61, 9–12. [Google Scholar] [CrossRef]

- Mendes, N.; Neto, P.; Simão, M.A.; Loureiro, A.; Pires, J.N. A novel friction stir welding robotic platform: Welding polymeric materials. Int. J. Adv. Manuf. Technol. 2016, 85, 37–46. [Google Scholar] [CrossRef]

- Eslami, S.; Francisco Miranda, J.; Mourão, L.; Tavares, P.J.; Moreira, P.M.G.P. Polyethylene friction stir welding parameter optimization and temperature characterization. Int. J. Adv. Manuf. Technol. 2018, 99, 127–136. [Google Scholar] [CrossRef]

- Simões, F.; Rodrigues, D.M. Material flow and thermo-mechanical conditions during Friction Stir Welding of polymers: Literature review, experimental results and empirical analysis. Mater. Des. 2014, 59, 344–351. [Google Scholar] [CrossRef]

- Nandhini, R.; Moorthy, M.K.; Muthukumaran, S.; Kumaran, S. Influence of process variables on the characteristics of friction-stir-welded polyamide 6,6 joints. Mater. Und Werkst. 2019, 50, 1139–1148. [Google Scholar] [CrossRef]

- Pirizadeh, M.; Azdast, T.; Rash Ahmadi, S.; Mamaghani Shishavan, S.; Bagheri, A. Friction stir welding of thermoplastics using a newly designed tool. Mater. Des. (1980–2015) 2014, 54, 342–347. [Google Scholar]

- Azarsa, E.; Mostafapour, A. Experimental investigation on flexural behavior of friction stir welded high density polyethylene sheets. J. Manuf. Process. 2014, 16, 149–155. [Google Scholar] [CrossRef]

- Eslami, S.; de Figueiredo, M.A.V.; Tavares, P.J.; Moreira, P.M.G.P. Parameter optimisation of friction stir welded dissimilar polymers joints. Int. J. Adv. Manuf. Technol. 2018, 94, 1759–1770. [Google Scholar] [CrossRef]

- Moochani, A.; Omidvar, H.; Ghaffarian, S.R.; Goushegir, S.M. Friction stir welding of thermoplastics with a new heat-assisted tool design: mechanical properties and microstructure. Weld. World 2019, 63, 181–190. [Google Scholar] [CrossRef]

- Nath, R.K.; Maji, P.; Barma, J.D. Development of a Self-Heated Friction Stir Welding tool for welding of polypropylene sheets. J. Braz. Soc. Mech. Sci. Eng. 2019, 41, 553. [Google Scholar] [CrossRef]

- Derazkola, H.A.; Eyvazian, A.; Simchi, A. Modeling and experimental validation of material flow during FSW of polycarbonate. Mater. Today Commun. 2020, 22, 100796. [Google Scholar] [CrossRef]

- Derazkola, H.A.; Simchi, A. Experimental and thermomechanical analysis of the effect of tool pin profile on the friction stir welding of poly(methyl methacrylate) sheets. J. Manuf. Process. 2018, 34, 412–423. [Google Scholar] [CrossRef]

- Mohammadi Kuhbanani, H.; Yasemi, H.; Aghajani Derazkola, H. Effects of Tool Tilt Angle and Plunge Depth on Properties of Polycarbonate FSW Joint. J. Mod. Process. Manuf. Prod. 2018, 7, 41–55. [Google Scholar]

- Lambiase, F.; Paoletti, A.; Di Ilio, A. Friction spot stir welding of polymers: control of plunging force. Int. J. Adv. Manuf. Technol. 2017, 90, 2827–2837. [Google Scholar] [CrossRef]

- Paoletti, A.; Lambiase, F.; Di Ilio, A. Analysis of forces and temperatures in friction spot stir welding of thermoplastic polymers. Int. J. Adv. Manuf. Technol. 2016, 83, 1395–1407. [Google Scholar] [CrossRef]

- Lambiase, F.; Paoletti, A.; Di Ilio, A. Effect of tool geometry on loads developing in friction stir spot welds of polycarbonate sheets. Int. J. Adv. Manuf. Technol. 2016, 87, 2293–2303. [Google Scholar] [CrossRef]

- Lambiase, F.; Paoletti, A.; Di Ilio, A. Effect of tool geometry on mechanical behavior of friction stir spot welds of polycarbonate sheets. Int. J. Adv. Manuf. Technol. 2017, 88, 3005–3016. [Google Scholar] [CrossRef]

- Lambiase, F.; Paoletti, A.; Di Ilio, A. Mechanical behaviour of friction stir spot welds of polycarbonate sheets. Int. J. Adv. Manuf. Technol. 2015, 80, 301–314. [Google Scholar] [CrossRef]

- Dashatan, S.H.; Azdast, T.; Ahmadi, S.R.; Bagheri, A. Friction stir spot welding of dissimilar polymethyl methacrylate and acrylonitrile butadiene styrene sheets. Mater. Des. 2013, 45, 135–141. [Google Scholar] [CrossRef]

- Paoletti, A.; Lambiase, F.; Di Ilio, A. Optimization of Friction Stir Welding of Thermoplastics. Procedia CIRP 2015, 33, 563–568. [Google Scholar] [CrossRef]

- Bilici, M.K. Application of Taguchi approach to optimize friction stir spot welding parameters of polypropylene. Mater. Des. 2012, 35, 113119. [Google Scholar] [CrossRef]

- Memduh, K. Friction stir spot welding parameters for polypropylene sheets. Sci. Res. Essays 2012, 7, 947–956. [Google Scholar]

