Effect of Ti Content on the Microstructure and Corrosion Resistance of CoCrFeNiTix High Entropy Alloys Prepared by Laser Cladding

Abstract

:1. Introduction

2. Experimental Procedures

3. Results

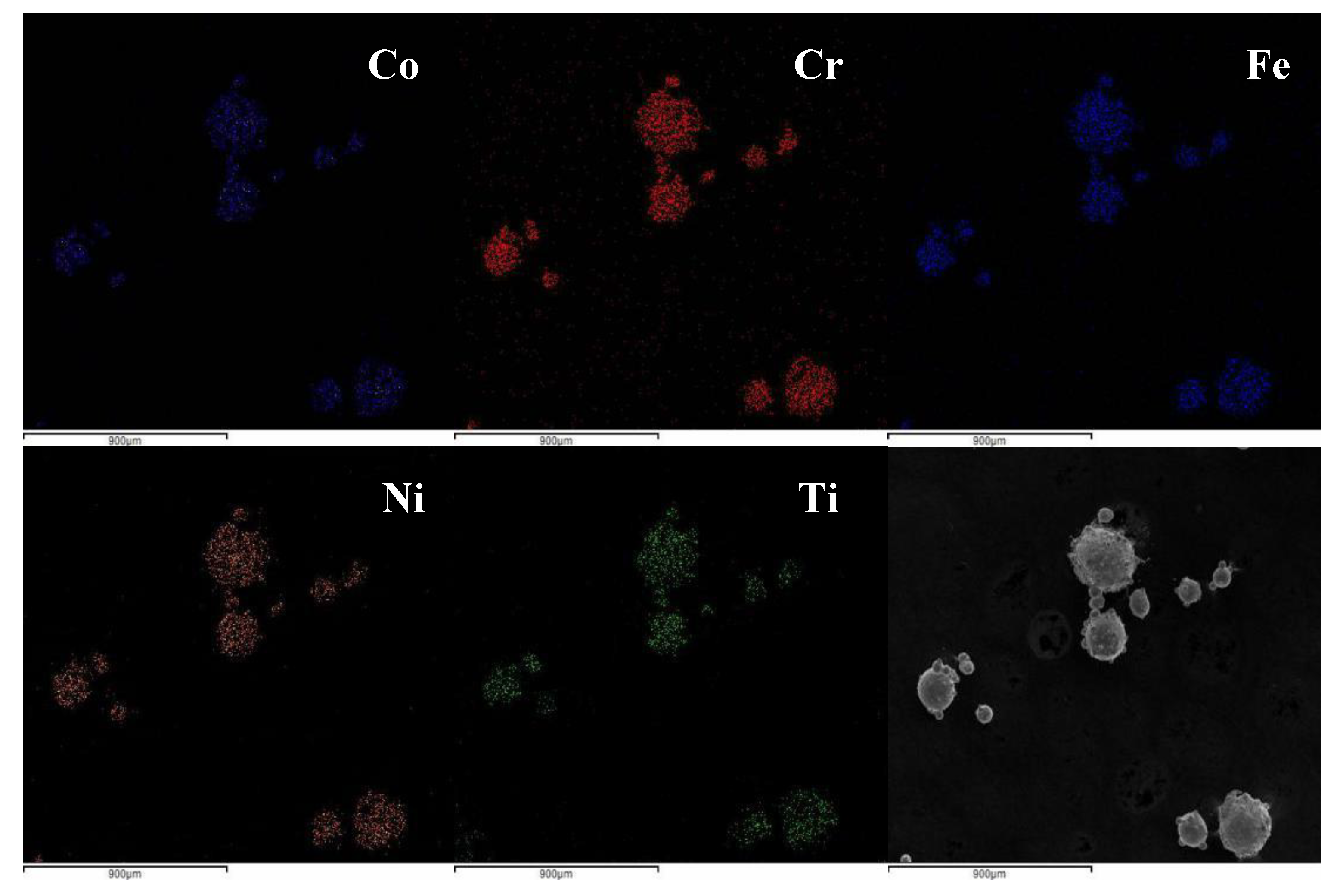

3.1. Microstructure of CoCrFeNiTix HEA powder

3.2. Microstructure of the CoCrFeNiTix HEAs

3.3. Microhardness of the CoCrFeNiTix HEAs

3.4. Corrosion Performance of CoCrFeNiTix HEAs

4. Discussion

5. Conclusions

- (1)

