The Influence of Severe Plastic Deformation and Subsequent Annealing on the Microstructure and Hardness of a Cu–Cr–Zr Alloy

Abstract

1. Introduction

2. Materials and Methods

2.1. Processing of Materials

2.2. Characterization of the Microstructure by Scanning Electron Microscopy

2.3. X-ray Line Profile Analysis

2.4. Transmission Electron Microscopy Study

2.5. Hardness Testing

3. Results

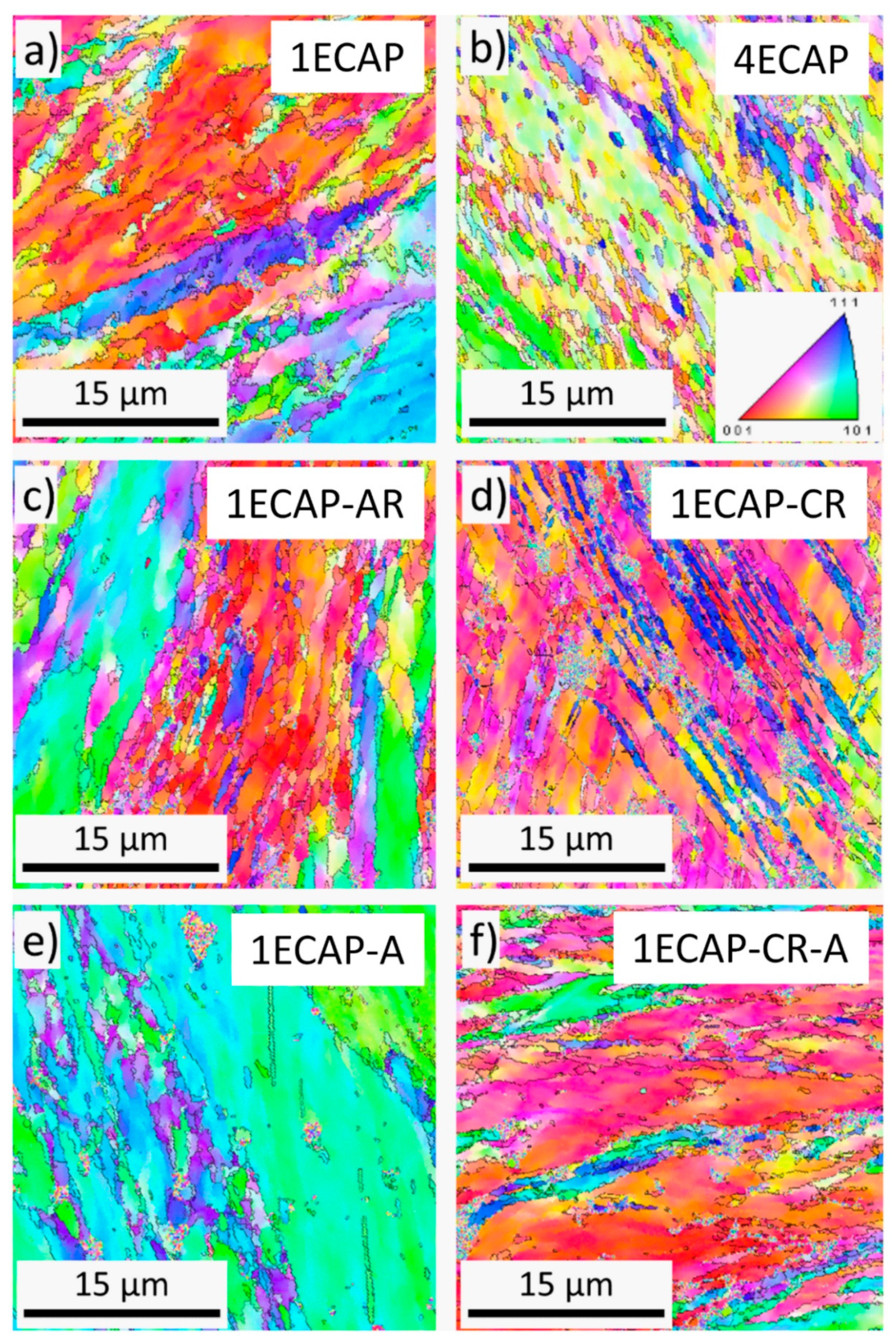

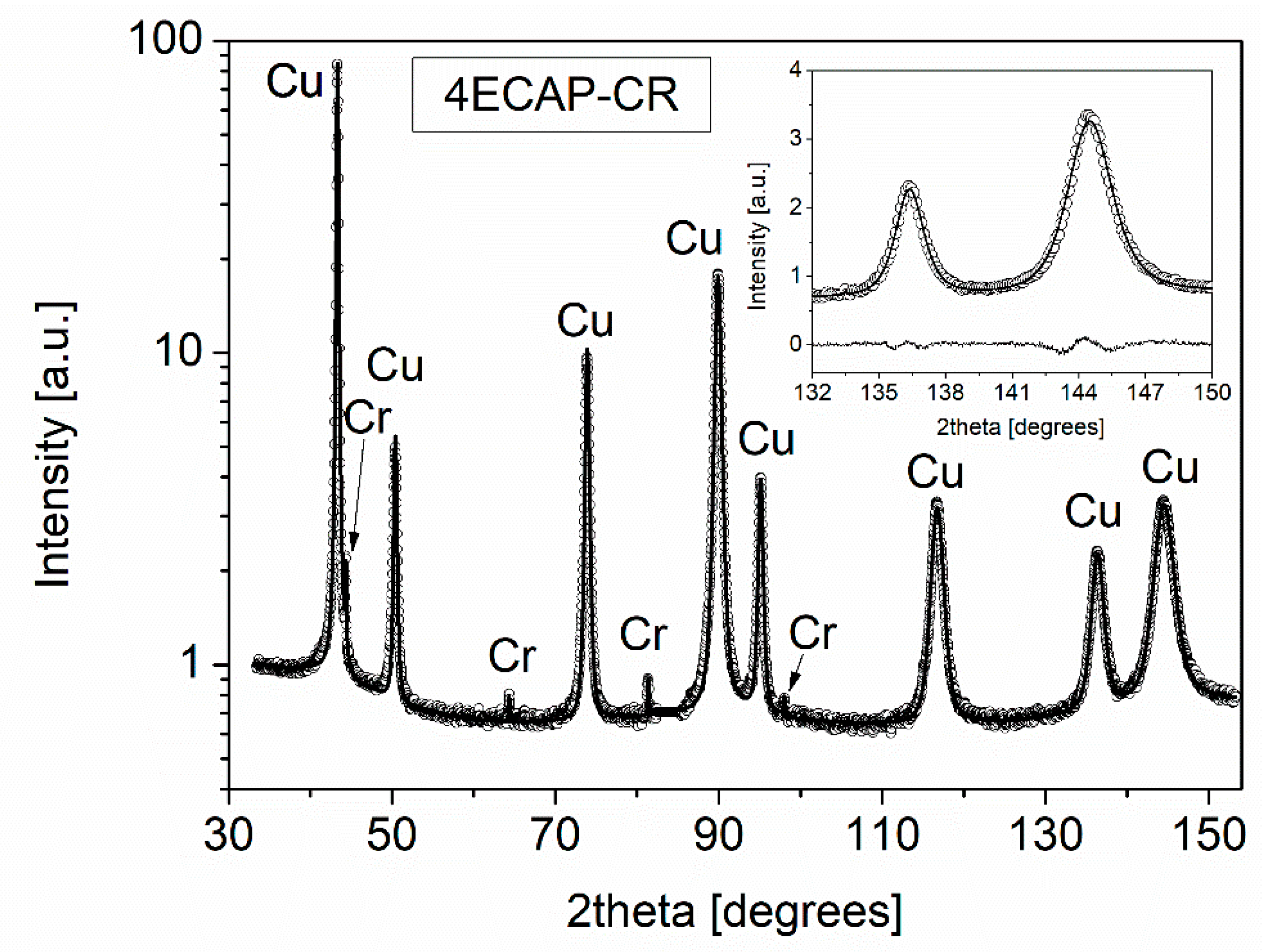

3.1. Microstructure Development During ECAP and Subsequent Rolling

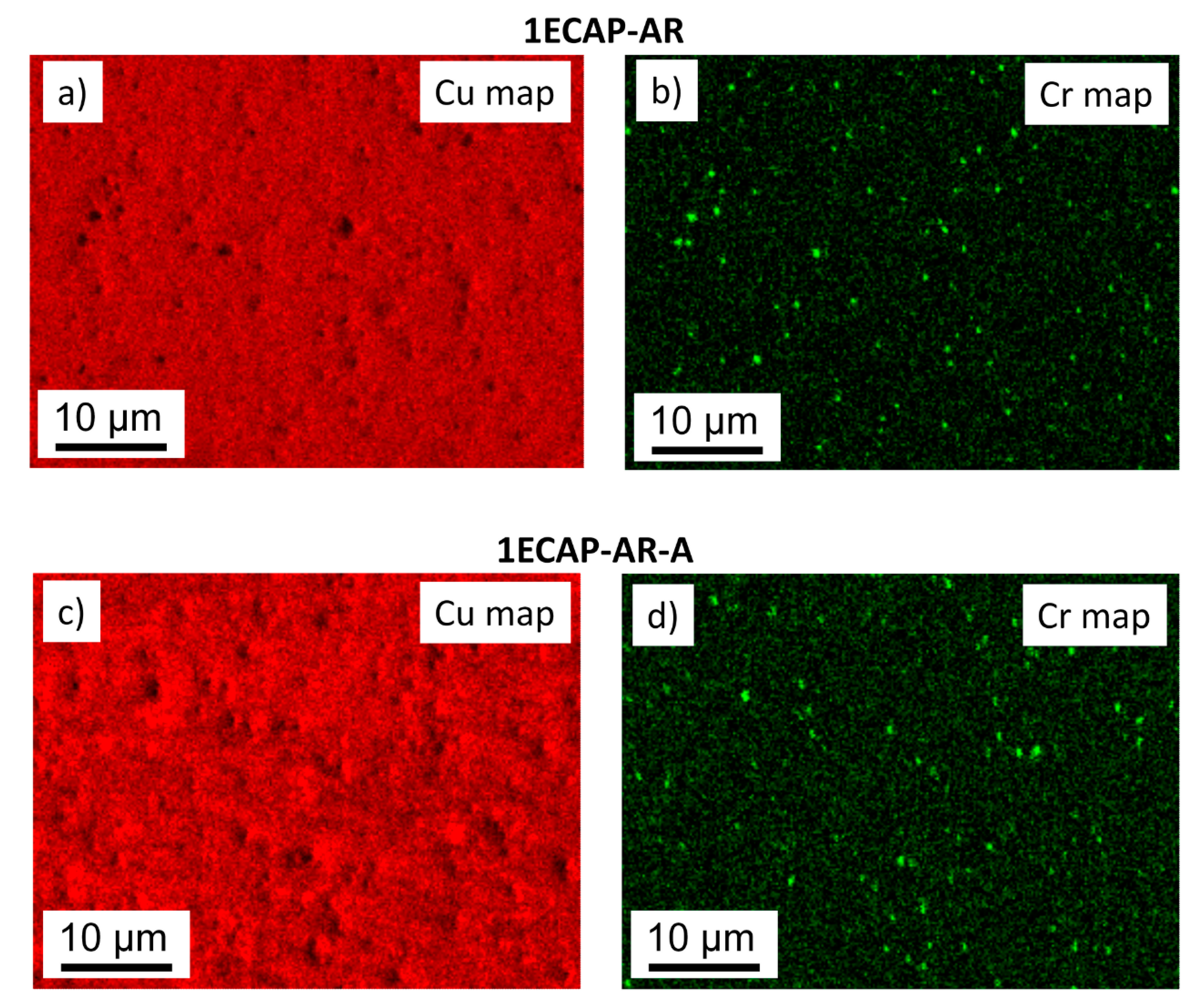

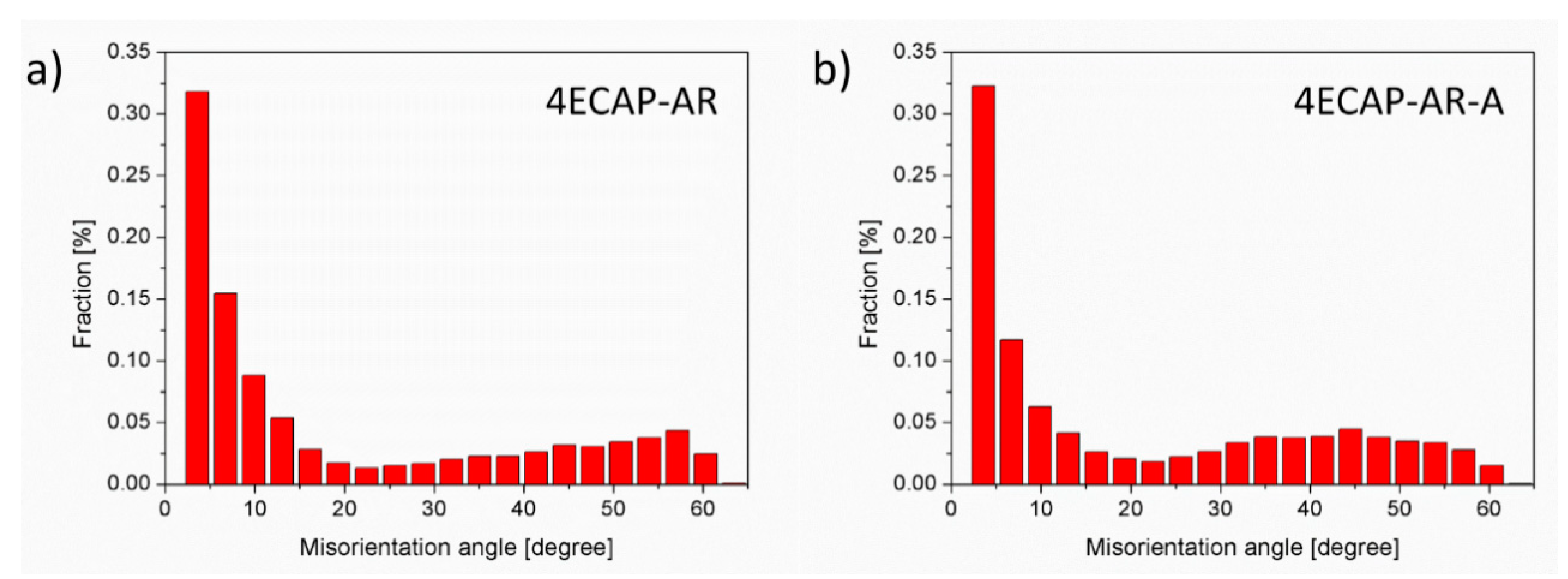

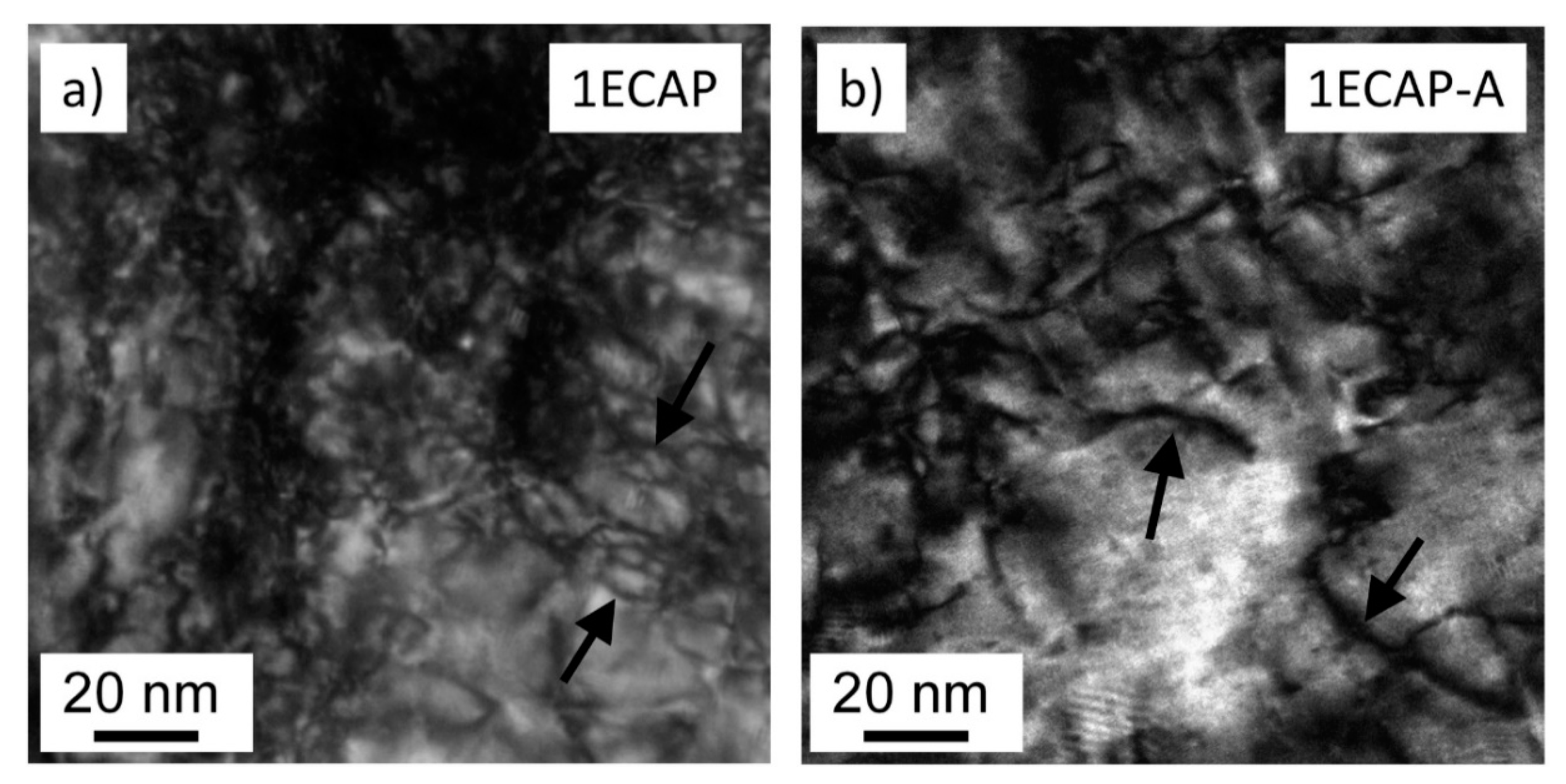

