Optimizing Gradation Design for Ultra-Thin Wearing Course Asphalt

Abstract

:1. Introduction

2. Materials and Methods

2.1. Raw Materials

2.1.1. Aggregates

2.1.2. Asphalt Binder

2.1.3. Mineral Filler

2.2. Methods and Preparation

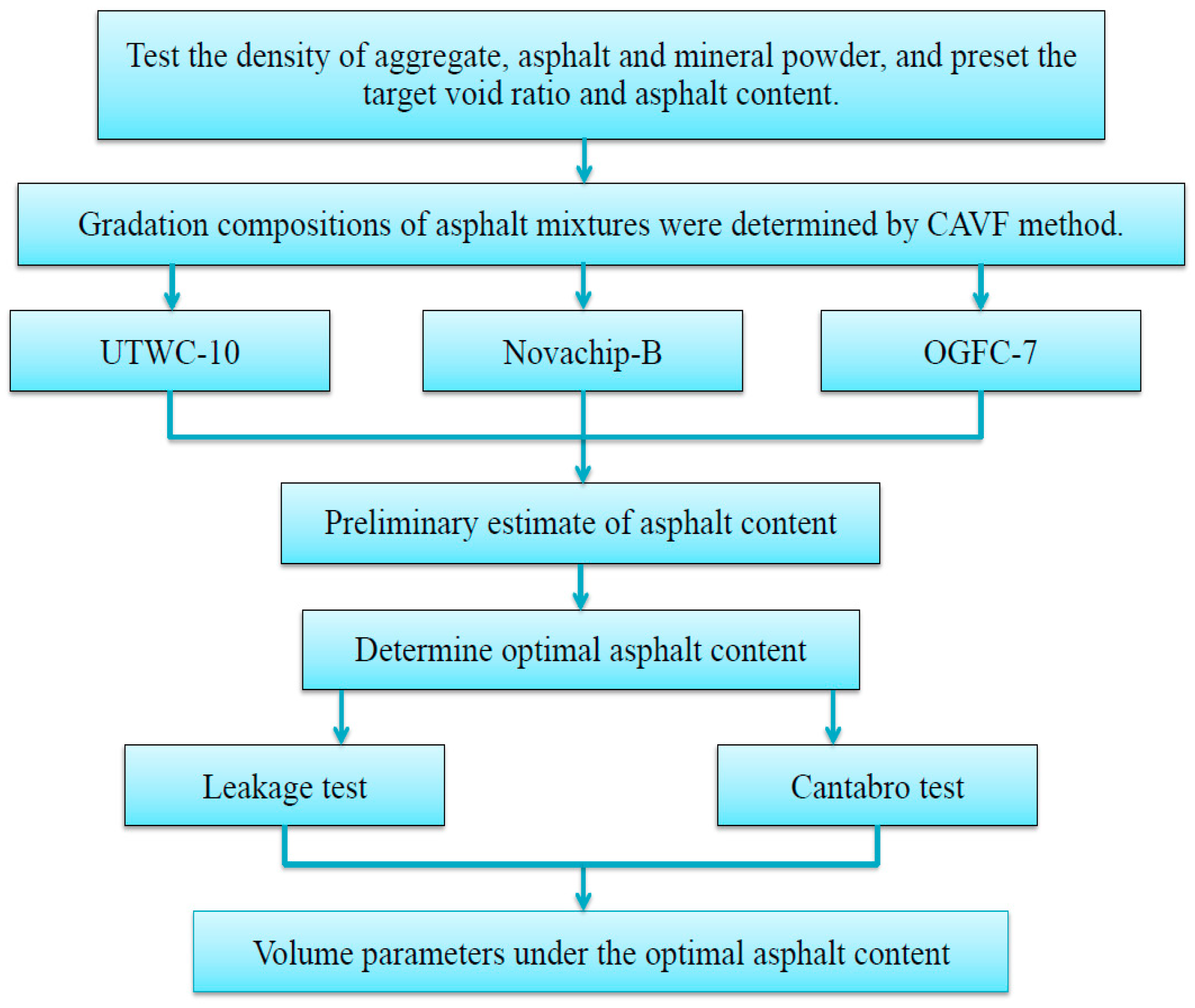

2.2.1. Asphalt Mixture Gradation Design

2.2.2. Determination of the Optimal Asphalt Content in Asphalt Mixture of the Ultra-Thin Wearing Course

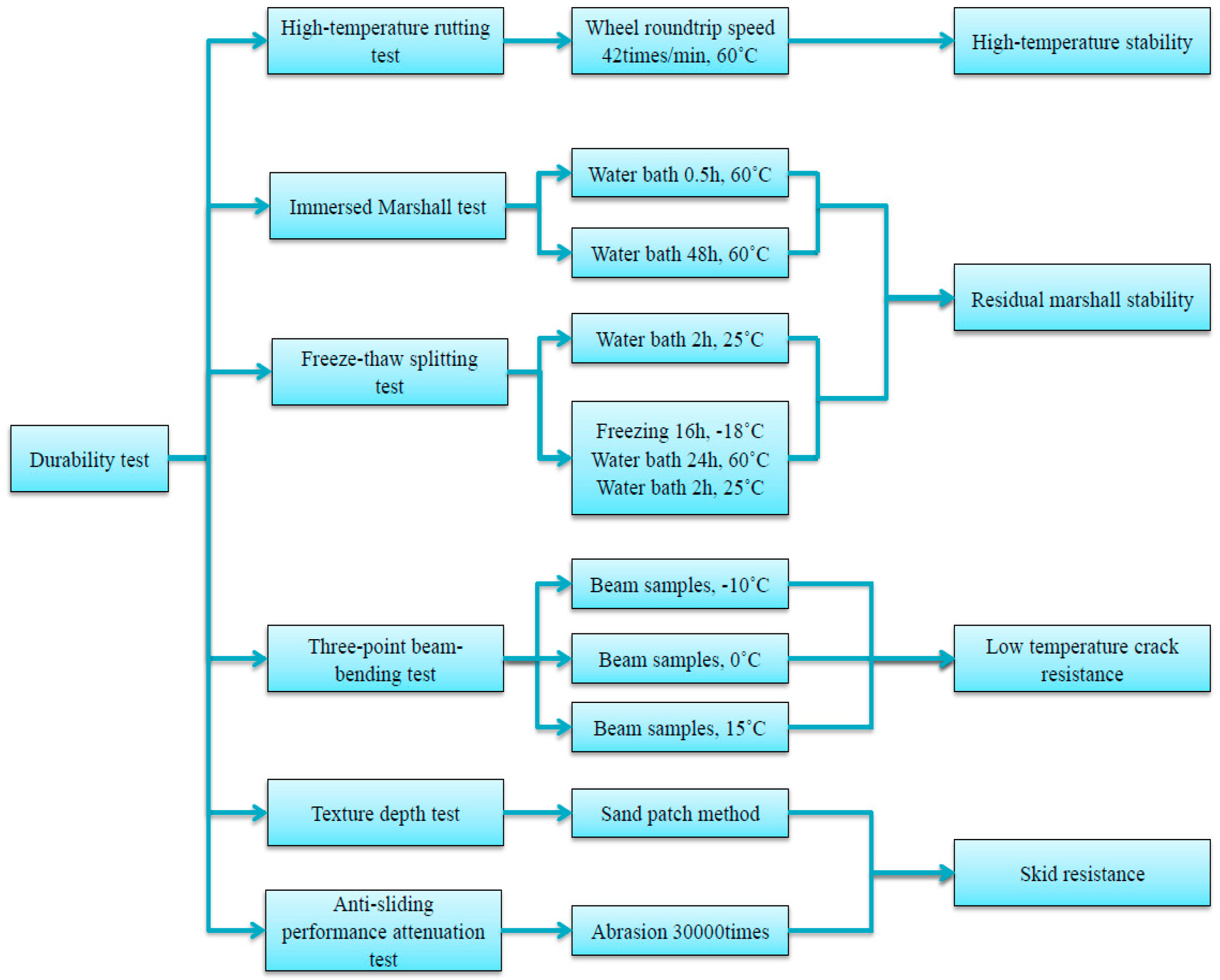

2.3. Methods and Tests

2.3.1. High-Temperature Rutting Test

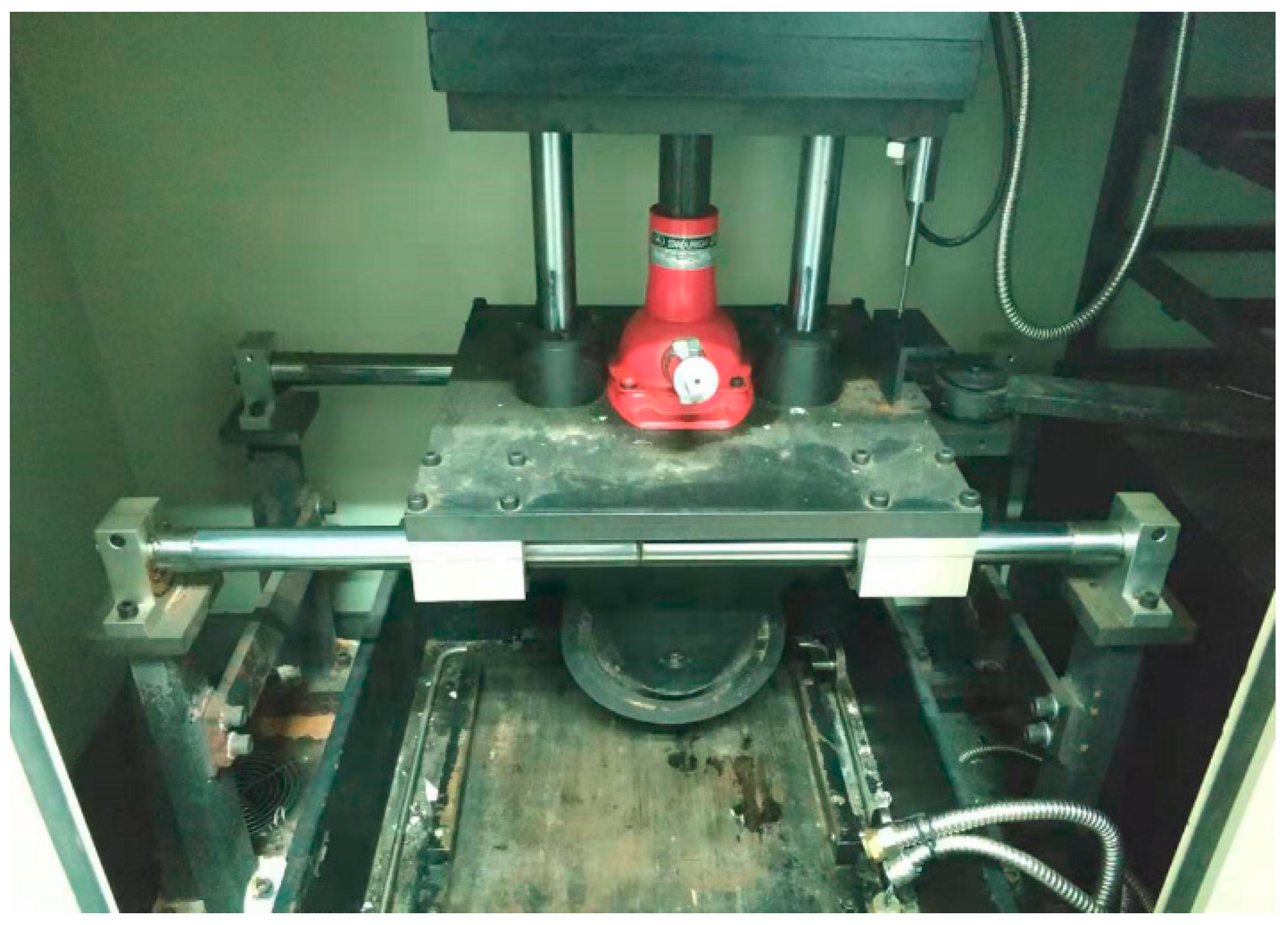

2.3.2. Three-point Beam-bending Test

2.3.3. Immersed Marshall Test

2.3.4. Freeze-Thaw Splitting Test

2.3.5. Texture Depth Test

2.3.6. British Pendulum Number (BPN) Test