- The CoCrFeNiTix HEA coatings were prepared on the surface of Q235 steel by laser cladding and the coatings were well bonded to the substrate. CoCrFeNiTi0.1 adopts an FCC phase, CoCrFeNiTi0.3 exhibits an FCC phase and a tetragonal FeCr phase, and CoCrFeNiTi0.5 adopts an FCC phase, a tetragonal FeCr phase, and a rhombohedral NiTi phase. The FCC phase, tetragonal FeCr phase, rhombohedral NiTi phase, and a hexagonal CoTi phase are all observed in the CoCrFeNiTi0.7 HEA.

- (2)

- The alloys assume the dendritic structure that is typical of HEAs. Ni and Ti are enriched in the interdendritic regions, whereas Cr and Fe are enriched in the dendrites.

- (3)

- With increasing Ti content, the hardness of the cladding layers also increases due to the combined effects of lattice distortion and dispersion strengthening.

- (4)

- In a 3.5 wt.% NaCl solution, pitting corrosion was the main form of corrosion on the CoCrFeNiTix HEA surfaces. CoCrFeNiTix HEAs have a higher corrosion potential and lower corrosion current density when compared with other HEAs. As the Ti content increases, the corrosion resistance is improved. Furthermore, the high energy barriers at the Cr2O3/TiO2 interfaces improve the corrosion resistance of the alloys.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Zhang, Y.; Yang, X.; Liaw, P. Alloy design and properties optimization of high-entropy alloys. Jom 2012, 64, 830–838. [Google Scholar] [CrossRef]

- Liang, X.B.; Wei, M.; Cheng, J.B. Reaserch progress in advanced materials of High entropy alloys. Mater. Eng. 2009, 12, 75–76. [Google Scholar]

- Chou, H.P.; Chang, Y.S.; Chen, S.K.; Yeh, J.W. Microstructure, thermo physical and electrical properties in AlxCoCrFeNi (0 ≤ x ≤ 2) High entropy alloys. Mater. Sci. Eng. 2009, 163, 184–189. [Google Scholar] [CrossRef]

- Miracle, D.B.; Senkov, O.N. A critical review of high entropy alloys (HEAs) and related concepts. Acta Mater. 2017, 122, 448–511. [Google Scholar] [CrossRef] [Green Version]

- Zhou, Y.J.; Zhang, Y.; Wang, Y.L.; Chen, G.L. Solid solution alloys of AlCoCrFeNiTix with excellent room-temperature mechanical properties. Appl. Phys. Lett. 2007, 90, 181904. [Google Scholar] [CrossRef]

- Liu, N.; Chen, C.; Chang, I.; Zhou, P.J.; Wang, X.J. Compositional Dependence of Phase Selection in CoCrCu0.1FeMoNi-Based High entropy alloys. Materials 2018, 11, 1290. [Google Scholar] [CrossRef] [Green Version]

- He, J.Y.; Liu, W.H.; Wang, H.; Wu, Y.; Liu, X.J.; Nieh, T.G.; Lu, Z.P. Effects of Al addition on structural evolution and tensile properties of the FeCoNiCrMn High entropy alloy system. Acta Mater. 2014, 62, 105–113. [Google Scholar] [CrossRef]

- Liu, W.H.; He, J.Y.; Huang, H.L.; Wang, H.; Lu, Z.P.; Liu, C.T. Effects of Nb additions on the microstructure and mechanical property of CoCrFeNi High entropy alloys. Intermetallics 2015, 60, 1–8. [Google Scholar] [CrossRef]

