Grain Structure Evolution of Al–Cu Alloys in Powder Bed Fusion with Laser Beam for Excellent Mechanical Properties

Abstract

1. Introduction

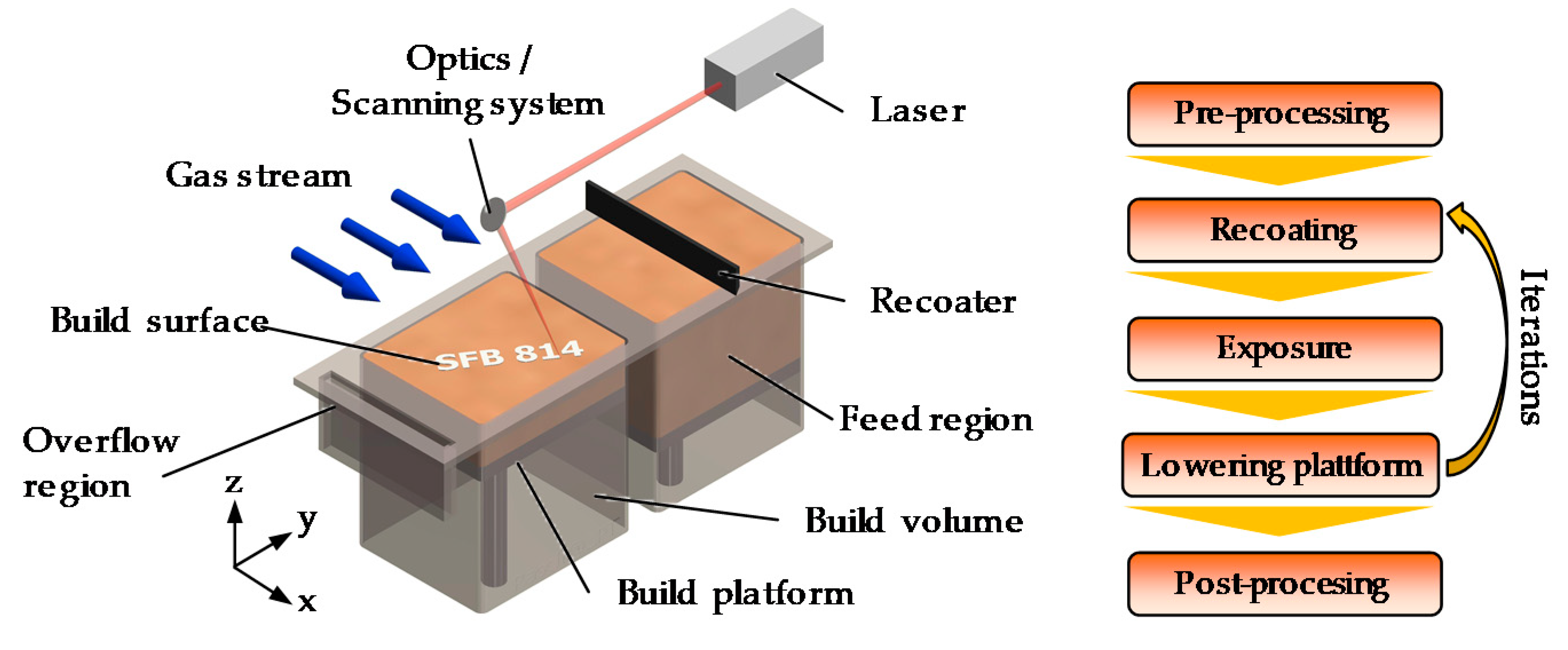

1.1. PBF-LB/M and Used Materials

1.2. Al–Cu Alloys in PBF-LB/M

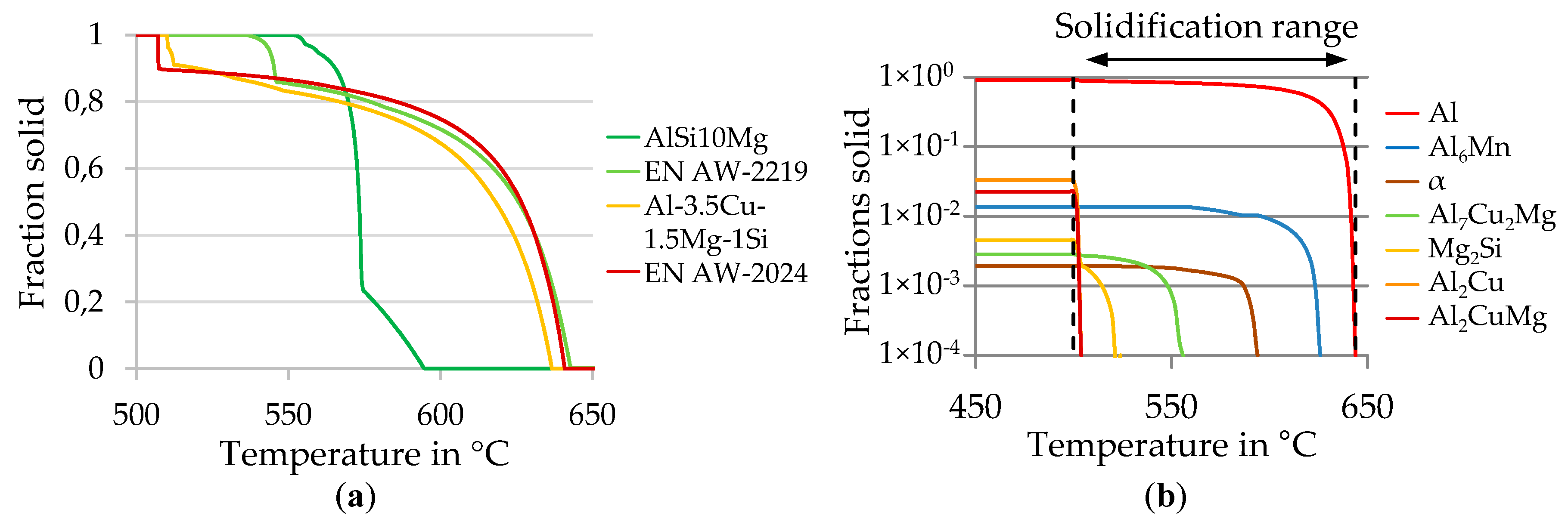

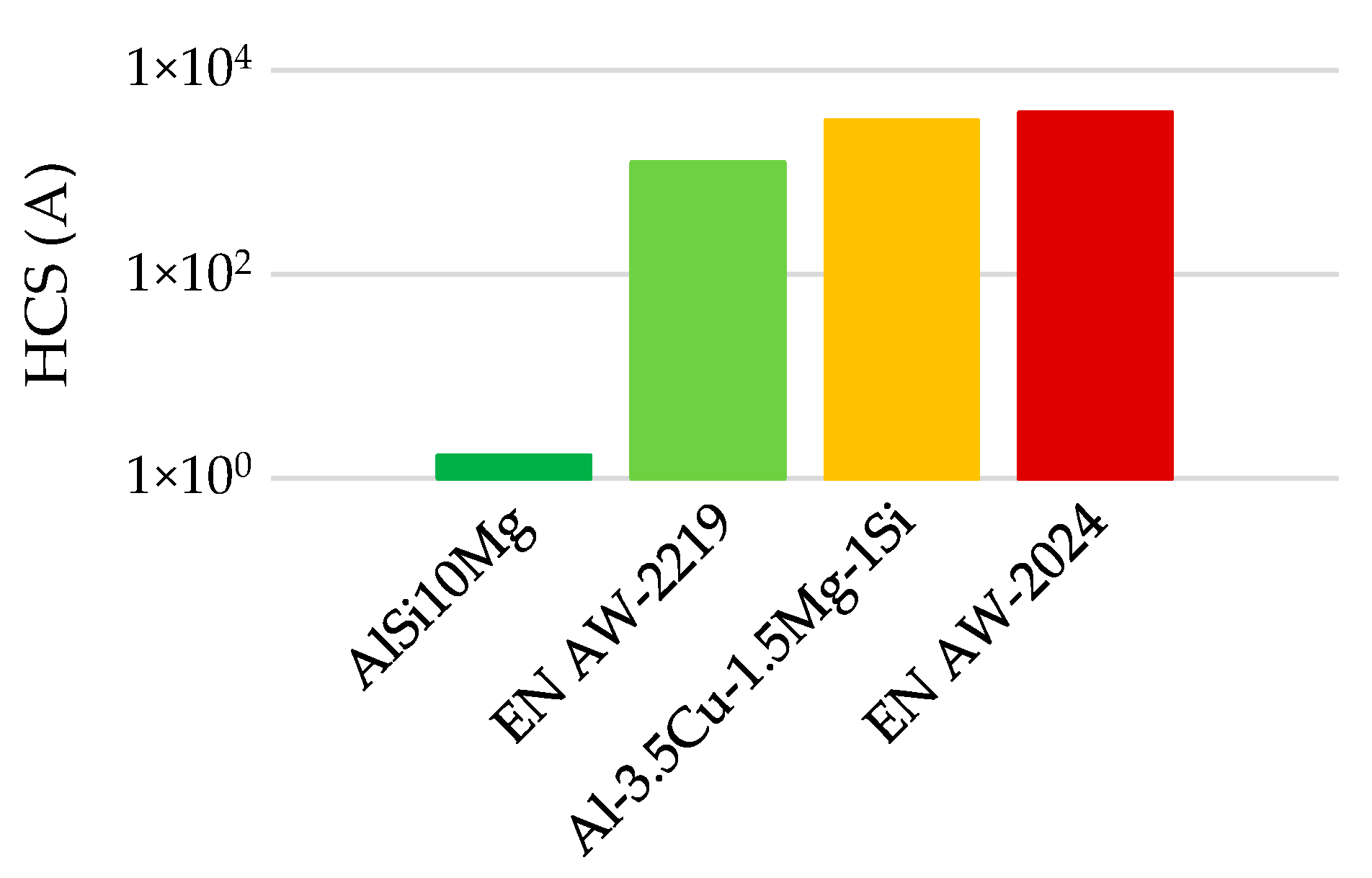

