Utilization of Waste Polysilicon Sludge in Concrete

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Mix Proportions and Methodology

3. Results and Discussion

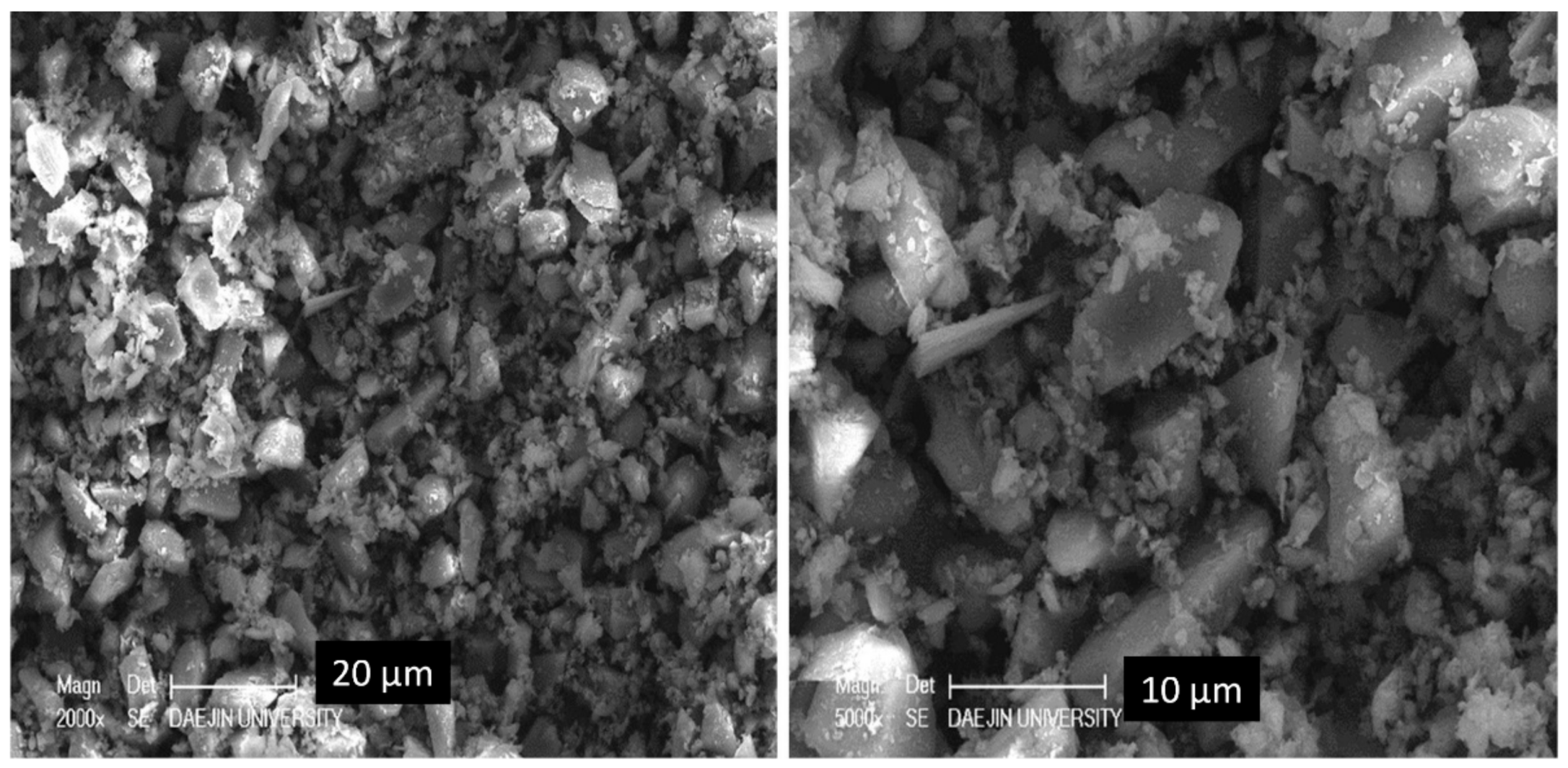

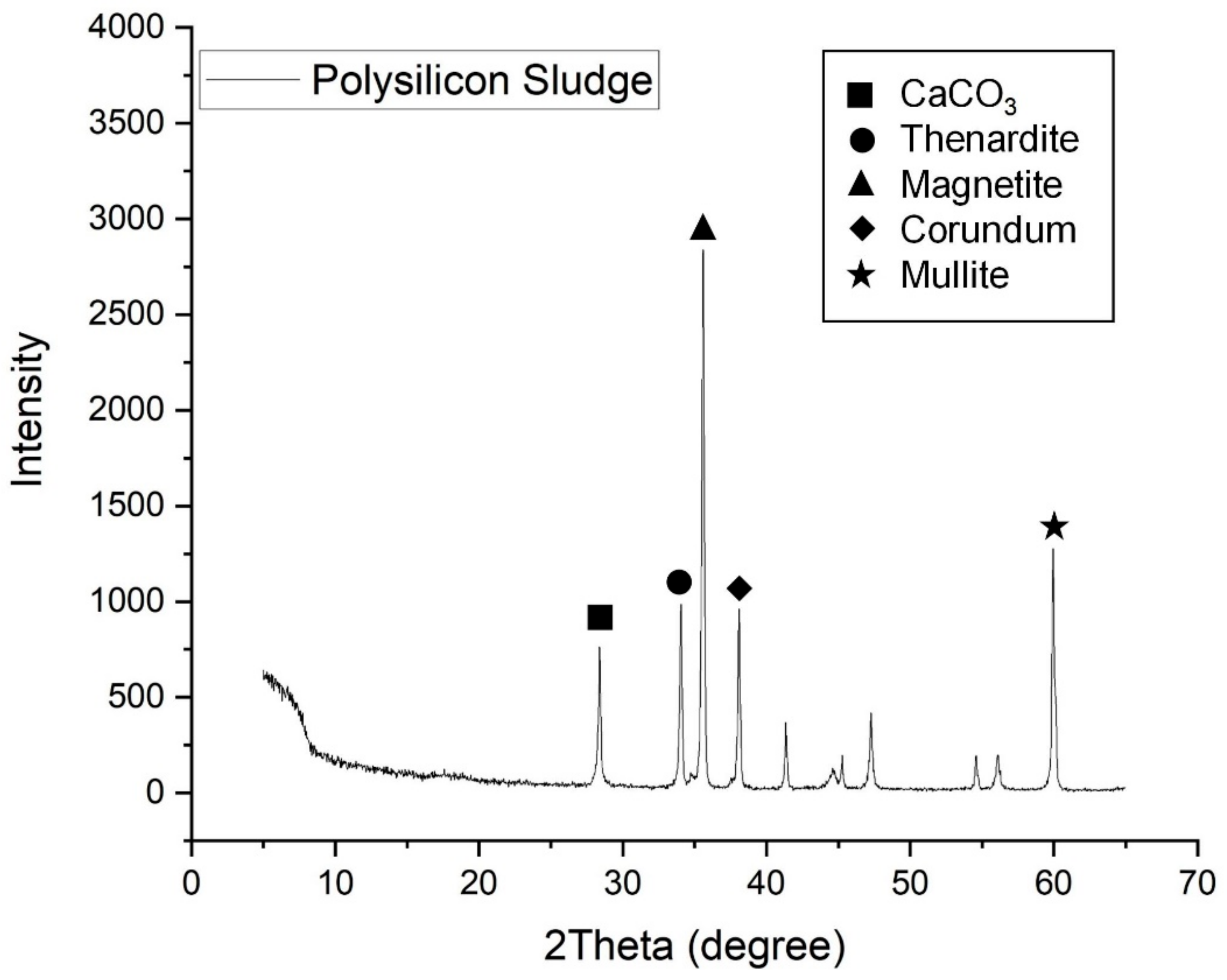

3.1. Properties of Polysilicon Sludge

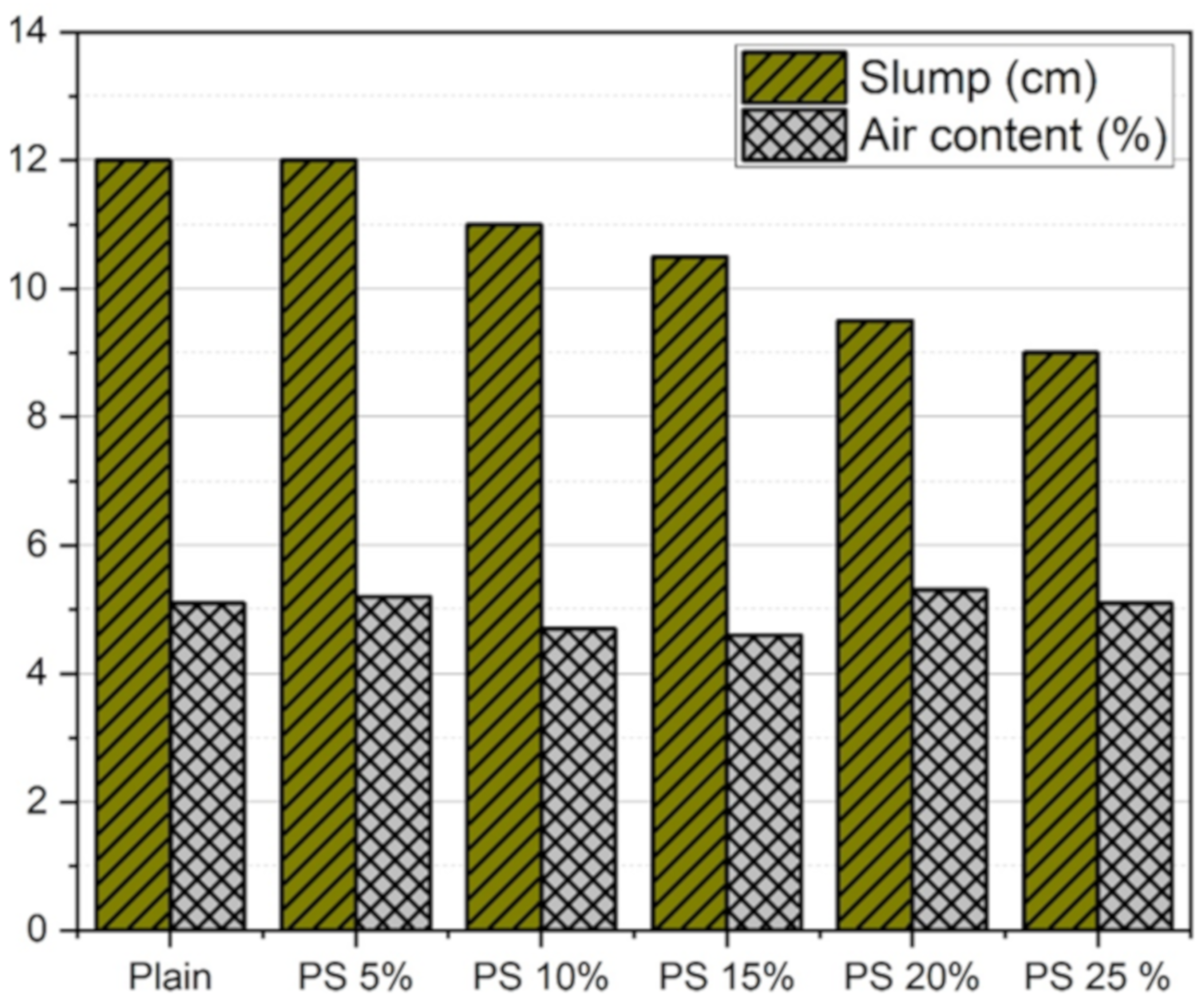

3.2. Fresh Concrete Properties

3.3. Compressive Strength

2C2S + 4H2O (H) → C-S-H + Ca(OH)2 (CH),

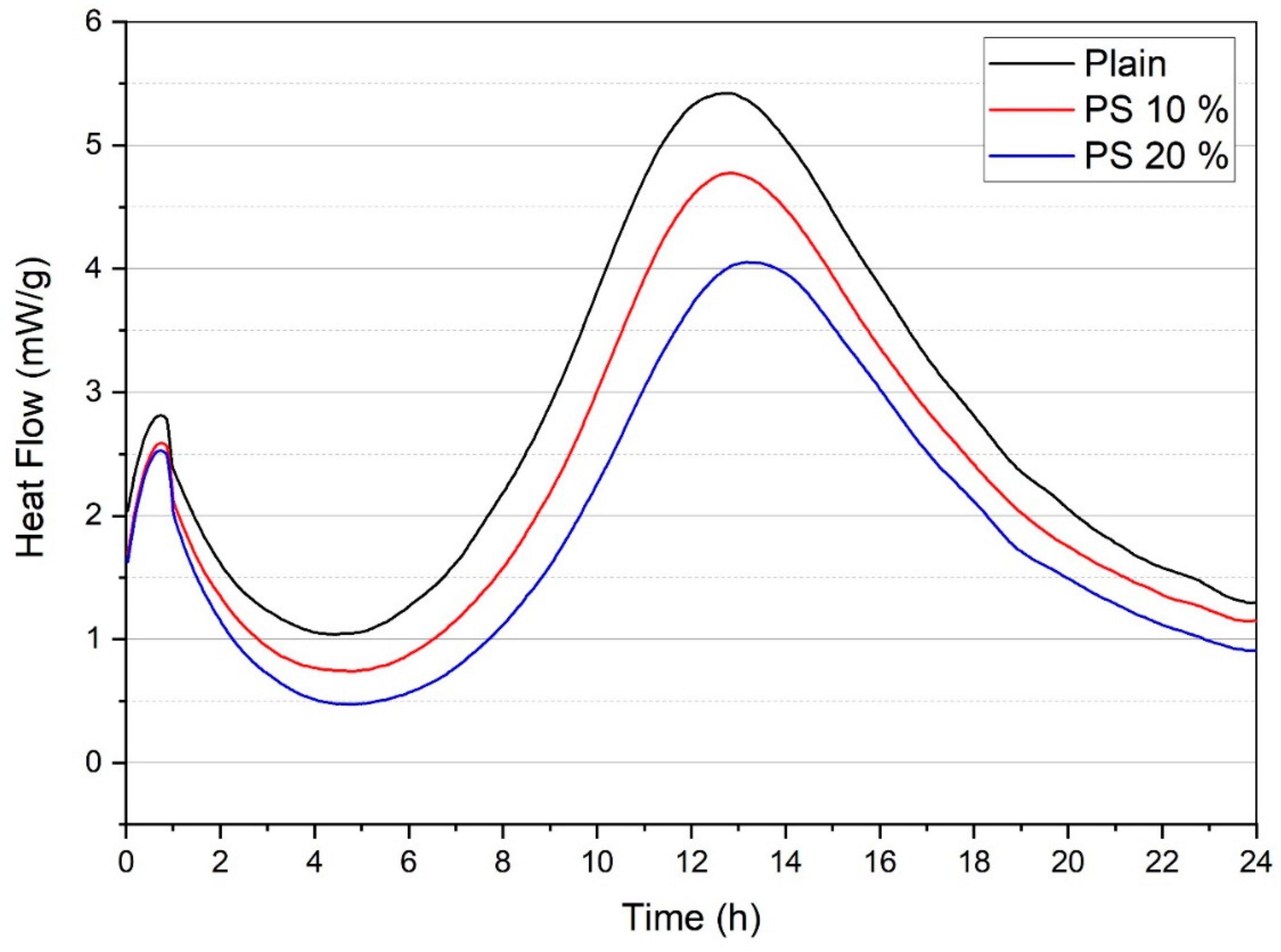