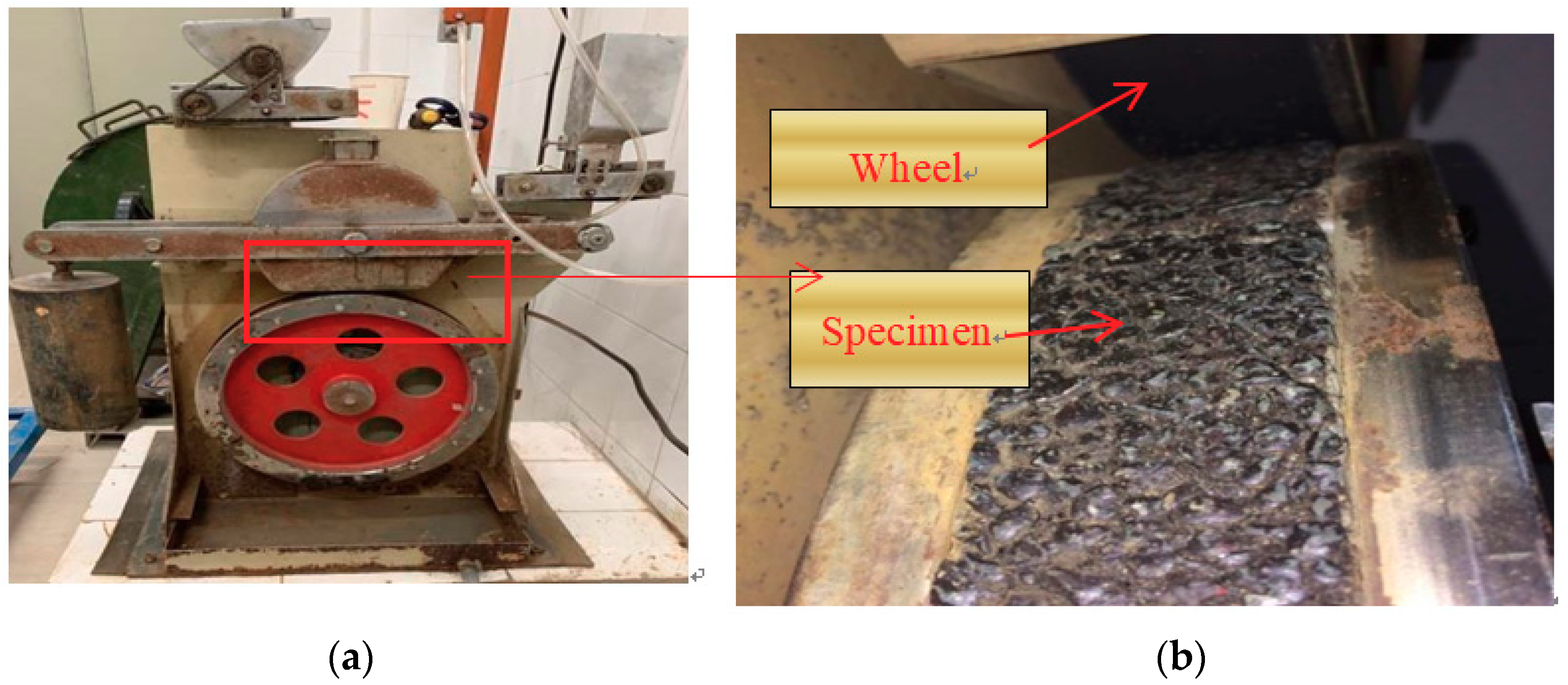

2.3.7. Anti-Sliding Performance Attenuation Test

3. Results and Discussion

3.1. High-Temperature Rutting Resistance

3.2. Low Temperature Crack Resistance

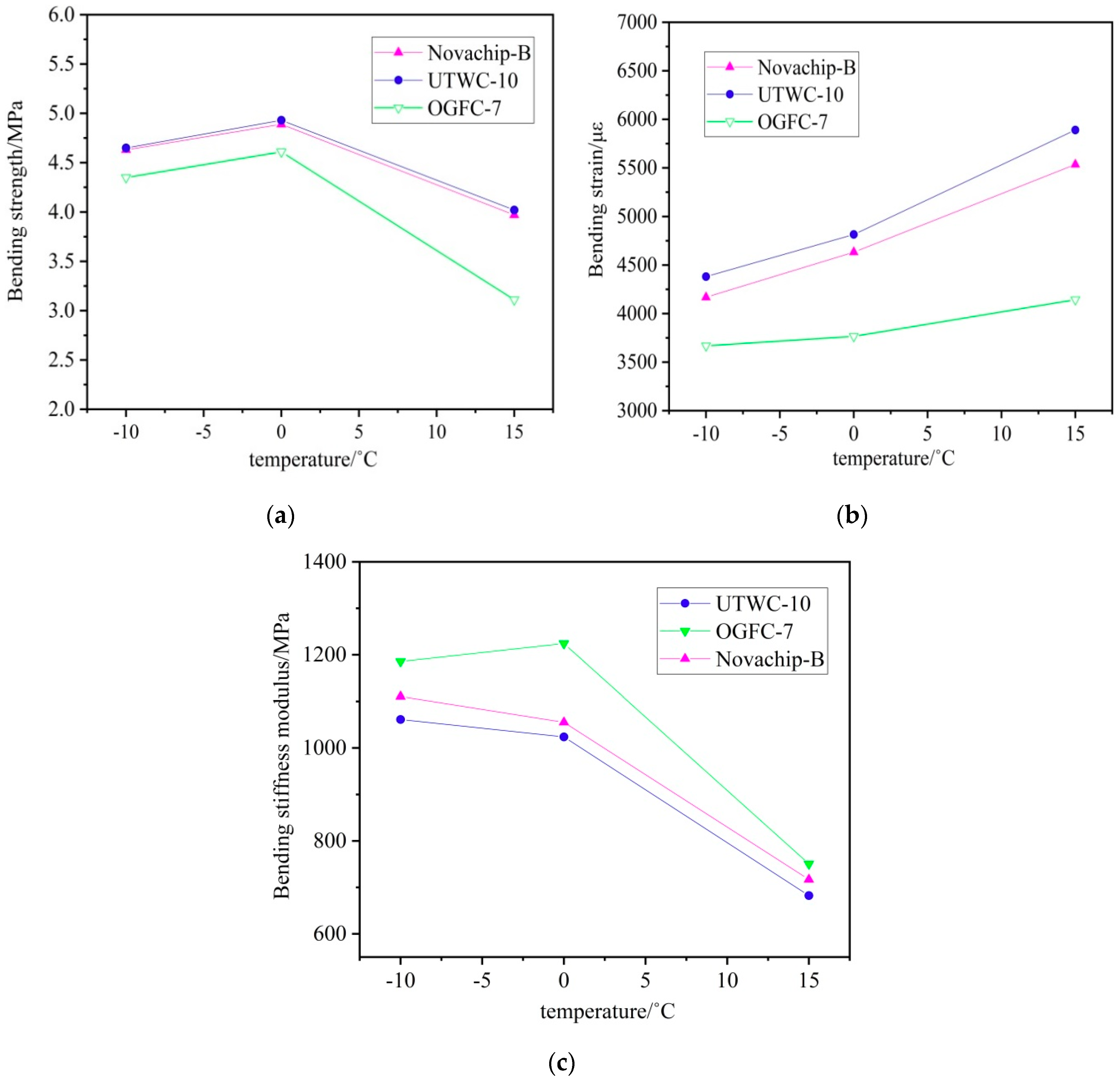

3.3. Water Stability

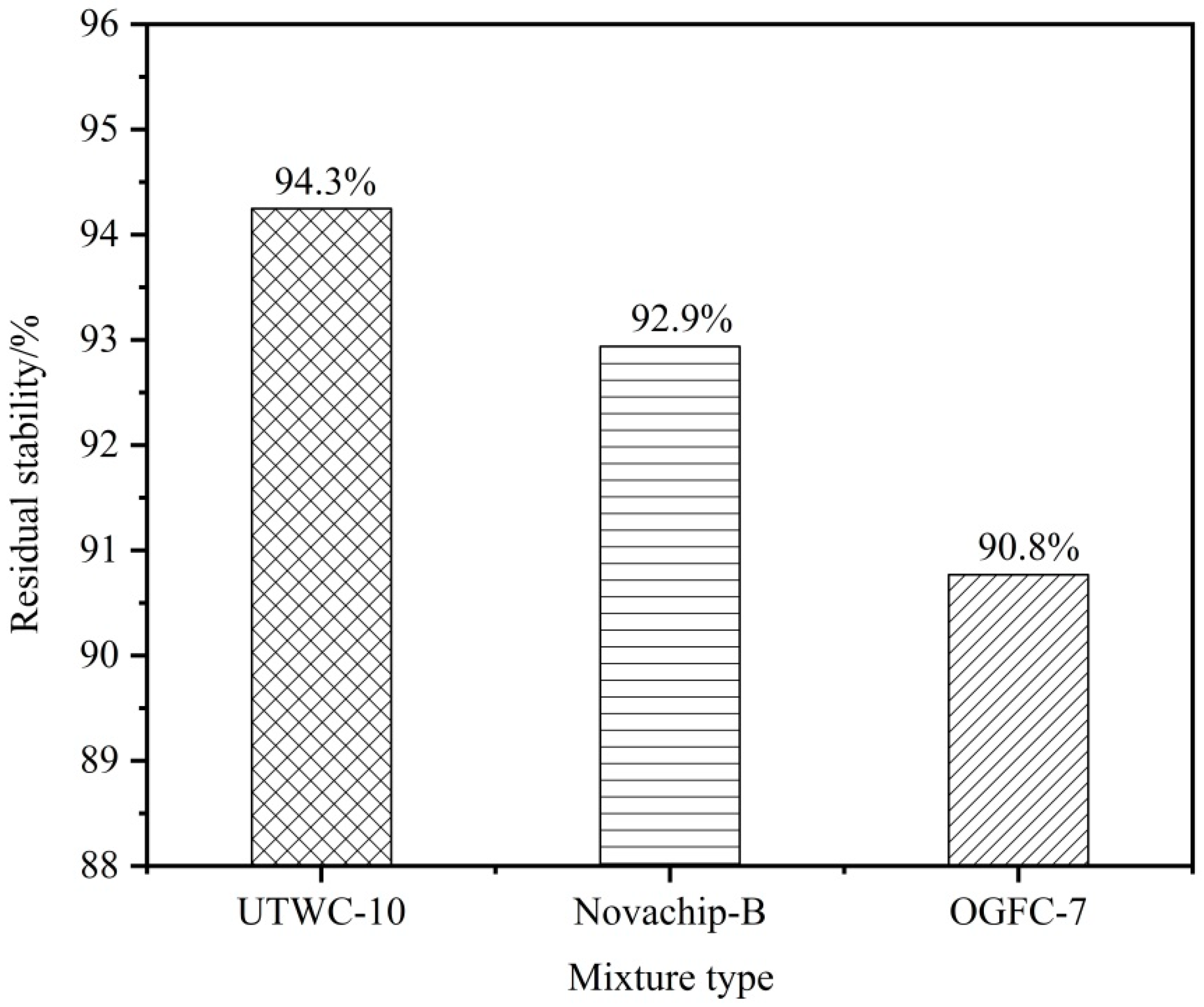

3.3.1. Immersed Marshall Test Results

3.3.2. Freeze-Thaw Splitting Test Results

3.4. Asphalt Mixture Surface Roughness

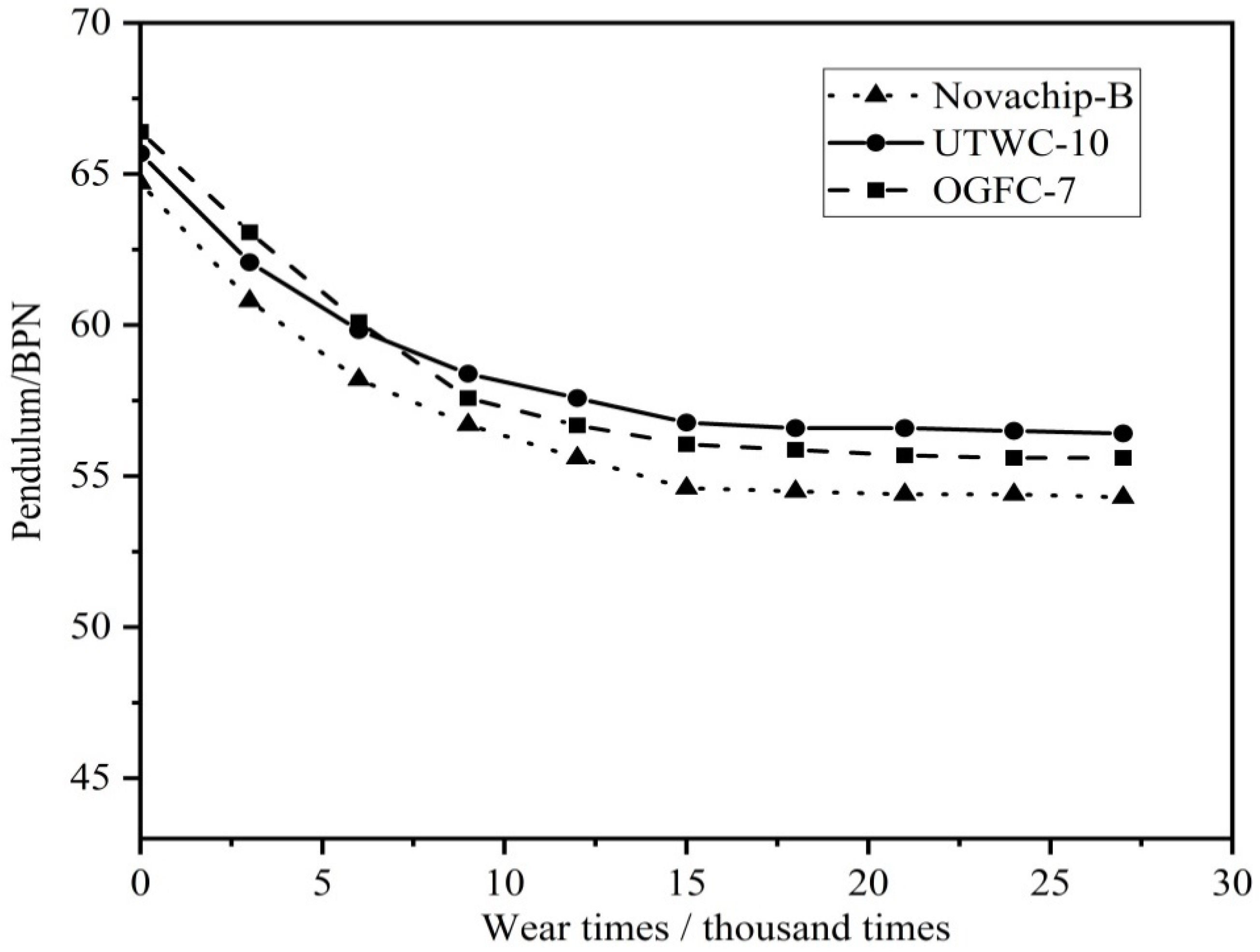

3.5. Anti-sliding Performance Attenuation

4. Conclusions

- (1)

- The DS of UTWC-10 asphalt mixture is as high as 5568 times/mm, which is much larger than Novachip-B and OGFC-7 asphalt mixture.

- (2)