- Wang, Z.H.; Wang, H.; He, D.Y.; Jiang, J.M.; Zhao, Q.Y. Microstructure of CoCrCuFeNiMn high entropy alloy by plasma cladding. Rare Met. Mater. Eng. 2015, 3, 644–648. [Google Scholar]

- Liu, N.; Zhu, Z.X.; Jin, Y.X.; Wang, X.J.; Gao, X.Y. Research progress of laser cladding technology to prepare high entropy alloy coatings. Mater. Rev. 2014, 5, 137–138. [Google Scholar]

- He, F.; Wang, Z.J.; Wang, J.; Wu, Q.F.; Chen, D.; Han, B.; Liu, J.J.; Wang, J.C.; Kai, J.J. Abnormal γ″-ε phase transformation in the CoCrFeNiNb0.25 high entropy alloy. Scr. Mater. 2018, 146, 281–285. [Google Scholar] [CrossRef]

- Wang, W.R.; Qi, W.; Xie, L.; Yang, X.; Li, J.T.; Zhao, Y. Microstructure and corrosion behavior of (CoCrFeNi)95Nb5 High entropy alloy coating fabricated by plasma spraying. Materials 2019, 12, 694. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Praveen, S.; Murty, B.S.; Kottada, R.S. Effect of molybdenum and niobium on the phase formation and hardness of nanocrystalline CoCrFeNi high entropy alloys. J. Nanosci. Nanotechnol. 2014, 14, 8106–8109. [Google Scholar] [CrossRef] [PubMed]

- Shun, T.T.; Chang, L.Y.; Shiu, M.H. Microstructures and mechanical properties of multiprincipal component CoCrFeNiTix alloys. Mater. Ence Eng. 2012, 556, 170–174. [Google Scholar] [CrossRef]

- Chuang, M.H.; Tsai, M.H.; Wang, W.R.; Lin, S.J.; Yeh, J.W. Microstructure and wear behaviour of AlxCo1.5CrFeNi1.5Tiy High entropy alloys. Acta Mater. 2011, 59, 6308–6317. [Google Scholar] [CrossRef]

- Löbel, M.; Lindner, T.; Mehner, T.; Lampke, T. Influence of Titanium on Microstructure, Phase Formation and Wear Behaviour of AlCoCrFeNiTix High entropy alloy. Entropy 2018, 20, 505. [Google Scholar] [CrossRef] [Green Version]

- Löbel, M.; Lindner, T.; Lampke, T. Enhanced Wear Behaviour of Spark Plasma Sintered AlCoCrFeNiTi High entropy alloy Composites. Materials 2018, 11, 2225. [Google Scholar] [CrossRef] [Green Version]

- Qiu, X.W.; Zhang, Y.P.; Liu, C.G. Effect of Ti content on structure and properties of Al2CrFeNiCoCuTix high-entropy alloy coatings. J. Alloys Compd. 2014, 585, 282–286. [Google Scholar] [CrossRef]

- Liu, L.; Qi, J.G.; Wang, B.; Zhao, Z.F.; Shao, J.; Zhang, Y. Microstructure and mechanical properties of CoCrFeNiVx high entropy alloys. Spec. Cast. Nonferrous Alloy. 2015, 11, 1130–1133. [Google Scholar]

- Wang, W.R.; Wang, J.Q.; Yi, H.G.; Qi, W.; Peng, Q. Effect of molybdenum additives on corrosion behavior of (CoCrFeNi)100−xMox High entropy alloys. Entropy 2018, 20, 908. [Google Scholar] [CrossRef] [Green Version]

- Liu, Q.; Wang, X.Y.; Huang, Y.B.; Xie, L.; Xu, Q.; Huang, J.X. Research progress of high entropy alloy design and computer simulation methods. Mater. Rep. 2019, S1, 392–397. [Google Scholar]