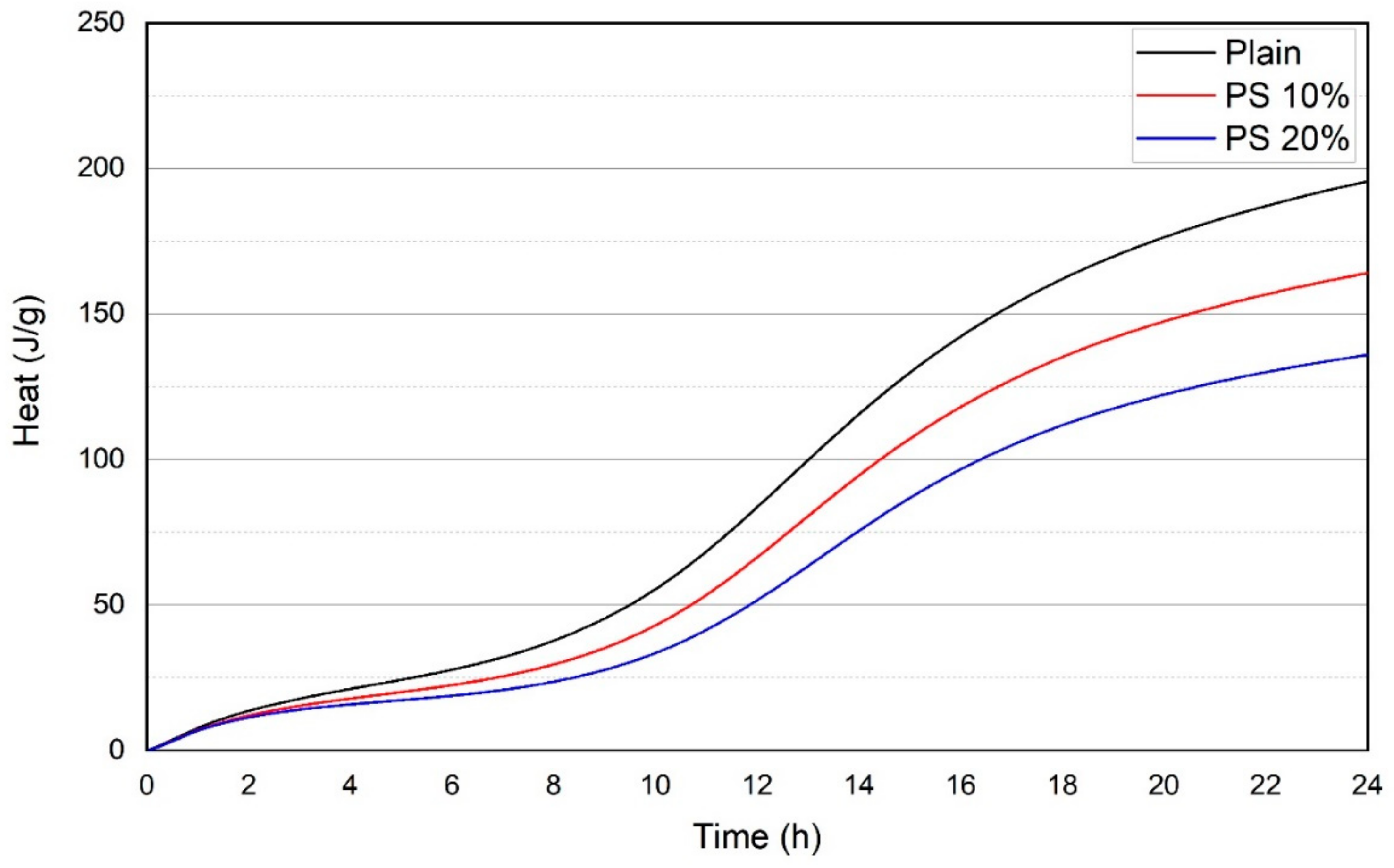

3.4. Heat Release Profiles

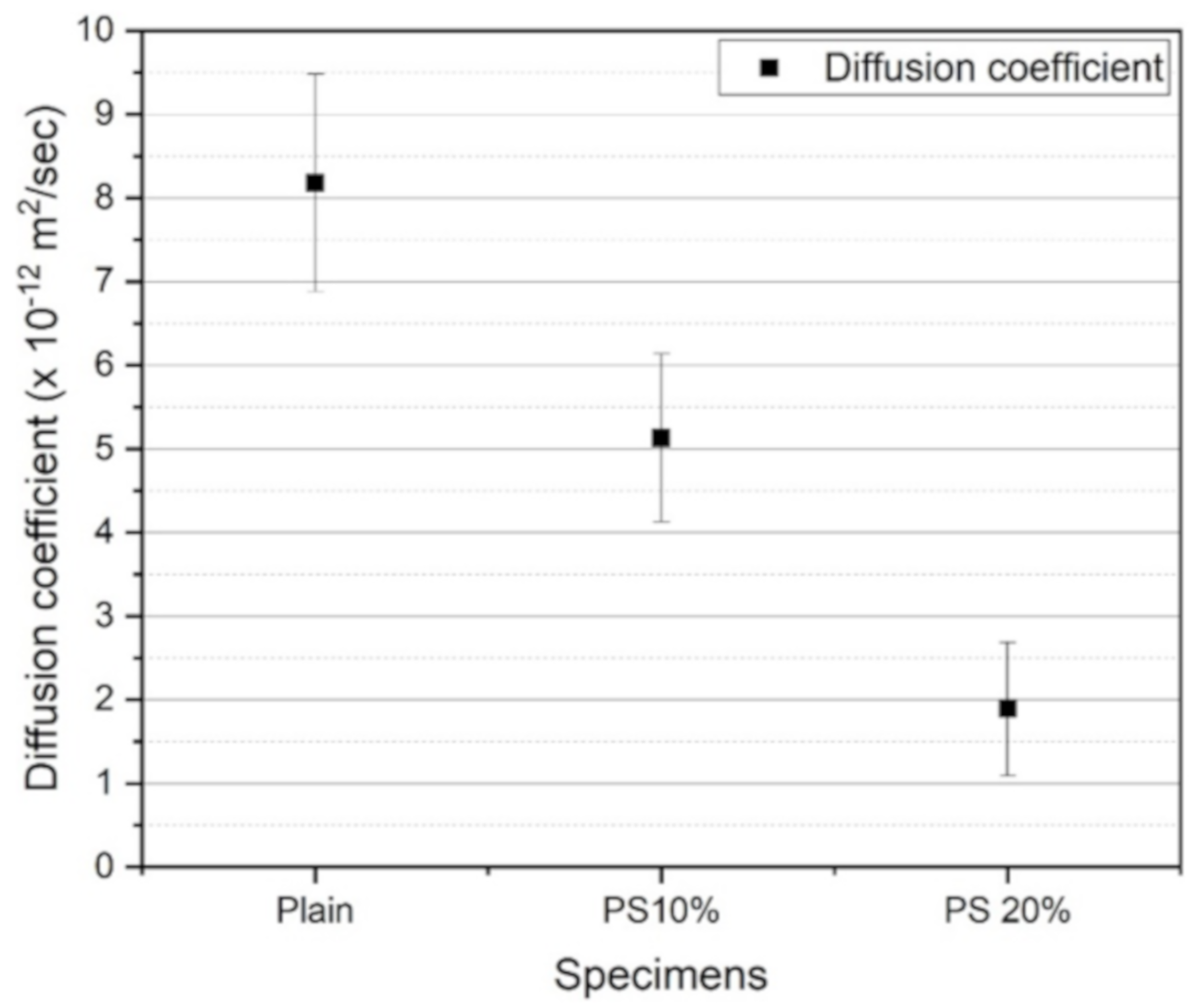

3.5. Chloride Penetration

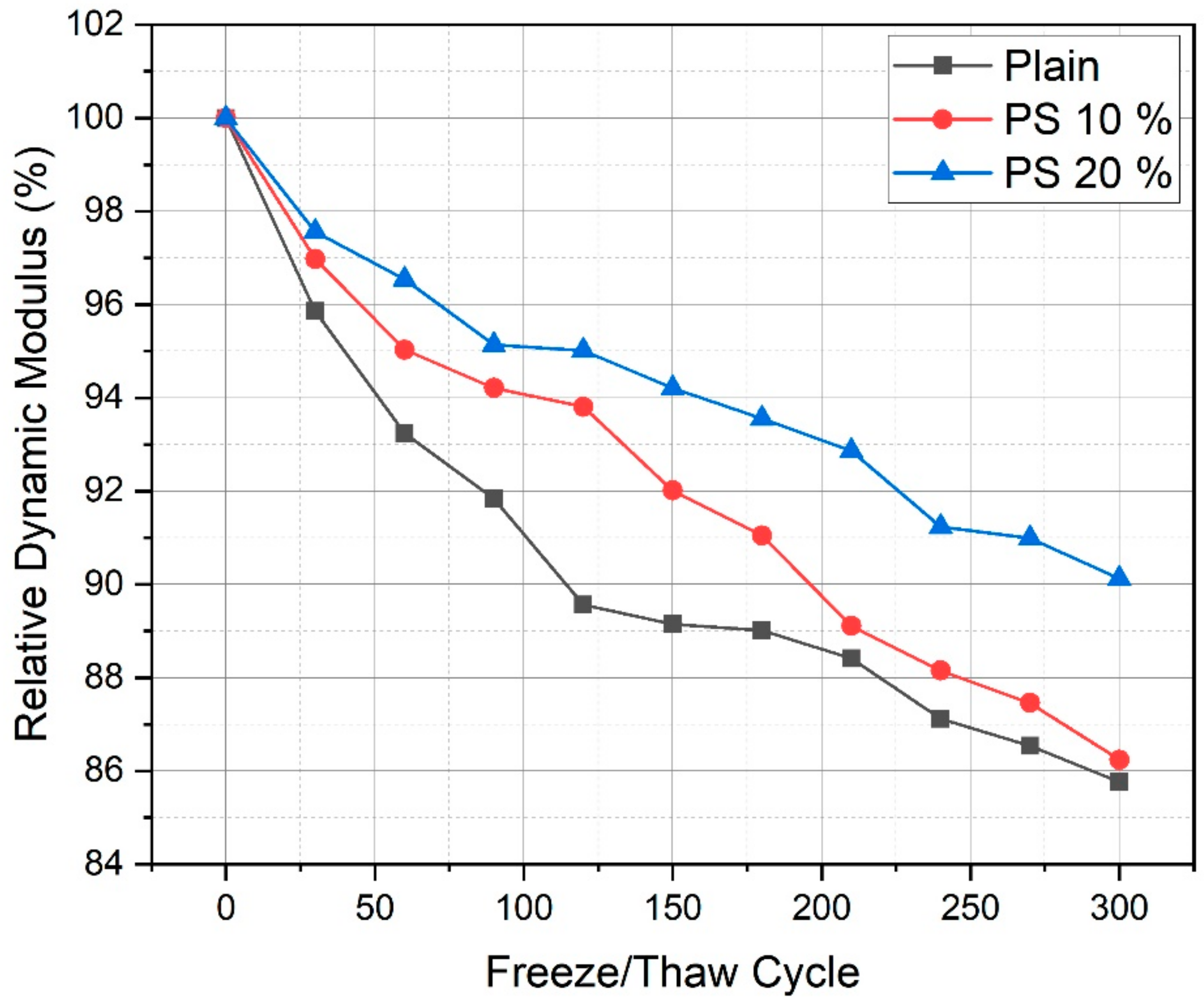

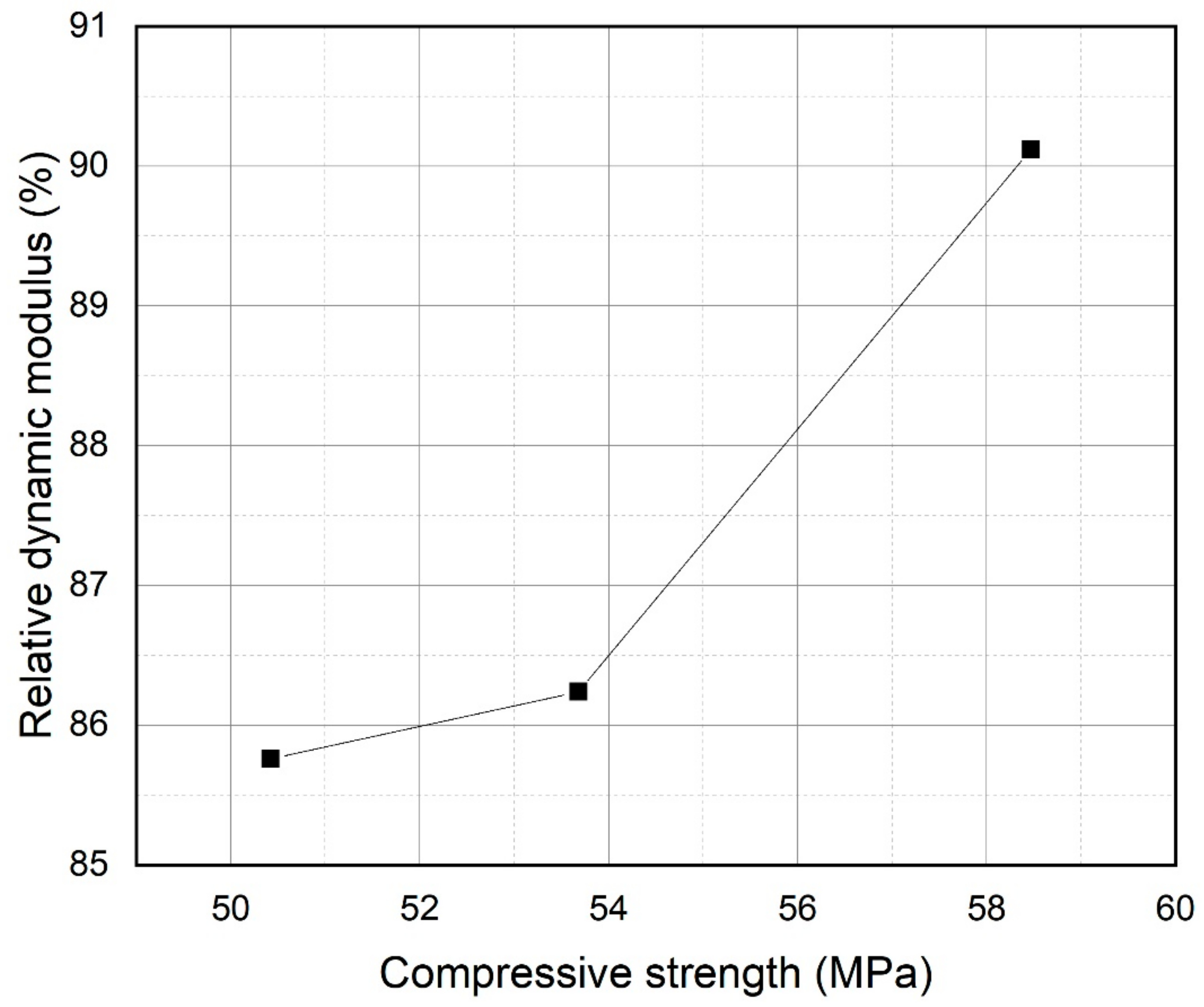

3.6. Freeze/Thaw Resistance

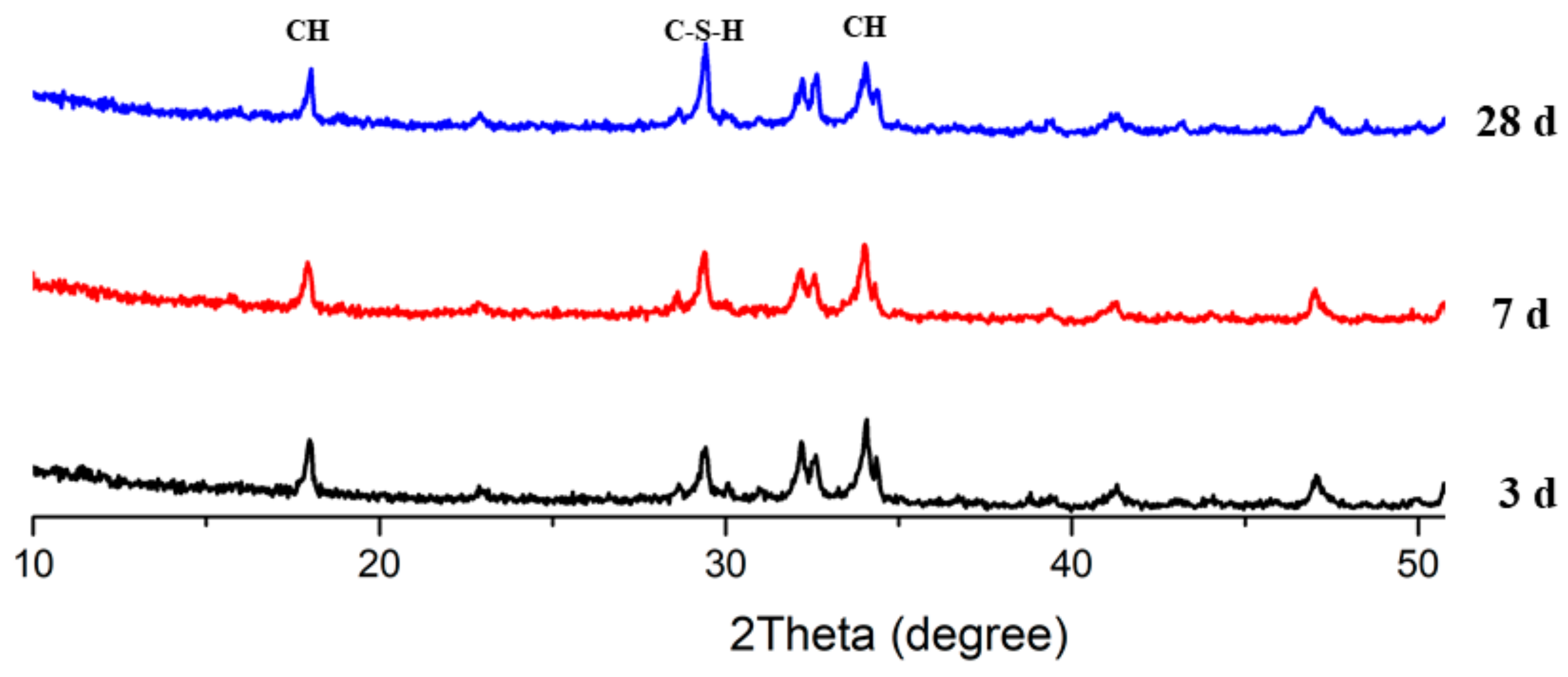

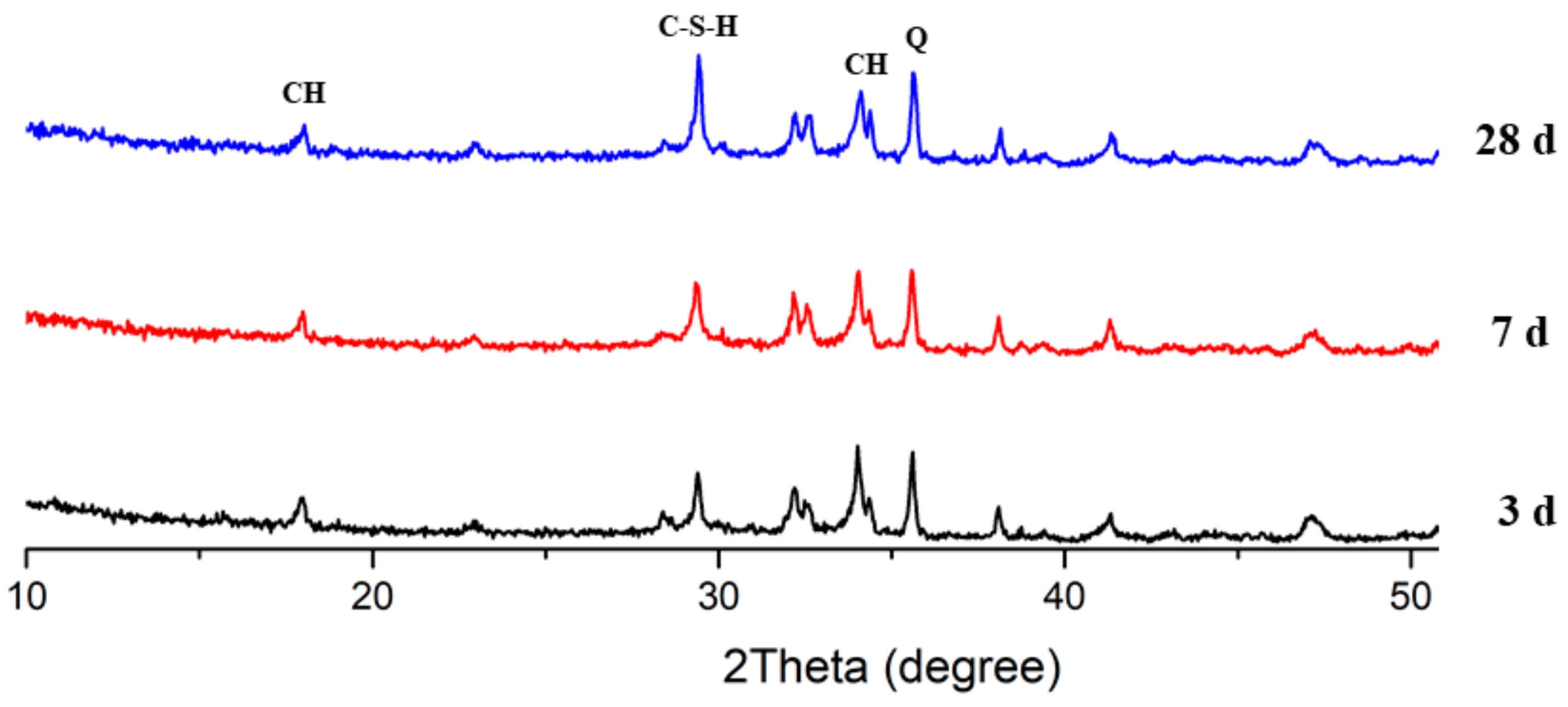

3.7. X-Ray Diffraction Analysis

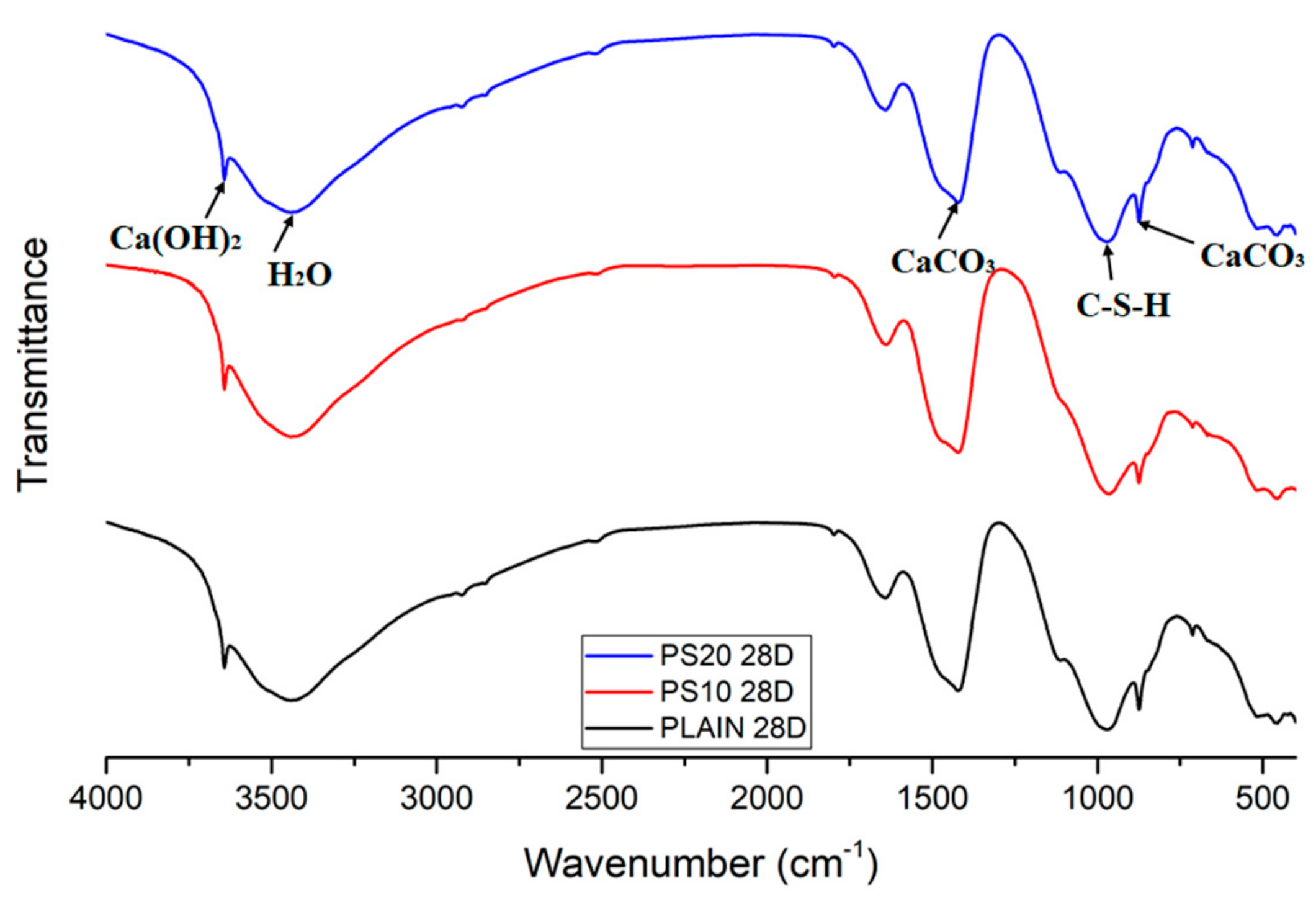

3.8. Fourier-Transform Infrared Spectroscopy