3.2. Changes in the Microstructure During Annealing of the SPD-Processed Samples

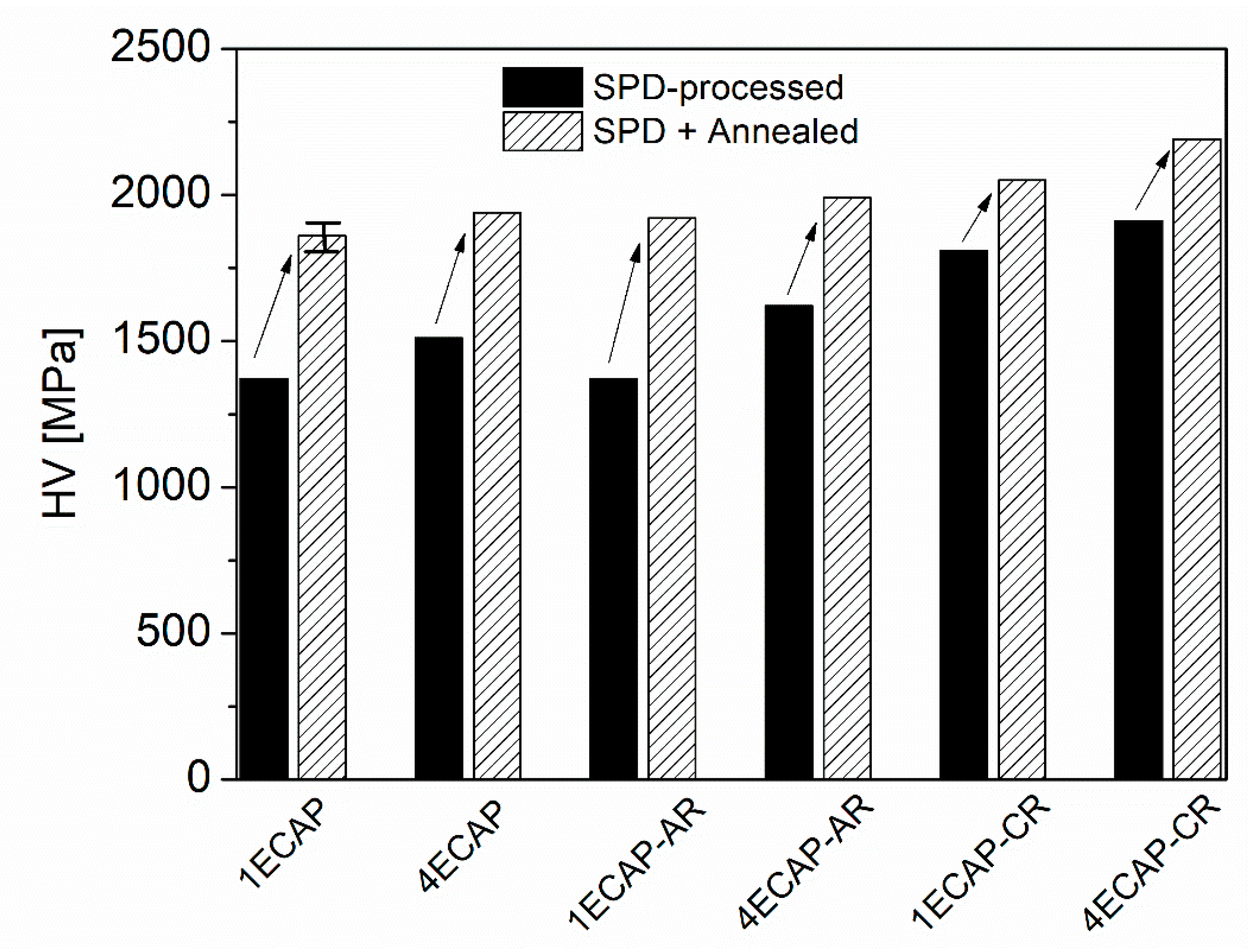

3.3. Effect of SPD-Processing and Subsequent Annealing on the Hardness

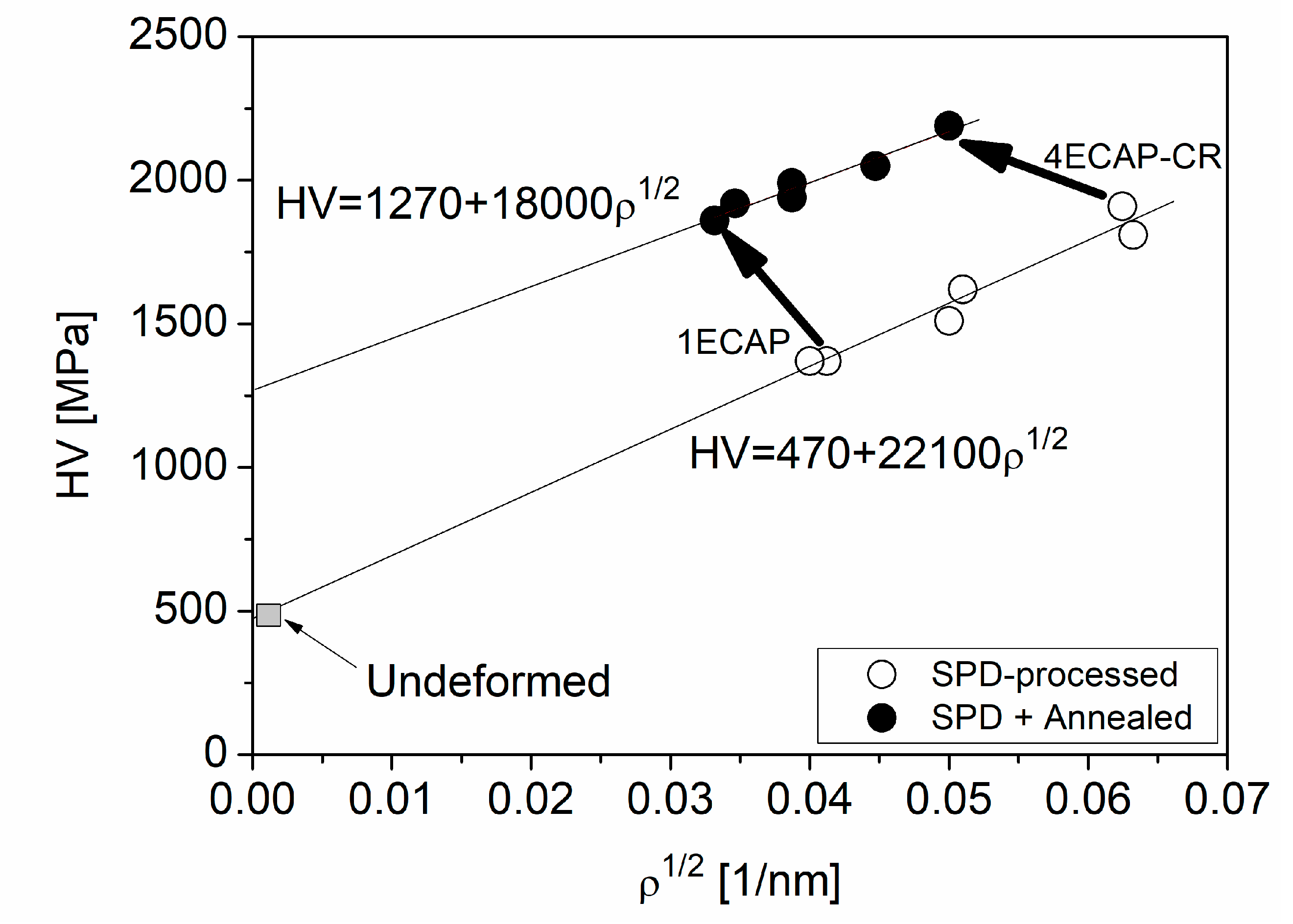

4. Discussion

5. Conclusions

- ECAP processing for one pass resulted in a dislocation density of ~17 × 1014 m−2 and a crystallite size of ~84 nm. The dislocation density increased to ~25 × 1014 m−2, while the crystallite size decreased to ~57 nm when the number of passes was raised to four. Additional rolling at ambient temperature did not yield a further change in the dislocation density and