- Wang, L.X.; Wen, B.; Yao, S. First-Principle Studies of AlCoCrCuFeNi High Entropy Alloys with the Pressure-Inducing. Rare Matal Mater. Eng. 2015, 7, 1574–1578. [Google Scholar]

- Nong, Z.S.; Zhu, J.C.; Yu, H.L.; Lai, Z.H. First principles calculation of intermetallic compounds in FeTiCoNiVCrMnCuAl system high entropy alloy. Trans. Nonferrous Met. Soc. China 2012, 22, 1437–1444. [Google Scholar] [CrossRef]

- Wang, Y.F.; Ma, S.G.; Chen, X.H.; Shi, J.Y.; Zhang, Y.; Qiao, J.W. Optimizing mechanical properties of AlCoCrFeNiTix High entropy alloys by tailoring microstructures. Acta Metall. Sin. 2013, 26, 277–284. [Google Scholar] [CrossRef] [Green Version]

- Sun, H.F.; Guo, N.N.; Wang, C.M.; Li, Z.L.; Zhu, H.Y. Study of the Microstructure of High entropy alloys AlFeCuCoNiCrTiX(x = 0, 05, 1.0). Appl. Mech. Mater. 2011, 66–68, 894–900. [Google Scholar] [CrossRef]

- Shen, Y.; He, G.Q.; Tian, D.D.; Fan, K.L. Effect of secondary dendrite arm spacing on tensile property and fatigue behavior of A319 aluminum alloy. Chin. J. Mater. Res. 2014, 28, 587–593. [Google Scholar]

- Pan, J.H.; Zou, Y.Z.; Zeng, J.M. The influences of SDAS on the aging kinetics of A357 alloy. Automot. Eng. 2009, 5, 45–49. [Google Scholar]

- Shang, C.Y.; Axinte, E.; Sun, J.; Li, X.T.; Li, P.; Du, J.W.; Qiao, P.C.; Wang, Y. CoCrFeNi(W1−xMox) High entropy alloy coatings with excellent mechanical properties and corrosion resistance prepared by mechanical alloying and hot pressing sintering. Mater. Des. 2017, 117, 193–202. [Google Scholar] [CrossRef]

- Shang, C.Y.; Axinte, E.; Ge, W.J.; Zhang, Z.T.; Wang, Y. High entropy alloy coatings with excellent mechanical, corrosion resistance and magnetic properties prepared by mechanical alloying and hot pressing sintering. Surf. Interfaces 2017, 9, 36–43. [Google Scholar] [CrossRef]

- Zhang, B.; Liu, L.; Li, T.S.; Li, Y.; Lei, M.K.; Wang, F.H. Adsorption and Diffusion Behavior of Cl− on Sputtering Fe–20Cr Nanocrystalline Thin Film in Acid Solution (pH = 2). J. Mater. Sci. Technol. 2015, 31, 1198–1206. [Google Scholar] [CrossRef]

- An, X.L.; Liu, Q.B.; Zheng, B. Effect of Titanium Content on Microstructure and Properties of FeWCrMnCoCuTix High Entropy Alloy Coating Prepared by Laser Cladding. Appl. Mech. Mater. 2014, 563, 21–24. [Google Scholar] [CrossRef]

- Kao, Y.F.; Lee, T.D.; Chen, S.K.; Chang, Y.S. Electrochemical passive properties of AlxCoCrFeNi (x = 0, 0.25, 0.50, 1.00) alloys in sulfuric acids. Corros. Sci. 2010, 52, 1026–1034. [Google Scholar] [CrossRef]