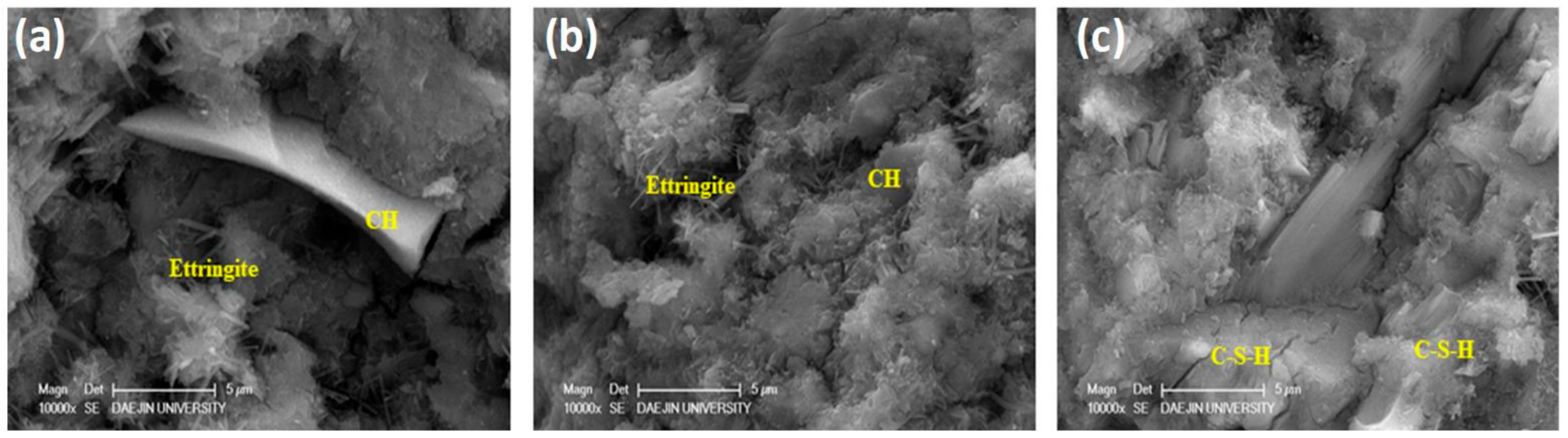

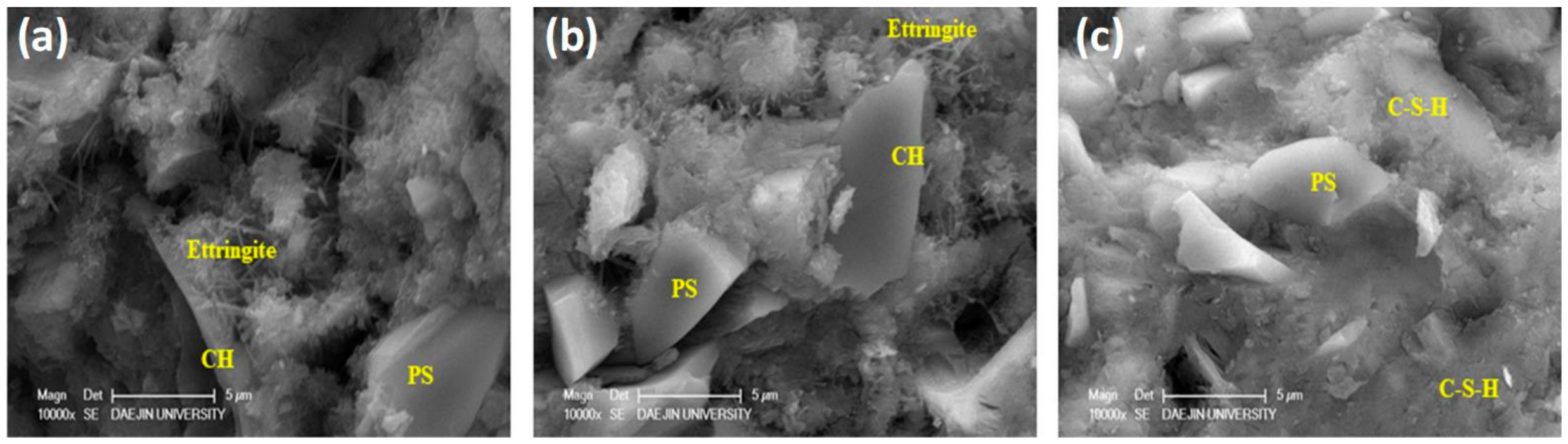

3.9. Scanning Electron Microscopy

4. Conclusions

- Polysilicon sludge particles are finer than cement particles and contain a large amount of SiO2 in amorphous form.

- The incorporation of PS particles as a cement replacement material reduced the early heat of hydration, suggesting a slower reaction rate of PS particles.