crystallite size. At the same time, cryorolling after ECAP resulted in an increase in the dislocation density to ~40 × 1014 m−2 and a small crystallite size of about 50 nm, irrespective of the number of ECAP passes.

- The heat treatment caused a significant reduction in the dislocation density and a change in the dislocation configuration, leading to a less shielded strain field of dislocations. This could be a result of the annihilation of dislocation dipoles during annealing. In addition, the oxygen content of the samples considerably increased, since the heat treatment was carried out in air.

- The hardness evolution during the SPD processing and subsequent annealing obeyed the Taylor relationship, indicating that the interaction between dislocations is the main hardening effect. The heat treatment yielded a three-fold increase in the threshold hardness in the Taylor equation, which could have been caused by the annihilation of mobile dislocations and the strengthening effect of oxygen interstitials.

Author Contributions

Funding

Conflicts of Interest

References

- Gubicza, J.; Dobatkin, S.V.; Khosravi, E.; Kuznetsov, A.A.; Lábár, J.L. Microstructural stability of Cu processed by different routes of severe plastic deformation. Mater. Sci. Eng. A 2011, 528, 1828–1832. [Google Scholar] [CrossRef]

- Islamgaliev, R.K.; Nesterov, K.M.; Valiev, R.Z. Structure, strength, and electric conductivity of a Cu-Cr copper-based alloy subjected to severe plastic deformation. Phys. Met. Metallogr. 2015, 116, 209–218. [Google Scholar] [CrossRef]

- Shangina, D.V.; Bochvar, N.R.; Dobatkin, S.V. Structure and properties of ultrafine-grained Cu-Cr alloys after high pressure torsion. Mater. Sci. Forum 2010, 667–669, 301–306. [Google Scholar] [CrossRef]

- Rodak, K. Cu-Cr and Cu-Fe alloys processed by new severe plastic deformation: Microstructure and properties. In Severe Plastic Deformation Techniques; InTech: Rijeka, Croatia, 2017. [Google Scholar]

