The Linear Hygroscopic Expansion Coefficient of Cement-Based Materials and Its Determination

Abstract

1. Introduction

2. CHE of Cement-Based Materials

2.1. Definition of CHE

2.2. Theoretical Derivation of CHE of Cement Based Materials

2.3. Rationality and Effectiveness of the Proposed CHE

3. Determination of LCHE by Inversion Method

3.1. The Inversion Method

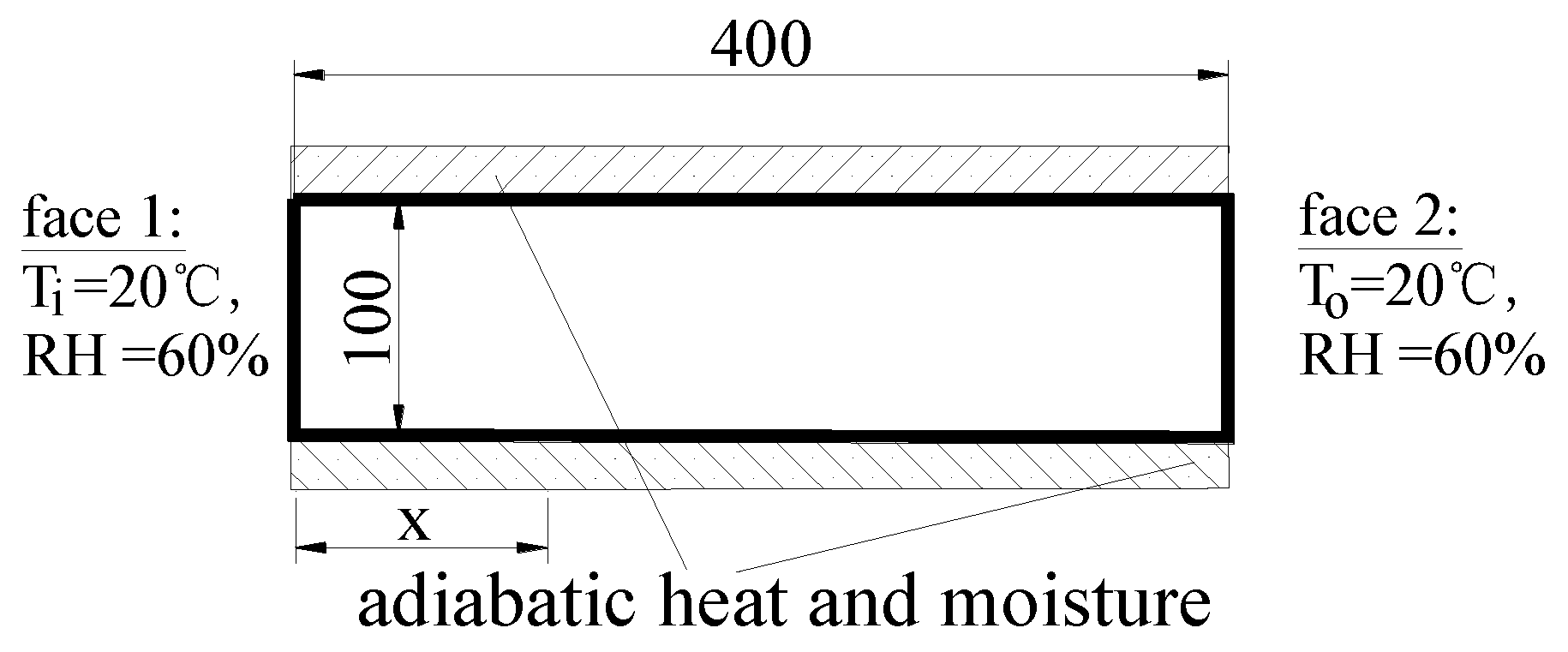

3.2. Drying Shrinkage Test