- Compressive strength at 28 days, chloride penetration resistance, and freeze/thaw resistance increased with incorporation of PS particles up to a 20% replacement level.

- Polysilicon sludge particles consumed calcium hydroxide and produced additional calcium silica hydrate resulting in an improved microstructure of the concrete specimens.

Author Contributions

Funding

Conflicts of Interest

References

- Shen, W.; Cao, L.; Li, Q.; Zhang, W.; Wang, G.; Li, C. Quantifying CO2 emissions from China’s cement industry. Renew. Sustain. Energy Rev. 2015, 50, 1004–1012. [Google Scholar] [CrossRef]

- Kajaste, R.; Hurme, M. Cement industry greenhouse gas emissions–management options and abatement cost. J. Clean. Prod. 2016, 112, 4041–4052. [Google Scholar] [CrossRef]

- Huang, L.; Krigsvoll, G.; Johansen, F.; Liu, Y.; Zhang, X. Carbon emission of global construction sector. Renew. Sustain. Energy Rev. 2018, 81, 1906–1916. [Google Scholar] [CrossRef]

- Li, B.; Ling, T.-C.; Yu, J.-G.; Wu, J.; Chen, W. Cement pastes modified with recycled glass and supplementary cementitious materials: Properties at the ambient and high temperatures. J. Clean. Prod. 2019, 241, 118155. [Google Scholar] [CrossRef]

- Papadakis, V.; Tsimas, S. Supplementary cementing materials in concrete: Part I: efficiency and design. Cem. Concr. Res. 2002, 32, 1525–1532. [Google Scholar] [CrossRef]