- Shakhova, I.; Yanushkevich, Z.; Fedorova, I.; Belyakov, A.; Kaibyshev, R. Grain refinement in a Cu-Cr-Zr alloy during multidirectional forging. Mater. Sci. Eng. A 2014, 606, 380–389. [Google Scholar] [CrossRef]

- Wei, W.; Wang, S.L.; Wei, K.X.; Alexandrov, I.V.; Du, Q.B.; Hu, J. Microstructure and tensile properties of Cu-Al alloys processed by ECAP and rolling at cryogenic temperature. J. Alloys Compd. 2016, 678, 506–510. [Google Scholar] [CrossRef]

- Gubicza, J. Defect Structure and Properties of Nanomaterials, 2nd ed.; Woodhead Publishing: Duxford, UK, 2017; ISBN 9780081019177. [Google Scholar]

- Kvackaj, T.; Kovacova, A.; Kocisko, R.; Bidulska, J.; Litynska–Dobrzynska, L.; Jenei, P.; Gubicza, J. Microstructure evolution and mechanical performance of copper processed by equal channel angular rolling. Mater. Charact. 2017, 134, 246–252. [Google Scholar] [CrossRef]

- Orłowska, M.; Bazarnik, P.; Lewandowska, M. The electrical conductivity of CuCrZr alloy after SPD processing. IOP Conf. Ser. Mater. Sci. Eng. 2014, 63, 12119. [Google Scholar]

- Kováčová, A.; Kvačkaj, T.; Kočiško, R.; Dragošek, L.; Lityńska-Dobrzyńska, L. The effect of severe plastic deformation and heat treatment on CuCrZr alloys. Acta Phys. Pol. A 2017, 131, 1336–1340. [Google Scholar] [CrossRef]

- Lee, T.R.; Chang, C.P.; Kao, P.W. The tensile behavior and deformation microstructure of cryo-rolled and annealed pure nickel. Mater. Sci. Eng. A 2005, 408, 131–135. [Google Scholar] [CrossRef]

- Stepanov, N.D.; Kuznetsov, A.V.; Salishchev, G.A.; Raab, G.I.; Valiev, R.Z. Effect of cold rolling on microstructure and mechanical properties of copper subjected to ECAP with various numbers of passes. Mater. Sci. Eng. A 2012, 554, 105–115. [Google Scholar] [CrossRef]

- Zhu, C.; Maa, A.; Jiang, J.; Li, X.; Song, D.; Yang, D.; Yuan, Y.; Chen, J. Effect of ECAP combined cold working on mechanical properties and electrical conductivity of conform-produced Cu-Mg alloys. J. Alloys Compd. 2014, 582, 135–140. [Google Scholar] [CrossRef]

- Song, D.; Wang, G.; Zhou, Z.; Klu, E.E.; Gao, B.; Ma, A.; Wu, Y.; Sun, J.; Jiang, J.; Ma, X. Developing a high-strength Al–11Si alloy with improved ductility by combining ECAP and cryorolling. Mater. Sci. Eng. A 2020, 773, 138880. [Google Scholar] [CrossRef]

- Simcák, D.; Kvackaj, T.; Kocisko, R.; Bidulsky, R.; Kepic, J.; Puchy, V. Evaluation of hight purity aluminium after asymmetric rolling at ambient and cryogenic temperatures. Acta Metall. Slovaca 2017, 23, 99–104. [Google Scholar] [CrossRef]

- Zhang, B. Physical Fundamentals of Nanomaterials; Zhang, B., Ed.; William Andrew Publishing: Boston, MA, USA, 2018; ISBN 9780124104174. [Google Scholar]

- Purcek, G.; Saray, O.; Nagimov, M.I.; Nazarov, A.A.; Safarov, I.M.; Danilenko, V.N.; Valiakhmetov, O.R.; Mulyukov, R.R. Microstructure and mechanical behavior of UFG copper processed by ECAP following different processing regimes. Philos. Mag. 2012, 92, 690–704. [Google Scholar] [CrossRef]

- Islamgaliev, R.K.; Nesterov, K.M.; Champion, Y.; Valiev, R.Z. Enhanced strength and electrical conductivity in ultrafine-grained Cu-Cr alloy processed by severe plastic deformation. IOP Conf. Ser. Mater. Sci. Eng. 2014, 63, 012118. [Google Scholar] [CrossRef]

- Kapoor, G.; Huang, Y.; Sarma, V.S.; Langdon, T.G.; Gubicza, J. Effect of Mo addition on the microstructure and hardness of ultrafine-grained Ni alloys processed by a combination of cryorolling and high-pressure torsion. Mater. Sci. Eng. A 2017, 688, 92–100. [Google Scholar] [CrossRef]

- Straumal, B.; Kilmametov, A.; Mazilkin, A.; Kogtenkova, O.; Baretzky, B.; Korneva, A.; Zieba, P. Diffusive and displacive phase transformations under high pressure torsion. Acta Metall. Slovaca 2019, 25, 230–252. [Google Scholar] [CrossRef]

- Besterci, M.; Sülleiová, K. Theoretical-experimental possibillities of microstructure quantification of dispersion strengthened materials. Acta Metall. Slovaca 2019, 25, 65–72. [Google Scholar] [CrossRef]

- Sun, Y.; Peng, L.; Huang, G.; Xie, H.; Mi, X.; Liu, X. Effects of Mg addition on the microstructure and softening resistance of Cu–Cr alloys. Mater. Sci. Eng. A 2020, 776, 139009. [Google Scholar] [CrossRef]

- Vinogradov, A.; Ishida, T.; Kitagawa, K.; Kopylov, V.I. Effect of strain path on structure and mechanical behavior of ultra-fine grain Cu-Cr alloy produced by equal-channel angular pressing. Acta Mater. 2005, 53, 2181–2192. [Google Scholar] [CrossRef]