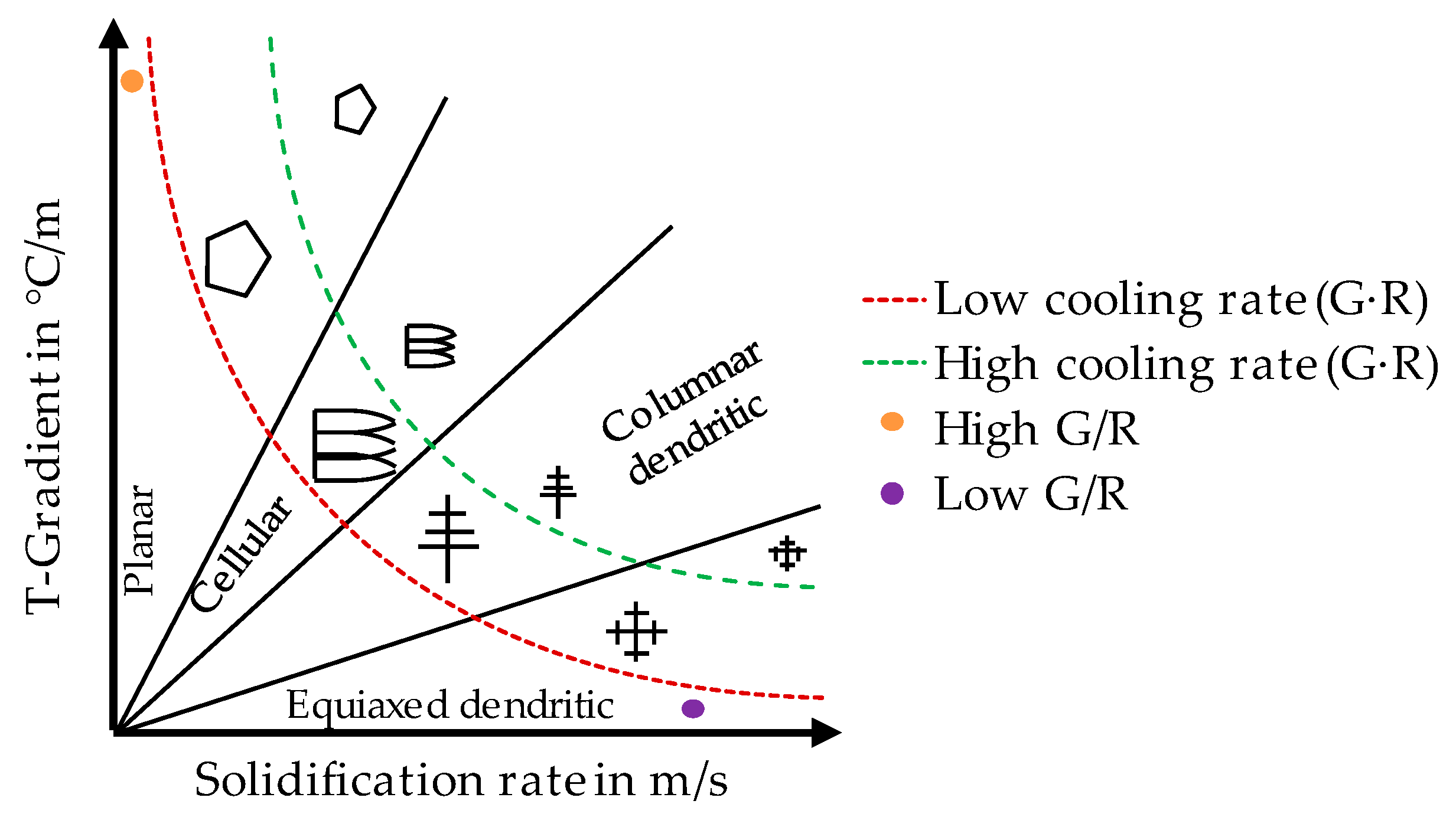

1.3. Metallurgical Properties of Al–Cu Alloys, Hot Tearing Phenomenon Criterion and Grain Morphology

1.4. Aims of the Work

2. Materials and Methods

2.1. Laser Powder Bed Fusion Machine

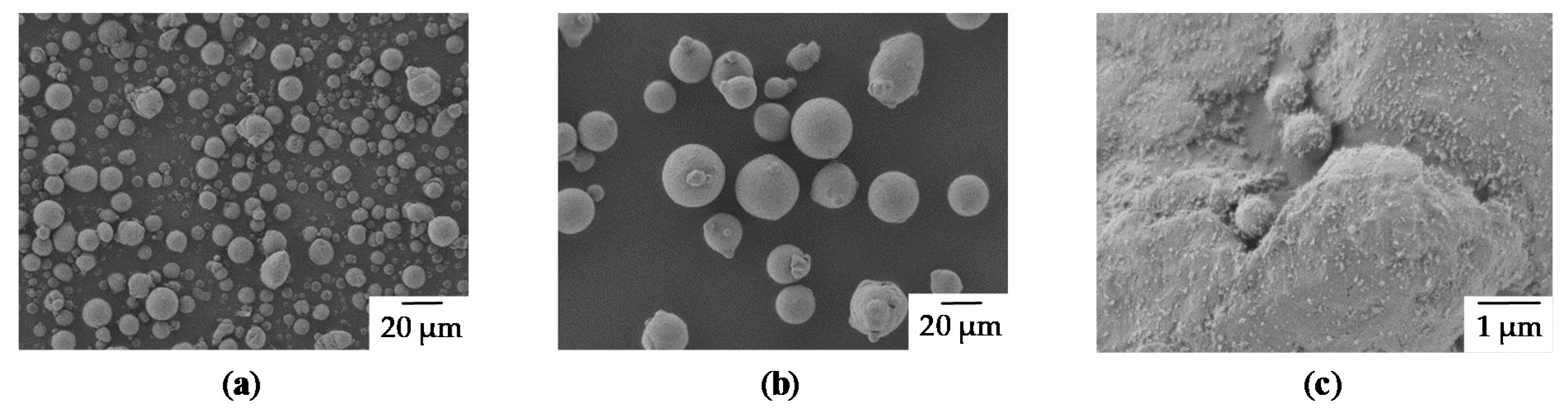

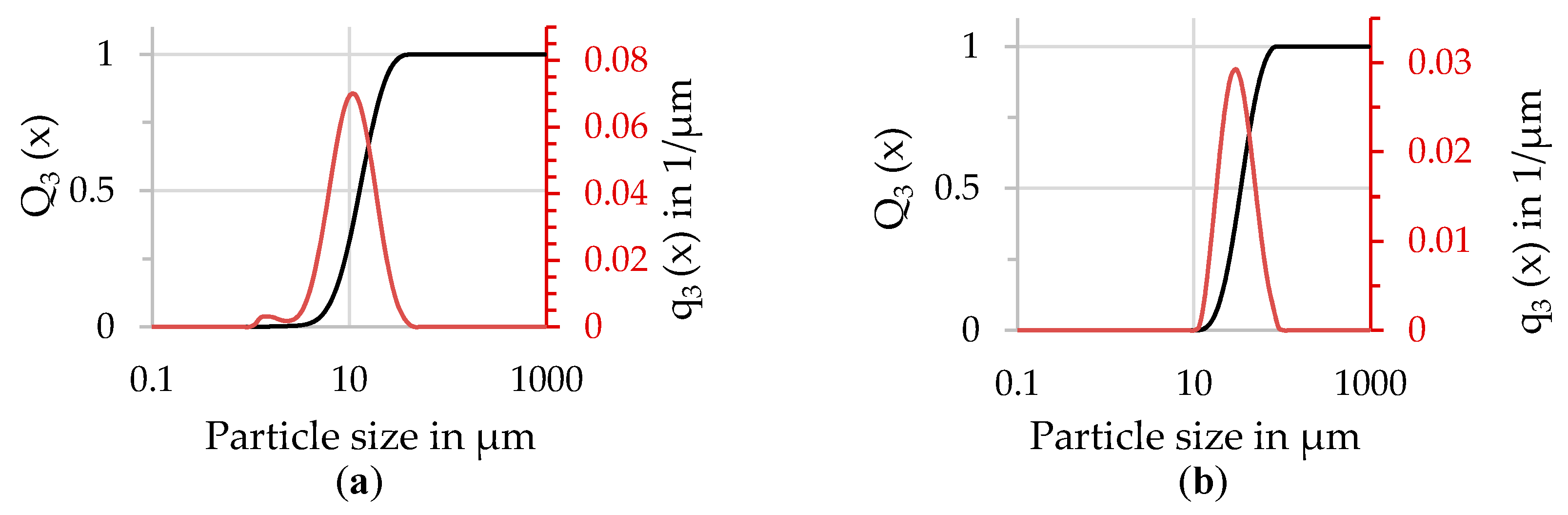