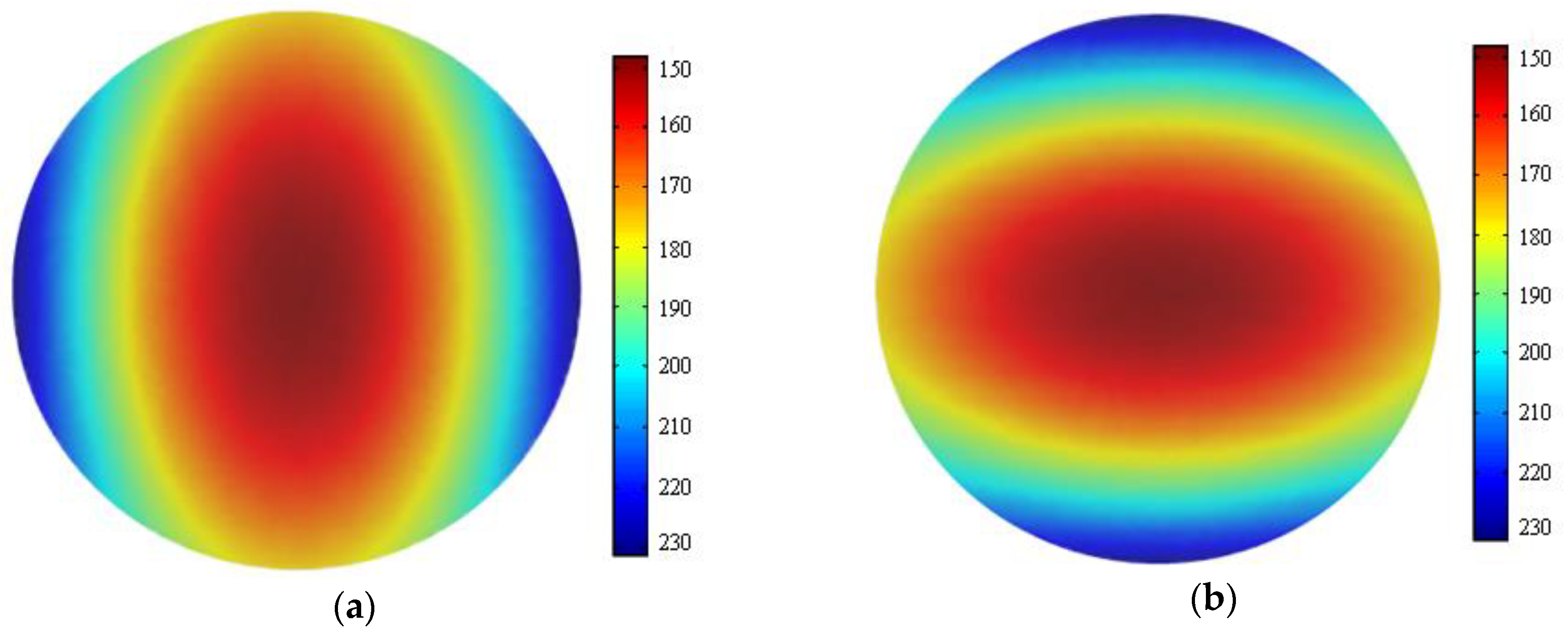

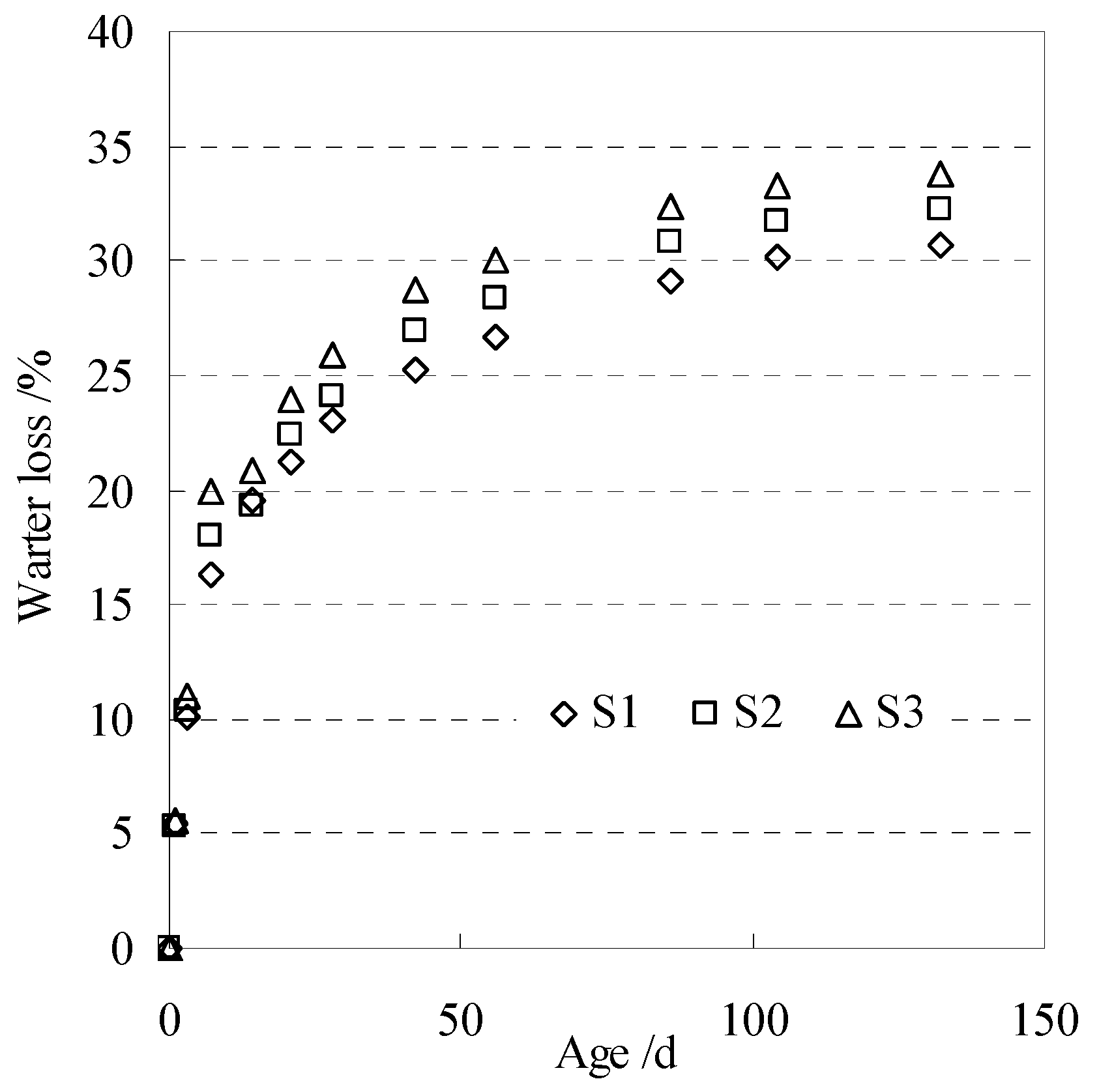

3.3. The Finite Element Analysis

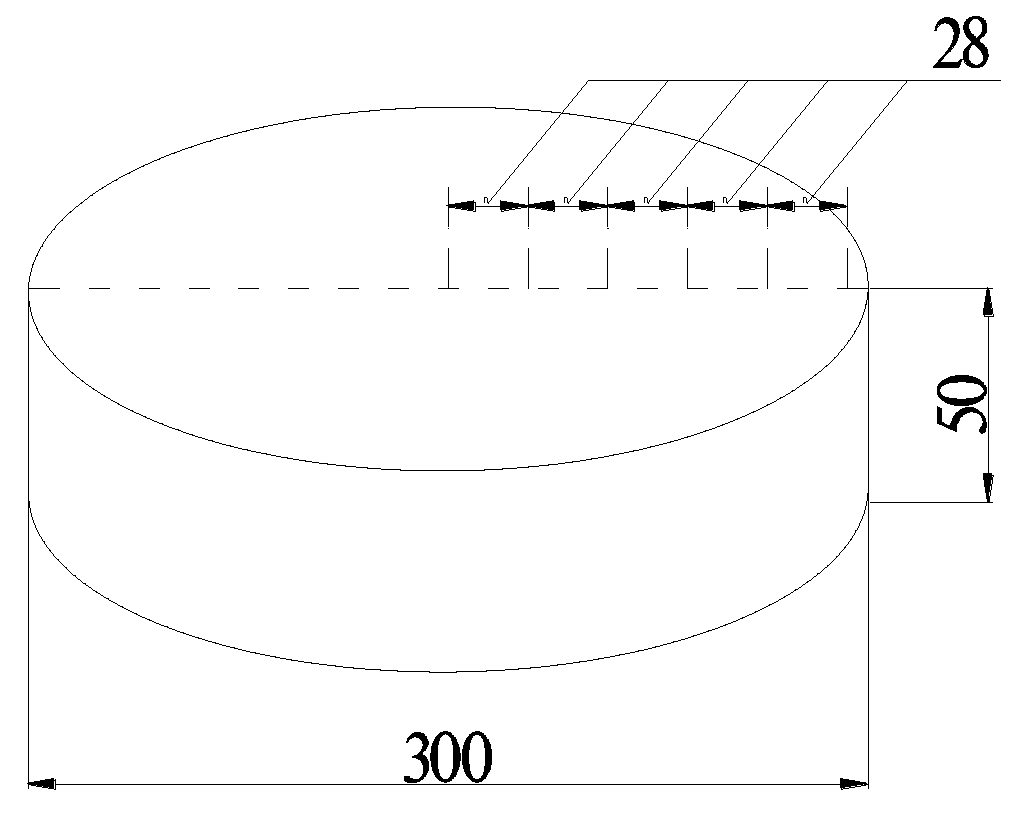

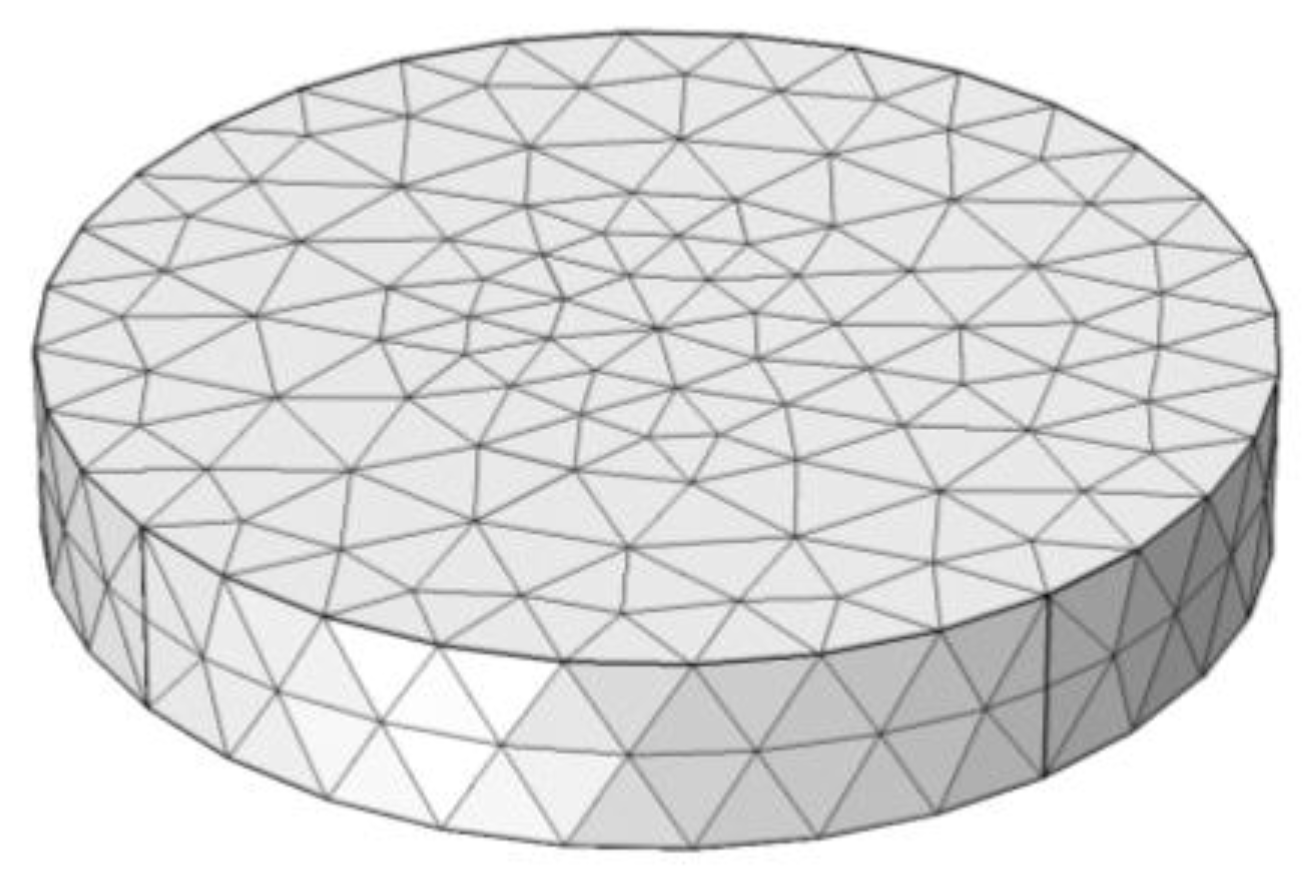

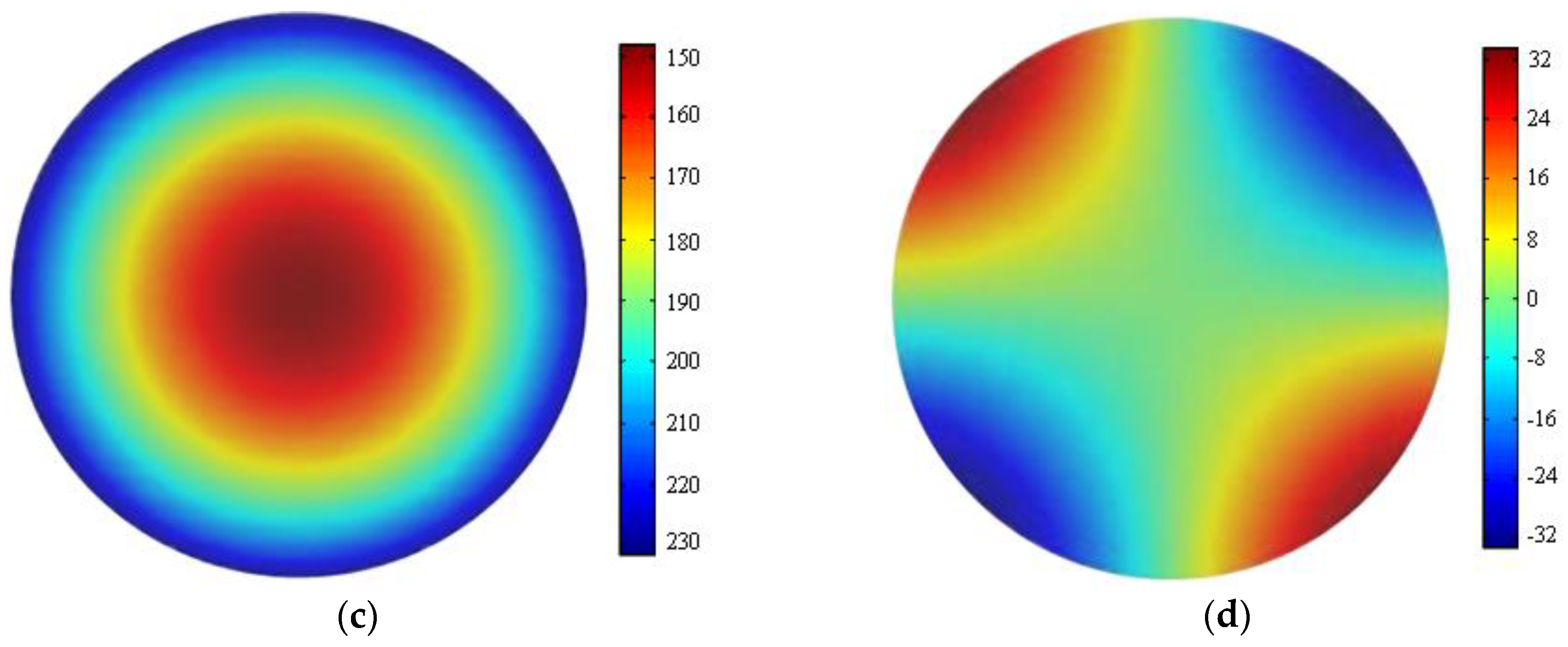