- Poon, C.S.; Lam, L.; Wong, Y.L. Effects of fly ash and silica fume on interfacial porosity of concrete. J. Mater. Civil Eng. 1999, 11, 197–205. [Google Scholar] [CrossRef]

- Mardani-Aghabaglou, A.; Sezer, G.İ.; Ramyar, K. Comparison of fly ash, silica fume and metakaolin from mechanical properties and durability performance of mortar mixtures view point. Constr. Build. Mater. 2014, 70, 17–25. [Google Scholar] [CrossRef]

- Gupta, L.K.; Vyas, A.K. Impact on mechanical properties of cement sand mortar containing waste granite powder. Constr. Build. Mater. 2018, 191, 155–164. [Google Scholar] [CrossRef]

- Usman, M.; Khan, A.Y.; Farooq, S.H.; Hanif, A.; Tang, S.; Khushnood, R.A.; Rizwan, S.A. Eco-friendly self-compacting cement pastes incorporating wood waste as cement replacement: A feasibility study. J. Clean. Prod. 2018, 190, 679–688. [Google Scholar] [CrossRef]

- Aliabdo, A.A.; Elmoaty, A.E.M.A.; Aboshama, A.Y. Utilization of waste glass powder in the production of cement and concrete. Constr. Build. Mater. 2016, 124, 866–877. [Google Scholar] [CrossRef]

- Pahlevani, F.; Sahajwalla, V. From waste glass to building materials–An innovative sustainable solution for waste glass. J. Clean. Prod. 2018, 191, 192–206. [Google Scholar]

- Quercia, G.; Van der Putten, J.; Hüsken, G.; Brouwers, H. Photovoltaic’s silica-rich waste sludge as supplementary cementitious material (SCM). Cem. Concr. Res. 2013, 54, 161–179. [Google Scholar] [CrossRef]

- Kalaw, M.; Culaba, A.; Hinode, H.; Kurniawan, W.; Gallardo, S.; Promentilla, M. Optimizing and characterizing geopolymers from ternary blend of Philippine coal fly ash, coal bottom ash and rice hull ash. Materials 2016, 9, 580. [Google Scholar] [CrossRef] [PubMed]

- Du, H.; Tan, K.H. Properties of high volume glass powder concrete. Cem. Concr. Res. 2017, 75, 22–29. [Google Scholar] [CrossRef]

- Lin, Y.-C.; Wang, T.-Y.; Lan, C.-W.; Tai, C.Y. Recovery of silicon powder from kerf loss slurry by centrifugation. Powder Technol. 2010, 200, 216–223. [Google Scholar] [CrossRef]

- Billiet, R.L.; Nguyen, H.T. Photovoltaic cells from silicon kerf. U.S. Patent 20,030,041,895A1, 6 March 2003. [Google Scholar]

- Green, M.A. Silicon solar cells: evolution, high-efficiency design and efficiency enhancements. Semicond. Sci. Technol. 1993, 8, 1. [Google Scholar] [CrossRef]

- Wang, T.; Lin, Y.; Tai, C.; Sivakumar, R.; Rai, D.; Lan, C. A novel approach for recycling of kerf loss silicon from cutting slurry waste for solar cell applications. J. Crystal Growth 2008, 310, 3403–3406. [Google Scholar] [CrossRef]

- Meng, K.; Guo, H.; Wang, Z.; Li, X.; Su, M.; Huang, B.; Hu, Q.; Peng, W. Self-assembly of porous-graphite/silicon/carbon composites for lithium-ion batteries. Powder Technol. 2014, 254, 403–406. [Google Scholar] [CrossRef]

- Ding, H.; Li, J.; Gao, Y.; Zhao, D.; Shi, D.; Mao, G.; Liu, S.; Tan, X. Preparation of silica nanoparticles from waste silicon sludge. Powder Technol. 2015, 284, 231–236. [Google Scholar] [CrossRef]

- Yamamoto, Y.; Yamada, T.; Satou, T.; Ishizuka, M.; Kinoshita, T.; Yasunaga, N. Development of Polishing Technique for Silicon Wafer; Advanced Materials and Optoelectronics, 3rd Technical report; Sumitomo Osaka Cement Co. Ltd.: Tokyo, Japan, 2002. [Google Scholar]

- Drouiche, N.; Cuellar, P.; Kerkar, F.; Medjahed, S.; Boutouchent-Guerfi, N.; Hamou, M.O. Recovery of solar grade silicon from kerf loss slurry waste. Renew. Sustain. Energy Rev. 2014, 32, 936–943. [Google Scholar] [CrossRef]

- Sinke, W.C.; Ballif, C.; Bett, A.; Dimmler, B.; Dimova-Malinovska, D.; Fath, P.; Mason, N.; Ferrazza, F.; Gabler, H.; Hall, M. A Strategic Research Agenda for Photovoltaic Solar Energy Technology; OPOCE: Brussels, Belgium, 2007. [Google Scholar]

- Lee, T.-C.; Liu, F.-J. Recovery of hazardous semiconductor-industry sludge as a useful resource. J. Hazardous Mater. 2009, 165, 359–365. [Google Scholar] [CrossRef] [PubMed]

- Lee, T.-C. Recycling of municipal incinerator fly-ash slag and semiconductor waste sludge as admixtures in cement mortar. Constr. Build. Mater. 2009, 23, 3305–3311. [Google Scholar] [CrossRef]

- Lee, T.-C.; Lin, K.-L.; Su, X.-W.; Lin, K.-K. Recycling CMP sludge as a resource in concrete. Constr. Build. Mater. 2012, 30, 243–251. [Google Scholar] [CrossRef]

- Chang, C.-J.; Tseng, L.; Lin, T.-S.; Wang, W.-J.; Lee, T.-C. Recycling of modified MSWI ash-mix slag and CMP sludge as a cement substitute and its optimal composition. Indian J. Eng. Mater. Sci. 2012, 19, 31–40. [Google Scholar]

- Yang, Z.; Zhang, Y.; Liu, L.; Seetharaman, S.; Wang, X.; Zhang, Z. Integrated utilization of sewage sludge and coal gangue for cement clinker products: promoting tricalcium silicate formation and trace elements immobilization. Materials 2016, 9, 275. [Google Scholar] [CrossRef] [PubMed]

- Du, L.; Folliard, K.J. Mechanisms of air entrainment in concrete. Cem. Concr. Res. 2005, 35, 1463–1471. [Google Scholar] [CrossRef]

- Moon, H.; Ramanathan, S.; Suraneni, P.; Shon, C.-S.; Lee, C.-J.; Chung, C.-W. Revisiting the effect of slag in reducing heat of hydration in concrete in comparison to other supplementary cementitious materials. Materials 2018, 11, 1847. [Google Scholar] [CrossRef]

- Jeon, I.K.; Ryou, J.S.; Jakhrani, S.H.; Kim, H.G. Effects of Light-Burnt Dolomite Incorporation on the Setting, Strength, and Drying Shrinkage of One-Part Alkali-Activated Slag Cement. Materials 2019, 12, 2874. [Google Scholar] [CrossRef]

- 492, NT Build. Concrete, Mortar and Cement-Based Repair Materials: Chloride Migration Coefficient from Non-Steady-State Migration Experiments; Nordtest: Espoo, Finland, 1999. [Google Scholar]

- ASTM, C., 666/C666M-03. Standard Test Method for Resistance of Concrete to Rapid Freezing and Thawing; ASTM International: West Conshohocken, PA, USA, 2008. [Google Scholar]

- Walker, H.N.; Lane, D.S.; Stutzman, P.E. Petrographic Methods of Examining Hardened Concrete: A Petrographic Manual; Virginia Transportation Research Council: Charlottesville, Virginia, July 2006. [Google Scholar]

- Neville, A.M. Properties of Concrete; Longman London: London, UK, 1995; Volume 4. [Google Scholar]

- Mehta, P.K. Pozzolanic and cementitious byproducts as mineral admixtures for concrete-a critical review. Spec. Publication 1983, 79, 1–46. [Google Scholar]

- Memon, A.; Radin, S.; Zain, M.F.M.; Trottier, J.-F. Effects of mineral and chemical admixtures on high-strength concrete in seawater. Cem. Concr. Res. 2002, 32, 373–377. [Google Scholar] [CrossRef]