- Purcek, G.; Yanar, H.; Saray, O.; Karaman, I.; Maier, H.J. Effect of precipitation on mechanical and wear properties of ultrafine-grained Cu-Cr-Zr alloy. Wear 2014, 311, 149–158. [Google Scholar] [CrossRef]

- Dobatkin, S.V.; Gubicza, J.; Shangina, D.V.; Bochvar, N.R.; Tabachkova, N.Y. High strength and good electrical conductivity in Cu-Cr alloys processed by severe plastic deformation. Mater. Lett. 2015, 153, 5–9. [Google Scholar] [CrossRef]

- Urbańczyk-Gucwa, A.; Rodak, K.; Płachta, A.; Sobota, J.; Rdzawski, Z. Characteristic structure of Cu-0.8Cr alloy using SPD deformation by rolling with cyclic movement of rolls method. Key Eng. Mater. 2016, 682, 3–9. [Google Scholar] [CrossRef]

- Xu, G.L.; Peng, L.J.; Huang, G.J.; Xie, H.F.; Yang, Z.; Feng, X.; Yin, X.Q.; Mi, X.J. Microstructural evolution and properties of a Cu–Cr–Ag alloy during continuous manufacturing process. Rare Met. 2019, 1–8. [Google Scholar] [CrossRef]

- Guo, X.; Xiao, Z.; Qiu, W.; Li, Z.; Zhao, Z.; Wang, X.; Jiang, Y. Microstructure and properties of Cu-Cr-Nb alloy with high strength, high electrical conductivity and good softening resistance performance at elevated temperature. Mater. Sci. Eng. A 2019, 749, 281–290. [Google Scholar] [CrossRef]

- Zhang, Y.; Sun, H.L.; Volinsky, A.A.; Tian, B.H.; Chai, Z.; Liu, P.; Liu, Y. Characterization of the hot deformation behavior of Cu-Cr-Zr alloy by processing maps. Acta Metall. Sin. 2016, 29, 422–430. [Google Scholar] [CrossRef]

- Fu, H.; Xu, S.; Li, W.; Xie, J.; Zhao, H.; Pan, Z. Effect of rolling and aging processes on microstructure and properties of Cu-Cr-Zr alloy. Mater. Sci. Eng. A 2017, 700, 107–115. [Google Scholar] [CrossRef]

- Li, R.; Guo, E.; Chen, Z.; Kang, H.; Wang, W.; Zou, C.; Li, T.; Wang, T. Optimization of the balance between high strength and high electrical conductivity in CuCrZr alloys through two-step cryorolling and aging. J. Alloys Compd. 2019, 771, 1044–1051. [Google Scholar] [CrossRef]

- Lamperti, A.; Ossi, P.M.; Rotshtein, V.P. Surface analytical chemical imaging and morphology of Cu-Cr alloy. Surf. Coatings Technol. 2006, 200, 6373–6377. [Google Scholar] [CrossRef]

- Feng, H.; Jiang, H.; Yan, D.; Rong, L. Thermal stability of ultrafine grained CuCrZr alloy produced by continuous extrusion. Trends J. Sci. Res. 2019, 4, 1–8. [Google Scholar] [CrossRef]

- Gubicza, J.; Hegedús, Z.; Lábár, J.L.; Sarma, V.S.; Kauffmann, A.; Freudenberger, J. Microstructure evolution during annealing of an SPD- processed supersaturated Cu-3 at.% Ag alloy. IOP Conf. Ser. Mater. Sci. Eng. 2014, 63, 012091. [Google Scholar] [CrossRef]

- Ribárik, G.; Ungár, T.; Gubicza, J. MWP-fit: A program for multiple whole-profile fitting of diffraction peak profiles by ab initio theoretical functions. J. Appl. Crystallogr. 2001, 34, 669–676. [Google Scholar] [CrossRef]

- Gubicza, J. X-ray Line Profile Analysis in Materials Science; IGI Global: Hershey, PA, USA, 2014; ISBN 9781466658523. [Google Scholar]

- Kamikawa, N.; Huang, X.; Tsuji, N.; Hansen, N. Strengthening mechanisms in nanostructured high-purity aluminium deformed to high strain and annealed. Acta Mater. 2009, 57, 4198–4208. [Google Scholar] [CrossRef]

- Man, O.; Pantělejev, L.; Kunz, L. Study of thermal stability of ultrafine-grained copper by means of electron back scattering diffraction. Mater. Trans. 2010, 51, 209–213. [Google Scholar] [CrossRef]

- Chengfan, G.; Tóth, L.S.; Beausir, B.; Williams, T.; Davies, C.H.J. Grain fragmentation in equal channel angular pressed copper. Mater. Sci. Forum 2010, 654–656, 1570–1573. [Google Scholar]

- Stepanov, N.; Kuznetsov, A.V.; Salishchev, G.; Raab, G.; Valiev, R. Effect of cold rolling on structure and mechanical properties of copper subjected to different numbers of passes of ECAP. Mater. Sci. Forum 2011, 667–669, 295–300. [Google Scholar] [CrossRef]

- Liu, F.; Yuan, H.; Yin, J.; Wang, J.T. Influence of stacking fault energy and temperature on microstructures and mechanical properties of fcc pure metals processed by equal-channel angular pressing. Mater. Sci. Eng. A 2016, 662, 578–587. [Google Scholar] [CrossRef]

- Gubicza, J. Annealing-induced hardening in ultrafine-grained and nanocrystalline materials. Adv. Eng. Mater. 2020, 22, 1900507. [Google Scholar] [CrossRef]

- Valiev, R.Z.; Sergueeva, A.V.; Mukherjee, A.K. The effect of annealing on tensile deformation behavior of nanostructured SPD titanium. Scr. Mater. 2003, 49, 669–674. [Google Scholar] [CrossRef]