3.3.1. Finite Element Model

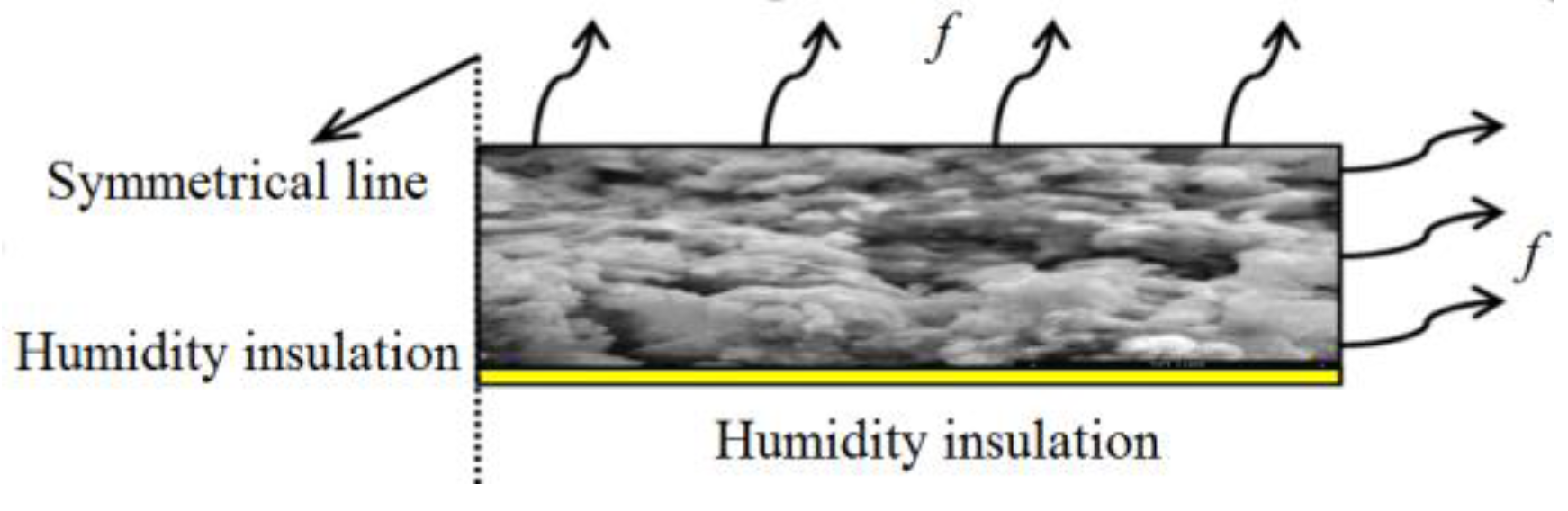

3.3.2. Boundary Conditions

3.3.3. Initial Conditions

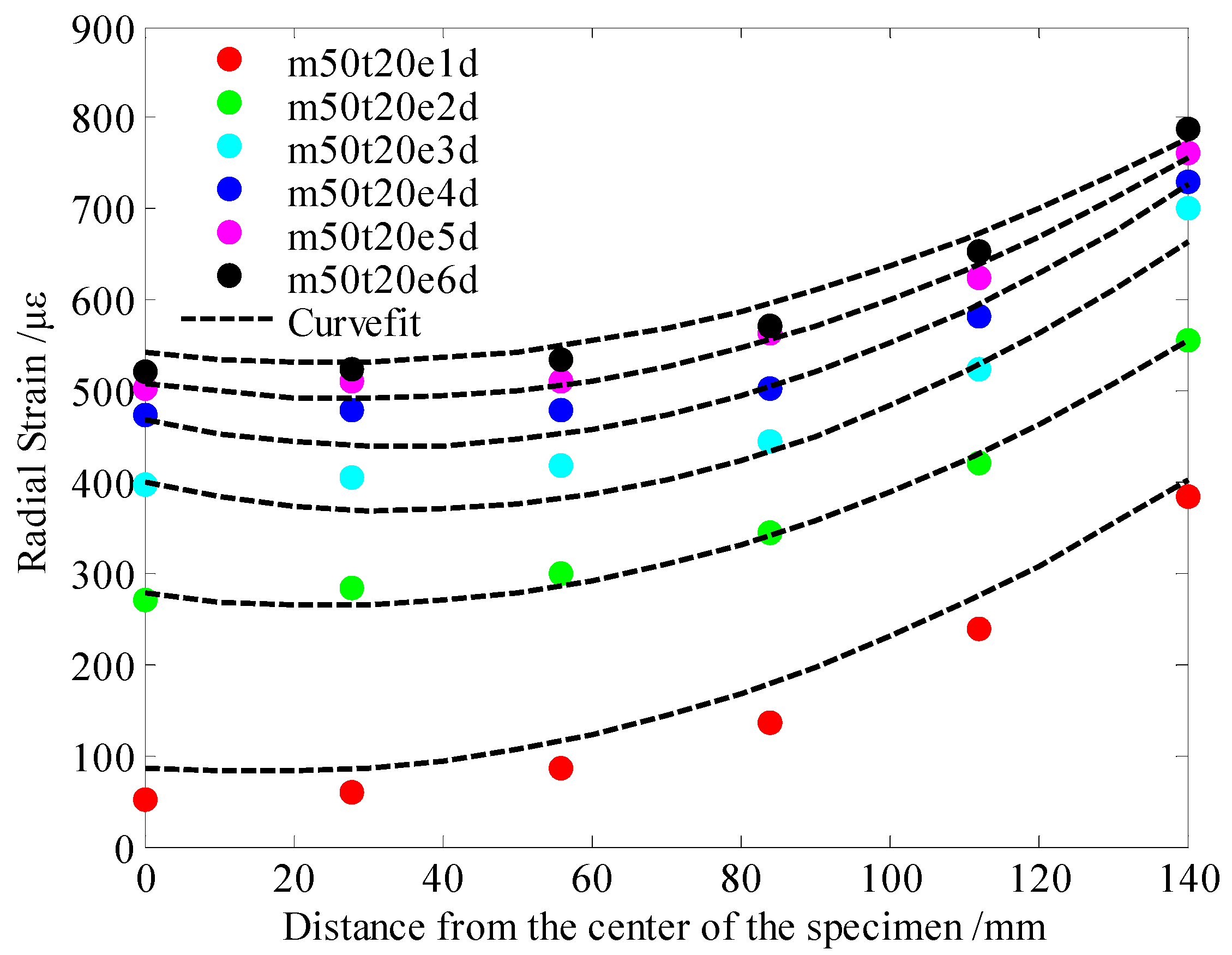

3.4. Inversion Analysis

4. Case Analysis on the Application of LCHE