2.2. Powder Material

2.3. Used Parameter Sets

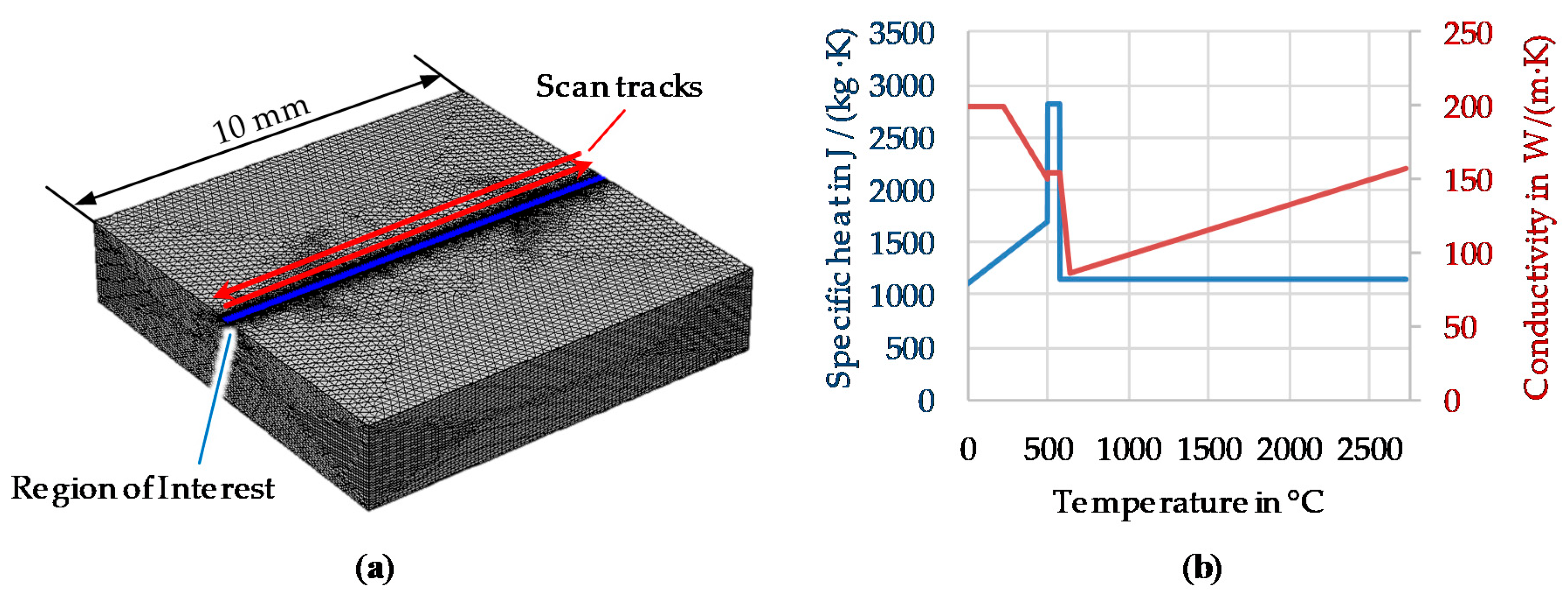

2.4. Simulation Setup

2.5. Characterization

3. Results and Discussion

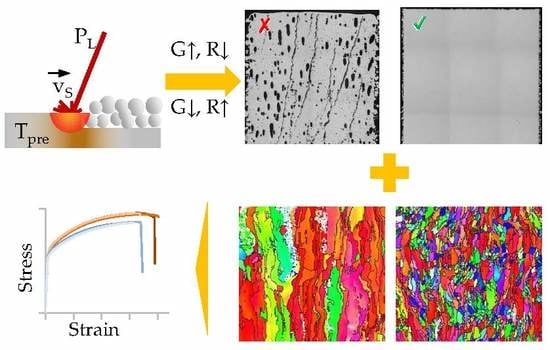

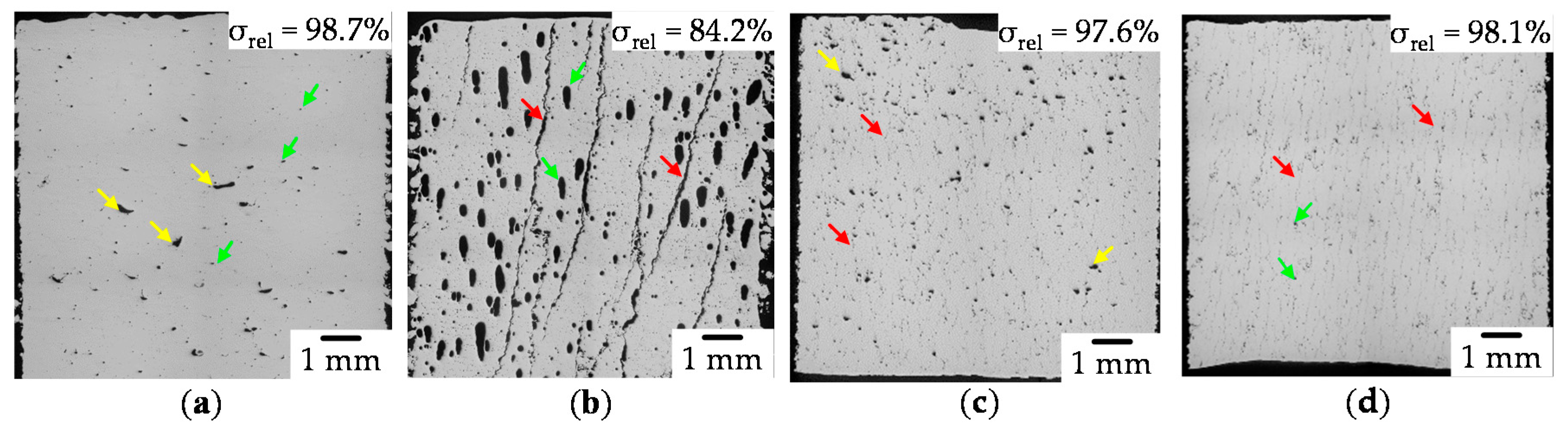

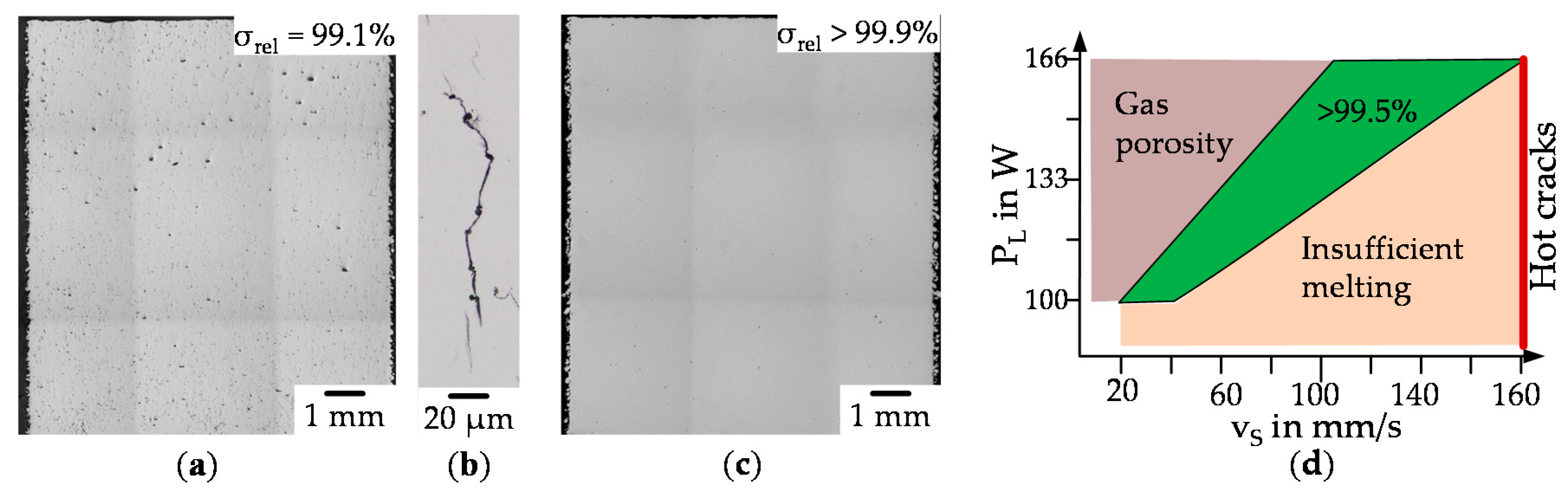

3.1. Process Window