- Luang, K.J.; Chen, L.; Lin, X.; Huang, H.S.; Tang, S.H.; Du, F.L. Wear and Corrosion Resistance of Al0.5CoCrCuFeNi High entropy alloy Coating Deposited on AZ91D Magnesium Alloy by Laser Cladding. Entropy 2018, 20, 915. [Google Scholar]

| Element | Co | Cr | Fe | Ni | Ti |

|---|---|---|---|---|---|

| Design value | 22.22 | 22.22 | 22.22 | 22.22 | 11.11 |

| Powder | 22.57 (+0.35) | 21.25 (−0.97) | 22.57 (+0.35) | 22.12 (−0.10) | 11.48 (+0.37) |

| Alloy | Region | Co | Cr | Fe | Ni | Ti |

|---|---|---|---|---|---|---|

| T1 | Design value | 24.44 | 24.44 | 24.44 | 24.44 | 2.44 |

| Interdendrite | 24.90 | 15.43 | 13.45 | 30.44 | 15.78 | |

| Dendrite | 23.48 | 26.00 | 26.65 | 23.17 | 0.96 | |

| T2 | Design value | 23.26 | 23.26 | 23.26 | 23.26 | 6.98 |

| Interdendrite | 24.81 | 15.37 | 13.13 | 29.89 | 16.80 | |

| Dendrite | 22.74 | 25.87 | 26.58 | 21.15 | 3.66 | |

| T3 | Design value | 22.22 | 22.22 | 22.22 | 22.22 | 11.11 |

| Interdendrite | 24.64 | 15.13 | 12.87 | 29.12 | 18.24 | |

| Dendrite | 21.75 | 24.87 | 26.32 | 18.91 | 8.15 | |

| T4 | Design value | 21.28 | 21.28 | 21.28 | 21.28 | 14.89 |

| Interdendrite | 24.43 | 14.89 | 12.61 | 28.65 | 19.42 | |

| Dendrite | 20.34 | 23.89 | 25.32 | 17.35 | 13.10 |

| Alloy | icorr (j/(A/cm2)) | Ecorr (V) | ∆E (V) |

|---|---|---|---|

| CoCrFeNiTi0.1 | 5.64 × 10−6 | −1.18 | 0.87 |

| CoCrFeNiTi0.3 | 4.23 × 10−6 | −1.16 | 1.01 |

| CoCrFeNiTi0.5 | 3.81 × 10−6 | −1.13 | 1.23 |

| CoCrFeNiTi0.7 | 1.04 × 10−6 | −1.11 | 1.34 |

| CoCrFeNiNb [12] | 7.23 × 10−6 | −0.37 | 0.63 |

| CoCrFeNiW [28] | 1.42 × 10−5 | −0.78 | 0.62 |

| CoCrFeNiCu [29] | 1.77 × 10−5 | −0.84 | 1.14 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, X.; Liu, Q.; Huang, Y.; Xie, L.; Xu, Q.; Zhao, T. Effect of Ti Content on the Microstructure and Corrosion Resistance of CoCrFeNiTix High Entropy Alloys Prepared by Laser Cladding. Materials 2020, 13, 2209. https://doi.org/10.3390/ma13102209

Wang X, Liu Q, Huang Y, Xie L, Xu Q, Zhao T. Effect of Ti Content on the Microstructure and Corrosion Resistance of CoCrFeNiTix High Entropy Alloys Prepared by Laser Cladding. Materials. 2020; 13(10):2209. https://doi.org/10.3390/ma13102209

Chicago/Turabian StyleWang, Xinyang, Qian Liu, Yanbin Huang, Lu Xie, Quan Xu, and Tianxiang Zhao. 2020. "Effect of Ti Content on the Microstructure and Corrosion Resistance of CoCrFeNiTix High Entropy Alloys Prepared by Laser Cladding" Materials 13, no. 10: 2209. https://doi.org/10.3390/ma13102209

APA StyleWang, X., Liu, Q., Huang, Y., Xie, L., Xu, Q., & Zhao, T. (2020). Effect of Ti Content on the Microstructure and Corrosion Resistance of CoCrFeNiTix High Entropy Alloys Prepared by Laser Cladding. Materials, 13(10), 2209. https://doi.org/10.3390/ma13102209