4.1. Indoor Dry Shrinkage Test

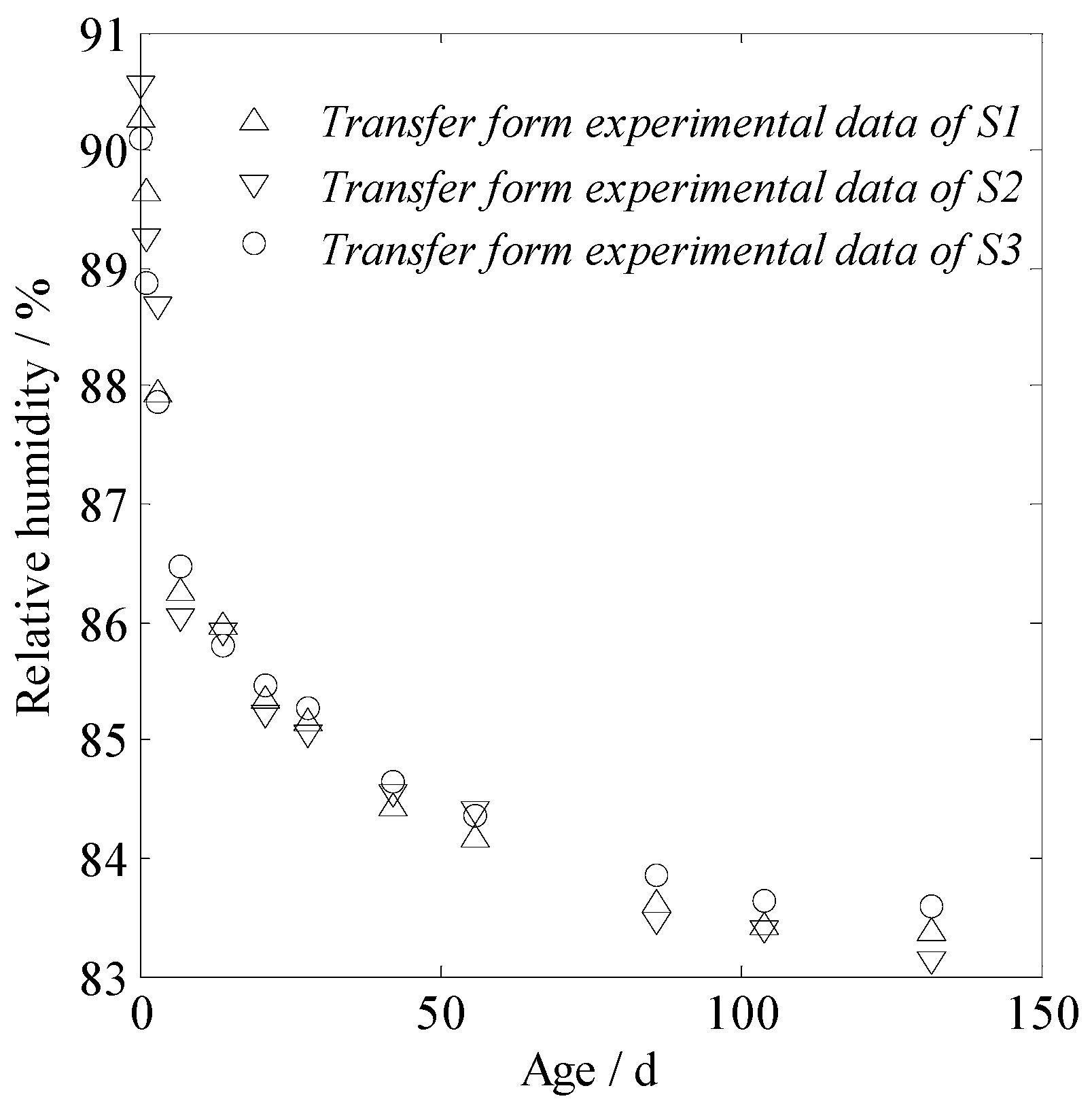

4.2. Internal Relative Humidity

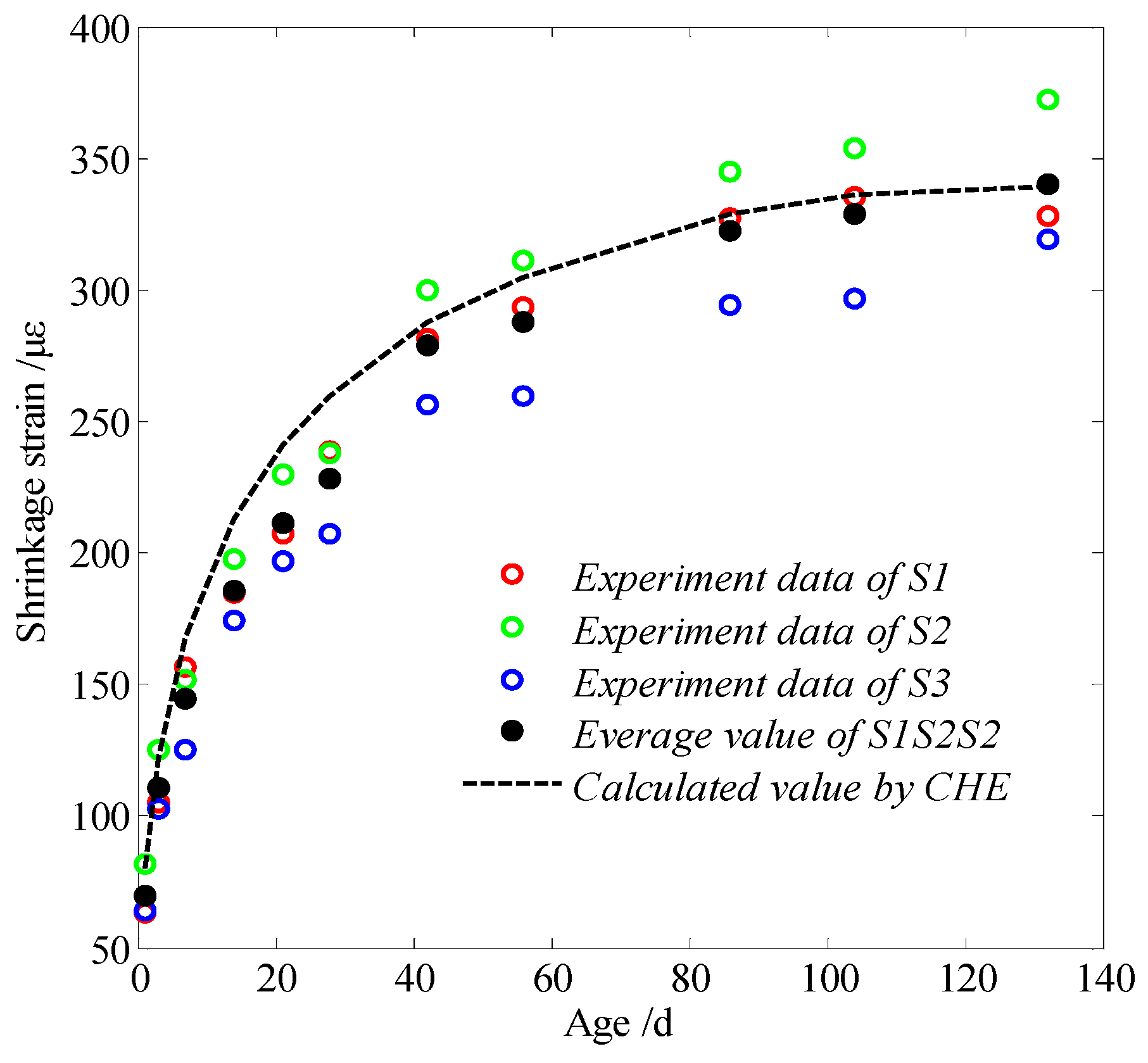

4.3. The Calculated and Measured Concrete Shrinkage

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Tian, Y.; Jin, N.; Jin, X. Coupling effect of temperature and relative humidity diffusion in concrete under ambient conditions. Constr. Build. Mater. 2018, 159, 673–689. [Google Scholar] [CrossRef]