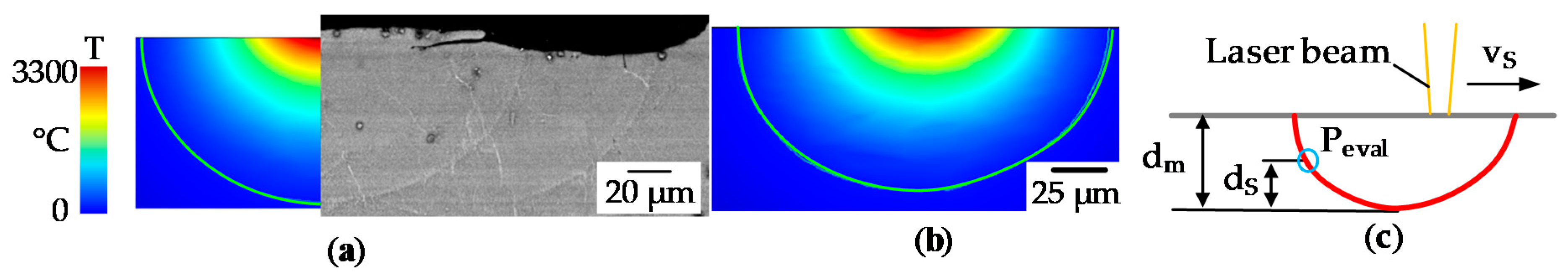

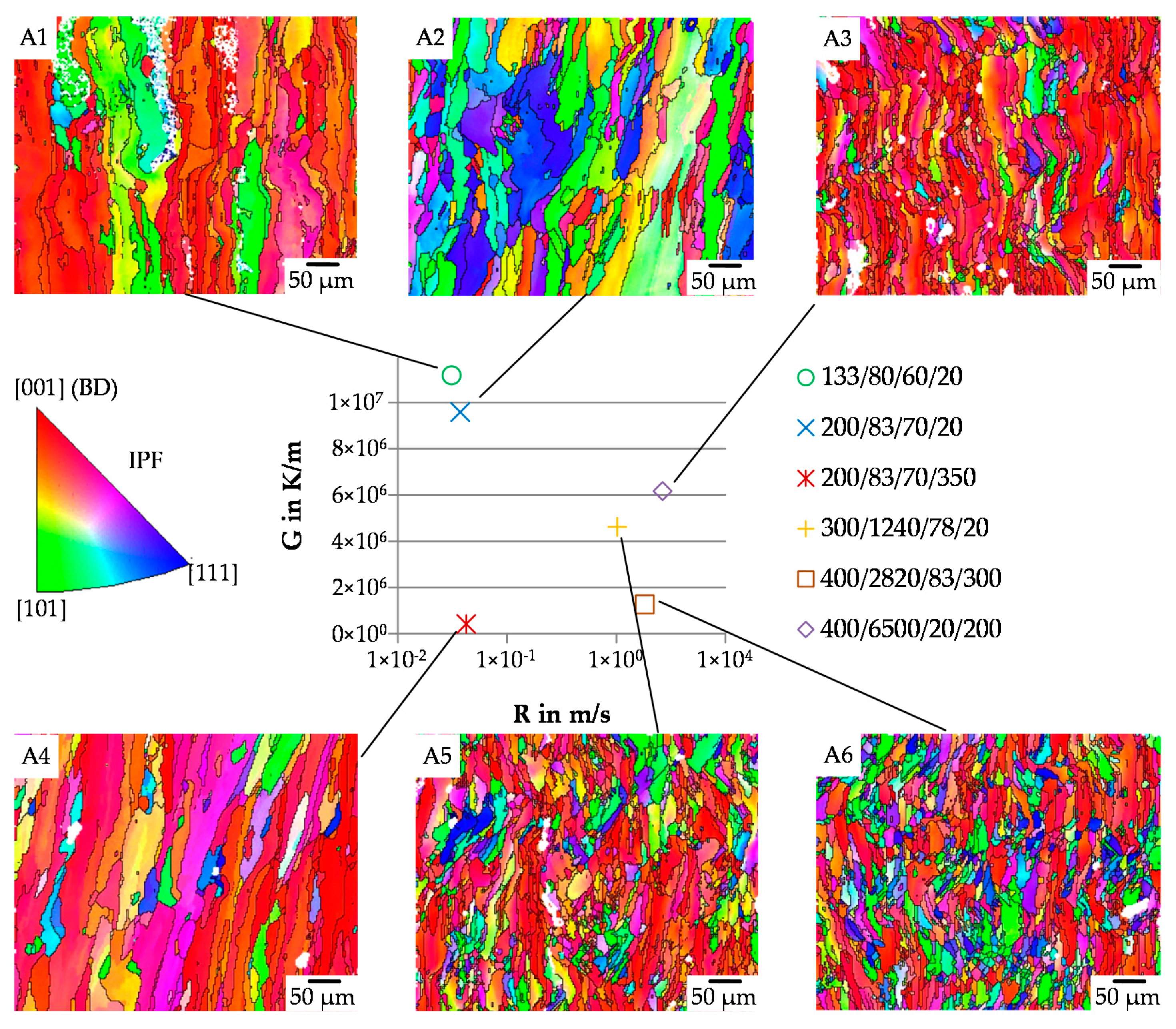

3.2. Simulation Results

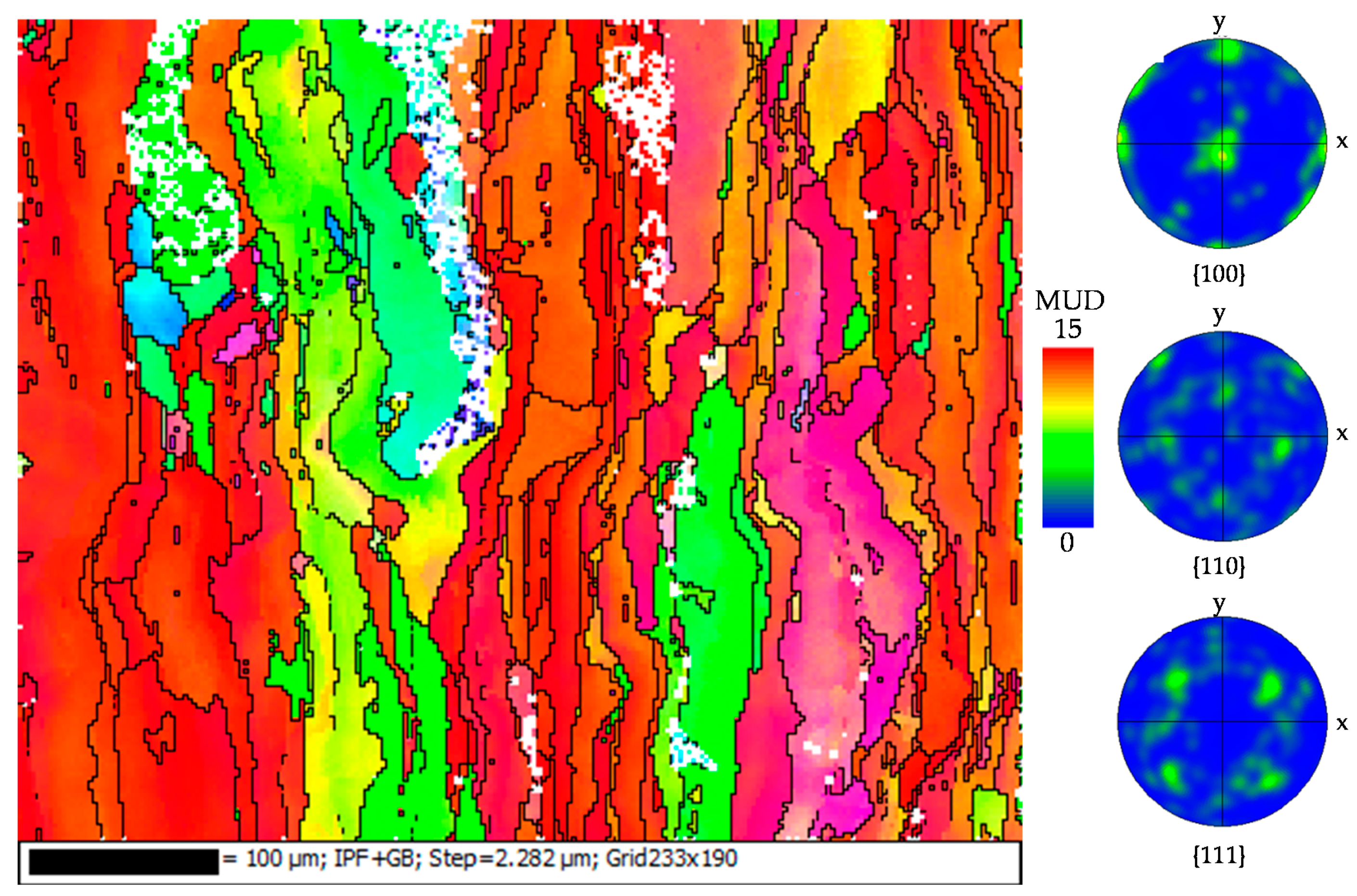

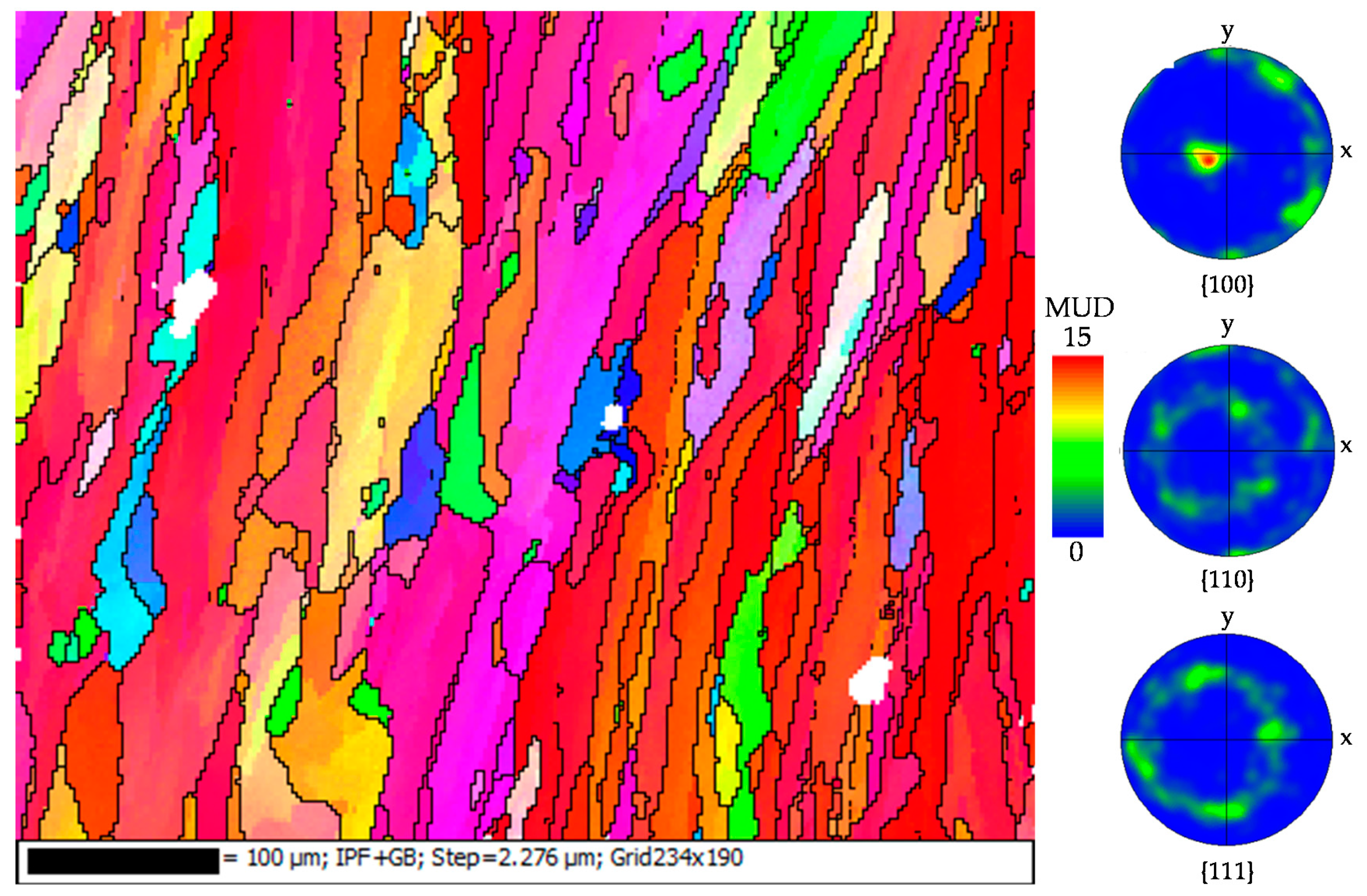

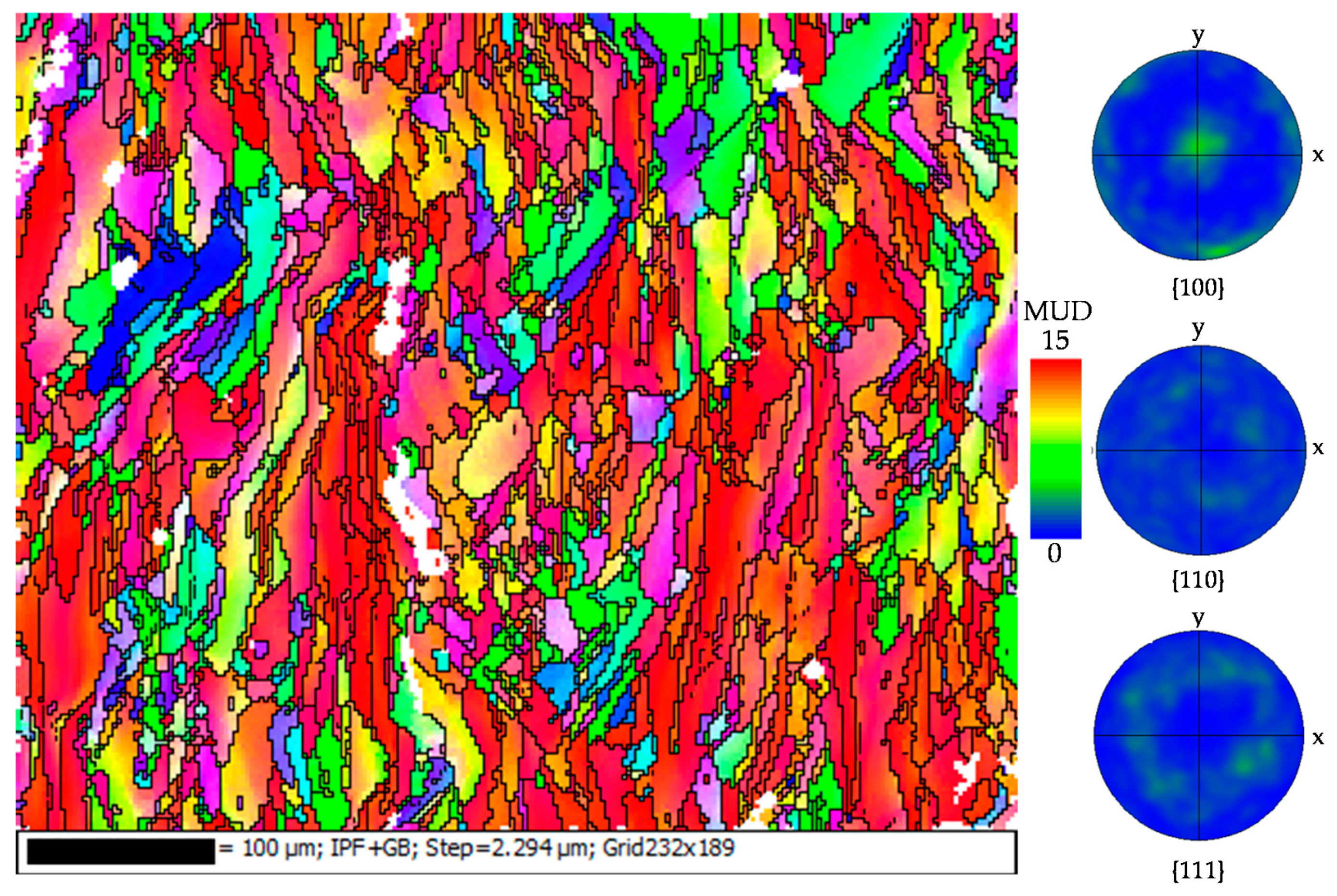

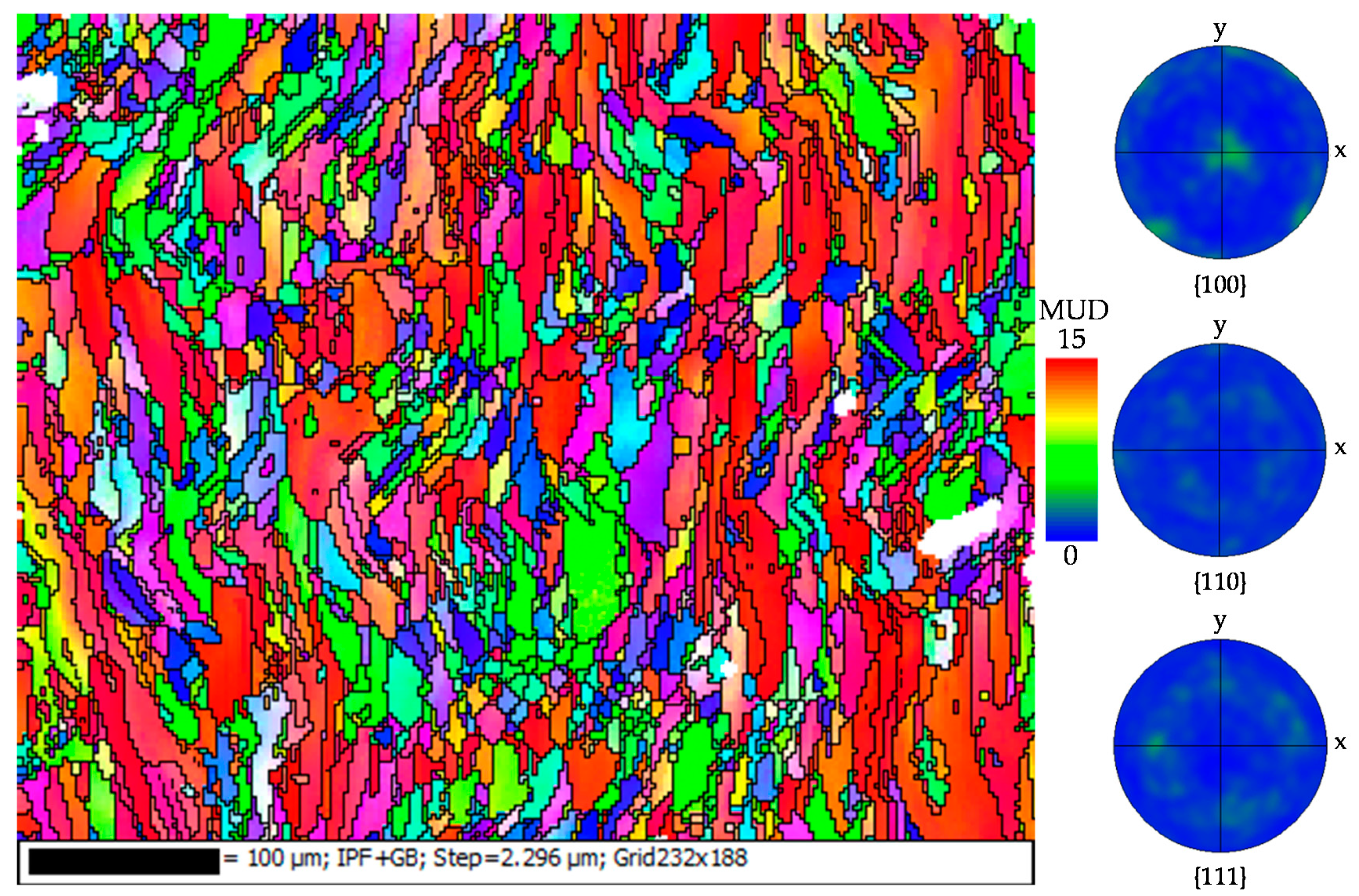

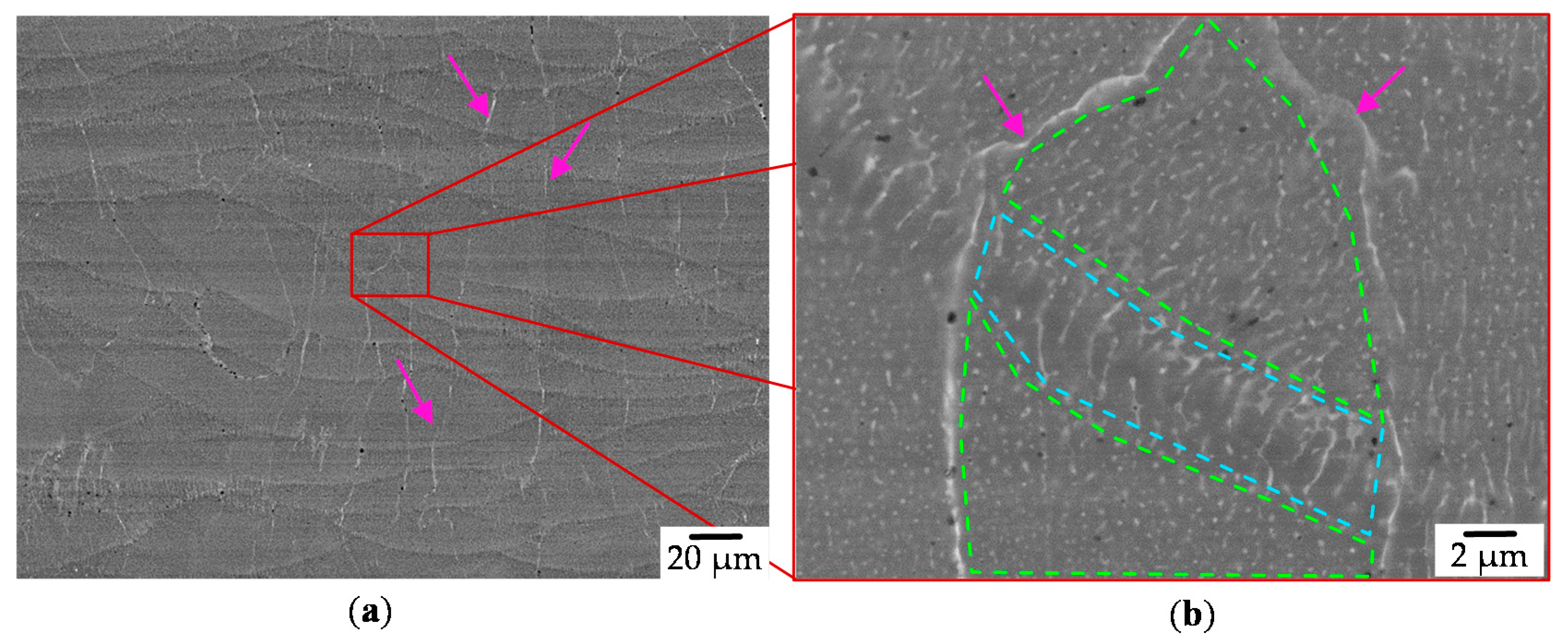