- The test results of low temperature bending beam tests, immersed Marshall tests, and freeze–thaw splitting tests proved that UTWC-10 asphalt mixture has satisfied crack resistance at low temperatures and the ability to resist water damage.

- (3)

- The results of texture depth test and pendulum test confirmed that UTWC-10 asphalt mixture can provide good compactness and frictional resistance.

- (4)

- The anti-sliding performance attenuation test system employed in the paper can closely simulate the skid resistance attenuation of roads at a long-term vehicle load. The test results show that the skid resistance of UTWC-10 is the best.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Appendix A. Volume Parameters of the Three Asphalt Mixtures

| Asphalt Content (%) | Void Ratio (%) | VMA (%) | VFA (%) | Stability (kN) | Flow Value (mm) | Asphalt Film Thickness (µm) |

|---|---|---|---|---|---|---|

| 4.4 | 14.1 | 23.6 | 40.1 | 6.69 | 27.0 | 7.6 |

| 4.7 | 13.3 | 23.5 | 43.4 | 7.40 | 32.3 | 8.7 |

| 5.0 | 12.1 | 21.9 | 44.7 | 8.64 | 27.4 | 10.3 |

| 5.3 | 11.3 | 21.5 | 47.4 | 7.25 | 30.7 | 11.1 |

| 5.6 | 11.0 | 21.2 | 48.1 | 6.30 | 34.4 | 12.3 |

| Sample Number | Mixture Quality (g) | Adhesive Quality (g) | Leakage Loss (%) | Average Leakage Rate (%) | Test Temperature (°C) |

|---|---|---|---|---|---|

| 1 | 1000.8 | 0.84 | 0.08 | 0.08 | 185 |

| 2 | 1000.1 | 0.77 | 0.08 | ||

| 3 | 1000.3 | 0.91 | 0.09 | ||

| 4 | 1000.1 | 0.72 | 0.07 |

| Asphalt Content (%) | Void Ratio (%) | VMA (%) | VFA (%) | Stability (kN) | Flow Value (mm) | Asphalt Film Thickness (µm) |