- Yang, Y.; Ma, L.; Huang, J.; Gu, C.; Xu, Z.; Liu, J.; Ni, T. Evaluation of the thermal and shrinkage stresses in restrained high-performance concrete. Materials 2019, 12, 3680. [Google Scholar] [CrossRef] [PubMed]

- Mehta, P.K.; Monteiro, P.J.M. Concrete: Structure, Properties, and Materials; McGraw-Hill: New York, NY, USA, 2006. [Google Scholar]

- Wang, K.; Jansen, D.C.; Shah, S.P.; Karr, A.F. Permeability study of cracked concrete. Cem. Concr. Res. 1997, 27, 381–393. [Google Scholar] [CrossRef]

- Han, M.Y.; Lytton, R.L. Theoretical prediction of drying shrinkage of concrete. J. Mater. Civ. Eng. 1995, 7, 204–207. [Google Scholar] [CrossRef]

- Mehta, P.K. Durability—Critical issues for the future. Concr. Int. 1997, 19, 27–32. [Google Scholar]

- Wang, Y.; Xi, Y. The effect of temperature on moisture transport in concrete. Materials 2017, 10, 926. [Google Scholar] [CrossRef]

- Xi, Y.; Bazant, Z.P.; Molina, L.; Jennings, H.M. Moisture diffusion in cementitious materials Moisture capacity and diffusivity. Adv. Cemt. Mater. 1994, 1, 258–266. [Google Scholar] [CrossRef]

- Aquino, W.; Hawkins, N.M.; Lange, D.A. Moisture distribution in partially enclosed concrete. ACI Mater. J. 2004, 101, 259–265. [Google Scholar]

- West, R.P.; Holmes, N. Predicting moisture movement during the drying of concrete floors using finite elements. Constr. Build. Mater. 2005, 19, 674–681. [Google Scholar] [CrossRef]

- Chen, D.; Qian, C. Determination of moisture diffusion in cement-based materials in the presence of knudsen diffusion. J. Build. Mater. 2009, 12, 635–638. [Google Scholar]

- Grasberger, S.; Meschke, G. Thermo-hygro-mechanical degradation of concrete: From coupled 3D material modelling to durability-oriented multifield structural analyses. Mater. Struct. 2004, 37, 244–256. [Google Scholar] [CrossRef]

- Pont, S.D.; Durand, S.; Schrefler, B.A. A multiphase thermo-hydro-mechanical model for concrete at high temperatures—Finite element implementation and validation under LOCA load. Nucl. Eng. Des. 2007, 237, 2137–2150. [Google Scholar] [CrossRef]

- Gatmiri, B.; Maghoul, P.; Duhamel, D. Two-dimensional transient thermo-hydro-mechanical fundamental solutions of multiphase porous media in frequency and time domains. Int. J. Solids Struct. 2010, 47, 595–610. [Google Scholar] [CrossRef]

- Beneš, M.; Štefan, R. Hygro-thermo-mechanical analysis of spalling in concrete walls at high temperatures as a moving boundary problem. Int. J. Heat Mass Transfer. 2015, 85, 110–134. [Google Scholar] [CrossRef]

- Gasch, T.; Malm, R.; Ansell, A. A coupled hygro-thermo-mechanical model for concrete subjected to variable environmental conditions. Int. J. Solids Struct. 2016, 91, 143–156. [Google Scholar] [CrossRef]

- Qian, C.; Chen, D.; Wang, H.; Wang, Y. Simultaneous heat and moisture transfer in concrete with time-dependent boundary conditions. Mag. Concr. Res. 2008, 60, 725–733. [Google Scholar] [CrossRef]

- Chen, D.; Qian, C.; Liu, C. A numerical simulation approach to calculating hygro-thermal deformation of concrete based on heat and moisture transfer in porous medium. Int. J. Civ. Eng. 2010, 8, 287–296. [Google Scholar]

- Chen, D.; Miao, C.; Liu, J.; Tang, M. Advances in multi-scale simulation of hygro-thermo-mechanical deformation behavior of structural concrete. Int. J. Civ. Eng. 2015, 13, 267–277. [Google Scholar]

- Chen, D. Study and Application of the Numerical Simulation of Hygro-Thermal Deformation of Concrete Based on Heat and Moisture Transfer in Porous Medium Porous Media; Southeast University: Nanjing, China, 2007. [Google Scholar]

- Le Duigou, A.; Merotte, J.; Bourmaud, A.; Davies, P.; Belhouli, K.; Baley, C. Hygroscopic expansion: A key point to describe natural fibre/polymer matrix interface bond strength. Compos. Sci. Technol. 2017, 151, 228–233. [Google Scholar] [CrossRef]

- Obeid, H.; Clément, A.; Fréour, S.; Jacquemin, F.; Casari, P. On the identification of the coefficient of moisture expansion of polyamide-6: Accounting differential swelling strains and plasticization. Mech. Mater. 2018, 118, 1–10. [Google Scholar] [CrossRef]

- Wang, H.; Mang, H.; Yuan, Y.; Pichler, B.L.A. Multiscale thermoelastic analysis of the thermal expansion coefficient and of microscopic thermal stresses of mature concrete. Materials 2019, 12, 2689. [Google Scholar] [CrossRef] [PubMed]