- Gubicza, J.; Pereira, P.H.R.; Kapoor, G.; Huang, Y.; Vadlamani, S.S.; Langdon, T.G. Annealing-induced hardening in ultrafine-grained Ni–Mo alloys. Adv. Eng. Mater. 2018, 20, 1800184. [Google Scholar] [CrossRef]

- Müllner, P.; Solenthaler, C. On the effect of deformation twinning on defect densities. Mater. Sci. Eng. A 1997, 230, 107–115. [Google Scholar] [CrossRef]

- Gubicza, J.; Chinh, N.Q.; Lábár, J.L.; Dobatkin, S.; Hegedus, Z.; Langdon, T.G. Correlation between microstructure and mechanical properties of severely deformed metals. J. Alloys Compd. 2009, 483, 271–274. [Google Scholar] [CrossRef]

- Yu, Q.; Qi, L.; Tsuru, T.; Traylor, R.; Rugg, D.; Morris, J.W.; Asta, M.; Chrzan, D.C.; Minor, A.M. Origin of dramatic oxygen solute strengthening effect in titanium. Science 2015, 347, 635–639. [Google Scholar] [CrossRef]

- Guo, J.; Duarte, M.J.; Zhang, Y.; Bachmaier, A.; Gammer, C.; Dehm, G.; Pippan, R.; Zhang, Z. Oxygen-mediated deformation and grain refinement in Cu-Fe nanocrystalline alloys. Acta Mater. 2019, 166, 281–293. [Google Scholar] [CrossRef]

| Abbreviation | Sample History |

|---|---|

| 1ECAP | 1 pass of ECAP |

| 1ECAP–A | 1 pass of ECAP + annealing at 430 °C |

| 4ECAP | 4 pass of ECAP |

| 4ECAP–A | 4 pass of ECAP + annealing at 430 °C |

| 1ECAP–AR | 1 pass of ECAP + rolling at ambient temperature |

| 1ECAP–AR–A | 1 pass of ECAP + rolling at ambient temperature + annealing at 430 °C |

| 4ECAP–AR | 4 pass of ECAP + rolling at ambient temperature |

| 4ECAP–AR–A | 4 pass of ECAP + rolling at ambient temperature + annealing at 430 °C |

| 1ECAP–CR | 1 pass of ECAP + cryorolling |

| 1ECAP–CR–A | 1 pass of ECAP + cryorolling + annealing at 430 °C |

| 4ECAP–CR | 4 pass of ECAP + cryorolling |

| 4ECAP–CR–A | 4 pass of ECAP + cryorolling + annealing at 430 °C |

| Sample | d [μm] | <x> [nm] | ρ [1014 m−2] | M |

|---|---|---|---|---|

| 1ECAP | 10 ± 2 | 84 ± 9 | 17 ± 2 | 3.3 ± 0.3 |

| 1ECAP–A | 13 ± 2 | 88 ± 9 | 11 ± 1 | 6.3 ± 0.7 |

| 4ECAP | 4 ± 1 | 57 ± 6 | 25 ± 2 | 2.2 ± 0.3 |

| 4ECAP–A | 4 ± 1 | 82 ± 9 | 15 ± 2 | 3.4 ± 0.3 |

| 1ECAP–AR | 4 ± 1 | 72 ± 8 | 16 ± 2 | 2.4 ± 0.3 |

| 1ECAP–AR–A | 5 ± 1 | 112 ± 13 | 12 ± 1 | 5.6 ± 0.6 |

| 4ECAP–AR | 1.8 ± 0.4 | 65 ± 7 | 26 ± 3 | 2.4 ± 0.3 |

| 4ECAP–AR–A | 2.2 ± 0.5 | 89 ± 9 | 15 ± 2 | 4.3 ± 0.5 |

| 1ECAP–CR | 2.0 ± 0.2 | 49 ± 6 | 40 ± 6 | 2.2 ± 0.3 |

| 1ECAP–CR–A | 6 ± 1 | 61 ± 7 | 20 ± 2 | 3.5 ± 0.4 |

| 4ECAP–CR | 1.3 ± 0.3 | 55 ± 6 | 39 ± 5 | 3.5 ± 0.4 |

| 4ECAP–CR–A | 1.7 ± 0.4 | 93 ± 10 | 25 ± 3 | 6.4 ± 0.7 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kapoor, G.; Kvackaj, T.; Heczel, A.; Bidulská, J.; Kočiško, R.; Fogarassy, Z.; Simcak, D.; Gubicza, J. The Influence of Severe Plastic Deformation and Subsequent Annealing on the Microstructure and Hardness of a Cu–Cr–Zr Alloy. Materials 2020, 13, 2241. https://doi.org/10.3390/ma13102241

Kapoor G, Kvackaj T, Heczel A, Bidulská J, Kočiško R, Fogarassy Z, Simcak D, Gubicza J. The Influence of Severe Plastic Deformation and Subsequent Annealing on the Microstructure and Hardness of a Cu–Cr–Zr Alloy. Materials. 2020; 13(10):2241. https://doi.org/10.3390/ma13102241

Chicago/Turabian StyleKapoor, Garima, Tibor Kvackaj, Anita Heczel, Jana Bidulská, Róbert Kočiško, Zsolt Fogarassy, Dusan Simcak, and Jenő Gubicza. 2020. "The Influence of Severe Plastic Deformation and Subsequent Annealing on the Microstructure and Hardness of a Cu–Cr–Zr Alloy" Materials 13, no. 10: 2241. https://doi.org/10.3390/ma13102241

APA StyleKapoor, G., Kvackaj, T., Heczel, A., Bidulská, J., Kočiško, R., Fogarassy, Z., Simcak, D., & Gubicza, J. (2020). The Influence of Severe Plastic Deformation and Subsequent Annealing on the Microstructure and Hardness of a Cu–Cr–Zr Alloy. Materials, 13(10), 2241. https://doi.org/10.3390/ma13102241