|---|---|---|---|---|---|---|

| 4.4 | 15.2 | 25.3 | 40.4 | 6.72 | 33.4 | 8.1 |

| 4.7 | 13.4 | 24.6 | 42.3 | 7.51 | 31.5 | 9.3 |

| 5.0 | 12.3 | 22.4 | 43.5 | 8.43 | 32.1 | 10.5 |

| 5.3 | 11.6 | 22.1 | 45.9 | 7.38 | 30.8 | 11.6 |

| 5.6 | 11.1 | 21.7 | 47.2 | 6.67 | 33.6 | 12.8 |

| Sample Number | Mixture Quality (g) | Adhesive Quality (g) | Leakage Loss (%) | Average Leakage Rate (%) | Test Temperature (°C) |

|---|---|---|---|---|---|

| 1 | 1000.1 | 0.71 | 0.07 | 0.09 | 185 |

| 2 | 1000.4 | 0.93 | 0.09 | ||

| 3 | 1000.6 | 1.14 | 0.11 | ||

| 4 | 1000.3 | 0.82 | 0.08 |

| Asphalt Content (%) | Leakage Loss (%) | Scattering Loss (%) | Void Ratio (%) | VMA (%) | VFA (%) | Stability (kN) | Flow Value (mm) |

|---|---|---|---|---|---|---|---|

| 3.9 | 0.08 | 24.87 | 24.8 | 27.7 | 25.4 | 5.82 | 34.8 |

| 4.2 | 0.11 | 19.12 | 22 | 28.1 | 26.7 | 6.53 | 36.8 |

| 4.5 | 0.17 | 13.88 | 20.3 | 28.3 | 28.3 | 6.80 | 38.5 |

| 4.8 | 0.33 | 13.29 | 19 | 28.6 | 30.5 | 5.41 | 41.2 |

| 5.1 | 0.47 | 11.6 | 18.3 | 29.1 | 32.9 | 5.07 | 40.3 |

References

- Xue, G. Study on design method and road performances of ultra-thin wearing course SMA-5 asphalt mixture. Highw. Transp. Res. Dev. 2009, 26, 18–21. [Google Scholar]

- Qian, Z.; Lu, Q. Design and laboratory evaluation of small particle porous epoxy asphalt surface mixture for roadway pavements. Constr. Build. Mater. 2015, 77, 110–116. [Google Scholar] [CrossRef]