- Alnaggar, M.; Di Luzio, G.; Cusatis, G. Modeling time-dependent behavior of concrete affected by alkali silica reaction in variable environmental conditions. Materials 2017, 10, 471. [Google Scholar] [CrossRef] [PubMed]

- Urgessa, G.; Choi, K.-B.; Yeon, J.H. internal relative humidity, autogenous shrinkage, and strength of cement mortar modified with superabsorbent polymers. Polymers 2018, 10, 1074. [Google Scholar] [CrossRef] [PubMed]

- Gawin, D.; Pesavento, F.; Schrefler, B.A. Hygro-thermo-chemo-mechanical modelling of concrete at early ages and beyond. Part II: Shrinkage and creep of concrete. Int. J. Numer. Meth. Eng. 2006, 67, 332–363. [Google Scholar] [CrossRef]

- Abbasnia, R.; Kanzadi, M.; Zadeh, M.S.; Ahmadi, J. Prediction of free shrinkage strain related to internal moisture loss. Int. J. Civ. Eng. 2009, 17, 92–98. [Google Scholar]

- Mindess, S.; Young, J.F. Concrete; Prentice-Hall: Upper Saddle River, NJ, USA, 1981. [Google Scholar]

- Grasley, Z.C.; Lange, D.A.; D’Ambrosia, M.D. Internal relative humidity and drying stress gradients in concrete. Mater. Struct. 2006, 39, 901–909. [Google Scholar] [CrossRef]

- Grasley, Z.C.; Lange, D.A. Thermal dilation and internal relative humidity of hardened cement paste. Mater. Struct. 2007, 40, 311–317. [Google Scholar] [CrossRef]

- Grasley, Z.C.; Lange, D.A. Modeling drying shrinkage stress gradients in concrete. Cem. Concr. Aggreg. 2004, 26, 115–122. [Google Scholar] [CrossRef]

- Bentz, D.P.; Jensen, O.M.; Hansen, K.K.; Oleson, J.F.; Stang, H.; Haecker, C.J. Influence of cement particle size distribution on early age autogenous strains and stresses in cement-based materials. J. Am. Ceram. Soc. 2001, 84, 129–135. [Google Scholar] [CrossRef]

- Lura, P.; Jensen, O.M.; van Breugel, K. Autogenous shrinkage in high-performance cement paste: An evaluation of basic mechanisms. Cem. Concr. Res. 2003, 33, 223–232. [Google Scholar] [CrossRef]

- Bentz, D.P.; Garboczi, E.J.; Quenard, D.A. Modelling drying shrinkage in reconstructed porous materials: Application to porous Vycor glass. Model. Simul. Mater. Sci. Eng. 1998, 6, 211–236. [Google Scholar] [CrossRef]

- Jeong, J.-H.; Park, Y.-S.; Lee, Y.-H. Variation of shrinkage strain within the depth of concrete beams. Materials 2015, 8, 7780–7794. [Google Scholar] [CrossRef] [PubMed]

- Xi, Y.; Jennings, H.M. Shrinkage of cement paste and concrete modelled by a multiscale effective homogenous theory. Mater. Struct. 1997, 30, 329–339. [Google Scholar] [CrossRef]

- Ayano, T.; Wittmann, F. Drying, moisture distribution, and shrinkage of cement-based materials. Mater. Struct. 2002, 35, 134–140. [Google Scholar] [CrossRef]

- Ait Belaid, K.; Belahrach, H.; Ayad, H. Numerical laplace inversion method for through-silicon via (TSV) noise coupling in 3D-IC design. Electronics 2019, 8, 1010. [Google Scholar] [CrossRef]

- Zhang, S.; Zhao, G. A Harmonious satellite-unmanned aerial vehicle-ground measurement inversion method for monitoring salinity in coastal saline soil. Remote Sens. 2019, 11, 1700. [Google Scholar] [CrossRef]

| Groups | Cement | PFA | Sand | Gravel | water |

|---|---|---|---|---|---|

| S1 | 320 | 100 | 720 | 1180 | 140 |

| S2 | 300 | 120 | 720 | 1180 | 140 |

| S3 | 280 | 140 | 720 | 1180 | 140 |

| Parameters | S1 | S2 | S3 |

|---|---|---|---|

| Compressive strength (MPa) | 45.8 | 45.5 | 44.1 |

| Porosity (%) | 9.6 | 10.2 | 9.8 |

| Apparent density (kg·m−3) | 2460 | 2475 | 2460 |

| Saturated moisture content (%) | 3.44 | 3.48 | 3.42 |

| Thermal conductivity (W·m−1K−1) | 3.01 | 2.99 | 3.05 |

| Volume fraction of aggregate (%) | 65 | 67 | 72 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, D.; Zhu, Q.; Zong, Z.; Xiang, T.; Liu, C. The Linear Hygroscopic Expansion Coefficient of Cement-Based Materials and Its Determination. Materials 2020, 13, 37. https://doi.org/10.3390/ma13010037

Chen D, Zhu Q, Zong Z, Xiang T, Liu C. The Linear Hygroscopic Expansion Coefficient of Cement-Based Materials and Its Determination. Materials. 2020; 13(1):37. https://doi.org/10.3390/ma13010037

Chicago/Turabian StyleChen, Depeng, Qilin Zhu, Zhifang Zong, Tengfei Xiang, and Chunlin Liu. 2020. "The Linear Hygroscopic Expansion Coefficient of Cement-Based Materials and Its Determination" Materials 13, no. 1: 37. https://doi.org/10.3390/ma13010037

APA StyleChen, D., Zhu, Q., Zong, Z., Xiang, T., & Liu, C. (2020). The Linear Hygroscopic Expansion Coefficient of Cement-Based Materials and Its Determination. Materials, 13(1), 37. https://doi.org/10.3390/ma13010037