- Bilici, M.K.; Yükler, A.İ.; Kurtulmuş, M. The optimization of welding parameters for friction stir spot welding of high density polyethylene sheets. Mater. Des. 2011, 32, 4074–4079. [Google Scholar] [CrossRef]

- Yan, Y.; Shen, Y.; Hou, W.; Li, J. Friction stir spot welding thin acrylonitrile butadiene styrene sheets using pinless tool. Int. J. Adv. Manuf. Technol. 2018, 97, 2749–2755. [Google Scholar] [CrossRef]

- Yan, Y.; Shen, Y.; Zhang, W.; Hou, W. Friction stir spot welding ABS using triflute-pin tool: Effect of process parameters on joint morphology, dimension and mechanical property. J. Manuf. Process. 2018, 32, 269–279. [Google Scholar] [CrossRef]

- Bilici, M.K.; Yükler, A.İ. Influence of tool geometry and process parameters on macrostructure and static strength in friction stir spot welded polyethylene sheets. Mater. Des. 2012, 33, 145–152. [Google Scholar] [CrossRef]

| Addition of Inserts | Molded in Connections | Flow Joining-Plastic Deformation-Thermoforming |

|---|---|---|

| Screw, nut, bolts and washers | Molded-in threads | Stacking (Air, Ultrasonic, Vibration, Friction) |

| Expansion inserts | Molded in inserts | Hemming |

| Self-tapping inserts | Snap-fits | – |

| Ultrasonic insert | – | – |

| Rivets | – | – |

| Advantages | Limits and Disadvantages |

|---|---|

| Simplicity | Stress concentration |

| Permanent or nonpermanent | Increase of weight |

| Possibly to be directly embedded into the mold (snap fits) | Costs |

| High mechanical behavior even at high temperatures | Visibility from one or both sides of the connector |

| Possibility to join materials with great differences | Many processes require pre-drilling |

| Advantages | Limits and Disadvantages |

|---|---|

| Localized heating | Relatively high forces involved |

| Low energy requirement | Requires high stiffness of the equipment |

| High strength Reduced material distortion and residual Stress | The process can worsen the appearance (especially on correspondence contact surface with the tool shoulder) of the weld seam. |

| Possibility to join different materials | High investment costs |

| No surface pretreatment is required | – |

| Relatively high speed | – |

| Easiness of automation | – |

| Low process variability | – |

| Category | Process Parameter | Brief Description | References |

|---|---|---|---|

| Processing Speeds | Rotation Speed | Rotational speed of the LFSW tool during the welding process | [13,25,29,36,38,39,40,41,42,43,44,45,46,47,48,49] |

| Welding Speed | Forward moving speed of the LFSW tool during the welding process along joint line | ||

| Processing Variables | Plunge Depth | Final penetration depth of LFSW tool on top surface of base materials. During the welding process LFSW tool plunge depth remains constant while the tool continues to rotate | [29,36,42,49,50] |

| Tilt Angle | Axial tilt of LFSW tool compare surface of base material normal axis. The tool tilt angle has negative amount toward LFSW tool forward moving direction | [28,38,39,40,41,42,45,50,51,52] | |

| Geometry | Tool probe profile | Force applied during the dwell phase when load-control is involved in the process | [15,29,42,43,44,45,48,49,51,52] |

| Category | Process Parameter | Brief Description | References |

|---|---|---|---|

| Processing Speeds | Plunge Rate | Speed of the tool during the plunging phase upon reaching the penetration depth | [49,75,78,79,80] |

| Rotation speed | Speed of the tool during the plunging and dwell phases | [49,79,81,82,83] | |

| Phases Length | Pre-heating time | Period of material pre-heating by slight plunging of the tool over the upper sheet | [49,79,81,82,83] |

| Dwell time | time elapsing since the tool has reached the final penetration depth and start of cooling. During this period, the tool plunge is stopped while the tool continues to rotate | [49,75,78,80,82] | |

| Cooling time | Period during which the tool is fully stopped (no plunging and rotation take place) | [49,81,82,83] | |

| Geometry | Plunge depth | Axial displacement of the tool since the first contact with the upper sheet to the final position. This should be greater than the upper sheet thickness and lower than the sum of the sheet thicknesses | [74,76,77] |

| Tool shoulder diameter | – | [74,76,77] | |

| Tool probe diameter | – | [76,77,84] | |

| Tool probe geometry | – | [76,77,84,85,86] | |

| Others | Plunge force | Force applied during the dwell phase when load-control is involved in the process | [74] |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lambiase, F.; Derazkola, H.A.; Simchi, A. Friction Stir Welding and Friction Spot Stir Welding Processes of Polymers—State of the Art. Materials 2020, 13, 2291. https://doi.org/10.3390/ma13102291

Lambiase F, Derazkola HA, Simchi A. Friction Stir Welding and Friction Spot Stir Welding Processes of Polymers—State of the Art. Materials. 2020; 13(10):2291. https://doi.org/10.3390/ma13102291

Chicago/Turabian StyleLambiase, Francesco, Hamed Aghajani Derazkola, and Abdolreza Simchi. 2020. "Friction Stir Welding and Friction Spot Stir Welding Processes of Polymers—State of the Art" Materials 13, no. 10: 2291. https://doi.org/10.3390/ma13102291

APA StyleLambiase, F., Derazkola, H. A., & Simchi, A. (2020). Friction Stir Welding and Friction Spot Stir Welding Processes of Polymers—State of the Art. Materials, 13(10), 2291. https://doi.org/10.3390/ma13102291