- Zhao, D.; Kane, M.; Do, M.T. Effect of aggregate and asphalt on pavement skid resistance evolution. Am. Soc. Civ. Eng. 2010, 46, 8–18. [Google Scholar]

- Sun, X.L.; Zhang, X.N.; Cai, X. Accelerated test-based study of long-term pavement performance of micro-surfacing. J. Tongji Univ. 2012, 40, 691–695. [Google Scholar]

- Krummenauer, K.; Andrade, J.O. Incorporation of chromium-tanned leather residue to asphalt micro-surface layer. Constr. Build. Mater. 2009, 23, 574–581. [Google Scholar] [CrossRef]

- Zhang, H.J.; Li, H.; Zhang, Y. Performance enhancement of porous asphalt pavement using red mud as alternative filler. Constr. Build. Mater. 2018, 160, 707–713. [Google Scholar] [CrossRef]

- Wang, X.W.; Gu, X.Y.; Dong, Q. Evaluation of permanent deformation of multilayer porous asphalt courses using an advanced multiply-repeated load test. Constr. Build. Mater. 2018, 160, 19–29. [Google Scholar] [CrossRef]

- Wu, K.H.; Zhang, X.N. Design of SMA-5 asphalt mixture for thin overlays. J. South China Univ. Technol. 2006, 34, 43–46. [Google Scholar]

- Liu, C.H.; Sha, Q.L. Comparision testing research on aggregate gradation of ultra-thin layer asphalt concrete SAC-10. China J. Highw. Transp. 2005, 18, 7–13. [Google Scholar]

- Audrius, V.; Tadas, A.; Viktoras, V.; Aleksandras, J.; Boris, F.; Ewa, Z. Asphalt wearing course optimization for road traffic noise reduction. Constr. Build. Mater. 2017, 152, 345–356. [Google Scholar]

- Hu, M.J.; Li, L.H.; Peng, F.X. Laboratory investigation of OGFC-5 porous asphalt ultra-thin wearing course. Constr. Build. Mater. 2019, 219, 101–110. [Google Scholar] [CrossRef]

- Wan, J.M.; Wu, S.P.; Xiao, Y.; Fang, M.J.; Song, W.; Pan, P.; Zhang, D. Enhanced ice and snow melting efficiency of steel slag based ultra-thin friction courses with steel fiber. J. Clean. Prod. 2019, 236, 117613. [Google Scholar] [CrossRef]

- Nekkanti, H.; Putman, B.J.; Danish, B. Influence of aggregate gradation and nominal maximum aggregate size on the performance properties of OGFC mixtures. Transp. Res. Rec. 2019, 1, 240–245. [Google Scholar] [CrossRef]

- David, A.H.; Xiao, F.P.; Serji, A. Investigation of Los Angeles value and alternate aggregate gradations in OGFC mixtures. Constr. Build. Mater. 2016, 110, 278–285. [Google Scholar]

- ISO 565-1990. Test Sieves-Metal Wire Cloth, Perforated Metal Plate and Electroformed Sheet-Nominal Sizes of Openings; International Organization for Standardization: Geneva, Switzerland, 1990. [Google Scholar]

- JTG E42-2005. Testing Procedures of Aggregate for Highway Engineering in China; General Administration of Quality Supervision, Inspection and Quarantine of the People’s Republic of China: Beijing, China, 2005.

- JTG E20-2011. Standard Test Method of Bitumen and Bituminous Mixture for Highway Engineering in China; General Administration of Quality Supervision, Inspection and Quarantine of the People’s Republic of China: Beijing, China, 2011.

- Zhang, X.N.; Wang, S.H.; Wu, K.H. CAVF method of asphalt mixture composition design. Highway 2001, 12, 17–20. (In Chinese) [Google Scholar]

- Ghazi, G.; Aroon, S. Mixture-property-independent asphalt film thickness model. Mater. Today Commun. 2019, 19, 482–486. [Google Scholar]

- Reza Pouranian, M.; Haddock, J.E. Determination of voids in the mineral aggregate and aggregate skeleton characteristics of asphalt mixtures using a linear-mixture packing model. Constr. Build. Mater. 2018, 188, 292–304. [Google Scholar] [CrossRef]

- Ding, X.H.; Ma, T. Effects by property homogeneity of aggregate skeleton on creep performance of asphalt concrete. Constr. Build. Mater. 2018, 171, 205–213. [Google Scholar] [CrossRef]

- Praticò, F.G.; Vaiana, R. A study on the relationship between mean texture depth and mean profile depth of asphalt pavements. Constr. Build. Mater. 2015, 101, 72–79. [Google Scholar] [CrossRef]

- Plati, C.; Pomoni, M.; Stergiou, T. Development of a mean profile depth to mean texture depth shift factor for asphalt pavements. Transp. Res. Rec. 2017, 1, 156–163. [Google Scholar] [CrossRef]