- Deboucha, W.; Oudjit, M.N.; Bouzid, A.; Belagraa, L. Effect of incorporating blast furnace slag and natural pozzolana on compressive strength and capillary water absorption of concrete. Procedia Eng. 2015, 108, 254–261. [Google Scholar] [CrossRef]

- Cerny, R.; Rovnaníková, P. Transport. Processes in Concrete; CRC Press: Boca Raton, FL, USA, 2002. [Google Scholar]

- ASTM Standards. Standard Practice for Measuring Hydration Kinetics of Hydraulic Cementitious Mixtures Using Isothermal Calorimetry; ASTM, C. 1679-08; Annual Book of ASTM Standards: West Conshohocken, PA, USA, 2008. [Google Scholar]

- Long, W.-J.; Tan, X.-W.; Xiao, B.-X.; Han, N.-X.; Xing, F. Effective use of ground waste expanded perlite as green supplementary cementitious material in eco-friendly alkali activated slag composites. J. Clean. Prod. 2019, 213, 406–414. [Google Scholar] [CrossRef]

- Qudoos, A.; Kim, H.G.; Ryou, J.-S. Effect of mechanical processing on the pozzolanic efficiency and the microstructure development of wheat straw ash blended cement composites. Constr. Build. Mater. 2018, 193, 481–490. [Google Scholar] [CrossRef]

- Leng, F.; Feng, N.; Lu, X. An experimental study on the properties of resistance to diffusion of chloride ions of fly ash and blast furnace slag concrete. Cem. Concr. Res. 2000, 30, 989–992. [Google Scholar] [CrossRef]

- Kong, Y.; Wang, P.; Liu, S.; Zhao, G.; Peng, Y. SEM analysis of the interfacial transition zone between cement-glass powder paste and aggregate of mortar under microwave curing. Materials 2016, 9, 733. [Google Scholar] [CrossRef]

- Fraj, A.B.; Bonnet, S.; Leklou, N.; Khelidj, A. Investigating the early-age diffusion of chloride ions in hardening slag-blended mortars on the light of their hydration progress. Constr. Build. Mater. 2019, 225, 485–495. [Google Scholar] [CrossRef]

- Mehta, P.K.; Monteiro, P.J. Concrete Microstructure, Properties and Materials; McGraw-Hill Education: New York, NY, USA, 2017. [Google Scholar]

- Coussy, O.; Monteiro, P.J. Poroelastic model for concrete exposed to freezing temperatures. Cem. Concr. Res. 2008, 38, 40–48. [Google Scholar] [CrossRef]

- Valenza, J.J.; Scherer, G.W. Mechanism for salt scaling. J. Am. Ceram. Soc. 2006, 89, 1161–1179. [Google Scholar] [CrossRef]

- Valenza II, J.J.; Scherer, G.W. A review of salt scaling: II. Mechanisms. Cem. Concr. Res. 2007, 37, 1022–1034. [Google Scholar] [CrossRef]

- Ramachandran, V.S.; Beaudoin, J.J. Handbook of Analytical Techniques in Concrete Science and Technology: Principles, Techniques and Applications; Elsevier: Amsterdam, The Netherlands, 2000. [Google Scholar]

- Fernández-Carrasco, L.; Torrens-Martín, D.; Morales, L.; Martínez-Ramírez, S. Infrared spectroscopy in the analysis of building and construction materials. Infrared Spectrosc.—Mater. Sci. Eng. Technol. INTECH 2012, 369–382. [Google Scholar] [CrossRef]

- Mollah, M.; Yu, W.; Schennach, R.; Cocke, D.L. A Fourier transform infrared spectroscopic investigation of the early hydration of Portland cement and the influence of sodium lignosulfonate. Cem. Concr. Res. 2000, 30, 267–273. [Google Scholar] [CrossRef]

- Varas, M.; de Buergo, M.A.; Fort, R. Natural cement as the precursor of Portland cement: Methodology for its identification. Cem. Concr. Res. 2005, 35, 2055–2065. [Google Scholar] [CrossRef]

- Cordeiro, G.; Toledo Filho, R.; Tavares, L.; Fairbairn, E. Pozzolanic activity and filler effect of sugar cane bagasse ash in Portland cement and lime mortars. Cem. Concr. Res. 2008, 30, 410–418. [Google Scholar] [CrossRef]

| Description | OPC | PS |

|---|---|---|

| SiO2 (%) | 20.8 | 96.44 |

| TiO2 (%) | - | 0.01 |

| Al2O3 (%) | 6.3 | 0.03 |

| Fe2O3 (%) | 3.2 | 3.276 |

| CaO (%) | 62.0 | 0.06 |

| Cl (%) | - | 0.03 |

| CuO (%) | - | 0.07 |

| ZnO (%) | - | 0.03 |

| MgO (%) | 2.9 | - |

| MnO (%) | - | 0.007 |

| SO3 (%) | 2.1 | 0.03 |

| Ignition loss (%) | 1.5 | - |

| Specific gravity (g/cm3) | 3.15 | 1.95 |

| Surface area (cm2/g) | 3410 | 7122 |

| Description | Fine Aggregate | Coarse Aggregate |

|---|---|---|

| Gmax (mm) | 4.75 | 25 |

| Gmin (mm) | 0.075 | 4.75 |

| Density (g/cm3) | 2.62 | 2.66 |

| Absorption rate (%) | 1.05 | 0.72 |

| Fineness modulus (FM) | 2.70 | 6.91 |

| Abrasion rate (AR) (%) | - | 25.1 |

| Unit volume mass (g/cm3) | - | 1.564 |

| - | Specific Gravity | pH (25 °C) | Cl− Content (%) | Alkali Content (%) | Color/Type | Usage |

|---|---|---|---|---|---|---|

| SP | 1.06 ± 0.05 | 6.5 ± 1.0 | < 0.01 | < 0.02 | Brown/liquid | C × 0.5% |

| AE | 1.04 ± 0.01 | - | - | - | Translucent/liquid | C × 0.2% |

| Types | W/B (%) | S/A (%) | Unit Weight (kg/m3) | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Water | OPC | Sand | Gravel | PS | AE | SP | |||

| Plain | 40.0 | 48 | 175 | 337 | 859 | 919 | - | 0.68 (C × 0.2%) | 1.69 (C × 0.5%) |

| PS 5% | 320 | 17 | |||||||

| PS 10% | 303 | 34 | |||||||

| PS 15% | 286 | 51 | |||||||

| PS 20% | 270 | 67 | |||||||

| PS 25% | 253 | 84 | |||||||

| Concrete Mix | Pozzolanic Activity Index (PAI) | ||

|---|---|---|---|

| 3 days | 7 days | 28 days | |

| Plain | 100 | 100 | 100 |

| PS 5% | 96.2 | 93.0 | 107.6 |

| PS 10% | 94.7 | 91.3 | 106.5 |

| PS 15% | 95.7 | 95.3 | 110.4 |

| PS 20% | 98.1 | 100.9 | 116.0 |

| PS 25% | 95.7 | 97.9 | 107.5 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Qudoos, A.; Jeon, I.K.; Kim, S.S.; Lee, J.B.; Kim, H.G. Utilization of Waste Polysilicon Sludge in Concrete. Materials 2020, 13, 251. https://doi.org/10.3390/ma13010251

Qudoos A, Jeon IK, Kim SS, Lee JB, Kim HG. Utilization of Waste Polysilicon Sludge in Concrete. Materials. 2020; 13(1):251. https://doi.org/10.3390/ma13010251

Chicago/Turabian StyleQudoos, Abdul, In Kyu Jeon, Seong Soo Kim, Jeong Bae Lee, and Hong Gi Kim. 2020. "Utilization of Waste Polysilicon Sludge in Concrete" Materials 13, no. 1: 251. https://doi.org/10.3390/ma13010251

APA StyleQudoos, A., Jeon, I. K., Kim, S. S., Lee, J. B., & Kim, H. G. (2020). Utilization of Waste Polysilicon Sludge in Concrete. Materials, 13(1), 251. https://doi.org/10.3390/ma13010251