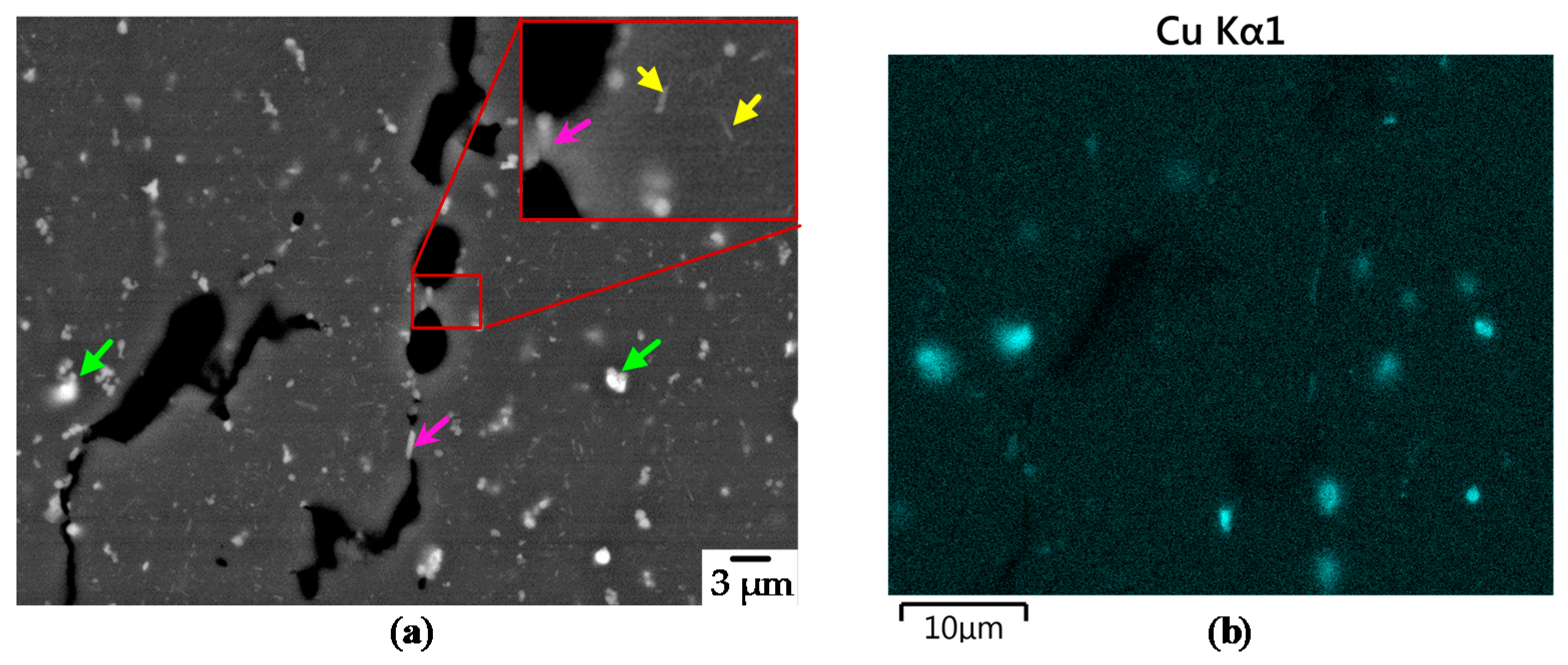

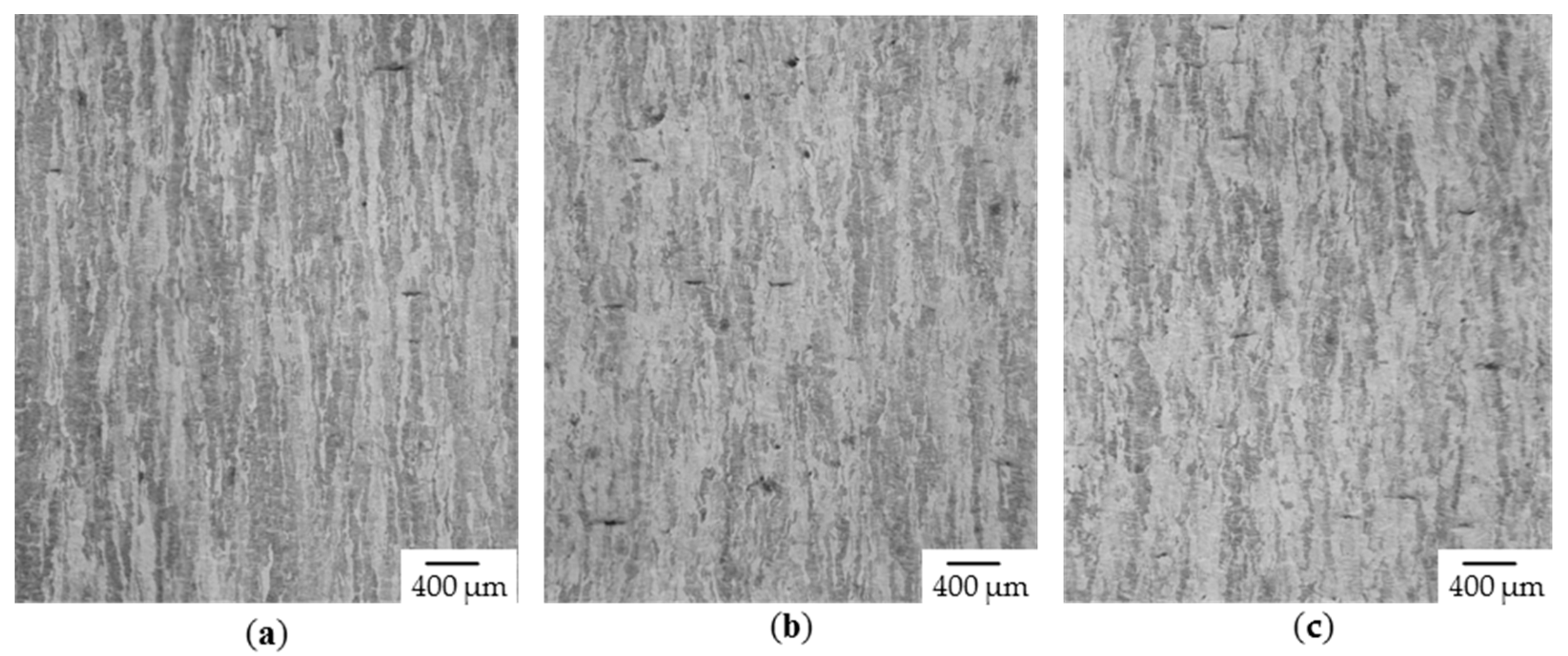

3.3. Microstructure Characterization

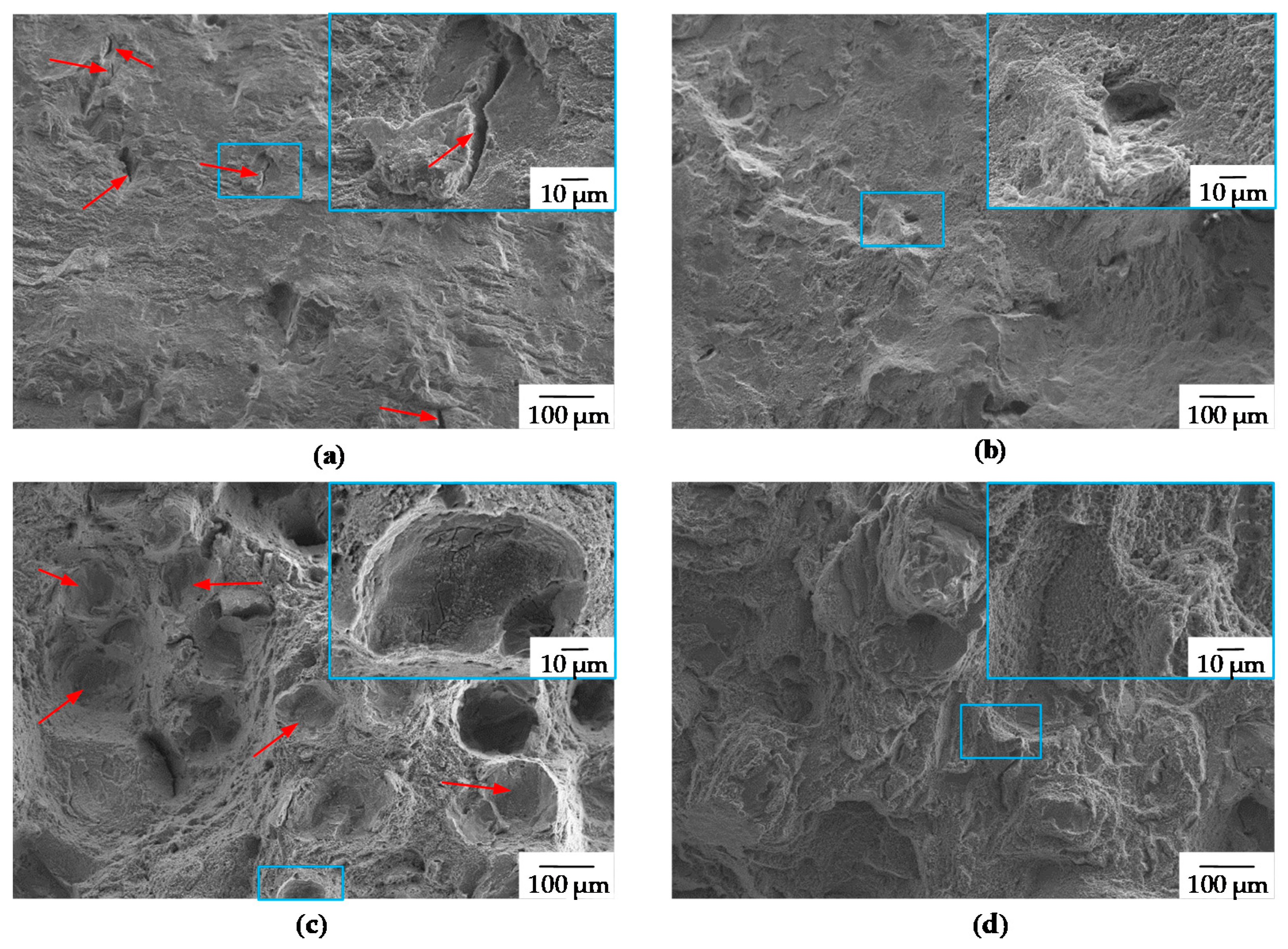

3.4. Mechanical Characterization

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Appendix A

References

- Hull, C.W. Apparatus for Production of Three Dimensional Object by Stereolithography. U.S. Patent No. 4,575,330, 11 March 1986. [Google Scholar]

- Schmidt, M.; Merklein, M.; Bourell, D.; Dimitrov, D.; Hausotte, T.; Wegener, K.; Overmeyer, L.; Vollertsen, F.; Levy, G.N. Laser based additive manufacturing in industry and academia. CIRP Ann. 2017, 66, 561–583. [Google Scholar] [CrossRef]