| Aggregate | Test Items | Standard Results | Test Results | ||

|---|---|---|---|---|---|

| 5–10 | 3–5 | 0–3 | |||

| Coarse aggregate | Crushed value (%) | ≤26 | 4.9 | 5.3 | - |

| Abrasion value (%) | ≤28 | 6.1 | 6.1 | - | |

| Polished value PSV | ≥42 | 49 | - | - | |

| Needle shape (%) | ≤15 | 3.2 | - | - | |

| Water absorption rate (%) | ≤2.0 | 0.87 | 0.96 | - | |

| Gross bulk density (g/cm3) | - | 2.90 | 2.89 | - | |

| Apparent density (g/cm3) | >2.6 | 2.93 | 2.92 | - | |

| Adhesion to asphalt (level) | ≥5 | 5 | - | - | |

| Fine aggregate | Apparent density (g/cm3) | ≥2.5 | - | - | 2.93 |

| Sand equivalent (%) | ≥60 | - | - | 87 | |

| Methylene blue value (g/kg) | ≤25 | - | - | 14 | |

| Test Items | Unit | Standard Results | Test Results |

|---|---|---|---|

| Penetration index (25 °C) | 0.1 mm | 40–80 | 43.1 |

| Softening Point TR&B | °C | ≥70 | 81.6 |

| Ductility (5 °C) | cm | ≥20 | 29 |

| Relative density of asphalt | g/cm3 | - | 1.023 |

| Rotational viscosity 135 °C | Pa·s | - | 2.958 |

| Flexible recovery 25 °C | % | ≥85 | 92 |

| Rotating film oven test (163 °C) | |||

| Quality loss | % | ≤0.6 | 0.09 |

| Penetration ratio | % | ≥65 | 79 |

| Ductility 5 °C | cm | ≥15 | 20 |

| Test Items | Unit | Standard Results | Test Results | |

|---|---|---|---|---|

| Apparent relative density | g/cm3 | ≥2.5 | 2.864 | |

| Hydrophilic coefficient | — | <1 | 0.6 | |

| Plasticity index | — | <4 | 1 | |

| Water content | % | ≥1 | 0.08 | |

| Particle size range | <0.6 mm | % | 100 | 100 |

| <0.15 mm | % | 90–100 | 99.1 | |

| <0.075 mm | % | 70–100 | 97.7 | |

| Gradation Type | Passing Rate (%) under Different Mesh Apertures (mm) | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| 13.2 | 9.5 | 8 | 6.7 | 4.75 | 2.36 | 1.18 | 0.6 | 0.3 | 0.15 | 0.075 | |

| Novachip-B | 100 | 97.6 | - | - | 32.5 | 25.3 | 17.6 | 13.9 | 9.8 | 7.5 | 5.6 |

| OGFC-7 | 100 | 100 | - | 98.3 | 86.2 | 20.3 | 16.8 | 15.4 | 12.3 | 10.0 | 6.4 |

| UTWC-10 | 100 | 98.8 | 96.5 | 87.7 | 34.0 | 27.8 | 23.3 | 16 | 11.4 | 7.7 | 5 |

| Asphalt Mixture Type | Optimal Asphalt Content (%) | Void Ratio (%) | VMA (%) | VFA (%) | Stability (kN) | Flow Value (mm) |

|---|---|---|---|---|---|---|

| UTWC-10 | 5.0 | 12.1 | 21.9 | 44.7 | 8.64 | 27.4 |

| Novachip-B | 5.0 | 12.3 | 22.4 | 43.5 | 8.43 | 32.1 |

| OGFC-7 | 4.5 | 20.3 | 28.3 | 28.3 | 6.80 | 38.5 |

| Gradation | 45 min Deformation (mm) | 60 min Deformation (mm) | Deformation Difference (mm) | DS (times/mm) | Mean Value of DS (times/mm) |

|---|---|---|---|---|---|

| UTWC-10 | 1.26 | 1.38 | 0.12 | 5250.00 | 5568 |

| 1.30 | 1.41 | 0.11 | 5727.27 | ||

| 1.28 | 1.39 | 0.11 | 5727.27 | ||

| Novachip-B | 1.47 | 1.63 | 0.16 | 3937.5 | 4025 |

| 1.51 | 1.66 | 0.15 | 4200.00 | ||

| 1.49 | 1.65 | 0.16 | 3937.5 | ||

| OGFC-7 | 2.10 | 2.30 | 0.20 | 3150.00 | 3150 |

| 2.13 | 2.33 | 0.21 | 2985.78 | ||

| 2.15 | 2.34 | 0.19 | 3314.22 |

| Asphalt Mixture Type | Original Splitting Strength (R1)/MPa | Freeze-thaw Splitting Strength (R2)/MPa | Strength Ratio | Standard Results |

|---|---|---|---|---|

| UTWC-10 | 0.765 | 0.706 | 92.3% | ≥80% |

| Novachip-B | 0.757 | 0.684 | 90.4% | |

| OGFC-7 | 0.543 | 0.469 | 86.4% |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cui, W.; Wu, K.; Cai, X.; Tang, H.; Huang, W. Optimizing Gradation Design for Ultra-Thin Wearing Course Asphalt. Materials 2020, 13, 189. https://doi.org/10.3390/ma13010189

Cui W, Wu K, Cai X, Tang H, Huang W. Optimizing Gradation Design for Ultra-Thin Wearing Course Asphalt. Materials. 2020; 13(1):189. https://doi.org/10.3390/ma13010189

Chicago/Turabian StyleCui, Wentian, Kuanghuai Wu, Xu Cai, Haizhu Tang, and Wenke Huang. 2020. "Optimizing Gradation Design for Ultra-Thin Wearing Course Asphalt" Materials 13, no. 1: 189. https://doi.org/10.3390/ma13010189

APA StyleCui, W., Wu, K., Cai, X., Tang, H., & Huang, W. (2020). Optimizing Gradation Design for Ultra-Thin Wearing Course Asphalt. Materials, 13(1), 189. https://doi.org/10.3390/ma13010189