- Wohlers, T.; Caffrey, T.; Campbell, I. Wohlers Report 2019; Wohler Associates, Inc.: Fort Collins, CO, USA, 2019; ISBN 978-0-9913332-5-7. [Google Scholar]

- ISO. DIN EN ISO/ASTM 52900 Additive Manufacturing—General Principles—Terminology; ISO: Geneva, The Switzerland, 2018. [Google Scholar]

- ISO. DIN EN ISO 17296-2 Additive Manufacturing—General Principles—Part2: Overview of Process Categories and Feedstock; ISO: Geneva, The Switzerland, 2016. [Google Scholar]

- Pauly, S.; Wang, P.; Kühn, U.; Kosiba, K. Experimental determination of cooling rates in selectively laser-melted eutectic Al-33Cu. Addit. Manuf. 2018, 22, 753–757. [Google Scholar] [CrossRef]

- Hooper, P.A. Melt pool temperature and cooling rates in laser powder bed fusion. Addit. Manuf. 2018, 22, 548–559. [Google Scholar] [CrossRef]

- Karg, M.C.H.; Ahuja, B.; Schaub, A.; Schmidt, J.; Sachs, M.; Mahr, A.; Wiesenmayer, S.; Wigner, L.; Wirth, K.-E.; Peukert, W.; et al. Effect of process conditions on mechanical behavior of aluminium wrought alloy EN AW-2618 additively manufactured by Laser Beam Melting in powder bed. In Proceedings of the Lasers in Manufacturing Conference 2015, Munich, Germany, 22–25 June 2015. [Google Scholar]

- Spierings, A.B.; Dawson, K.; Kern, K.; Palm, F.; Wegener, K. SLM-processed Sc- and Zr- modified Al-Mg alloy: Mechanical properties and microstructural effects of heat treatment. Mater. Sci. Eng. A 2017, 701, 264–273. [Google Scholar] [CrossRef]

- Dursun, T.; Soutis, C. Recent developments in advanced aircraft aluminium alloys. Mater. Des. 2014, 56, 862–871. [Google Scholar] [CrossRef]

- Aboulkhair, N.T.; Simonelli, M.; Parry, L.; Ashcroft, I.; Tuck, C.; Hague, R. 3D printing of Aluminium alloys: Additive Manufacturing of Aluminium alloys using selective laser melting. Prog. Mater. Sci. 2019, 106, 100578. [Google Scholar] [CrossRef]

- Karg, M.; Ahuja, B.; Schmidt, M. Processability of High Strength Aluminium-Copper Alloys AW-2022 and 2024 by Laser Beam Melting in Powder Bed. In Proceedings of the 25th Solid Freeform Fabrication Symposium (SFF), Austin, TX, USA, 4 August 2014; pp. 420–436. [Google Scholar]

- Ahuja, B.; Karg, M.; Nagulin, K.Y.; Schmidt, M. Fabrication and characterization of high strength Al-Cu alloys processed using Laser Beam Melting in metal powder bed. In Proceedings of the Physics Procedia, Kobe, Japan, 15–19 September 2014; Volume 56, pp. 135–146. [Google Scholar]

- Karg, M.C.H.; Ahuja, B.; Wiesenmayer, S.; Kuryntsev, S.V.; Schmidt, M. Effects of process conditions on the mechanical behavior of aluminium wrought alloy EN AW-2219 (AlCu6Mn) additively manufactured by laser beam melting in powder bed. Micromachines 2017, 8, 23. [Google Scholar] [CrossRef]

- Zhang, H.; Zhu, H.; Qi, T.; Hu, Z.; Zeng, X. Selective laser melting of high strength Al-Cu-Mg alloys: Processing, microstructure and mechanical properties. Mater. Sci. Eng. A 2016, 656, 47–54. [Google Scholar] [CrossRef]

- DIN. DIN EN 485-2:2018 Aluminium and Aluminium Alloys—Sheet, Strip and Plate—Part 2: Mechanical Properties; DIN: Berlin, Germany, 2018. [Google Scholar]

- Nie, X.; Zhang, H.; Zhu, H.; Hu, Z.; Ke, L.; Zeng, X. Analysis of processing parameters and characteristics of selective laser melted high strength Al-Cu-Mg alloys: From single tracks to cubic samples. J. Mater. Process. Technol. 2018, 256, 69–77. [Google Scholar] [CrossRef]

- Zhang, H.; Zhu, H.; Nie, X.; Yin, J.; Hu, Z.; Zeng, X. Effect of Zirconium addition on crack, microstructure and mechanical behavior of selective laser melted Al-Cu-Mg alloy. Scr. Mater. 2017, 134, 6–10. [Google Scholar] [CrossRef]

- Nie, X.; Zhang, H.; Zhu, H.; Hu, Z.; Ke, L.; Zeng, X. Effect of Zr content on formability, microstructure and mechanical properties of selective laser melted Zr modified Al-4.24Cu-1.97Mg-0.56Mn alloys. J. Alloys Compd. 2018, 764, 977–986. [Google Scholar] [CrossRef]

- Lopez-Botello, O.; Martinez-Hernandez, U.; Ramírez, J.; Pinna, C.; Mumtaz, K. Two-dimensional simulation of grain structure growth within selective laser melted AA-2024. Mater. Des. 2017, 113, 369–376. [Google Scholar] [CrossRef]

- Wang, P.; Gammer, C.; Brenne, F.; Prashanth, K.G.; Mendes, R.G.; Rümmeli, M.H.; Gemming, T.; Eckert, J.; Scudino, S. Microstructure and mechanical properties of a heat-treatable Al-3.5Cu-1.5Mg-1Si alloy produced by selective laser melting. Mater. Sci. Eng. A 2018, 711, 562–570. [Google Scholar] [CrossRef]

- Wang, P.; Deng, L.; Prashanth, K.G.; Pauly, S.; Eckert, J.; Scudino, S. Microstructure and mechanical properties of Al-Cu alloys fabricated by selective laser melting of powder mixtures. J. Alloys Compd. 2018, 735, 2263–2266. [Google Scholar] [CrossRef]

- Karg, M.C.H.; Rasch, M.; Schmidt, K.; Spitzer, S.A.E.; Karsten, T.F.; Schlaug, D.; Biaciu, C.-R.; Gorunov, A.I.; Schmidt, M. Laser alloying advantages by dry coating metallic powder mixtures with SiOx nanoparticles. Nanomaterials 2018, 8, 862. [Google Scholar] [CrossRef]

- Campbell, J. Structure, defects and properties of the finished casting. In Castings; Elsevier: Amsterdam, The Netherlands, 2003; pp. 267–305. [Google Scholar]

- Manitsas, D.; Andersson, J. Hot Cracking Mechanisms in Welding Metallurgy: A Review of Theoretical Approaches. MATEC Web Conf. 2018, 188, 1–8. [Google Scholar] [CrossRef]

- Clyne, T.W.; Davies, G.J. Quantitative Solidification Cracking Test for Castings and an Evaluation of Cracking in Aluminium-Magnesium Alloys. Br. Foundrym. 1975, 68, 238–244. [Google Scholar]

- Rappaz, M.; Drezet, J.M.; Gremaud, M. A new hot-tearing criterion. Metall. Mater. Trans. A Phys. Metall. Mater. Sci. 1999, 30, 449–455. [Google Scholar] [CrossRef]

- Drezet, J.M.; Allehaux, D. Application of the rappaz-drezet-gremaud hot tearing criterion to welding of aluminium alloys. In Hot Cracking Phenomena in Welds I; Spinger-Verlag: Berlin, Germany, 2008; pp. 19–37. [Google Scholar]

- Taylor, J.A.; Grandfield, J.F.; Prasad, A. (Eds.) Aluminium Cast House Technology XI; Trans Tech Publications Ltd.: Zürich, Switzerland, 2010; Volume 630, ISBN 0878493166. [Google Scholar]

- Kou, S. Welding Metallurgy, 2nd ed.; Wiley-Interscience: New York, NY, USA, 2002; Volume 4, ISBN 3175723993. [Google Scholar]

- Norman, A.F.; Ducharme, R.; Mackwood, A.; Kapadia, P.; Prangnell, P.B. Application of thermal modelling to laser beam welding of aluminium alloys. Sci. Technol. Weld. Join. 1998, 3, 260–266. [Google Scholar] [CrossRef]

- Ghosh, S.; Ma, L.; Ofori-Opoku, N.; Guyer, J.E. On the primary spacing and microsegregation of cellular dendrites in laser deposited Ni-Nb alloys. Model. Simul. Mater. Sci. Eng. 2017, 25, 065002. [Google Scholar] [CrossRef]

- Easton, M.; Sweet, L.; Wang, H.; Grandfield, J.; Davidson, C.J.; Stjohn, D.H.; Couper, M.J. Observation and prediction of the hot tear susceptibility of ternary Al-Si-Mg alloys. Metall. Mater. Trans. A Phys. Metall. Mater. Sci. 2012, 43, 3227–3238. [Google Scholar] [CrossRef]

- Otto Fuchs KG AlCu4Mg1—FUCHS AK24/25. Available online: https://www.otto-fuchs.com/fileadmin/user_upload/Infocenter/Werkstoffinformationen/Al-Datenblaetter/AK24-25.pdf (accessed on 29 September 2019).

- Karg, M.C.H.; Munk, A.; Ahuja, B.; Backer, M.V.; Schmitt, J.P.; Stengel, C.; Kuryntsev, S.V.; Schmidt, M. Expanding particle size distribution and morphology of aluminium-silicon powders for Laser Beam Melting by dry coating with silica nanoparticles. J. Mater. Process. Technol. 2019, 264, 155–171. [Google Scholar] [CrossRef]

- BSI. EN 573-3:2019 Aluminium and Aluminium Alloys—Chemical Composition and Form of Wrought Products—Part 3: Chemical Composition and Form of Products; BSI: London, UK, 2019. [Google Scholar]

- Cross, C.E. On the Origin of Weld Solidification Cracking. In Hot Cracking Phenomena in Welds; Bölinghaus, T., Herold, H., Eds.; Springer-Verlag: Berlin, Germany, 2005; pp. 3–18. ISBN 9788578110796. [Google Scholar]

- Comsol, A.B. Heat Transfer Module User´s Guide V5.4; Comsol, Inc.: Burlington, NJ, USA, 2018; p. 274. [Google Scholar]

- Promoppatum, P.; Yao, S.C.; Pistorius, P.C.; Rollett, A.D. A Comprehensive Comparison of the Analytical and Numerical Prediction of the Thermal History and Solidification Microstructure of Inconel 718 Products Made by Laser Powder-Bed Fusion. Engineering 2017, 3, 685–694. [Google Scholar] [CrossRef]

- Caiazzo, F.; Alfieri, V. Simulation of Laser Heating of Aluminum and Model validation via Two-Color Pyrometer and Shape Assessment. Materials 2018, 11, 1506. [Google Scholar] [CrossRef] [PubMed]

- Guo, Z.; Saunders, N.; Miodownik, A.P.; Schillé, J.P. Modelling of materials properties and behaviour critical to casting simulation. Mater. Sci. Eng. A 2005, 413–414, 465–469. [Google Scholar] [CrossRef]

- Elmer, J.W.; Giedt, W.H.H.; Eagar, T.W. The transition from shallow to deep penetration weld—Eagar095 1990. Weld. Res. Suppl. 1990, 69, 167–176. [Google Scholar]

- Otsu, N. A Threshold Selection Method from Gray-Levl Histograms. Trans. Syst. Man Cybern. 1979, 9, 62–66. [Google Scholar] [CrossRef]

- VDI. VDI 3405 VDI 3405 PART 2—Beam Melting of Metallic Parts, Qualification, Quality Assurance and Post Processing; VDI: Düsseldorf, Germany, 2013; pp. 2–3. [Google Scholar]

- ISO. DIN EN ISO 6892-1:2019 Metallic Materials—Tensile Testing—Part 1: Method of Test at Room Temperature (ISO/FDIS 6892-1:2019); ISO: Geneva, Switzerland, 2019. [Google Scholar]

- Zhang, B.; Li, Y.; Bai, Q. Defect Formation Mechanisms in Selective Laser Melting: A Review. Chin. J. Mech. Eng. 2017, 30, 515–527. [Google Scholar] [CrossRef]

- Cunningham, R.; Zhao, C.; Parab, N.; Kantzos, C.; Pauza, J.; Fezzaa, K.; Sun, T.; Rollett, A.D. Keyhole threshold and morphology in laser melting revealed by ultrahigh-speed x-ray imaging. Science 2019, 363, 849–852. [Google Scholar] [CrossRef]

- Al-Bermani, S.S.; Blackmore, M.L.; Zhang, W.; Todd, I. The origin of microstructural diversity, texture, and mechanical properties in electron beam melted Ti-6Al-4V. Metall. Mater. Trans. A Phys. Metall. Mater. Sci. 2010, 41, 3422–3434. [Google Scholar] [CrossRef]

- Helmer, H.; Bauereiß, A.; Singer, R.F.; Körner, C. Grain structure evolution in Inconel 718 during selective electron beam melting. Mater. Sci. Eng. A 2016, 668, 180–187. [Google Scholar] [CrossRef]

- Yan, X.Y.; Chang, Y.A.; Xie, F.Y.; Chen, S.L.; Zhang, F.; Daniel, S. Calculated phase diagrams of aluminum alloys from binary Al-Cu to multicomponent commercial alloys. J. Alloys Compd. 2001, 320, 151–160. [Google Scholar] [CrossRef]

- Gharbi, O.; Jiang, D.; Feenstra, D.R.; Kairy, S.K.; Wu, Y.; Hutchinson, C.R.; Birbilis, N. On the corrosion of additively manufactured aluminium alloy AA2024 prepared by selective laser melting. Corros. Sci. 2018, 143, 93–106. [Google Scholar] [CrossRef]

- Ostermann, F. Anwendungstechnologie Aluminium; Springer-Verlag: Berlin, Germany, 2014; ISBN 9783662438060. [Google Scholar]

| Mechanical Properties | O | T3 | T4 | T62 |

|---|---|---|---|---|

| Yield Strength (MPa) | <140 | >290 | >275 | 345 |

| UTS (MPa) | <220 | >435 | >425 | 435 |

| A (%) | >13 | >14 | >13 | 5 |

| Material | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Other | Al |

|---|---|---|---|---|---|---|---|---|---|---|

| EN AW-2024 [36] | 0.5 | 0.5 | 3.8–4.9 | 0.3–0.9 | 1.2–1.8 | 0.1 | 0.25 | 0.15 | á 0.05, tot. 0.15 | balance |

| Raw powder | 0.17 | 0.1 | 3.78 | 0.66 | 1.33 | 0.00 | 0.02 | 0.00 | - | balance |

| PBF-LB/EN AW-2024 | 0.12 | 0.08 | 3.82 | 0.63 | 1.25 | 0.00 | 0.00 | 0.00 | - | balance |

| Set | PL (W) | vs (mm/s) | Δy (µm) | dS (µm) | Tpre (°C) | G (K/m) | R (m/s) | GxR (K/s) | G/R (K·s/m²) |

|---|---|---|---|---|---|---|---|---|---|

| 1 | 200 | 83–180 | 70 | 40 | 20 | ∙∙∙ | ∙∙ | ∙∙ | ∙∙∙ |

| 2 | 200 | 83–200 | 70 | 40 | 350 | ∙ | ∙ | ∙ | ∙ |

| 3 | 300, 400 | 580–1240 | 76–170 | 50 | 20 | ∙∙∙∙ | ∙∙∙ | ∙∙∙∙ | ∙∙ |

| 4 | 400 | 1560–2940 | 47–159 | 50 | 300 | ∙∙ | ∙∙∙∙ | ∙∙∙ | ∙ |

| Set | PL (W) | vs (mm/s) | Δy (µm) | dS (µm) | Tpre (°C) | G (K/m) | R (m/s) | GxR (K/s) | G/R (K·s/m²) |

|---|---|---|---|---|---|---|---|---|---|

| 5 | 400 | 3500–9000 | 20–60 | 20 | 200 | ∙∙∙∙ | ∙∙∙∙ | ∙∙∙∙ | ∙∙∙ |

| 6 | 100, 133, 166 | 20–160 | 60–170 | 20 | 20 | ∙∙∙ | ∙∙ | ∙∙∙ | ∙∙∙ |

| Sample | PL W | vs mm/s | Δy µm | Tpre °C | dm,ex µm | dm,sim µm | RL - | G K/m | R m/s | GxR K/s | G/R K·s/m² |

|---|---|---|---|---|---|---|---|---|---|---|---|

| A1 | 133 | 80 | 60 | 20 | 76 | 75 | 0.70 | 1.1 × 107 | 3.1 × 10−2 | 3.5 × 105 | 3.6 × 108 |

| A2 | 200 | 83 | 70 | 20 | 86 | 89 | 0.74 | 9.6 × 106 | 3.8 × 10−2 | 3.6 × 105 | 2.6 × 108 |

| A3 | 400 | 6500 | 200 | 200 | 27 | 27 | 0.87 | 6.2 × 106 | 2.7 | 1.6 × 107 | 2.3 × 106 |

| A4 | 200 | 83 | 70 | 350 | - | 268 | 0.74 | 4.1 × 105 | 4.3 × 10−2 | 1.8 × 104 | 9.7 × 106 |

| A5 | 300 | 1240 | 78 | 20 | 53 | 55 | 0.86 | 4.6 × 106 | 1.0 | 4.7 × 106 | 4.5 × 106 |

| A6 | 400 | 2820 | 83 | 300 | 56 | 58 | 0.87 | 1.3 × 106 | 1.8 | 2.3 × 106 | 6.9 × 105 |

| Property | Present Work | Zhang [15] | Wang [22] | Wrought [16] | ||||

|---|---|---|---|---|---|---|---|---|

| Orientation | hor. | ver. | hor. | ver. | hor. | ver. | ver. | - |

| Heat-treatment | a. b. | a. b. | T4 | T4 | a. b. | a. b. | T6 | T4 |

| Chem. in range | yes | no | no | yes | ||||

| Rp0.2 in MPa | 227 ± 1 | 212 ± 0 | 295 ± 3 | 277 ± 5 | 276.2 ± 41 | 223 ± 4 | 368 ± 6 | >275 |

| Rm in MPa | 387 ± 1 | 318 ± 2 | 478 ± 3 | 433 ± 4 | 402.4 ± 9.5 | 366 ± 7 | 455 ± 10 | >425 |

| A in % | 18.1 ± 0.7 | 7.3 ± 6 | 18.3 ± 1.7 | 14.6 ± 2.6 | 6 ± 1.4 | 5.3 ± 0.3 | 6.2 ± 1.8 | >14 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rasch, M.; Heberle, J.; Dechet, M.A.; Bartels, D.; Gotterbarm, M.R.; Klein, L.; Gorunov, A.; Schmidt, J.; Körner, C.; Peukert, W.; et al. Grain Structure Evolution of Al–Cu Alloys in Powder Bed Fusion with Laser Beam for Excellent Mechanical Properties. Materials 2020, 13, 82. https://doi.org/10.3390/ma13010082

Rasch M, Heberle J, Dechet MA, Bartels D, Gotterbarm MR, Klein L, Gorunov A, Schmidt J, Körner C, Peukert W, et al. Grain Structure Evolution of Al–Cu Alloys in Powder Bed Fusion with Laser Beam for Excellent Mechanical Properties. Materials. 2020; 13(1):82. https://doi.org/10.3390/ma13010082

Chicago/Turabian StyleRasch, Michael, Johannes Heberle, Maximilian A. Dechet, Dominic Bartels, Martin R. Gotterbarm, Lukas Klein, Andrey Gorunov, Jochen Schmidt, Carolin Körner, Wolfgang Peukert, and et al. 2020. "Grain Structure Evolution of Al–Cu Alloys in Powder Bed Fusion with Laser Beam for Excellent Mechanical Properties" Materials 13, no. 1: 82. https://doi.org/10.3390/ma13010082

APA StyleRasch, M., Heberle, J., Dechet, M. A., Bartels, D., Gotterbarm, M. R., Klein, L., Gorunov, A., Schmidt, J., Körner, C., Peukert, W., & Schmidt, M. (2020). Grain Structure Evolution of Al–Cu Alloys in Powder Bed Fusion with Laser Beam for Excellent Mechanical Properties. Materials, 13(1), 82. https://doi.org/10.3390/ma13010082